Appendix B

Initialization Function Callbacks for the Simulation.

clear all; close all; clc;

%This block of code establishes the properties of each beam element

a = 0.0254; b = 0.0016; L = 0.25;

E = 72*10^9; I = a*b^3/12;

Li = [12 6*L -12 6*L;6*L 4*L^2 -6*L 2*L^2;-12 -6*L 12 -6*L;6*L 2*L^2 -6*L 4*L^2];

k_beam = E*I/L^3*[Li];

rho_beam = 2.8*10^3; %Beam density kg/m^3

A_beam = a*b; %Beam cross sectional area

mb = rho_beam*A_beam; %Beam mass per unit length

%This block creates the empty stiffness matrix [k]

k = zeros(14,14);

% This block fills in the stiffness matrix components

% Row 1 components start at index = 1% Row 2 components start at index = 15

k(1,1) = k_beam(3,3) + k_beam(1,1); k(2,1) = k_beam(4,3) + k_beam(2,1);

k(1,2) = k_beam(3,4) + k_beam(1,2); k(2,2) = k_beam(4,4) + k_beam(2,2);

k(1,3) = k_beam(1,3); k(2,3) = k_beam(2,3);

k(1,4) = k_beam(1,4); k(2,4) = k_beam(2,4);

% Row 3 components start at index = 29% Row 4 components start at index = 43

k(3,1) = k_beam(3,1); k(4,1) = k_beam(4,1);

k(3,2) = k_beam(3,2); k(4,2) = k_beam(4,2);

k(3,3) = k_beam(3,3) + k_beam(1,1); k(4,3) = k_beam(4,3) + k_beam(2,1);

k(3,4) = k_beam(3,4) + k_beam(1,2); k(4,4) = k_beam(4,4) + k_beam(2,2);

k(3,5) = k_beam(1,3); k(4,5) = k_beam(2,3);

k(3,6) = k_beam(1,4); k(4,6) = k_beam(2,4);

% Row 5 components start at index = 59% Row 6 components start at index = 73

k(5,3) = k_beam(3,1); k(6,3) = k_beam(4,1);

k(5,4) = k_beam(3,2); k(6,4) = k_beam(4,2);

k(5,5) = k_beam(3,3) + k_beam(1,1); k(6,5) = k_beam(4,3) + k_beam(2,1);

k(5,6) = k_beam(3,4) + k_beam(1,2); k(6,6) = k_beam(4,4) + k_beam(2,2);

k(5,7) = k_beam(1,3); k(6,7) = k_beam(2,3);

k(5,8) = k_beam(1,4); k(6,8) = k_beam(2,4);

% Row 7 components start at index = 89% Row 8 components start at index = 103

k(7,5) = k_beam(3,1); k(8,5) = k_beam(4,1);

k(7,6) = k_beam(3,2); k(8,6) = k_beam(4,2);

k(7,7) = k_beam(3,3); k(8,7) = k_beam(4,3);

k(7,8) = k_beam(3,4); k(8,8) = k_beam(4,4) + k_beam(2,2);

k(8,9) = k_beam(2,3);

k(8,10) = k_beam(2,4);

% Row 9 components start at index = 120% Row 10 components start at index = 134

k(9,8) = k_beam(3,2); k(10,8) = k_beam(4,2);

k(9,9) = k_beam(3,3) + k_beam(1,1); k(10,9) = k_beam(4,3) + k_beam(2,1);

k(9,10) = k_beam(3,4) + k_beam(1,2); k(10,10) = k_beam(4,4) + k_beam(2,2);

k(9,11) = k_beam(1,3); k(10,11) = k_beam(2,3);

k(9,12) = k_beam(1,4); k(10,12) = k_beam(2,4);

% Row 11 components start at index = 149% Row 12 components start at index = 163

k(11,9) = k_beam(3,1); k(12,9) = k_beam(4,1);

k(11,10) = k_beam(3,2); k(12,10) = k_beam(4,2);

k(11,11) = k_beam(3,3) + k_beam(1,1); k(12,11) = k_beam(4,3) + k_beam(2,1);

k(11,12) = k_beam(3,4) + k_beam(1,2); k(12,12) = k_beam(4,4) + k_beam(2,2);

k(11,13) = k_beam(1,3); k(12,13) = k_beam(2,3);

k(11,14) = k_beam(1,4); k(12,14) = k_beam(2,4);

% Row 13 components start at index = 179% Row 14 components start at index = 193

k(13,11) = k_beam(3,1); k(14,11) = k_beam(4,1);

k(13,12) = k_beam(3,2); k(14,12) = k_beam(4,2);

k(13,13) = k_beam(3,3); k(14,13) = k_beam(4,3);

k(13,14) = k_beam(3,4); k(14,14) = k_beam(4,4);

%Display stiffness matrix to check

k = k;

%END STIFFNESS MATRIX. START MASS MATRIX

%Assemble individual beam inertia matrix

I_beam = ones(1,8); %Creates empty matrix of I’s for eight node points

I_beam = [I_beam.*I]; %Fill in matrix values with beam inertia

I_beam(1) = 0; %First node point inertia = 0

%This block of code creates the individual beam mass matrix “m_beam”

mi = [156 22*L 54 -13*L;22*L 4*L^2 13*L -3*L^2;54 13*L 156 -22*L;-13*L -3*L^2 -22*L 4*L^2];

m_beam = mb*L/420*mi;

%This block of code establishes the value of each point mass (mp)

%and the system point mass matrix (M)

mp = 0.455; %Point masses, M

M = [0 mp mp mp 2*mp mp mp mp]; %Matrix of 8 point masses (0 First point mass)

%Creates a 14 × 14 empty mass matrix [m]

m = zeros(14,14);

%Fill in the system mass matrix components

% Row 1 components start at index = 1% Row 2 components start at index = 15

m(1,1) = m_beam(3,3) + m_beam(1,1) + M(2); m(2,1) = m_beam(4,3) + m_beam(2,1);

m(1,2) = m_beam(3,4) + m_beam(1,2); m(2,2) = m_beam(4,4) + m_beam(2,2);

m(1,3) = m_beam(1,3); m(2,3) = m_beam(2,3);

m(1,4) = m_beam(1,4); m(2,4) = m_beam(2,4);

% Row 3 components start at index = 29% Row 4 components start at index = 43

m(3,1) = m_beam(3,1); m(4,1) = m_beam(4,1);

m(3,2) = m_beam(3,2); m(4,2) = m_beam(4,2);

m(3,3) = m_beam(3,3) + m_beam(1,1) + M(3); m(4,3) = m_beam(4,3) + m_beam(2,1);

m(3,4) = m_beam(3,4) + m_beam(1,2); m(4,4) = m_beam(4,4) + m_beam(2,2);

m(3,5) = m_beam(1,3); m(4,5) = m_beam(2,3);

m(3,6) = m_beam(1,4); m(4,6) = m_beam(2,4);

% Row 5 components start at index = 59% Row 6 components start at index = 73

m(5,3) = m_beam(3,1); m(6,3) = m_beam(4,1);

m(5,4) = m_beam(3,2); m(6,4) = m_beam(4,2);

m(5,5) = m_beam(3,3) + m_beam(1,1) + M(4); m(6,5) = m_beam(4,3) + m_beam(2,1);

m(5,6) = m_beam(3,4) + m_beam(1,2); m(6,6) = m_beam(4,4) + m_beam(2,2);

m(5,7) = m_beam(1,3); m(6,7) = m_beam(2,3);

m(5,8) = m_beam(1,4); m(6,8) = m_beam(2,4);

% Row 7 components start at index = 89

m(7,5) = m_beam(3,1);

m(7,6) = m_beam(3,2);

m(7,7) = m_beam(3,3) + 3*mb + M(5) + M(6) + M(7) + M(8);

m(7,8) = m_beam(3,4);

% Row 8 components start at index = 103% Row 9 components start at index = 120

m(8,5) = m_beam(4,1); m(9,8) = m_beam(3,2);

m(8,6) = m_beam(4,2); m(9,9) = m_beam(3,3) + m_beam(1,1) + M(6);

m(8,7) = m_beam(4,3); m(9,10) = m_beam(3,4) + m_beam(1,2);

m(8,8) = m_beam(4,4) + m_beam(2,2); m(9,11) = m_beam(1,3);

m(8,9) = m_beam(2,3); m(9,12) = m_beam(1,4);

m(8,10) = m_beam(2,4);

% Row 10 components start at index = 134% Row 11 components start at index = 149

m(10,8) = m_beam(4,2); m(11,9) = m_beam(3,1);

m(10,9) = m_beam(4,3) + m_beam(2,1); m(11,10) = m_beam(3,2);

m(10,10) = m_beam(4,4) + m_beam(2,2); m(11,11) = m_beam(3,3) + m_beam(1,1) + M(7);

m(10,11) = m_beam(2,3); m(11,12) = m_beam(3,4) + m_beam(1,2);

m(10,12) = m_beam(2,4); m(11,13) = m_beam(1,3);

m(11,14) = m_beam(1,4);

% Row 12 components start at index = 163

m(12,9) = m_beam(4,1);

m(12,10) = m_beam(4,2);

m(12,11) = m_beam(4,3) + m_beam(2,1);

m(12,12) = m_beam(4,4) + m_beam(2,2);

m(12,13) = m_beam(2,3);

m(12,14) = m_beam(2,4);

% Row 13 components start at index = 179% Row 14 components start at index = 193

m(13,11) = m_beam(3,1); m(14,11) = m_beam(4,1);

m(13,12) = m_beam(3,2); m(14,12) = m_beam(4,2);

m(13,13) = m_beam(3,3) + M(8); m(14,13) = m_beam(4,3);

m(13,14) = m_beam(3,4); m(14,14) = m_beam(4,4);

%Display the system mass matrix to check

m = m;

%Calculate the natural frequencies and normal modes

[NormalModes,EigenValues] = eig(inv(m)*k);

NaturalFrequencies = diag(EigenValues^0.5);

ModeShapes = NormalModes;

%Check Orthogonality like Homework 1 confirm diagonal matrix of 1’s

%to satisfy Equation 24 on slide 17

OrthoMass = NormalModes’*m*NormalModes;

OrthoStiff = NormalModes’*k*NormalModes;

StiffCheck = OrthoStiff/EigenValues;

Equation24_OrthoCheck = diag(diag(StiffCheck/OrthoMass));

%Spacecraft Radius to be used designating rigid modal coordinate

R = 0.381;

FeeE = NormalModes; %Designate Elastic mode shapes array FeeE

Omega = NaturalFrequencies; %Designate variable name ‘Omega’ as natural frequencies

%Designate Rigid modal coordinate FeeR

FeeR = [R + L 1 R + L*2 1 R + L*3 1 R + L*4 1 -L 1 -L*2 1 -L*3 1];

Di = FeeE’*m*diag(FeeR); %Calculate Rigid-Elastic Coupling Coefficient

DiCheck = det(Di); %Confirm Di is singular...det(Di = 0)

Z = 0.0005;

Izz = 14;

w = diag(NaturalFrequencies); %Generate a diagonal matrix of natural frequency

Iw = 0.0912;

Td = 0; %Disturbance Torque

Tc = 0.1; %Control Torque is Iw*qddot_wheel

T = Td + Tc; %Total Torque is sum of disturbance and control torques

%Start State Space Development

NatFreq = diag(EigenValues).^0.5;

r = 0.381; %Radius of the wheel (large rigid body)

freqs = sqrt(EigenValues); %

NatFreq = EigenValues(1:5,1:5);

freqs = freqs(1:5,1:5);

zeta = 0.0005; %Given damping ratio for all modes

Izz = 14;

phi_E = NormalModes(1:14,1:5);

phi_R = [r + L,1,r + 2*L,1,r + 3*L,1,r + 4*L,1,-L,1,-2*L,1,-3*L,1]’;

M_II = m;

Di = [phi_E’*M_II*phi_R];

M_state = [Izz Di’;

Di eye(5)];

C_damp = [zeros(6,6)];

C_damp(2:6,2:6) = 2*zeta*freqs;

K = [zeros(6,6)];

K(2:6,2:6) = NatFreq;

A = [zeros(6),eye(6,6);

-inv(M_state)*K, -inv(M_state)*C_damp];

Bprime = [1;0;0;0;0;0];

B = [0 0 0 0 0 0 (inv(M_state)*Bprime)’]’;

C = zeros(12,12); C(1,1) = 1;

D = zeros(12,1);

[Gnum,Gden] = ss2tf(A,B,C,D);

G1 = tf(Gnum(1,:),Gden)

%Manually input Transfer Function to check

NUM = [1.998e-015 0.1268 0.007582 166.9 5.591 4.718e004 771 3.412e006 1.218e004 1.576e007 1.475e004 7.11e006];

DEN = [1 0.06125 1326 46.15 3.781e005 6683 2.808e007 1.388e005 1.813e008 2.065e005 9.954e007 0 0];

G = tf(NUM,DEN);

%Put PID controller Transfer function into workspace

It = 14; Z = 0.516931;

Bandwidth = 4; wn = Bandwidth; T = 10/Z/wn;

Kd = 2*Z*wn*It + It/T;

Kp = wn^2 + 2*Z*wn/T;

Ki = wn^2/T;

PID = tf([Kd Kp Ki],[0 1 0]);

%DESIGN FILTERS TO SMOOTH OUT MODE 1

%Design Bandpass filter for w = 10^-0.1478 = 0.711541 Hz

wz = 0.711541;Zz = 0.1;wp = wz;Zp = 0.0005;

BP1 = tf([1/wz^2 2*Zz/wz 1],[1/wp^2 2*Zp/wp 1]);

PID_BP1 = PID*BP1;

%Design Notch filter for w = 10^-0.109 = 0.778037 Hz

wz = 0.778037;Zz = 0.0005;wp = wz;Zp = 0.1;

Notch1 = tf([1/wz^2 2*Zz/wz 1],[1/wp^2 2*Zp/wp 1]);

Mode_1 = PID*BP1*Notch1;

%DESIGN FILTERS TO SMOOTH OUT MODE 2

%Design Bandpass filter for w = 10^0.3223

wz = 10^0.3223;Zz = 0.1;wp = wz;Zp = 0.0005;

BP2 = tf([1/wz^2 2*Zz/wz 1],[1/wp^2 2*Zp/wp 1]);

%Design Notch filter for w = 10^0.405

wz = 10^0.405;Zz = 0.0006;wp = wz;Zp = 0.1;

Notch2 = tf([1/wz^2 2*Zz/wz 1],[1/wp^2 2*Zp/wp 1]);

Mode_2 = Mode_1*BP2*Notch2;

%Design Lead filter for wz~1, wp~3

%wz = 1;Zz = 1;wp = 3;Zp = 1;

%Lead = tf([1/wz^2 2*Zz/wz 1],[1/wp^2 2*Zp/wp 1]);

%Mode_2 = Mode_2*Lead;

%DESIGN FILTERS TO SMOOTH OUT MODE 3

%Design Bandpass filter for w = 10^1.0110

wz = 10^1.0110;Zz = 0.1;wp = wz;Zp = 0.0005;

BP3 = tf([1/wz^2 2*Zz/wz 1],[1/wp^2 2*Zp/wp 1]);

%Design Notch filter for w = 10^1.0128

wz = 10^1.0128;Zz = 0.0005;wp = wz;Zp = 0.1;

Notch3 = tf([1/wz^2 2*Zz/wz 1],[1/wp^2 2*Zp/wp 1]);

Mode_3 = Mode_2*BP3*Notch3;

%DESIGN FILTERS TO SMOOTH OUT MODE 4

%Design Bandpass filter for w = 10^1.49035

wz = 10^1.49035;Zz = 0.1;wp = wz;Zp = 0.0005;

BP4 = tf([1/wz^2 2*Zz/wz 1],[1/wp^2 2*Zp/wp 1]);

%Design Notch filter for w = 10^1.492

wz = 10^1.492;Zz = 0.0005;wp = wz;Zp = 0.1;

Notch4 = tf([1/wz^2 2*Zz/wz 1],[1/wp^2 2*Zp/wp 1]);

Mode_4 = Mode_3*BP4*Notch4;

%CALCULATE SYSTEM NATURAL FREQUENCIES

[NaturalFrequencies,Damping,EigenValue] = damp(G);

NaturalFrequencies = NaturalFrequencies;

Appendix C

Stop Function Callbacks for the Simulation.

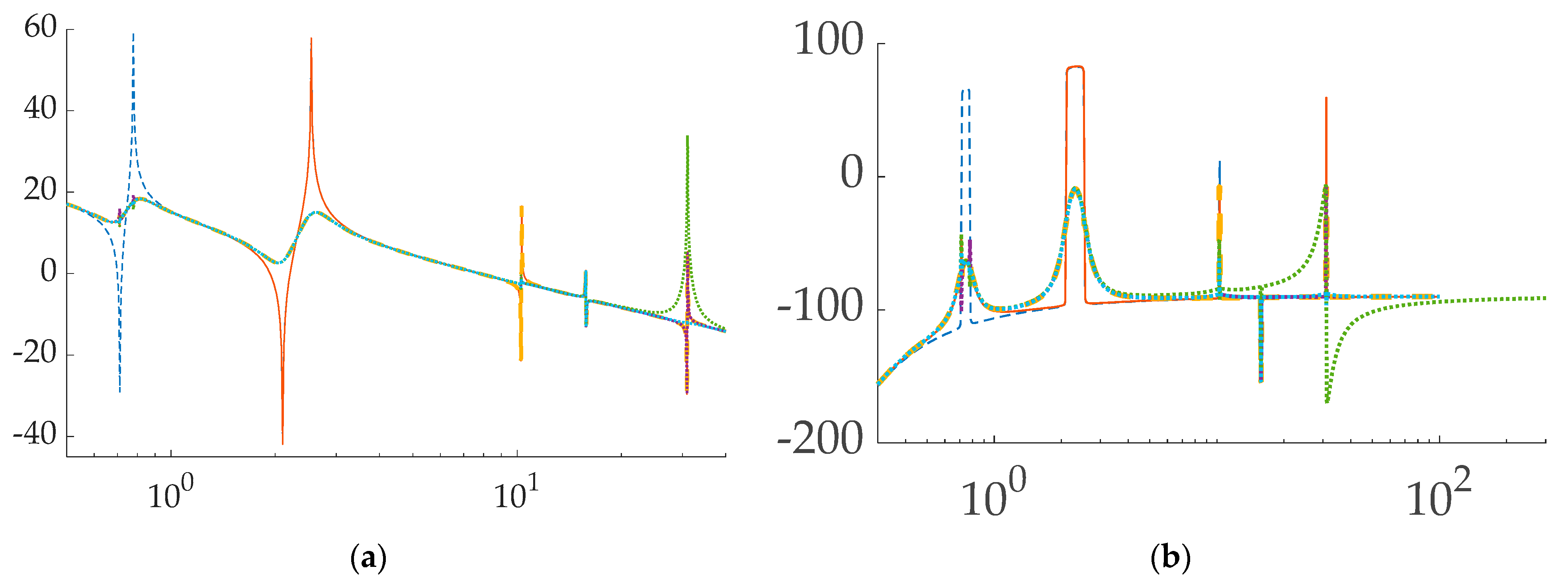

[mag1,phase1,wout1] = bode(G); Mag1 = 20*log10(mag1(:)); Phase1 = phase1(:);

[mag2,phase2,wout2] = bode(G*PID); Mag2 = 20*log10(mag2(:)); Phase2 = phase2(:);

[mag3,phase3,wout3] = bode(G*PID*BP1); Mag3 = 20*log10(mag3(:)); Phase3 = phase3(:);

[mag4,phase4,wout4] = bode(G*PID*BP1*Notch1); Mag4 = 20*log10(mag4(:)); Phase4 = phase4(:);

[mag5,phase5,wout5] = bode(G*PID*BP1*Notch1*BP2); Mag5 = 20*log10(mag5(:)); Phase5 = phase5(:);

[mag6,phase6,wout6] = bode(G*PID*BP1*Notch1*BP2*Notch2); Mag6 = 20*log10(mag6(:)); Phase6 = phase6(:);

[mag7,phase7,wout7] = bode(G*PID*BP1*Notch1*BP2*Notch2*BP3); Mag7 = 20*log10(mag7(:)); Phase7 = phase7(:);

[mag8,phase8,wout8] = bode(G*PID*BP1*Notch1*BP2*Notch2*BP3*Notch3); Mag8 = 20*log10(mag8(:)); Phase8 = phase8(:);

[mag9,phase9,wout9] = bode(G*PID*BP1*Notch1*BP2*Notch2*BP3*Notch3*BP4); Mag9 = 20*log10(mag9(:)); Phase9 = phase9(:);

[mag10,phase10,wout10] = bode(G*PID*BP1*Notch1*BP2*Notch2*BP3*Notch3*BP4*Notch4); Mag10 = 20*log10(mag10(:)); Phase10 = phase10(:);

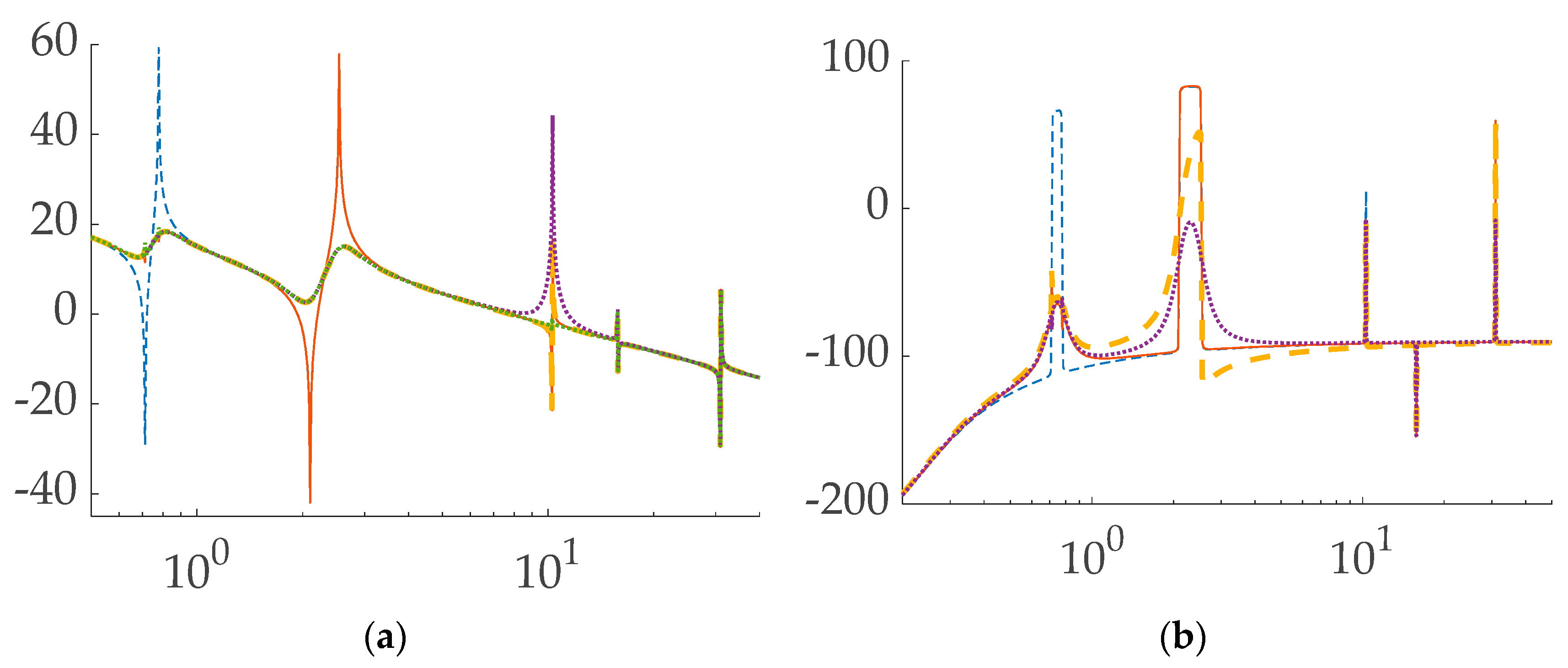

figure(1); hold on;

semilogx(wout1,Mag1,’--’,’LineWidth’,1);

semilogx(wout2,Mag2,’LineWidth’,1);

semilogx(wout3,Mag3,’--’,’LineWidth’,3);

semilogx(wout4,Mag4,’:’,’LineWidth’,2);

hold off; grid on; axis([0.5,40, −100, 150]); set(gca, ‘FontSize’,28, ‘FontName’,‘Palatino Linotype’);

legend(‘Flexible space robot’,’PID’,’PID + Bandpass’,’PID + Notch + Bandpass’)

figure(2); hold on; set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

semilogx(wout1,Phase1,’--’,’LineWidth’,1);

semilogx(wout2,Phase2,’LineWidth’,1);

semilogx(wout3,Phase3,’--’,’LineWidth’,3);

semilogx(wout4,Phase4,’:’,’LineWidth’,2);

hold off; grid on;

figure(3); hold on;

semilogx(wout2,Mag2,’--’,’LineWidth’,1);

semilogx(wout4,Mag4,’LineWidth’,1);

semilogx(wout5,Mag5,’--’,’LineWidth’,3);

semilogx(wout6,Mag6,’:’,’LineWidth’,2);

hold off; grid on; axis([0.5,40, −100, 150]); set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

legend(‘PID controlled Flexible space robot’,’PID + Mode 1’,’PID + Mode 1 + Bandpass’,’PID + Mode 1 + Notch + Bandpass’)

figure(4); hold on; set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

semilogx(wout2,Phase2,’--’,’LineWidth’,1);

semilogx(wout4,Phase4,’LineWidth’,1);

semilogx(wout5,Phase5,’--’,’LineWidth’,3);

semilogx(wout6,Phase6,’:’,’LineWidth’,2);

hold off; grid on;

figure(5); hold on;

semilogx(wout2,Mag2,’--’,’LineWidth’,1);

semilogx(wout4,Mag4,’LineWidth’,1);

semilogx(wout6,Mag6,’--’,’LineWidth’,3);

semilogx(wout7,Mag7,’:’,’LineWidth’,2);

semilogx(wout8,Mag8,’:’,’LineWidth’,2);

hold off; grid on; axis([0.5,40, −100, 150]); set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

legend(‘PID controlled Flexible space robot’,’PID + Mode 1’,’PID + Mode 2’,’PID + Mode 1 + Mode 2 + Bandpass’,’PID + Mode 1 + Mode 2 + Bandpass + Notch’)

figure(6); hold on; set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

semilogx(wout2,Phase2,’--’,’LineWidth’,1);

semilogx(wout4,Phase4,’LineWidth’,1);

semilogx(wout6,Phase6,’--’,’LineWidth’,3);

semilogx(wout7,Phase7,’:’,’LineWidth’,2);

semilogx(wout8,Phase8,’:’,’LineWidth’,2);

hold off; grid on;

figure(7); hold on;

semilogx(wout2,Mag2,’--’,’LineWidth’,1);

semilogx(wout4,Mag4,’LineWidth’,1);

semilogx(wout6,Mag6,’--’,’LineWidth’,3);

semilogx(wout8,Mag8,’:’,’LineWidth’,2);

semilogx(wout9,Mag9,’:’,’LineWidth’,2);

semilogx(wout10,Mag10,’:’,’LineWidth’,2);

hold off; grid on; axis([0.5,40, −100, 150]); set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

legend(‘PID controlled Flexible space robot’,’PID + Mode 1’,’PID + Mode 2’,’PID + Mode 1 + Mode 2 + Mode 3’,’PID + Mode 1 + Mode 2 + Mode 3 + Bandpass + Notch’)

figure(8); hold on; set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

semilogx(wout2,Phase2,’--’,’LineWidth’,1);

semilogx(wout4,Phase4,’LineWidth’,1);

semilogx(wout6,Phase6,’--’,’LineWidth’,3);

semilogx(wout8,Phase8,’:’,’LineWidth’,2);

semilogx(wout9,Phase9,’:’,’LineWidth’,2);

semilogx(wout10,Phase10,’:’,’LineWidth’,2);

hold off; grid on;

sys1 = G*PID/(1 + G*PID);

sys2 = (G*PID*BP1/(1 + G*PID*BP1));

sys3 = (G*PID*BP1*Notch1/(1 + G*PID*BP1*Notch1));

sys4 = (G*PID*BP1*Notch1*BP2/(1 + G*PID*BP1*Notch1*BP2));

sys5 = (G*PID*BP1*Notch1*BP2*Notch2/(1 + G*PID*BP1*Notch1*BP2*Notch2));

sys6 = (G*PID*BP1*Notch1*BP2*Notch2*BP3/(1 + G*PID*BP1*Notch1*BP2*Notch2*BP3));

sys7 = (G*PID*BP1*Notch1*BP2*Notch2*BP3*Notch3/(1 + G*PID*BP1*Notch1*BP2*Notch2*BP3*Notch3));

sys8 = (G*PID*BP1*Notch1*BP2*Notch2*BP3*Notch3*BP4/(1 + G*PID*BP1*Notch1*BP2*Notch2*BP3*Notch3*BP4));

sys9 = (G*PID*BP1*Notch1*BP2*Notch2*BP3*Notch3*BP4*Notch4/(1 + G*PID*BP1*Notch1*BP2*Notch2*BP3*Notch3*BP4*Notch4));

figure(9); step(sys1,sys2); legend(‘PID’,’PID + BP1’);set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

figure(10); step(sys1,sys3); legend(‘PID’,’PID + BP1 + Notch1’); set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

figure(11); step(sys1,sys4); legend(‘PID’,’PID + Mode 1 + BP2’); set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

figure(12); step(sys1,sys5); legend(‘PID’,’PID + Mode 1 + BP2 + Notch 2’); set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

figure(13); step(sys1,sys6); legend(‘PID’,’PID + Mode 1 + Mode 2 + BP3’); set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

figure(14); step(sys1,sys7); legend(‘PID’,’PID + Mode 1 + Mode 2 + BP3 + Notch3’); set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

figure(15); step(sys1,sys8); legend(‘PID’,’PID + Mode 1 + Mode 2 + Mode 3 + BP4’); set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);

figure(16); step(sys1,sys9); legend(‘PID’,’PID + Mode 1 + Mode 2 + Mode 3 + BP4 + Notch4’); set(gca, ‘FontSize’,28, ‘FontName’,’Palatino Linotype’);