2.1. Monitoring and Controlling Real-Life Buildings

In buildings, multiple energy-related services (such as heating) are required to create a comfortable indoor climate. The apparatus to supply such services is often indicated as a

building automation and control system (BACS). A BACS encompasses all technical components, including software, that are necessary to obtain information on and control a building’s indoor climate [

9]. The most vital parts of a BACS comprise

heating, ventilation, and air conditioning (HVAC) components, as well as lighting and shading applications [

10]. Sources such as [

11] give an overview of those techniques and a broad set of standards are formulated to provide guidelines for proper design and application, such as [

12,

13,

14,

15].

Over the past decades, the understanding of BACS evolved from numerous, individual systems that serve a dedicated purpose (e.g., heating a single room), to integrated BACS systems that manage building-wide energy use, applying high-level controllers [

16].

A very promising approach to building-wide control is model-based control, or

model predictive control (MPC) [

3]. MPC applies models to predict system behavior, receiving continuous feedback in the form of measurements from the real-life building [

17,

18]. Thus, MPC usually requires detailed knowledge of the current building state and its environment, as well as the ability to influence the building [

19,

20].

To model BACS components, building envelopes, or other energy system components, different approaches exist [

6]. The so-called

white-box models are based on the principal physical correlations which characterize the system. These first-principle models are usually derived from in-depth knowledge of the system. On the contrary,

black-box models rely fully on empirical relations to depict a system’s behavior, which is why they are also referred to as

data-driven models. Data-driven models are derived from measurements obtained from a real-life system, and range from simple curves (e.g., for production efficiency), to modern

artificial neural network (ANN) or

long short-term memory (LSTM) modeling approaches [

21]. Being a mixture of white-box and black-box models,

gray-box models employ features of both modeling paradigms. Gray-box models usually incorporate important underlying physics, while the model’s parameters are fitted to real-life data [

5]. Further information on modeling and MPC can be found in [

3,

5,

6].

Applying MPC to building HVAC systems such as

air handling units (AHU) or

variable air volume (VAV) systems is an active field of research. In the most common approach for existing buildings, the current BACS is interfaced with the model-based controller via a dedicated interface [

17,

18,

22,

23,

24,

25,

26,

27]. For example the authors in [

18,

23] implement their model-based controller in MATLAB (Registered trademarks and proprietary names are not generally indicated as such in this publication. However, the absence of such indications does not imply that these names belong to the public domain with respect to trademark or copyright law.) [

28], interfacing the BACS via its energy management tool, WebCTRL [

29]. While Winkler et al. [

24] also use the WebCTRL interface for implementing set-points, they retrieve sensor data by sending and receiving BACnet [

30] telegrams on the communication bus directly. In [

31], the so-called Building Controls Virtual Test Bed (BCVTB) is used to connect a controller and a BACS. In other cases, where no BACS exists or where one cannot be used, building automation components are addressed directly for the implementation of MPC set-points [

32,

33,

34,

35,

36]. Such studies are usually limited to smaller buildings [

32,

34], a subset of thermal zones [

33,

35], or individual rooms [

36]. However, the density of sensors and actuators deployed at the room level tends to be higher. This not only serves the purpose of enabling enhanced control, but also increases the availability of on-site measurement data, e.g., for in-depth monitoring and model calibration [

37].

Energy saving potentials of sensor and control networks in the U.S. building sector were analyzed in [

38]. According to Sofos et al. [

38], the annual final energy savings in the year 2030 are estimated at 5% of the total final energy consumption in the U.S. building sector of 2018. Moreover, enabling advanced (model-based) control and human-in-the-loop control, the resulting overall energy savings are expected to be even 2–3-times higher. Hence, equipping buildings with sensor and control networks that go beyond the control of AHUs and VAV units, therefore, promises a significant reduction in the final energy consumption in this area [

36,

38].

Depending on the building structure and envelope type, either wired or wireless sensors and actuators, or a combination of both, are used [

27,

39]. As retrofitting measures in existing buildings are costly, in the case of existing buildings, wireless devices are preferred [

39]. Compared to wired sensors, wireless devices can be deployed and installed easily. However, wired sensor and control networks, in general, tend to be more reliable and secure [

38,

40]. Consequently, there is a wide range of sensor and actuator types, technologies, and communication protocols.

Table 1 gives an overview of the most common protocols used for sensor and control networks in the building sector.

From

Table 1, it becomes obvious that multiple different technologies can coexist. This leads to higher implementation hurdles with an increasing number of devices due to increased efforts for device provisioning, bookkeeping, and registration [

38]. Similarly, data collection and distribution architectures gain importance [

3,

10]. Hence, recent publications deal with the implementation of suitable

information and control technologies (ICT) in buildings: Sauer et al. [

37] investigate a setup based mainly on LoRaWAN [

41] and 1-Wire [

42] components, comprising 112 temperature and humidity sensors in three different buildings. To gather sensor data, they used Node-RED [

43], in combination with a time-series database. In [

44], the authors present an approach for connecting an existing BACS based on BACnet with a monitoring service in the cloud using FIWARE [

45]. They also depict how cloud-based control with FIWARE is implemented, showcasing a controller applied to a virtual room. To implement model-based control for a laboratory with an area of 27

, the authors in [

46,

47] equipped the room with several sensors, including air multisensors, occupancy sensors, and meters. Heater control set-points were implemented through actuators attached to distributed fan coil units. Field-level communication was handled by a dedicated gateway and data was stored in a central database. In addition to the application of model-based control, room users were also granted access to a monitoring dashboard showing air quality measures and energy use statistics. Communicating these indicators to users can contribute to reducing energy wastage in buildings by making the users aware of the energy-related effects of their behavior.

Some sources also report the need to develop specific metering devices for in situ tests. For example, refs. [

48,

49] design and apply measurement devices to deal with refurbishment in ancient buildings and the specific need of condensation monitoring.

2.2. Energy-Related Interaction of Users with Buildings

An extensive survey on the role of users and their activities in the context of energy-intelligent buildings was conducted by Nguyen and Aiello [

51]. They found that most BACS lacked consideration of user activity and occupancy in building automation, although these two quantities can be considered as the most important inputs to a BACS. By analyzing relevant literature in that field, they draw the following conclusions for successful and effective BACS operation:

no static assumptions regarding occupancy shall be made, as user activity is highly dynamic;

maintaining user comfort remains crucial to assure user acceptance of retrofitted, ICT-based solutions;

control of heating and lighting shall be based on occupancy and activity;

energy savings in the range of 40% can be accomplished through activity-based control;

reduced control performance can be tolerated to some extent in favor of reduced costs and increased ease of sensor/actuator interactions.

Additionally, they stress that energy-use-related information feedback to building users affects occupants’ behavior and, consequently, energy consumption. A recently published paper by Harputlugil and de Wilde [

52] reviews published studies on users and their interactions with buildings. The authors conclude that despite the high amount of publications on individual effects (e.g., manual ventilation habits or heating set-point selection patterns), holistic and interdisciplinary considerations of user–building interactions are rarely found. In addition, energy-related consequences of user–building interactions, generally speaking, still remain underestimated, misunderstood, or even disregarded in current approaches. According to [

52] more attention should be paid to individual users’ lifestyles and behavioral backgrounds when refining patterns from measured user-related data. In that regard, standardized data gathering and analysis methods were identified to be of particular significance. Finally, the authors underline that user behavior studies are typically limited to individual buildings and short time-spans, which clearly obstructs one from obtaining a holistic and in-depth understanding of energy-related user behaviors in buildings.

From the above findings, the following important research topics are summarized as follows. First, the behavior of building users highly affects energy consumption; consequently, user behavior should be fully accounted for in building energy control strategies. Secondly, user behavior should be observed and analyzed holistically in an extensive real-life use case, preferably over a long time horizon. Lastly, there is unused potential to positively affect energy-related user behaviors by giving users feedback and raising awareness, e.g., through dashboards.

To close the summarized research gaps, the need for a suitable and appropriate research environment arises.

2.3. Living Labs as Gap-Bridging Environments

In the general sense, the term “living lab” (also “living laboratory”) describes the concept of innovation within real-life contexts, with active participation from users, businesses, and governments [

53,

54,

55]. The concept is applied across several domains, notably health and well-being, democracy and government, service and development, and energy [

53]. A key feature of living labs that distinguishes them from test beds is that users are “co-producers” of the innovation, beyond being observed subjects [

53,

54]. Furthermore, living labs operate in a live production environment, unlike test beds, which are run in isolated and controlled environments. Nevertheless, the term “living lab” is sometimes (erroneously) used to describe a test bed.

In Germany, the equivalent term “Reallabore (der Energiewende)”, as defined by the German Federal Ministry for Economic Affairs and Climate Action (Bundesministerium für Wirtschaft und Klimaschutz, or BMWK) takes on an additional implication: the provision of a “legal sandbox”, in which selected laws are relaxed to facilitate ground-breaking research [

56]. The “Reallabore” concept serves to accelerate the transfer of technology and innovation by enabling the implementation of sustainable energy technologies under real conditions on an industrial scale. These technologies include concepts that hold a large potential but are still not ready for market roll-out—as judged by the so-called

technology readiness level (TRL)—thereby bridging the critical phase between technology development and market roll-out [

57].

Living labs make extensive use of ICT for data gathering and analysis, as well as for the deployment and interconnection of the components that comprise the solutions in question. From the stated characteristics of living labs, certain requirements for any deployment begin to emerge, among which are that the disruptions caused by the study have real-world implications and must be compensated for in advance. As will be discussed in detail in

Section 3 below, the LLEC builds this fact into its very architecture via various techniques and approaches, such as the ability to switch comfortably between default and scientific operation mode (via the “kill-switch” concept), multi-modal user interactions with technology (e.g., manual vs. automatic room temperature control), and testing phases/limited trials (space-limited controllers, access-controlled dashboards, etc.).

In the literature, there are examples of living labs and similar setups in the field of energy research. In [

58], the implementation of an extensive sensor and control network in two real-life buildings at the Construction and Engineering Research Laboratory (CERL, USA) is shown. The authors assess the two existing buildings and their retrofitting potential in detail as well as sensors and technologies for instrumenting the buildings. Special emphasis was placed on retrofitting cost analysis and real-life implementation barriers of wireless devices. While they show the successful implementation of mode-based control of the buildings, user–building interactions and acceptance of the retrofit was not investigated. Additionally, by today’s standards the instrumentation techniques described have been superseded. Winkler et al. [

24] investigate a model-based control approach, minimizing the cost of energy based on i.a. human-in-the-loop data obtained through a mobile app. Their setup consists of an existing building, comprising a floor area of 465

, controlling zone air temperature and AHU set-points for eight zones. They interface with facility management and provide a (software) “kill switch” to prevent BACS failure. On the user side, occupancy detection is performed with PIR sensors, and a Markov model is used to predict occupancy. They analyze and evaluate MPC performance using the

predicted mean vote (PMV) metric. The project ran for 20 days and for a single building.

The

Living Lab smartEnergy project of the FZI Forschungszentrum Informatik [

59] researches the coupling of different energy-demand sectors such as electricity, mobility, space heating and cooling, and gas supply using innovative energy management solutions. These solutions are tested in one building with real live-in occupants.

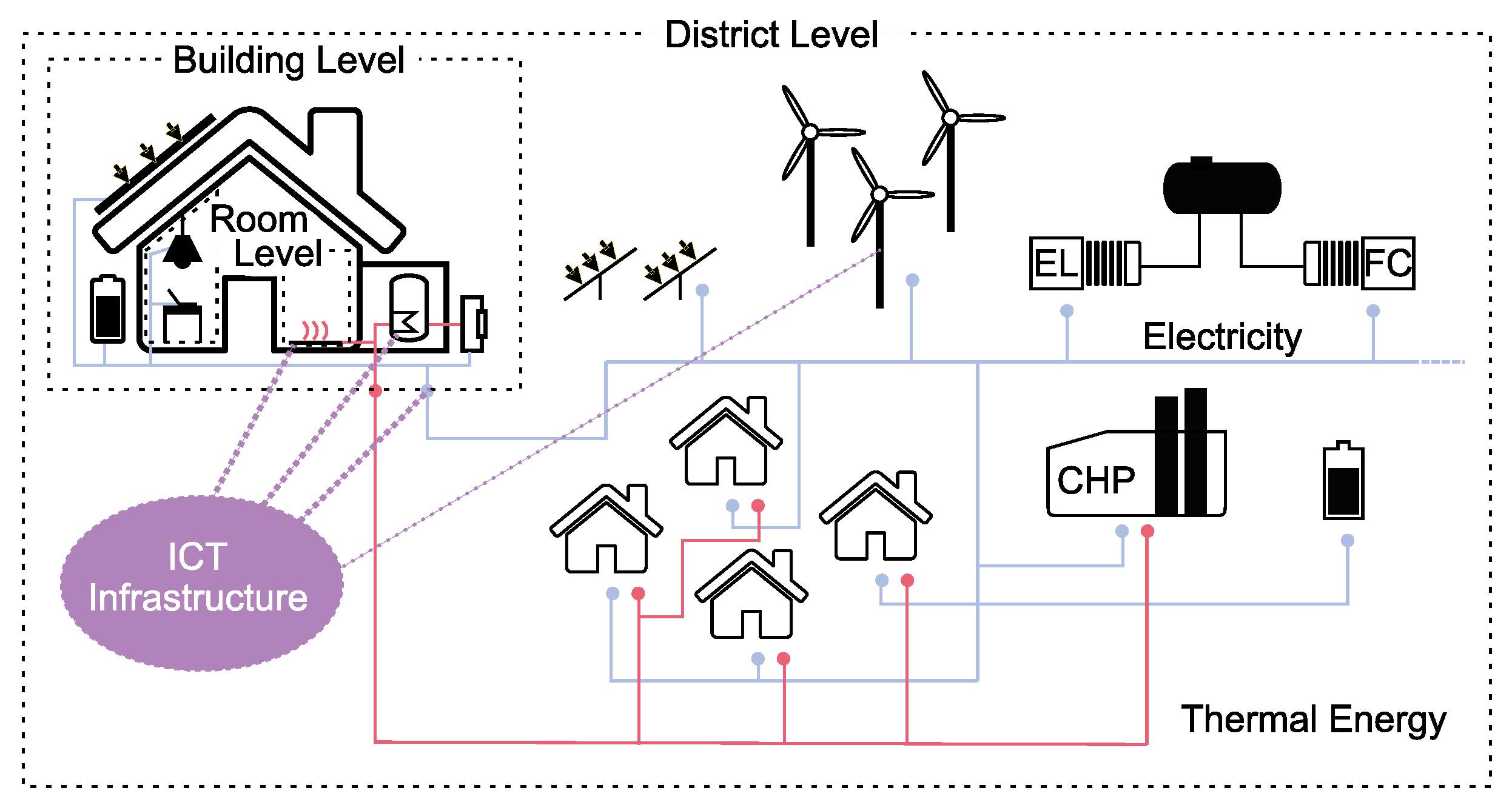

In [

60], the

Energy Lab 2.0 project at the Karlsruhe Institute of Technology (KIT) is described. In the project, the need for an integrated ICT solution, comprising monitoring, control, simulation, and visualization, is investigated. The authors integrate energy supply and storage units as well as buildings in their ICT platform, which then gives users feedback regarding the operation of individual components. Although the approach is on the district level, the integration of buildings is a rather small part.

The Energy Smart Home Lab (ESHL) was developed at KIT in several projects and demonstrates the possibilities of connecting the areas of living (smart home), transport (electromobility), and energy (smart grid) in an integrated approach such as this. The ESHL consists of a 60-square-metre two-bedroom flat equipped with state-of-the-art technology, such as smart appliances and a multi-model energy system. During longer periods, the houses are inhabited by real users. During these periods, residents had a complete overview of current energy flows and consumption, and innovative control concepts were tested using scheduling.

The presented LLEC addresses the gaps identified in the foregoing discussion, and the methodology employed is described in the two sections that follow. LLEC is part of the funding program “Energiewendebauen” by the Bundesministerium für Wirtschaft und Klimaschutz. A cross-evaluation of all funded (university or technology) campus projects (as a subgroup of district projects), as well as a description of the LLEC-preceding projects “EnEff:Campus RWTH Aachen/FZ Jülich—integrales Planungshilfsmittel” and “EnEff:Campus—Living Roadmap FZ Jülich” is given in [

61].