Abstract

The risk of physical destruction of a pressure cylinder increases with increasing temperature load. Acetylene is a significant hazardous gas in cylinders. If the destruction pressure is reached, the cylinder is torn into two or more pieces, followed by the gas release to the environment. The presence of ignition sources could lead to the formation of the fireball phenomenon. This phenomenon generally reaches approximately ten meters in diameter and can be accompanied by a blast wave and a spread of the cylinder’s fragments or surrounding objects. The consequences of this type of fire could be fatal. Shooting through the cylinder shell may lead to the mitigation, if not elimination, of the effects of the uncontrolled destruction mentioned above. As a result of the review of relevant publications, several states commonly use this method as a standard procedure. Internal gas is released through the resulting hole, the pressure drops down and the gas creates a fire jet or disperses to surroundings. This study is based on a large-scale experiment where acetylene cylinders were placed inside a prepared woodpile and exposed to fire. In the fire condition, the cylinders exploded and created fireballs, or were penetrated via shooting and created fire jets. The results from these tests were compared, focusing on the shooting procedure, then analyzed and discussed.

1. Introduction

Flammable gases are present almost in all industry sectors. Currently, gases are connected with transport or heavy industry. Flammable gases are used for fire cutting or welding but also for heating via flame, especially in households. Gases are stored inside pressure cylinders for better manipulation and transport inside houses, small workrooms, or in construction. Pressure cylinders present great advantages in connection with manipulation, but also risks connected with using flammable gases. Pressure cylinders are exposed to higher temperatures during a fire, and these conditions change the properties of the cylinders. Cylinders are over-dimensioned to resist higher temperatures but only to a certain limit. If this limit is exceeded, cylinder material loses key properties, bursts, and the content (gas) is released. When the gas is flammable, the fireball phenomenon is observed after ignition by surrounding flames.

This physical destruction presents dangerous risks and direct threats to people, animals, ambient infrastructure and last but not least rescue services. The early detection of a pressure cylinder in a fire and its immediate cooling is necessary for ensuring safety. Methodological instruction for the fire brigade determines the options for how to intervene in the case of a pressure cylinder in a fire. Cooling of the cylinder’s shell is performed by a stream of water or placement in a water bath. This prevention is very effective, but there is a limitation connected, especially with acetylene pressure cylinders. The pressure and temperature inside the cylinder increase as an effect of physiochemical processes which are initiated via flames, and these processes can continue even after extinguishing the fire. If the limit of the cylinder is achieved, the pressure cylinder is torn into two or more pieces and content is released. Due to the risk of destruction still being present after the fire is extinguished, acetylene pressure cylinders have to be checked for 24 h. These restrictions of lengthy periods of cooling and closing of safety areas could be limiting especially for an industrial complex, built-up areas or transport infrastructure. There exist several types of pressure release valves or fuses which can reduce increasing pressure and release inside overpressure. These safety systems can malfunction or be damaged by flames, and therefore the risk of destruction is still possible.

There is a solution used in several countries that seems very effective: shooting through the cylinder releases overpressure and there is no risk of physiochemical destruction. Although it is effective, shooting brings additional risk; therefore, it is necessary to carry it out with sufficient respect and know all risks and understand all situations.

This problem is well-known in the Czech Republic, where the Methodological Regulations for Firefighters are developed. The Battle order for firefighters—tactical procedure of intervention: Fires with a presence of acetylene pressure cylinders [1] was prepared in the Czech as Methodological List no. 33. For other technical gases in the pressure cylinders, Methodological List no. 32 [2] is used. In these regulations, all necessary information is mentioned step by step, to describe how to effectively and safely lead the fire intervention with attention given to existing risks and unexpected situations. In these Methodological Lists, shooting through the cylinders is mentioned as an option in extreme situations where it is not possible to stop uncontrolled destruction. The shooting can only be carried out by specialists of the police department, but it is not further written how to perform it, the specification of intervention, who is responsible or other options and unknown situations. Shooting through the cylinders is not a new trend in the Czech Republic. Kratochvíl [3] focused their dissertation thesis on the thermal stress of the pressure cylinders during a fire. The pressure cylinders were exposed to a fire and left to physically destruct, or the risk of destruction was eliminated via shooting. The safety zones and distances for the fire brigade and other forces were determined as a result of these experiments. These safety distances are listed in the Methodological List. Another experimental measurement between the years 2012 and 2014 was performed in Kaznějov. During these tests, the appropriate ammunition was chosen and the results of pressure cylinders in fire conditions were described by Hora et al. [4].

The concept of shooting through the pressure cylinder as a prevention of physiochemical destruction in Sweden is used as a standard procedure. The Sweden Gas Association examined the tests on how to use heated cylinders. The destruction of non-cooled acetylene pressure cylinders was delayed by 18 h. The requirement from the industry was to find the method and shorten the time of interruption of operating time. The ammunition selection by Lamnevik [5] in 1996 is described. The aims of this study were the verification of calculations and a better understanding of the ignition of releasing acetylene. Currently, this prevention is used in Sweden, and the procedure by Björnström and Setterwall [6] is described. In this book, the conditions, process, permission and other details are mentioned. In Sweden, the tracking ammunition, which is able to ignite releasing gas, was developed. A similar approach can be assumed for northern countries. At least in Norway, this procedure is normally used as a standard method for the elimination of acetylene pressure cylinder destruction. During a 14-day period this method was used twice. During a barn fire, the acetylene pressure cylinder was detected. The cylinder was in a fire, and it was not possible to find out the condition of the cylinder [7]. The risk of destruction was eliminated via shooting. In a second incident, safety zones of 1000 m were enacted and several houses were evacuated. After shooting through the cylinders, traffic was restored [8]. In the United Kingdom, Operational Guidance Incidents Involving Hazardous Material [9] was written in connection with pressure cylinder differences in the form of the use of a pressure relief valve. However, this effective relief of the pressure may fail. After opening the relief valve the gas is released through a small hole. The option of shooting is also not mentioned in Fire and Rescue Authorities Operational Guidance: Incidents involving acetylene [10]. However, an extensive study focusing on acetylene safety during and after a fire by the Department for Communities and Local Government [11] was performed. The document summarized existing knowledge, research, risk quantification and comparison on the current state in the European Union and the United Kingdom. In Germany, several experiments focusing on acetylene pressure cylinders were performed at BAM—a senior scientific and technical federal institute. In 1995, a large experiment that focused on exothermic decomposition ignited by recoil or cylinder wall heating was conducted [12]. During these tests, basic knowledge regarding pressure and temperature was determined. The investigation was focused on extinguishing, interruption of extinguishing and the behavior during these steps. In addition, the bundles were exposed to fire conditions. In Germany, shooting was tried as a prevention before acetylene pressure cylinder destruction, but this option is not used as a standard procedure [13]. BAM tested acetylene cylinders again in the project Acetylene cylinders in the fire for British Compressed Gas Association in 2009 [14]. This project aimed to find a new procedure when acetylene cylinders are exposed to fire. The project consists of three phases, laboratory experiments, mathematical model heat transfer and large-scale tests. If the single acetylene cylinder is cooled for one hour and controlled for another hour without any signs of internal process, the destruction of the cylinder has not occurred. Results are described in the detail by Ferrero et al. [15,16]. Attention has also been dedicated to the acetylene pressure cylinder in Poland. Case studies were carried out with acetylene cylinders [17,18] or with oxygen [19], and performed by the University of Wroclaw. Except for ignition with a bonfire, the local heating was tested, where a gas burner was used. Large-scale experiments within the project BLOW [20] were conducted in 2014. Although the knowledge seems to be sufficient, experimental tests were performed and the data are available, and in many countries the standard procedure based on the EIGA recommendation is used during a fire of acetylene cylinders [21]. Even though shooting the cylinders as prevention is effective, the standard procedure of cooling the cylinder shell is still primary.

This study presents a comparison of uncontrolled and controlled destruction of acetylene pressure cylinders. In the large-scale experimental tests, the acetylene cylinders were exposed to fire and left to their uncontrolled destruction, or the pressure was released by penetrating the shell of the cylinder. Tests were carried out in a military area with the cooperation of the Czech armed forces, police department, Fire and Rescue services, the Technical Institute of Fire Protection and Faculty of Safety Engineering. One of the main parts of these tests was training and shooting of the cylinder verification. In addition, the selected parameters for detailed analysis and understanding of all processes during the cylinder heating were recorded.

2. Materials and Methods

In the first step of the experimental study, the thermal load, which guarantees certain repeatability for the experiment, had to be determined. Thermal loads were used in the previous experiments, for example a woodpile, liquid fire or some types of burners. In the standard [22] requirements for Class A fire extinguishers, woodpiles were derived because of measurement repeatability and also for a good simulation of a fire condition. The selected parameters for the evaluation of the woodpile were measured and analyzed. The results were written and published by Mynarz et al. [23]. For controlled destruction, the applicable ammunition available across the special forces, army and police department of the Czech Republic was selected and then used for penetrating the cylinder shell.

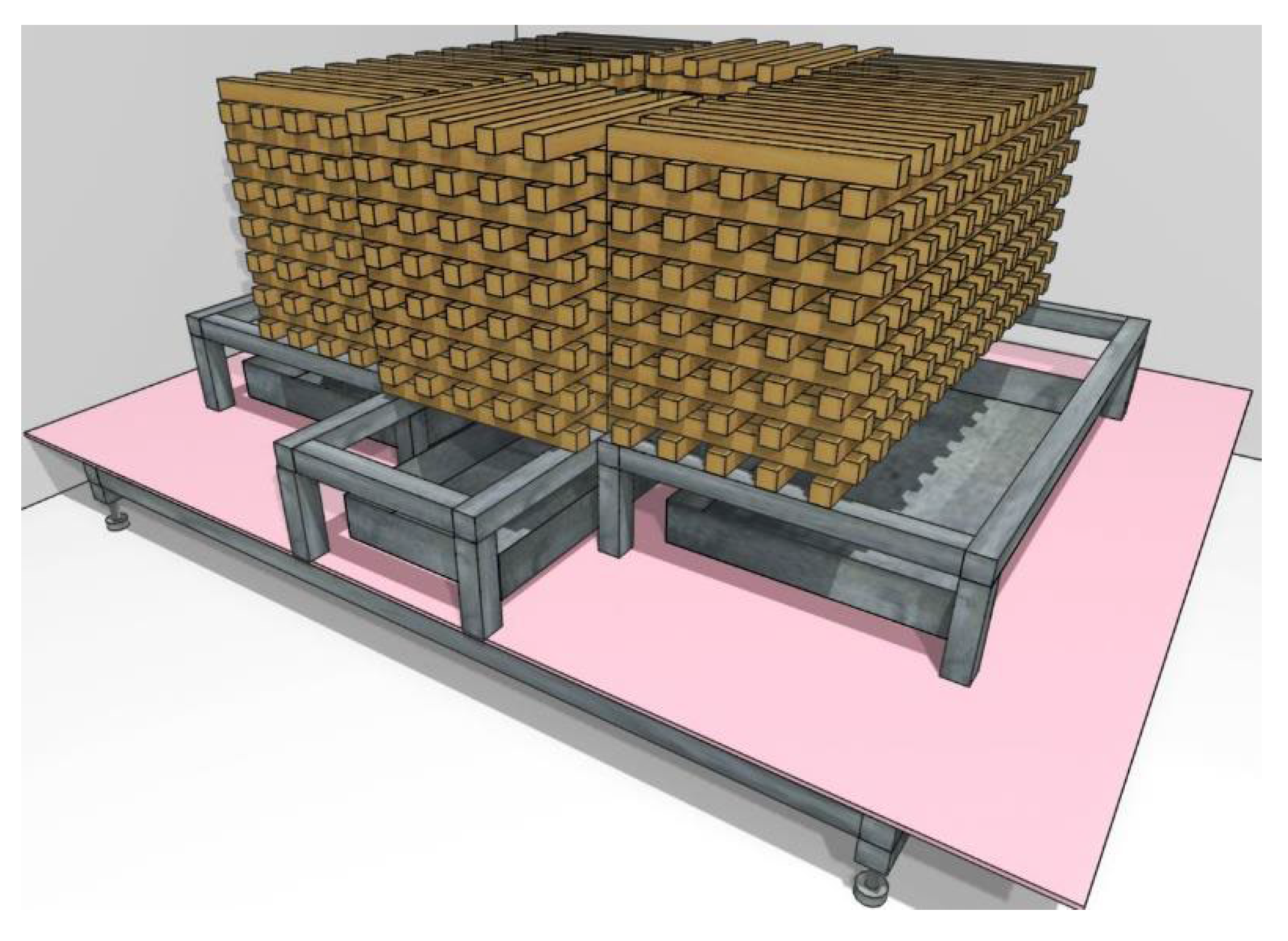

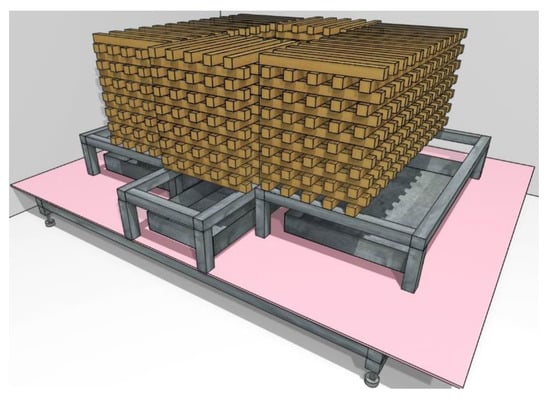

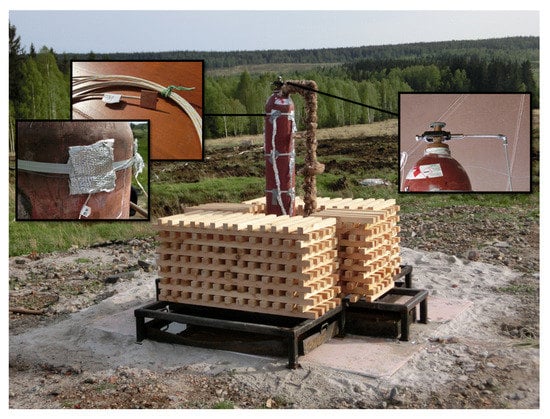

The acetylene cylinders were placed inside the prepared woodpile in the experimental measurement. The original woodpile was modified using a combination of two 5A woodpiles and two 13A woodpiles, see Figure 1. The bases were made from square hollow structural steel sections. Under the bases, tubs were placed with dimensions exceeding the planned woodpile dimensions by 100 mm. Remote-control ignition initiated the disposal of 14 L of n-Heptane on the water surface in metal tubs. This pool fire ignited the individual woodpiles. Under the single 5A woodpile were 2 L of n-Heptane, in the total amount of 4 L under the 5A woodpiles. For the single 13A woodpile the amount was 5 L, in a total of 10 L of n-Heptane.

Figure 1.

The 13A and 5A Woodpiles combination.

This type of woodpile was evaluated separately with empty cylinders and after the acetylene cylinders were used and data were recorded. At the same time, the ammunition was selected and tested on the empty acetylene cylinders without the heat load. The aim of this step was to select appropriate ammunition which is available for special forces and would be useful for penetrating the shell of the cylinders. The place of the ammunition impact was recorded by high-speed camera. Six different types of ammunition were tested at different distances from the cylinder. The angels of the cylinders were changed from 90°, 60° and 30°. The bottoms and tops of cylinders were also tested and shot. The results showed the best ammunition which would be useful for shooting through the cylinders shells as a controlled destruction.

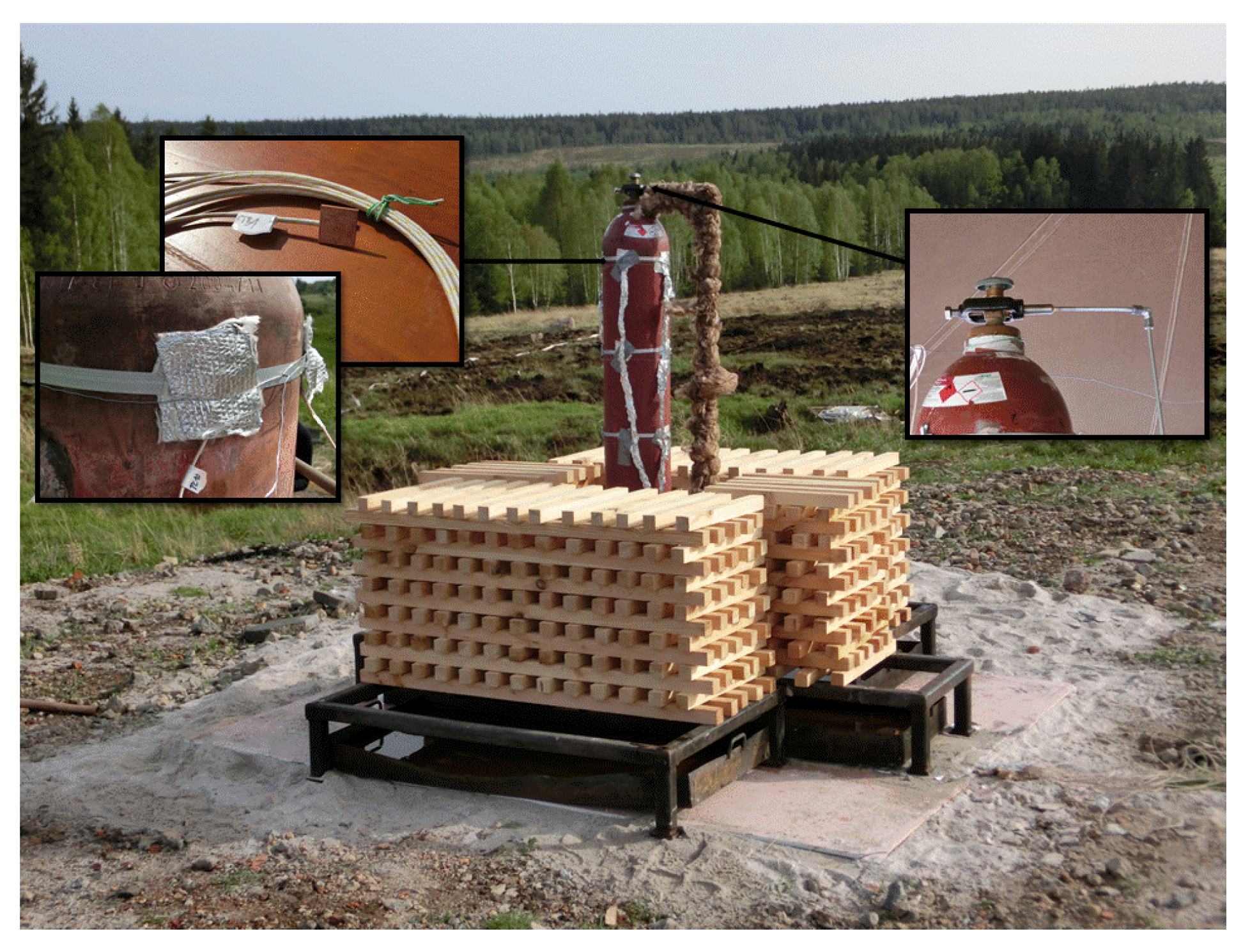

After this, the tests with full acetylene cylinders started. Thermocouples for measuring the shell’s temperature were placed circumferentially every 90° at certain height levels. For each height level, 4 thermocouples were added. The pressure was measured via a pressure transducer connected to the valve outlet using an adapter and pipeline. An established acetylene cylinder inside the prepared woodpile is shown in Figure 2. The experimental measurements were recorded by digital and high-speed cameras. From these video recorders, the average sizes of both phenomena were estimated. In addition, the records were used for identifying the cylinder fragments.

Figure 2.

Acetylene cylinder inside prepared woodpile.

During the experimental tests, a total of 6 acetylene cylinders were tested. Uncontrolled destruction was performed for 3 acetylene cylinders, the same as 3 acetylene cylinders underwent the controlled destruction. For tests the standard acetylene cylinders with volumes of 50 L were used. In these cylinders, an amount of 10 kg of acetylene is dissolved in porous mass and acetone as a solvent. These tests provided an option for practical training and cooperation between participating forces and Fire and Rescue services. They were able to witness the real situation with the resulting consequences. All tests were performed under strict supervision and with high awareness of the safety of all participating persons.

3. Results

The obtained data from experimental measurements were analyzed and compared. The section bellow shows the results from each test. In this large-scale study, several steps were provided. As mentioned, the selection of the source of fire and ammunition type was determined before experimentation.

3.1. Testing Woodpile

It was important to ensure repeatability for all tests and find the appropriate source of the thermal load. Based on the previous studies, the woodpile was selected as a sufficient source with high repeatability. The selected parameters, such as shell temperature and the pressure inside the cylinder, were measured. During the test, n-Heptane burned out after 138 s and at this time, the flame was fully expanded throughout the woodpile. This fact influenced the temperature from the start of measuring. After that, the temperature and fire stabilized and the bonfire burned for almost 15 min before it burnt out and collapsed. In the most intense burning, the flames reached a height of about 6.5 m. Depending on the surrounding conditions, the cylinders were in direct fire during the burning of the bonfire (see Figure 3). In some cases, the fire was influenced by wind and affected by the season.

Figure 3.

Fully expanded fire around the acetylene cylinder.

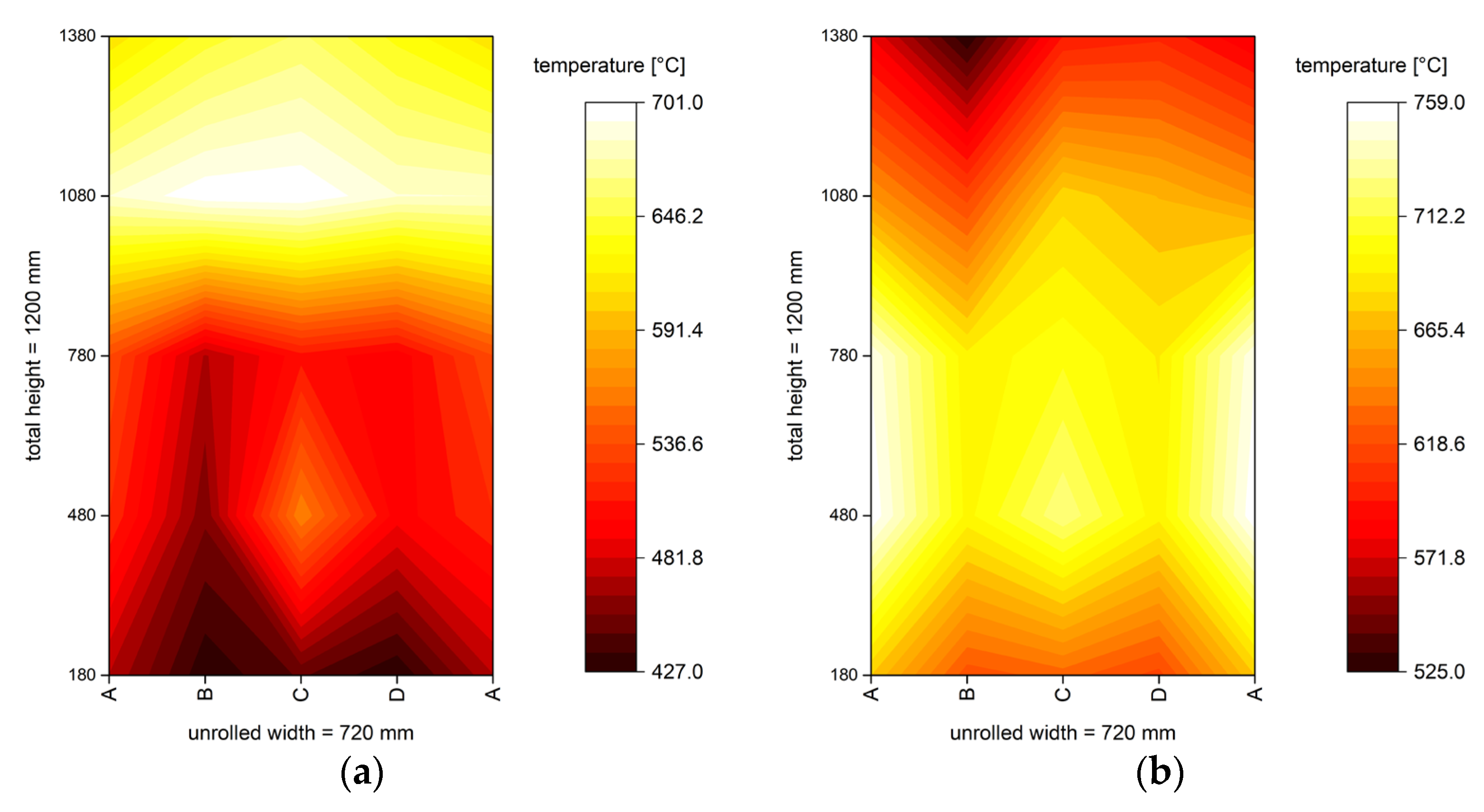

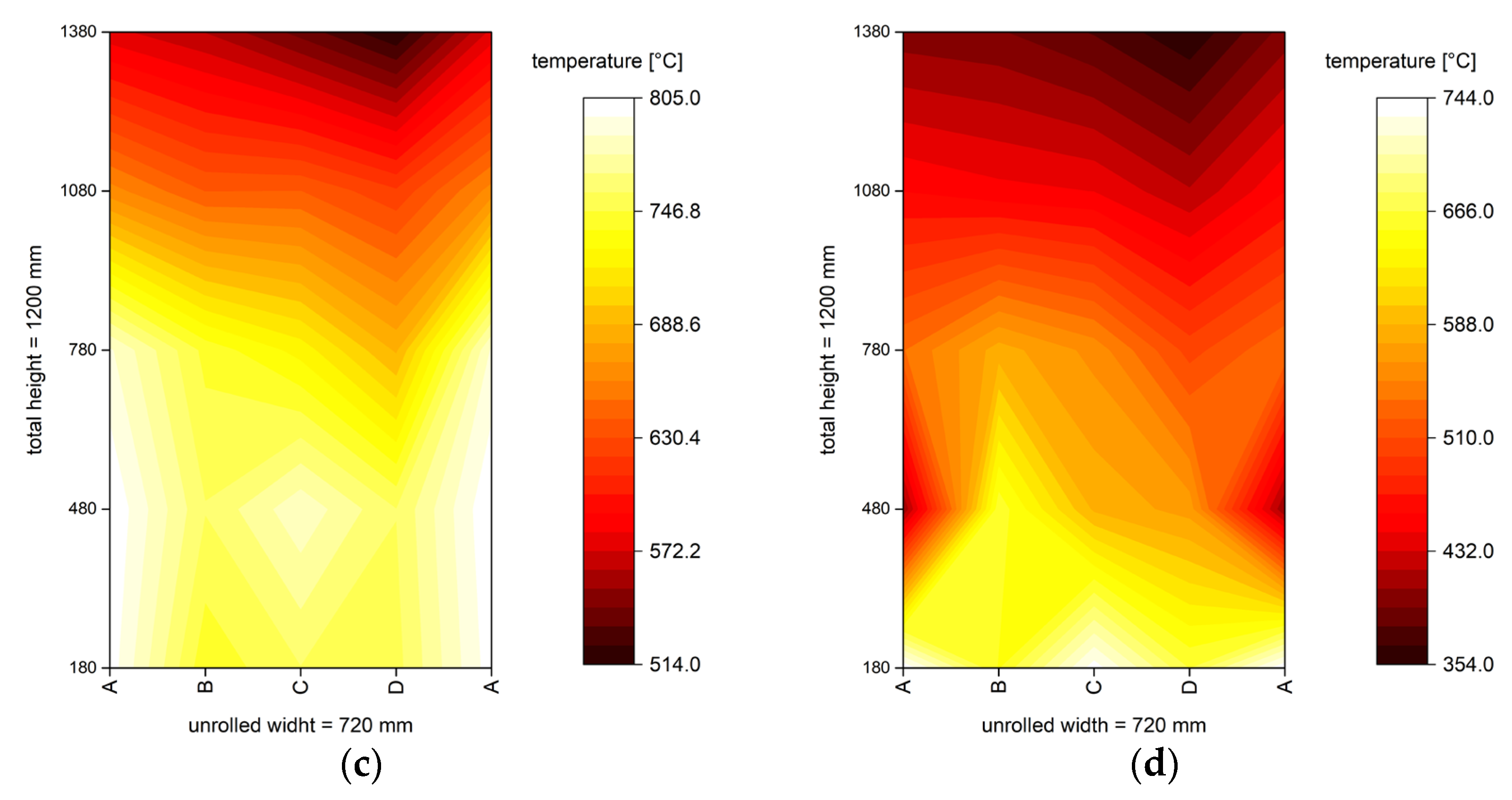

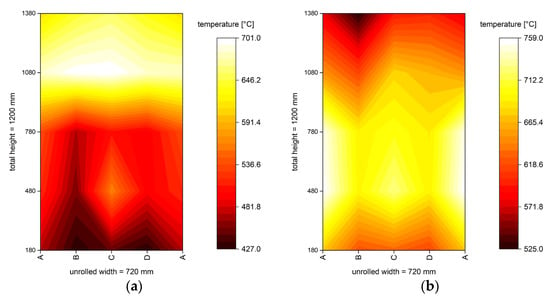

Figure 4 shows the temperature distribution on the shell of the cylinder inside this prepared woodpile. Intensive increasing of temperature was determined in the higher part of the cylinder due to the burning of wood prisms from the start of the test. At the start of the test, the fire was at a height of 6.5 m. After that, the highest temperatures were in the middle of the test, around 10 min. By 15 and 20 min into the test, visible changes took place and the fire moved into the lower part of the cylinder. The temperature was determined to be 700 °C and higher during the test. At the end of the test, the temperature was more than 800 °C. Woodpile collapse was determined at approximately 15 min, which is shown in Figure 4, point (c), where the temperature was targeted in the lower part of the cylinder.

Figure 4.

Temperature distribution on the unrolled cylinder shell: (a) 5 min; (b) 10 min; (c) 15 min; (d) 20 min.

3.2. Ammunition Selection

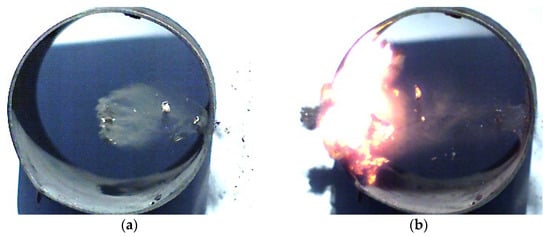

Based on the cooperation with special forces, six types of ammunition were selected for penetrating the shell of acetylene cylinders. The aims of these tests were detailed recording of the ammunition’s impact and selecting suitable ammunition. If ammunition is able to penetrate a cylinder’s shell, it must stay inside the cylinder. This is a necessary requirement for preventing secondary risk. From the obtained data, it can be said that the limit angle of the cylinder is 30°, but the penetration is conditioned by ammunition. After the ammunition impact with the shell of the cylinders, very small fragments are developed. With increasing distance, the risk of inaccurate shooting also increases, and especially if the cylinder is inclined at a limiting angle, there is a risk of deviation off center and nonpenetration of the cylinder shell. During the tests with empty acetylene cylinders, the option of penetrating the bottom and top of the cylinder was also tested. There was a presumption of impossibility of penetrating these parts of the cylinder. In the test, the top of the cylinder was able to be penetrated, however, the bottom was not. In the case of bottom, the ammunition core was ejected in the direction of arrival. This is shown in Figure 5, where the core of the ammunition is circled and fragments were also recorded.

Figure 5.

Shooting on the cylinder bottom.

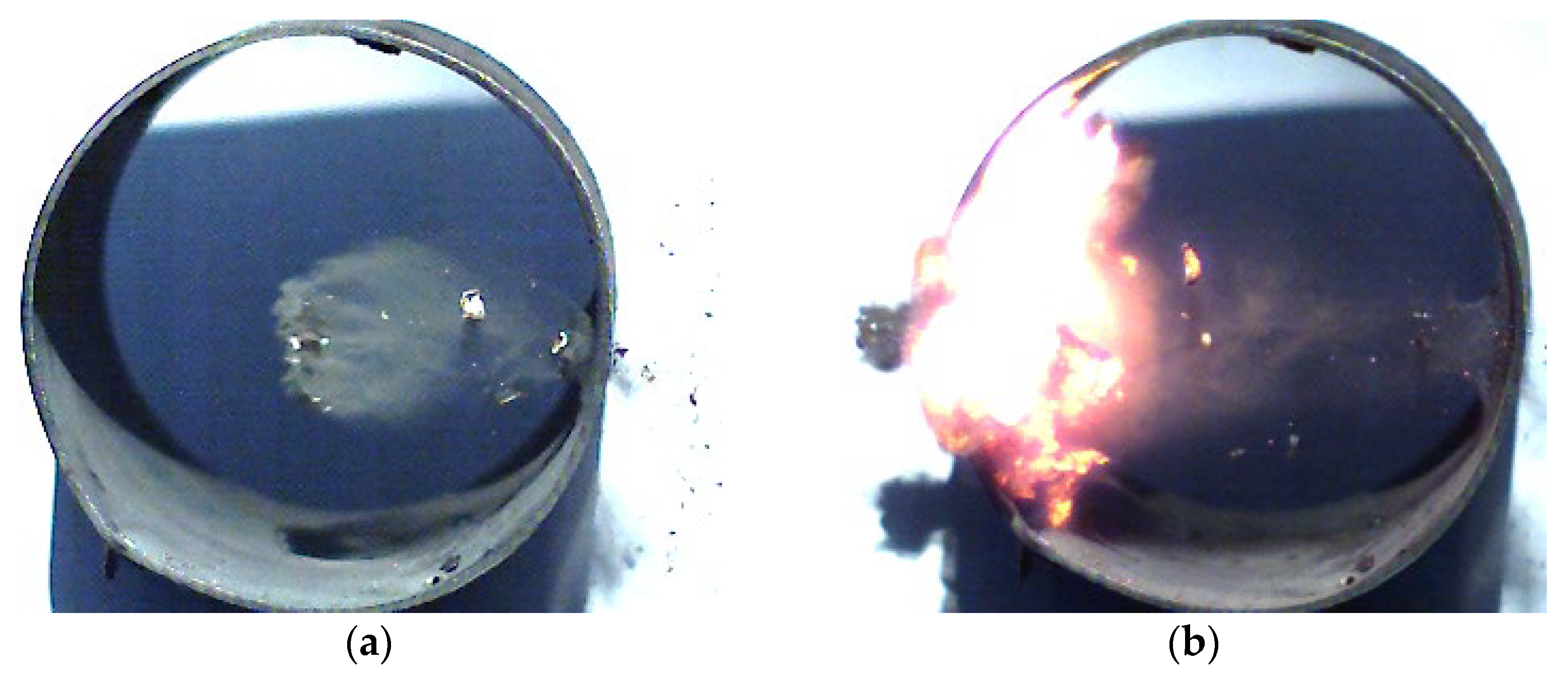

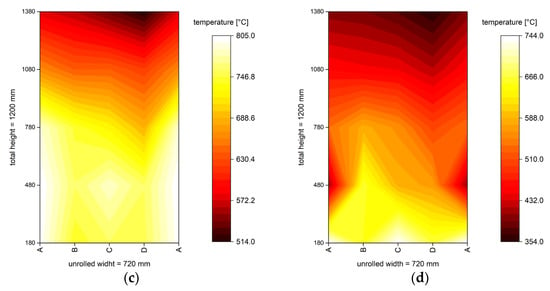

The cylinder cutouts were also prepared and penetrated via shooting and recorded with high-speed cameras. These cutouts corresponded to thicknesses of 200 and 300 bar pressure cylinders. In this case, the stationary equipment from a distance of 25 m was used for shooting with selected ammunition. During the puncture of the cylinder shell, superfine fragments and powder particles were developed. These particles and fragments were ignited immediately after hitting the opposite wall. This process is shown in Figure 6.

Figure 6.

Shooting through the cylinder’s cutouts: (a) shell puncture; (b) burnout of powder particles.

The selection of ammunition was also supported by analysis of hole size and comparation. Instead of only shell penetration, the hole size must be large enough to assure gas release. A graphical editor was used for detailed analysis of the performed holes. The areas of the shots were graphically marked and the bullet area was subtracted. Every hole was photographed with a digital camera which was placed vertical to the illuminated hole with the appropriate scale. As is shown in Table 1, some ammunition was not used in each horizontal position. Ammunition .308 AP was excessively effective and went through the cylinder, and the hole area was minimal for gas release. However, this ammunition just confirmed the purpose of its use. The largest area for gas release was developed with ammunition .338, especially for Magnum, but a similar size was determined for Lock Base and also Scenar. However, the .338 Magnum was no longer able to be used with the change of horizontal positions by 60° and 30°. The ammunitions were selected based on the experiences of special forces, usability and availability. The best commercially available ammunition is Lock Base, which showed certain stability and was able to penetrate cylinders in all tested horizontal positions. This ammunition had similar-sized hole areas in each horizontal position. Based on these tests, the ammunition was chosen for testing with full acetylene cylinders inside the fire. It is recommended to use ammunition with range of 5.56–12.7 mm, and directly type 7.62 mm .308 Win as a usual caliber or 7.62 mm NATO.

Table 1.

Average areas of individual shots.

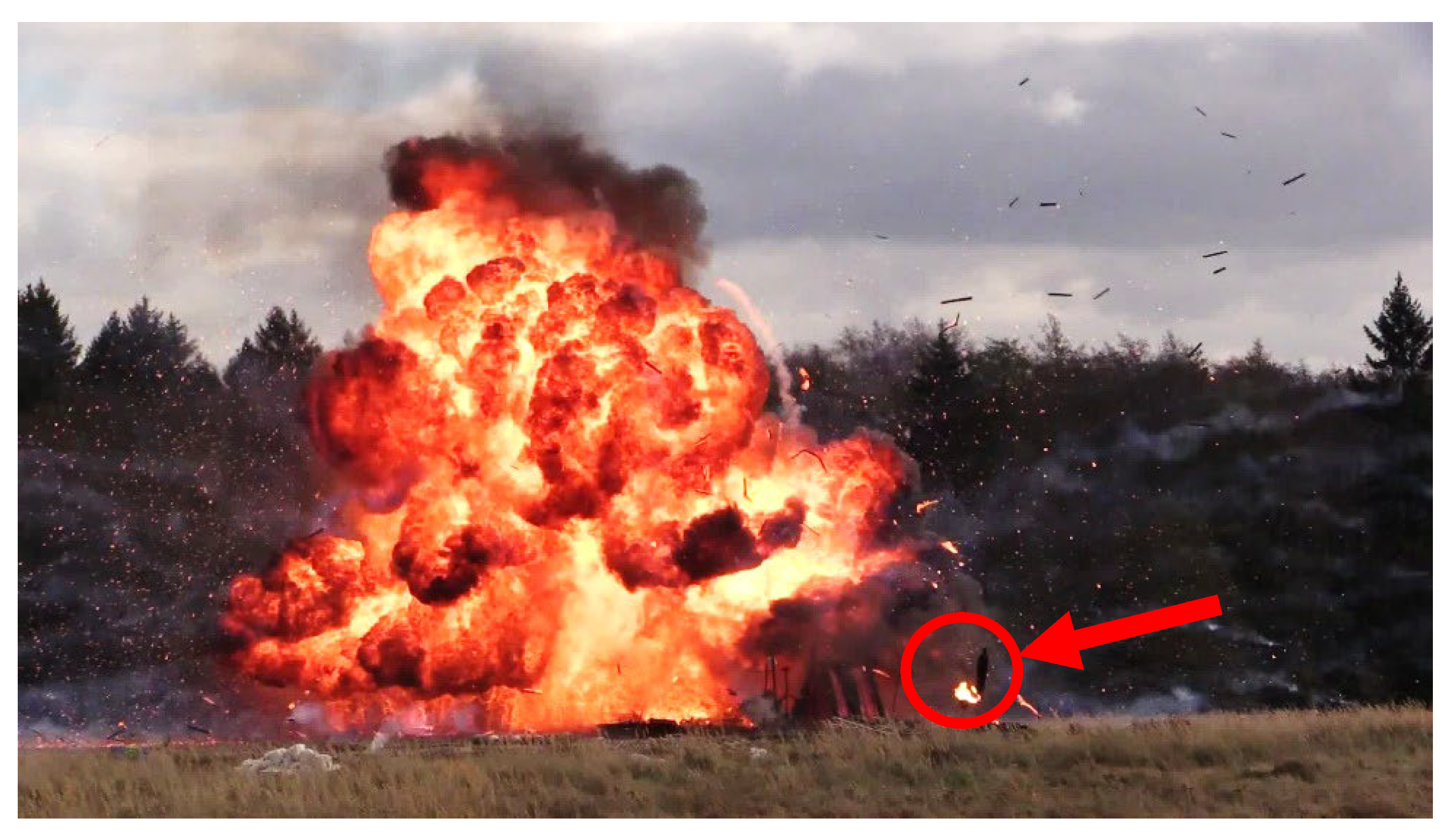

3.3. Uncontrolled and Controlled Destruction

Uncontrolled destruction represents a situation where the acetylene cylinder is exposed to the fire condition for so long that it is torn into two or more pieces and the content is released. As acetylene is a flammable gas, after its release the fireball phenomenon is observed. This fireball showed an average size of more than 10 m in diameter; however, fragments of the cylinder and the wood prisms were propelled in a distance of more than 100 m, which presents a secondary risk. The behavior of exposed high-pressure cylinders is also unpredictable and difficult to anticipate after exploding. The cylinders were torn into two, sometimes three pieces. Figure 7 represents uncontrolled destruction with a fireball. There is a visible part of the cylinder (marked with a red circle and arrow) which was ejected into the environment, as well as wooden prisms.

Figure 7.

Uncontrolled destruction of acetylene cylinder (fireball).

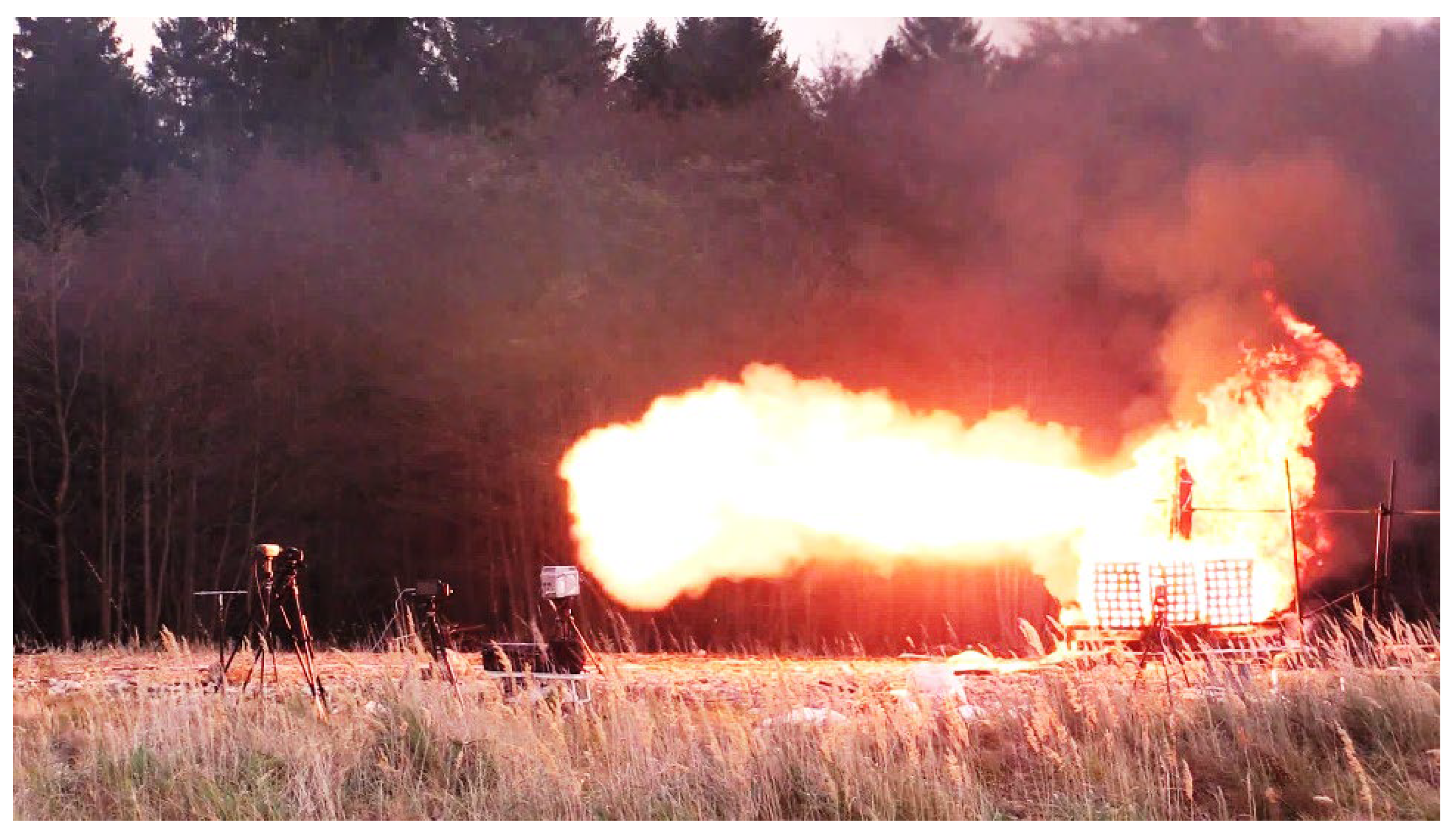

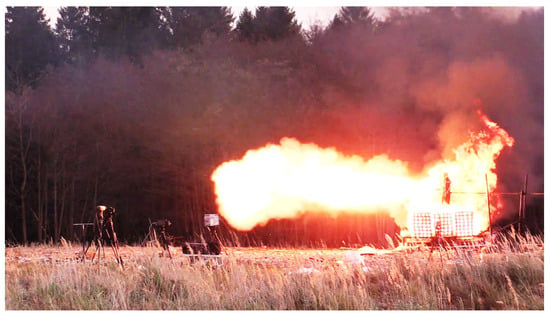

In the case of controlled destruction, the content leaked and pressure inside the cylinder dropped. Leaking flammable gases were ignited, but a fire jet phenomenon was observed instead. The resulting flame did not extend to distances greater than 10 m, and more importantly, after the flammable gas had burned off, no risk of explosion and associated physical damage remained. The result of this phenomena is shown in Figure 8. The time for the shooting was estimated based on experience and the pressure increase. Usually, when the pressure of 30 bar was achieved, the commander instructed for shooting. This study tested options with one or more shooters at the same time.

Figure 8.

Controlled destruction of pressure cylinder (fire jet).

During the tests, the temperature on the shell of the cylinders and the internal pressure were measured and recorded. In particular, the pressure was important for the comparison of these two effects. There was a noticeable difference between these two types of destructions. Uncontrolled destruction caused immediate pressure drop and the content was released after the disruption of the cylinder shell. The destruction pressures for uncontrolled destruction were 61.2, 49.9 and 55.0 bar with times of failure of 450, 400 and 500 s. Compared to that, after penetration of the cylinder shell, the content was released with a declining trend in several seconds. The destruction pressure was achieved after 6 min in direct fire. The time for shell penetration was derived based on practical experience. Regardless of the time of the acetylene cylinder in the fire, if 35 bar was achieved, the controlled destruction was performed. The pressures in the time of shooting were 37.1, 38.7 and 38.5 bar. The controlled destruction in the times of failure were 373, 366 and 395 s. After penetrating the cylinder shell, there was no risk of physical destruction.

4. Discussion

Based on the reference literature review and experimental measurements, the shooting through the acetylene cylinder shell as a prevention of physical destruction is effective. Measurements provided renewal of theoretical knowledge and practical experience. Shooting is very effective but represents a secondary risk. For this reason, it is necessary to have the procedure, operation and other requirements precisely specified. Penetration of cylinder shells is quick and more or less predictable. These facts can contribute to the effectiveness of fire intervention, safe time and also water, which would be normally used for cooling or water bath.

As it was mentioned, in the Czech Republic Methodological List no. 33 [1] for fire with the presence of acetylene cylinders in fire condition is used. In this document, all essential knowledge and procedures for fire with acetylene cylinders is described. Shooting is mentioned in point no. 39 as an extreme solution in the case when it is not possible to stop cylinder destruction. It is necessary to consider that flammable gas will be ignited, and the resultant fire jet may reach up to ten meters. The cylinder can explode due to the inside pressure. Shooting can be performed only by specialists from the police department.

The fact of lacking a description of procedures, conditions and specifications for shooting was the impetus for the study. Using this technique is necessary to prepare an extension in a certain way that follows Methodological List no. 33. This list is still primary, and after detection of an acetylene cylinder it is necessary to cool the cylinder shell. The time of the cylinder exposure to fire is not always clear, as well as the temperature and heat flux density and the amount of the gas inside. From the start, it is important to answer several questions. The method of shooting could be used only for acetylene pressure cylinders. According to evaluation of the conditions, this method could be used, and the acetylene pressure cylinder penetrated via shooting. It is necessary to consider potential risks in the case of unsuccessful shooting, used ammunition, the position of shooters and the accuracy.

More shots ensure the faster gas release and have to be distributed along the entire length. The most advantageous is a combination of two shots at once into the lower part of the cylinder. This method can be used only for acetylene cylinders. For use with other gases, it is necessary to consider different working pressures, construction of cylinders, material, hardness, etc. Called shooters should have sufficient knowledge and training for this situation, as the shooter always decides on the position and other specifications. The shooter is responsible for the action itself. Emphasis should be placed on the communication among intervening forces.

After successful shooting, the gas is released and initiated with the result of the fire jet. Immediately after releasing, outflow gas reaches a distance of about 10 m and then burns with approximate distance of fire of about 3 m. With decreasing amount of gas, the size of the flame decreases until it burns out. The releasing gas can accumulate if it is not initiated. Accumulation in a closed space can create explosive concentration.

The next step in this problem can be addressed at the training: an option for the shooting of the other pressure cylinders, for example, an oxygen pressure cylinder or a combination of acetylene with oxygen pressure cylinder. For another experiment, other ignition sources can be used, such as a pool fire. With the increasing use of this method in the Czech Republic, knowledge and experience will be accrued. In connection with the current state of knowledge, it is necessary to count on ammunition that will be able to ignite releasing gas. What could be really interesting is the modeling of these situations and an option to predict the behavior of the acetylene cylinders. Modeling and computer animations are popular and can be helpful in the case of extraordinary events. A comparison of the pressure relief valve with shooting can be another part of this research and can give differences between these two ways of preventing the explosion of the pressure cylinder. Another point to be discussed might be the distances from the cylinders of presenting special forces or specialists able to perform this prevention. In this methodological procedure, shooting is understood as speeding up the lengthy cooling of the acetylene cylinder and quick elimination of the uncontrolled destruction.

5. Conclusions

This study is based on safety research and aimed to summarize the data from large-scale experiments and develop procedures for shooting through the acetylene pressure cylinder inside the fire as a prevention of uncontrolled destruction. Several experimental measurements were performed, during which six cylinders were examined in detail. Based on the obtained data and the reference literature review, the procedure for shooting through the acetylene cylinder could be derived. This procedure could be used and implemented in the standard procedures for Fire and Rescue services. The result of this is that shooting could be a systematic decision for the possibility of using shooting through the acetylene cylinder as a prevention and elimination of the risk of uncontrolled destruction. The methodological procedure considers the training of shooters, commanders or members of the fire brigade to prepare for this emergency.

From the experimental measurement, the basic rules were derived. Shooting should be carried out from distances no less than 100 m. This is in addition to the possibility of uncontrolled explosion, where the safety distance of 300 m is determined. It is impossible to aim the shot onto the bottom of the cylinders. Shooting is ideal to be performed vertical to the pressure cylinders while aiming at the center of the cylinder. After penetrating the shell of the cylinder, the ammunition must stay inside. It is necessary to consider the dispersion of the fragments during penetration. The critical angle is the inclination of the cylinder at approximately 30°. The probability of precise shooting decreases with increasing distances. The optimal distance is 100 m, and after penetration a hole with a diameter of 8 mm is made.

According to the obtained data, destruction pressure could be achieved in 6 min in the direct flame or fire condition. This ascertainment gives not much time for the procedure of shooting through the cylinder. The cylinder’s shell lost material properties due to higher temperatures, and it was not able to reach the destruction pressure which is determined from the test on destruction by water at ordinary temperatures. For this reason, the lower destruction pressure 49.9 bar and the higher 61.2 bar were measured, which are less than the destruction pressure 90 bar determined from water destruction and the safety coefficient. In comparison to the study from Poland, this finding is higher by almost 10 bar, but similar results in Germany were measured. Similar results in fireball diameter size were observed, as well as the length of the fire jet.

Author Contributions

Conceptualization, V.J.; methodology, V.J., M.M. and P.L.; investigation, V.J., M.M. and P.L; writing—original draft preparation, V.J.; writing—review and editing, V.J. and M.M.; supervision, M.M.; project administration, P.L.; All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Ministry of the Interior of the Czech Republic, grant number VI20172020103, entitled “Safety of pressure cylinders in working conditions and the possibility of defusing pressure cylinders shot through”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

Within the experimental measurements, the authors witnessed a professional approach of all interested institutions, including shooters, policemen, firefighters, scientists and paramedics. This cooperation resulted in the use of this methodological procedure in real intervention.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Methodological Regulations for Firefighters, Battle Order for Firefighters—Tactical Procedure of Intervention: Fires with a Presence of Acetylene Pressure Cylinders. Available online: http://metodika.cahd.cz/bojovy_rad/P_33_Acetylen.pdf (accessed on 18 November 2020).

- Methodological Regulation for Firefighters, Battle Order for Firefighters—Tactical Procedure of Intervention: Fires with a Presence of Pressure Cylinders with Technical Compressed and Liquified Gases. Available online: http://metodika.cahd.cz/bojovy_rad/P_32_Technicke_plyny.pdf (accessed on 18 November 2020).

- Kratochvíl, V. Heat Stress of the Steel Pressure Cylinders during a Fire. Ph.D. Thesis, Technical University of Ostrava, Ostrava, Czech Republic, 2004. [Google Scholar]

- Hora, J.; Karl, J.; Suchý, O. Pressure cylinders under fire condition. Perspect. Sci. 2016, 7, 208–221. [Google Scholar] [CrossRef] [Green Version]

- Lamnevik, S. Beskjutning av Acetylengaseflaskor Inomhus 2: Beskjutning av Acetylentuber Med AK 4 och 7.62 mm Ammunition. 1996. Available online: https://rib.msb.se/Filer/pdf/6784.pdf (accessed on 22 November 2020).

- Björnsröm, H.; Setterwall, T. Beskjutning av acetylengasflaskor. Sjuhäradsbygdens tryckeri AB. 2002. Available online: https://www.msb.se/RibData/Filer/pdf/18393.pdf (accessed on 22 November 2020).

- Fear of Gas Explosion in Kvinnherad. Available online: https://norwaytoday.info/news/fear-gas-kvinnherad/ (accessed on 12 February 2021).

- The Police in Control of Gas Cylinder Fires. Available online: https://norwaytoday.info/news/gas-cylinder-fires/ (accessed on 12 February 2021).

- Chief Fire & Rescue Adviser. Fire and Rescue Service Operational Guidance: Incidents Involving Hazardous Materials; The Stationery Office: London, UK, 2012. [Google Scholar]

- Chief Fire & Rescue Adviser. Fire and Rescue Authorities Operational Guidance: Incidents Involving Acetylene; The Stationery Office: London, UK, 2014. [Google Scholar]

- Department for Communities & Local Government. Safety of Acetylene Containing Cylinders During and After Involment in a Fire: Fire Research Technical Report; Department for Communities & Local Government: London, UK, 2017. [Google Scholar]

- Explosionsgefaren Beim Umgang Mit Acetylenflaschen Und-Bündeln Nach der Einleitung Eines Acetylenzerfalls: Abschlußbericht Zum Forschungsvorhaben 13 RG 9001. BAM. 1995. Internally report. Available online: https://opus4.kobv.de/opus4-bam/frontdoor/index/index/docId/36243 (accessed on 18 November 2020).

- Rönnfeldt, L.; Voss, S. Beschuß von zerknallgefährdeten Acetylengasflaschen. BrandSchutz—Dtsch. Feuerwehr-Ztg. 1999, 2, 121–124. [Google Scholar]

- Research Report “Acetylene cylinders in a fire, phase 3: Experiments, observations, and conclusions”. BAM R&D Project Vh 2514. 2010; Internally report.

- Ferrero, F.; Beckmann-Kluge, M.; Schmidtchen, U.; Holtappels, K. Modelling the heat transfer in acetylene cylinders during and after the exposure to fire. J. Loss Prev. Process Ind. 2010, 23, 654–661. [Google Scholar] [CrossRef]

- Ferrero, F.; Beckmann-Kluge, M.; Kreißig, M.; Hensel, C.; Schmidtchen, U.; Holtappels, K. Preventing the explosion of acetylene cylinders involved in fire with help of numerical modeling. J. Loss Prev. Process Ind. 2012, 25, 364–372. [Google Scholar] [CrossRef]

- Półka, M.; Salamonowicz, Z.; Batko, P. The explosion of acetylene cylinders—Case study. In Proceedings of the 9th International Symposion on Hazards, Prevention, Mitigation of Industrial Explosion, Cracow, Poland, 22–27 July 2012. [Google Scholar]

- Półka, M.; Kukfisz, B. Butle i wiązki acetylenowe w warunkach pożaru. Przegląd Nauk.-Inżynieria Kształtowanie Sr. 2018, 27, 516–523. [Google Scholar] [CrossRef]

- Kukfisz, B.; Ptak, S.; Półka, M.; Woliński, M. Fire and explosion hazards caused by oxygen cylinders. WIT Trans. Built Environ. 2018, 174, 141–151. [Google Scholar] [CrossRef]

- Ejsmont, J.; Świeczko-Źurek, B.; Ronowski, G. Shooting Gas Cylinders to Prevent Their Explosion in Fire. In Proceedings of the Conference of Word Academy Of Science: Engineering And Technology Conference, Venice, Italy, 14–15 August 2017. [Google Scholar]

- European Industrial Gases Association (EIGA). Handling of Gas Cylinders During and After Exposure to Heat or Fire: Safety Information; European Industrial Gases Association: Brussels, Belgium, 2014. [Google Scholar]

- ČSN EN 3-7+A1. Portable Fire Extinguishers—Part 7: Characteristic, Performance Requirements, and Test Methods; Czech Normalization Institute: Prague, Czech Republic, 2008.

- Mynarz, M.; Jankuj, V.; Lepik, P. Thermal loading of pressure cylinders in a fire. In Proceedings of the International Multidisciplinary Scientific Geoconference Surveying Geology and Mining Ecology Management, SGEM, Albena, Bulgaria, 28 June–7 July 2019; Volume 19, pp. 767–774. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).