Energy Consumption Characteristics for Design Parameters of Permanent Magnet-Based Al Billet Heater

Abstract

:1. Introduction

2. Theoretical Background

2.1. Electromagnetic–Thermal Analysis for Permanent Magnetic Heating System

2.2. Numerical Analysis of Electromagnetic–Thermal Heating Characteristics

3. Numerical Analysis and Verification

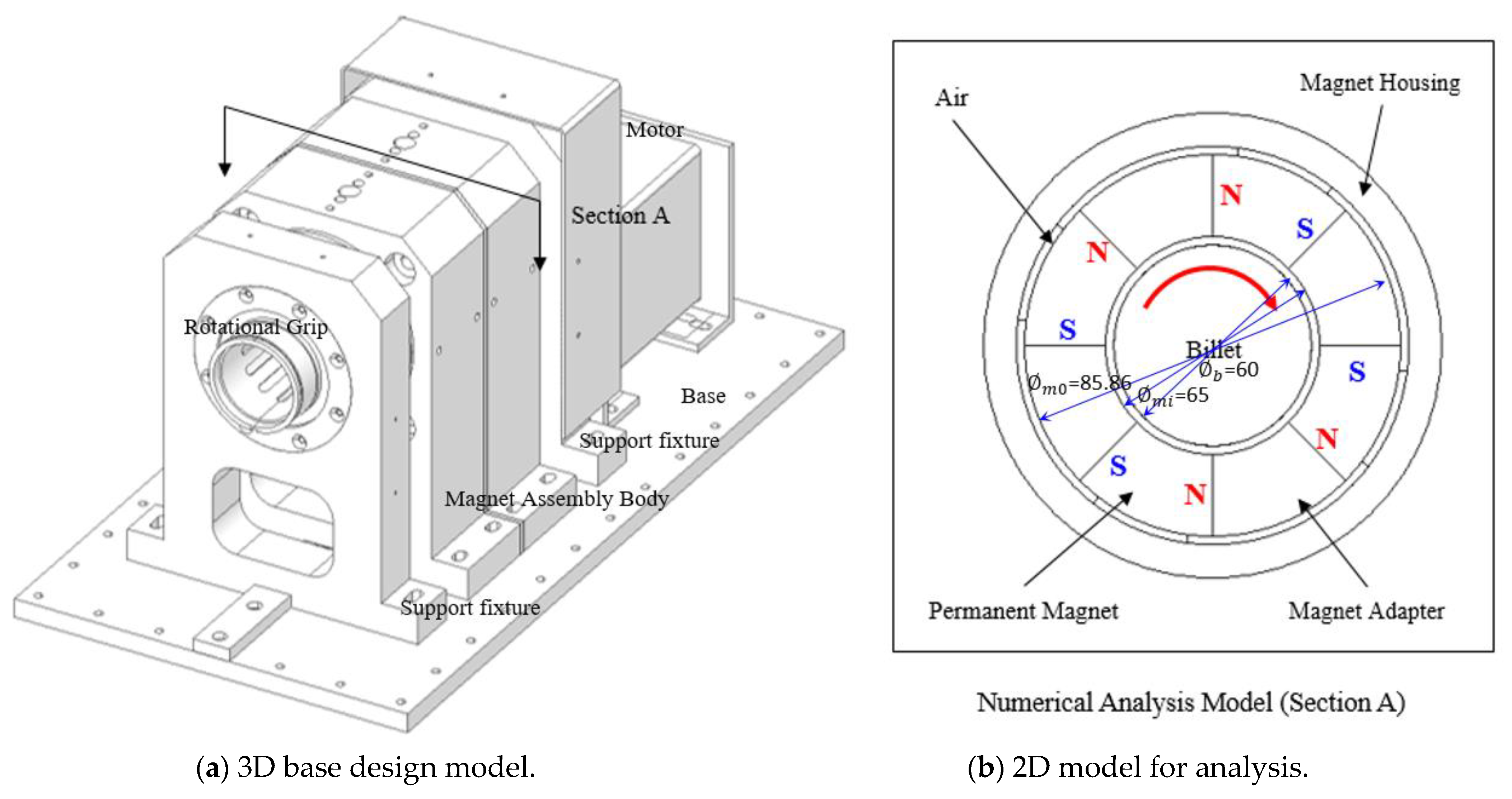

3.1. Base Model of Induction Heating with Permanent Magnet

3.2. Properties and Boundary Conditions of Billet Heating

3.3. Comparison between Numerical Analysis and Experiment

3.3.1. Analysis of the Base Model

3.3.2. Experiment Results Using the Base Model

3.3.3. Comparison between Analysis and Experiment Results

4. Heating Characteristic Effects on Design Parameters

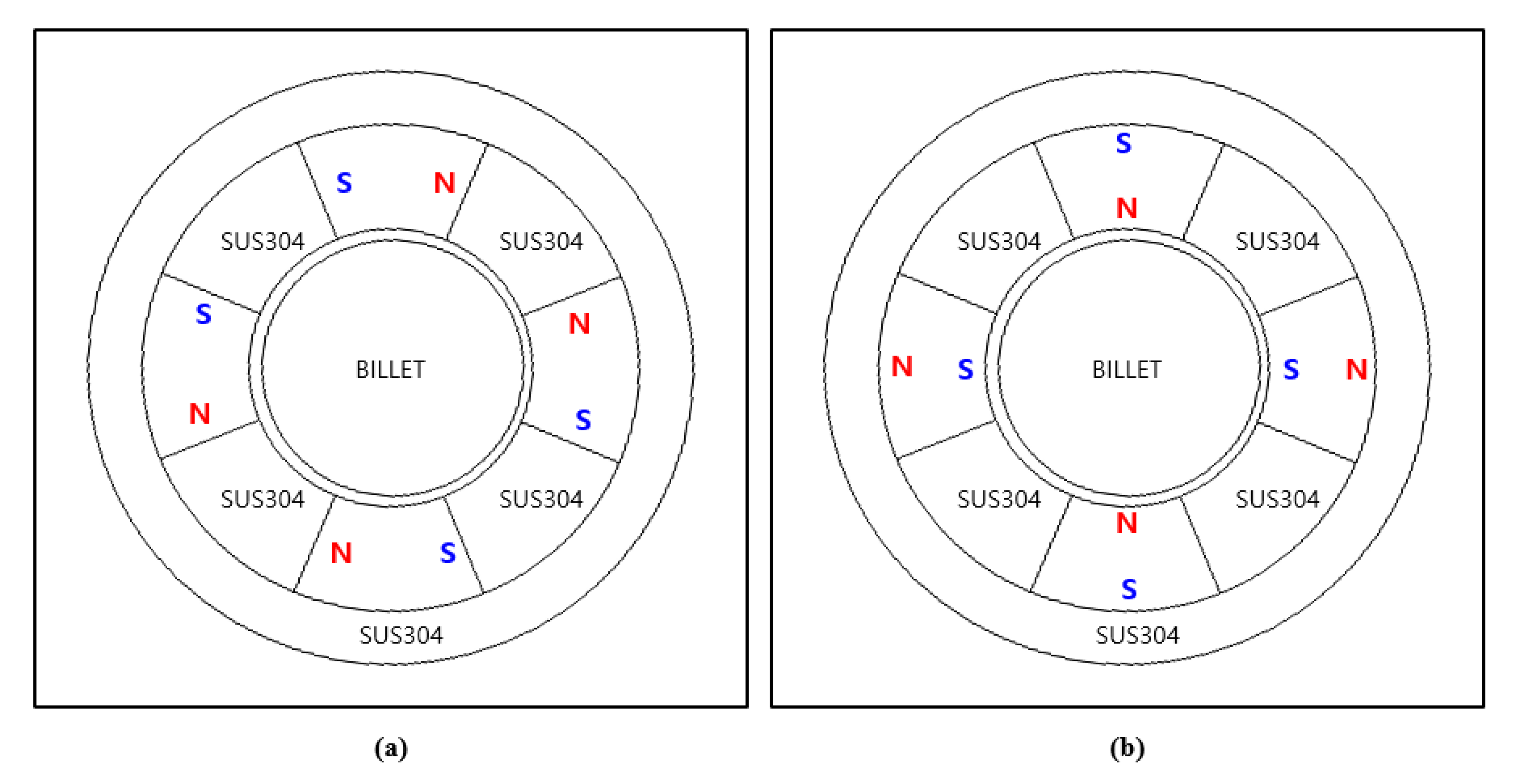

4.1. Heating Effect for Magnetic Polarity Direction

4.2. Heating Effect Based on Number of Magnets

4.3. Analysis of Effects of Change in the Clearance between Billet and Permanent Magnet

4.4. Heating Effect for Billet Assemble Eccentricity

4.5. Effects of Magnet Arrangement Clearance

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Mallick, P.K. Materials, Design and Manufacturing for Light Weight Vehicles; Woodhead Publication: Sawston, UK, 2010. [Google Scholar]

- Elmarakbi, A. Advanced Composite Materials for Automotive Applications: Structural Integrity and Crashworthiness; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Marshall, G.J.; Bolingbroke, R.K.; Gray, A. microstructural Control in an Aluminum Core Alloy for Brazing Sheet Applications Metall. Metall. Mater. Trans. A 1993, 24, 1935–1942. [Google Scholar] [CrossRef]

- Trivedi, A.; Dwivedi, V.K.; Agarwal, M. Cladding techniques that achieve a solid metallurgical bond with the least amount of base material dilution—An overview. ICMED 2021, 309, 01091. [Google Scholar] [CrossRef]

- Khan, H.A.; Asim, K.; Akram, F.; Hameed, A.; Khan, A.; Mansoor, B. Roll Bonding Processes: State-of-the-Art and Future Perspectives. Metals 2021, 11, 1344. [Google Scholar] [CrossRef]

- Wang, K.; Khan, H.A.; Li, Z.; Lyu, S.; Li, J. Micro friction stir welding of multilayer aluminum alloy sheets. J. Mater. Process. Technol. 2018, 260, 137–145. [Google Scholar] [CrossRef]

- Khan, H.; Li, J.; Shao, C. Analyses of friction stir riveting processes: A review. ASME J. Manuf. Sci. Eng. 2017, 139, 090801. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Li, Y.; Banu, M.; Li, J.; Guo, W.; Khan, H. Effect of interfacial preheating on welded joints during ultrasonic composite welding. J. Mater. Process. Technol. 2017, 246, 116–122. [Google Scholar] [CrossRef]

- Göken, M.; Höppel, H.W. Tailoring Nanostructured, Graded, and Particle-Reinforced Al Laminates by Accumulative Roll Bonding. Adv. Mater. 2011, 23, 2663–2668. [Google Scholar] [CrossRef]

- Bay, N.; Clemensen, C.; Juelstorp, O.; Wanheim, T. Bond Strength in Cold Roll Bonding. CIRP Ann. Manuf. Technol. 1985, 34, 221–224. [Google Scholar] [CrossRef]

- Frolov, Y.; Haranich, Y.; Bobukh, O.; Remez, O.; Voswinkel, D.; Grydin, O. Deformation of expanded steel mesh inlay inside aluminum matrix during the roll bonding. J. Manuf. Process. 2020, 58, 857–867. [Google Scholar] [CrossRef]

- Diop, M.A.; Xiaomeng, C.; Hassan, M.I. Billet heat treatment using flue gas for energy efficiency and batching cycle time reduction. Energy Procedia 2017, 105, 3377–3383. [Google Scholar] [CrossRef]

- Magnusson, N.; Bersas, R.; Runde, M. Induction heating of aluminum billets using HTS DC Coils. Inst. Phys. Conf. Ser. 2004, 181, 1104–1109. [Google Scholar]

- Fabbri, M.; Morandi, A.; Ribani, P.L. Operational Constraints on the DC induction heating of aluminum billets. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2008, 18, 816–819. [Google Scholar]

- Magnusson, N.; Runde, M. Efficiency Analysis of a High-temperature Superconducting Induction Heater. IEEE Trans. Appl. Supercond. 2003, 13, 1616–1619. [Google Scholar] [CrossRef]

- Choi, J.; Kim, K.; Park, M.; Yu, I.-K.; Kim, S.; Sim, K.; Kim, H.-J. Practical design and operating characteristic analysis of a 10 kW HTS DC induction heating machine. Phys. C Supercond. Its Appl. 2014, 504, 120–126. [Google Scholar] [CrossRef]

- Morandi, A.; Fabbri, M.; Ribani, P.L. Design of a superconducting saddle magnet for DC induction heating of aluminum billets. IEEE Trans. Appl. Supercond. 2008, 18, 816–819. [Google Scholar] [CrossRef]

- Araneo, R.; Dughiero, F.; Fabbri, M.; Forzan, M.; Geri, A.; Morandi, A. Electromagnetic and thermal analysis of the induction heating of aluminum billets rotating in DC magnetic field. COMPEL-Int. J. Comput. Math. Electr. Electron. Eng. 2008, 27, 467–479. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, J.; Li, Z.Y.; Jin, Z.; Hong, Z. Study on a numerical method for calculating the heating process of HTS DC induction heater. IEEE Trans. Appl. Supercond. 2013, 24, 1–5. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, H.; Li, Z.; Ping, Y.; Jin, Z.; Hong, Z. Study of the temperature uniformity of aluminium billets heated by superconducting DC induction heaters. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2015, 34, 357–370. [Google Scholar] [CrossRef]

- Kim, J.G.; Hahn, S.Y.; Choi, J.H.; Semertzidis Yannis, K. A Design study on a Multibillet HTS Induction Heater with REBCO Racetrack Coils. IEEE-Inst. Electr. Electron. Eng. 2019, 8, 1051–8223. [Google Scholar] [CrossRef]

- Yan, X.; Dai, S.; Ma, T. Electromagnetic and Thermal Analysis of Cylindrical Aluminum Billet Heated by 1MW HTS DC Induction Heater. IEEE Access 2020, 8, 144112–144121. [Google Scholar] [CrossRef]

- Bojarevics, A.; Beinerts, T. Experiments on liquid metal flow induced by rotating magnetic dipole. Magnetohydrodynamics 2010, 46, 333–338. [Google Scholar] [CrossRef]

- Bullo, M.; Bertazzo, M.; Dughiero, F.; Forzan, M.; Zerbetto, M. Experimental results of a 55 kw permananet magnet heater prototype. Proc. HES-13 2013, 2013, 377–384. [Google Scholar]

- Ye, L.; Liang, C.; Liu, Y.; Li, D.; Liu, Z. Performance analysis and test of a novel eddy-current braking & heating system for electric bus. Energy Convers. Manag. 2019, 183, 440–449. [Google Scholar]

- Chai, Y.-Y.; Yoon, K.Y. Development of Heater Driven by Motor by using eddy current. J. KIECS 2019, 14, 935–942. [Google Scholar]

- Mach, F.; Karban, P.; Dolezel, I. Induction heating of cylindrical nonmagnetic ingots by rotation in static magnetic field generated by permanenet magnets. J. Comput. Appl. Math. 2012, 236, 4732–4744. [Google Scholar] [CrossRef] [Green Version]

- Du, H.; Li, J.; Qu, Y. Mathematical Modeling of Eddy-Current Loss for a New Induction Heating Device. Math. Probl. Eng. 2014. [Google Scholar] [CrossRef] [Green Version]

- Bensaidane, H.; Lubin, T.; Mezani, S.; Ouazir, Y.; Rezzoug, A. A New Topology for Induction Heating System with PM Excitation: Electromagnetic Model and Experimental Validations. IEEE Trans. Magn. Inst. Electr. Electron. Eng. 2015, 12, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Aliferov, A.I.; Vlasov, D.S.; Promzelev, V.A.; Morev, A.E. Induction heating based on permanent magnets with magnetic field concentrators. Int. Conf. Actual Issues Mech. Eng. 2017, 133, 495–499. [Google Scholar]

- Zerbetto, M.; Forzan, M.; Dughiero, F. Permanent Magnet Heater for a precise control of temperature in aluminum billets before extrusion. Mater. Today Proc. 2015, 2, 4812–4819. [Google Scholar] [CrossRef]

- Piscini, L.; Matt, D.; Gimeno, A. Comparison of different Surface Mounted Permanent Magnet patterns. IEEE Stud. Conf. Electr. Mach. Syst. 2018. [Google Scholar] [CrossRef]

- N’Gotta, P. Development of permanent magnet quadrupole for particles accelerator. Phys. Des. Accel. 2015, 2015, 52. [Google Scholar]

- Zhu, Z.Q.; Member, S.; Xia, Z.P.; Howe, D. Comparison of Halbach Magnetized Brushless Machines Based on Discrete Magnet Segments or a Single Ring Magnet. IEEE Trans. Magn. 2002, 38, 2997–2999. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.K.; Hong, S.I. Effect of Intermetallic Compound Layer on Peel Strength and Crack Propagation Behavior in Cu/Al/Cu Clad Composites. Metals 2019, 9, 1155. [Google Scholar] [CrossRef] [Green Version]

- Kim, I.-K.; Hong, S.I. Mechanochemical joining in cold roll-cladding of tri-layered Cu/Al/Cu composite and the interface cracking behavior. Mater. Des. 2014, 57, 625–631. [Google Scholar] [CrossRef]

- Summers, P.; Chen, Y.; Rippe, C.; Allen, B.; Mouritz, A.; Case, S.; Lattimer, B. Overview of aluminum alloy mechanical properties during and after fires. Fire Sci. Rev. 2015, 4, 3. [Google Scholar] [CrossRef] [Green Version]

- Lubin, T.; Netter, D.; Leveque, J.; Rezzoug, A. Induction Heating of Aluminum Billet Subjected to a Strong Rotating Magnetic Field produced by Superconducting Windings. IEEE Trans. Magn. Inst. Electr. Electron. Eng. 2009, 45, 2118–2127. [Google Scholar] [CrossRef] [Green Version]

- Rudnev, V.; Loveless, D.; Cook, R.L. Theoretical Background from: Handbook of Induction Heating; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Kumar, R.; La Rocca, A.; Vakil, G.; Gerada, D.; Gerada, C.; Fernandes, B.G. Significance of Anisotropic Thermal Expansion in High Speed Electric Machines Employing NdFeB Permanent Magnets. Energies 2021, 14, 7558. [Google Scholar] [CrossRef]

- Deng, D.; Murakawa, H. Numerical Simulation of Temperature Field and Residual Stress in Multi-pass Welds in Stainless Steel Pipe and Comparison with Experimental Measurements. Comput. Mater. Sci. 2006, 37, 269–277. [Google Scholar] [CrossRef]

| Description | 20 °C | 100 °C | 300 °C | 500 °C | |

|---|---|---|---|---|---|

| Al | Electrical Resistivity [Ω·m] | 2.65 × 10−8 | 3.56 × 10−8 | 6.61 × 10−8 | 1.23 × 10−7 |

| Volumetric Heat Capacity [J/m3·K] | 2.40 × 106 | 2.50 × 106 | 2.65 × 106 | 2.90 × 106 | |

| Density [kg/m3] | 2700 | 2681 | 2640 | 2590 | |

| Thermal Conductivity [W/m·K] | 236 | 228 | 220 | 210 | |

| SUS 304 | Electrical Resistivity [Ω·m] | 7.20 × 10−7 | 7.69 × 10−7 | 9.00 × 10−7 | 1.05 × 10−6 |

| Volumetric Heat Capacity [J/m3·K] | 3.68 × 106 | 3.90 × 106 | 4.09 × 106 | 4.29 × 106 | |

| Density [kg/m3] | 7960 | 7880 | 7790 | 7710 | |

| Thermal Conductivity [W/m·K] | 13.4 | 15.35 | 17.3 | 21.3 | |

| NdFeB | Flux Density [T] | 1.2 | 1.1 | - | - |

| Electrical Resistivity [Ω·m] | 1.5 × 10−6 | 1.52 × 10−6 | - | - | |

| Volumetric Heat Capacity [J/m3·K] | 3.42 × 106 | - | - | - | |

| Density [kg/m3] | 7600 | - | - | - | |

| Thermal Conductivity [W/m·K] | 6.61 | - | - | - | |

| Condition | Value | Unit | |

|---|---|---|---|

| Geometric Condition | Pole | 4 | EA |

| Magnetic Direction | Tangential | - | |

| Clearance | 2.5 | mm | |

| Boundary Condition | Rotational speed | 4000 | RPM |

| Sink Temperature | 293 | K | |

| Uniform Heat Source | variable | W/m3 | |

| Number of Magnets | 4 | 8 | 10 | 12 | 14 |

|---|---|---|---|---|---|

| Energy consumption (Tangential, kWh/ton) | 370.91 | 311.46 | 296.78 | 286.75 | 326.27 |

| Energy consumption (Normal, kWh/ton) | 325.68 | 278.83 | 283.20 | 299.17 | 335.01 |

| Case01 | Case02 | Case03 | Case04 | Case05 | Case06 | |

|---|---|---|---|---|---|---|

| Outer Radius [mm] | 46.60 | 46.93 | 47.26 | 47.60 | 47.93 | 48.27 |

| Inner Radius [mm] | 30.50 | 31.00 | 31.50 | 32.00 | 32.50 | 33.00 |

| Clearance [mm] | 0.50 | 1.00 | 1.50 | 2.00 | 2.50 | 3.00 |

| Magnetic Flux Density [T] | Current Density [×106, A/m2] | Power Loss Density [W/m3] | ||

|---|---|---|---|---|

| Case01 | Min | 796 × 10−9 | −266 | 455 × 10−9 |

| Max | 1.398 | 266 | 188 × 107 | |

| Case02 | Min | 194 × 10−8 | −211 | 997 × 10−11 |

| Max | 1.350 | 211 | 119 × 107 | |

| Case03 | Min | 605 × 10−9 | −176 | 825 × 10−9 |

| Max | 1.258 | 176 | 826 × 106 | |

| Case04 | Min | 200 × 10−8 | −152 | 131 × 10−9 |

| Max | 1.248 | 152 | 614 × 106 | |

| Case05 | Min | 671 × 10−9 | −134 | 200 × 10−8 |

| Max | 1.243 | 134 | 479 × 106 | |

| Case06 | Min | 574 × 10−9 | 120 | 200 × 10−9 |

| Max | 1.238 | −120 | 385 × 106 | |

| Eccentricity [mm] | 0 | 0.5 | 1.0 | 1.5 | 2.0 | |

|---|---|---|---|---|---|---|

| Power Loss [kW] | NM = 4 | 3.23 | 3.24 | 3.25 | 3.27 | 3.29 |

| NM = 12 | 3.49 | 3.50 | 3.57 | 3.70 | 3.90 | |

| Torque Ripple [mN·m] | NM = 4 | 0.01 | 0.02 | 0.06 | 0.15 | 0.37 |

| NM = 12 | 0.08 | 0.13 | 0.21 | 0.70 | 0.91 | |

| Inner Radius [mm] | Outer Radius [mm] | Theta [Degree] | Clearance Angle [Degree] | |

|---|---|---|---|---|

| Case01 | 30.5 | 52.84 | 10 | 20 |

| Case02 | 30.5 | 46.60 | 15 | 15 |

| Case03 | 30.5 | 43.14 | 20 | 10 |

| Case04 | 30.5 | 40.93 | 25 | 5 |

| Case05 | 30.5 | 39.94 | 28 | 2 |

| Magnetic Flux Density [T] | Current Density [×106, A/m2] | Power loss Density [W/m3] | ||

|---|---|---|---|---|

| Case01 | Min | 136 × 10−8 | −265 | 828 × 10−9 |

| Max | 1.456 | 265 | 186 × 107 | |

| Case02 | Min | 734 × 10−9 | −266 | 394 × 10−9 |

| Max | 1.439 | 266 | 188 × 107 | |

| Case03 | Min | 178 × 10−8 | −273 | 564 × 10−10 |

| Max | 1.862 | 273 | 193 × 107 | |

| Case04 | Min | 184 × 10−8 | −288 | 313 × 10−8 |

| Max | 2.378 | 288 | 220 × 107 | |

| Case05 | Min | 641 × 10−9 | −354 | 633 × 10−8 |

| Max | 2.961 | 354 | 333 × 107 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hur, D.-J.; Song, S.-I.; Lee, H.-J. Energy Consumption Characteristics for Design Parameters of Permanent Magnet-Based Al Billet Heater. Appl. Sci. 2022, 12, 3052. https://doi.org/10.3390/app12063052

Hur D-J, Song S-I, Lee H-J. Energy Consumption Characteristics for Design Parameters of Permanent Magnet-Based Al Billet Heater. Applied Sciences. 2022; 12(6):3052. https://doi.org/10.3390/app12063052

Chicago/Turabian StyleHur, Deog-Jae, Seong-Il Song, and Hyun-Ju Lee. 2022. "Energy Consumption Characteristics for Design Parameters of Permanent Magnet-Based Al Billet Heater" Applied Sciences 12, no. 6: 3052. https://doi.org/10.3390/app12063052