Study on Filling Capacity of Optical Glass in a Novel Rapid Hot Embossing Process

Abstract

:1. Introduction

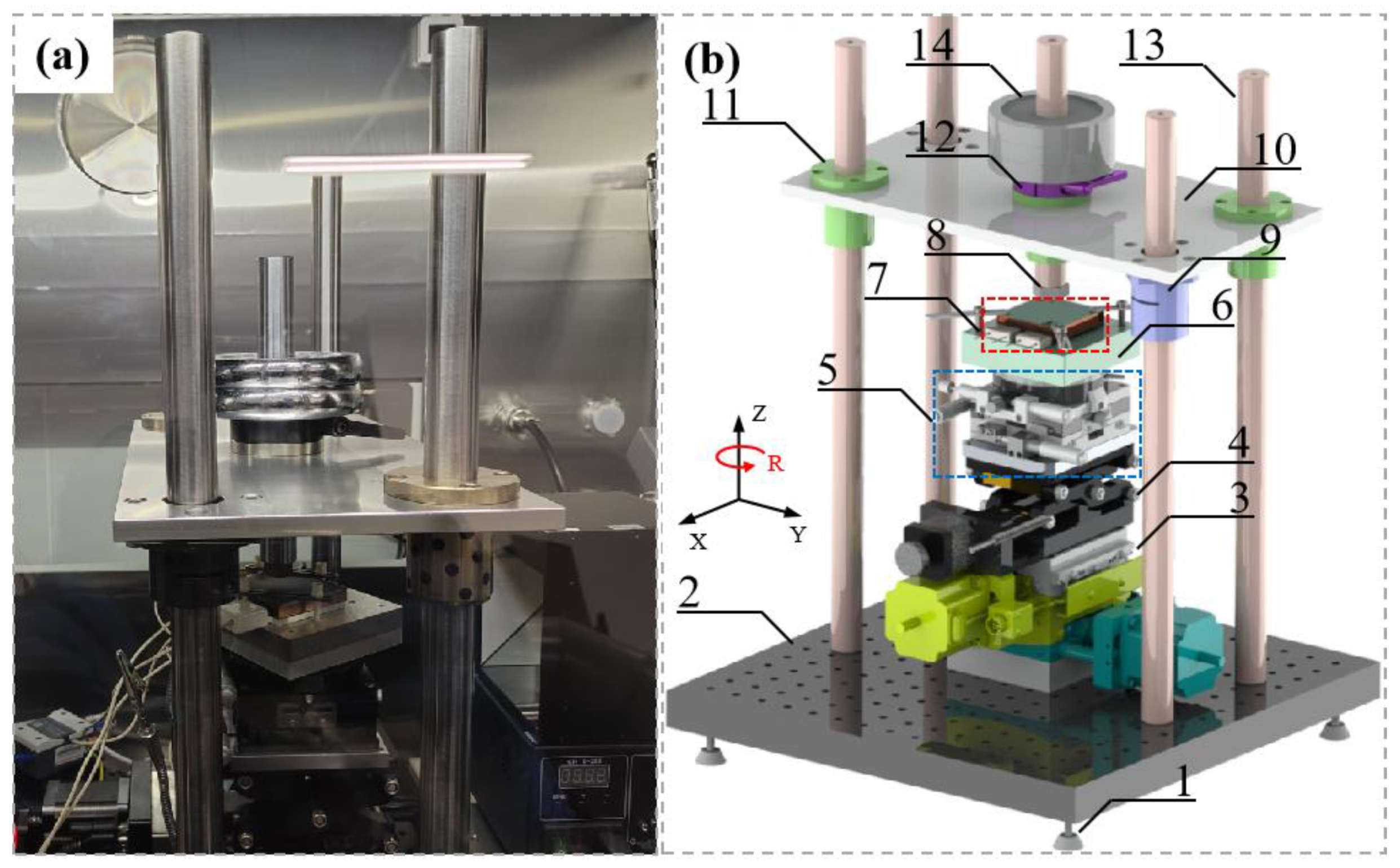

2. Development of the Novel Rapid Hot Embossing Tool

2.1. Precision Loading Module

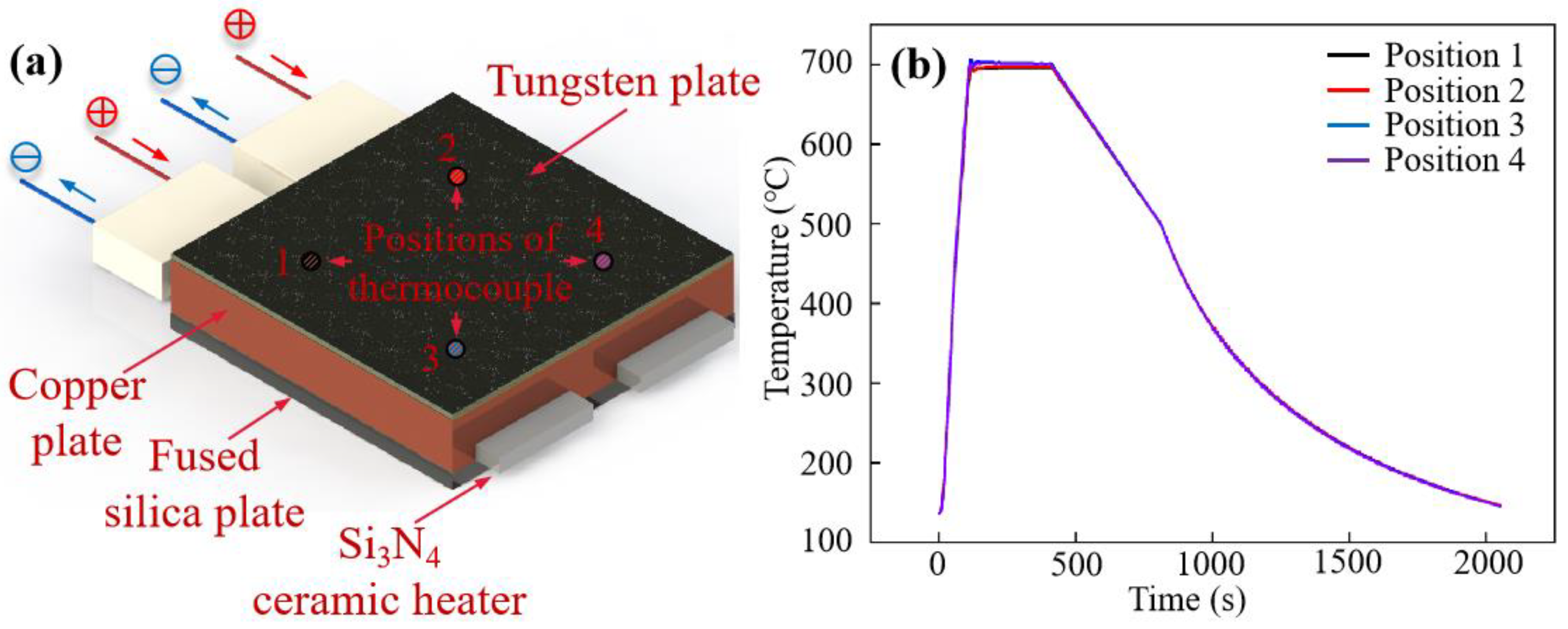

2.2. Rapid Heating Module

3. Materials and Methods

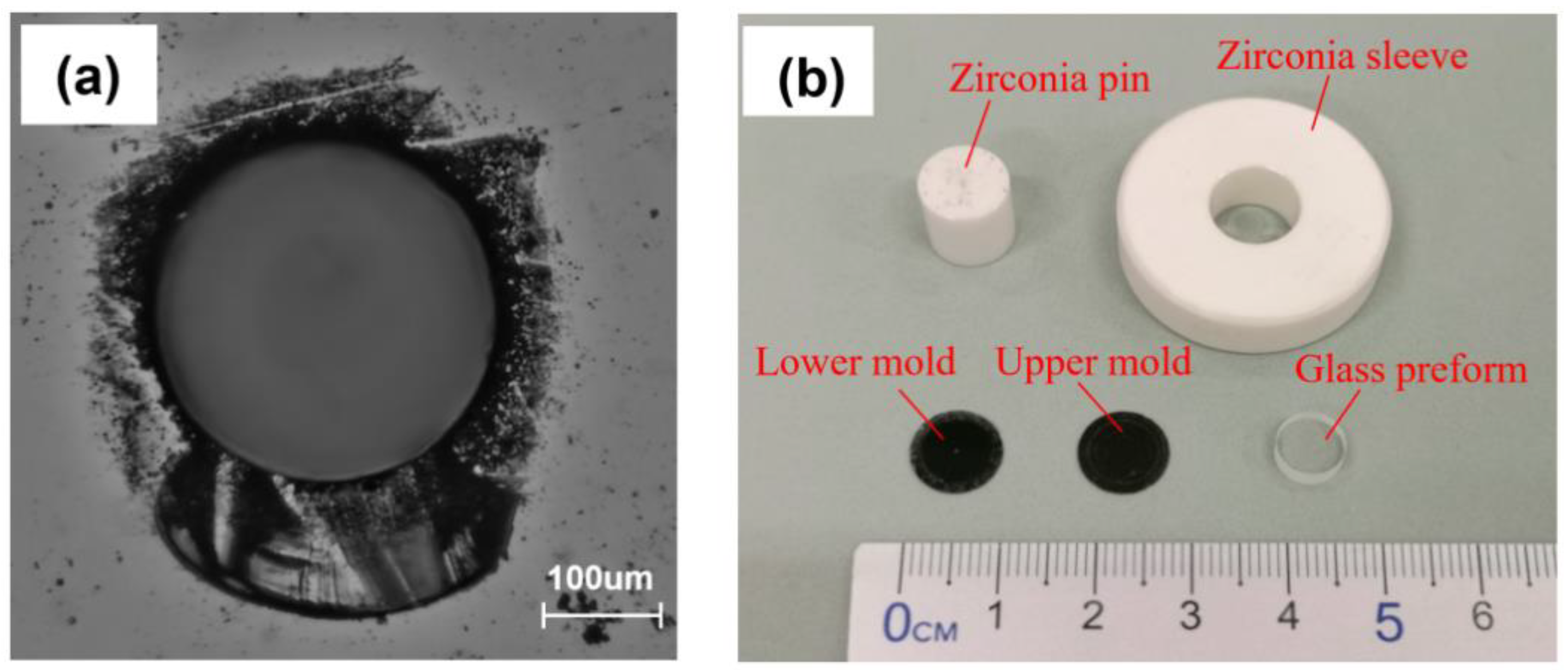

3.1. Glass, Mold and the Mold Kit

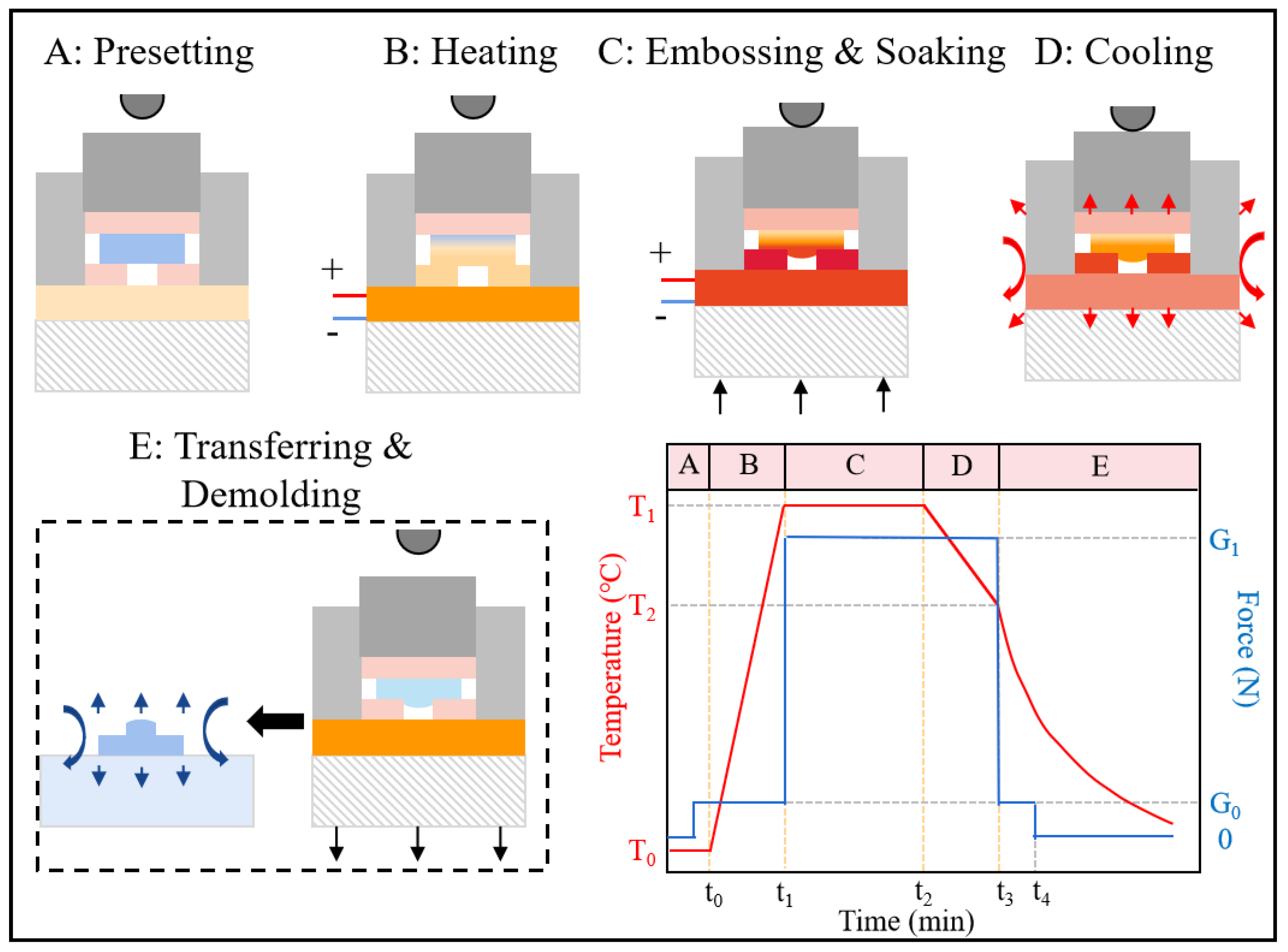

3.2. The Hot Embossing Process

3.3. Experimental Scheme

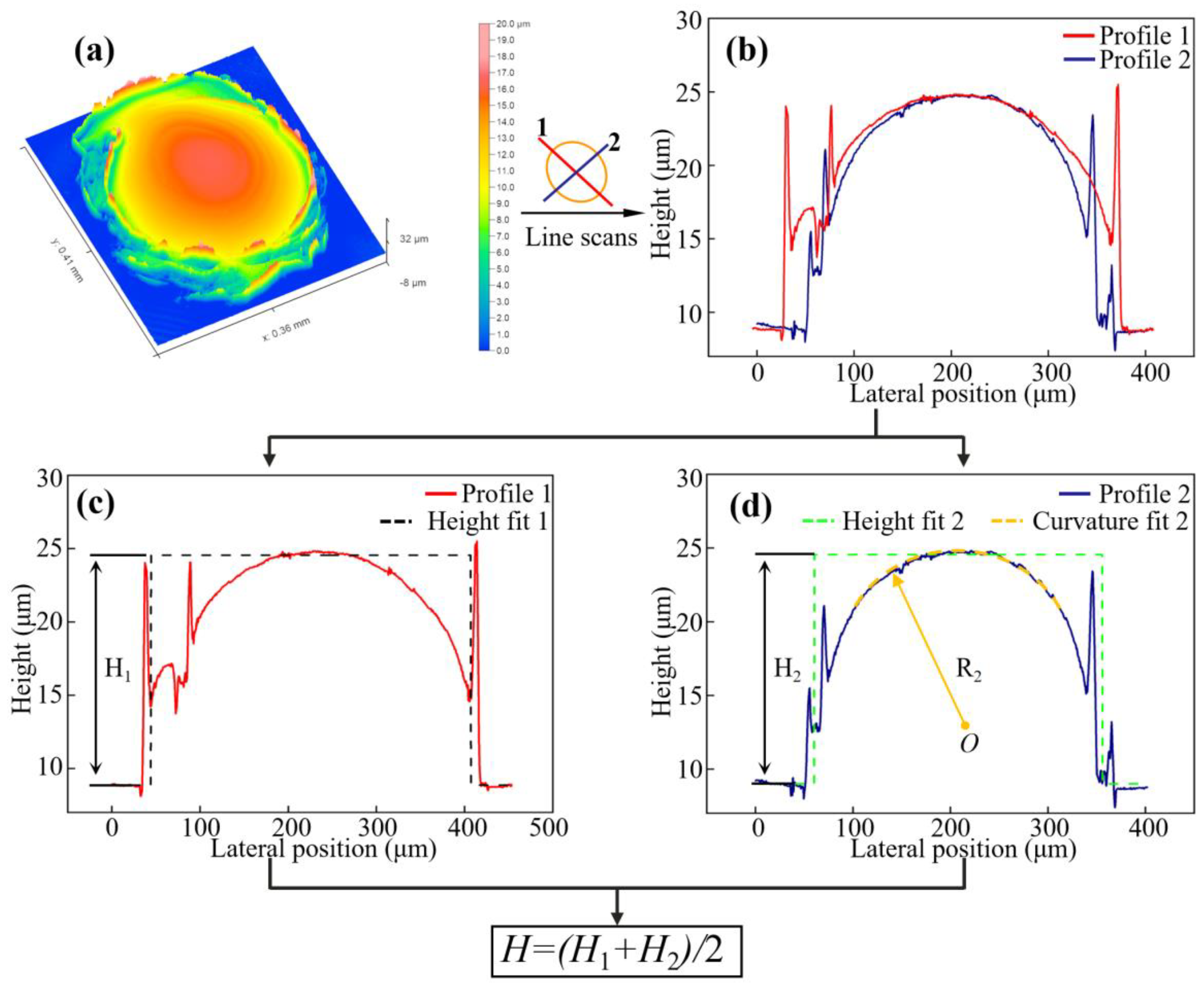

3.4. Characterization of the Filling Capacity

4. Results and Discussion

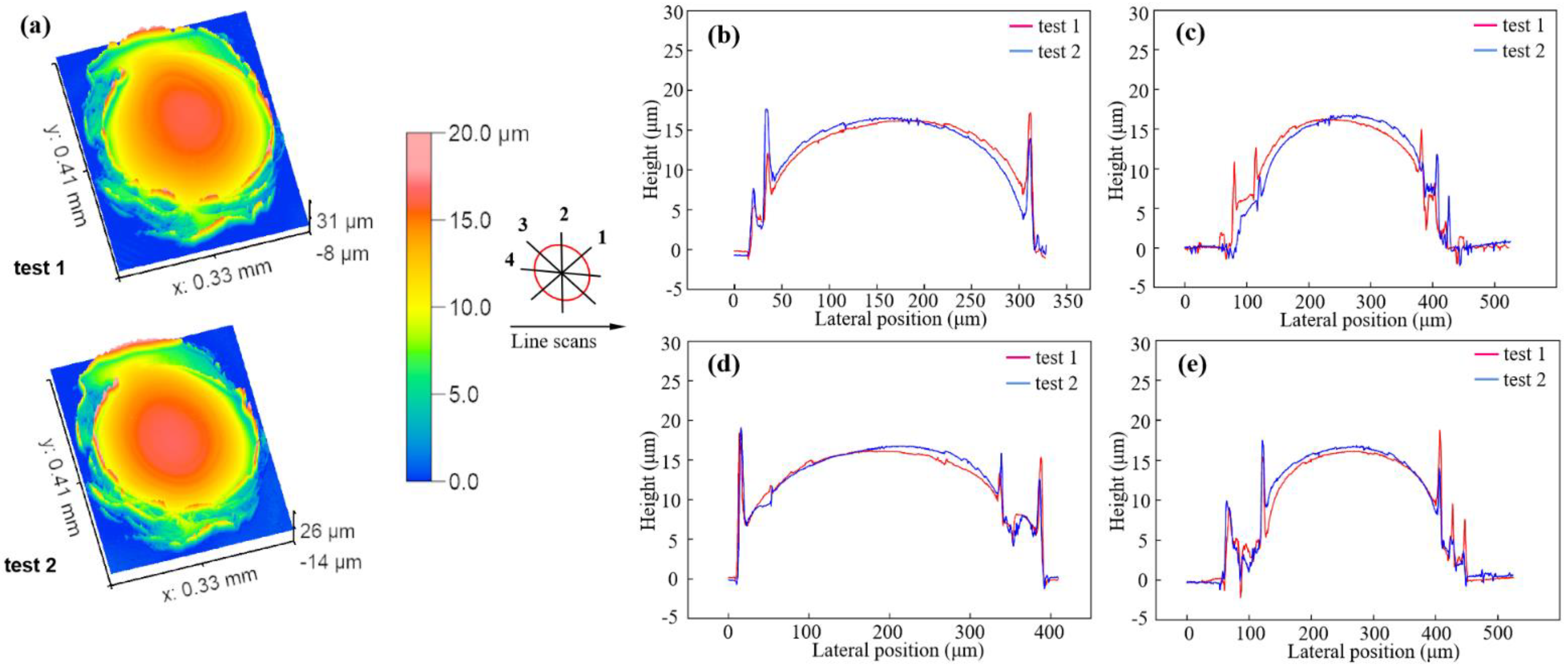

4.1. Reproducibility of the Novel Rapid Hot Embossing Device

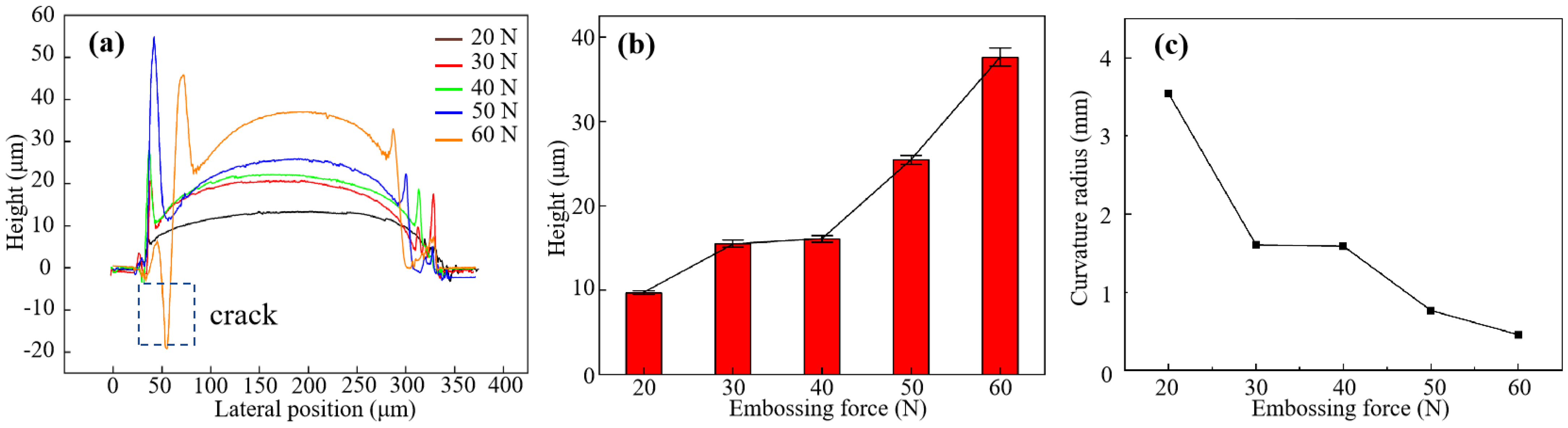

4.2. Effect of Embossing Force on the Filling Capacity

4.3. Effect of Embossing Temperature on the Filling Capacity

4.4. Effect of Soaking Time on the Filling Capacity

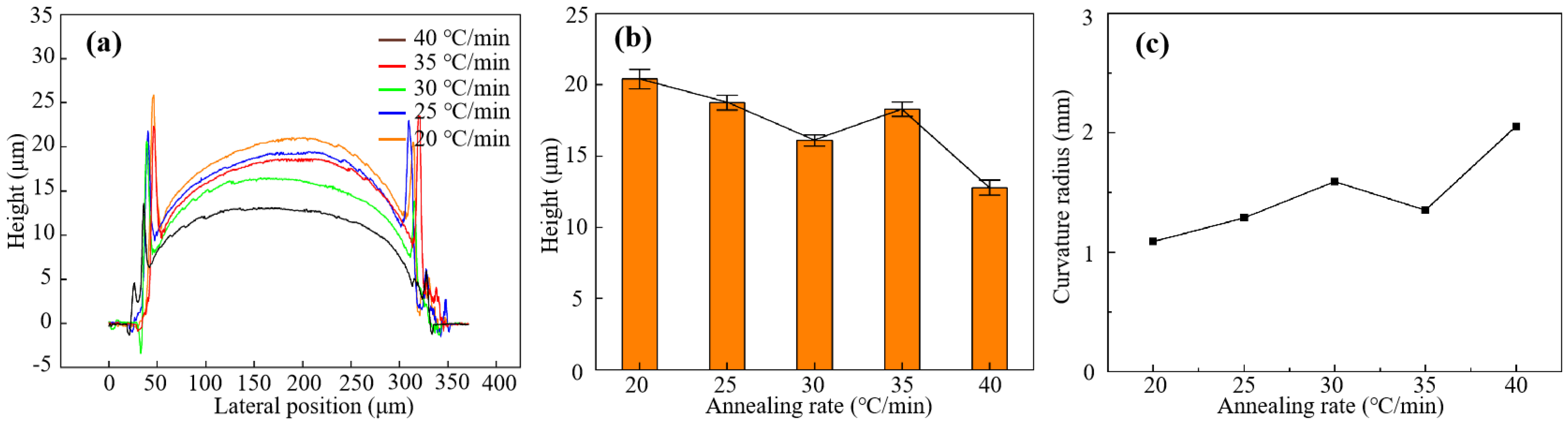

4.5. Effect of Annealing Rate on the Filling Capacity

5. Conclusions

- (1)

- The tailor-made novel rapid hot embossing device allows a maximum temperature of 800 °C and a heating rate of 300 °C/min, with decent temperature control accuracy and uniform temperature distribution. Besides, it is demonstrated to have a satisfactory reproducibility in imprinting microlenses on the N-BK7 glass.

- (2)

- The glass microlens can be fabricated by just applying a small embossing force of 20 N at the appropriate temperature.

- (3)

- The filling capacity of glass is improved by increasing embossing force, embossing temperature and soaking time, but decreasing annealing rate.

- (4)

- The filling capacity of N-BK7 glass is more sensitive to embossing force and embossing temperature, compared to soaking time and annealing rate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Li, K.; Gong, F. Fabrication and Optical Characterization of Polymeric Aspherical Microlens Array Using Hot Embossing Technology. Appl. Sci. 2021, 11, 882. [Google Scholar] [CrossRef]

- Tagantsev, D.K. Producing optical microelements from glasses by means of extrusion. J. Opt. Technol. 2014, 81, 748–753. [Google Scholar] [CrossRef]

- Colafemina, J.P.; Militão Dib, M.H.; Jasinevicius, R.G. Hot embossing of aspherical Fresnel microlenses: Design, process, and characterization. Int. J. Adv. Manuf. Technol. 2021, 113, 935–953. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Ke, K.-C.; Chang, N.-W.; Yang, S.-Y. Development of an UV rolling system for fabrication of micro/nano structure on polymeric films using a gas-roller-sustained seamless PDMS mold. Microsyst. Technol. 2018, 24, 2941–2948. [Google Scholar] [CrossRef]

- Greener, J.; Li, W.; Ren, J.; Voicu, D.; Pakharenko, V.; Tang, T.; Kumacheva, E. Rapid, cost-efficient fabrication of microfluidic reactors in thermoplastic polymers by combining photolithography and hot embossing. Lab Chip 2010, 10, 522–524. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.L.; Wu, T.Y.; Hsu, H.Y.; Yang, S.Y.; Wei, P.K. Low-Cost and Rapid Fabrication of Metallic Nanostructures for Sensitive Biosensors Using Hot-Embossing and Dielectric-Heating Nanoimprint Methods. Sensors 2017, 17, 1548. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schneider, P.; Steitz, C.; Schäfer, K.H.; Ziegler, C. Hot embossing of pyramidal micro-structures in PMMA for cell culture. Phys. Status Solidi 2009, 206, 501–507. [Google Scholar] [CrossRef]

- Li, K.; Xu, G.; Liu, X.; Gong, F. Deformation Behavior of Glass Nanostructures in Hot Embossing. ACS Appl. Mater. Interfaces 2020, 12, 36311–36319. [Google Scholar] [CrossRef] [PubMed]

- Yun, D.; Kim, J.-B. Material modeling of pmma film for hot embossing process. Polymers 2021, 13, 3398. [Google Scholar] [CrossRef] [PubMed]

- Haponow, L.; Kettle, J.; Allsop, J. Optimization of a continuous hot embossing process for fabrication of micropyramid structures in thermoplastic sheets. J. Vac. Sci. Technol. B 2021, 39, 012203. [Google Scholar] [CrossRef]

- Tsai, Y.-P.; Hung, J.-C.; Yin, L.-C.; Hung, C. Ultrasonic vibration-assisted optical glass hot embossing process. Int. J. Adv. Manuf. Technol. 2012, 60, 1207–1213. [Google Scholar] [CrossRef]

- Fang-Yu, F.; Hsin-Chung, C.; Chiung-Fang, H.; Yi, L.; Wei-Chun, L.; Yung-Kang, S.; Liping, W. Replicability of process conditions of ultrasonic hot embossing for micropattern fabrication on thermoplastic substrates. J. Manuf. Process. 2020, 60, 283–291. [Google Scholar] [CrossRef]

- Cheng, C.; Ke, K.-C.; Yang, S.-Y. Application of graphene–polymer composite heaters in gas-assisted micro hot embossing. RSC Adv. 2017, 7, 6336–6344. [Google Scholar] [CrossRef] [Green Version]

- Nagarajan, P.; Yao, D. Uniform shell patterning using rubber-assisted hot embossing process. I. Experimental. Polym. Eng. Sci. 2011, 51, 592–600. [Google Scholar] [CrossRef]

- He, Y.; Wu, W.; Zhang, T.; Fu, J. Micro structure fabrication with a simplified hot embossing method. RSC Adv. 2015, 5, 39138–39144. [Google Scholar] [CrossRef]

- Ming, W.; Chen, Z.; Du, J.; Zhang, Z.; Zhang, G.; He, W.; Ma, J.; Shen, F. A comprehensive review of theory and technology of glass molding process. Int. J. Adv. Manuf. Technol. 2020, 107, 2671–2706. [Google Scholar] [CrossRef]

- Liu, X.; Mo, R.; Li, K.; Shen, J.; Ma, J.; Gong, F. Manufacturing of 3D Microlens Array Mold on Bulk Metallic Glass by Self-Aligned Multi-Ball Hot Embossing. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 8, 1209–1223. [Google Scholar] [CrossRef]

- Omar, F. Hot Embossing Process Parameters: Simulation and Experimental Studies. Ph.D. Thesis, Cardiff University, Cardiff, UK, 2013. [Google Scholar]

- Li, K.; Xu, G.; Luo, H.; Liu, X.; Gong, F. Glass flow behaviors in micro-channels during hot embossing. Ceram. Int. 2020, 46, 21517–21526. [Google Scholar] [CrossRef]

| Experiment Number | Embossing Force (N) | Embossing Temperature (°C) | Soaking Time (Min) | Annealing Rate (°C·Min) |

|---|---|---|---|---|

| 1 | 20 | 720 | 8 | 30 |

| 2 | 30 | 720 | 8 | 30 |

| 3 | 40 | 720 | 8 | 30 |

| 4 | 50 | 720 | 8 | 30 |

| 5 | 60 | 720 | 8 | 30 |

| 6 | 40 | 700 | 8 | 30 |

| 7 | 40 | 710 | 8 | 30 |

| 8 | 40 | 730 | 8 | 30 |

| 9 | 40 | 740 | 8 | 30 |

| 10 | 40 | 720 | 6 | 30 |

| 11 | 40 | 720 | 7 | 30 |

| 12 | 40 | 720 | 9 | 30 |

| 13 | 40 | 720 | 10 | 30 |

| 14 | 40 | 720 | 8 | 20 |

| 15 | 40 | 720 | 8 | 25 |

| 16 | 40 | 720 | 8 | 35 |

| 17 | 40 | 720 | 8 | 40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Gong, F.; Wang, X.; Yang, G. Study on Filling Capacity of Optical Glass in a Novel Rapid Hot Embossing Process. Appl. Sci. 2022, 12, 3404. https://doi.org/10.3390/app12073404

Li J, Gong F, Wang X, Yang G. Study on Filling Capacity of Optical Glass in a Novel Rapid Hot Embossing Process. Applied Sciences. 2022; 12(7):3404. https://doi.org/10.3390/app12073404

Chicago/Turabian StyleLi, Jianzhi, Feng Gong, Xin Wang, and Gao Yang. 2022. "Study on Filling Capacity of Optical Glass in a Novel Rapid Hot Embossing Process" Applied Sciences 12, no. 7: 3404. https://doi.org/10.3390/app12073404