Thermal–Structural Coupling Analysis of Subsea Connector Sealing Contact

Abstract

:1. Introduction

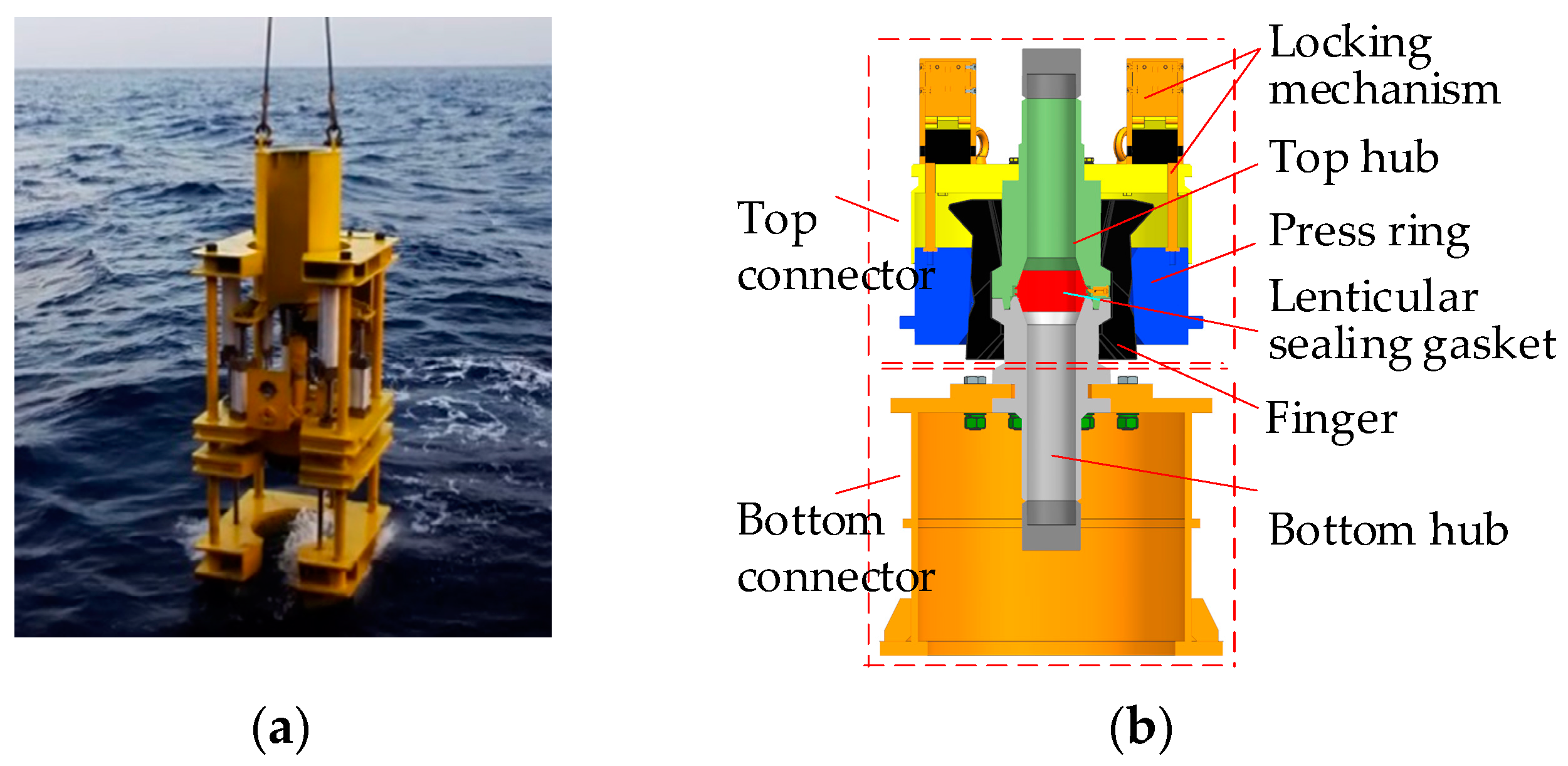

2. The Structure of the Subsea Connector

3. Research on the Heat Transfer Model of the Subsea Connector

3.1. Heat Transfer Model of the Seawater Layer between the Hub and Collet

3.2. Heat Transfer Model of the Seawater Layer between the Hub and Lenticular Sealing Gasket

3.3. The Heat Transfer Model of the Outer Surface of the Finger and the Press Ring

4. Thermal–Structural Coupling Mathematical Model of the Subsea Connector

4.1. Three-Dimensional Stress Caused by the Steady-State Temperature Field

4.2. Three-Dimensional Stress Caused by Internal Pressure Load

4.3. Three-Dimensional Stress Transformed by Contact Stress

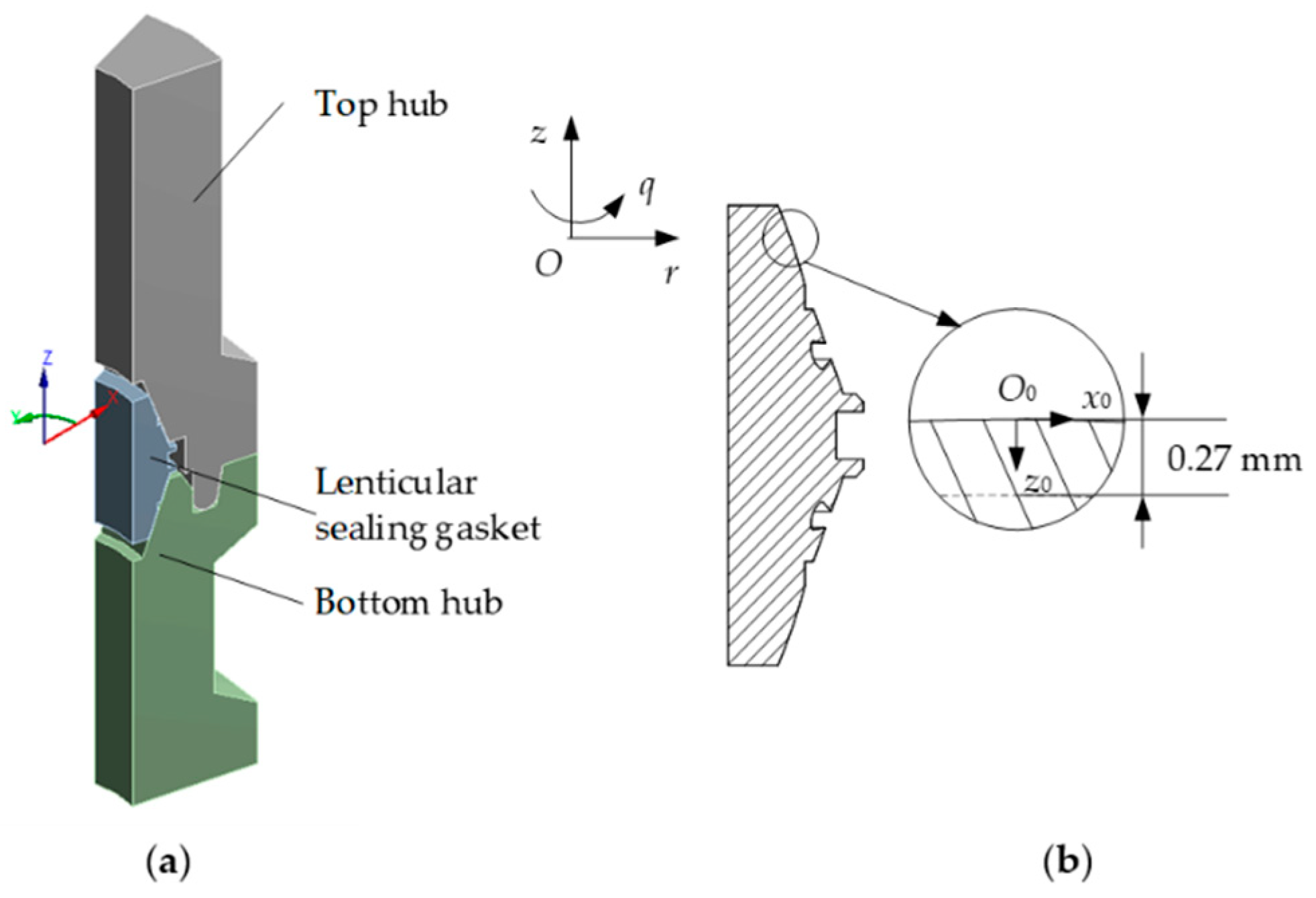

4.3.1. Contact Mechanic Analysis of the Lenticular Sealing Structure

4.3.2. Conversion of Contact Stress

4.3.3. Thermal–Structural Coupling Stress

5. Numerical Simulation of Thermal–Structural Coupling of the Subsea Connector

5.1. Steady-State Temperature Field Analysis of the Subsea Connector

5.2. The Overall Temperature Field Distribution of the Connector Sealing Structure

Temperature Field Distribution of the Lenticular Sealing Gasket

5.3. Analysis of Coupling Stress Examples under a Steady-State Temperature Field

5.4. Coupling Stress Analysis in the Pressure Shock Mode

6. Conclusions

- (1)

- Considering the heat transfer problem of the subsea connector in deep water, the equivalent heat transfer models of seawater layer between the lenticular sealing gasket and hubs, between hubs and fingers, and outside the outer surface of the fingers and the press ring are established, and the relationship between equivalent thermal conductivity, composite heat transfer coefficient, and temperature is solved.

- (2)

- The mathematical model of steady-state thermal structural coupling of the subsea connector is established and verified by the simulation analysis. The theoretical analysis of the radial stress, circumferential stress, and axial stress is 5.28%, 8.82%, and 5.32% larger than the simulation analysis, and the sealing width is 12.10% smaller.

- (3)

- The steady-state temperature distribution of the subsea connector under rated working condition is simulated. The finite element simulation shows that in the center path of the connector’s lenticular sealing gasket, the hub’s falling temperature is 60.01 °C and the temperature gradient is −1.05 °C/mm, which are the maximum values of all parts. The values of the sealing gasket, finger, and press ring decrease in turn. The temperature field of the lenticular sealing gasket is symmetrically distributed, and the temperature is always in the high temperature stage (126~150 °C), which has little influence on the mechanical properties of the material, so as to ensure its stable sealing performance.

- (4)

- The numerical simulation of pressure shock mode under steady temperature field shows that the maximum equivalent stress of the sealing gasket exceeds the theoretical yield limit of the material under the combined action of temperature and pressure, resulting in plastic deformation, which indicates that the lenticular sealing gasket is sensitive to high pressure shock under high temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Bai, Y.; Bai, Q. Subsea Pipelines and Risers, 1st ed.; Elsevier Science Ltd.: Kidlington, UK, 2005; pp. 3–19. [Google Scholar]

- Toshiyuki, S.; Wataru, M. Thermal Stress Analysis and Sealing Performance Evaluation of Pipe Flange Connections with Spiral Wound Gaskets under Elevated Temperature. In Proceedings of the ASME Pressure Vessels and Piping Conference, San Diego, CA, USA, 25–29 July 2004. [Google Scholar]

- Abid, M.; Ullah, B. Three-Dimensional Nonlinear Finite-Element Analysis of Gasketed Flange Joint under Combined Internal Pressure and Variable Temperatures. J. Eng. Mech. 2007, 133, 222–229. [Google Scholar] [CrossRef]

- Zhou, X.; Chou, X.; Zhang, B.; Chen, G. Finite Element Analysis of Bolt-Connected Flange Transient Temperature Field. Press. Vess. T 2007, 24, 8–11, 16. [Google Scholar]

- Al-Turki, L.I.; Drummond, J.L.; Agojci, M.; Gosz, M.; Tyrus, J.M.; Lin, L. Contact versus flexure fatigue of a fiber-filled composite. Dent. Mater. 2007, 23, 648–653. [Google Scholar] [CrossRef] [PubMed]

- Avanzini, A.; Donzella, G. A computational procedure for life assessment of UHP reciprocating seals with reference to fatigue and leakage. Int. J. Mater. Prod. Technol. 2007, 30, 33. [Google Scholar] [CrossRef]

- Omiya, Y.; Sawa, T. Thermal Stress Analysis and the Sealing Performance Evaluation of Bolted Flange Connection at Elevated Temperature. In Proceedings of the ASME 2009 Pressure Vessels and Piping Conference, Prague, Czech Republic, 26–30 July 2009. [Google Scholar]

- Toshiyuki, S.; Yoshio, T.; Hiroyasu, T. Effect of Material Properties of Gasket on the Sealing Performance of Pipe Flange Connections at Elevated Temperature. In Proceedings of the ASME 2015 Pressure Vessels and Piping Conference, Boston, MA, USA, 19–23 July 2015. [Google Scholar]

- Luo, Y.; Liu, X.; Hao, J.; Wang, Z.; Liu, L.; Lin, X. Research on thermal fatigue failure mechanism of aviation electrical connectors. Acta Armamentarii 2016, 7, 1266–1274. [Google Scholar]

- Wang, L.; Chen, X.; Fan, Z.; Xue, J. FEM Stress Analysis of Bolted Flange Joints in Elevated Temperature Service Condition. In Proceedings of the ASME 2018 Pressure Vessels and Piping Conference, Prague, Czech Republic, 15–20 July 2018. [Google Scholar]

- Abdullah, O.I.; Schlattmann, J.; Jobair, H.; Beliardouh, N.E.; Kaleli, H. Thermal stress analysis of dry friction clutches. Ind. Lubr. Tribol. 2018, 72, 189–194. [Google Scholar] [CrossRef]

- Lanzhu, Z.; Guangkai, X. Analysis of the metal-to-metal contact flange joint subject to external bending moment. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2018, 233, 234–241. [Google Scholar]

- Tang, L.; He, W.; Zhu, X.; Zhou, Y. Sealing Performance Analysis of an End Fitting for Marine Unbonded Flexible Pipes Based on Hydraulic-Thermal Finite Element Modeling. Energies 2019, 12, 2198. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Ding, X.; Zhang, W.; Yan, R.; Sun, B. Fractal prediction model for the thermo-elastic normal contact stiffness of frictional interfaces in dry gas seals. J. Vib. Shock. 2020, 39, 257–263. [Google Scholar]

- Wang, Q.; Hu, Y.P.; Ji, H.H. Leakage, heat transfer and thermal deformation analysis method for contacting finger seals based on coupled porous media and real structure models. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 2077–2093. [Google Scholar] [CrossRef]

- Fukuoka, T.; Yao, Y. Evaluation of Thermal and Mechanical Behaviors of Pipe Flange Connections for Low Temperature Fluids by Numerical Analysis and Experiments. Mar. Eng. 2015, 50, 671–677. [Google Scholar] [CrossRef] [Green Version]

- Tsuta, T.; Yamaji, S. Boundary element analysis of contact thermo-elastoplastic problems with creep and the numerical technique. In Proceedings of the 5th BEM Conference, Hiroshima, Japan, 8–11 November 1983; p. 576. [Google Scholar]

- Sharqawy, M.H. New correlations for seawater and pure water thermal conductivity at different temperatures and salinities. Desalination 2013, 313, 97–104. [Google Scholar] [CrossRef]

- Kretzschmar, H.; Cooper, J.R.; Dittmann, A.; Friend, D.G.; Gallagher, J.S.; Harvey, A.H.; Knobloch, K.; Mareš, R.; Miyagawa, K.; Okita, N.; et al. Supplementary Release on Backward Equations for the Functions T(p,h), v(p,h) and T(p,s), v(p,s) for Region 3 of the IAPWS Industrial Formulation 1997 for the Thermodynamic Properties of Water and Steam. J. Eng. Gas Turbines Power 2007, 129, 294–303. [Google Scholar] [CrossRef]

- Cooper, J.R.; Dooley, R.B. Revised Release on the IAPWS Industrial Formulation 1997 for the Thermodynamic Properties of Water and Steam. In Proceedings of the International Association for the Properties of Water and Steam, Lucerne, Switzerland, 26–31 August 2007; pp. 1–49. [Google Scholar]

- Abid, M.; Khan, K.A.; Chattha, J.A. Performance of a Flange Joint using Different Gaskets under Combined Internal Pressure and Thermal Loading, a FEM Approach. Mech. Based Des. Struct. Mach. 2008, 36, 212–223. [Google Scholar] [CrossRef]

- Cheng, X.; Peng, W.; Sun, L.; Li, X.; Yin, Z. Analysis of the fracture pattern and failure time of LNG outer tanks under the action of thermal load. Nat. Gas Ind. 2015, 35, 103–109. [Google Scholar]

- Hetnarski, R.B. Encyclopedia of Thermal Stresses; Springer: Dordrecht, The Netherlands, 2014; pp. 1241–1522. [Google Scholar]

- Lu, G.C.; Chu, G.N. Research of Directional Stress Distribution on the Fully Plastic Bulged Pressure Hull. Adv. Mater. Res. 2014, 1082, 412–415. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, H.; He, D.; Du, C.; Xu, L.; He, Y.; Zheng, Y.; Ye, Z. Contact mechanical behaviors of radial metal seal for the interval control valve in intelligent well: Modeling and theoretical study. Energy Sci. Eng. 2019, 8, 1337–1352. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, H.; Wang, D.; Xu, Y. Metal sealing mechanism and experimental study of the subsea wellhead connector. J. Braz. Soc. Mech. Sci. Eng. 2019, 42, 26. [Google Scholar] [CrossRef]

- Polycarpou, A.A.; Etsion, I. A Model for the Static Sealing Performance of Compliant Metallic Gas Seals Including Surface Roughness and Rarefaction Effects. Tribol. Trans. 2000, 43, 237–244. [Google Scholar] [CrossRef]

- Johnson, K. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1987; pp. 12–119, 451–481. [Google Scholar]

- Yun, F.; Wang, L.; Yao, S.; Liu, J.; Liu, T.; Wang, R. Analytical and experimental study on sealing contact characteristics of subsea collet connectors. Adv. Mech. Eng. 2017, 9, 168781401770170. [Google Scholar] [CrossRef] [Green Version]

| Parts | Material Parameter | Boundary Conditions | ||||||

|---|---|---|---|---|---|---|---|---|

| E(MPa) | ν | ρ (g/cm3) | λk (W∙m−1∙K−1) | α* (/°C) | qmax (MPa) | P (MPa) | τ (°C) | |

| Gasket | 2.06 × 105 | 0.25 | 7.93 | 16.7 | 1.70 × 10−5 | 458.03 | 34.5 | 10.17 |

| Hubs | 2.1 × 105 | 0.3 | 7.93 | 16.3 | 1.68 × 10−5 | |||

| Time (s) | Maximum Contact Stress (MPa) | Maximum Equivalent Stress (MPa) | ||

|---|---|---|---|---|

| Lenticular Sealing Gasket | Hub | Finger | ||

| 10 | 458.76 | 251.85 | 176.64 | 111.79 |

| 20 | 492.59 | 275.22 | 195.21 | 113.00 |

| 30 | 459.06 | 251.88 | 176.99 | 111.87 |

| 40 | 458.76 | 251.85 | 176.64 | 111.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, F.; Liu, D.; Xu, X.; Jiao, K.; Hao, X.; Wang, L.; Yan, Z.; Jia, P.; Wang, X.; Liang, B. Thermal–Structural Coupling Analysis of Subsea Connector Sealing Contact. Appl. Sci. 2022, 12, 3194. https://doi.org/10.3390/app12063194

Yun F, Liu D, Xu X, Jiao K, Hao X, Wang L, Yan Z, Jia P, Wang X, Liang B. Thermal–Structural Coupling Analysis of Subsea Connector Sealing Contact. Applied Sciences. 2022; 12(6):3194. https://doi.org/10.3390/app12063194

Chicago/Turabian StyleYun, Feihong, Dong Liu, Xiujun Xu, Kefeng Jiao, Xiaoquan Hao, Liquan Wang, Zheping Yan, Peng Jia, Xiangyu Wang, and Bin Liang. 2022. "Thermal–Structural Coupling Analysis of Subsea Connector Sealing Contact" Applied Sciences 12, no. 6: 3194. https://doi.org/10.3390/app12063194