Design and Evaluation of a Shaping and Pruning Machine for Dwarf and Densely Planted Jujube Trees

Abstract

:1. Introduction

2. Materials and Methods

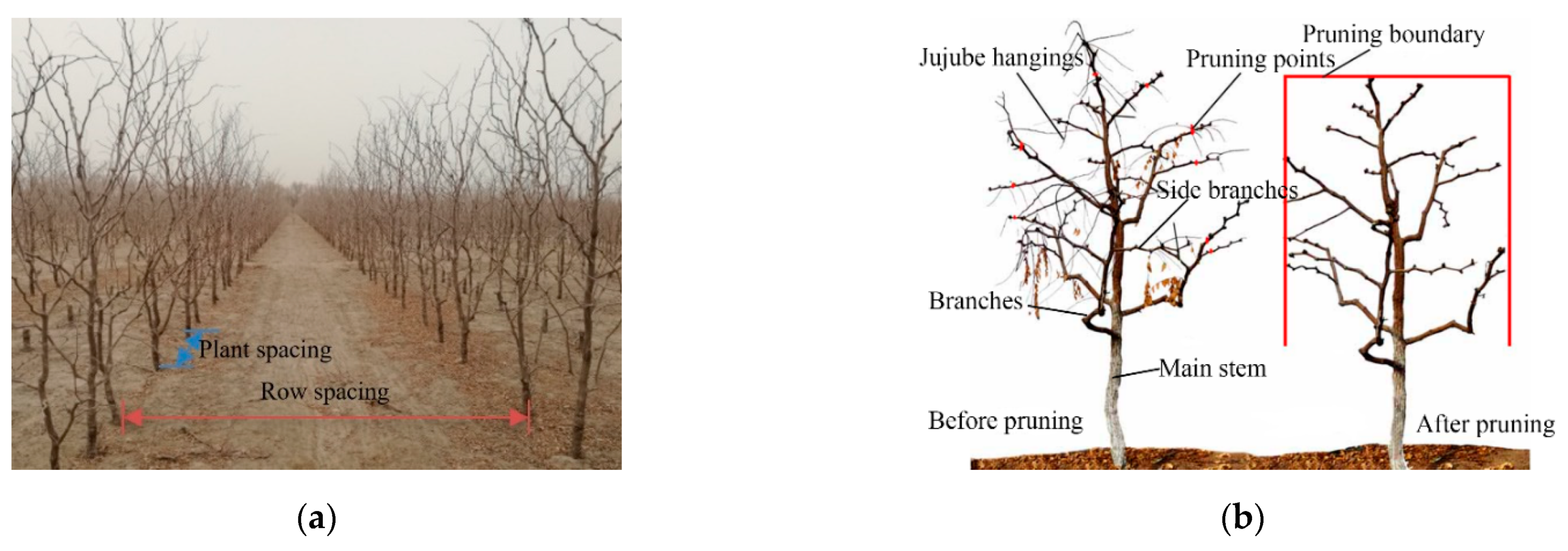

2.1. Planting Modes and Agronomic Pruning Requirements of Jujube Trees

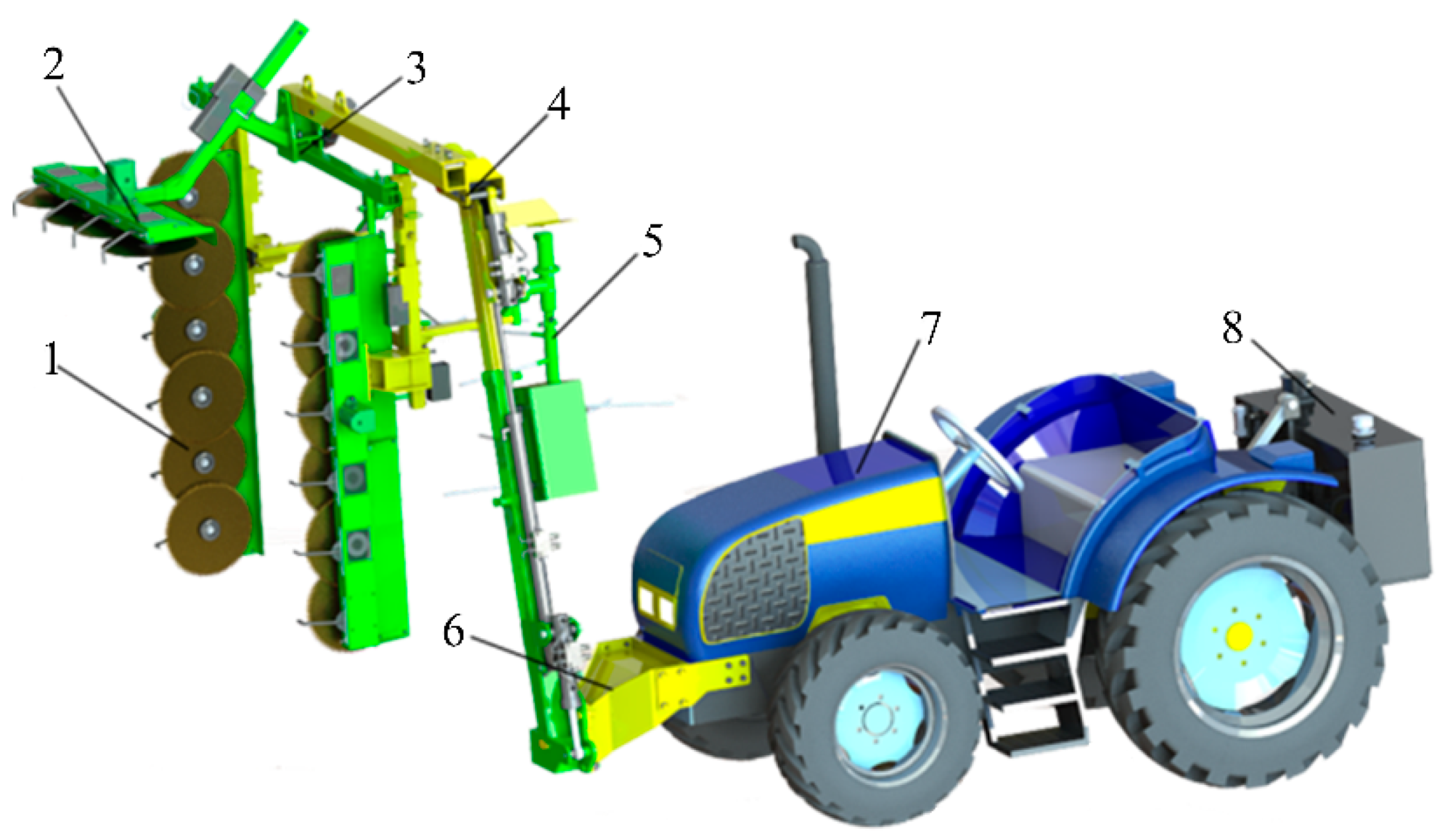

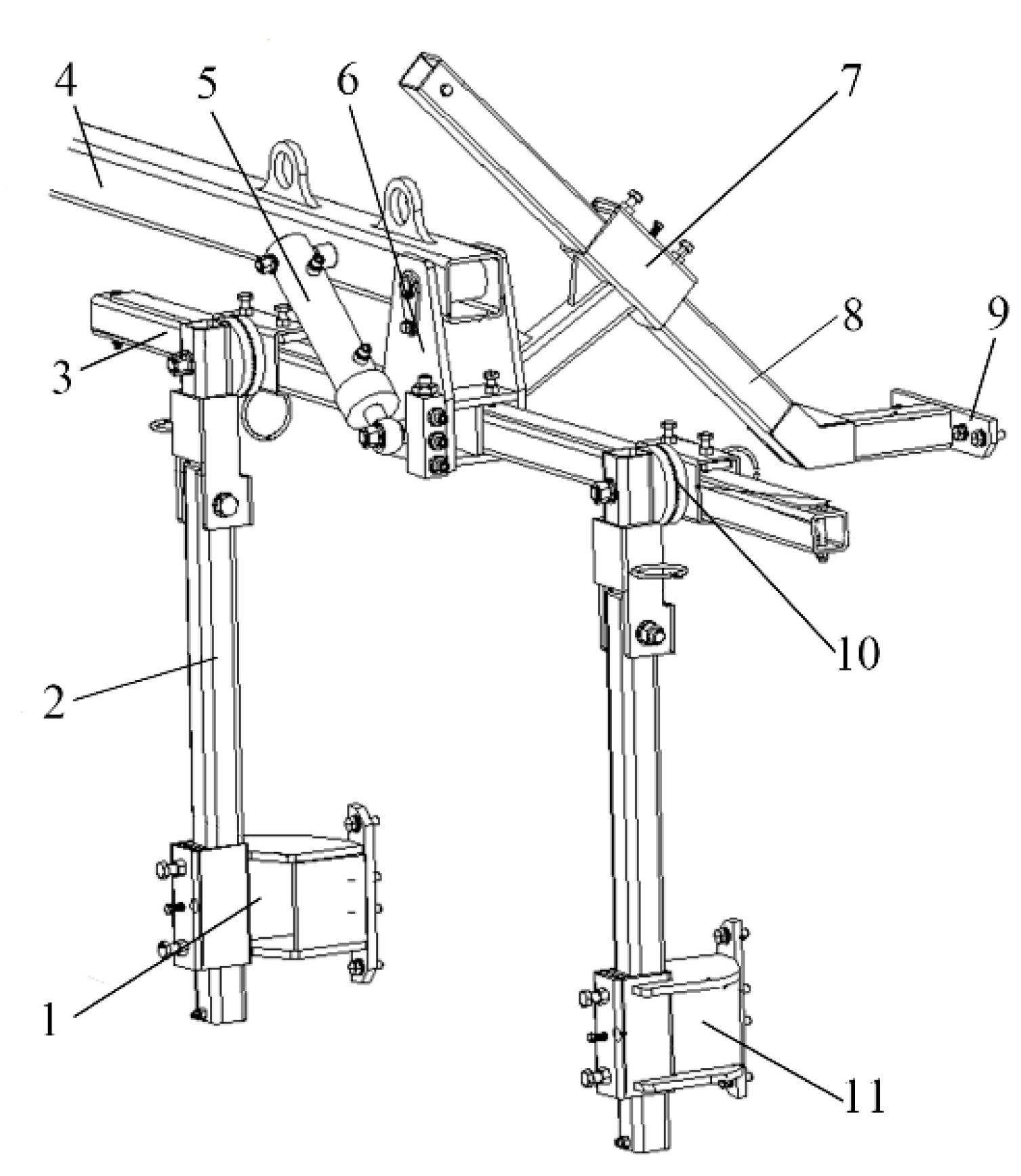

2.2. The Structure and Working Principles of the Pruning Machine

2.2.1. The Structure and Main Technical Parameters of the Pruning Machine

2.2.2. Working Principle of Overall Machine

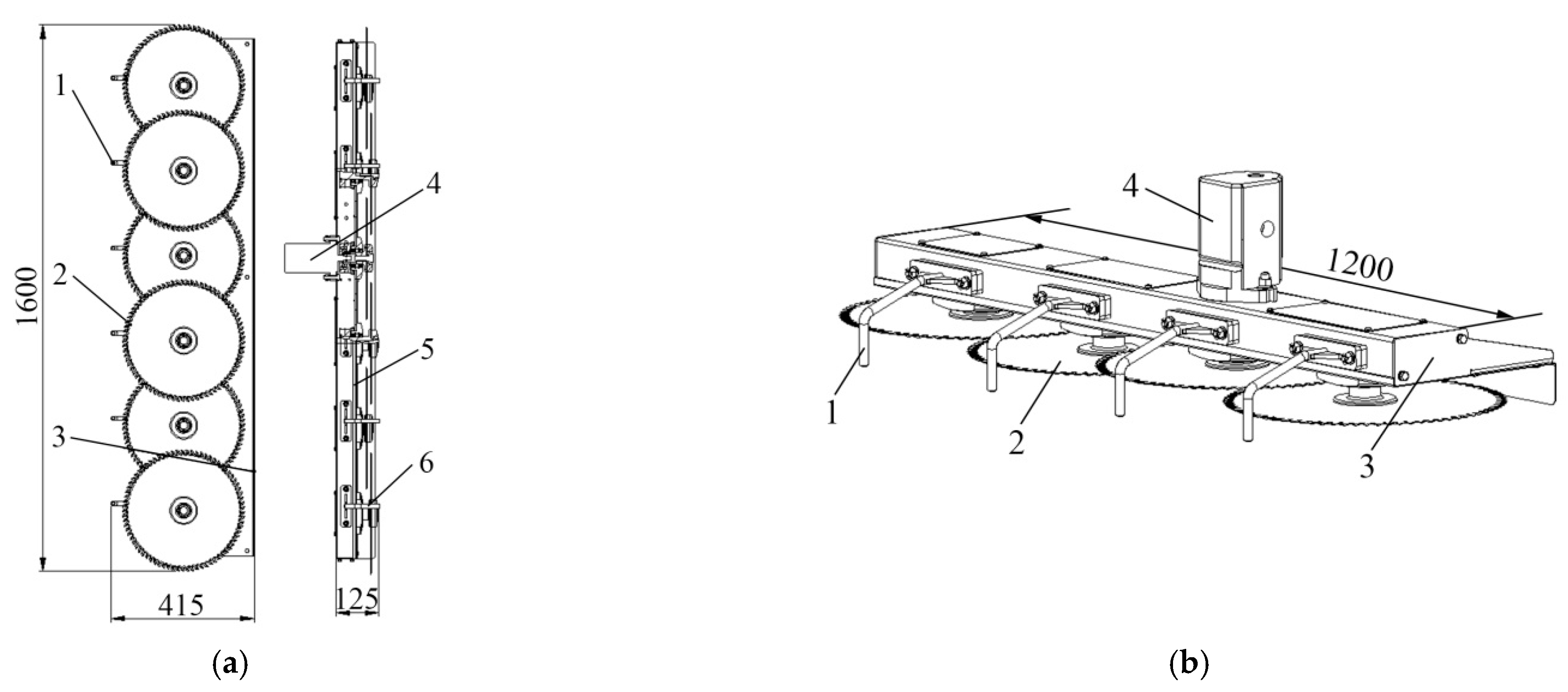

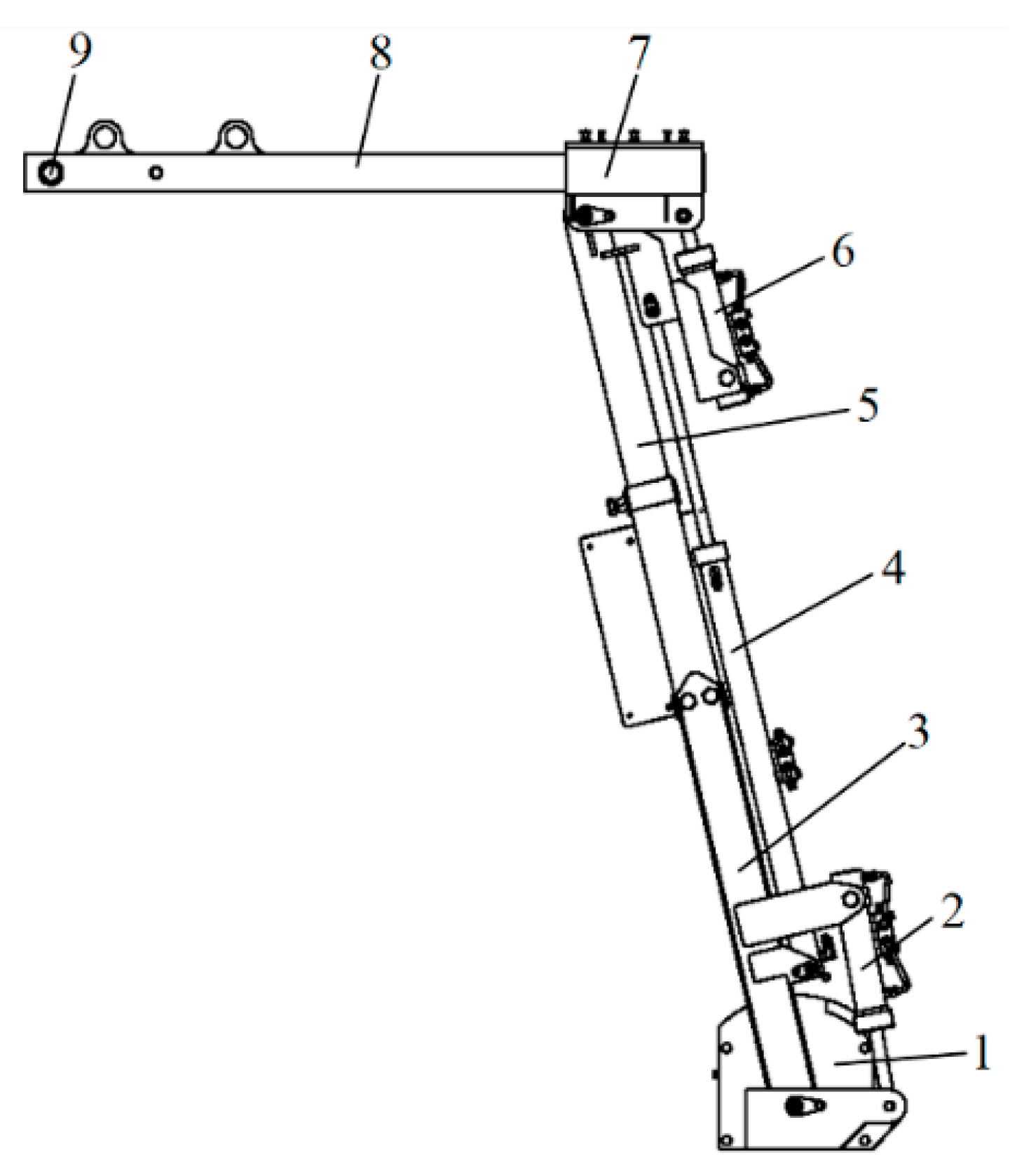

2.3. Design of Pruning Device

2.3.1. Design of the Structure

2.3.2. Analysis of Cutter Rotation Speed

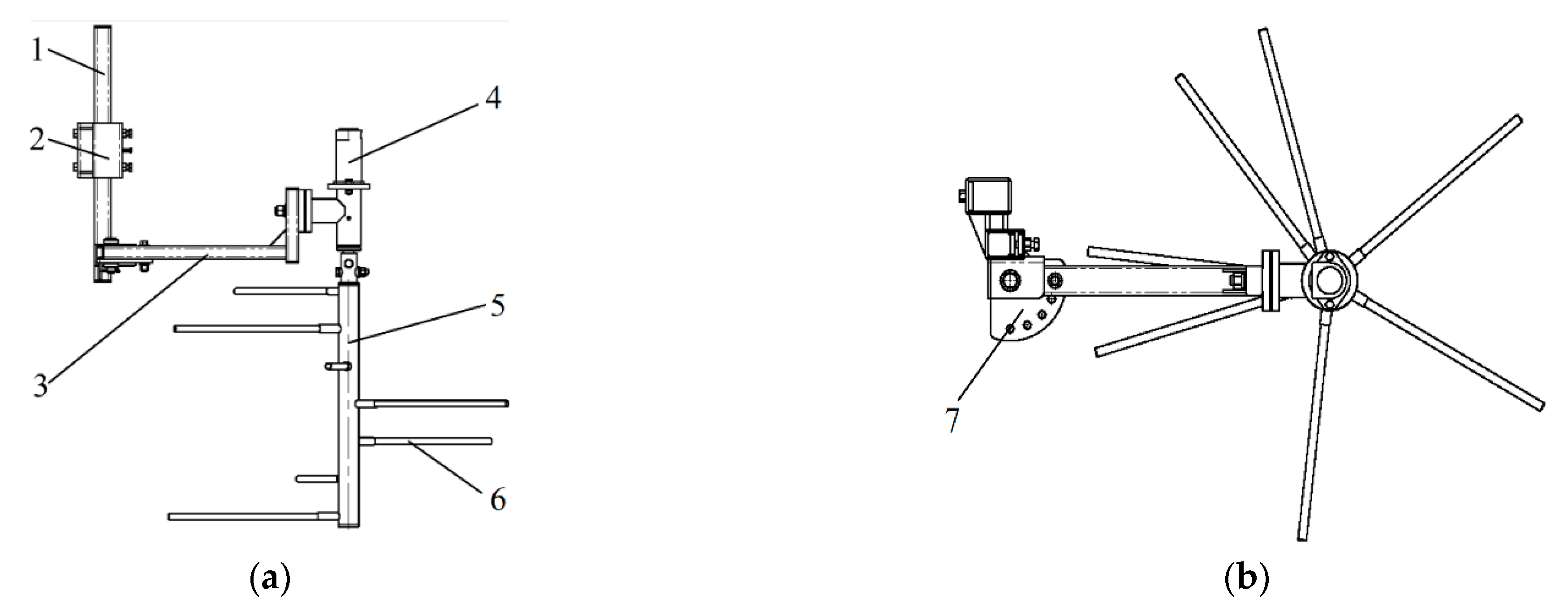

2.4. Design of Removal Mechanism for Jujube Hangings

2.5. Design of Shaping Frame

2.5.1. Design of Shaping and Pruning Frame

2.5.2. Design of Shaping Adjustment Frame

2.6. Field Performance Test

2.6.1. Test Conditions

2.6.2. The Evaluation Index

2.6.3. Quadratic Regression Orthogonal Test

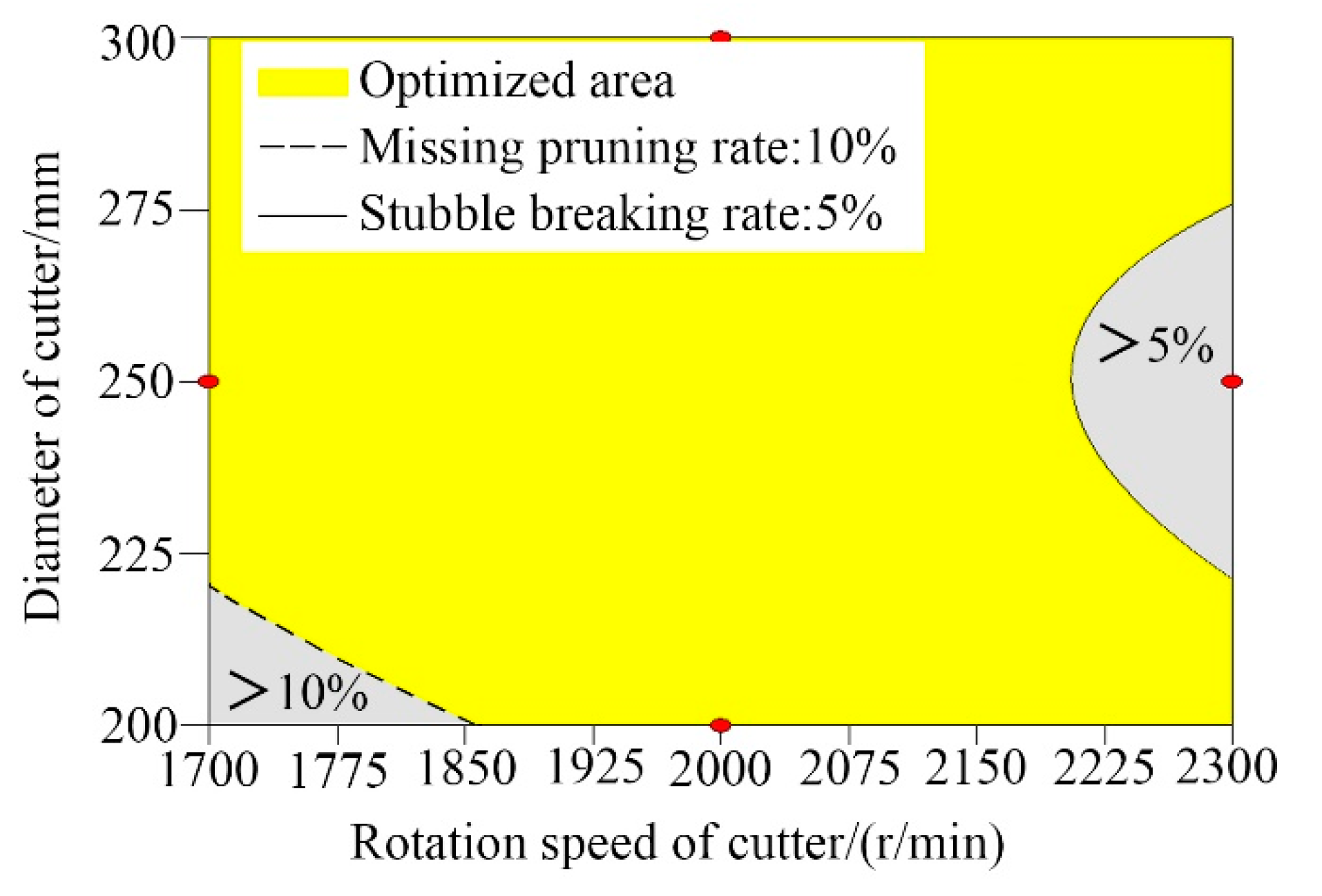

2.6.4. Parameter Optimization and Field Validation Test

3. Results

3.1. Results of the Quadratic Regression Orthogonal Test

3.1.1. Analysis of Variance for Test Results

3.1.2. Response Surface Analysis

3.2. Results of Parameter Optimization and Field Validation Test

3.2.1. Results of Parameter Optimization

3.2.2. Results of Field Validation Test

4. Discussion

5. Conclusions

- (1)

- Through investigation of dwarf and densely planted jujube gardens in Xinjiang, it was determined that the shapes of the main trunks of jujube trees have become the primary standard for the development of dwarf and densely planted jujube gardens in Xinjiang. Before artificial pruning, the height of the jujube canopy was between 600–1900 mm, and the diameter of the canopy was between 1050–2000 mm. After artificial pruning, the height of jujube canopy was between 400–1600 mm, and the diameter of the canopy was between 800–1400 mm.

- (2)

- In this study, a shaping and pruning machine for jujube trees was developed to address the difficulties of highly labor-intensive and poorly efficient artificial pruning of dwarf and densely planted jujube trees in Xinjiang. The machine is mainly composed of a pruning device, removal mechanism for jujube hangings, shaping and pruning frame, shaping and adjusting frame, connecting seat, hydraulic system, tractor, etc. The range of height adjustment for the machine is 600–2200 mm, and the range of width adjustment is 800–1400 mm. The designed height of the side pruning assembly is 1600 mm, and the length of the top pruning assembly is 1200 mm. Circular saw blades are used as the cutting tool for the pruning device. The critical speed of the cutting tool to avoid missed cuttings is 1020 r/min according to a theoretical analysis of the process of cutting jujube branches. The structural and operating specifications of the machine, as well as its major components, were determined. This machine can perform rapid shaping and pruning of large-scale dwarf and densely planted jujube trees.

- (3)

- A quadratic regression orthogonal test with three factors and three levels was designed according to the test principle of Box-Behnken with the machine forward speed, cutter rotation speed, and cutter diameter as influencing factors, and the missed pruning rate and stubble breakage rate as evaluation indexes. The experimental results were optimized by Design-Expert V8.0.6.1 software, and the optimal parameter combination was obtained as follows: The rotation speed of the cutter was 2300 r/min, the diameter of the cutter was 250 mm, and the forward speed was 0.3 m/s. The predicted missed pruning rate and stubble breakage rate of the model were 5.07% and 4.61%, respectively.

- (4)

- The field validation test was carried out according to the optimal parameter combination. The results showed that the average missed pruning rate was 5.46% and the average stubble breakage rate was 5.10%. The relative error between the actual test values and the predicted value of the missed pruning rate and the stubble breakage rate were 7.69% and 10.63%, respectively. The coefficients of variation for the missed pruning rate and stubble breakage rate were 9.16% and 11.76%, respectively. The results indicated that the operational performance of the shaping and pruning machine for jujube trees met the design requirements.

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pan, J.B.; Ding, K.; Fu, W.; Zhang, Z.Y.; Zhang, B.C.; Lou, Z.X. Optimal design and test of airflow distribution device of air-blowing ground jujube picker. Int. Agric. Eng. J. 2019, 28, 164–172. [Google Scholar]

- Qu, Y.Y. Effects of Water-Saving Irrigation on Yield and Quality of Red Jujube in Semi-Arid Mountainous Areas of Northern Shanxi. Master’s Thesis, Northwest A&F University, Yulin, China, 2019. [Google Scholar]

- Fu, W.; Zhang, Z.Y.; Ding, K.; Cao, W.B.; Kan, Z.; Pan, J.B.; Liu, Y.D. Design and test of 4ZZ-4A2 full-hydraulic self-propelled jujube harvester. Int. J. Agric. Biol. Eng. 2018, 11, 104–110. [Google Scholar] [CrossRef]

- Liu, J.A.; Liu, L.H. Current Situation and Countermeasures of Jujube Industry in China. For. Econ. 2018, 40, 57–59. [Google Scholar]

- Lei, S.B.; Ding, L.P.; Li, J.B.; Ayiken, Y. Study on Bending and Compression Characteristics of Pruning Branches of Jujube. J. Agric. Mech. Res. 2022, 44, 198–203. [Google Scholar]

- Gao, W.H.; Han, R. Xinjiang Statistical Yearbook; China Statistics Press: Beijing, China, 2020. [Google Scholar]

- Ge, Y.; Fang, J.; Wang, S.L.; Liu, R.; Chen, Z.Y. Status of Mechanized Pruning Techniques Zaoyuan Close Planting Dwarf. J. Agric. Mech. Res. 2013, 35, 249–252. [Google Scholar]

- Zhang, B.; Fu, W.; Wang, X.F.; Lou, Z.X.; Liu, Y.D.; Fu, Y.X.; Chen, Y.Y. Bench test and parameter optimization of jujube pruning tools. IAEJ 2020, 29, 58–68. [Google Scholar]

- Liu, Y.D.; Pan, J.B.; Chen, Y.Y.; Zhang, Z.Y.; Fu, W. Design and Finite Element Analysis of the Connecting Seat Jujube Pruning Machine. J. Chin. Agric. Mech. 2018, 40, 29–33. [Google Scholar]

- Shen, M.R.; Luo, P.Z.; Lin, S.Y. Orchard Machinery; Shanghai Science and Technology Press: Shanghai, China, 1983. [Google Scholar]

- Jensen, F.; Christensen, L.; Beede, R.; Leavitt, G. Effects of mechanical pruning on grapes. Calif. Agric. 1980, 34, 33–34. [Google Scholar]

- Giametta, G.; Zimbalatti, G. Mechanical pruning in new olive-groves. J. Agric. Eng. Res. 1997, 68, 15–20. [Google Scholar] [CrossRef]

- Vivaldi, G.A.; Strippoli, G.; Pascuzzi, S.; Stellacci, A.M.; Camposeo, S. Olive genotypes cultivated in an adult high-density orchard respond differently to canopy restraining by mechanical and manual pruning. Sci. Hortic. 2015, 192, 391–399. [Google Scholar] [CrossRef]

- Velazquez, M.B.; Gonzalez, E.F. The influence of mechanical pruning in cost reduction, production of fruit, and biomass waste in citrus orchards. Appl. Eng. Agric. 2010, 26, 531–540. [Google Scholar] [CrossRef]

- Fan, X.; Zhang, H.; Li, C.; Meng, W. The Development of the Pneumatic Cutting Machine Used in a Dwarf Dense Planting Jujube Garden. J. Shandong Agric. Univ. 2014, 45, 694–697. [Google Scholar]

- Li, S.G.; Kang, F.; Li, W.B.; Zhou, S.Z.; Han, X.M. Progress advance on pruning mechanization and automation of fruit trees. J. Northeast Agric. Univ. 2017, 48, 88–96. [Google Scholar]

- Yang, Z.; Guo, X.L.; Wang, L.Y.; Wu, L.J.; Chen, L.B. Review on electric pruning equipments and technology in orchard. J. Fruit Sci. 2015, 32, 712–719. [Google Scholar]

- Wu, L.J.; Yang, Z.; Wang, W.Z.; Wang, L.Y. Application and Development of Pneumatic Pruning Machine for Fruit Trees. Modern Agric. Equip. 2013, 202, 54–57. [Google Scholar]

- Ma, P.Y.; Li, S.J.; Zhang, Y.L.; Gu, Y.; Zhang, Z.Y.; Liu, H.; Zhang, C.; Li, J. Design and test of a knapsack electric fruit branch trimmer. J. Huazhong Agric. Univ. 2019, 38, 127–133. [Google Scholar]

- Chueca, P.; Mateu, G.; Garcerá, C.; Fonte, A.; Ortiz, C.; Torregrosa, A. Yield and Economic Results of Different Mechanical Pruning Strategies on ‘Navel Foyos’ Oranges in the Mediterranean Area. Agriculture 2021, 11, 82. [Google Scholar] [CrossRef]

- Ottanelli, A.; Marone, E.; Fiorino, P. A new device to improve the mechanical winter pruning in olive trees hedgerows. Adv. Hortic. Sci. 2019, 33, 113–122. [Google Scholar]

- Wu, L.; Yang, Z.; Duan, J.; Wang, L.; Wang, W.; Liu, J.; Wang, L. Experiment on influencing factors of cutting force of blades of trim tool for longan branch. Trans. Chin. Soc. Agric. Eng. 2012, 28, 8–14. [Google Scholar]

- Sun, J.F.; Huo, D.F.; Li, B.; Xing, K.F.; Wang, W.Q.; Yang, Z. Wear Performance of Electric Pruning Scissors Based on Bionic Micro-structure. Trans. Chin. Soc. Agric. Mach. 2020, 51, 593–602. [Google Scholar]

- Ding, S.M.; Xue, X.Y.; Cai, C.; Cui, L.F.; Chen, C. Optimization and experiment of blade parameter for pear branches cutting device. Trans. Chin. Soc. Agric. Eng. 2015, 31, 75–82. [Google Scholar]

- Luo, H.F.; Tang, C.Z.; Zou, D.S.; Li, S.C.; Wu, W.G.; Zou, Y.M. Experiment on reciprocating cutting of eulaliopsis binata stem. Trans. Chin. Soc. Agric. Eng. 2012, 28, 13–17. [Google Scholar]

- He, L.; Schupp, J. Sensing and Automation in Pruning of Apple Trees: A Review. Agronomy 2018, 8, 211. [Google Scholar] [CrossRef] [Green Version]

- Fu, W.; Liu, Y.D.; Kan, Z.; Pan, J.B.; Cui, J.; Zhang, H.M. The Situation and Expectation of Fruit Tree Pruning Machine. J. Agric. Mech. Res. 2017, 39, 7–11. [Google Scholar]

- Xue, C.L.; Li, J.P.; Huo, P.; Bian, Y.L.; Li, X.H. Simulation and test of hydraulic system of reciprocating grape leaf trimmer. J. Hebei Agric. Univ. 2021, 44, 100–106. [Google Scholar]

- Moore, P.W. Mechanical pruning for citrus. Calif. Agric. 1958, 11, 7–10. [Google Scholar]

- Poni, S.; Tombesi, S.; Palliotti, A.; Ughini, V.; Gatti, M. Mechanical winter pruning of grapevine: Physiological bases and applications. Sci. Hortic. 2016, 204, 88–98. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Nati, C.; Cantini, C.; Sani, G.; Picchi, G.; Biocca, M. Integrating olive grove maintenance and energy biomass recovery with a single-pass pruning and harvesting machine. Biomass Bioenergy 2011, 35, 808–813. [Google Scholar] [CrossRef]

- Long, K. Design and Experimental Research on Reciprocating Vines Pruning Machine. Master’s Thesis, Xinjiang Agricultural University, Urumqi, China, 2014. [Google Scholar]

- Wang, Z.; Wang, L.H.; Fu, W.; Jiang, Y.L.; Kan, Z.; Li, C.S. The Design of the Wine Grape Trimming Device. J. Northeast Agric. Univ. 2017, 39, 105–110. [Google Scholar]

- Zhang, D.X.; Min, L.Q.; Li, Q.J.; Liu, X.F.; Ren, D.M.; Zhang, C.Y.; Liang, R.Q. Design of PJS-1 Two-flank Type Grapevine Pruning Machine. Agric. Equip. Veh. Eng. 2016, 54, 77–81. [Google Scholar]

- Chang, J.X.; Zhang, Y.L.; Li, S.J.; Zhang, W.; Ma, P.Y. Design of citrus trimmer with bilateral and neat trim. J. Huazhong Agric. Univ. 2019, 38, 104–111. [Google Scholar]

- Zhang, J.X.; Huang, T.; Wang, M.B. Design and Experiment of Single Motor Reciprocating Grape Pruning Machine. Trans. Chin. Soc. Agric. Mach. 2021, 52, 106–116. [Google Scholar]

- Liu, X.C.; Liu, X.F.; Zhang, L.F.; Min, L.Q.; Chu, Y.H.; Ren, D.M. Design and research of wide band combination copying prune machine for new orchard. J. Chin. Agric. Mech. 2020, 41, 65–71. [Google Scholar]

- Li, M.; Ma, L.; Zong, W.; Luo, C.; Huang, M.; Song, Y. Design and Experimental Evaluation of a Form Trimming Machine for Horticultural Plants. Appl. Sci. 2021, 11, 2230. [Google Scholar] [CrossRef]

- Liu, J.; Deng, Y.J.; Wang, C.; Dai, J.J.; Zhao, P.; Shu, R.; Liu, Z. Design and Test of a Self-propelled Bilateral Mulberry Pruner. J. Chin. Agric. Mech. 2021, 43, 105–110+120. [Google Scholar]

- Cui, J. The Design and Experimental Research of Jujube Harvest Device Based on Self-Excited Vibration and Force Compensation. Master’s Thesis, Shihezi University, Shihezi, China, 2017. [Google Scholar]

- Zhen, J. Design of Experiments and Data Analysis; South China University of Technology Press: Guangzhou, China, 2016. [Google Scholar]

- Huang, M.S.; Shi, L.; Zhang, Y.T.; Chen, C.L.; Sun, Y.F.; Xie, Q.; Kong, F.T. Optimization experiments of machine-mounted seed cotton pre-treatment apparatus for cotton stripper harvester. Trans. Chin. Soc. Agric. Eng. 2016, 32, 21–29. [Google Scholar]

- Yang, S.M.; Chen, X.G.; Yan, L.M.; Mo, Y.S.; Jiang, D.L.; Zhang, H.M. Design and Experiment on Belt-type Curl-up Film Device for Residual Plastic Film Recycling Machine. Trans. Chin. Soc. Agric. Mach. 2021, 52, 135–144. [Google Scholar]

- Huang, T. Design and Test of Reciprocating Grape Pruning Machine. Master’s Thesis, Xinjiang Agricultural University, Urumqi, China, 2021. [Google Scholar]

- Xin, Y.J. Analysis of Variance and Experimental Design; China Financial and Economic Publishing House: Beijing, China, 2001. [Google Scholar]

- Ge, Y.; Zhang, L.X.; Gu, J.W.; Fu, W.; Zhu, R.G.; Zhang, H.M. Parameter optimization and experiment of dual roller harvesting device for safflower. Trans. Chin. Soc. Agric. Eng. 2015, 31, 35–42. [Google Scholar]

- Han, H.M.; Zhou, Y.; Jia, S.X.; Cai, W.L.; Wen, X.Y. Design of Summer Wine Grape Pruning Machine. J. Chin. Agric. Mech. 2020, 42, 81–86+92. [Google Scholar]

- Liu, Y.; Zhou, Y.; Lv, W.; Huang, H.D.; Zhang, G.Z.; Tu, M.; Huang, L. Design and Experiment of Hydraulic Scouring System of Wide-Width Lotus Root Digging Machine. Agriculture 2021, 11, 1110. [Google Scholar] [CrossRef]

| State | The Height of the Tree (mm) | The Height of the Canopy (mm) | The Height of the Canopy above the Ground (mm) | The Diameter of the Canopy (mm) |

|---|---|---|---|---|

| Before artificial pruning | 1200~2500 | 600~1900 | 600~800 | 1050~2000 |

| After artificial pruning | 800~2250 | 400~1600 | 800~1400 |

| Parameters | Value |

|---|---|

| Corresponding power (kW) | ≥45 |

| Rotation speed of cutter (r/min) | 1700~2300 |

| Adjustment range of pruning height (mm) | 600~2200 |

| Adjustment range of pruning width (mm) | 800~1400 |

| Size of pruning device (Length × width × height) (mm) | 1700 × 500 × 1800 |

| Weight of overall machine (kg) | 450 |

| Coding | Test Factors | ||

|---|---|---|---|

| Rotation Speed of Cutter X1/(r/min) | Diameter of Cutter X2/(mm) | Forward Speed X3/(m/s) | |

| 1 | 2300 | 300 | 1.0 |

| 0 | 2000 | 250 | 0.65 |

| −1 | 1700 | 200 | 0.3 |

| No. | Test Factors | Missed Pruning Rate P1/% | Stubble Breakage Rate P2/% | ||

|---|---|---|---|---|---|

| X1 | X2 | X3 | |||

| 1 | −1 | −1 | 0 | 13.8 | 11.4 |

| 2 | 1 | −1 | 0 | 9.0 | 7.6 |

| 3 | −1 | 1 | 0 | 12.1 | 9.6 |

| 4 | 1 | 1 | 0 | 8.9 | 7.4 |

| 5 | −1 | 0 | −1 | 8.7 | 7.2 |

| 6 | 1 | 0 | −1 | 5.3 | 4.5 |

| 7 | −1 | 0 | 1 | 14.1 | 11.9 |

| 8 | 1 | 0 | 1 | 9.5 | 7.7 |

| 9 | 0 | −1 | −1 | 8.8 | 7.4 |

| 10 | 0 | 1 | −1 | 8.5 | 7.2 |

| 11 | 0 | −1 | 1 | 12.7 | 10.6 |

| 12 | 0 | 1 | 1 | 12.5 | 10.2 |

| 13 | 0 | 0 | 0 | 8.8 | 7.5 |

| 14 | 0 | 0 | 0 | 9.0 | 7.2 |

| 15 | 0 | 0 | 0 | 9.2 | 7.1 |

| 16 | 0 | 0 | 0 | 9.6 | 8.0 |

| 17 | 0 | 0 | 0 | 9.1 | 7.6 |

| 18 | 0 | 0 | 0 | 9.3 | 7.4 |

| Evaluation Indexes | Difference Source | Sum of Squares | Degree of Freedom | Mean Square | F Value | P Value |

|---|---|---|---|---|---|---|

| Missed pruning rate P1/% | Model | 81.95 | 5 | 16.39 | 119.19 | <0.0001 |

| Residual | 1.65 | 12 | 0.14 | |||

| Lack of Fit | 1.28 | 7 | 0.18 | 2.44 | 0.1713 | |

| Pure Error | 0.37 | 5 | 0.075 | |||

| Stubble breakage rate P2/% | Model | 55.39 | 6 | 9.23 | 64.10 | <0.0001 |

| Residual | 1.58 | 11 | 0.14 | |||

| Lack of Fit | 1.07 | 6 | 0.18 | 1.74 | 0.2803 | |

| Pure Error | 0.51 | 5 | 0.10 |

| Index | Max | Min | Avg. | S.D. | C.V. |

|---|---|---|---|---|---|

| Missed pruning rate/% | 6.2 | 4.8 | 5.46 | 0.50 | 9.16 |

| Stubble breakage rate/% | 5.8 | 4.2 | 5.10 | 0.60 | 11.76 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Liu, Y.; Zhang, H.; Shen, C.; Fu, W. Design and Evaluation of a Shaping and Pruning Machine for Dwarf and Densely Planted Jujube Trees. Appl. Sci. 2022, 12, 2699. https://doi.org/10.3390/app12052699

Zhang B, Liu Y, Zhang H, Shen C, Fu W. Design and Evaluation of a Shaping and Pruning Machine for Dwarf and Densely Planted Jujube Trees. Applied Sciences. 2022; 12(5):2699. https://doi.org/10.3390/app12052699

Chicago/Turabian StyleZhang, Bin, Yudong Liu, Huiming Zhang, Congju Shen, and Wei Fu. 2022. "Design and Evaluation of a Shaping and Pruning Machine for Dwarf and Densely Planted Jujube Trees" Applied Sciences 12, no. 5: 2699. https://doi.org/10.3390/app12052699

APA StyleZhang, B., Liu, Y., Zhang, H., Shen, C., & Fu, W. (2022). Design and Evaluation of a Shaping and Pruning Machine for Dwarf and Densely Planted Jujube Trees. Applied Sciences, 12(5), 2699. https://doi.org/10.3390/app12052699