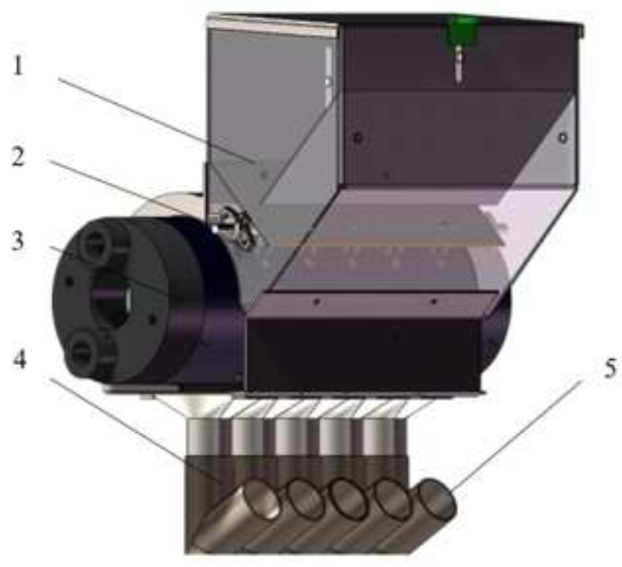

Figure 1.

The main structure of the rice-metering device. 1. seed box, 2. outer drum, 3. ventilation housing, 4. seeding tubes, and 5. air delivery ports.

Figure 1.

The main structure of the rice-metering device. 1. seed box, 2. outer drum, 3. ventilation housing, 4. seeding tubes, and 5. air delivery ports.

Figure 2.

Schematic diagram of the seeding process by the vacuum central drum seed-metering device.

Figure 2.

Schematic diagram of the seeding process by the vacuum central drum seed-metering device.

Figure 3.

The main structure of the seeding drum. 1. the outer drum, 2. the outer suction holes, 3. The inner suction holes, 4. the inner drum, 5. the negative pressure zone, 6. the positive pressure zone, and 7. the ventilation housing.

Figure 3.

The main structure of the seeding drum. 1. the outer drum, 2. the outer suction holes, 3. The inner suction holes, 4. the inner drum, 5. the negative pressure zone, 6. the positive pressure zone, and 7. the ventilation housing.

Figure 4.

The main structure diagram of the ventilation housing. (a) Front view and (b) side view.

Figure 4.

The main structure diagram of the ventilation housing. (a) Front view and (b) side view.

Figure 5.

The zone map of the ventilation housing.

Figure 5.

The zone map of the ventilation housing.

Figure 6.

The wedge-type agitating device. (a) 1 mm agitating device, (c) 2 mm agitating device, and (b) 1∼2 mm arc-shaped agitating device.

Figure 6.

The wedge-type agitating device. (a) 1 mm agitating device, (c) 2 mm agitating device, and (b) 1∼2 mm arc-shaped agitating device.

Figure 7.

Sketch map of the agitating device arrangement. 1. the ventilation housing, 2. the seed box, 3. the outer drum, 4. the agitating devices, and 5. the cleaning devices.

Figure 7.

Sketch map of the agitating device arrangement. 1. the ventilation housing, 2. the seed box, 3. the outer drum, 4. the agitating devices, and 5. the cleaning devices.

Figure 8.

The main structure of JPS-12 Force analysis of seeds. (a) The test-bed, (b) operating platform, and (c) the software main interface.

Figure 8.

The main structure of JPS-12 Force analysis of seeds. (a) The test-bed, (b) operating platform, and (c) the software main interface.

Figure 9.

The sucking probability of different holes under different diameters. (a) 10 rpm 1.0 kPa, (b) 10 rpm 1.5 kPa, (c) 10 rpm 2.0 kPa, (d) 20 rpm 1.IPa, (e) 20 rpm 1.5 kPa, (f) 20 rpm 2.0 kPa, (g) 30 rpm 1.0 kPa, (h) 30 rpm 1.5 kPa, (i) 30 rpm 2.0 kPa, (j) 40 rpm 1.0 kPa, (k) 40 rpm 1.5 kPa, (l) 40 rpm 2.0 kPa, (m) 50 rpm 1.0 kPa, (n) 50 rpm 1.5 kPa, (o) 50 rpm 2.0 kPa, (p) 60 rpm 1.0 kPa, (q) 60 rpm 1.5 kPa, and (r) 60 rpm 2.0 kPa.

Figure 9.

The sucking probability of different holes under different diameters. (a) 10 rpm 1.0 kPa, (b) 10 rpm 1.5 kPa, (c) 10 rpm 2.0 kPa, (d) 20 rpm 1.IPa, (e) 20 rpm 1.5 kPa, (f) 20 rpm 2.0 kPa, (g) 30 rpm 1.0 kPa, (h) 30 rpm 1.5 kPa, (i) 30 rpm 2.0 kPa, (j) 40 rpm 1.0 kPa, (k) 40 rpm 1.5 kPa, (l) 40 rpm 2.0 kPa, (m) 50 rpm 1.0 kPa, (n) 50 rpm 1.5 kPa, (o) 50 rpm 2.0 kPa, (p) 60 rpm 1.0 kPa, (q) 60 rpm 1.5 kPa, and (r) 60 rpm 2.0 kPa.

Figure 10.

The seeding quantity uniformity test of row metering.

Figure 10.

The seeding quantity uniformity test of row metering.

Figure 11.

The graph chart of the seeding amount for the different sowing tubes in group A.

Figure 11.

The graph chart of the seeding amount for the different sowing tubes in group A.

Figure 12.

The graph chart of the seeding amount for the different sowing tubes in group B.

Figure 12.

The graph chart of the seeding amount for the different sowing tubes in group B.

Figure 13.

The graph chart of the seeding amount for the different sowing tubes in group C.

Figure 13.

The graph chart of the seeding amount for the different sowing tubes in group C.

Figure 14.

The graph chart of the seeding amount for the different seeding tubes in average.

Figure 14.

The graph chart of the seeding amount for the different seeding tubes in average.

Figure 15.

The high-speed photography test-bed for seed dropping trajectory. 1. The metering device test-bed, 2. fill-in light, 3. the metering device, 4. the grid plate, 5. the computer, 6. the high speed camera, and 7. the operating platform.

Figure 15.

The high-speed photography test-bed for seed dropping trajectory. 1. The metering device test-bed, 2. fill-in light, 3. the metering device, 4. the grid plate, 5. the computer, 6. the high speed camera, and 7. the operating platform.

Figure 16.

The Photron Fastcam viewer for high-speed digital imaging.

Figure 16.

The Photron Fastcam viewer for high-speed digital imaging.

Figure 17.

The dropping trajectory t of the rice seeds.

Figure 17.

The dropping trajectory t of the rice seeds.

Figure 18.

The view of the optimized seed tube and its 3D printed model.

Figure 18.

The view of the optimized seed tube and its 3D printed model.

Table 1.

The average triaxial size of six varieties hybrid rice seeds.

Table 1.

The average triaxial size of six varieties hybrid rice seeds.

| Cultivar | Average Length/mm | Average Width/mm | Average Thickness/mm |

|---|

| Ruanhuayou1179 | 9.82 | 2.28 | 1.82 |

| Shunliangyou1179 | 9.72 | 2.64 | 2.04 |

| Jingliangyou 1212 | 8.48 | 2.42 | 1.85 |

| Teyou338 | 8.22 | 2.87 | 2.14 |

| Wuyou1179 | 8.62 | 2.56 | 1.99 |

Table 2.

The basic physical properties of Jingliangyou 1212 rice.

Table 2.

The basic physical properties of Jingliangyou 1212 rice.

| Varieties | Average Length/mm | Average Width/mm | Average Thickness/mm | Moisture Content/% | Average Thousand Seed Weight/g | Standard Deviation |

|---|

| Jingliangyou 1212 | 8.48 | 2.42 | 1.85 | 19.13 | 21.83 | 0.21 |

Table 3.

The factor and level in experiment.

Table 3.

The factor and level in experiment.

| Factor | Levels |

|---|

| 1 | 2 | 3 | 4 | 5 | 6 |

|---|

| A Rotational speed (r/min) | 10 | 20 | 30 | 40 | 50 | 60 |

| B Negative pressure (kPa) | 1.0 | 1.5 | 2.0 | | | |

| C Holes diameter (mm) | 1.5 | 2 | 2 (Chamfering 45°) | | | |

Table 4.

The experiment arrangement and test results L18(6 × 36).

Table 4.

The experiment arrangement and test results L18(6 × 36).

| Treatment | A Speed | B Negative Pressure | C Bore Size | 0 Seed Rate/% | 1 Seed Rate/% | 2 Seed Rate/% | 3 Seed Rate/% | ≥4 Seed Rate/% | 1–3 Seed Rate/% |

|---|

| 1 | 1 | 1 | 1 | 9.6 | 63.0 | 23.1 | 4.3 | 0 | 90.40 |

| 2 | 1 | 2 | 2 | 0.3 | 20.1 | 49.7 | 20.7 | 9.2 | 90.50 |

| 3 | 1 | 3 | 3 | 15.5 | 21.7 | 28.3 | 22.0 | 12.5 | 72.00 |

| 4 | 2 | 1 | 1 | 10.9 | 63.5 | 24.3 | 1.3 | 0 | 89.10 |

| 5 | 2 | 2 | 2 | 0.3 | 31.3 | 50.3 | 15.1 | 3.0 | 84.70 |

| 6 | 2 | 3 | 3 | 4.7 | 11.0 | 39.3 | 25.0 | 20.0 | 75.30 |

| 7 | 3 | 1 | 2 | 2.6 | 63.8 | 30.9 | 2.6 | 0 | 97.40 |

| 8 | 3 | 2 | 3 | 39.1 | 33.2 | 16.1 | 8.6 | 3.0 | 57.90 |

| 9 | 3 | 3 | 1 | 13.8 | 54.6 | 25.7 | 5.3 | 0.7 | 85.50 |

| 10 | 4 | 1 | 3 | 63.2 | 28.3 | 7.6 | 0.7 | 0.3 | 36.50 |

| 11 | 4 | 2 | 1 | 22.3 | 65.1 | 12.6 | 0 | 0 | 77.70 |

| 12 | 4 | 3 | 2 | 14.1 | 41.8 | 41.4 | 2.6 | 0 | 85.90 |

| 13 | 5 | 1 | 2 | 17.4 | 65.8 | 16.1 | 0.7 | 0 | 82.60 |

| 14 | 5 | 2 | 3 | 49.3 | 32.9 | 12.8 | 3.9 | 1.0 | 49.70 |

| 15 | 5 | 3 | 1 | 46.1 | 48.7 | 5.3 | 0 | 0 | 53.90 |

| 16 | 6 | 1 | 3 | 96.7 | 3.3 | 0 | 0 | 0 | 3.30 |

| 17 | 6 | 2 | 1 | 66.4 | 30.6 | 3.0 | 0 | 0 | 33.60 |

| 18 | 6 | 3 | 2 | 70.1 | 29.3 | 0.6 | 0 | 0 | 29.90 |

Table 5.

The intuitionistic analysis for qualified rate.

Table 5.

The intuitionistic analysis for qualified rate.

| Factor | A | B | C |

|---|

| 488.58 | 199.50 | 215.28 |

| 498.18 | 197.04 | 235.5 |

| 482.4 | 161.19 | 147.33 |

| 400.02 | | |

| 372.36 | | |

| 131.76 | | |

| 84.30 | 66.55 | 71.76 |

| 83.03 | 65.68 | 78.50 |

| 80.40 | 53.73 | 49.11 |

| 66.70 | | |

| 62.06 | | |

| 21.96 | | |

| 62.34 | 12.82 | 29.39 |

| Factor Priorities | A | C | B |

| Optimization options | A1B1C2 | | |

Table 6.

The variance analysis for the qualification rate.

Table 6.

The variance analysis for the qualification rate.

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|

| Correction model | 11,129.028a | 9 | 1236.559 | 11.100 | 0.001 |

| Intercept distance | 79,507.427 | 1 | 79,507.427 | 713.716 | 0.000 |

| A | 8279.023 | 5 | 1655.805 | 14.864 | 0.001 |

| B | 6.524 | 2 | 3.262 | 0.029 | 0.971 |

| C | 2843.481 | 2 | 1421.741 | 12.763 | 0.003 |

| Error (Inaccuracy) | 891.194 | 8 | 111.399 | | |

| Total | 91,527.650 | 18 | | | |

| Total corrected | 12,020.223 | 17 | | | |

Table 7.

The intuitionistic analysis for the missing rate.

Table 7.

The intuitionistic analysis for the missing rate.

| Factor | A | B | C |

|---|

| 25.40 | 200.40 | 215.28 |

| 15.90 | 177.70 | 173.70 |

| 55.50 | 164.30 | 268.50 |

| 99.60 | | |

| 112.8 | | |

| 233.2 | | |

| 8.47 | 33.40 | 35.88 |

| 5.30 | 29.62 | 28.95 |

| 18.50 | 27.38 | 44.75 |

| 33.20 | | |

| 37.60 | | |

| 77.73 | | |

| 72.43 | 6.02 | 15.8 |

| Factor Priorities | A | C | B |

| Optimization options | A2B3C2 | | |

Table 8.

The variance analysis for the missing rate.

Table 8.

The variance analysis for the missing rate.

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|

| Correction model | 13,035.533a | 9 | 1448.393 | 11.117 | 0.001 |

| Intercept distance | 16,344.320 | 1 | 16,344.320 | 125.447 | 0.000 |

| A | 10,657.167 | 5 | 2131.433 | 16.359 | 0.001 |

| B | 111.003 | 2 | 55.502 | 0.426 | 0.667 |

| C | 2267.363 | 2 | 1133.682 | 8.701 | 0.010 |

| Error (Inaccuracy) | 1042.307 | 8 | 130.288 | | |

| Total | 30,422.160 | 18 | | | |

| Total corrected | 14,077.840 | 17 | | | |

Table 9.

The intuitionistic analysis for re-seeding rate.

Table 9.

The intuitionistic analysis for re-seeding rate.

| Factor | A | B | C |

|---|

| 21.70 | 0.30 | 0.70 |

| 23.00 | 16.20 | 12.20 |

| 3.70 | 33.20 | 36.80 |

| 0.30 | | |

| 1.00 | | |

| 0.00 | | |

| 7.23 | 0.05 | 0.12 |

| 7.56 | 2.70 | 2.03 |

| 1.23 | 5.53 | 6.13 |

| 0.1 | | |

| 0.33 | | |

| 0.00 | | |

| 7.56 | 5.48 | 6.01 |

| Factor Priorities | A | C | B |

| Optimization options | A3B1C1 | | |

Table 10.

The variance analysis for the over sowing rate.

Table 10.

The variance analysis for the over sowing rate.

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|

| Correction model | 404.598a | 9 | 44.955 | 3.031 | 0.067 |

| Intercept distance | 137.227 | 1 | 137.227 | 9.253 | 0.016 |

| A | 200.996 | 5 | 40.199 | 2.711 | 0.101 |

| B | 90.234 | 2 | 45.117 | 3.042 | 0.104 |

| C | 113.368 | 2 | 56.684 | 3.822 | 0.068 |

| Error (Inaccuracy) | 118.644 | 8 | 14.831 | | |

| Total | 660.470 | 18 | | | |

| Total corrected | 523.243 | 17 | | | |

Table 11.

Experimental data of the seeding quantity uniformity.

Table 11.

Experimental data of the seeding quantity uniformity.

| Repeat | Seed Quantity/g | Mean/g | SD | CV |

|---|

| 1 | 2 | 3 | 4 | 5 |

|---|

| A | 85.561 | 68.643 | 81.86 | 64.988 | 69.778 | 74.17 | 8.04 | 10.84% |

| B | 73.823 | 73.517 | 87.26 | 81.449 | 66.842 | 76.58 | 7.07 | 9.23% |

| C | 78.17 | 87.26 | 72.05 | 90.008 | 69.595 | 79.42 | 8.07 | 10.16% |

| Average seed quantity | 79.18 | 76.47 | 80.39 | 78.81 | 68.74 | 76.72 | 4.19 | 5.45% |

Table 12.

Fitting equation of the seed throwing trajectory.

Table 12.

Fitting equation of the seed throwing trajectory.

| Seeding Drum Speed/(rpm) | Fitting Equation for Seeding Trajectory Y | Correlation Coefficient R2 |

|---|

| 10 | | 0.990 |

| 15 | | 0.995 |

| 20 | | 0.995 |

| 25 | | 0.999 |

| 30 | | 0.990 |

| 35 | | 0.998 |

| 40 | | 0.998 |

| 45 | | 0.999 |

| 50 | | 0.999 |

| 55 | | 0.999 |

| 60 | | 0.999 |