Structural Design and Position Tracking of the Reconfigurable SCARA Robot by the Pre-Filter AFE PID Controller

Abstract

:1. Introduction

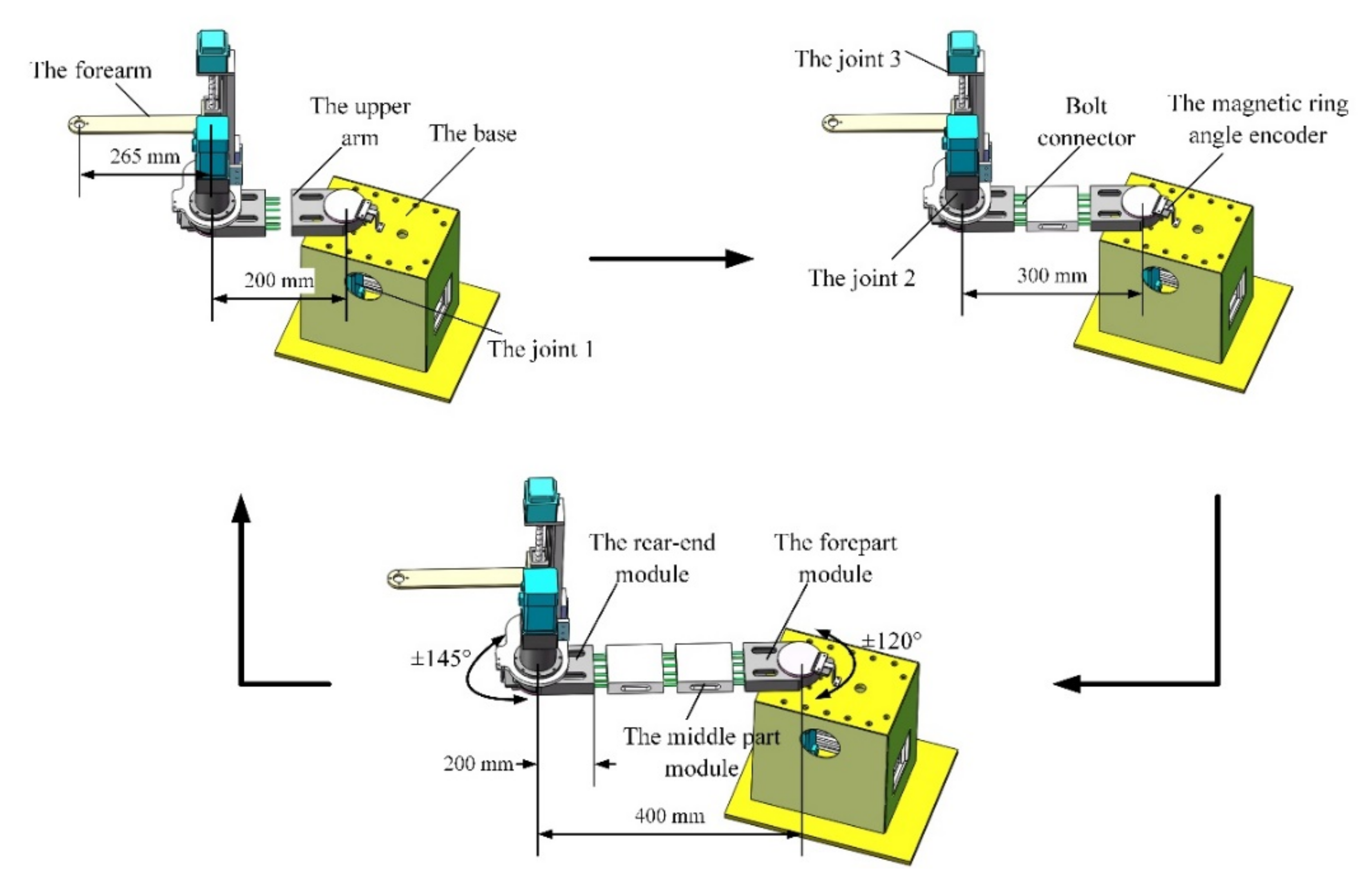

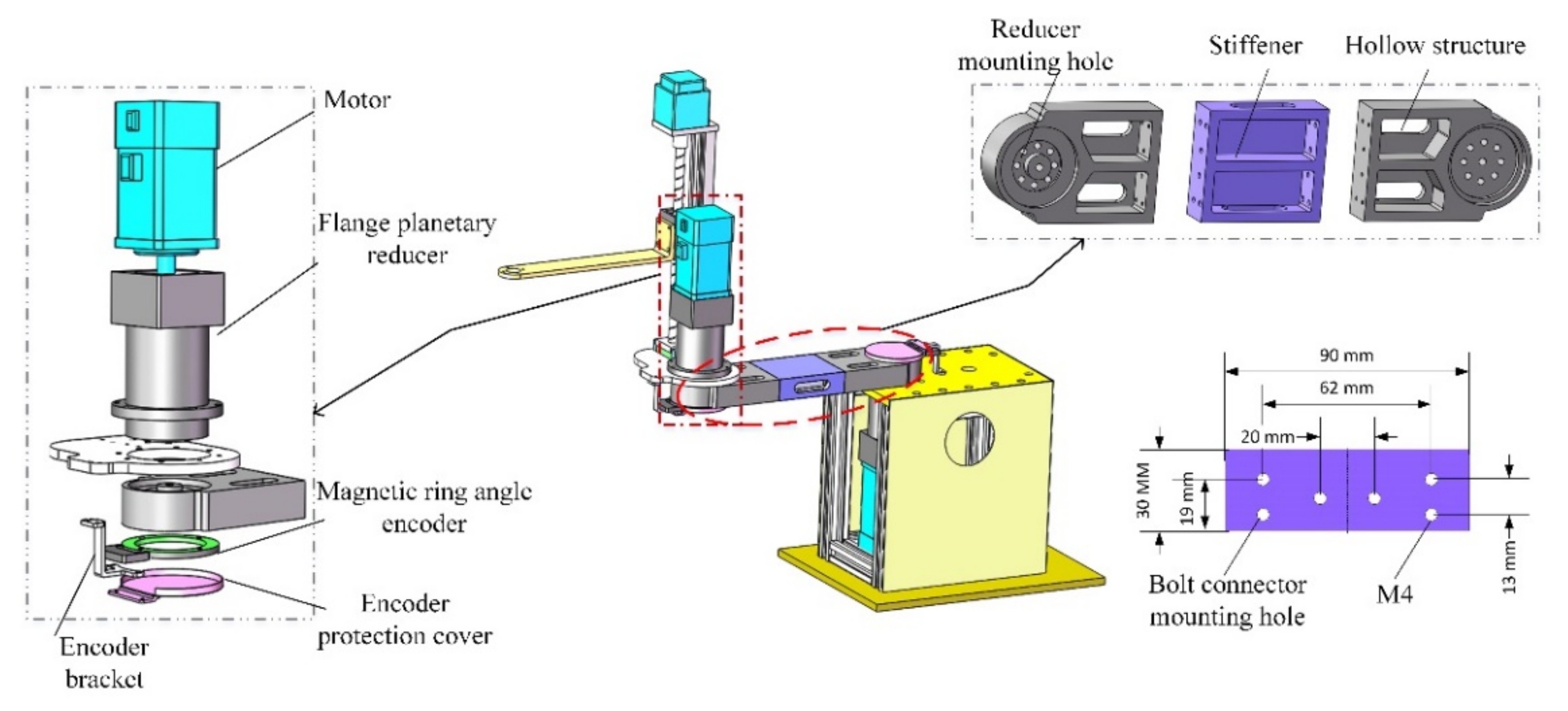

2. Mechanical Design

3. Structure Optimization

3.1. Multi-Objective Optimization Models

3.2. Optimization Results

4. Pre-Filter Acceleration Feedback Enhanced PID Controller

4.1. Pre-Filter Acceleration Feedback Enhanced Control Strategy

4.2. Controller

5. Experiments and Discussions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Song, C.Y.; Feng, H.; Chen, Y. Reconfigurable mechanism generated from the network of Bennett linkages. Mech. Mach. Theory 2015, 88, 49–62. [Google Scholar] [CrossRef]

- Valero, F.; Díaz-Rodríguez, M.; Vallés, M.; Besa, A.; Bernabéu, E.; Valera, Á. Reconfiguration of a parallel kinematic manipulator with 2T2R motions for avoiding singularities through minimizing actuator forces. Mechatronics 2020, 69, 102382. [Google Scholar] [CrossRef]

- EOstergaard, H.; Kassow, K.; Beck, R.; Lund, H.H. Design of the ATRON lattice-based self-reconfigurable robot, Auton. Robots 2006, 21, 165–183. [Google Scholar]

- Murata, S.; Yoshida, E.; Kamimura, A.; Kurokawa, H.; Tomita, K.; Kokaji, S. M-TRAN: Self-reconfigurable modular robotic system, IEEE/ASME Trans. Mechatron 2002, 7, 431–441. [Google Scholar]

- Yim, M.; Zhang, Y.; Roufas, K.; Duff, D.; Eldershaw, C. Connecting and disconnecting for chain self-reconfiguration with PolyBot, IEEE/ASME Trans. Mechatron 2002, 7, 442–451. [Google Scholar]

- Rus, D.; Vona, M. Crystalline robots: Self-reconfiguration with compressible unit modules, Auton. Robots 2001, 10, 107–124. [Google Scholar]

- Yu, C.H.; Haller, K.; Ingber, D.; Nagpal, R. Morpho: A self-deformable modular robot inspired by cellular structure. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Nice, France, 22–26 September 2008; pp. 3571–3578. [Google Scholar]

- Bucolo, M.; Buscarino, A.; Famoso, C.; Frasca, M. Control of imperfect dynamical systems. Nonlinear Dyn. 2019, 98, 2989–2999. [Google Scholar] [CrossRef]

- Wai, R.-J.; Chen, P.-C. Robust neural-fuzzy-network control for robot manipulator including actuator dynamics. IEEE Trans. Ind. Electron. 2006, 53, 1328–1349. [Google Scholar] [CrossRef]

- Zamanian, A.H.; Richer, E. Adaptive notch filter for pathological tremor suppression using permanent magnet linear motor. Mechatronics 2019, 63, 102273. [Google Scholar] [CrossRef]

- Yang, C.; Jiang, Y.; He, W.; Na, J.; Li, Z.; Xu, B. Adaptive parameter estimation and control design for robot manipulators with finite-time convergence. IEEE Trans. Ind. Electron. 2018, 65, 8112–8123. [Google Scholar] [CrossRef]

- Kim, J.; Jin, M.; Choi, W.; Lee, J. Discrete time delay control for hydraulic excavator motion control with terminal sliding mode control. Mechatronics 2019, 60, 15–25. [Google Scholar] [CrossRef]

- He, W.; Zhang, S. Control design for nonlinear flexible wings of a robotic aircraft. IEEE Trans. Control Syst. Technol. 2017, 25, 351–357. [Google Scholar] [CrossRef]

- Zhong, G.; Deng, H.; Li, J. Chattering-free variable structure controller design via fractional calculus approach and its application. Nonlinear Dyn. 2015, 81, 679–694. [Google Scholar] [CrossRef]

- He, W.; Chen, Y.; Yin, Z. Adaptive neural network control of an uncertain robot with full-state constraints. IEEE Trans. Cybern. 2016, 46, 620–629. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Dong, Y.; Sun, C. Adaptive neural impedance control of a robotic manipulator with input saturation. IEEE Trans. Syst. Man Cybern. Syst. 2016, 46, 334–344. [Google Scholar] [CrossRef]

- Morbi, A.; Ahmadi, M.; Chan, A.; Langlois, R. Stability-guaranteed assist-as-needed controller for powered orthoses. IEEE Trans. Control Syst. Technol. 2014, 22, 745–752. [Google Scholar] [CrossRef]

- Xu, W.L.; Han, J.D.; Tso, S.K. Experimental study of contact transition control incorporating joint acceleration feedback. IEEE/ASME Trans. Mechatron. 2000, 5, 292–301. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.L.; Han, J.D.; Tso, S.K.; Wang, Y.C. Contact transition control via joint acceleration feedback. IEEE Trans. Ind. Electron. 2000, 47, 150–158. [Google Scholar] [CrossRef]

- Aguirre-Ollinger, G.; Colgate, J.; Peshkin, M.; Goswami, A. Inertia compensation control of a one-degree-of-freedom exoskeleton for lower-limb assistance: Initial experiments. IEEE Trans. Neural Syst. Rehabil. Eng. 2012, 20, 68–77. [Google Scholar] [CrossRef] [Green Version]

- Kikuuwe, R. A sliding-mode-like position controller for admittance control with bounded actuator force. IEEE/ASME Trans. Mechatron. 2014, 19, 1489–1500. [Google Scholar]

- Wang, C.; Liu, X.; Yang, X.; Hu, F.; Jiang, A.; Yang, C. Trajectory tracking of an omni-directional wheeled mobile robot using a model predictive control strategy. Appl. Sci. 2018, 8, 231. [Google Scholar] [CrossRef] [Green Version]

- Chao, C.-T.; Sutarna, N.; Chiou, J.-S.; Wang, C.-J. Equivalence between fuzzy PID controllers and conventional PID controllers. Appl. Sci. 2017, 7, 513. [Google Scholar] [CrossRef] [Green Version]

| Link i | 𝜃𝑖 Rot z [deg] | 𝑑𝑖 Disp z [mm] | 𝑎𝑖 Disp x [mm] | 𝛼𝑖 Rot x [deg] |

|---|---|---|---|---|

| 1 | −120° ≤ 𝜃1 ≤ 120° | 0 | 200/300/400 | 0 |

| 2 | −145° ≤ 𝜃2 ≤ 145° | 0 | 265 | 0 |

| 3 | 0 | 0 ≤ d3 ≤ 200 | 0 | 180° |

| F0/N | c/mm | t/mm | |

|---|---|---|---|

| Minimum value | 1500 | 6 | 27 |

| Maximum value | 2500 | 10 | 33 |

| No. | c/mm | t/mm | F0/N | L/m | M/kg | f/Hz |

|---|---|---|---|---|---|---|

| 1 | 8 | 33 | 2500 | 5.67 × 10−5 | 1.105 | 501.6 |

| 2 | 8 | 27 | 2500 | 5.97 × 10−5 | 0.801 | 430.69 |

| 3 | 8 | 27 | 1500 | 4.36 × 10−5 | 0.801 | 430.48 |

| 4 | 8 | 30 | 2000 | 5.16 × 10−5 | 0.953 | 465.64 |

| 5 | 6 | 30 | 1500 | 1.53 × 10−4 | 0.821 | 418.34 |

| 6 | 6 | 33 | 2000 | 1.01 × 10−4 | 0.983 | 451.35 |

| 7 | 10 | 30 | 2500 | 4.36 × 10−5 | 1.054 | 500.58 |

| 8 | 10 | 27 | 2000 | 3.87 × 10−5 | 0.902 | 463.15 |

| 9 | 10 | 30 | 1500 | 2.85 × 10−5 | 1.054 | 500.48 |

| 10 | 8 | 30 | 2000 | 5.16 × 10−5 | 0.953 | 465.64 |

| 11 | 10 | 33 | 2000 | 3.53 × 10−5 | 1.209 | 538.92 |

| 12 | 8 | 33 | 1500 | 3.96 × 10−5 | 1.105 | 501.66 |

| 13 | 6 | 27 | 2000 | 1.76 × 10−4 | 0.669 | 383.19 |

| 14 | 6 | 30 | 2500 | 2.04 × 10−4 | 0.821 | 418.57 |

| 15 | 8 | 30 | 2000 | 5.16 × 10−5 | 0.953 | 465.64 |

| 16 | 8 | 30 | 2000 | 5.16 × 10−5 | 0.953 | 465.64 |

| Models | Goodness of Fit | |

|---|---|---|

| R2 | C.V | |

| 0.9946 | 0.0902 | |

| 0.9999 | 0.0011 | |

| 0.9719 | 0.0164 | |

| No. | c/mm | t/mm | F0/N | L/m | M/kg | f/Hz |

|---|---|---|---|---|---|---|

| 1 | 9.32 | 27.36 | 1547 | 3.32 × 10−5 | 0.871 | 457.92 |

| 2 | 8.27 | 29 | 1558 | 4.25 × 10−5 | 0.9 | 459.62 |

| 3 | 8.96 | 28.68 | 1578 | 3.49 × 10−5 | 0.919 | 468.27 |

| 4 | 8.85 | 29.04 | 1548 | 3.78 × 10−5 | 0.932 | 470.59 |

| 5 | 8.83 | 29.39 | 1577 | 4.05 × 10−5 | 0.95 | 474.98 |

| 6 | 8.84 | 29.73 | 1723 | 3.17 × 10−5 | 0.977 | 478.93 |

| Optimization Objective | Initial Design Scheme | Optimized Design Scheme | Rate of Change |

|---|---|---|---|

| L/m | 1.01 × 10−4 | 3.31 × 10−5 | 67.23% reduction |

| M/kg | 0.983 | 0.993 | 1.02% increase |

| f/Hz | 451.35 | 489.26 | 8.4% increase |

| Name | Type | Manufacturer | Main Parameters |

|---|---|---|---|

| First joint motor | 60ST-M00630 | Yichuan Motor Co., Ltd. | Rated Power: 400 W Maximum torque: 3.9 N.m Rated speed: 3500 rpm |

| Second joint motor | 60ST-M01330 | Yichuan Motor Co., Ltd. | Rated Power: 200 W Maximum torque:1.9 N.m Rated speed: 3500 rpm |

| Third joint motor | 57EBP98ALC | TCQ Electrical Technology Co., Ltd. | Rated Power: 200 W Maximum torque: 1.27 N.m Step angle: 1.8 deg |

| First joint reducer | PLH90-40 | SKISIA Co., Ltd. | Reduction ratio: 40 Maximum allowable torque: 84 N.m Dorsal space: 30 arcmin |

| Second joint reducer | PLH60-35 | SKISIA Co., Ltd. | Reduction ratio: 35 Maximum allowable torque: 224 N.m Dorsal space: 30 arcmin |

| Angle encoder | MRA7D049AA025B00 | Renishaw Corporation | Resolution: 5 µm Grid spacing: 20 µm |

| STM32 controller | STMF103VET6 | Xingyi Electronic Technology Co., Ltd. | Operating rate: 72 MHz, 3 ADCs and 1 DAC |

| Computer | INS14-3476 | DELL Corporation | Processor: Intel i5-7200U RAM: 4 GB |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhao, C.; Mei, D.; Tang, G.; Zhang, L.; Zhu, D. Structural Design and Position Tracking of the Reconfigurable SCARA Robot by the Pre-Filter AFE PID Controller. Appl. Sci. 2022, 12, 1626. https://doi.org/10.3390/app12031626

Wang Y, Zhao C, Mei D, Tang G, Zhang L, Zhu D. Structural Design and Position Tracking of the Reconfigurable SCARA Robot by the Pre-Filter AFE PID Controller. Applied Sciences. 2022; 12(3):1626. https://doi.org/10.3390/app12031626

Chicago/Turabian StyleWang, Yanjie, Chun Zhao, Dong Mei, Gangqiang Tang, Lei Zhang, and Denglin Zhu. 2022. "Structural Design and Position Tracking of the Reconfigurable SCARA Robot by the Pre-Filter AFE PID Controller" Applied Sciences 12, no. 3: 1626. https://doi.org/10.3390/app12031626