The Application of Generative Algorithms in Human-Centered Product Development

Abstract

:1. Introduction

Generative Design, Optimization and Generative Algorithms

- Conceptualization and ideation: Initial design work that establishes the product or component to be created. The extent of design detailing can vary at this stage but often only a loose spatial envelope and the key functionalities are defined.

- Design domain definition: The generative design algorithm must operate within a particular design “space” in order to advance particular solutions. Defining the design domain requires the designer to decide upon the boundaries of the design. Often this includes defining areas of material stiffness or flexibility, establishing a spatial profile in which the forms should be generated, or defining a functional profile.

- Method selection: Building algorithms requires command over the optimization and topological transformation methods. Defining these facilitates the algorithmic design work.

- Integration of design domain definition with concepts using CAD environment: Once the constraints have been adequately set up, the design domain definitions established in stage two can be advanced and integrated into a CAD environment allowing the generation of models.

- Generation of CAD models: Within the selected CAD environment, models will be generated that conform to the defined design constraints. Most CAD environment will allow secondary editing after the generative stages.

2. Generative Design in the Design Process

2.1. Generative Design, HCD and Ergonomics

2.2. Summary of Literature

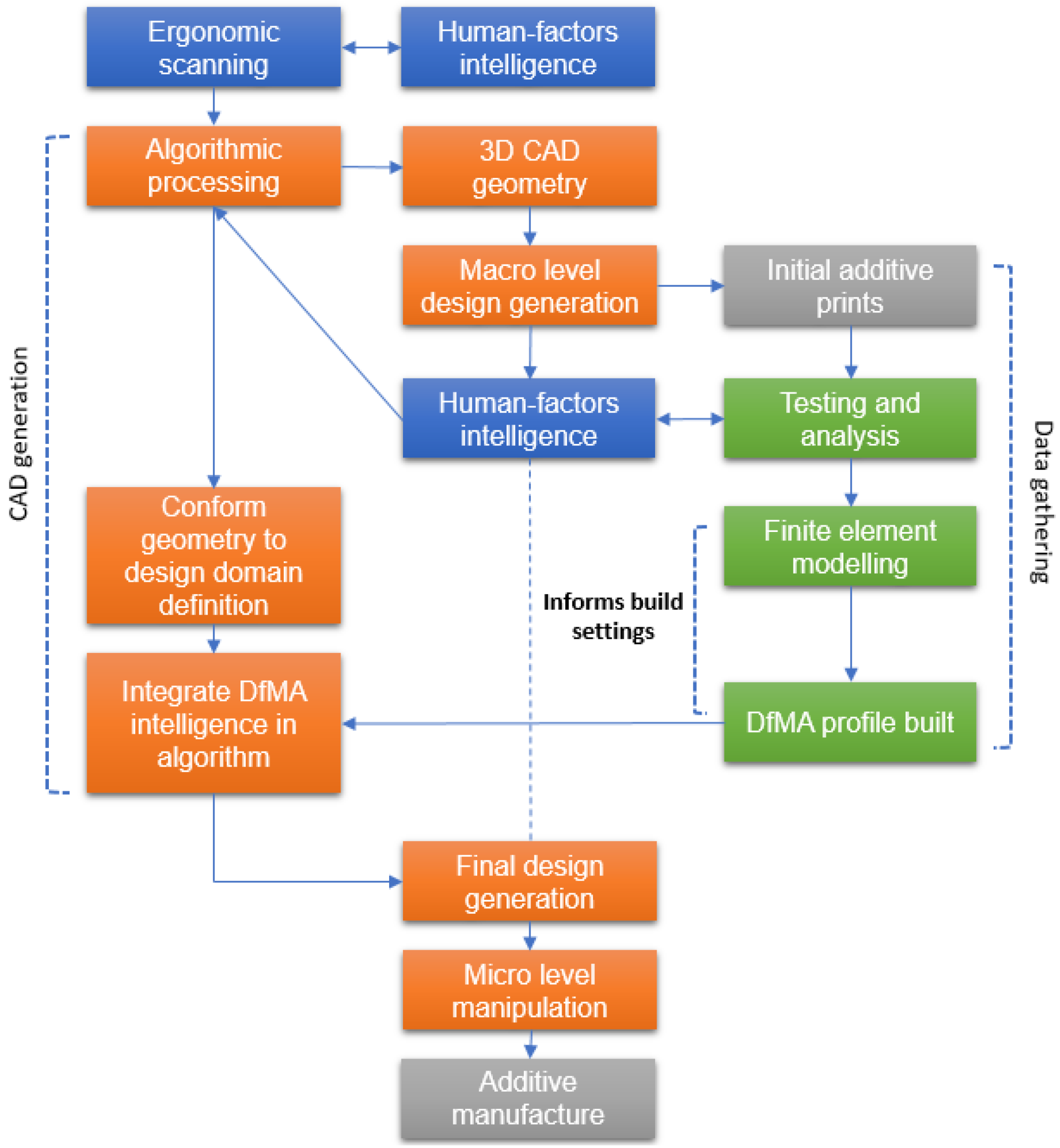

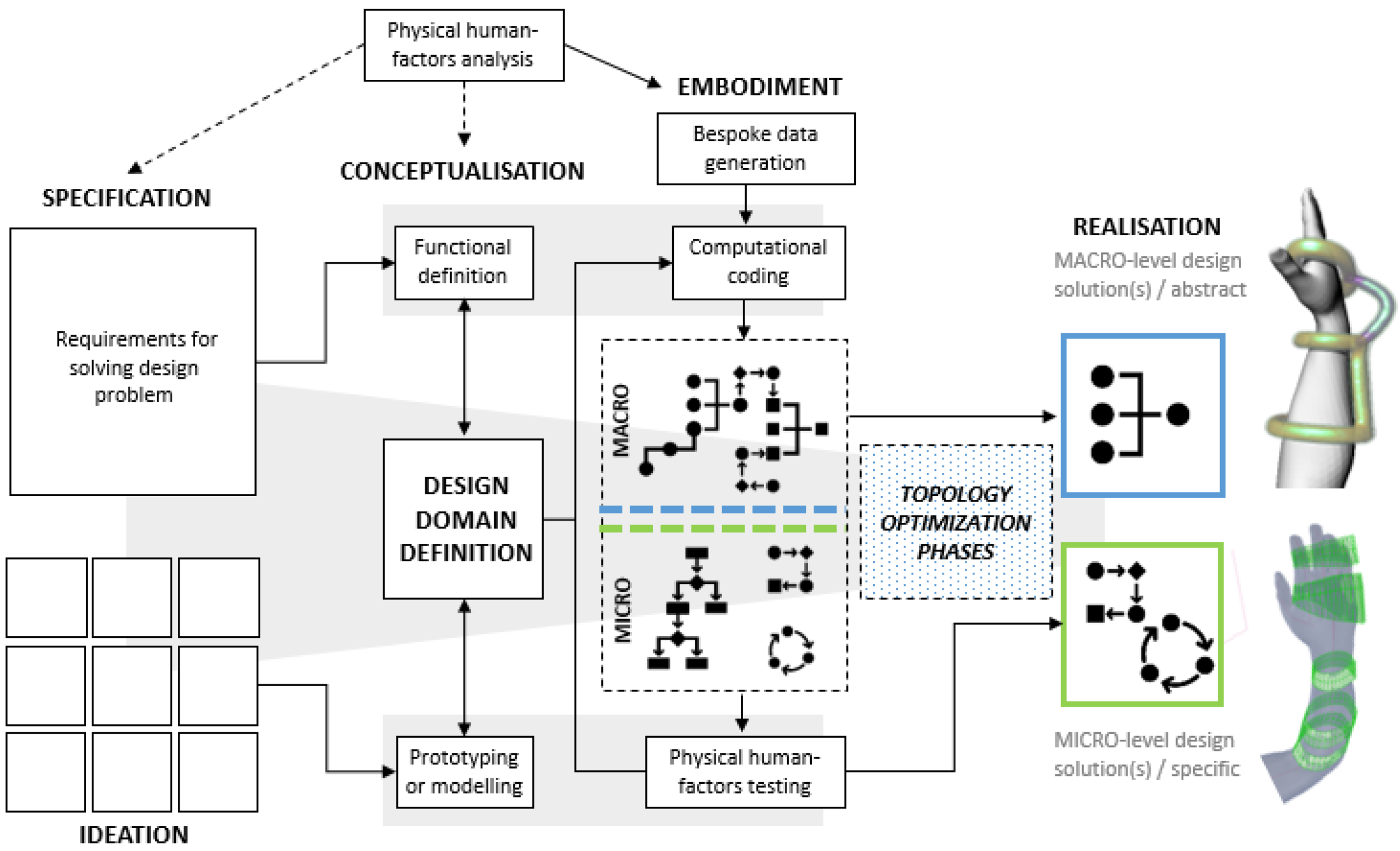

3. A Generative Design Workflow for Attuned Ergonomics

- Specification/ideation stage: The core requirements for the product are set out within the specifications which run in conjunction to initial ideation. This is perhaps the most well-aligned element to the traditional design methodologies, whereby sets of specifications and design concepts would be explored iteratively.

- Conceptualization stage: The pre-algorithm phase, in which the functionality of the concepts are explored in the abstract. This stage may also include sketch modelling or other forms of prototyping that help to examine which design features need the most computational resources.

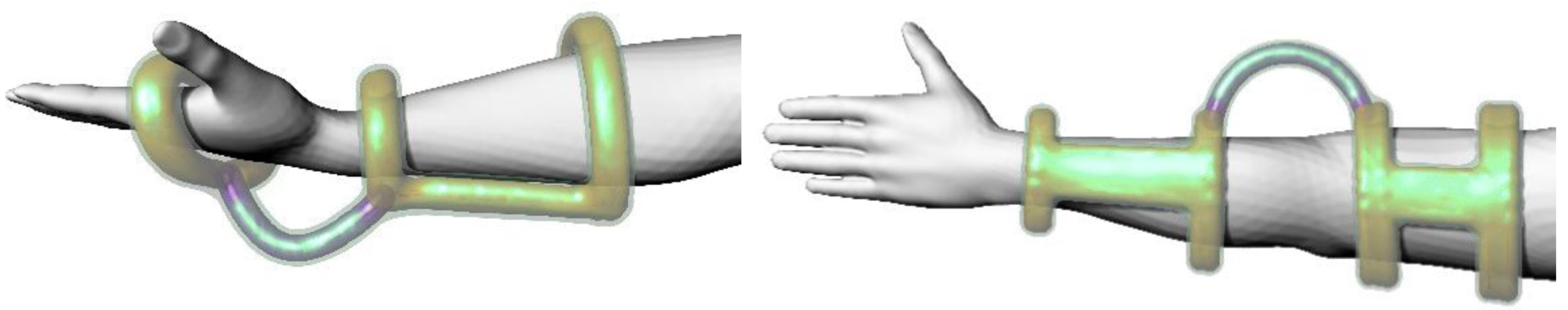

- Embodiment stage: The algorithmic stage, in which the abstract understandings of form and functionality explored in the first two stages become refined and are built into an algorithmic definition. The algorithmic definition has a macro stage detailing the broad form features, and a micro stage detailing the functionality and design detailing.

- Realization stage: The finalization of design after generative design explorations. The generative solutions will be focused on the macro (structural) level or the micro (detailing) level.

4. Application to Product Development Process

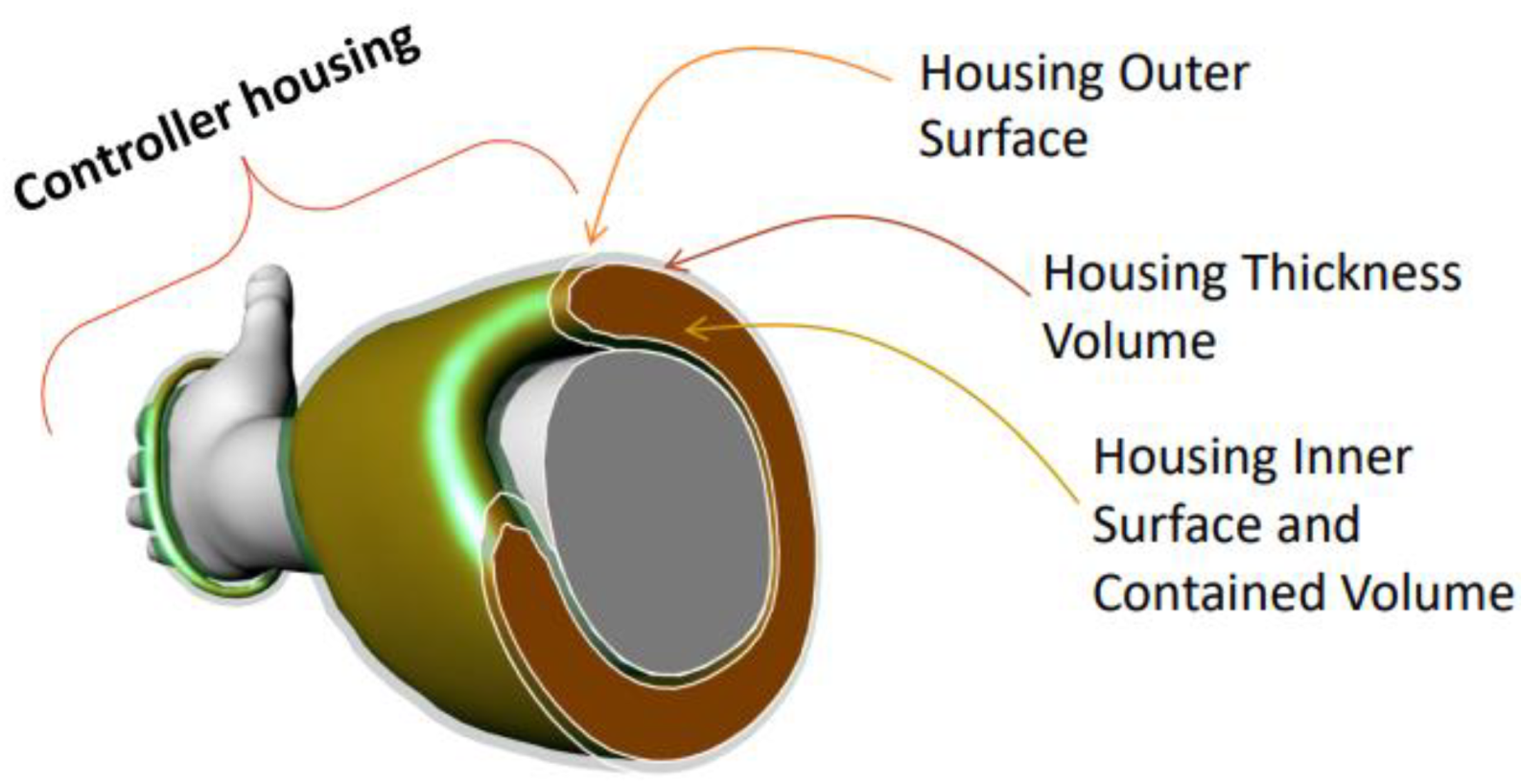

4.1. Micro and Macro Level Design

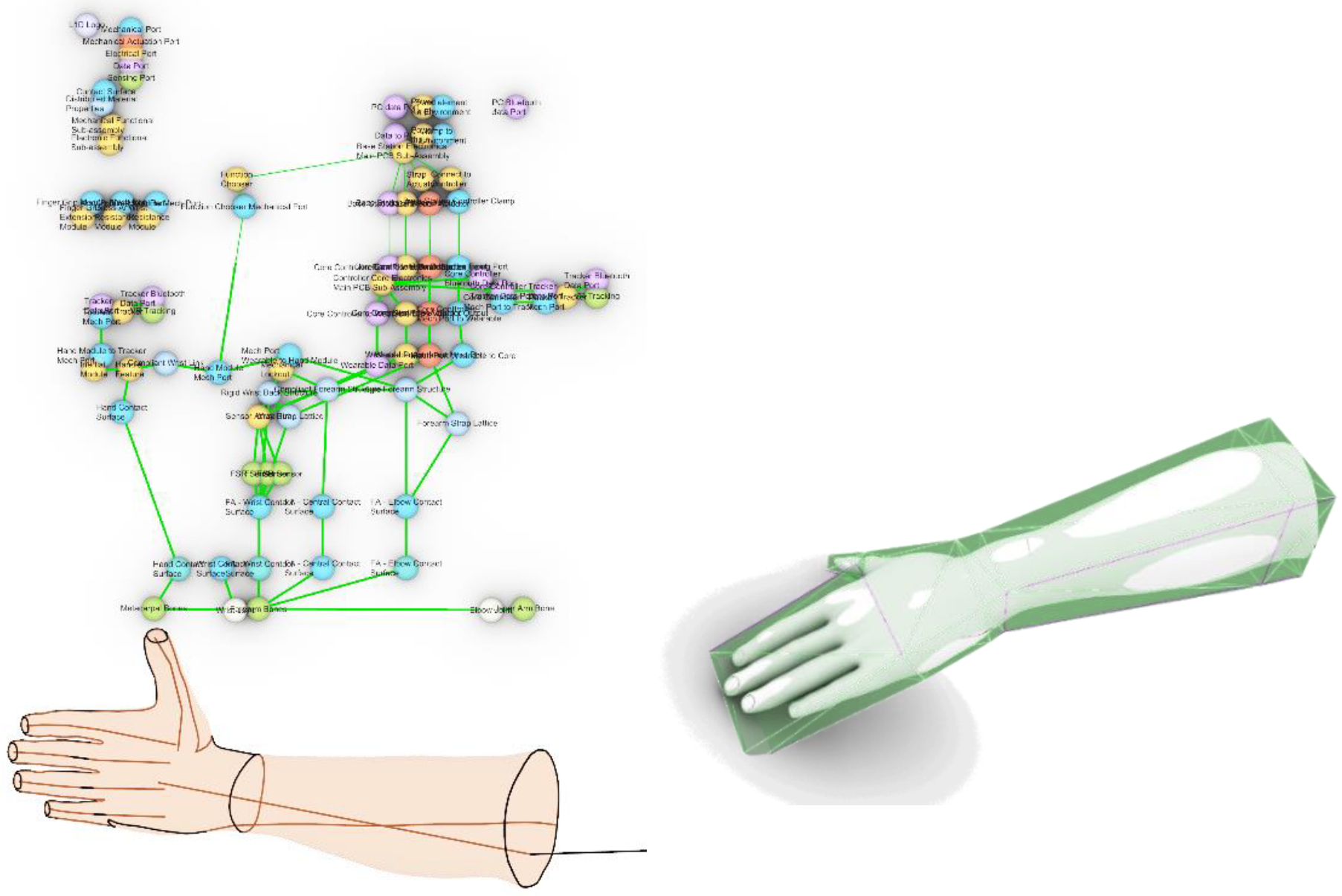

4.2. Conceptulisation Stage: Graphing and SBF Approach

4.3. Embodiment Stage: Macro–Level SBF Solutions

4.4. Realization Stage: Generation of Device Concepts

4.5. Implicaions for Design Practice

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Terzidis, K. Algorithmic Architecture, 1st ed.; Routledge: London, UK, 2006. [Google Scholar]

- Caetano, I.; Santos, L.; Leitão, A.M. Computational design in architecture: Defining parametric, generative, and algorithmic design. Front. Archit. Res. 2020, 9, 287–300. [Google Scholar] [CrossRef]

- Celaschi, F. Advanced design-driven approaches for an Industry 4.0 framework: The human-centred dimension of the digital industrial revolution. Strateg. Des. Res. J. 2017, 10, 97–104. [Google Scholar] [CrossRef] [Green Version]

- Giacomin, J. What Is Human Centred Design? Des. J. 2014, 17, 606–623. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Quian, X.; Wang, M.Y. Advances in generative design. Comput. Aided Des. 2019, 116, 102733. [Google Scholar] [CrossRef]

- Aghaei Meibodi, M. Generative Design Exploration: Computation and Material Practice. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2016. [Google Scholar]

- Benyus, J.M. Biomimicry: Innovation Inspired by Nature; Harper Collins: London, UK, 1997. [Google Scholar]

- Stasiuk, D. Design Modeling Terminology. 2018. Available online: https://archinate.files.wordpress.com/2018/06/dstasiuk-design-modeling-terminology1.pdf (accessed on 2 March 2022).

- Celani, G.; Vaz, C.E. CAD Scripting and Visual Programming Languages for Implementing Computational Design Concepts: A Comparison from a Pedagogical Point of View. Int. J. Archit. Comput. 2012, 10, 121–137. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Kikuchi, N. Generating optimal topologies in structural design using a homogenization method. Appl. Mech. Eng. 1988, 71, 197–224. [Google Scholar] [CrossRef]

- Barbieri, L.; Muzzupappa, M. Performance-Driven Engineering Design Approaches Based on Generative Design and Topology Optimization Tools: A Comparative Study. Appl. Sci. 2022, 12, 2106. [Google Scholar] [CrossRef]

- Yildiz, A.R.; Kaya, N.; Ozturk, F.; Alankus, O. Optimal design of vehicle components using topology design and optimisation. Int. J. Veh. Des. 2004, 34, 387–398. [Google Scholar] [CrossRef]

- Sigmund, O.; Maute, K. Topology optimization approaches. Struct. Multidiscip. Optim. 2013, 48, 1031–1055. [Google Scholar] [CrossRef]

- Mountstephens, J.; Teo, J. Progress and Challenges in Generative Product Design: A Review of Systems. Computers 2020, 9, 80. [Google Scholar] [CrossRef]

- Yamada, T.; Izui, K.; Nishiwaki, S.; Takezawa, A. A topology optimization method based on the level set method incorporating a fictitious interface energy. Comput. Methods Appl. Mech. Eng. 2010, 199, 45–48. [Google Scholar] [CrossRef] [Green Version]

- Bendsøe, M.P.; Sigmund, O. Material interpolation schemes in topology optimization. Arch. Appl. Mech. 1999, 69, 635–654. [Google Scholar] [CrossRef]

- Bendsøe, M.P. Optimal shape design as a material distribution problem. Struct. Optim. 1989, 1, 193–202. [Google Scholar] [CrossRef]

- Mattheck, C.; Burkhardt, S. A new method of structural shape optimization based on biological growth. Int. J. Fatigue 1990, 12, 185–190. [Google Scholar] [CrossRef]

- Sokolowski, J.; Zochowski, A. On Topological Derivative in Shape Optimization. Ph.D. Thesis, Technopole de Nancy-Brabois, Lorraine, France, 1997. [Google Scholar]

- Wang, M.Y.; Wang, X.; Guo, D. A level set method for structural topology optimization. Comput. Methods Appl. Mech. Eng. 2003, 192, 227–246. [Google Scholar] [CrossRef]

- Bourdin, B.; Chambolle, A. Design-dependent loads in topology optimization. ESAIM: Control. Optim. Calc. Var. 2003, 9, 19–48. [Google Scholar] [CrossRef]

- Elgin, M.C. The Application of Generative Design in Product Development. Ph.D. Thesis, Arizona State University, Phoenix, AZ, USA, 2019. [Google Scholar]

- Lévy, P.P. Beyond Kansei Engineering: The Emancipation of Kansei Design. Int. J. Des. 2013, 7, 83–94. [Google Scholar]

- Krish, S. A practical generative design method. CAD Comput. Aided Des. 2011, 43, 88–100. [Google Scholar] [CrossRef]

- Brossard, M.; Gatto, G.; Gentile, A.; Merle, T.; Wlezien, C. How Generative Design Could Reshape the Future of Product Development. Mckinsey Co. 2020. Available online: https://www.mckinsey.com/business-functions/operations/our-insights/how-generative-design-could-reshape-the-future-of-product-development (accessed on 25 March 2022).

- Lobos, A. Applying Generative Systems to Product Design. In Proceedings of the XXII Generative Art Conference—GA2019, Rome, Italy, 19–21 December 2019. [Google Scholar]

- Nordin, A. Challenges in the industrial implementation of generative design systems: An exploratory study. Artif. Intell. Eng. Des. Anal. Manuf. 2018, 32, 16–31. [Google Scholar] [CrossRef]

- Fantini, M.; De Crescenzio, F.; Brognara, L.; Baldini, N. Design and Rapid Manufacturing of a customized foot orthosis: A first methodological study. In Advances on Mechanics, Design Engineering and Manufacturing: Lecture Notes in Mechanical Engineering; Eynard, B., Nigrelli, V., Oliveri, S., Peris-Fajarnes, G., Rizzuti, S., Eds.; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Karwowski, W. Ergonomics and human factors: The paradigms for science, engineering, design, technology and management of human-compatible systems. Ergonomics 2005, 48, 436–463. [Google Scholar] [CrossRef]

- Fargnoli, M. Design for Safety and Human Factors in Industrial Engineering: A review towards a unified framework. In Proceedings of the 11th Annual International Conference on Industrial Engineering and Operations Management, Singapore, 7–11 March 2021. [Google Scholar]

- Sadeghi, L.; Dantan, J.; Siadat, A.; Marsot, J. Design for human safety in manufacturing systems: Applications of design theories, methodologies, tools and techniques. J. Eng. Des. 2016, 27, 844–877. [Google Scholar] [CrossRef] [Green Version]

- Norman, D.A. Emotional Design: Why We Love (or Hate) Everyday Things; Basic Books: New York, NY, USA, 2004. [Google Scholar]

- Desmet, P.M.A. A multilayered model of product emotions. Des. J. 2003, 6, 4–13. [Google Scholar] [CrossRef] [Green Version]

- Desmet, P.M.A.; Pohlmeyer, A.E. Positive design: An introduction to design for subjective well-being. Int. J. Des. 2013, 7, 5–19. [Google Scholar]

- Krippendorff, K. The Semantic Turn: A New Foundation for Design; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Crilly, N.; Moultrie, J.; Clarkson, P.J. Seeing things: Consumer response to the visual domain in product design. Des. Stud. 2004, 25, 547–577. [Google Scholar] [CrossRef] [Green Version]

- Oxman, N. Material-Based Design Computation; MIT Press: Cambridge, MA, USA, 2010. [Google Scholar]

- De Crescenzio, F.; Fantini, M.; Asllani, E. Generative design of 3D printed hands-free door handles for reduction of contagion risk in public buildings. Int. J. Interact. Des. Manuf. 2022, 16, 253–261. [Google Scholar] [CrossRef]

- Desmet, P.; Hekkert, P. Framework of product experience. Int. J. Des. 2007, 1, 1. [Google Scholar]

- Sansoni, S.; Wodehouse, A.; McFadyen, A.K.; Buis, A. The aesthetic appeal of prosthetic limbs and the Uncanny Valley: The role of personal characteristics in attraction. Int. J. Des. 2015, 9, 67–81. [Google Scholar]

- Wang, Y.; Tan, Q.; Pu, F.; Boone, D.; Zhang, M. A Review of the Application of Additive Manufacturing in Prosthetic and Orthotic Clinics from a Biomechanical Perspective. Engineering 2020, 6, 1258–1266. [Google Scholar] [CrossRef]

- Li, J.; Tanaka, H. Rapid customization system for 3D-printed splint using programmable modeling technique—A practical approach. 3D Print. Med. 2018, 4, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Paterson, A. Digitisation of the splinting process: Exploration and evaluation of a computer aided design approach to support additive manufacture. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2013. Available online: https://hdl.handle.net/2134/13021 (accessed on 25 March 2022).

- Mothersill, P.; Bove, V.M., Jr. The EmotiveModeler: An emotive form design CAD tool. In Proceedings of the CHI 2015: Extended Abstracts Publication of the 33rd Annual CHI Conference on Human Factors in Computing Systems, Seoul, Korea, 18–23 April 2015; ACM: New York, NY, USA, 2015; pp. 339–342. [Google Scholar] [CrossRef]

- Ulrich, K.; Eppinger, T. Product Design and Development; McGraw-Hill Inc.: New York, NY, USA, 1994. [Google Scholar]

- Ainsworth, T. Form vs. matter. In The Stanford Encyclopedia of Philosophy; Zalta, E.N., Ed.; Metaphysics Research Lab, Center for the Study of Language and Information, Stanford University: Stanford, CA, USA, 2016; Available online: https://plato.stanford.edu/archives/spr2016/entries/form-matter (accessed on 1 March 2022).

- Gero, J.S.; Kannengiesser, U. The Function-Behaviour-Structure ontology of design. In An Anthology of Theories and Models of Design; Chakrabarti, A., Blessing, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Pugh, S. Engineering design—unscrambling the research issues. J. Eng. Des. 1990, 1, 65–72. [Google Scholar] [CrossRef]

- Goldstein, M.H.; Sommer, J.; Buswell, N.T.; Li, X.; Sha, Z.; Demirel, H.O. Uncovering Generative Design Rationale in the Undergraduate Classroom. In Proceedings of the 2021 IEEE Frontiers in Education Conference (FIE), Lincoln, NE, USA, 13–16 October 2021. [Google Scholar]

| Method | Description |

|---|---|

| The process involves splitting a structure down into microscale voids and optimizing material distribution (density) based on given design constraints. The method is highly developed and notable variants include the Simplified Isotropic Material with Penalization (SIMP) and Rational Approximation of Material Properties (RAMP) approaches [16,17] |

| Finite element analysis is utilized to train optimization software in an evolutionary fashion to follow particular material distribution paths [18] |

| Applications of functional shape derivatives with respect to microscale changes in shape topology, such as adding small defects, e.g., seeding points or infinitesimal holes [19] |

| The structure under optimization is implicitly represented by a moving boundary embedded in a scalar function (known as the “level set” function) of a higher dimensionality. The method is flexible in handling complex topological change [20] |

| The method developed as a way to represent the surface dynamics of phase-transition phenomena such as solid-liquid transitions. By utilizing the approach, perimeter control can be implemented which enables optimization [21] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urquhart, L.; Wodehouse, A.; Loudon, B.; Fingland, C. The Application of Generative Algorithms in Human-Centered Product Development. Appl. Sci. 2022, 12, 3682. https://doi.org/10.3390/app12073682

Urquhart L, Wodehouse A, Loudon B, Fingland C. The Application of Generative Algorithms in Human-Centered Product Development. Applied Sciences. 2022; 12(7):3682. https://doi.org/10.3390/app12073682

Chicago/Turabian StyleUrquhart, Lewis, Andrew Wodehouse, Brian Loudon, and Craig Fingland. 2022. "The Application of Generative Algorithms in Human-Centered Product Development" Applied Sciences 12, no. 7: 3682. https://doi.org/10.3390/app12073682

APA StyleUrquhart, L., Wodehouse, A., Loudon, B., & Fingland, C. (2022). The Application of Generative Algorithms in Human-Centered Product Development. Applied Sciences, 12(7), 3682. https://doi.org/10.3390/app12073682