The Effect of Vapor Pressure Deficit Regulation on the Growth of Tomato Plants Grown in Different Planting Environments

Abstract

:1. Introduction

2. Materials and Methods

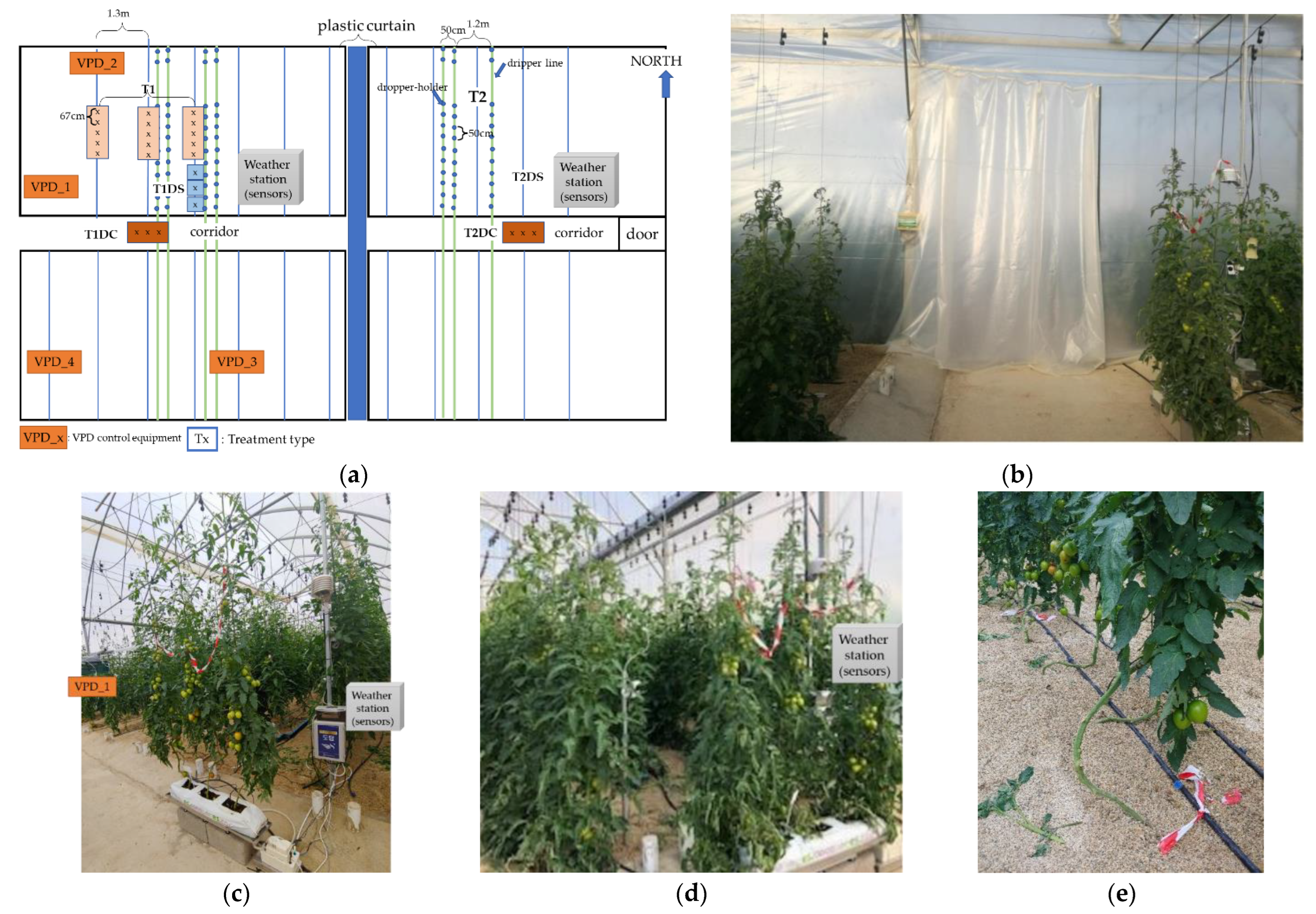

2.1. Location and Facilities

2.2. Cultivation Environment Settings

2.3. Sensor Installation

2.4. Tomato Crop Management

2.5. Data Collection from Field Trials

- Growth parameters: From the transplant of the crops with a biweekly frequency, four characterizations of the following growth parameters of the crops were carried out: phenological index (BBCH index), crop height, number of expanded leaves developed per plant, and number of tomato fruits produced per plant. These characterizations were carried out on each of the plants of the treatments and at five different moments of the tomato crop cycle 9, 23, 36, 49, and 64 days after transplanting the crops in the greenhouse. The growth parameters were measured only up to the moment of 64 days during the vegetative growth phase.

- Yield: The production of tomato fruits was characterized in every harvesting episode developed during the trial. A total of 19 harvesting episodes were developed during the field trial. The fresh weight and the number of harvested fruits were characterized as commercial and non-commercial fruits. The commercial tomato fruits were classified into commercial categories based on their diameter.

- Qualitative characteristics: A composite sample consisting of six mature tomato fruits was taken from each of the experimental treatments. The six fruits of each composite sample were used to prepare a homogeneous sample in which the following quality parameters were characterized: fresh weight, diameter, hardness, and sugar content. The sugar content in fruits was measured by refractometry with the use of a portable refractometer (model PAL-1, Atago, Tokyo, Japan). The hardness was measured using a portable durometer (model 53215TP, Turoni, Forli, Italy). The color was measured using a portable colorimeter (model CR-400, Konica Minolta, Japan) to measure the three dimensions of the color space by means of the coordinates L*, a*, and b*.

2.6. Statistical Analysis

3. Results and Discussion

3.1. Effect of VPD Regulation on Tomato Crops in Soil

3.1.1. Effect of VPD Regulation on Growth

3.1.2. Effect of VPD Regulation on Yield

3.2. Effect of VPD Regulation on Tomato Crops in Soil above PVC Trays

3.2.1. Effect of VPD Regulation on Growth

3.2.2. Effect of VPD Regulation on Yield

3.3. Effect of VPD Regulation on Tomato Crops in Coconut Fiber above PVC Trays

3.3.1. Effect of VPD Regulation on Growth

3.3.2. Effect of VPD Regulation on Yield

3.4. Effect of Growing Media

3.5. Qualitative Characteristics

4. Related Work

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Iwaniak, A.; Janczukowicz, W.; Rodziewicz, J. New trends in environmental engineering, agriculture, food production, and analysis. Appl. Sci. 2021, 11, 2745. [Google Scholar] [CrossRef]

- Lawrence, M. The relationship between relative humidity and the dewpoint temperature in moist air: A simple conversion and applications. Bull. Am. Meteorol. Soc. 2005, 86, 225–234. [Google Scholar] [CrossRef]

- Richard, G.A.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration—Guidelines for Computing Crop Water Requirements-FAO Irrigation and Drainage Paper 56; FAO: Rome, Italy, 1998. [Google Scholar]

- Bakker, J.C. Analysis of Humidity Effects on Growth and Production of Glasshouse Fruit Vegetables. Ph.D. Dissertation, Agricultural University, Wageningen, The Netherlands, 1991; p. 155. [Google Scholar]

- Zhang, D.; Du, Q.; Zhang, Z.; Jiao, X.; Song, X.; Li, J. Vapour pressure deficit control in relation to water transport and water productivity in greenhouse tomato production during summer. Sci. Rep. 2017, 7, 43461. [Google Scholar] [CrossRef] [PubMed]

- Wollaeger, H.; Runkle, E. Why Should Greenhouse Growers Pay Attention to Vapor Pressure Deficit and Not Relative Humidity? Michigan State. University and MSU Department of Horticulture. 2015. Available online: https://www.canr.msu.edu/news/why_should_greenhouse_growers_pay_attention_to_vapor_pressure_deficit_and_n (accessed on 23 December 2021).

- Leonardi, C.; Guichard, S.; Bertin, N. High vapour pressure deficit influences growth, transpiration and quality of tomato fruits. Sci. Hortic. 2000, 84, 285–296. [Google Scholar] [CrossRef]

- Leuschner, C. Air humidity as an ecological factor for woodland herbs: Leaf water status, nutrient uptake, leaf anatomy, and productivity of eight species grown at low or high vpd levels. Flora 2002, 197, 262–274. [Google Scholar] [CrossRef]

- Gholipoor, M.; Prasad, P.V.V.; Mutava, R.N.; Sinclair, T.R. Genetic variability of transpiration response to vapor pressure deficit among sorghum genotypes. Field Crops Res. 2010, 119, 85–90. [Google Scholar] [CrossRef]

- Sinclair, T.R.; Devi, J.; Shekoofa, A.; Choudhary, S.; Sadok, W.; Vadez, V. Limited-transpiration response to high vapor pressure deficit in crop species. Plant Sci. 2017, 260, 109–118. [Google Scholar] [CrossRef]

- Grossiord, C.; Buckley, T.N.; Cernusak, L.A.; Novick, K.A.; Poulter, B.; Siegwolf, R.T.W.; Sperry, J.S.; McDowell, N.G. Plant responses to rising vapor pressure deficit. New Phytol. 2020, 226, 1550–1566. [Google Scholar] [CrossRef] [Green Version]

- Oren, R.; Sperry, J.S.; Katul, G.G.; Pataki, D.E.; Ewers, B.E.; Phillips, N.; Schäfer, K.V.R. Survey and synthesis of intra- and interspecific variation in stomatal sensitivity to vapour pressure deficit. Plant Cell Environ. 1999, 22, 1515–1526. [Google Scholar] [CrossRef] [Green Version]

- Novick, K.A.; Ficklin, D.L.; Stoy, P.C.; Williams, C.A.; Bohrer, G.; Oishi, A.C.; Papuga, S.A.; Blanken, P.D.; Noormets, A.; Sulman, B.N.; et al. The increasing importance of atmospheric demand for ecosystem water and carbon fluxes. Nat. Clim. Chang. 2016, 6, 1023–1027. [Google Scholar] [CrossRef] [Green Version]

- Novick, K.A.; Konings, A.G.; Gentine, P. Beyond soil water potential: An expanded view on isohydricity including land–atmosphere interactions and phenology. Plant Cell Environ. 2019, 42, 1802–1815. [Google Scholar] [CrossRef] [PubMed]

- Harmanto, S.V.M.; Babel, M.S.; Tantau, H.J. Water requirement of drip irrigated tomatoes grown in greenhouse in tropical environment. Agric. Water Manag. 2005, 71, 225–242. [Google Scholar] [CrossRef]

- Lu, N.; Nukaya, T.; Kamimura, T.; Zhang, D.; Kurimoto, I.; Takagaki, M. Control of vapor pressure deficit (VPD) in greenhouse enhanced tomato growth and productivity during the winter season. Sci. Hortic. 2015, 197, 17–23. [Google Scholar] [CrossRef]

- Aljubury, I.M.A.; Ridha, H.D.A. Enhancement of evaporative cooling system in a greenhouse using geothermal energy. Renew. Energy 2017, 111, 321–331. [Google Scholar] [CrossRef]

- Zarnescu, A.; Ungurelu, R.; Varzaru, G. Controlling the temperature and humidity in a greenhouse. In Proceedings of the IEEE 25th International Symposium for Design and Technology in Electronic Packaging (SIITME), Cluj-Napoca, Romania, 23–26 October 2019. [Google Scholar]

- Inoue, T.; Sunaga, M.; Ito, M.; Yuchen, Q.; Matsushima, Y.; Sakoda, K.; Yamori, W. Minimizing VPD fluctuations maintains higher stomatal conductance and photosynthesis, resulting in improvement of plant growth in lettuce. Front. Plant Sci. 2021, 12, 458. [Google Scholar] [CrossRef]

- Mantovani, D.; Veste, M.; Freese, D. Effects of drought frequency on growth performance and transpiration of young black locust (Robinia pseudoacacia L.). Int. J. For. Res. 2014, 2014, 821891. [Google Scholar]

- Sivapalan, S. Effect of a polymer on growth and yield of soybeans (Glycine Max) grown in a coarse textured soil. In Proceedings of the Irrigation 2001 Regional Conference, Sivapalan, Siva, 11–12 July 2001; IAA: Toowoomba, Australia, 2001; pp. 93–99. [Google Scholar]

- Akhter, J.; Mahmood, K.; Malik, K.A.; Mardan, A.; Ahmad, M.; Iqbal, M.M. Effects of hydrogel amendment on water storage of sandy loam and loam soils and grainling growth of barley, wheat and chickpea. Plant Soil Environ. 2004, 50, 463–469. [Google Scholar] [CrossRef] [Green Version]

- El-Hady, O.A.; Wanas, S.A. Water and fertilizer use efficiency by cucumber grown under stress on sandy soil treated with acrylamide hydrogels. J. Appl. Sci. Res. 2006, 2, 1293–1297. [Google Scholar]

- Sarvas, M.; Pavlenda, P.; Takacova, E. Effect of hydrogel application on survival and growth of pine grainling in reclamations. J. For. Sci 2007, 53, 204–209. [Google Scholar]

- Almeria Temperature History. 2018. Available online: https://weatherspark.com/h/m/38216/2018/11/Historical-Weather-in-November-2018-in-Almer%C3%ADa-Spain#Figures-Temperature (accessed on 22 March 2022).

- SSL Smart Farm Platform. Available online: http://www.ezsmartfarm.com/ (accessed on 5 January 2022).

- Statgraphics Technologies Inc. Available online: https://www.statgraphics.com/ (accessed on 22 December 2021).

- Holder, R.; Cockshull, K.E. Effects of humidity on the growth and yield of glasshouse tomatoes. J. Hortic. Sci. 1990, 65, 31–39. [Google Scholar] [CrossRef]

- Guichard, S.; Gary, C.; Leonardi, C.; Bertin, N. Analysis of growth and water relations of tomato fruits in relation to air vapor pressure deficit and plant fruit load. J. Plant Growth Regul. 2005, 24, 201–213. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, Z.; Li, J.; Chang, Y.; Du, Q.; Pan, T. Regulation of vapor pressure deficit by greenhouse micro-fog systems improved growth and productivity of tomato via enhancing photosynthesis during summer season. PLoS ONE 2015, 10, e0133919. [Google Scholar] [CrossRef] [PubMed]

- Jiao, X.-C.; Song, X.-M.; Zhang, D.-L.; Du, Q.-J.; Li, J.-M. Coordination between vapor pressure deficit and CO2 on the regulation of photosynthesis and productivity in greenhouse tomato production. Sci. Rep. 2019, 9, 8700. [Google Scholar] [CrossRef] [PubMed]

- López, J.; Way, D.A.; Sadok, W. Systemic effects of rising atmospheric vapor pressure deficit on plant physiology and productivity. Glob. Change Biol. 2021, 27, 1704–1720. [Google Scholar] [CrossRef]

| Treatment ID | VPD Condition | Growing Medium | #Tomato Crops |

|---|---|---|---|

| T1 | With VPD regulation | Soil | 15 |

| T1DS | Soil in tray | 3 | |

| T1DC | Coconut fiber substrate in tray | 3 | |

| T2 | Without VPD regulation | Soil | 15 |

| T2DS | Soil in tray | 3 | |

| T2DC | Coconut fiber substrate in tray | 3 |

| Parameters | HCO3− | NH4+ | NO3− | H2PO4− | SO4− | K+ | Ca+2 | Mg+2 | CI− | pH | CE(dS/m−1) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (mmol I−1) | 0.4 | 1.1 | 15.2 | 1.7 | 2.5 | 7.1 | 5.8 | 1.6 | 9.1 | 5.8 | 1.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noh, H.; Lee, J. The Effect of Vapor Pressure Deficit Regulation on the Growth of Tomato Plants Grown in Different Planting Environments. Appl. Sci. 2022, 12, 3667. https://doi.org/10.3390/app12073667

Noh H, Lee J. The Effect of Vapor Pressure Deficit Regulation on the Growth of Tomato Plants Grown in Different Planting Environments. Applied Sciences. 2022; 12(7):3667. https://doi.org/10.3390/app12073667

Chicago/Turabian StyleNoh, Hyemin, and Jihyun Lee. 2022. "The Effect of Vapor Pressure Deficit Regulation on the Growth of Tomato Plants Grown in Different Planting Environments" Applied Sciences 12, no. 7: 3667. https://doi.org/10.3390/app12073667

APA StyleNoh, H., & Lee, J. (2022). The Effect of Vapor Pressure Deficit Regulation on the Growth of Tomato Plants Grown in Different Planting Environments. Applied Sciences, 12(7), 3667. https://doi.org/10.3390/app12073667