1. Introduction

It is well known that shielding of uncharged radiation (X-rays, gamma rays, and neutrons) is relatively more challenging than charged radiation (alpha and beta particles). Depending on the extent of exposure, symptoms such as vomiting, hair loss and rash can appear. Severe exposure may also lead to cancer and heart problems [

1,

2,

3,

4]. To reduce such damage, time, distance, and Shielding Three factors should be considered. The exposure time to radiation should be minimized, and the intensity of radiation is inversely proportional to the square of the distance, so a safe distance from the radiation source should be maintained. Among them, shielding is the most effective in attenuating the intensity of radiation [

5,

6]. In addition, for the safe isolation of radioactive waste, radiation emission should be kept to a minimum during the quarantine period. In particular, the adsorbed material used to recover radioactive ions can reduce the risk of radioactive waste, and although it is smaller in volume than the existing radioactive waste, it becomes a new radioactive waste, so an isolated storage space capable of shielding against radiation is required [

7,

8,

9,

10]. As such, inorganic/organic composite materials are commonly used in radiation shielding [

1,

2,

4,

7,

8], and as organic materials began to be considered as radiation shielding materials, interest in shielding materials in the form of organic/inorganic composite materials increased. For this purpose, thick concrete or lead is used. At this time, if the radioactive waste containing radioactive ions itself becomes a shielding material in the isolation area and attenuates the radiated radiation, it can be of great help in reducing the thickness of the shielding wall. If a structure with the purpose of recovery and isola-tion, such as a cesium adsorption nonwoven fabric attenuates the intensity of radiation emitted from the adsorbed radioactive ions even a little, the isolation and storage of radi-oactive waste can be made easier. Numerous studies related to radiation shielding materials have been conducted. For example, research on radiation shielding materials is being conducted in various ways, such as concrete [

4,

9], polymer composite materials [

1,

2,

8,

11], heavy metals [

3,

12], and other materials [

5,

7]. Most studies have focused on specific materials, and few studies have considered the structure of composite materials. However, as the use of composite materials as a radiation shielding material is on the rise, it is necessary to study the linear attenuation coefficient considering the structure of the composite material. Materials for the purpose of recovering or isolating radioactive ions, such as ce-sium adsorption nonwovens, are mostly composites with a large surface area and com-plex internal structure. It is thought that more efficient radioactive waste management will be possible if radiation shielding research considering the structure of the composite material is applied to the composite material [

11,

12,

13,

14,

15]. In this study, MCNP (Monte Carlo N-Particle transport code) was used to compensate for this limitation. The interaction be-tween particles and other materials was derived from a statistical approach and theoretically, and the possibility of radiation shielding of cesium adsorbed nonwovens through shielding simulation was reviewed. The purpose of this work is to investigate radiation shielding effectiveness of various composite materials for the 661.7 keV gamma-rays emitted by 137Cs. It is integral to note that adsorption of cesium ions was not considered in this work. The shielding effectiveness was studied by evaluating the linear attenuation coefficient using MCNP simulations.

2. Radiation Shielding Simulation

For shielding simulation, MCNP (Monte Carlo N-Particle transport code) distributed by RSICC (Radiation Safety Information Computational Center) of the US National Laboratory was used [

16,

17,

18,

19,

20,

21]. MCNP is mainly used for simulating nuclear fission processes, but because it can simulate the interaction of neutrons and photons with electrons or combined electrons/neutrons/photons among different particles, it is used in radiation shielding, radiation dosimetry, radiography and medical physics. Broadly, the input file contains geometric, material, source and tally specifications pertinent to the model under investigation. This is achieved via cell, surface and data cards (and terms pertinent to variance reduction if desired) defined in the input file [

22,

23,

24,

25]. Simulation of a complex environment with many variables, such as radiation shielding, is difficult to derive theoretical results with computer code that applies deterministic methods. Therefore, MCNP, which can derive results by statistically approaching the interaction of radioactive particles with other substances, was used [

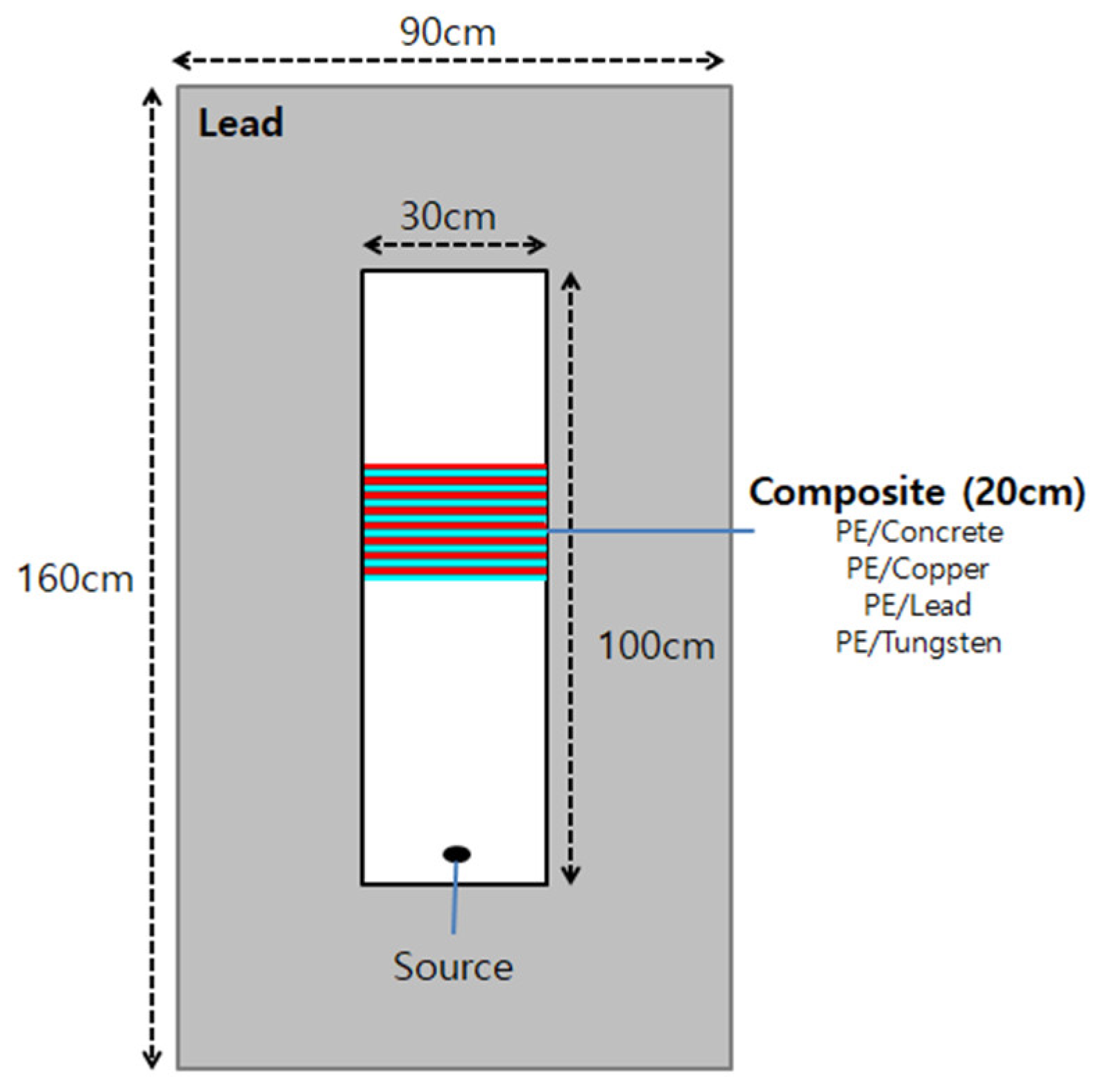

16]. In order to reduce the computational error to less than 0.05%, it was set to repeat the experiment a sufficient number of times, and for lead and tungsten, a dispersion reduction technique was used to obtain more accurate results. In addition, rather than applying the energy intensity emitted by the actual radioactive particles, we tried to investigate the trend by adjusting the energy level step by step in the low energy region. To complement the structure, the number of layered structures of the layered composite was changed to 2, 4, 8, 16, 32, and 64 layers, and the thickness of each layer and the interface width of the two materials constituting the composite were designed differently. At this time, a layered composite was constructed so that the two materials were alternately positioned. The structure used in the simulation is shown in

Figure 1. The simulation was carried out in a cuboid space of 30 cm × 30 cm × 100 cm that was covered with 30 cm of lead on all sides, and the radiation source was positioned 10 cm above the center of the floor, and the distance between the energy source and the composite material was set to 20 cm. The thickness of the designed composite material was 20 cm, and it was placed in the center of the cuboid space, and the value of the linear attenuation coefficient was obtained using the radiation dose before and after passing through the composite material.

For the matrix of the composite material applied to the simulation, polyethylene (PE), which is a representative general-purpose polymer and is also used as a neutron shielding material, was used. In this simulation, the purpose of this simulation is to investigate the change in shielding ability due to the structure rather than the shielding effect by the material, and to analyze the shielding ability of the cesium adsorption nonwoven fabric using this, so PE, which is easily accessible in general, was used. As an inorganic material forming a composite structure with PE, concrete, lead, copper, tungsten, etc. are applied as radiation shielding materials in large structures. Inorganic materials were also selected mainly for materials commonly used in shielding materials, and four materials with different shielding abilities were used to investigate the conditions of composite attenuation due to the composite structure. Since it was not possible to consider all the various types of composite materials in the simulation model, the structure was simplified and layered, fiber, and particle composite structures were applied to the modeling. As shown in

Table 1, in 4 types of composites with a combination of PE/concrete, PE/copper, PE/lead, and PE/tungsten, the gamma ray energy is changed at 1, 10, 30, 50, 80, and 100 MeV in a low energy region. At this time, an isotropic source was used as the energy source, and the amount of radiation passing through the composite in a space surrounded by lead was simulated as shown in

Figure 1. In addition, by changing the ratio of the two materials to 1:9, 3:7, 5:5, 7:3, 9:1, the content of the two materials was changed to investigate the shielding ability at that time.

As in the previous simulation, the layered composite material was changed to 2, 4, 8, 16, 32 and 64 layers. At this time, the thickness of each layer was changed to 0.1, 0.05, 0.025, 6.25 × 10

−3, 3.125 × 10

−3 cm and the overall thickness was maintained at 0.2 cm.

Figure 2 shows the schematic diagram of the structure actually applied in the simulation program.

The fibrous composite material changed the structure by varying the diameter of the fibers. Although there may be changes in the structure depending on the direction of the fibers, if this part is considered, the structure setting becomes too complicated, and concrete, copper, lead, and tungsten were regularly arranged side by side. A total of 4 fiber diameters were set: 0.0461, 0.0798, 0.1128, 0.1457 cm (

Table 2,

Figure 3).

Gamma ray energy was divided into 9 levels, 0.1, 0.3, 0.5, 0.8, 1.0, 1.5, 2.0, 5.0 and 10.0 MeV. The thickness of the composite material was set to 2 mm, and the radiation dose before and after could be obtained through simulation. The linear attenuation coefficient was compared using the radiation intensity obtained here. In this case, the simulation used F2 Tally to predict the intensity through the composite surface opposite the radiation source. Flux was used for the intensity, and “photons: effective intensity per fluency (psv/cm

2) AP” (ICRP 166,

Appendix A,

Table A1) was used for the conversion factor. In the shielding simulation of the cesium adsorption nonwoven fabric, there is a limit to applying all of the fibrous structure of the nonwoven fabric, so a structure in which polyester fiber was used as a matrix and zeolite and Prussian Blue used as adsorption materials were added in the form of particles was applied. In addition, since the purpose of the nonwoven fabric is to adsorb cesium, the magnitude of gamma ray energy was set to 0.662 MeV for radioactive cesium. The contents of zeolite and Prussian blue were 20, 30, and 40% in consideration of the ratio applied to the previously produced cesium adsorption nonwoven fabric. As a result, the gamma ray shielding ability of the cesium adsorption nonwoven fabric could be predicted.

3. Theoretical Approach to Linear Attenuation Factor of Composite Materials

The attenuated radiation intensity can be calculated using the linear attenuation coefficient of the composite and the thickness of the shielding material.

where

= the intensity incident on the shield;

= the amount of radiation passing through the shielding material of thickness t;

μcomp = effective attenuation factor of the composite;

t = thickness of the shielding material.

By substituting Equation (2) into Equation (1), Equation (3) can be obtained.

Using Equation (3), it is possible to theoretically calculate the linear attenuation coefficient of the composite material ignoring the attenuation due to refraction and scattering at the interface of the material constituting the composite material. The radiation dose shielded by the layered composite made of two materials is equal to the sum of the radiation dose shielded by material A and the radiation dose shielded by material B. Since radiation passing through the composite passes through material A and then through material B, the initial dose through material B is equal to the dose through material A. Therefore, by Equation (3), the amount of radiation shielded by the composite made of two materials can be calculated as follows.

where

= effective attenuation factor of A;

= effective attenuation factor of B;

, = thickness of A and B, respectively.

By Equations (3) and (4), the effective attenuation coefficient of the composite can be calculated as follows.

where

= Calculated value of effective attenuation factor of composite;

t = Thickness of A + Thickness of B (

+

).

If the effective attenuation coefficient of the materials constituting the composite material and the ratio of each material are known through Equation (5), the theoretical effective attenuation coefficient of the composite material can be calculated.

4. Effective Attenuation Factor for Layered Composites

In the same structure as that of the effective attenuation coefficient simulation of the composite, an independent shielding simulation of each material was performed, and the attenuation coefficient values obtained from the simulation results were compared with the WinXcom [

26] standard data provided by NIST to secure the reliability of the simulation results. Since the standard data of WinXcom shows the mass attenuation coefficient value according to the photon energy, the mass attenuation coefficient values of concrete, copper, lead, and tungsten were calculated using MCNP and compared

Figure 4—the MCNP value is calculated in simulation and there is no error bar-, and the coefficient of determination (R2) was calculated. The coefficient of determination is a coefficient indicating to what extent the regression line can adequately explain the data. The coefficient of crystallinity for each material was calculated as 0.63 for concrete, 0.80 for copper, 0.92 for lead, and 0.99 for tungsten. In general, the data is considered reliable when coefficient of determination is >0.6 [

27] and this was true for all the materials considered in this work. The disagreement apparent above 10 MeV is likely due to photon-neutron reactions, which were not considered in MCNP simulations [

22]. Here, concrete is not a single substance, but a mixture of various substances such as clay, iron ore, and limestone, so it is difficult to find any particular tendency.

The magnitude of the linear attenuation coefficient of each material was in the order of tungsten > lead > copper > concrete > PE (

Figure 5). In particular, when the energy of gamma rays is 100 MeV, the linear attenuation coefficient of concrete has almost the same value as PE.

The thickness of the composite needed to attenuate 99.99% of the radiation was also calculated using Equation (5). (

Table 3).

When the shielding rate is 99.99%,

= 0.0001.

Shielding material thickness is when the shielding rate is 99.99%.

Since the thickness of the designed composite material is 20 cm, the case where the calculated value is thinner than this and can cover more than 99.99% was excluded from the simulation. PE/concrete and PE/copper composites all had t

99.99 values of 20 cm or more regardless of the conditions, but in the case of PE/lead and PE/tungsten composites, t

99.99 values were calculated to be less than 20 cm under some conditions. (

Table 4).

Figure 6 shows the simulation results of linear attenuation coefficient of a 20 cm layered composite. The change in the linear attenuation coefficient of the composite material according to the layered structure was very small. However, it was confirmed that the linear attenuation coefficient of the entire composite material changed slightly as the number of layers of the layered composite material increased when PE and materials with a large difference in linear attenuation coefficient were compounded. In addition, although it cannot be said that there is a specific trend, it was found that gamma rays are refracted at the interface of the two materials as they pass through the composite material, and thus are affected by energy. Since this composite material has a layered structure, an interface exists in the direction perpendicular to the incident radiation, but if the internal structure is more complex, the effect will be greater.

5. Linear Attenuation Factor of Fibrous Composites

In the case of the 20 cm layered composite, it was found through simulation that the radiation was weak, but was affected at the interface of the composite. Therefore, it was possible to confirm the attenuation effect of radiation at the interface between the two materials constituting the composite material through the simulation of the 2 mm layered composite material and the 2 mm fibrous composite material after lowering the radiation energy. Similar to the result of the layered composite, the tendency of the PE/concrete composite was not found in the linear attenuation coefficient of the fibrous composite (

Figure 7), and it was confirmed that it had a very small linear attenuation coefficient value compared to other composites. The reason why this tendency did not appear in PE/concrete composites is thought to be that the radiation attenuation effect of PE/concrete composites is very insignificant. In spite of setting a sufficient number of iterations to minimize the error in the simulation, the linear attenuation coefficient of PE/concrete is very small, and the error generated has a relatively large effect on the result, so it is considered that there is no tendency. The reason why this tendency did not appear in PE/concrete composites is thought to be that the radiation attenuation effect of PE/concrete composites is very insignificant. In spite of setting a sufficient number of iterations to minimize the error in the simulation, the linear attenuation coefficient of PE/concrete is very small, and the error generated has a relatively large effect on the result, so it is considered that there is no tendency. There was no trend according to the thickness of the fibers, and although the value of the linear attenuation coefficient was larger as the gamma ray energy decreased, this trend was not absolute. On the other hand, PE/copper, PE/lead, and PE/tungsten composites showed a clear trend in fiber diameter, but the trend decreased as the gamma ray energy increased. The linear attenuation coefficient according to the energy appeared similar to that of the film-type layered composite, and it was confirmed that the linear attenuation coefficient showed a tendency to decrease as the diameter of the fiber decreased. The slope of the fiber diameter/linear attenuation coefficient graph showed a larger negative value as the energy of gamma rays was small and the linear attenuation coefficient of the two materials constituting the composite material was large. In the case of a fibrous composite, in contrast with the layered composite, the angle between the incident direction of gamma rays and the interface between the two materials constituting the composite is varied, and as the diameter of the fiber decreases, the interface between the two materials in the composite expands. It is thought to be more active than this. As the fibrous diameter decreases, the internal structure of the composite becomes more complex, and as the fibrous diameter decreases, it is more densely laminated to the matrix, so the reactive interface increases in the process of radiation passing, and the frequency of refraction and reflection phenomena increases accordingly. That is, as the diameter of the fibers decreases, the interference of the composite material with the passing radiation increases, and the energy of the radiation decreases while the linear attenuation coefficient increases (

Figure 8). However, as the gamma-ray energy increases, the interaction with the material as it passes through the composite decreases, which appears to decrease the effect of the fiber diameter in the composite on the linear attenuation coefficient.

In the graph of the fiber diameter and the linear attenuation coefficient, when each graph in which the material and energy used for the composite are different is expressed as a linear function, the constant value corresponding to the slope and the y-intercept is the difference in the linear attenuation coefficient of the two materials composing the composite. is shown as a graph for

Figure 9.

The slope value was followed very similarly to the equation with a curved graph, and the equation is as follows.

(m = slope of fibrous diameter vs linear attenuation coefficient graph; = difference in the linear attenuation coefficient of the two materials constituting the composite.)

The constant value can be expressed as a graph in the form of a straight line, and the formula is as follows.

()

Through Equations (9) and (10) derived above, it is thought that the linear attenuation coefficient of the composite material different from the diameter of the fiber can be predicted only with the linear attenuation coefficient of the two materials used for the fibrous composite. This is expected to be helpful when designing composite materials for radiation shielding in the future.

Figure 10,

Figure 11,

Figure 12 and

Figure 13 show the linear attenuation coefficient of the fibrous composite material according to the gamma-ray energy. Previously,

Figure 5 shows that the attenuation coefficient of the five materials used for modeling (concrete, PE, copper, lead, and tungsten) decreases as the radiation energy increases. However,

Figure 10,

Figure 11,

Figure 12 and

Figure 13 show the attenuation coefficient according to the radiation energy of PE (matrix) and inorganic material (fiber) composites. These graphs are data to investigate the effect of the ‘difference in the attenuation coefficient of materials’ on the ‘decrease in the attenuation coefficient according to the increase in radiation energy’ for four composites made of different materials through the difference in the linear attenuation coefficient (difference in linear damping coefficient between two materials: PE/concrete < PE/copper < PE/lead < PE/tungsten). To compare the linear attenuation coefficients of 0.1 MeV and 10.0 MeV, the composite material with the largest difference was PE/tungsten with a fiber diameter of 0.0461 cm, and the difference became smaller as the diameter of the fiber increased. From this, it was confirmed that the larger the

value, the greater the effect of the fiber diameter, that is, the structure. When the thickness of the layer was reduced in the layered composite and the diameter of the fiber in the fibrous composite was decreased, the increase in the shielding efficiency of the fibrous composite was larger than that of the layered composite as the internal interface area of the two composites increased. In the case of a layered composite, the angle between the incident radiation and the internal interface of the composite is 90°, so it is considered that this is due to the amount of refraction of the radiation generated at the interface between the two materials is very small. It can be concluded that the attenuation is larger as the addition, it was confirmed that the greater the difference in the linear attenuation coefficient between the fibrous material and the matrix material, the greater the attenuation due to gamma ray scattering at the interface between the two materials.

6. Comparison of Shielding Ability According to the Structure of Composite Materials

In this study, three types of composite materials were set and the radiation shielding efficiency was compared. By varying the layer thickness in the layered composite material, the fiber diameter in the fibrous composite material, and the particle diameter in the particulate composite material, the interface of the composite material was increased to induce a structural change inside the composite material. The linear attenuation coefficients of layered composites and fibrous composites have been investigated, and if there is a difference in the linear attenuation coefficients, it can be expected that the difference is due to the structure of the composite, not the difference due to the material. In order to compare the gamma-ray shielding ability by the structure of the composite material, the increase rate of the linear attenuation coefficient when the interlayer thickness of the layered composite material and the diameter of the fiber in the fibrous composite material became about 1/2 are graphed in

Figure 14,

Figure 15 and

Figure 16. As confirmed in the previous results, the increase rate of the linear attenuation coefficient due to the internal structure of the composite containing the fibrous composite and the particulate additive was greater than that of the layered composite, and the particle-added composite showed the largest increase. The linear attenuation coefficient increase rate of the layered composite is less than 10% under all conditions, and it is judged that the gamma-ray attenuation effect due to the layered structure is very small compared to other structures. In other words, it can be said that the attenuation effect due to scattering and refraction of gamma rays is large in the composite material of the other two structures compared to the layered composite material. Considering this, it is judged that it is possible to improve the shielding ability of the shielding material due to the change in the shape of the additive even if the type of material does not change. The attenuation effect of gamma rays is expected to be relatively large.

In spite of the attenuation effect of gamma rays according to the composite structure, when the linear attenuation coefficients of the three composites are compared, the linear attenuation coefficients of the particle-added composites are mostly small, and when the gamma-ray energy is 0.1 MeV, in the case of the PE/tungsten composites, the layered composites It can be seen that the linear attenuation coefficient of has the highest value with a large difference (

Figure 17,

Figure 18 and

Figure 19). The purpose of this study is to examine the shielding effect caused by the composite structure, not the shielding effect of the radiation shielding composite. However, since the effect of the composite structure cannot be reflected only by simulation modeling, the internal interface of the composite material has been increased by modeling with a layered, fibrous, and granular structure composite material. From this point of view, the structure of the composite was changed by varying the layer thickness for the layered composite, the fiber diameter for the fibrous composite, and the particle diameter for the particle-added composite. In addition, by comparing the linear attenuation coefficients of each, the shielding performance according to the structural complexity was analyzed. This result is analyzed to be due to the problem of the designed composite material structure. In the case of a layered composite, an inorganic material layer is present in a portion corresponding to the total area of the composite. Therefore, gamma rays passing through the composite material pass through the inorganic material at least once regardless of the interaction with the material, and finally, the path through which the gamma rays pass through the inorganic material is at least 0.1 cm. However, in the case of a fibrous composite and a composite in which inorganic materials are added in the form of particles, the path through the inorganic material may become very short by design. In fact, since the gamma-ray shielding ability of the composite material depends on the inorganic material rather than PE, in this case, the composite material’s shielding ability can be measured to be small.

8. Conclusions

In this study, MCNP was used to simulate a composite designed under various conditions with different contents and structures of PE/concrete, PE/copper, PE/lead, and PE/tungsten composite materials and from this, the gamma-ray shielding ability of composites was analyzed. As a result of simulations of composites with various structures, the linear attenuation coefficient of the layered composite was not significantly affected by the thickness of the inorganic material layer compared to the composite with other structures. A straight line graph that is inversely proportional to the thickness of the inorganic material layer was checked, but the proportionality constant was negligibly small and no particular trend could be confirmed. In the analysis of the linear attenuation coefficient according to the content of inorganic materials, as expected, it was confirmed that the linear attenuation coefficient of the composite material increased as the content of the inorganic material increased in all structural composites. As the energy of gamma rays approached 100 MeV, the difference in linear attenuation coefficient values of all composites decreased in the composite material simulation of 20 cm. In the 2 mm fibrous composite, the increase in the linear attenuation coefficient according to the decrease in the diameter of the fibrous was evident in the composites except for the PE/concrete composite. In addition, the slope at this time could be expressed as a graph of the difference in the linear attenuation coefficient of the two materials constituting the composite. Through the results, it can be seen that there is a radiation attenuation effect due to the structure of the composite material. In addition, it is expected that the more complex the structure of the composite material, the greater the difference in the linear attenuation coefficient between the materials constituting the composite material, the greater the refractive attenuation effect due to the composite structure. Therefore, in the case of radioactive cesium adsorption nonwoven fabric used for the purpose of removing radioactive cesium from radioactive contaminated water or contaminated soil, it is expected that the attenuation effect due to the structure of the adsorption nonwoven fabric can be expected. Finally, assuming that the cesium ions adsorbed on the non-woven fabric are located in the center of the non-woven fabric and the pores in the non-woven fabric occupy half the volume of the non-woven fabric, using a 4 cm thickness non-woven fabric containing 30% Prussian Blue will block more than 50% of gamma rays. If the cesium adsorption nonwoven fabric has such a shielding ability, the intensity of radiation emitted from the adsorbed radioactive cesium can be partially attenuated after adsorbing radioactive cesium, which is expected to facilitate the isolation of radioactive waste.