Sous Vide Cooking Effects on Physicochemical, Microbiological and Sensory Characteristics of Pork Loin

Abstract

:1. Introduction

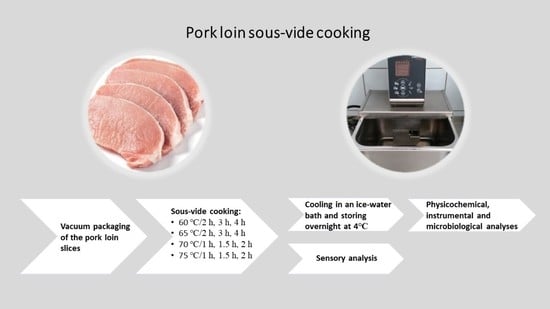

2. Materials and Methods

2.1. Preparation of Samples

2.2. Cooking Loss

2.3. Moisture Content

2.4. pH Measurement

2.5. Water Activity

2.6. Colour Determination

2.7. Instrumental Texture Analysis

2.8. Microbiological Analysis

2.9. Sensory Analysis

2.10. Statistical Analysis

3. Results and Discussion

3.1. Cooking Loss

3.2. Moisture Content

3.3. Water Activity

3.4. pH Value

3.5. Colour

3.6. Instrumental Texture Analysis

3.6.1. Shear Force

3.6.2. Texture Profile Analysis (TPA)

3.7. Microbiological Analyses

3.8. Sensory Analysis

3.9. Relationships between Selected Attributes of Cooked Samples

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akoğlu, I.T.; Bıyklı, M.; Akoğlu, A.; Kurhan, Ş. Determination of the quality and shelf life of sous vide cooked turkey cutlet stored at 4 and 12 °C. Rev. Bras. Cienc. Avic. 2018, 20, 1–8. [Google Scholar] [CrossRef]

- Bhat, Z.F.; Morton, J.D.; Zhang, X.; Mason, S.L.; Bekhit, A.E.A. Sous-vide cooking improves the quality and in-vitro digestibility of Semitendinosus from culled dairy cows. Food Res. Int. 2020, 127, 108708. [Google Scholar] [CrossRef] [PubMed]

- Sánchez del Pulgar, J.; Gázquez, A.; Ruiz-Carrascal, J. Physico-chemical, textural and structural characteristics of sous-vide cooked pork cheeks as affected by vacuum, cooking temperature, and cooking time. Meat Sci. 2012, 90, 828–835. [Google Scholar] [CrossRef] [PubMed]

- Dominguez-Hernandez, E.; Salaseviciene, A.; Ertbjerg, P. Low-temperature long-time cooking of meat: Eating quality and underlying mechanisms. Meat Sci. 2018, 143, 104–113. [Google Scholar] [CrossRef] [Green Version]

- Bryan, E.E.; Smith, B.N.; Dilger, R.N.; Dilger, A.C.; Boler, D.D. Technical note: A method for detection of differences in cook loss and tenderness of aged pork chops cooked to differing degrees of doneness using sous-vide. J. Anim. Sci. 2019, 97, 3348–3353. [Google Scholar] [CrossRef]

- Clausen, M.P.; Christensen, M.; Djurhuus, T.H.; Duelund, L.; Mouritsen, O.G. The quest for umami: Can sous vide contribute? Int. J. Gastron. Food Sci. 2018, 129–133. [Google Scholar] [CrossRef] [Green Version]

- James, B.J.; Yang, S.W. Effect of cooking method on the toughness of bovine M. Semitendinosus. Int. J. Food Eng. 2012, 8, 1–18. [Google Scholar] [CrossRef]

- Hong, G.E.; Kim, J.H.; Ahn, S.J.; Lee, C.H. Changes in meat quality characteristics of the sous-vide cooked chicken breast during refrigerated storage. Korean J. Food Sci. Anim. Resor. 2015, 35, 757–764. [Google Scholar] [CrossRef] [Green Version]

- Roldán, M.; Antequera, T.; Martin, A.; Mayoral, A.I.; Ruiz, J. Effect of different temperature-time combinations on physicochemical, microbiological, textural and structural features of sous-vide cooked lamb loins. Meat Sci. 2013, 93, 572–578. [Google Scholar] [CrossRef]

- Christensen, L.; Ertbjerg, P.; Løje, H.; Risbo, J.; van den Berg, F.W.J.; Christensen, M. Relationship between meat toughness and properties of connective tissue from cows and young bulls treated at low temperatures for prolonged times. Meat Sci. 2013, 93, 787–795. [Google Scholar] [CrossRef]

- Christensen, L.; Gunvig, A.; Tørngren, M.A.; Aaslyng, M.D.; Knøchel, S.; Christensen, M. Sensory characteristics of meat cooked for prolonged times at low temperature. Meat Sci. 2012, 90, 485–489. [Google Scholar] [CrossRef] [PubMed]

- Baldwin, D.E. Sous vide cooking: A review. Int. J. Gastron. Food Sci. 2012, 1, 15–30. [Google Scholar] [CrossRef] [Green Version]

- Christensen, M.; Purslow, P.P.; Larsen, L.M. The effect of cooking temperature on mechanical properties of whole meat, single muscle fibres and perimysial connective tissue. Meat Sci. 2000, 55, 301–307. [Google Scholar] [CrossRef]

- Becker, A.; Boulaaba, A.; Pingen, S.; Krischek, C.; Klein, G. Low temperature cooking of pork meat—Physicochemical and sensory aspects. Meat Sci. 2016, 118, 82–88. [Google Scholar] [CrossRef]

- Lien, R.; Hunt, M.C.; Anderson, S.; Kropf, D.H.; Loughin, T.M.; Dikeman, M.E.; Velazco, J. Effects of endpoint temperature on the internal color of pork loin chops of different quality. J. Food Sci. 2002, 67, 1007–1010. [Google Scholar] [CrossRef]

- Geileskey, A.; King, R.D.; Corte, D.; Pinto, P.; Ledward, D.A. The kinetics of cooked meat haemoprotein formation in meat and model systems. Meat Sci. 1998, 48, 189–199. [Google Scholar] [CrossRef]

- King, N.J.; Whyte, R. Does it look cooked? A review of factors that influence cooked meat color. J. Food Sci. 2006, 71, R31–R40. [Google Scholar] [CrossRef]

- Becker, A.; Boulaaba, A.; Pingen, S.; Röhner, A.; Klein, G. Low temperature, long time treatment of porcine M. longissimus thoracis et lumborum in a combi steamer under commercial conditions. Meat Sci. 2015, 110, 230–235. [Google Scholar] [CrossRef]

- Dominguez-Hernandez, E.; Ertbjerg, P. Effect of LTLT heat treatment on cathepsin B and L activities and denaturation of myofibrillar proteins of pork. Meat Sci. 2021, 175, 108454. [Google Scholar] [CrossRef]

- Christensen, L.; Ertbjerg, P.; Aaslyng, M.D.; Christensen, M. Effect of prolonged heat treatment from 48 °C to 63 °C on toughness, cooking loss and color of pork. Meat Sci. 2011, 88, 280–285. [Google Scholar] [CrossRef]

- Jeong, K.O.H.; Shin, S.Y.; Kim, Y.S. Effects of sous-vide method at different temperatures, times and vacuum degrees on the quality, structural, and microbiological properties of pork ham. Meat Sci. 2018, 143, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Zielbauer, B.I.; Franz, J.; Viezens, B.; Vilgis, T.A. Physical aspects of meat cooking: Time dependent thermal protein denaturation and water loss. Food Biophys. 2016, 11, 34–42. [Google Scholar] [CrossRef]

- Vaudagna, S.R.; Pazos, A.A.; Guidi, S.M.; Sanchez, G.; Carp, D.J.; Gonzales, C.B. Effect of salt addition on sous vide cooked whole beef muscles from Argentina. Meat Sci. 2008, 79, 470–482. [Google Scholar] [CrossRef] [PubMed]

- Ángel-Rendón, S.V.; Filomena-Ambrosio, A.; Hernández-Carrión, M.; Llorca, E.; Hernando, I.; Quiles, A.; Sotelo-Díaz, I. Pork meat prepared by different cooking methods. A microstructural, sensorial and physicochemical approach. Meat Sci. 2020, 163, 108089. [Google Scholar] [CrossRef] [PubMed]

- AOAC International. Official methods of analysis 950.46. In Moisture in Meat, 18th ed.; AOAC International: Gaithersburg, MD, USA, 2005. [Google Scholar]

- ISO 4833-1:2013; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganism—Part 1: Colony Count at 30 °C by the Pour Plate Technique. 2005. Available online: https://www.iso.org/standard/59509.html (accessed on 11 January 2022).

- ISO/DIS 6888-2:2020; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Coagulase-Positive Staphylococci (Staphylococcus aureus and Other Species)—Part 2: Technique Using Rabbit Plasma Fibrinogen Agar Medium. Available online: https://webstore.ansi.org/standards/iso/isodis68882020-2405117 (accessed on 11 January 2022).

- ISO 21528-2:2017; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Enterobacteriaceae —Part 2: Colony—Count Technique. Available online: https://www.iso.org/standard/63504.html (accessed on 11 January 2022).

- ISO 6579-1:2017; Microbiology of the Food Chain—Horizontal Method for the Detection, Enumeration and Serotyping of Salmonella—Part 1: Detection of Salmonella spp. Available online: https://www.iso.org/obp/ui/#iso:std:iso:6579:-1:ed-1:v1:en (accessed on 11 January 2022).

- ISO 11290-1:2017; Microbiology of the Food Chain—Horizontal Method for the Detection, and Enumeration of Listeria monocytogenes and of Listeria spp.—Part 1: Detection Method. Available online: https://www.iso.org/standard/60313.html (accessed on 11 January 2022).

- PN-EN ISO 8586:2014-03; Sensory Analysis. General Guidance for Selection, Training and Monitoring of Selected Assessors and Experts. Polish Committee for Standardization: Warsaw, Poland, 2014.

- ISO 4121:2003; Sensory Analysis—Guidelines for the Use of Quantitative Response Scales. Available online: https://www.iso.org/standard/33817.html (accessed on 11 January 2022).

- Ayub, H.; Ahmad, A. Physiochemical changes in sous-vide and conventionally cooked meat. Int. J. Gastron. Food Sci. 2019, 17, 100145. [Google Scholar] [CrossRef]

- Hwang, S.I.; Lee, E.J.; Hong, G.P. Effects of temperature and time on the cookery properties of sous-vide processed pork loin. Food Sci. Anim. Resour. 2019, 39, 65–72. [Google Scholar] [CrossRef]

- Gerber, N.; Scheeder, M.R.L.; Wenk, C. The influence of cooking and fat trimming on the actual nutrient intake from meat. Meat Sci. 2009, 81, 148–154. [Google Scholar] [CrossRef]

- Oz, F.; Aksu, M.; Turan, M. The effects of different cooking methods on some quality criteria and mineral composition of beef steaks. J. Food Process. Pres. 2017, 41, e13008. [Google Scholar] [CrossRef]

- Tornberg, E. Effect of heat on meat proteins—Implications on structure and quality of meat products. Meat Sci. 2005, 70, 493–508. [Google Scholar] [CrossRef]

- Lawrie, R.A.; Ledward, D.A. Lawrie’s Meat Science; Woodhead Publishing Limited: Cambridge, UK, 2006. [Google Scholar]

- Purslov, P.P.; Oiseth, S.; Hughes, J.; Warner, R.D. The structural basis of cooking loss in beef: Variations with temperature and ageing. Food Res. Int. 2016, 89, 739–748. [Google Scholar] [CrossRef]

- Park, Y.W. Moisture and water activity. In Handbook of Processed Meat and Poultry Analysis, 1st ed.; Nollet, L.M.L., Toldra, F., Eds.; CRC Press: Boca Raton, FL, USA; London, UK; New York, NY, USA, 2008; pp. 35–40. [Google Scholar]

- Resconi, V.C.; Escudero, A.; Campo, M.M. The development of aromas in ruminant meat. Molecules 2013, 18, 6748–6781. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bıyklı, M.; Akoğlu, A.; Kurhan, Ş.; Akoğlu, I.T. Effect of different sous vide cooking temperature-time combinations on the physicochemical, microbiological, and sensory properties of turkey cutlet. Int. J. Gastron. Food Sci. 2020, 20, 100204. [Google Scholar] [CrossRef]

- Díaz, P.; Nieto, G.; Garrido, M.D.; Bañón, S. Microbial, physical-chemical and sensory spoilage during the refrigerated storage of cooked pork loin processed by the sous vide method. Meat Sci. 2008, 80, 287–292. [Google Scholar] [CrossRef] [PubMed]

- Haghighi, H.; Belmonte, A.M.; Masino, F.; Minelli, G.; Lo Fiego, D.P.; Pulvirenti, A. Effect of time and temperature on physicochemical and microbiological properties of sous vide chicken breast fillets. Appl. Sci. 2021, 11, 3189. [Google Scholar] [CrossRef]

- Vasanthi, C.; Venkataramanujam, V.; Dushyanthan, K. Effect of cooking temperature and time on the physico-chemical, histological and sensory properties of female carabeef (buffalo) meat. Meat Sci. 2007, 76, 274–280. [Google Scholar] [CrossRef]

- Bojarska, U.; Batura, J.; Cierach, M. The effect of measurement site on the evaluation of tom breast muscle color. Pol. J. Food Nutr. Sci. 2003, 53, 45–49. [Google Scholar]

- Vaudagna, S.R.; Sánchez, G.; Neira, M.S.; Insani, E.M.; Picallo, A.B.; Gallinger, M.M.; Lasta, J.A. Sous vide cooked beef muscles: Effects of low temperature–long time (LT–LT) treatments on their quality characteristics and storage stability. Int. J. Food Sci. Tech. 2002, 37, 425–441. [Google Scholar] [CrossRef]

- Botinestean, C.; Keenan, D.F.; Kerry, J.P.; Hamill, R.M. The effect of thermal treatments including sous-vide, blast freezing and their combinations on beef tenderness of M. Semitendinosus steaks targeted at elderly consumers. LWT Food Sci. Technol. 2016, 74, 154–159. [Google Scholar] [CrossRef]

- Smith, D.S. Quantifying color variation: Improved formulas for calculating hue with segment classification. Appl. Plant Sci. 2014, 2, 1300088. [Google Scholar] [CrossRef]

- Sun, S.; Rasmussen, F.D.; Cavender, G.A.; Sullivan, G.A. Texture, color and sensory evaluation of sous-vide cooked beef steaks processed using high pressure processing as method of microbial control. LWT Food Sci. Technol. 2019, 103, 169–177. [Google Scholar] [CrossRef]

- Mokrzycki, W.; Tatol, M. Color difference Delta E—A survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

- Ismail, I.; Hwang, Y.-H.; Bakhsh, A.; Joo, S.-T. The alternative approach of low temperature-long time cooking on bovine semitendinosus meat quality. Asian-Australas. J. Anim. Sci. 2019, 32, 282–289. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brüggemann, D.A.; Brewer, J.; Risbo, J.; Bagatolli, L. Second harmonic generation microscopy: A tool for spatially and temporally resolved studies of heat induced structural changes in meat. Food Biophys. 2010, 5, 1–8. [Google Scholar] [CrossRef]

- Palka, K.; Daun, H. Changes in texture, cooking losses, and myofibrillar structure of bovine M. semitendinosus during heating. Meat Sci. 1999, 51, 237–243. [Google Scholar] [CrossRef]

- Commission Regulation (EC) No. 2073/2005 of 15 November 2005 on Microbiological criteria for foodstuffs. Official Journal of the European Union, L 388, 48, 1-26. The Commission of the European Communities: Brussels, Belgium, 2005; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=OJ:L:2005:338:FULL&from=EN (accessed on 14 September 2021).

- Aaslyng, M.D.; Meinert, L. Meat flavor in pork and beef—From animal to meal. Meat Sci. 2017, 132, 112–117. [Google Scholar] [CrossRef]

- Przybylski, W.; Jaworska, D.; Kajak-Siemaszko, K.; Sałek, P.; Pakuła, K. Effect of heat treatment by the sous-vide method on the quality of poultry meat. Foods 2021, 10, 1610. [Google Scholar] [CrossRef]

- Chansataporn, W.; Nopharatana, M.; Samuhasaneetoo, S.; Siriwattanayotin, S.; Tangduangdee, C. Effects of temperature on the main intermediates and products of the Maillard reaction in the chicken breast meat model system. Int. J. Agric. Technol. 2019, 15, 539–556. [Google Scholar]

- Anderson, D.B.; Breidenstein, B.B.; Kauffan, R.G.; Cassens, R.G.; Bray, R.W. Effect of cooking on fatty acid composition of beef lipids. Int. J. Food Sci. Technol. 1971, 6, 141–152. [Google Scholar] [CrossRef]

- Rotola-Pukkila, M.; Pihlajaviita, S.T.; Kaimainen, M.; Hopia, A. Concentration of umami compounds in pork meat and cooking juice with different cooking times and temperatures. J. Food Sci. 2015, 80, C2711–C2716. [Google Scholar] [CrossRef]

- Roldán, M.; Antequera, T.; Armenteros, M.; Ruiz, J. Effect of different temperature-time combinations on lipid and protein oxidation of sous-vide cooked lamb loins. Food Chem. 2014, 149, 129–136. [Google Scholar] [CrossRef]

- Souza, C.M.; Boler, D.D.; Clark, D.L.; Kutzler, L.W.; Holmer, S.F.; Summerfield, J.W.; Cannon, J.E.; Smit, N.R.; McKeith, F.K.; Killefer, J. The effects of high pressure processing on pork quality, palatability, and further processed products. Meat Sci. 2011, 87, 419–427. [Google Scholar] [CrossRef] [PubMed]

| Sample | Cooking Loss (%) | Moisture Content (%) | Water Activity (-) | pH (-) |

|---|---|---|---|---|

| Raw pork loin | nd | 72.45 ± 0.34 i | 0.993 ± 0.001 a | 5.78 ± 0.01 a |

| 60 °C | ||||

| 2 h | 18.16 ± 1.07 a | 68.91 ± 0.28 h | 0.995 ± 0.003 a | 5.80 ± 0.37 a |

| 3 h | 21.13 ± 1.12 abc | 67.54 ± 0.58 fgh | 0.993 ± 0.002 a | 5.81 ± 0.10 a |

| 4 h | 22.46 ± 1.05 bc | 67.50 ± 0.41 fgh | 0.991 ± 0.004 a | 5.80 ± 0.10 a |

| 65 °C | ||||

| 2 h | 19.55 ± 0.46 ab | 68.16 ± 0.20 gh | 0.993 ± 0.002 a | 5.81 ± 0.22 a |

| 3 h | 24.41 ± 0.54 cd | 66.90 ± 0.11 efg | 0.993 ± 0.002 a | 5.82 ± 0.11 a |

| 4 h | 29.64 ± 0.74 def | 66.31 ± 0.14 defg | 0.994 ± 0.001 a | 5.80 ± 0.07 a |

| 70 °C | ||||

| 1 h | 25.21 ± 1.52 cde | 65.91 ± 0.37 cdef | 0.993 ± 0.003 a | 5.84 ± 0.17 a |

| 1.5 h | 28.79 ± 0.46 def | 64.00 ± 0.28 abc | 0.994 ± 0.001 a | 5.86 ± 0.02 a |

| 2 h | 30.58 ± 0.43 f | 65.27 ± 0.34 cde | 0.995 ± 0.002 a | 5.85 ± 0.14 a |

| 75°C | ||||

| 1 h | 29.05 ± 1.06 ef | 64.90 ± 0.29 bcd | 0.994 ± 0.002 a | 5.88 ± 0.09 a |

| 1.5 h | 31.61 ± 0.54 fg | 63.24 ± 0.53 ab | 0.994 ± 0.003 a | 5.90 ± 0.03 a |

| 2 h | 36.66 ± 0.63 g | 62.32 ± 0.70 a | 0.994 ± 0.001 a | 5.91 ± 0.01 a |

| Level of significance | ||||

| Temperature | *** | *** | NS | NS |

| Time | *** | *** | NS | NS |

| Temperature × time interaction | * | NS | NS | NS |

| Sample | Colour L* | Colour a* | Colour b* | Chroma C* | Hue Angle h° | ∆E* |

|---|---|---|---|---|---|---|

| Raw pork loin | 54.72 ± 0.8 b | 8.35 ± 0.33 b | 5.30 ± 0.22 d | 9.89 ± 0.44 c | 32.40 ± 0.79 c | nd |

| 60 °C | ||||||

| 2 h | 70.16 ± 1.05 a | 7.45 ± 0.20 a | 14.60 ± 0.12 c | 15.59 ± 0.15 ab | 59.71 ± 0.61 ab | 21.20 |

| 3 h | 70.05 ± 1.01 a | 7.53 ± 0.18 a | 14.72 ± 0.10 c | 15.93 ± 0.11 ab | 60.88 ± 0.58 ab | 21.28 |

| 4 h | 70.61 ± 0.71 a | 7.44 ± 0.06 a | 14.65 ± 0.21 c | 15.44 ± 0.19 a | 60.41 ± 0.38 a | 19.44 |

| 65 °C | ||||||

| 2 h | 70.68 ± 0.56 a | 7.45 ± 0.06 a | 14.59 ± 0.08 c | 15.58 ± 0.08 ab | 60.72 ± 0.18 ab | 25.61 |

| 3 h | 71.02 ± 1.05 a | 7.49 ± 0.43 a | 14.43 ± 0.36 bc | 15.99 ± 0.47 ab | 61.71 ± 1.07 ab | 21.92 |

| 4 h | 70.61 ± 0.33 a | 7.49 ± 0.10 a | 14.34 ± 0.20 abc | 16.04 ± 0.21 ab | 61.82 ± 0.34 ab | 18.96 |

| 70 °C | ||||||

| 1 h | 70.89 ± 0.82 a | 7.57 ± 0.21 a | 14.13 ± 0.31 abc | 16.18 ± 0.35 ab | 62.41 ± 0.51 ab | 15.56 |

| 1.5 h | 70.57 ± 0.08 a | 7.58 ± 0.08 a | 14.08 ± 0.07 abc | 16.33 ± 0.08 ab | 62.93 ± 0.26 ab | 15.82 |

| 2 h | 70.81 ± 0.74 a | 7.62 ± 0.15 a | 13.58 ± 0.15 ab | 16.38 ± 0.17 ab | 62.95 ± 0.48 ab | 16.07 |

| 75 °C | ||||||

| 1 h | 71.21 ± 0.58 a | 7.63 ± 0.19 a | 13.41 ± 0.20 a | 16.44 ± 0.25 ab | 63.00 ± 0.45 b | 19.68 |

| 1.5 h | 71.63 ± 0.94 a | 7.76 ± 0.20 a | 13.90 ± 0.11 abc | 16.55 ± 0.15 b | 62.94 ± 0.62 ab | 19.15 |

| 2 h | 71.45 ± 0.10 a | 7.86 ± 0.04 a | 13.46 ± 0.09 abc | 16.41 ± 0.09 ab | 63.03 ± 0.19 b | 17.01 |

| Level of significance | ||||||

| Temperature | NS | NS | *** | *** | *** | nd |

| Time | NS | NS | *** | * | ** | nd |

| Temperature × time interaction | NS | NS | NS | NS | NS | nd |

| Sample | Shear Force [N] | Hardness [N] | Springiness [cm] | Cohesiveness [-] | Chewiness [N × cm] |

|---|---|---|---|---|---|

| 60 °C | |||||

| 2 h | 23.80 ± 0.95 ef | 60.26 ± 3.33 a | 0.50 ± 0.01 abc | 0.56 ± 0.01 de | 17.51 ± 0.01 ab |

| 3 h | 17.63 ± 1.70 abcd | 58.84 ± 3.67 a | 0.46 ± 0.01 ab | 0.51 ± 0.01 ab | 16.00 ± 0.01 ab |

| 4 h | 25.61 ± 0.68 f | 54.77 ± 4.19 a | 0.46 ± 0.02 ab | 0.51 ± 0.02 a | 13.65 ± 0.01 a |

| 65 °C | |||||

| 2 h | 18.24 ± 1.39 bcd | 79.29 ± 4.06 bcde | 0.53 ± 0.01 cd | 0.57 ± 0.01 cd | 24.01 ± 0.01 cde |

| 3 h | 13.29 ± 1.01 a | 71.12 ± 4.23 abc | 0.51 ± 0.01 abcd | 0.59 ± 0.01 def | 21.19 ± 0.01 bcd |

| 4 h | 19.95 ± 0.52 cde | 72.91 ± 2.85 abcd | 0.45 ± 0.01 a | 0.52 ± 0.01 abc | 17.34 ± 0.01 abc |

| 70 °C | |||||

| 1 h | 22.47 ± 1.30 def | 69.20 ± 2.22 ab | 0.52 ± 0.01 bcd | 0.60 ± 0.00 def | 21.32 ± 0.01 bcd |

| 1.5 h | 18.40 ± 1.19 abcd | 90.11 ± 3.46 cdef | 0.49 ± 0.01 abc | 0.55 ± 0.01 abcd | 24.14 ± 0.01 bcde |

| 2 h | 14.66 ± 0.53 ab | 90.04 ± 2.92 def | 0.53 ± 0.01 cd | 0.60 ± 0.01 def | 28.13 ± 0.01 def |

| 75 °C | |||||

| 1 h | 21.97 ± 1.20 def | 95.29 ± 5.68 ef | 0.57 ± 0.01 d | 0.62 ± 0.01 ef | 34.34 ± 0.01 f |

| 1.5 h | 17.98 ± 0.36 abcd | 121.84 ± 5.42 g | 0.57 ± 0.01 d | 0.64 ± 0.01 f | 45.22 ± 0.00 g |

| 2 h | 14.61 ± 0.44 abc | 107.46 ± 3.28 fg | 0.51 ± 0.01 abcd | 0.56 ± 0.01 bcd | 31.85 ± 0.01 ef |

| Level of significance | |||||

| Temperature | *** | *** | *** | *** | *** |

| Time | *** | *** | *** | *** | *** |

| Temperature × time interaction | NS | NS | *** | *** | *** |

| Sample | Total Mesophilic Microorganisms | Coagulase-Positive Staphylococci | Enterobacteriaceae | Salmonella spp. | Listeria Monocytogenes |

|---|---|---|---|---|---|

| [log cfu/g] | Presence in 25 g | ||||

| Raw pork loin | 3.59 ± 0.21 c | 1.95 ± 0.26 b | 3.07 ± 0.09 b | NP | NP |

| 60 °C | |||||

| 2 h | 1.79 ± 0.16 a | <1.00 a | <1.00 a | NP | NP |

| 3 h | 1.33 ± 0.45 a | <1.00 a | <1.00 a | NP | NP |

| 4 h | 2.01 ± 0.79 b | <1.00 a | <1.00 a | NP | NP |

| 65 °C | |||||

| 2 h | 1.43 ± 0.31 a | <1.00 a | <1.00 a | NP | NP |

| 3 h | 1.16 ± 0.22 a | <1.00 a | <1.00 a | NP | NP |

| 4 h | 1.20 ± 0.16 a | <1.00 a | <1.00 a | NP | NP |

| 70 °C | |||||

| 1 h | 1.65 ± 0.40 a | <1.00 a | <1.00 a | NP | NP |

| 1.5 h | 1.73 ± 0.04 a | <1.00 a | <1.00 a | NP | NP |

| 2 h | 1.10 ± 0.14 a | <1.00 a | <1.00 a | NP | NP |

| 75 °C | |||||

| 1 h | 1.30 ± 0.25 a | <1.00 a | <1.00 a | NP | NP |

| 1.5 h | 1.43 ± 0.31 a | <1.00 a | <1.00 a | NP | NP |

| 2 h | 1.10 ± 0.14 a | <1.00 a | <1.00 a | NP | NP |

| Sample | Overall Appearance 1 | Colour Uniformity 2 | Aroma Intensity 3 | Tenderness 4 | Juiciness 5 | Meat Flavour Intensity 3 | Flavour Acceptability 1 | Overall Acceptability 1 |

|---|---|---|---|---|---|---|---|---|

| 60 °C | ||||||||

| 2 h | 7.79 ± 0.33 a | 8.36 ± 0.27 abc | 6.79 ± 0.46 a | 6.14 ± 0.38 abc | 7.43 ± 0.25 d | 6.86 ± 0.31 a | 7.50 ± 0.20 ab | 7.36 ± 0.27 ab |

| 3 h | 8.29 ± 0.19 ab | 8.14 ± 0.35 abc | 7.29 ± 0.37 a | 6.50 ± 0.59 abc | 6.57 ± 0.42 cd | 7.64 ± 0.41 ab | 8.14 ± 0.21 b | 7.79 ± 0.15 ab |

| 4 h | 8.71 ± 0.24 ab | 7.79 ± 0.46 ab | 7.64 ± 0.60 a | 7.00 ± 0.51 bc | 6.43 ± 0.44 bcd | 8.64 ± 0.27 b | 8.43 ± 0.33 b | 8.14 ± 0.35 b |

| 65 °C | ||||||||

| 2 h | 8.23 ± 0.20 ab | 7.77 ± 0.26 ab | 7.15 ± 0.32 a | 7.00 ± 0.28 bc | 6.54 ± 0.40 bcd | 7.23 ± 0.38 ab | 7.23 ± 0.36 ab | 7.08 ± 0.35 ab |

| 3 h | 8.00 ± 0.23 a | 7.46 ± 0.31 a | 7.77 ± 0.32 a | 6.15 ± 0.62 abc | 4.54 ± 0.57 abc | 7.85 ± 0.30 ab | 6.85 ± 0.48 ab | 6.69 ± 0.43 ab |

| 4 h | 9.17 ± 0.21 b | 9.33 ± 0.19 c | 8.33 ± 0.26 a | 8.17 ± 0.53 c | 6.42 ± 0.53 bcd | 8.50 ± 0.40 ab | 7.08 ± 0.38 ab | 7.25 ± 0.49 ab |

| 70 °C | ||||||||

| 1 h | 7.81 ± 0.23 a | 7.94 ± 0.30 abc | 6.88 ± 0.40 a | 6.31 ± 0.37 abc | 5.56 ± 0.52 abcd | 7.94 ± 0.21 ab | 7.25 ± 0.50 ab | 6.50 ± 0.41 ab |

| 1.5 h | 8.92 ± 0.23 ab | 9.08 ± 0.26 bc | 8.08 ± 0.26 a | 7.00 ± 0.49 abc | 6.17 ± 0.42 bcd | 8.25 ± 0.35 ab | 7.17 ± 0.34 ab | 7.33 ± 0.31 ab |

| 2 h | 8.27 ± 0.14 ab | 8.55 ± 0.25 abc | 7.64 ± 0.31 a | 6.00 ± 0.62 abc | 5.36 ± 0.51 abcd | 7.82 ± 0.35 ab | 6.64 ± 0.43 ab | 6.36 ± 0.53 ab |

| 75 °C | ||||||||

| 1 h | 8.07 ± 0.21 ab | 8.53 ± 0.19 abc | 7.33 ± 0.40 a | 4.67 ± 0.41 a | 4.40 ± 0.46 ab | 7.40 ± 0.40 ab | 6.67 ± 0.54 ab | 6.33 ± 0.47 ab |

| 1.5 h | 7.93 ± 0.27 a | 8.20 ± 0.24 abc | 7.80 ± 0.30 a | 5.00 ± 0.52 ab | 3.80 ± 0.43 a | 7.93 ± 0.32 ab | 6.80 ± 0.60 ab | 6.20 ± 0.55 a |

| 2 h | 8.67 ± 0.19 ab | 9.00 ± 0.21 bc | 7.67 ± 0.41 a | 5.50 ± 0.54 ab | 4.58 ± 0.53 abc | 8.08 ± 0.36 ab | 6.00 ± 0.44 a | 6.00 ± 0.49 a |

| Level of significance | ||||||||

| Temperature | NS | NS | NS | *** | *** | NS | *** | *** |

| Time | *** | NS | NS | ** | ** | ** | NS | * |

| Temperature × time interaction | ** | *** | NS | NS | NS | NS | NS | NS |

| Attribute | Moisture Content | Shear Force | Hardness | Chewiness | Springiness | Cohesiviness | Tenderness | Juiciness | Overall Acceptability |

|---|---|---|---|---|---|---|---|---|---|

| Cooking loss | −0.031 | −0.157 | 0.369 *** | 0.411 *** | 0.280 ** | 0.316 *** | −0.172 | −0.322 *** | −0.275 ** |

| Moisture content | - | 0.261 ** | −0.150 | −0.193 | −0.216 * | −0.160 | −0.153 | −0.044 | 0.016 |

| Shear force | - | - | −0.077 | −0.064 | −0.131 * | −0.212 *** | 0.056 | 0.068 | 0.122 |

| Hardness | - | - | - | 0.588 *** | 0.392 *** | 0.336 *** | −0.156 * | −0.162 * | −0.197 * |

| Chewiness | - | - | - | - | 0.512 *** | 0.504 *** | −0.162 * | −0.219 ** | −0.312 *** |

| Springiness | - | - | - | - | - | 0.583 *** | 0.008 | −0.092 | −0.200 * |

| Cohesiviness | - | - | - | - | - | - | −0.090 | −0.091 | −0.240 ** |

| Tenderness | - | - | - | - | - | - | - | 0.617 *** | 0.561 *** |

| Juiciness | - | - | - | - | - | - | - | - | 0.662 *** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurp, L.; Danowska-Oziewicz, M.; Kłębukowska, L. Sous Vide Cooking Effects on Physicochemical, Microbiological and Sensory Characteristics of Pork Loin. Appl. Sci. 2022, 12, 2365. https://doi.org/10.3390/app12052365

Kurp L, Danowska-Oziewicz M, Kłębukowska L. Sous Vide Cooking Effects on Physicochemical, Microbiological and Sensory Characteristics of Pork Loin. Applied Sciences. 2022; 12(5):2365. https://doi.org/10.3390/app12052365

Chicago/Turabian StyleKurp, Lidia, Marzena Danowska-Oziewicz, and Lucyna Kłębukowska. 2022. "Sous Vide Cooking Effects on Physicochemical, Microbiological and Sensory Characteristics of Pork Loin" Applied Sciences 12, no. 5: 2365. https://doi.org/10.3390/app12052365

APA StyleKurp, L., Danowska-Oziewicz, M., & Kłębukowska, L. (2022). Sous Vide Cooking Effects on Physicochemical, Microbiological and Sensory Characteristics of Pork Loin. Applied Sciences, 12(5), 2365. https://doi.org/10.3390/app12052365