5.1. Model Setup

OpenStudio (EnergyPlus) 8.0 software was used to model a residential solar home to test the effects of increasing the insulation value of external wall structures on the energy consumption and demand on the home’s HVAC unit. Varying the value of air infiltration in the home was also tested for its effects. The EnergyPlus 8.0 software was used to perform the energy calculations throughout a year-long period on the model using weather data files for both Birmingham, AL, the home’s final resting place, and Denver, CO, where the home was placed for the month of October 2017 to compete in the U.S. Department of Energy’s Solar Decathlon competition.

The home was drawn in Sketchup Make using the OpenStudio plug-in. The model was drawn based on the as-built drawings. The building’s visual representation in Sketchup was created using the outer dimensions of the house. The model was created having two thermal zones, one an unconditioned crawlspace area, 2 feet tall and the other conditioned area that has 2 bedrooms, 1 shared bathroom, a safe room, and a large open space which contains the living room, kitchen, and dining room. Energyplus does not perform calculations based on computational fluid dynamics and, therefore, the conditioned zone was modeled as one large space with no internal wall structures.

Figure 2 shows the plan view of the house.

The electrical appliance loads matching appliances likely to be used in the actual house were created in the OpenStudio model and set up with schedules that, as accurately as possible, represent patterns in which a four-person household might use them. Schedules for heating and cooling were created using the 74 °F (23 °C) maximum and 68 °F (20 °C) minimum allowed temperatures for maximum points at the Solar Decathlon competition. A staggered double 2″ × 4″ exterior wall construction was modeled with 2″ × 6″ bottom and top plates to form the wall frame. Vertical exterior walls were modeled as having from outside-in: cement (Hardie) siding, with 1″ (R5) rigid foam board, 0.5″ plywood sheathing, respective wood stud structure filled with 1″ closed-cell sprayed foam, and two layers of batt insulation, 2″ and 3″, respectively, and ½″ plywood and gypsum board. The roof and the floor framing were handled in the same manner, but with 2″ × 8″ using 5.5″ rigid foam insulation on the outside and 1″ closed-cell-sprayed foam on the inside.

Table 5 shows the layering of materials used for the different construction sets used to build the house.

The effects of air infiltration were tested using the model with a staggered double 2″ × 4″ wall structure and varying the air tightness values ranging from 0.05 CFM/ft2 to 0.15 CFM/ft2 with 0.05 CFM/ft2 increments.

5.2. Modeling Results

In

Table 6, the recommended HVAC sizing is based on design day data which used 21 January and 21 July for heating and cooling values, respectively. The conditions on these days are considered to be indicative of the harsh conditions during these parts of the year. It can be seen that even the most insulated wall structure in Denver requires more heating capacity than the least insulated wall structure in Birmingham. Birmingham requires more cooling than Denver but with the single 2″ × 6″ wall structure, the cooling requirement is only 6.2% higher for Birmingham than Denver and the heating required in Denver is 24.6% greater than Birmingham. It can be seen that in Birmingham, cooling values are between 5% and 8% higher than those for heating, whereas in Denver cooling values are around 30% lower than heating.

In

Table 7, the highest annual total peak load was seen in July for Birmingham and in June for Denver. October is listed in this table to estimate the demand the competition house might be expected to meet during the competition. The house has a smaller peak load in Denver, likely due to milder temperatures during the early part of fall.

In

Table 8, the effect of the increased air infiltration can be seen. Heating the house is affected the most by increased infiltration. In Birmingham, the required heating capacity almost doubles when the infiltration rate increases from 0.3 to 1.5 ACH. In Denver, the same increase in infiltration requires approximately a 91% increase in HVAC capacity. For cooling, the increase in capacity is only 31% for Birmingham, and 27% for Denver.

In

Table 9, the highest annual total peak load was seen in July. October is listed in this table to estimate the demand the competition house might be expected to meet during the competition. It can be seen that the house will have a smaller peak load in Denver during the competition, likely due to milder temperatures during the early part of fall. It can also be seen that in the model tested, wall construction has only a small effect on peak demand of the house. The greatest difference in performance of 4.0% is found in Denver in the month of July.

Table 10 shows that the total peak demand is influenced more by the amount of air infiltration than by the change in wall types. Both cities show an approximately 10% increase in peak demand during the hot month of July. Birmingham sees a larger effect during October than Denver does. This is likely due to the milder temperature in Denver during this time of the year while Birmingham is still typically in the cooling season.

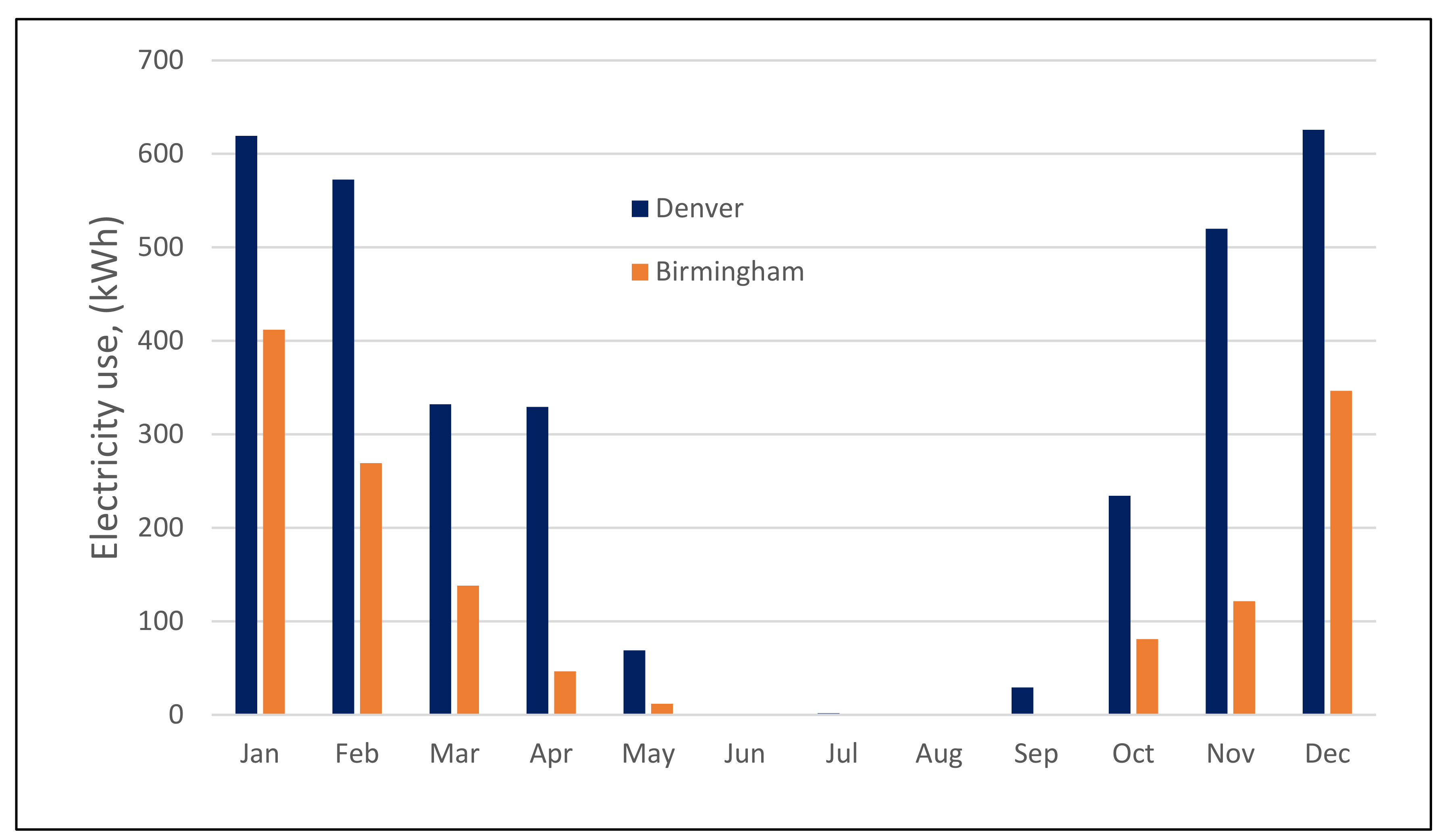

Figure 3 and

Figure 4 show annual electricity consumption for heating and cooling for each month.

Figure 3 shows that in Denver, electricity use for heating is considerably higher than that in Birmingham. The total electricity use for heating in Denver and Birmingham is 3335 and 1428 kWh, respectively. Heating electricity is 12% of total electricity use in Birmingham while it is 26% in Denver. This means that any effort to reduce heating electricity for a building located in Denver will have a larger impact on the total electricity bill of the house compared to that in Birmingham.

For cooling, as seen in

Figure 4, Birmingham requires more electricity for most months. The results presented in

Figure 3 and

Figure 4 are in line with what was expected according to the weather condition of the two cities. The total electricity use for cooling in Denver and Birmingham is 2568 and 4155 kWh, respectively. In Birmingham, cooling constitutes 34% of total electricity use while that fraction is 20% in Denver. In contrast to heating, improving the building performance with respect to cooling load has a larger impact in the total electricity cost of the building in Birmingham.

Based on the results of the energy modeling performed on the as-built condition of the house, a 2-ton ductless heat pump system is sufficient to deliver heating and cooling needs of the building. The study revealed that, as expected, cooling is the dominant design factor in Birmingham while in Denver, the dominant design factor is heating. The annual cooling electricity in Birmingham is 62% more than that in Denver. Heating electricity required in Birmingham is 57% less than that in Denver. When both electricity use for cooling and heating is considered, the two cities require nearly the same energy in kWh per year.

Selecting insulation material for the house is a multi-faceted task. The ultimate goal is to keep the inside conditions at a comfortable range by limiting heat transfer through the house’s envelope, and also to minimize infiltration of unconditioned outside air to the house through gaps, cracks, and openings. In order to achieve these goals, conscientious decisions must be made. Health concerns are the most important factors, and most commercially available insulating materials have deficiencies in that area. Construction-phase issues includes skin- and eye-irritant chemical fumes, microfiber inhalation, and skin abrasion. Post-construction issues include flammability, off-gassing, end-of-life environmental issues, and also the same issues as those during construction-phase whenever repair and replace work is required. On the other hand, there is the issue of achieving the highest R-value that is possible in a compact space, and so hard choices have to be made. Usually, environmentally benign materials do not provide high R-values or lack other required features such as fireproofing. The exterior vertical walls of the house are built in a staggered double 2″ × 4″ stud manner with 2″ × 6″ plates on the top and bottom of the wall frame. This provides a cavity space for insulation equal to 5.5 in (14 cm). This cavity is filled with 1 in (2.5 cm) of closed-cell foam sprayed on the ZIP system

® wall sheathing. A 2-in (5 cm) layer of fiberglass batt insulation is installed over the spray foam. An additional 3″ (7.6 cm) layer of fiberglass paper-faced batt insulation is in place. Then, in order to provide a rigid backing to prevent gypsum boards from cracking due to transportation-induced vibration, plywood sheets are installed to close the wall cavity. Gypsum board is installed on the plywood sheets. On the outside of the exterior sheathing, a 1-in (2.5 cm) slab of rigid foam insulation provides an additional R-5 insulation to the wall.

Table 5 shows the thickness of each individual layer of the vertical exterior walls. Since the house is built in several modules for transportation, there are seams where the modules come in contact. All seams are sealed with weather-resistant tape.

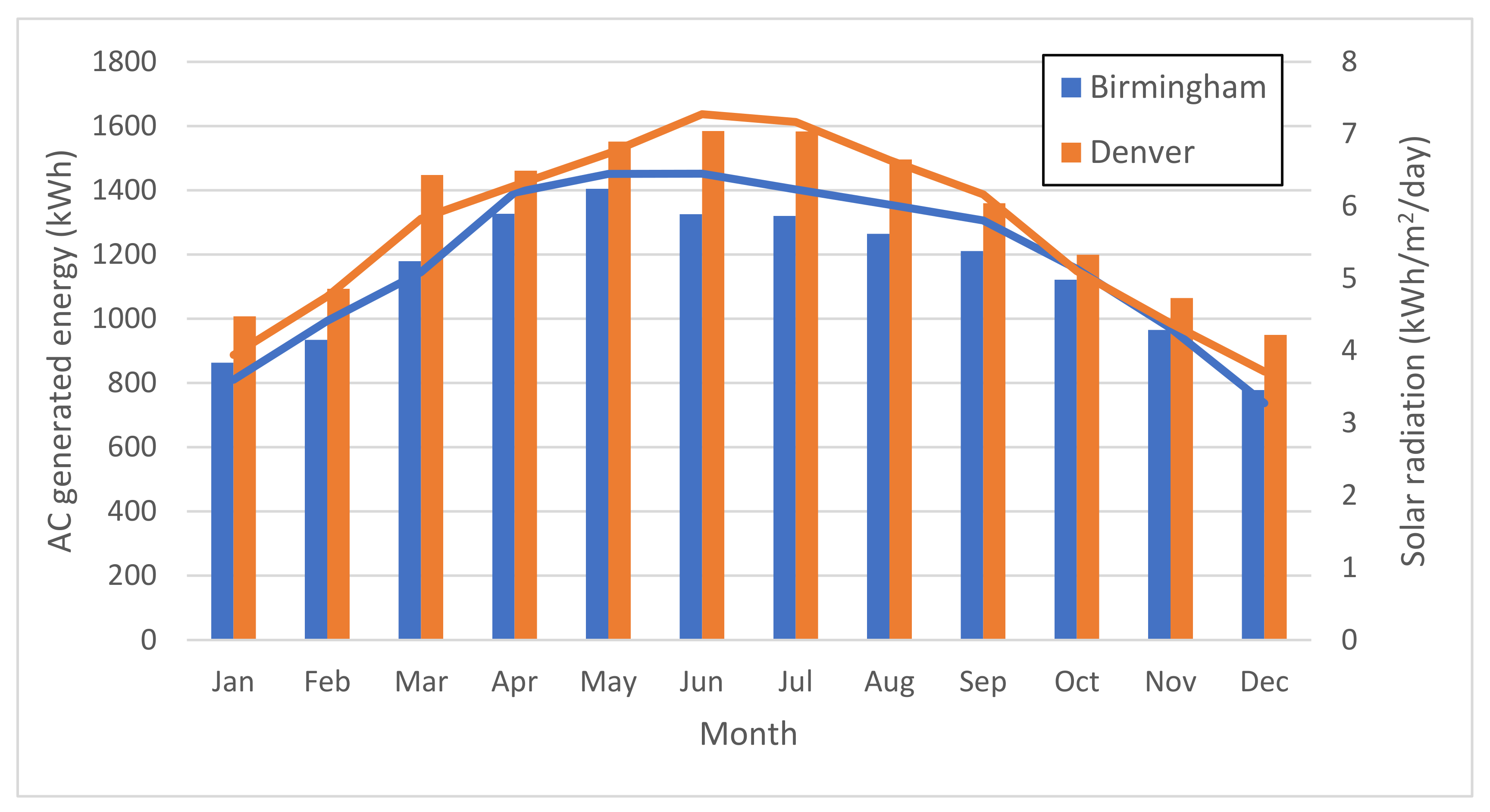

Monthly PV electricity generation by the installed system was simulated using the PVWatts calculator [

19]. The roof tilt angle (19°) was used in the model as the PV panels were installed flat (parallel) on the roof. The nominal (peak) PV capacity of 9.9 kW was entered as the capacity of the system in the calculator.

Figure 5 presents the results of the simulation.

It can be seen that at the given tilt angle, the PV system generates less energy in Birmingham as expected because the average solar radiation on a daily basis is smaller than that in Denver.