Effect of Various Proportions of Rice Husk Powder on Swelling Soil from New Cairo City, Egypt

Abstract

:1. Introduction

2. Materials and Methods

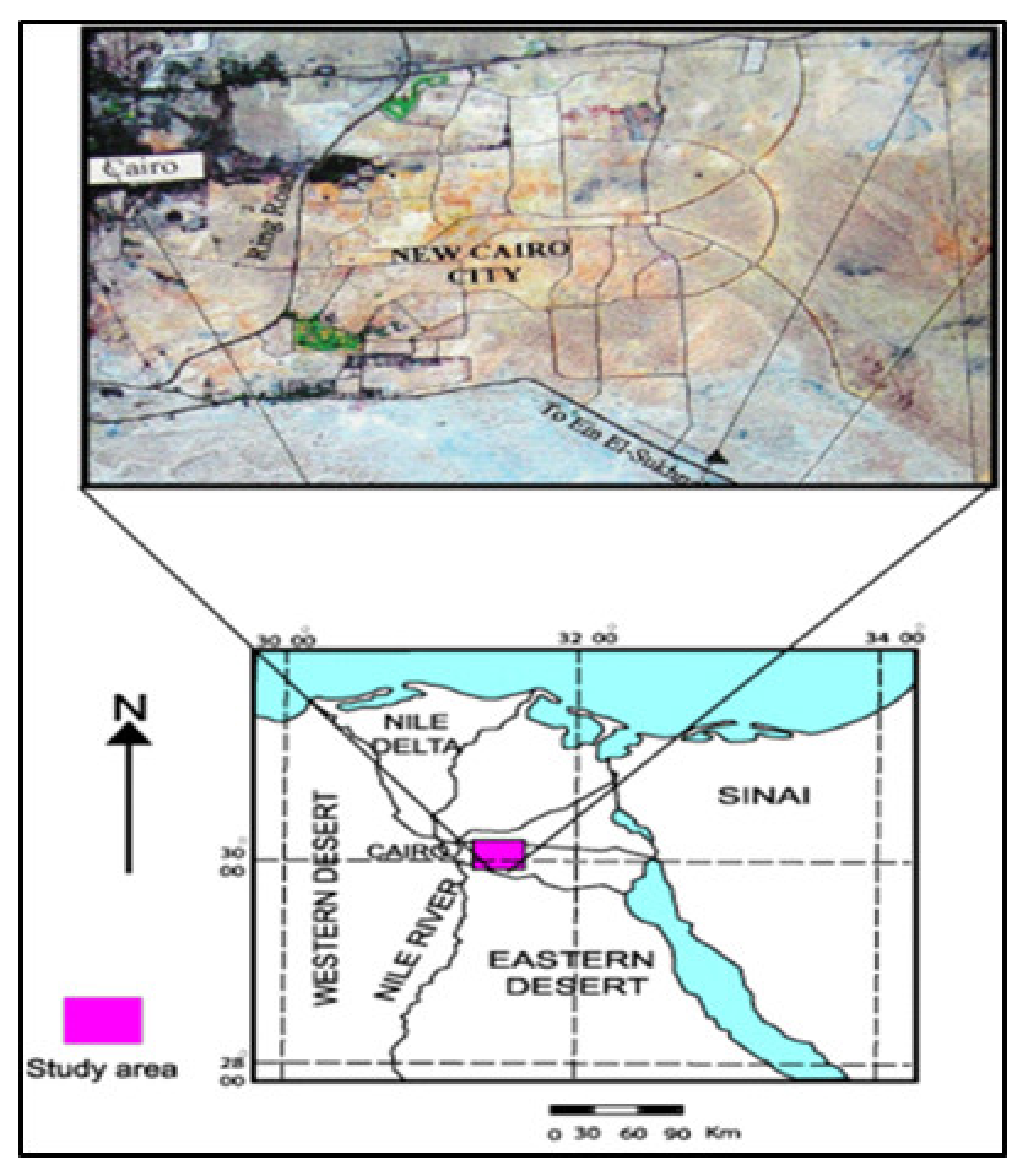

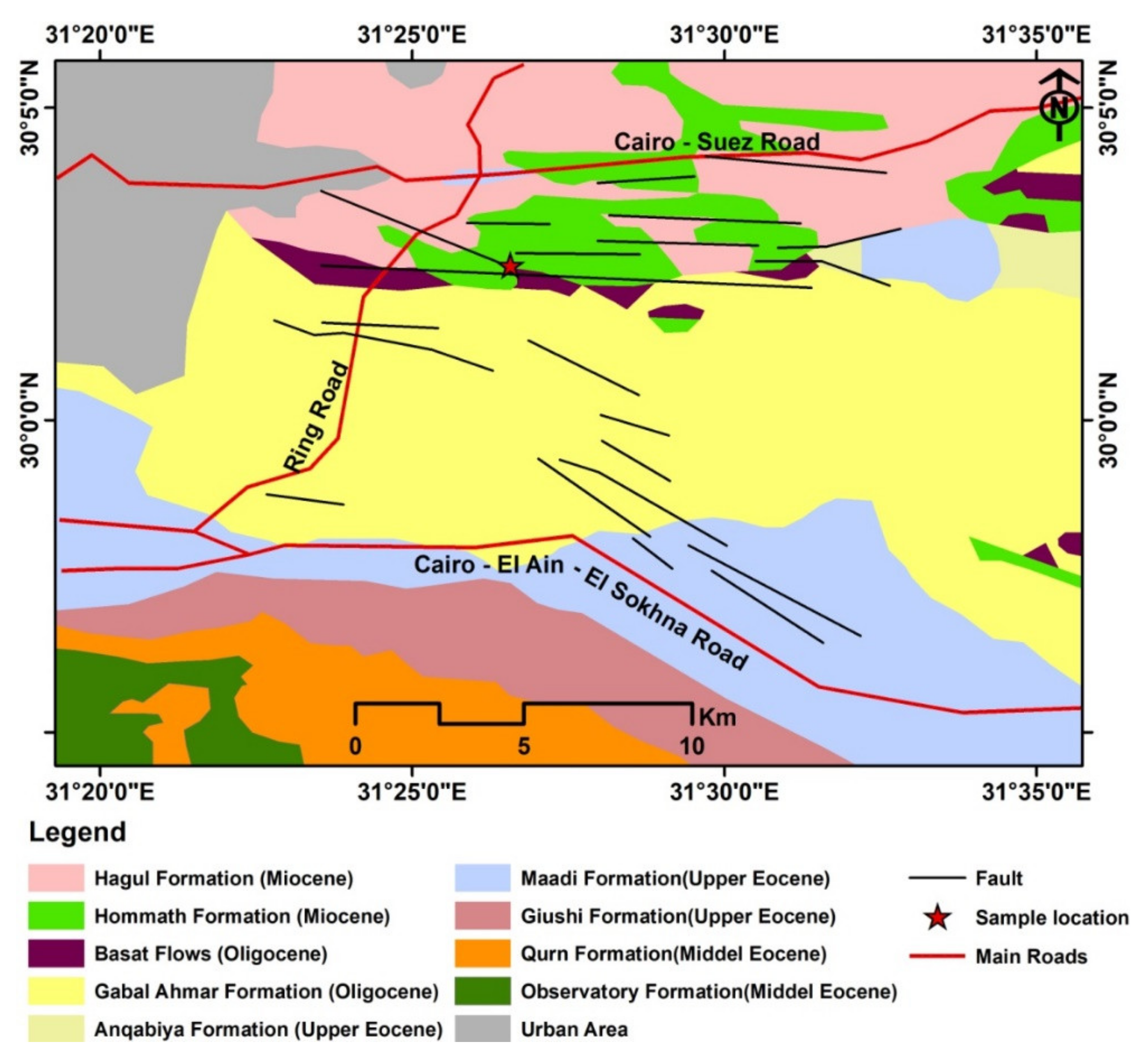

2.1. Geological Setting

2.2. Sampling

2.2.1. Swelling Soil

2.2.2. Rice Husk Powder (RHP)

2.2.3. Soil Sample Preparation

2.3. Analysis

2.3.1. Free Swell (FS) Test

2.3.2. Swelling Potential (S)

2.3.3. Swelling Pressure (SP)

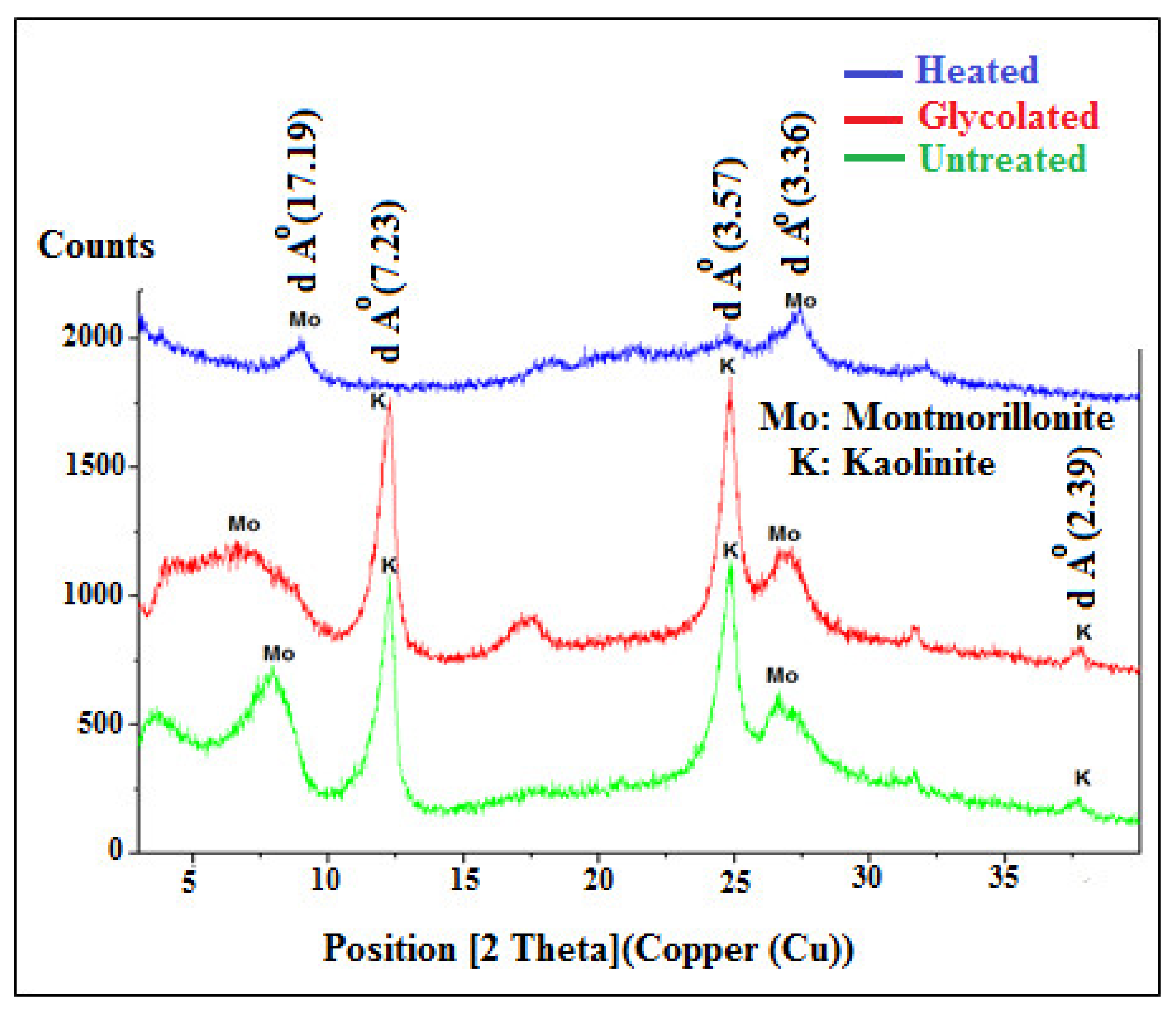

2.3.4. X-ray Diffraction Analysis

3. Results and Discussion

3.1. Geotechnical Characteristics Evaluation before Using RHP

3.2. Geotechnical Characteristics Evaluation after Using RHP

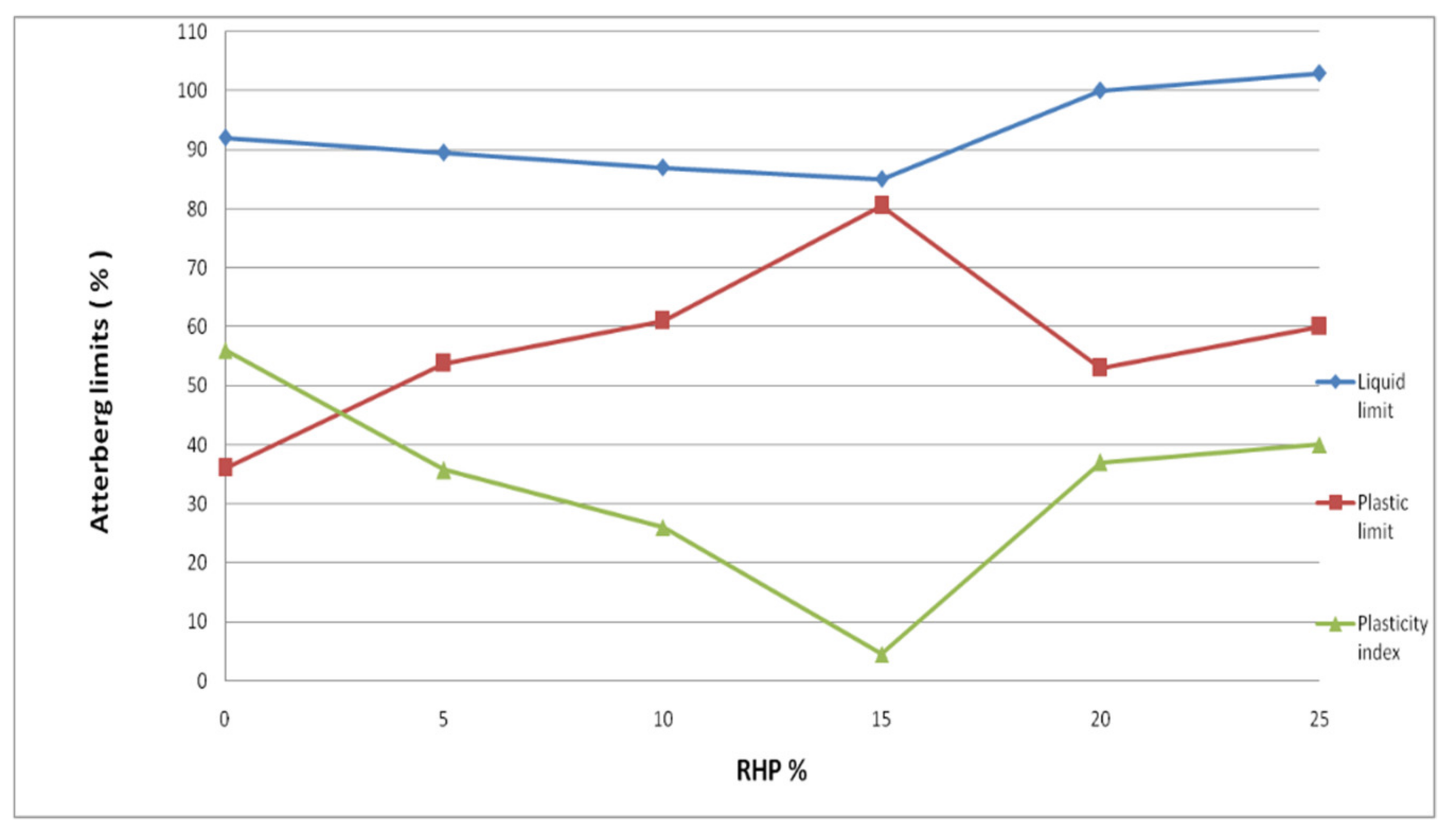

3.2.1. Effect of RHP on Atterberg Limits

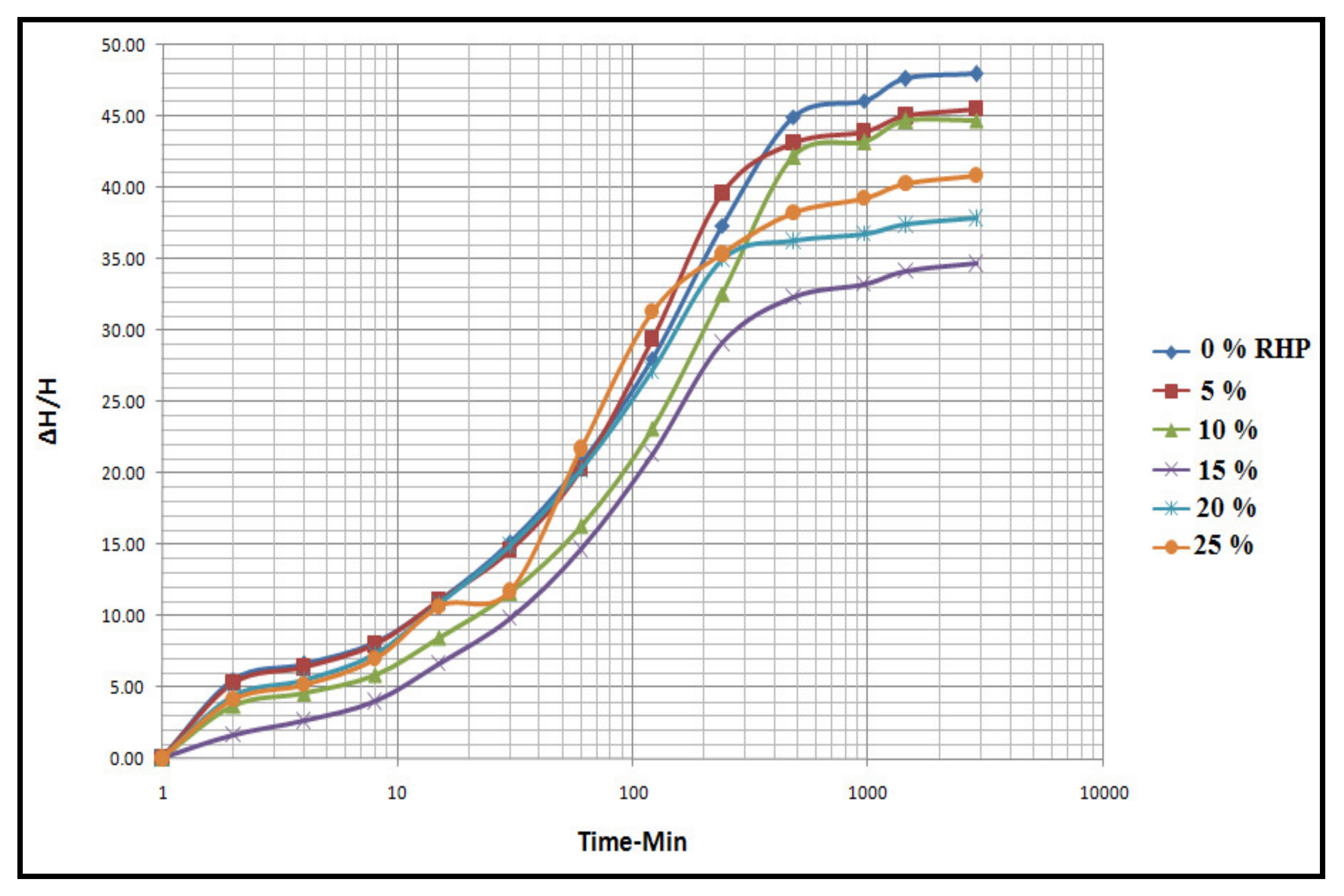

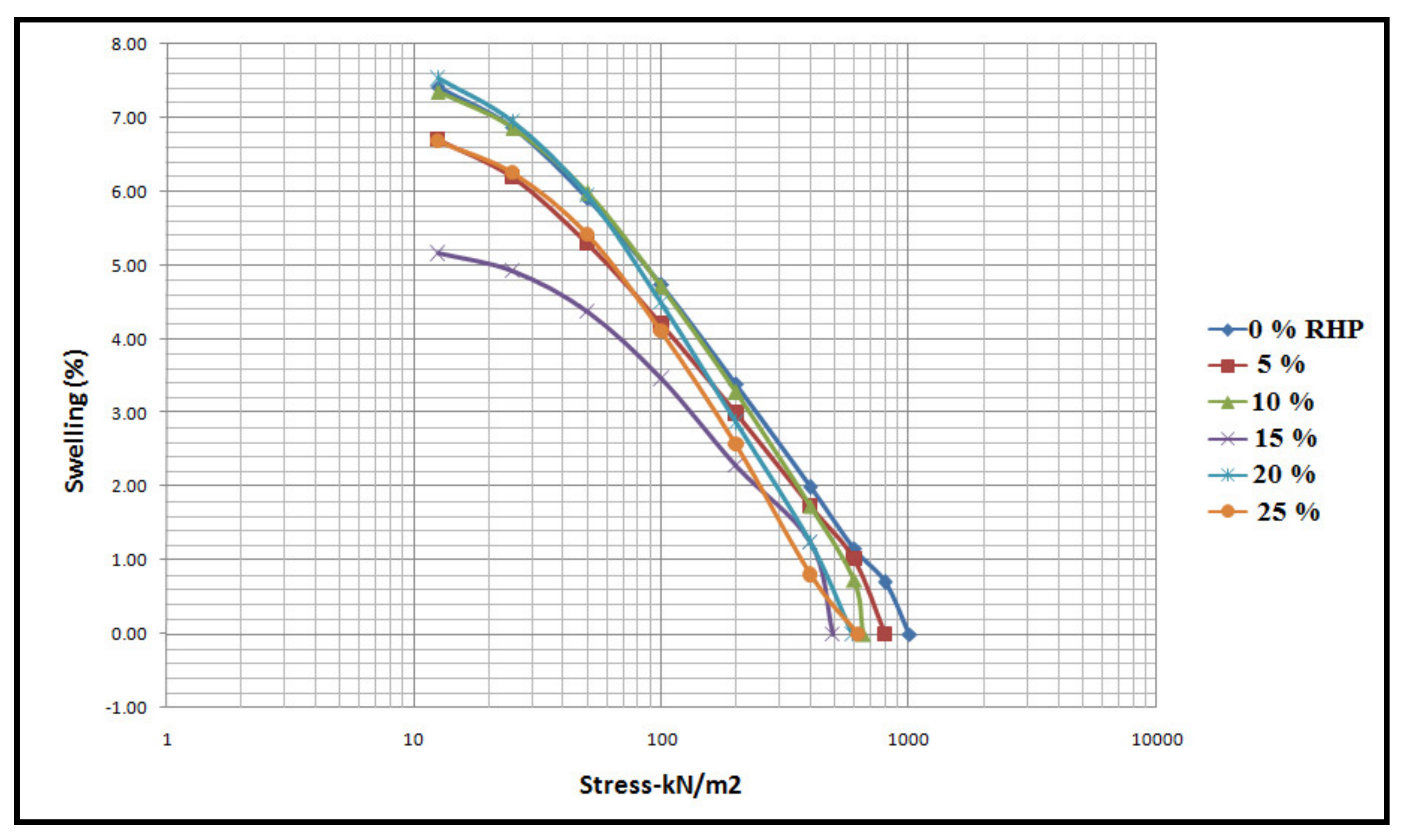

3.2.2. Effect of RHP on S and SP

3.3. Comparison of other Research Studies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmed, T.M.; Ihab, A.H. Evaluation of treatment methods used for construction on expansive soils in Egypt. In Proceedings of the 7th International Conference on Case Histories in Geotechnical and Engineering, Chicago, IL, USA, 2 May 2013; Volume 14, pp. 1–6. [Google Scholar]

- Zheng, J.L.; Yang, H.P. Expansive Soil in Highway Engineering; China Communications Press: Beijing, China, 2009. [Google Scholar]

- Petry, T.M.; Little, D.N. Review of stabilization of clays and expansive soils in pavements and lightly loaded structures-history, practice, and future. J. Mater. Civ. Eng. 2002, 14, 447–460. [Google Scholar] [CrossRef]

- Mir, B.A. Some studies on the effect of fly ash and lime on physical and mechanical properties of expansive clay. Int. J. Civ. Eng. 2015, 13, 203–212. [Google Scholar]

- Antonia, A. Modification of clayey soils properties with the addition of lime and fly ash. Int. J. Eng. Sci. Res. Technol. 2016, 5, 529–536. [Google Scholar] [CrossRef]

- Yilmaz, F.; Yurdakul, M. Evaluation of marble dust for soil stabilization. Acta Phys. Pol. A 2017, 132, 710–711. [Google Scholar] [CrossRef]

- Swapna, K.; Giridhar, K. Experimental investigation of soil stabilization by using coir fiber, fly ash and CaCl2. Int. J. Adv. Technol. Innov. Res. 2017, 9, 563–568. [Google Scholar]

- Divya, P.; Mamta, B.; Sayli, D.M.; Suvarna, R. Soil stabilization using plastic waste. Int. J. Res. Sci. Eng. 2017, 3, 258–268. [Google Scholar]

- Sanjeev, N.; Kanav, C.; Diksha, S. Stabilization of expansive soil using nano-materials. In Proceedings of the International Interdisciplinary Conference on Science Technology Engineering Management Pharmacy and Humanities, Singapore, 22–23 April 2017; pp. 432–439. [Google Scholar]

- Sakr, M.A.H.; Omar, A.E.; Saad, A.M.; Moayedi, H. Geotechnical parameters modelling and the radiation safety of expansive clayey soil treated with waste marble powder: A case study at west Gulf of Suez, Egypt. Environ. Earth Sci. 2021, 80, 263. [Google Scholar] [CrossRef]

- Duong, N.T.; Nguyen, N. Effect of different types of rice husk ash on some geotechnical properties of cement-admmixed soil. Iraqi Geol. J. 2020, 35, 1–12. [Google Scholar] [CrossRef]

- Jai, A.; Choudhary, A.K.; Jha, J.N. Influence of rice husk ash on the swelling and strength characterisrics of expansive soil. Geotech. Geol. Eng. 2020, 38, 2239–2302. [Google Scholar] [CrossRef]

- Daryati, M.A.; Ramadan, M.A. Improvement of expansive soils stabilized with rice husk ash (RHA). J. Phys. Conf. Ser. 2020, 1625, 12006. [Google Scholar] [CrossRef]

- Hight, D.W.; Gasparre, A.; Nishimura, S.; Minh, N.A.; Jardine, R.J.; Coop, M.R. Characteristics of the London Clay from the Terminal 5 site at Heathrow Airport. Geotechnique 2007, 57, 3–18. [Google Scholar] [CrossRef]

- Kiełbasiński, K.; Dobak, P.; Kaczmarek, Ł.; Kowalczyk, S. The Influences of Local Glacitectonic Disturbance on Overconsolidated Clays for Upland Slope Stability Conditions: A Case Study. Appl. Sci. 2021, 11, 10718. [Google Scholar] [CrossRef]

- Nagrale, S.D.; Hemant, H.; Pankaj, R.M. Utilization of rice husk ash. Int. J. Eng. Res. 2012, 2, 1–5. [Google Scholar]

- Anita, R.; Monika, X.; Ratika, M.K. Use of rice husk ash as fertilizer amendment to soil and its effect on crop germination. In Proceedings of the National Conference on Emerging Trends in Chemistry-Biology Interface, Nainital, India, 3–5 November 2011; pp. 32–34. [Google Scholar]

- Memon, T.A.; Harijan, K.; Soomro, M.I.; Meghwar, S.; Valasai, G.D.; Khoharo, H. Potential of electricity generation from rice husk—A case study of rice mill. Sindh Univ. Res. J. Sci. Ser. 2017, 49, 495–498. [Google Scholar] [CrossRef]

- Ganta, M.; Baskar, R.; Rama, J.S.K. Rice husk ash as a potential supplementary cementitious material in concrete solution towards sustainable construction. Innov. Infrastruct. Solut. 2022, 7, 51. [Google Scholar] [CrossRef]

- Canakci, H.; Aziz, A.; Celik, F. Soil stabilization of clay with lignin, rice husk powder and ash. Geomech. Eng. 2015, 8, 67–79. [Google Scholar] [CrossRef]

- Robert, M.B. Soil stabilization with fly ash and rice husk ash. Int. J. Res. Rev. Appl. Sci. 2009, 1, 209–217. [Google Scholar]

- Anisur Rahman, M.D.; Ahmed, A. A comparative study of the effects of rice husk ash and lime on the geotechnical properties of lateritic soil for use as highway materials. Int. J. Innov. Res. Sci. Eng. Technol. 2016, 5, 20251–20259. [Google Scholar] [CrossRef]

- Liu, Y.; Yunhe, S.; Abdoullah, N.; Guoqing, Z.; Yuexin, S.; Qin, Y. Utilization of cementitious material from residual rice husk ash and lime in stabilization of expansive soil. J. Adv. Civ. Eng. 2019, 2019, 520527. [Google Scholar] [CrossRef]

- Abdel-Aal, M.E. Hydrogeological Evaluation of the Ground Water Resources in Cairo District (A. R. E.). Master’s Thesis, Faculty of Science, Ain Shams University, Cairo, Egypt, 1982. [Google Scholar]

- Sweden, A.H. A note on the geology of greater Cairo area. Ann. Geol. Surv. Egypt 1991, XVII, 239–251. [Google Scholar]

- Said, R. The Geology of Egypt; Elsevier: Amsterdam, The Netherlands; New York, NY, USA, 1962. [Google Scholar]

- El-Sorogy, A.; Abd-Elmoneim, M.; Mowafi, A.; Al-Kahtany, K.; Gahlan, H. Facies Analysis and Biostratigraphy of the Miocene Sequence, Cairo-Suez District, Egypt. J. Earth Sci. 2017, 28, 1–8. [Google Scholar] [CrossRef]

- Saad, A.M. Mechanical behavior and geoelectrical analysis of shallow foundation beds at industrial area, New Cairo-Egypt. Middle East J. Appl. Sci. 2016, 6, 430–441. [Google Scholar]

- ASTM D-4318Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils, American Society of Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2010.

- ASTM D-2435Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading, American Society of Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2011.

- Holtz, W.G.; Gibbs, H.J. Engineering properties of expansive clays. Trans. Am. Soc. Civ. Eng. 1956, 121, 63–64. [Google Scholar] [CrossRef]

- Gibb, R.J. Clay mineral mounting techniques for X-ray diffraction analysis. J. Sediment. Petrol. 1968, 38, 242–244. [Google Scholar] [CrossRef]

- Egyptian Code. Soil Mechanics and Foundations Design and Construction; ECP202/5-2001 Laboratory Tests; National Center for Housing & Construction Research: Cairo, Egypt, 2001. [Google Scholar]

- Chen, F.H. Foundations on Expansive Soils; Elsevier Scientific Publishing Company: Amsterdam, The Netherlands, 1988. [Google Scholar]

- Seed, H.B.; Woodward, R.J.; Lundgren, R. Predication of swelling potential for compacted clays. J. Soil Mech. Found. Eng. Div. ASCE 1962, 88, 53–87. [Google Scholar] [CrossRef]

- Geraid, J. Review of expansive soils. J. Geotech. Eng. Div. 1974, 100, 667–687. [Google Scholar]

- Casagrande, A. Classification and identification of soils, transactions. Trans. Am. Soc. Civ. Eng. 1948, 113, 901–930. [Google Scholar] [CrossRef]

- Akbulut, S.; Arasan, S. The variations of cation exchange capacity, pH and Zeta Potential in expansive soils treated by additives. Int. J. Civ. Struct. Eng. 2010, 1, 139–150. [Google Scholar]

- Mitchell, J.; Soga, K. Fundamentals of Soil Behavior, 3rd ed.; John Wiley and Sons Inc.: New York, NY, USA, 2005; pp. 35–81. [Google Scholar]

- ASTM C-618Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete, American Society of Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2019.

| Parameter No. | Index Properties | Results |

|---|---|---|

| 1 | Specific gravity | 2.6 |

| 2 | Initial water content (%) | 25 |

| 3 | Passing sieve No 40 (%) | 99.5 |

| 4 | Passing sieve No 200 (%) | 92 |

| 5 | Liquid limit (%) | 92 |

| 6 | Plastic limit (%) | 36 |

| 7 | Plasticity index (%) | 56 |

| 8 | Shrinkage limit | 13.6 |

| 9 | Free swell (%) | 200 |

| 10 | Free swell index | 100 |

| 11 | Swelling pressure (kN/m2) | 1003 |

| 12 | Swelling potential % | 48.5 |

| 13 | Soil classification according to (USCS) | EH |

| Compound | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | Cl |

|---|---|---|---|---|---|---|---|---|---|

| As received husk | 82.55 | 0.87 | 2.05 | 0.25 | 3.15 | 0.14 | 5.28 | 0.87 | 0.07 |

| Washed husk | 90.89 | 1.20 | 2.42 | 0.73 | 1.54 | 0.11 | 1.52 | 0.35 | 0.01 |

| PI (%) | S (%) | SP (kPa) | Degree of Expansion |

|---|---|---|---|

| ≤15 | 0–1.5 | ˂196 | Low |

| 15–30 | 1.5–5 | 196–392 | Medium |

| 30–50 | 5–25 | 392–687 | High |

| <50 | ˃25 | ˃687 | Very High |

| S.No. | RHP (%) | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index (%) |

|---|---|---|---|---|

| 1 | 0 | 92 | 36 | 56 |

| 2 | 5 | 89.5 | 53.8 | 35.7 |

| 3 | 10 | 87 | 61 | 32 |

| 4 | 15 | 85 | 80.5 | 4.5 |

| 5 | 20 | 100 | 53 | 37 |

| 6 | 25 | 103 | 60 | 40 |

| Mean value | 92.75 | 57.4 | 34.2 | |

| Standard deviation | 6.60 | 13.19 | 15.30 | |

| Variance | 44 | 174 | 235 |

| S.No. | RHP (%) | Swelling Pressure kN/m2 | Swelling Potential (%) |

|---|---|---|---|

| 1 | 0 | 1003 | 48 |

| 2 | 5 | 800 | 45.5 |

| 3 | 10 | 653 | 44.7 |

| 4 | 15 | 489 | 34.6 |

| 5 | 20 | 593 | 38 |

| 6 | 25 | 624 | 40.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sakr, M.A.H.; Omar, A.E.; Ene, A.; Hanfi, M.Y. Effect of Various Proportions of Rice Husk Powder on Swelling Soil from New Cairo City, Egypt. Appl. Sci. 2022, 12, 1616. https://doi.org/10.3390/app12031616

Sakr MAH, Omar AE, Ene A, Hanfi MY. Effect of Various Proportions of Rice Husk Powder on Swelling Soil from New Cairo City, Egypt. Applied Sciences. 2022; 12(3):1616. https://doi.org/10.3390/app12031616

Chicago/Turabian StyleSakr, Mohamed A. H., Ali E. Omar, Antoaneta Ene, and Mohamed Y. Hanfi. 2022. "Effect of Various Proportions of Rice Husk Powder on Swelling Soil from New Cairo City, Egypt" Applied Sciences 12, no. 3: 1616. https://doi.org/10.3390/app12031616