Ontology-Based Production Simulation with OntologySim

Abstract

:1. Introduction

2. Foundation

2.1. Ontology

- Clarity pursues the goal to design definitions objectively and formally and to prefer fully consistent definitions whenever possible.

- Coherence is the property of being logical and consistent.

- Extendability allows the ontology to be extended or modified regarding new relations and vocabularies.

- Minimal encoding bias means that the chosen representation goes beyond the current implementation to ensure knowledge-sharing over the current use-case.

- Minimal ontological commitment: An ontology should have few requirements and restrictions on the modeled world to represent specialized and individual circumstances.

2.2. Simulation

2.3. Term Ontology-Based Simulation

- Lvl1: Production capacity: The ontology contains information about the capacity and structure of the ontology, such as machines, transporters, and queues.

- Lvl2: Process specification: The next level adds information regarding processes, setup behavior and resource change.

- Lvl3: Product specification: An ontology enables products to be produced in simulation. This means that production plans are included in the ontology and the current processing step of the product is known in the ontology at any time.

- Lvl4: Event & history specification: Events and data from the past lay the foundation for processes and allow the determination of the next simulation step.

- Lvl5: Simulation specification: The highest ontology integration level contains all information of the previous levels and focuses on all further necessary information, such as current time steps or work orders, to be contained in the ontology. Fully ontology-based simulations allow saving the ontology, and, thus, the simulation core and current status, at any time without information loss. This is possible when both the data management and the simulation kernel are integrated into the ontology.

3. Related Work

3.1. Literature Review

- Concepts/schemata for production simulation:This category is characterized by the fact that schemes and concepts for a simulation are presented, but the active use has not yet been implemented or has only been carried out for an example case. Some of the concepts differ greatly in scope and structure of the ontology. Thus, multi-agent approaches were designed, such as that by Karageorgos et al. [36], who define an agent-based approach to support logistics and production planning; and Mönch and Stehli [37], who store data based on domain-related predicates, such as machine structure and task-related predicates, such as scheduling. Additionally, there are concepts for the description of the factory layout [38] by ontological means. Furthermore, there are databases, such as ONKI [39], available, which hold production data sets and ontology schemata for production.

- Real world application (CPS, MES):These ontology approaches are characterized by the fact that a virtual representation of a production plant and a Manufacturing Execution System (MES) is extended by an ontology to maintain flexibility. In these approaches, the ontology often serves as a classic knowledge database. Examples are the use of ontologies for MES and OPC-UA interfaces [40] and a digital twin for a Cyber-physical Production system (CPS) [28]. A different approach is followed by the virtual factory data model presented by Terkaj [41], which aims at representing factory objects, i.e., from products to machines, virtually, in a static way.

- External data source to facilitate easier production simulation start:These papers pursue the integration of different external data sources to create a uniform simulation data model through an ontology. It is noticeable for this type of concept that multiple ontologies are used for modeling [42,43,44]. The simulation models are either converted into executable models, as in Silver et al. [42], or the ontology serves as a knowledge database adjunct to the simulation model [43,44]. Benjamin et al. [43] introduce an ontology-driven framework based on scheduling, simulation and optimization ontology. Du et al. [44] implement a framework, where multiple databases are integrated into multiple ontologies and then combined to one core ontology model. A hybrid approach focuses on modeling external data sources, a static virtual model of the factory and its history, presented by Terkaj and Urgo [45], likewise uses ontologies and extends so far static representations with the system’s history and evolution. Thus, these can be classified as a digital shadow [3]. An extension of this approach is described by Terkaj et al. [46], who use this continuously synchronized, ontology-based virtual model to enable ”in situ” simulation of future system behavior. Hence, the approach aims at enabling a foresighted digital twin [3].

- Fully ontology-based simulations:A similar approach to the OntologySim is only provided by the paper of Warden et al. [47]. Here, an attempt was made to create a simulation for transport logistics utilizing several ontologies, which were divided into different layers. The goals regarding ”scalable, portable and reusable domain models [...] fell short [...] and turned out to yield more pain than gain” [47].

3.2. Simulation Programs

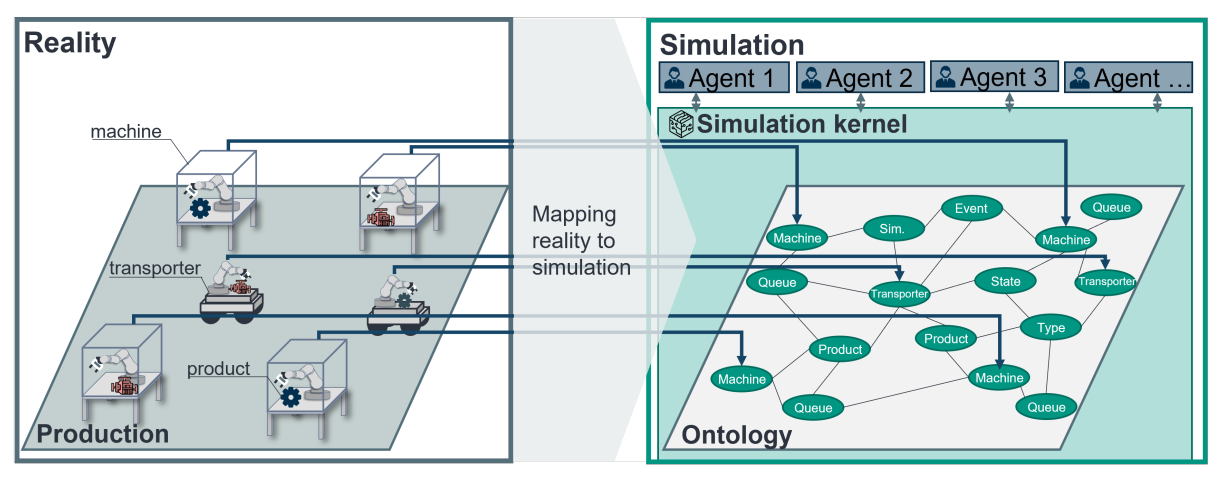

4. Proposed Ontology-Based Simulation

4.1. OntologySim Conceptualization

4.2. Unique Selling Proposition (USP)

- Saving, Loading of Simulation:Interrupting the simulation during runtime enables new use cases and possibilities, which are shown in Figure 7. When saving the simulation, the current state of the ontology is stored in a single OWL file. This saved data is sufficient to restart the simulation, as all essential information is contained in the ontology. In particular, the following new use cases are enabled:

- -

- The stored image can be run on other computational units and enables the easy extraction of information data.

- -

- -

- -

- A real world digital twin is enabled, as up-to-the-minute virtual models can be started with the exact same initial situation [3].

- Extendable during simulation run:Saving and loading the simulation provides the basis for the simulation to be extended during a run. In addition to changing the strategy, adjustments can also be made to the manufacturing system which affect resources, such as machines, transporters, or processes. Thus, for example, transporters can be removed or added, or process times can be changed. It is also possible to add data and information that is not needed currently for the simulation. By adding supplementary nodes, it is possible to link external (real-world) data or to model the current description in detail. An example would be the addition of installation space sizes for the product, novel products added to the portfolio [33], or changes in the shopfloor management, as well as increased worker competencies [61].

- Extendable open source application:Another advantage compared to the majority of simulations reviewed in Section 3 is that OntologySim is implemented with the basic idea of being an open-source publication and software. Thus, the focus of the implementation is to make the simulation easily adaptable and to provide clearly defined and explained interfaces. This makes it possible to simply extend the simulation with self-implemented agents and access the ontology through standardized wrapper methods.

- Generalization:The interaction of the ontology and the Python modules enables a good generalization of simulation models. It is possible to model different production systems, be it line production, a workshop production or matrix production, or any combination. The ontology can be extended and customized to meet specific requirements. This includes the possible integration of information about tangible objects, such as products, intangible information, such as production planning, and control organization [33,58], or ever-changing, human-centered Industry 4.0 implementations [61].

- Step wise going back in simulation:Going back within a single simulation run in a step-by-step manner is another special feature of the OntologySim. Going back enables a better analysis of the simulation and increases the traceability and understanding of complex production systems [60]. This feature is made possible by the fact that, at any point in time, a defined state is available, and the past events are stored. These two properties are sufficient to recreate the past and explicitly analyze its states. By doing so, the analysis of ”what-if” scenarios within a single simulation run can be evaluated without the need to instantiate many different simulations, for instance, for time-constraint adherence predictions [59,60].

- Digital twin:The OntologySim can ideally serve as a digital twin. It possesses the unique ability to serve as digital twin, digital master, and, to some degree, digital shadow, all at once. Starting from any current state in the real system, the ontology can be created and updated externally, manually, or by connection to data sources, such as MES or ERP systems. Then, an instantiation, or, in other terms, a simulation run, can be started directly within the OntologySim framework. This enables increasing digital twin capabilities for production systems [3].

4.3. Classification of simulation

5. Design Principles for the OntologySim

5.1. Machine

5.2. Event

5.3. Product Type

6. Procedure of OntologySim

6.1. Configuration of the Simulation (1)

6.2. Reasoning/Loading of the Simulation (2)

6.3. Running through the Simulation (3)

6.4. Logging & Storage of KPIs (4)

7. Technical Description

7.1. Basic Building Block of the Ontologysim

7.2. Visualization

8. Discussion

9. Summary and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Nee, A.Y.; Ong, S.; Chryssolouris, G.; Mourtzis, D. Augmented reality applications in design and manufacturing. CIRP Ann. 2012, 61, 657–679. [Google Scholar] [CrossRef]

- Duray, R.; Ward, P.T.; Milligan, G.W.; Berry, W.L. Approaches to mass customization: Configurations and empirical validation. J. Oper. Manag. 2000, 18, 605–625. [Google Scholar] [CrossRef]

- May, M.C.; Overbeck, L.; Wurster, M.; Kuhnle, A.; Lanza, G. Foresighted digital twin for situational agent selection in production control. Procedia CIRP 2021, 99, 27–32. [Google Scholar] [CrossRef]

- Mourtzis, D. Simulation in the design and operation of manufacturing systems: State of the art and new trends. Int. J. Prod. Res. 2020, 58, 1927–1949. [Google Scholar] [CrossRef]

- Durán-Muñoz, I.; Bautista-Zambrana, M.R. Applying ontologies to terminology: Advantages and disadvantages. Hermes-J. Lang. Commun. Bus. 2013, 65–77. [Google Scholar] [CrossRef] [Green Version]

- Cheng, H.; Zeng, P.; Xue, L.; Shi, Z.; Wang, P.; Yu, H. Manufacturing ontology development based on Industry 4.0 demonstration production line. In Proceedings of the 2016 Third International Conference on Trustworthy Systems and Their Applications (TSA), Wuhan, China, 18–22 September 2016; pp. 42–47. [Google Scholar]

- Lamy, J.B. Owlready: Ontology-oriented programming in Python with automatic classification and high level constructs for biomedical ontologies. Artif. Intell. Med. 2017, 80, 11–28. [Google Scholar] [CrossRef] [Green Version]

- Gruber, T.R. Toward principles for the design of ontologies used for knowledge sharing? Int. J. -Hum.-Comput. Stud. 1995, 43, 907–928. [Google Scholar] [CrossRef]

- Shamsfard, M.; Barforoush, A.A. Learning ontologies from natural language texts. Int. J. -Hum.-Comput. Stud. 2004, 60, 17–63. [Google Scholar] [CrossRef]

- Knublauch, H.; Oberle, D.; Tetlow, P.; Wallace, E.; Pan, J.; Uschold, M. A semantic web primer for object-oriented software developers. In W3c Working Group Note W3C. 2006. Available online: https://www.w3.org/TR/sw-oosd-primer/ (accessed on 27 December 2021).

- Wand, Y.; Weber, R. An ontological model of an information system. IEEE Trans. Softw. Eng. 1990, 16, 1282–1292. [Google Scholar] [CrossRef]

- Gruninger, Michael, L.J. Ontology: Applications and design. Commun. ACM 2002, 45, 39–41.

- Berners-Lee, T.; Hendler, J.; Lassila, O. The semantic web. Sci. Am. 2001, 284, 34–43. [Google Scholar] [CrossRef]

- McGuinness, D.L.; Van Harmelen, F. OWL web ontology language overview. W3C Recomm. 2004, 10, 2004. [Google Scholar]

- Jurisica, I.; Mylopoulos, J.; Yu, E. Ontologies for knowledge management: An information systems perspective. Knowl. Inf. Syst. 2004, 6, 380–401. [Google Scholar] [CrossRef]

- Pérez, J.; Arenas, M.; Gutierrez, C. Semantics and Complexity of SPARQL. In The Semantic Web-ISWC 2006; Springer: Berlin/Heidelberg, Germany, 2006; pp. 30–43. [Google Scholar]

- Lamy, J.B. Ontology-oriented programming for biomedical informatics. In Transforming Healthcare with the Internet of Things; IOS Press: Amsterdam, The Netherlands, 2016; pp. 64–68. [Google Scholar]

- Kalyanpur, A.; Pastor, D.J.; Battle, S.; Padget, J.A. Automatic Mapping of OWL Ontologies into Java. In SEKE; Citeseer: Princeton, NJ, USA, 2004; Volume 4, pp. 98–103. [Google Scholar]

- Goldman, N.M. Ontology-oriented programming: Static typing for the inconsistent programmer. In The Semantic Web-ISWC 2003; Springer: Berlin/Heidelberg, Germany, 2003; pp. 850–865. [Google Scholar]

- Seaborne, A.; Manjunath, G.; Bizer, C.; Breslin, J.; Das, S.; Davis, I.; Harris, S.; Idehen, K.; Corby, O.; Kjernsmo, K.; et al. SPARQL/Update: A language for updating RDF graphs. W3c Memb. Submiss. 2008, 15, 1–13. [Google Scholar]

- World Wide Web Consortium. OWL 2 Web Ontology Language Document Overview. 2012. Available online: https://www.w3.org/TR/owl2-overview/ (accessed on 27 December 2021).

- Knublauch, H.; Fergerson, R.W.; Noy, N.F.; Musen, M.A. The Protégé OWL plugin: An open development environment for semantic web applications. In The Semantic Web-ISWC 2004; Springer: Berlin/Heidelberg, Germany, 2004; pp. 229–243. [Google Scholar]

- Kalyanpur, A.; Parsia, B.; Sirin, E.; Grau, B.C.; Hendler, J. Swoop: A web ontology editing browser. J. Web Semant. 2006, 4, 144–153. [Google Scholar] [CrossRef] [Green Version]

- Haase, P.; Lewen, H.; Studer, R.; Tran, D.T.; Erdmann, M.; d’Aquin, M.; Motta, E. The Neon Ontology Engineering Toolkit. 2008. Available online: http://neon-toolkit.org/wiki/Main_Page.html (accessed on 27 December 2021).

- Horridge, M.; Bechhofer, S. The owl api: A java api for owl ontologies. Semant. Web 2011, 2, 11–21. [Google Scholar] [CrossRef]

- Jean-Baptiste, L. Constructs, restrictions, and class properties. In Ontologies with Python; Springer: Berlin/Heidelberg, Germany, 2021; pp. 135–156. [Google Scholar]

- Adel, A.Z.; Zebari, S.; Jacksi, K. Football Ontology Construction using Oriented Programming. J. Appl. Sci. Technol. Trends 2020, 1, 24–30. [Google Scholar]

- Liu, C.; Jiang, P.; Jiang, W. Web-based digital twin modeling and remote control of cyber-physical production systems. Robot. -Comput.-Integr. Manuf. 2020, 64, 101956. [Google Scholar] [CrossRef]

- Ingenieure, V.D. VDI 3633 Simulation von Logistik-, Materialfluß- und Produktionssytemen—VDI 3633 Entwurf|Begriffsdefinitionen; Beuth: Düsseldorf, Germany, 1996. [Google Scholar]

- HrdliczNa, V. Leitfaden für Simulationsbenutzer in ProduNtion und LogistiN. ASIM Mitteilungen 1997, 58. [Google Scholar]

- May, M.C.; Kiefer, L.; Kuhnle, A.; Stricker, N.; Lanza, G. Decentralized multi-agent production control through economic model bidding for matrix production systems. Procedia CIRP 2021, 96, 3–8. [Google Scholar] [CrossRef]

- Greschke, P. Matrix-Produktion: Konzept einer Taktunabhängigen Fließfertigung; BoD–Books on Demand Gmbh: Norderstedt, Germany, 2020. [Google Scholar]

- May, M.C.; Schmidt, S.; Kuhnle, A.; Stricker, N.; Lanza, G. Product Generation Module: Automated Production Planning for optimized workload and increased efficiency in Matrix Production Systems. Procedia CIRP 2021, 96, 45–50. [Google Scholar] [CrossRef]

- Panetto, H.; Baïna, S.; Morel, G. Mapping the IEC 62264 models onto the Zachman framework for analysing products information traceability: A case study. J. Intell. Manuf. 2007, 18, 679–698. [Google Scholar] [CrossRef]

- Wolfswinkel, J.F.; Furtmueller, E.; Wilderom, C.P. Using grounded theory as a method for rigorously reviewing literature. Eur. J. Inf. Syst. 2013, 22, 45–55. [Google Scholar] [CrossRef]

- Karageorgos, A.; Mehandjiev, N.; Weichhart, G.; Hämmerle, A. Agent-based optimisation of logistics and production planning. Eng. Appl. Artif. Intell. 2003, 16, 335–348. [Google Scholar] [CrossRef]

- Mönch, L.; Stehli, M. An ontology for production control of semiconductor manufacturing processes. In Multiagent System Technologies; MATES 2003. Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2003; pp. 156–167. [Google Scholar]

- Scholz, J.; Schabus, S. An indoor navigation ontology for production assets in a production environment. In Geographic Information Science; GIScience 2014. Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2014; pp. 204–220. [Google Scholar]

- Viljanen, K.; Tuominen, J.; Hyvönen, E. Ontology libraries for production use: The Finnish ontology library service ONKI. In European Semantic Web Conference; Springer: Berlin/Heidelberg, Germany, 2009; pp. 781–795. [Google Scholar]

- Katti, B. Ontology-Based Approach to Decentralized Production Control in the Context of Cloud Manufacturing Execution Systems. Ph.D. Thesis, Technical University Kaiserslautern, Kaiserslautern, Germany, 2020. [Google Scholar]

- Terkaj, W.; Pedrielli, G.; Sacco, M. Virtual factory data model. In Proceedings of the Workshop on Ontology and Semantic Web for Manufacturing, Graz, Austria, 24–27 July 2012; pp. 29–43. [Google Scholar]

- Silver, G.A.; Miller, J.A.; Hybinette, M.; Baramidze, G.; York, W.S. An ontology for discrete-event modeling and simulation. Simulation 2011, 87, 747–773. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Benjamin, P.; Patki, M.; Mayer, R. Using ontologies for simulation modeling. In Proceedings of the 2006 Winter Simulation Conference, Monterey, CA, USA, 3–6 December 2006; pp. 1151–1159. [Google Scholar]

- Du, J.; Jing, H.; Choo, K.K.R.; Sugumaran, V.; Castro-Lacouture, D. An ontology and multi-agent based decision support framework for prefabricated component supply chain. Inf. Syst. Front. 2020, 22, 1467–1485. [Google Scholar] [CrossRef]

- Terkaj, W.; Urgo, M. Ontology-based modeling of production systems for design and performance evaluation. In Proceedings of the 2014 12th IEEE International Conference on Industrial Informatics (INDIN), Porto Alegre, Brazil, 27–30 July 2014; pp. 748–753. [Google Scholar]

- Terkaj, W.; Tolio, T.; Urgo, M. A virtual factory approach for in situ simulation to support production and maintenance planning. CIRP Ann. 2015, 64, 451–454. [Google Scholar] [CrossRef]

- Warden, T.; Porzel, R.; Gehrke, J.D.; Herzog, O.; Langer, H.; Malaka, R. Towards Ontology-Based Multiagent Simulations: The Plasma Approach; ECMS: Kuala, Lumpur, 2010; pp. 50–56. [Google Scholar]

- Gurjanov, A.; Zakoldaev, D.; Shukalov, A.; Zharinov, I. The ontology in description of production processes in the Industry 4.0 item designing company. J. Phys. 2018, 1059, 012010. [Google Scholar] [CrossRef]

- Fumagalli, L.; Pala, S.; Garetti, M.; Negri, E. Ontology-based modeling of manufacturing and logistics systems for a new MES architecture. In IFIP International Conference on Advances in Production Management Systems; Springer: Berlin/Heidelberg, Germany, 2014; pp. 192–200. [Google Scholar]

- Mazzola, L.; Kapahnke, P.; Vujic, M.; Klusch, M. CDM-Core: A Manufacturing Domain Ontology in OWL2 for Production and Maintenance; KEOD: Setubal, Portugal, 2016; pp. 136–143. [Google Scholar]

- Guizzardi, G.; Wagner, G. Towards an ontological foundation of discrete event simulation. In Proceedings of the 2010 Winter Simulation Conference, Baltimore, MD, USA, 5–8 December 2010; pp. 652–664. [Google Scholar]

- Ansari, F.; Khobreh, M.; Seidenberg, U.; Sihn, W. A problem-solving ontology for human-centered cyber physical production systems. CIRP J. Manuf. Sci. Technol. 2018, 22, 91–106. [Google Scholar] [CrossRef]

- Chen, R.S.; Tu, M.A. Development of an agent-based system for manufacturing control and coordination with ontology and RFID technology. Expert Syst. Appl. 2009, 36, 7581–7593. [Google Scholar] [CrossRef]

- Matloff, N. Introduction to discrete-event simulation and the simpy language. Dept. Comput. Sci. Univ. Calif. Davis 2008, 2, 1–33. [Google Scholar]

- Kuhnle, A.; May, M.C.; Schäfer, L.; Lanza, G. Explainable reinforcement learning in production control of job shop manufacturing system. Int. J. Prod. Res. 2021, 1–23. [Google Scholar] [CrossRef]

- Borshchev, A.; Brailsford, S.; Churilov, L.; Dangerfield, B. Multi-method modelling: AnyLogic. Discrete-Event Simulation and System Dynamics for Management Decision Making; Wiley: West Sussex, UK, 2014; pp. 248–279. [Google Scholar]

- ISO 22400-2; Automation Systems and Integration—Key Performance Indicators (KPIs) for Manufacturing Operations Management—Part 2: Definitions and Descriptions. International Organization for Standardization: Geneva, Switzeralnd, 2014.

- Overbeck, L.; Hugues, A.; May, M.C.; Kuhnle, A.; Lanza, G. Reinforcement Learning Based Production Control of Semi-automated Manufacturing Systems. Procedia CIRP 2021, 103, 170–175. [Google Scholar] [CrossRef]

- May, M.C.; Maucher, S.; Holzer, A.; Kuhnle, A.; Lanza, G. Data analytics for time constraint adherence prediction in a semiconductor manufacturing use-case. Procedia CIRP 2021, 100, 49–54. [Google Scholar] [CrossRef]

- May, M.C.; Behnen, L.; Holzer, A.; Kuhnle, A.; Lanza, G. Multi-variate time-series for time constraint adherence prediction in complex job shops. Procedia CIRP 2021, 103, 55–60. [Google Scholar] [CrossRef]

- Kandler, M.; May, M.C.; Kurtz, J.; Kuhnle, A.; Lanza, G. Development of a Human-Centered Implementation Strategy for Industry 4.0 Exemplified by Digital Shopfloor Management. In Towards Sustainable Customization: Bridging Smart Products and Manufacturing Systems; Springer: Berlin/Heidelberg, Germany, 2021; pp. 738–745. [Google Scholar]

- Wurster, M.; Michel, M.; May, M.C.; Kuhnle, A.; Stricker, N.; Lanza, G. Modelling and condition-based control of a flexible and hybrid disassembly system with manual and autonomous workstations using reinforcement learning. J. Intell. Manuf. 2022, 33, 575–591. [Google Scholar] [CrossRef]

- Kiefer, L.; May, M.C. Read the Docs: OntologySim. 2021. Available online: https://ontologysim.readthedocs.io (accessed on 30 December 2021).

- Kiefer, L.; May, M.C. OntologySim_react. 2021. Available online: https://github.com/larsKiefer/ontologysim_react (accessed on 27 December 2021).

- Kiefer, L.; May, M.C. OntologySim. 2021. Available online: https://github.com/larsKiefer/ontologysim (accessed on 27 December 2021).

- Kang, N.; Zhao, C.; Li, J.; Horst, J.A. A Hierarchical structure of key performance indicators for operation management and continuous improvement in production systems. Int. J. Prod. Res. 2016, 54, 6333–6350. [Google Scholar] [CrossRef]

| Ontology System | Real World | Simulation | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Approach by | Ontology Schema | Multi Agent System | Multiple Ontology | Ontology as Data Storage | Application Framework | External Data Source | Cyber-Physical-System (CPS) | Manufacturing Execution System (MES) | Ontology Integration Level | Intervention | Visualization | Main Goal |

| Concepts / schemata for production simulation | ||||||||||||

| Terkaj and Urgo [45] | ● | ◯ | ◯ | ● | ● | ● | ◯ | ◯ | 4 | ◯ | ◯ | Performance |

| Terkaj et al. [41] | ● | ◯ | ◯ | ● | ◯ | ◯ | ◯ | ◯ | 3 | ◯ | ◯ | Virtual model |

| Viljanen et al. [39] | ● | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | - | ◯ | ◯ | Database |

| Mönch and Stehli [37] | ● | ● | ◯ | ● | ● | ◯ | ◯ | ◯ | 3 | ◯ | ◯ | MAS |

| Cheng et al. [6] | ● | ● | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | 3 | ◯ | ◯ | Concept |

| Scholz and Schabus [38] | ● | ◯ | ◯ | ● | ◯ | ◯ | ◯ | ◯ | 1 | ◯ | ◯ | Schema |

| Gurjanov et al. [48] | ● | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | 2 | ◯ | ◯ | Product |

| Karageorgos et al. [36] | ● | ● | ◯ | ● | ◯ | ◯ | ◯ | ◯ | 3 | ◯ | ◯ | MAS |

| Fumagalli et al. [49] | ● | ◯ | ◯ | ● | ◯ | ◯ | ◯ | ◐ | 3 | ◯ | ◯ | MES |

| Mazzola et al. [50] | ● | ◯ | ◯ | ◯ | ◯ | ● | ◯ | ◯ | 2 | ◯ | ◯ | Concept |

| Guizzardi and Wagner [51] | ● | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | 4 | ◯ | ◯ | DES |

| External data source to facilitate easier production simulation start | ||||||||||||

| Du et al. [44] | ● | ● | ● | ● | ● | ● | ◯ | ◯ | 3 | ◯ | ● | AnyLogic |

| Terkaj et al. [46] | ● | ◯ | ◯ | ● | ● | ● | ◯ | ◯ | 4 | ◯ | ● | Speed |

| Benjamin et al. [43] | ● | ● | ● | ● | ● | ● | ◯ | ◯ | 3 | ◯ | ◯ | Framework |

| Silver et al. [42] | ● | ◐ | ● | ◯ | ● | ● | ◯ | ◯ | 3 | ◯ | ◯ | Parsing |

| Real world application (CPS, MES) | ||||||||||||

| Liu et al. [28] | ● | ◯ | ◯ | ● | ◯ | ◯ | ● | ● | 3 | ◯ | ● | digital twin |

| Ansari et al. [52] | ● | ◯ | ◯ | ● | ● | ◯ | ● | ◯ | 2 | ◯ | ◯ | Problem |

| Katti et al. [40] | ● | ◯ | ◯ | ● | ◯ | ◯ | ● | ● | 2 | ◯ | ◯ | OPC UA |

| Chen and Tu [53] | ● | ◯ | ◯ | ● | ◯ | ◯ | ◐ | ◐ | 1 | ◯ | ● | CPS |

| Fully ontology-based simulations | ||||||||||||

| Warden et al. [47] | ● | ● | ◯ | ● | ● | ◯ | ◯ | ◯ | 4 | ◯ | ◯ | Scheduling |

| Legend: ● regarded ◐ rudimentary regarded ◯ not regarded | ||||||||||||

| User-Friendliness | Availability | Modularity | |||||

|---|---|---|---|---|---|---|---|

| Simulation | Visualization | Ease of Use | First Start | KPI Usage | Open Source | Intervention | Flexibility |

| SimPy [54] | ◯ | ◐ | ● | ◐ | ● | ◯ | ◐ |

| AnyLogic [56] | ● | ◐ | ● | ◐ | ◯ | ◯ | ◐ |

| Siemens PLM | ● | ◐ | ● | ◐ | ◯ | ◯ | ◐ |

| Legend: ● implemented ◐ partly implemented ◯ not possible | |||||||

| Ontology System | Real World | Simulation | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Approach by | Ontology Schema | Multi Agent System | Multiple Ontology | Ontology as Data Storage | Application Framework | External Data Source | Cyber-Physical-System (CPS) | Manufacturing Execution System (MES) | Ontology Integration Level | Intervention | Visualization | Main Goal |

| Proposed Implementation as Fully ontology-based simulations | ||||||||||||

| OntologySim [64,65] | ● | ● | ● | ● | ● | ◯ | ◯ | ◯ | 5 | ● | ● | Simulation |

| Legend: ● regarded ◐ rudimentary regarded ◯ not regarded | ||||||||||||

| Applicability | Availability | Modularity | ||||||

|---|---|---|---|---|---|---|---|---|

| Simulation | Visualization | GUI Changeability | Speed | KPI Standards | Open Source | Intervention | Changeability | Flexibility |

| SimPy [54] | ◯ | ◐ | ● | ◐ | ● | ◯ | ◯ | ◐ |

| AnyLogic [56] | ● | ◐ | ● | ◐ | ◯ | ◯ | ◯ | ◐ |

| Siemens PLM | ● | ◐ | ● | ◐ | ◯ | ◯ | ◯ | ◐ |

| OntologySim | ● | ◐ | ◐ | ● | ● | ● | ● | ● |

| Legend: ● implemented ◐ partly implemented ◯ not possible | ||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

May, M.C.; Kiefer, L.; Kuhnle, A.; Lanza, G. Ontology-Based Production Simulation with OntologySim. Appl. Sci. 2022, 12, 1608. https://doi.org/10.3390/app12031608

May MC, Kiefer L, Kuhnle A, Lanza G. Ontology-Based Production Simulation with OntologySim. Applied Sciences. 2022; 12(3):1608. https://doi.org/10.3390/app12031608

Chicago/Turabian StyleMay, Marvin Carl, Lars Kiefer, Andreas Kuhnle, and Gisela Lanza. 2022. "Ontology-Based Production Simulation with OntologySim" Applied Sciences 12, no. 3: 1608. https://doi.org/10.3390/app12031608

APA StyleMay, M. C., Kiefer, L., Kuhnle, A., & Lanza, G. (2022). Ontology-Based Production Simulation with OntologySim. Applied Sciences, 12(3), 1608. https://doi.org/10.3390/app12031608