Design of Cognitive Assistance Systems in Manual Assembly Based on Quality Function Deployment

Abstract

:1. Introduction

2. Literature Review

2.1. Manual Assembly and Complexity

- Single workstations (work is performed at one workstation and involves specific or variations of tasks and processes);

- Continuous flow assembly systems (workpiece carrier flows from one station to the next without interruptions using assembly lines, each station being assigned to a specific task);

- Intermittent assembly (multiple workstations are assigned to specific tasks; the product moves from one station to the next in fixed cycle times) [58].

2.2. Cognitive Assistance Systems

2.3. Qualtity Function Deployment

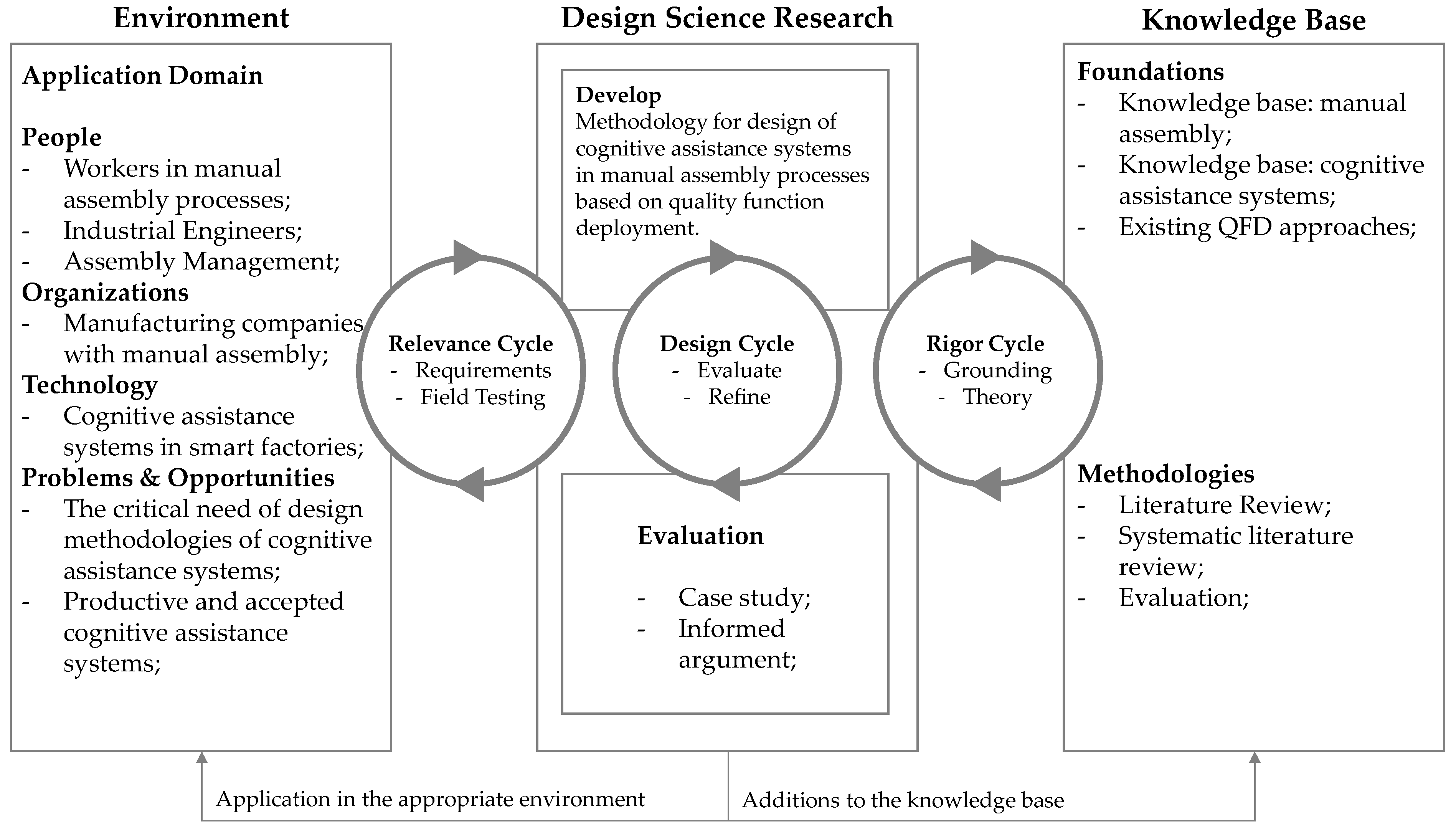

3. Foundations and Methods

- The application of QFD enables the structured documentation of requirements as well as the derivation of assistance potentials and their systematic design;

- The clear differentiation between design attributes and the systematic design of these attributes enables a structured approach by means of the QFD method.

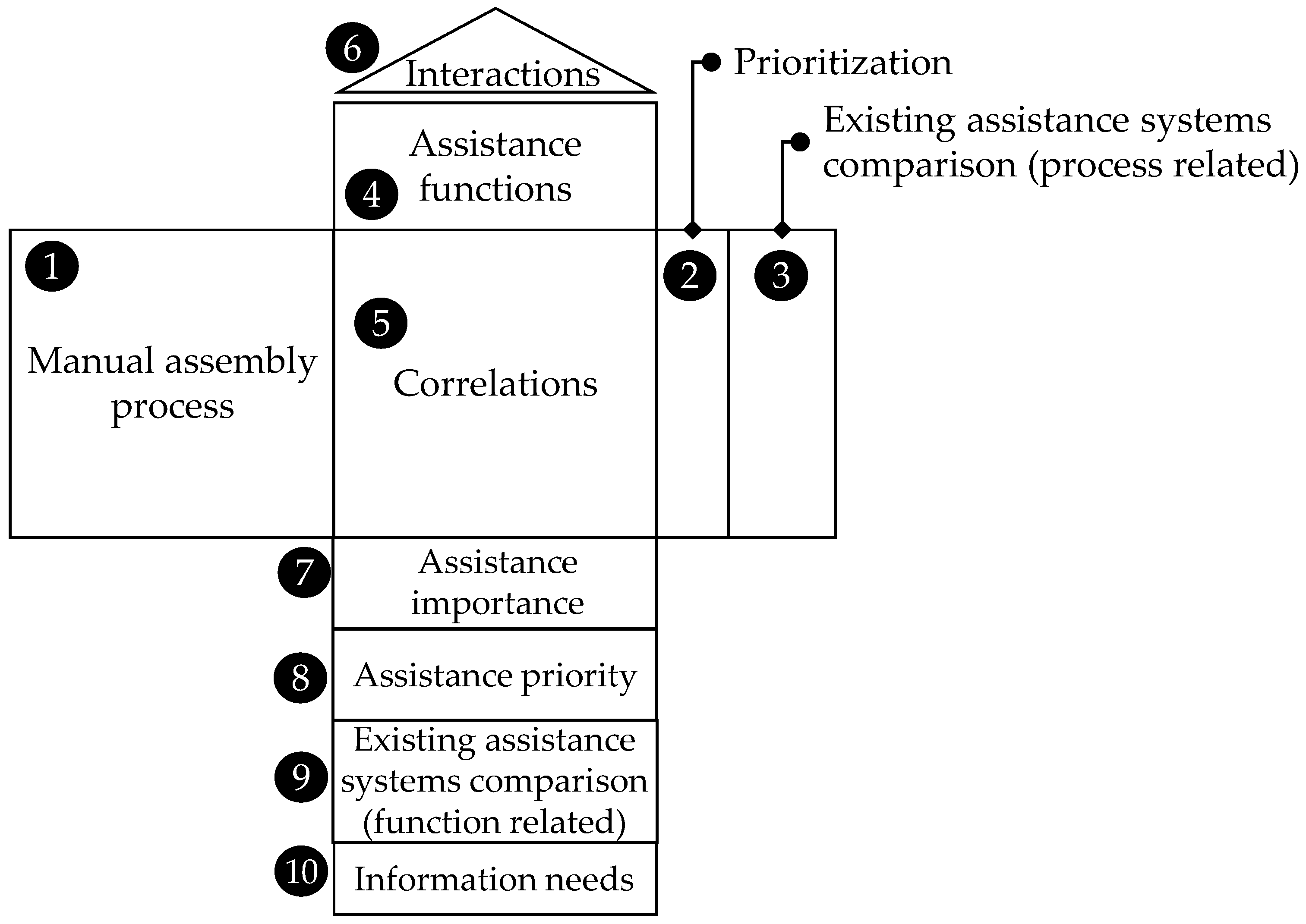

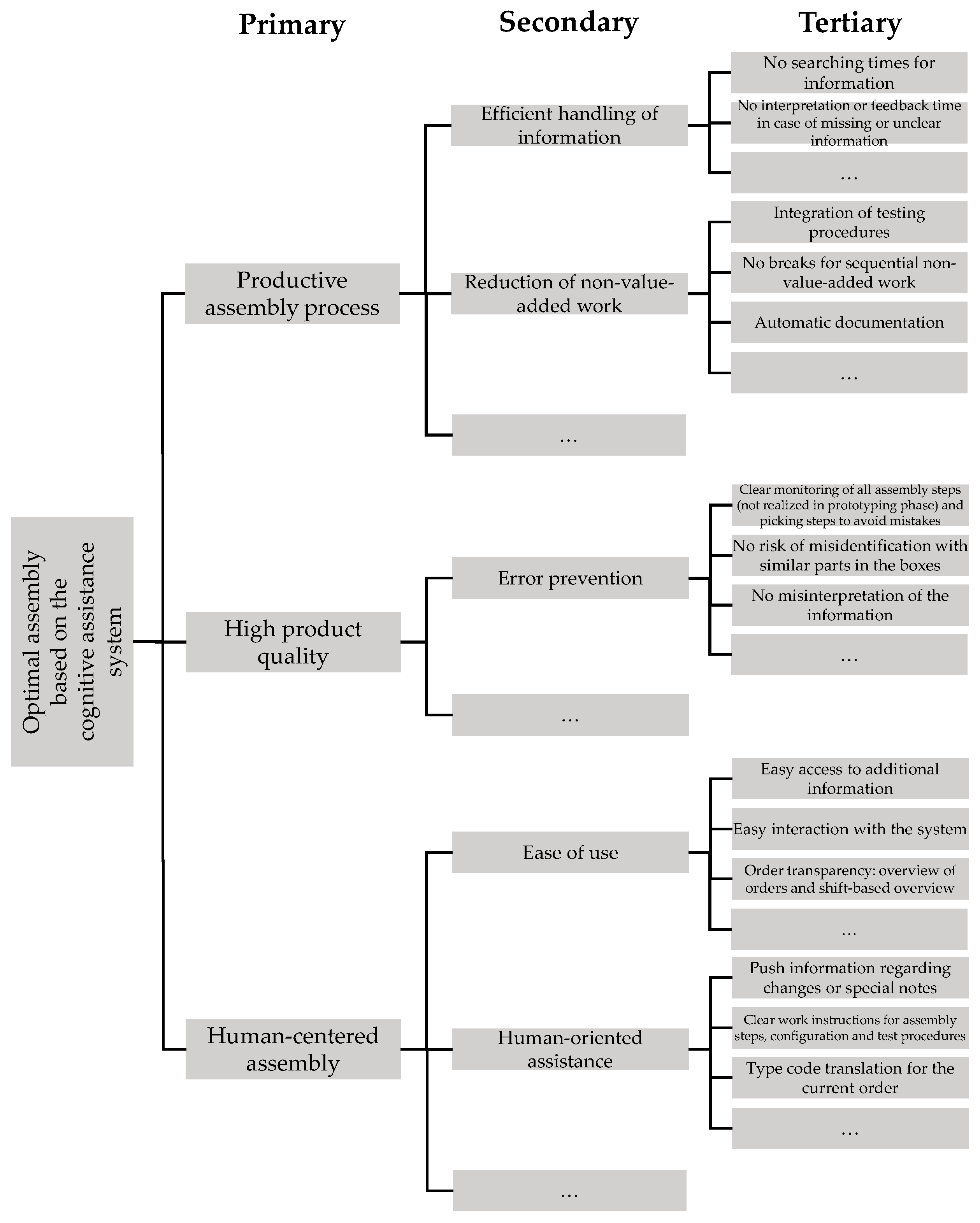

4. Conceptual Adaptation of the QFD Method

4.1. Suitability of the Method

4.2. A New Proposed Conceptual Approach: Cognitive Assistance System-QFD

4.3. Development of the Cognitive Assistance System-QFD (CAS-QFD) Method

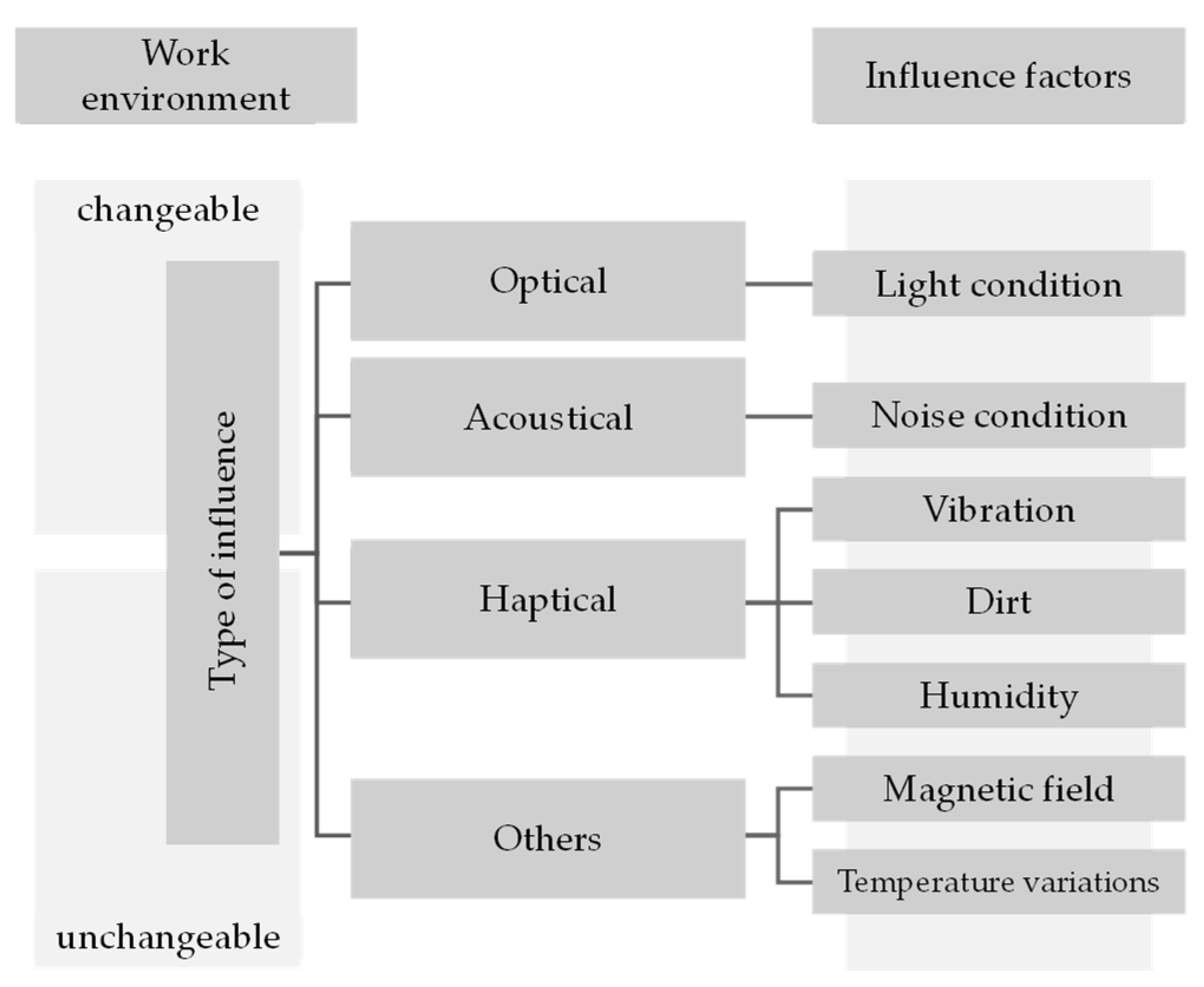

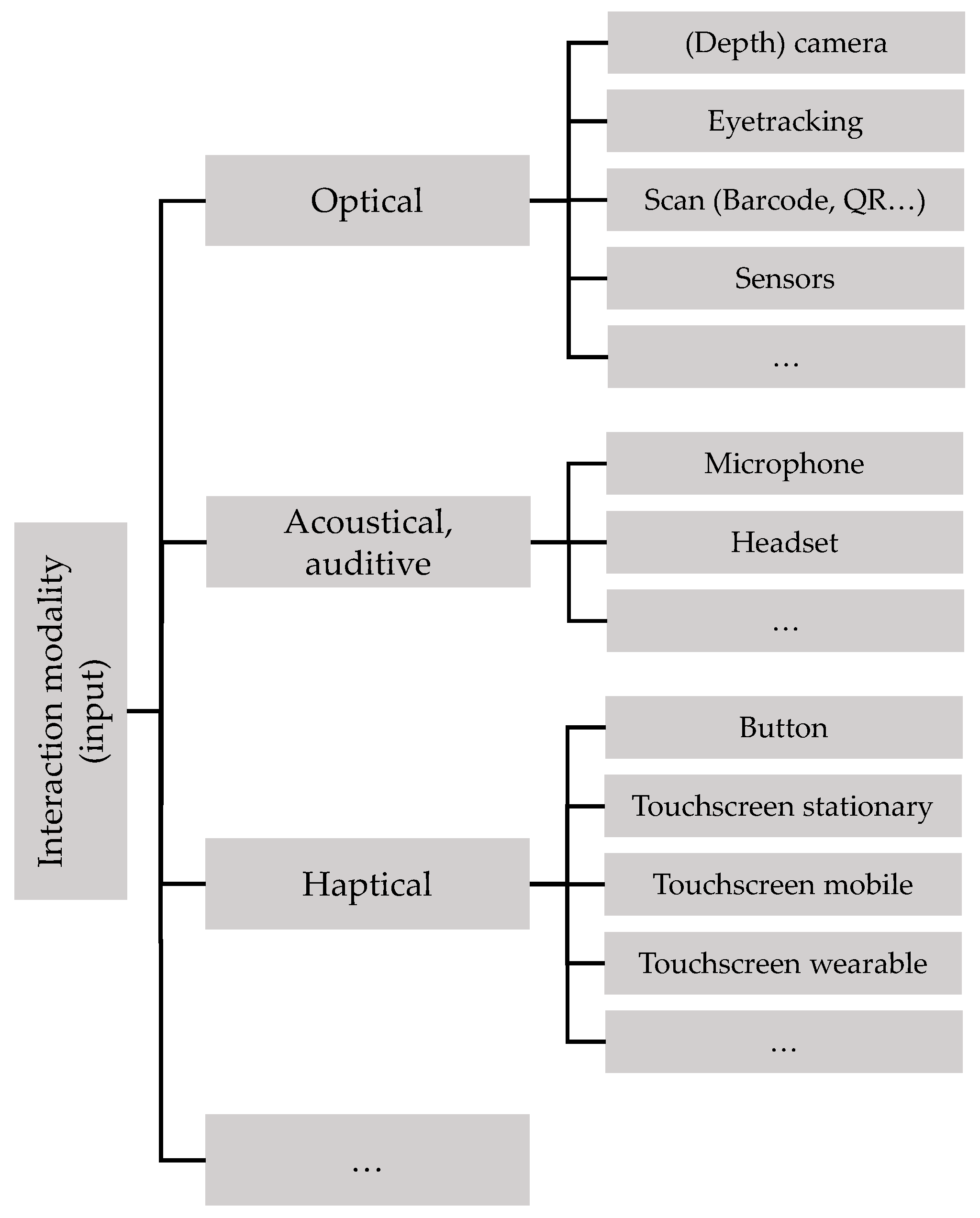

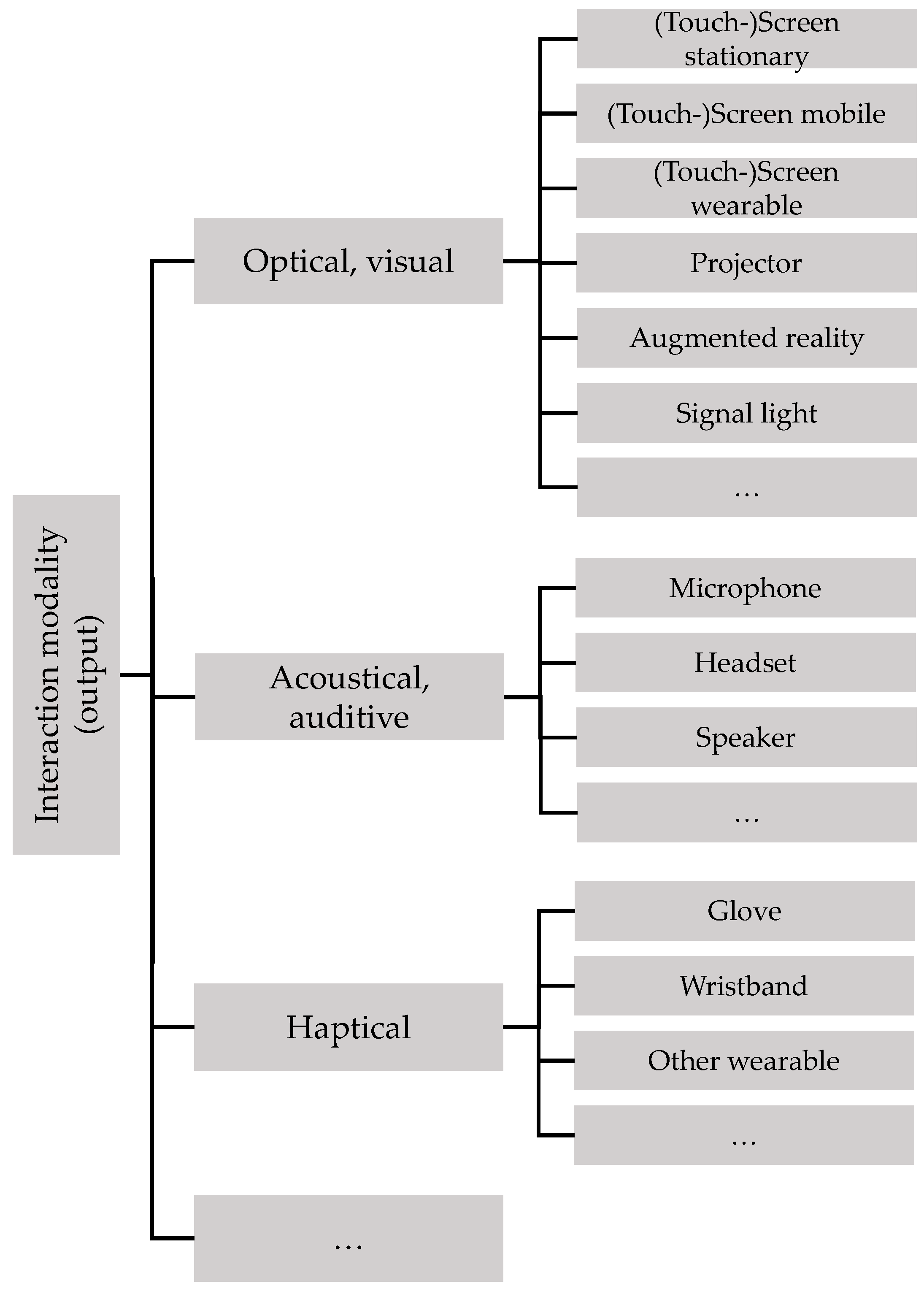

4.3.1. Analysis of the Manual Assembly Process and Identification of Requirements

4.3.2. Assistance Concept Design

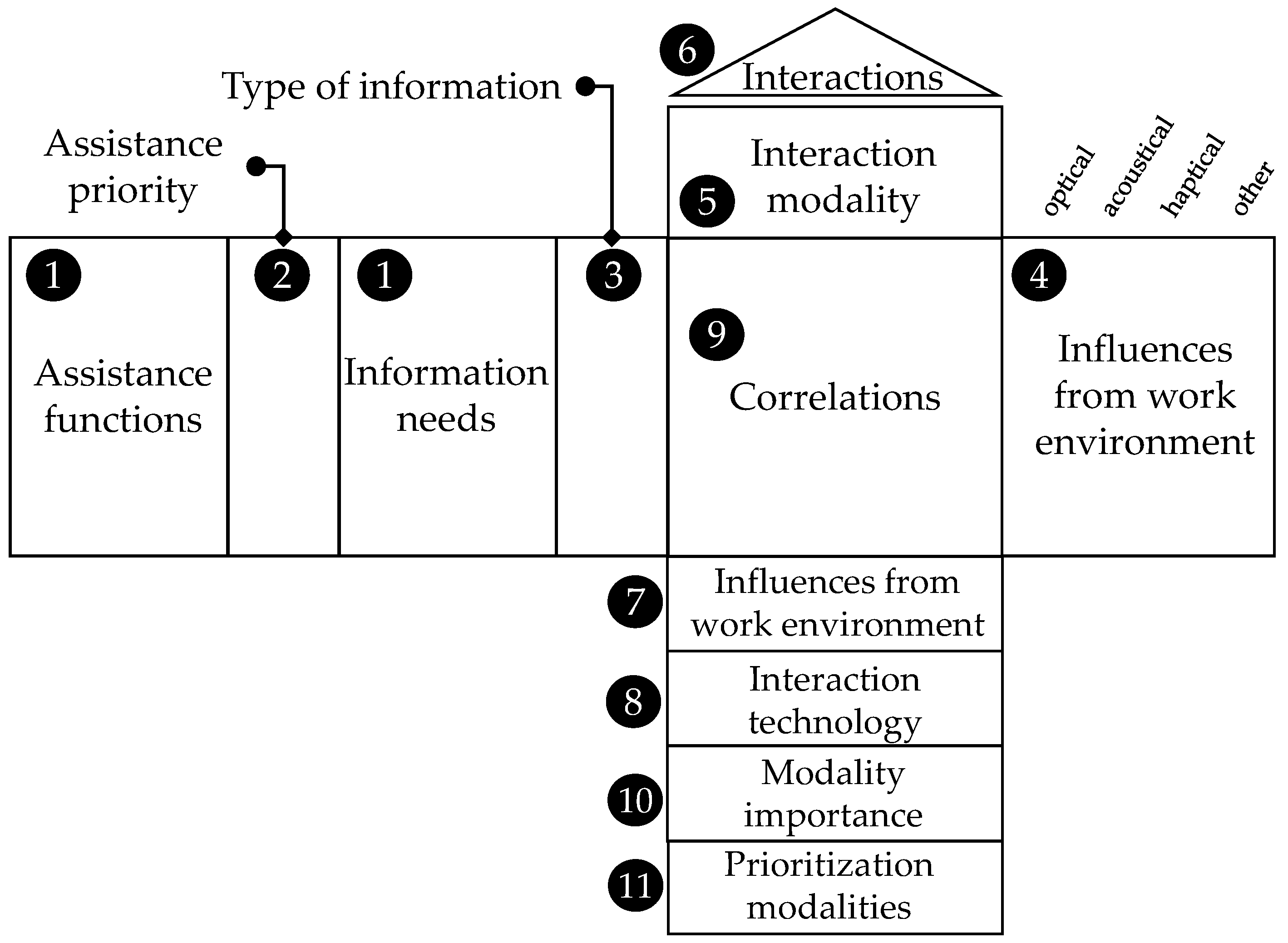

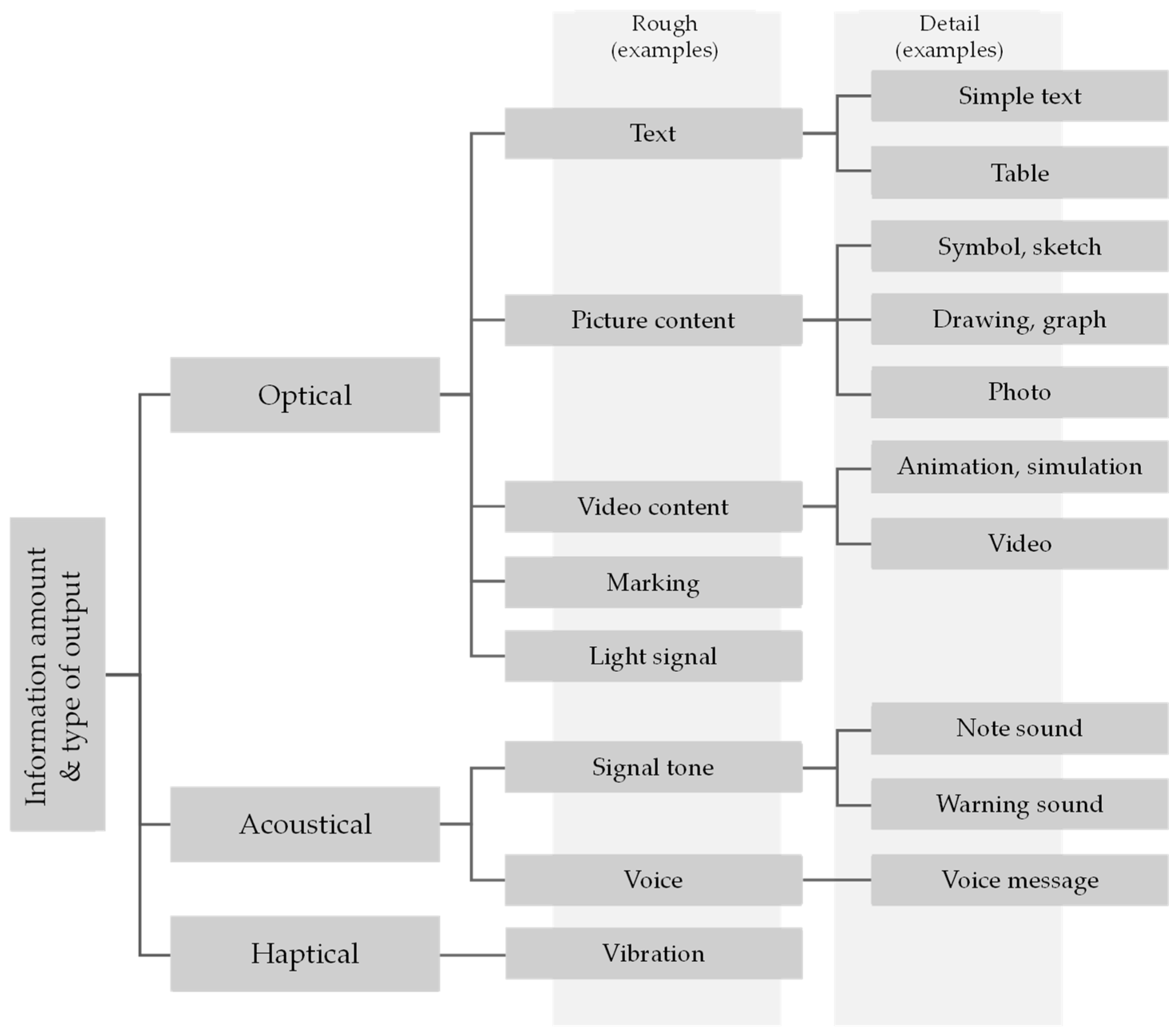

4.3.3. Assistance Detail Design

5. Results

5.1. Evaluation Method

5.2. Company Profile

5.3. Application of the CAS-QFD

5.3.1. Phase 1: Preparation

- Group 1: 70% of the assembly workers are semi-skilled workers between 26 and 52 years;

- Group 2: 30% of the assembly workers are new employees/beginners between 20 and 25 years.

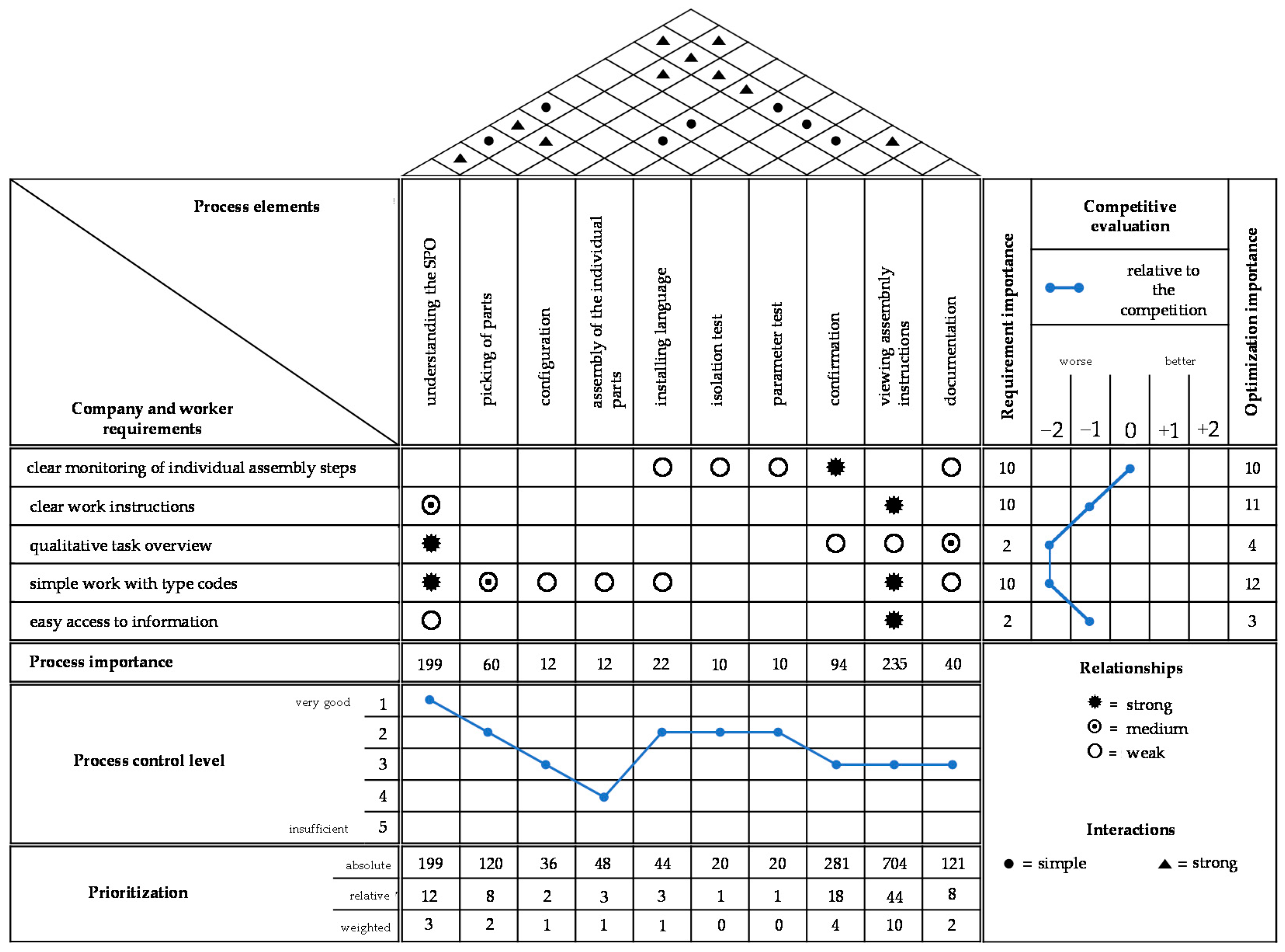

5.3.2. Phase 2: Analyzing Assembly Process

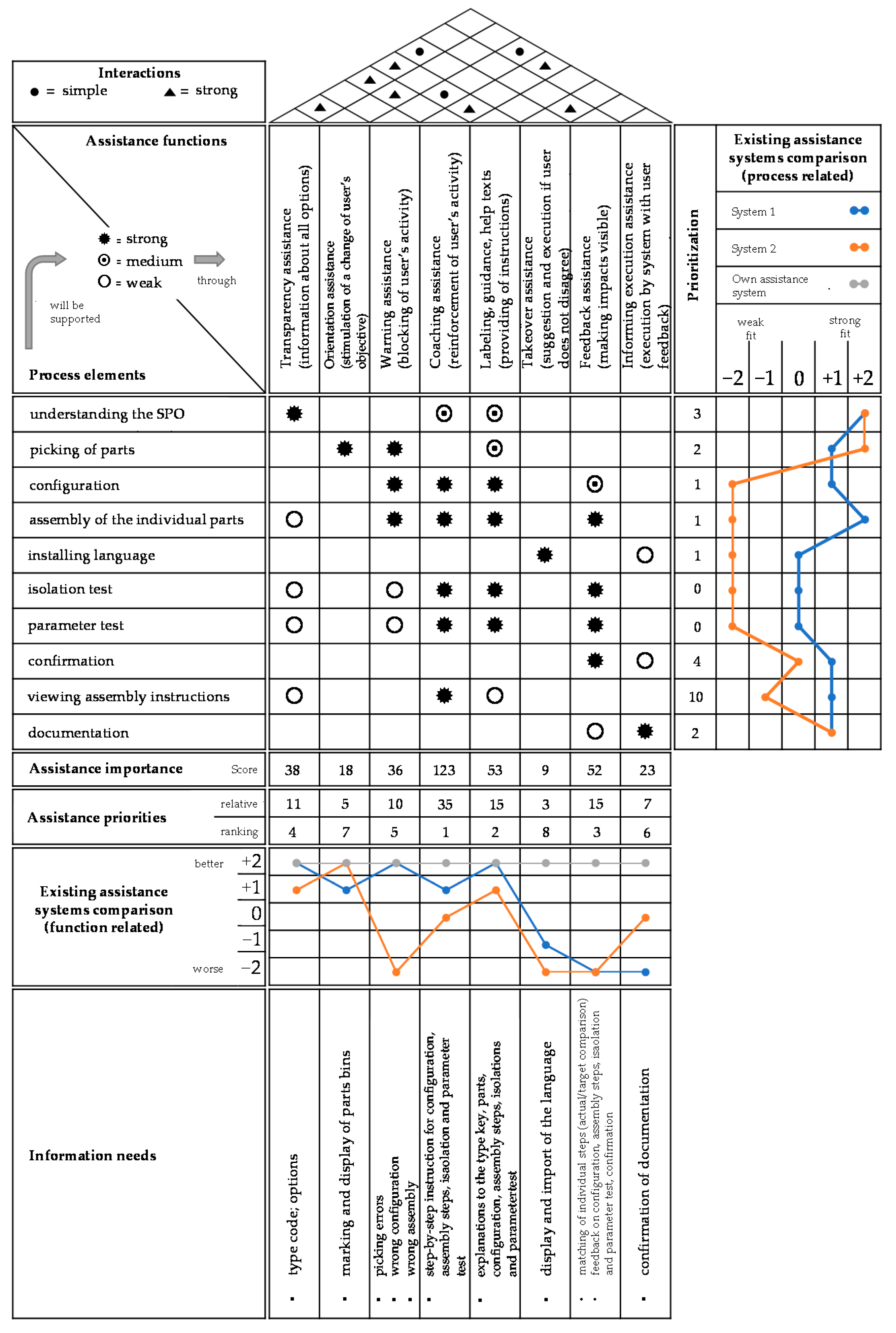

5.3.3. Phase 3: Cognitive Assistance System Concept

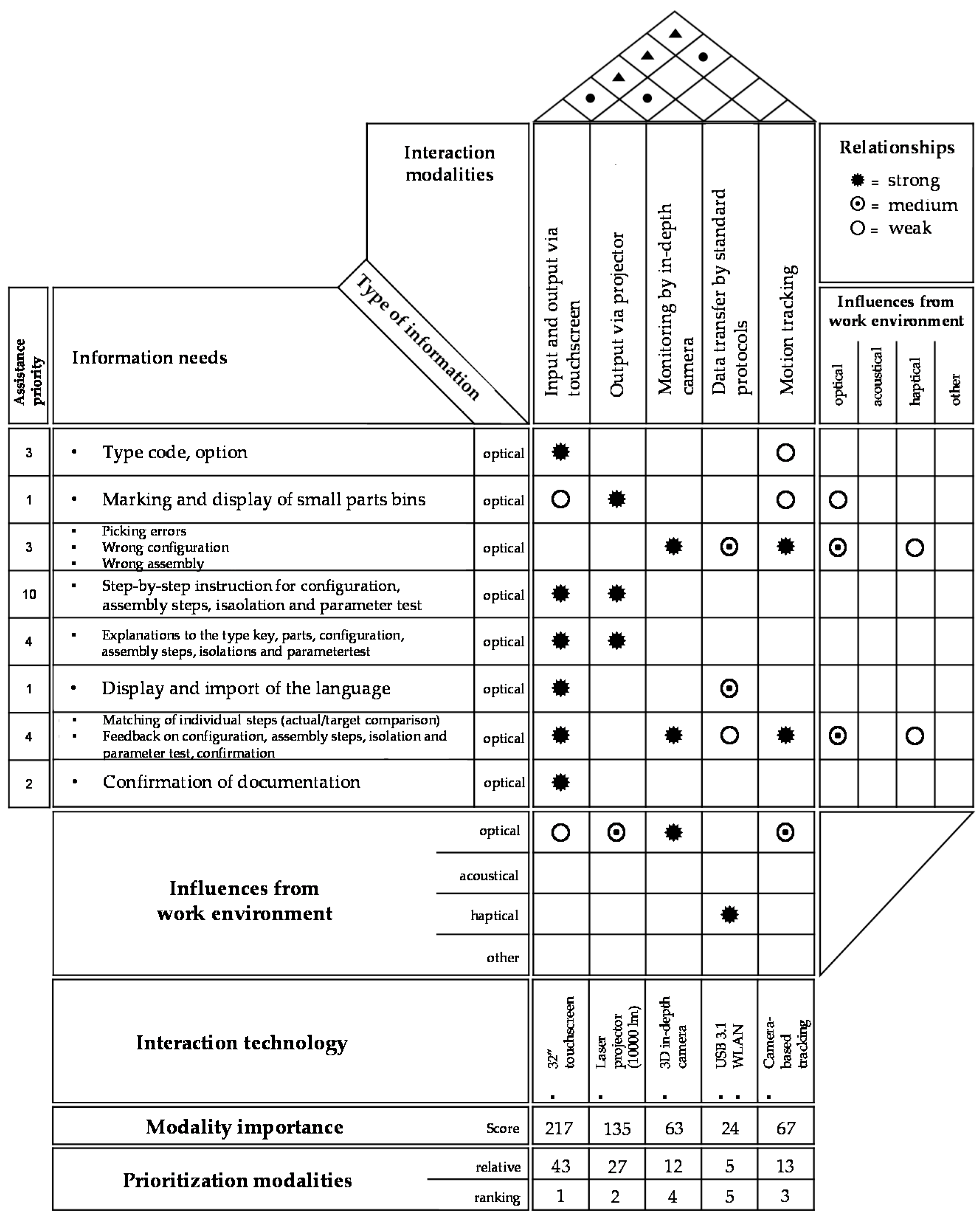

5.3.4. Phase 4: Detail Design

5.3.5. Cognitive Assistance System Planning Summary

- The assistance system is computer-based;

- Workers need to log into the assistance system;

- The orders are displayed to the worker via the touchscreen combined with the defined shipment date (priority ranking);

- The type code is processed by the system and the essential information is made available to the worker in an automated and interpreted format;

- The picking of the parts is supported by a laser projection, which lights up the required boxes for small parts;

- The correct picking (right part in the right quantity) is monitored by a camera. In case of a wrong pick, a visual warning is displayed;

- The configuration is completed according to visual instructions (pictures) via the touch screen and by verification of the settings by the system. For this purpose, the board is connected to the system via USB. If necessary, a visual warning is displayed in the event of incorrect configuration;

- The individual parts are assembled according to visual instructions via the touchscreen and by monitoring the assembly on the system side. For this purpose, the assembly steps are monitored, recorded with a depth camera and the assembly result is compared with a reference/actual comparison. If necessary, a visual warning is displayed in the event of incorrect assembly;

- Detail level of instructions could be based on the experience level of the workers;

- Changes of assembly procedures are displayed and must be confirmed by the worker;

- The isolation and parameter tests are performed according to visual instructions via the touchscreen. If necessary, a visual warning is displayed in the event of non-conformance with target values;

- Confirmation and documentation are performed automatically by the system with the camera via a reference/actual comparison. The user receives visual confirmation of each step via the touchscreen.

5.3.6. Phase 5: Prototype Realization and Testing

6. Discussion and Limitations

6.1. Discussion

6.2. Limitations

6.3. Theoretical Implications

6.4. Managerial Implications

6.5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kagermann, H. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0: Securing the Future of German Manufacturing Industry; Final Report of the Industrie 4.0 Working Group; Forschungsunion: Berlin, Germany, 2013. [Google Scholar]

- Kagermann, H. Change through Digitization—Value Creation in the Age of Industry 4.0. In Management of Permanent Change; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Ansari, F.; Seidenberg, U. A Portfolio for Optimal Collaboration of Human and Cyber Physical Production Systems in Problem-Solving. In Proceedings of the 13th International Association for Development of the Information Society (IADIS) International Conference on Cognition and Exploratory Learning in the Digital Age (CELDA), Mannheim, Germany, 28–30 October 2016. [Google Scholar]

- Birkel, H.S.; Veile, J.W.; Müller, J.M.; Hartmann, E.; Voigt, K.-I. Development of a Risk Framework for Industry 4.0 in the Context of Sustainability for Established Manufacturers. Sustainability 2019, 11, 384. [Google Scholar] [CrossRef] [Green Version]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Wagner, T.A.; Herrmann, C.; Thiede, S. Industry 4.0 Impacts on Lean Production Systems. Procedia CIRP 2017, 63, 125–131. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Vuksanović Herceg, I.; Kuč, V.; Mijušković, V.M.; Herceg, T. Challenges and Driving Forces for Industry 4.0 Implementation. Sustainability 2020, 12, 4208. [Google Scholar] [CrossRef]

- Munir, S.; Stankovic, J.A.; Liang, C.J.M.; Lin, S. Cyber Physical System Challenges for Human-in-the-Loop Control. In Proceedings of the Presented as part of the 8th International Workshop on Feedback Computing, USENIX, San Jose, CA, USA, 24–28 June 2013; Volume 4, pp. 1–4. [Google Scholar]

- Siemieniuch, C.E.; Sinclair, M.A.; Henshaw, M.J.C. Global drivers, sustainable manufacturing and systems ergonomics. Appl. Ergon. 2015, 51, 104–119. [Google Scholar] [CrossRef] [Green Version]

- Bänziger, T.; Kunz, A.; Wegener, K. Optimizing Human–Robot Task Allocation Using a Simulation Tool Based on Standardized Work Descriptions. J. Intell. Manuf. 2020, 31, 1635–1648. [Google Scholar] [CrossRef]

- Romero, D. Towards an Operator 4.0 Typology: A Human-Centric Perspective on the Fourth Industrial Revolution Technologies. In Proceedings of the CIE46, Tianjin, China, 29–31 October 2016. [Google Scholar]

- Kaasinen, E.; Schmalfuß, F.; Özturk, C.; Aromaa, S.; Boubekeur, M.; Heilala, J.; Heikkilä, P.; Kuula, T.; Liinasuo, M.; Mach, S.; et al. Empowering and engaging industrial workers with Operator 4.0 solutions. Comput. Ind. Eng. 2020, 139, 105678. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef] [Green Version]

- Neumann, W.P.; Winkelhaus, S.; Grosse, E.H.; Glock, C.H. Industry 4.0 and the human factor—A systems framework and analysis methodology for successful development. Int. J. Prod. Econ. 2021, 233, 107992. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0. Towards a Sustainable, Human-Centric and Resilient European Industry. Available online: https://op.europa.eu/en/publication-detail/-/publication/468a892a-5097-11eb-b59f-01aa75ed71a1/ (accessed on 15 January 2022).

- Reiman, A.; Kaivo-oja, J.; Parviainen, E.; Takala, E.P.; Lauraeus, T. Human factors and ergonomics in manufacturing in the industry 4.0 context—A scoping review. Technol. Soc. 2021, 65, 101572. [Google Scholar] [CrossRef]

- Fiasche, M.; Pinzone, M.; Fantini, P.; Alexandru, A.; Taisch, M. Human-Centric Factories 4.0: A Mathematical Model for Job Allocation. In Proceedings of the 2016 IEEE 2nd International Forum on Research and Technologies for Society and Industry Leveraging a Better Tomorrow, Bologna, Italy, 7–9 September 2016. [Google Scholar] [CrossRef]

- Peruzzini, M.; Pellicciari, M. A framework to design a human-centred adaptive manufacturing system for aging workers. Adv. Eng. Inform. 2017, 33, 330–349. [Google Scholar] [CrossRef]

- Hunter, S.L. Ergonomic evaluation of manufacturing system designs. J. Manufact. Syst. 2002, 20, 429–444. [Google Scholar] [CrossRef]

- Bidanda, B.; Ariyawongrat, P.; Needy, K.L.; Norman, B.A.; Tharmmaphornphilas, W. Human related issues in manufacturing cell design, implementation, and operation: A review and survey. Comput. Ind. Eng. 2005, 48, 507–523. [Google Scholar] [CrossRef]

- Syberfeldt, A.; Holm, M.; Danielsson, O.; Wang, L.; Brewster, R.L. Support systems on the industrial shop-floors of the future—Operators’ perspective on augmented reality. Procedia CIRP 2016, 44, 108–113. [Google Scholar] [CrossRef]

- Almagrabi, H.; Malibari, A.; McNaught, J. A Survey of Quality Prediction of Product Reviews. Int. J. Adv. Comput. Sci. Appl. 2015, 10, 49–58. [Google Scholar] [CrossRef] [Green Version]

- Peruzzini, M.; Grandi, F.; Pellicciari, M. Exploring the potential of Operator 4.0 interface and monitoring. Comput. Ind. Eng. 2020, 139, 105600. [Google Scholar] [CrossRef]

- Fantini, P.; Pinzone, M.; Taisch, M. Placing the operator at the centre of Industry 4.0 design: Modelling and assessing human activities within cyber-physical systems. Comput. Ind. Eng. 2018, 139, 105058. [Google Scholar] [CrossRef]

- Frigo, M.A.; da Silva, E.C.C.; Barbosa, G.F. Augmented Reality in Aerospace Manufacturing: A Review. J. Ind. Intell. Inf. 2016, 4, 125–130. [Google Scholar] [CrossRef]

- Makris, S.; Karagiannis, P.; Koukas, S.; Matthaiakis, A.S. Augmented reality system for operator support in human–robot collaborative assembly. CIRP Ann. 2016, 4, 61–64. [Google Scholar] [CrossRef]

- Nee, A.Y.; Ong, S.K. Virtual and augmented reality applications in manufacturing. IFAC Proc. Vol. 2013, 46, 15–26. [Google Scholar] [CrossRef] [Green Version]

- Matyi, H.; Veres, P.; Bányai, T.; Demin, V.; Tamás, P. Digitalization in Industry 4.0: The Role of Mobile Devices. J. Prod. Eng. 2020, 23, 75–78. [Google Scholar] [CrossRef]

- Kong, X.T.R.; Luo, H.; Huang, G.Q.; Yang, X. Industrial wearable system: The human-centric empowering technology in Industry 4.0. J. Intell. Manuf. 2018, 17, 1–17. [Google Scholar] [CrossRef]

- Chan, M.; Estève, D.; Fourniols, J.Y.; Escriba, C.; Campo, E. Smart wearable systems: Current status and future challenges. Artif. Intell. Med. 2012, 20, 137–156. [Google Scholar] [CrossRef]

- Hao, Y.; Helo, P. The role of wearable devices in meeting the needs of cloud manufacturing: A case study. Robot. Comput. Integr. Manuf. 2017, 45, 168–179. [Google Scholar] [CrossRef]

- Zhou, J.; Lee, I.; Thomas, B.; Menassa, R.; Farrant, A.; Sansome, A. In-situ support for automotive manufacturing using spatial augmented reality. Int. J. Virtual Real. 2012, 11, 33–41. [Google Scholar] [CrossRef] [Green Version]

- Simonetto, M.; Peron, M.; Fragapane, G.; Sgarbossa, F. Digital Assembly Assistance System in Industry 4.0 Era: A Case Study with Projected Augmented Reality. In Advanced Manufacturing and Automation X; IWAMA. Lecture Notes in Electrical Engineering; Wang, Y., Martinsen, K., Yu, T., Wang, K., Eds.; Springer: Singapore, 2020; Volume 737. [Google Scholar] [CrossRef]

- Mark, B.; Rauch, E.; Matt, D. Study of the impact of projection-based assistance systems for improving the learning curve in assembly processes. Procedia CIRP 2020, 88, 98–103. [Google Scholar] [CrossRef]

- Sorostinean, R.; Gellert, A.; Pirvu, B.-C. Assembly Assistance System with Decision Trees and Ensemble Learning. Sensors 2021, 21, 3580. [Google Scholar] [CrossRef]

- Gellert, A.; Sorostinean, R.; Pirvu, B.-C. Robust Assembly Assistance Using Informed Tree Search with Markov Chains. Sensors 2022, 22, 495. [Google Scholar] [CrossRef]

- Precup, S.-A.; Gellert, A.; Matei, A.; Gita, M.; Zamfirescu, C.-B. Towards an Assembly Support System with Dynamic Bayesian Network. Appl. Sci. 2022, 12, 985. [Google Scholar] [CrossRef]

- Ruppert, T.; Jaskó, S.; Holczinger, T.; Abonyi, J. Enabling Technologies for Operator 4.0: A Survey. Appl. Sci. 2018, 8, 1650. [Google Scholar] [CrossRef] [Green Version]

- Aljinović, A.; Gjeldum, N.; Bilić, B.; Mladineo, M. Optimization of Industry 4.0 Implementation Selection Process towards Enhance-ment of a Manual Assembly Line. Energies 2022, 15, 30. [Google Scholar] [CrossRef]

- Chu, C.-H.; Liao, C.-J.; Lin, S.-C. Comparing Augmented Reality-Assisted Assembly Functions—A Case Study on Dougong Structure. Appl. Sci. 2020, 10, 3383. [Google Scholar] [CrossRef]

- Kolla, S.; Sanchez, A.; Plapper, P. Comparing Effectiveness of Paper Based and Augmented Reality Instructions for Manual Assembly and Training Tasks. In Proceedings of the Conference on Learning Factories (CLF), Graz, Austria, 1–2 July 2021. [Google Scholar]

- Vernim, S.; Reinhart, G. Usage Frequency and User-Friendliness of Mobile Devices in Assembly. Procedia CIRP 2016, 57, 510–515. [Google Scholar] [CrossRef]

- Funk, M.; Kosch, T.; Greenwald, S.; Schmidt, A. A benchmark for interactive augmented reality instructions for assembly tasks. In Proceedings of the 14th International Conference on Mobile and Ubiquitous Multimedia (MUM’15). Association for Computing Machinery, New York, NY, USA, 30 November–2 December 2015; pp. 253–257. [Google Scholar] [CrossRef]

- Fletcher, S.R.; Johnson, T.L.; Adlon, T. Adaptive automation assembly: Identifying system requirements for technical efficiency and worker satisfaction. Comput. Ind. Eng. 2020, 139, 105772. [Google Scholar] [CrossRef]

- Pimminger, S.; Kurschl, W.; Panholzer, L.; Schönböck, J. Exploring the Learnability of Assembly Tasks Using Digital Work Instructions in a Smart Factory. Procedia CIRP 2021, 104, 696–701. [Google Scholar] [CrossRef]

- Jenderny, S.; Foullois, M.; Kato-Beiderwieden, A.-L.; Bansmann, M.; Wöste, L.; Lamß, J.; Maier, G.W.; Röcker, C. Development of an instrument for the assessment of scenarios of work 4.0 based on socio-technical criteria. In Proceedings of the 11th PErvasive Technologies Related to Assistive Environments Conference on–PETRA’18, Corfu, Greece, 26–29 June 2018; ACM Press: New York, NY, USA, 2018; pp. 319–326. [Google Scholar]

- Bauer, W.; Klapper, J. A development scenario of the work area “intralogistics” under the influence of industry 4.0 technologies and its evaluation on the basis of a Delphi study. In Proceedings of the 20th Congress of the International Ergonomics Association (IEA 2018), Florence, Italy, 26–30 August 2018; Springer: Cham, Switzerland, 2019; Volume 825, pp. 812–821. [Google Scholar] [CrossRef]

- Werrlich, S.; Nitsche, K.; Notni, G. Demand Analysis for an Augmented Reality based Assembly Training. In Proceedings of the 10th International Conference on Pervasive Technologies Related to Assistive Environments (PETRA’17). Association for Computing Machinery, New York, NY, USA, 21–23 June 2017; pp. 416–422. [Google Scholar] [CrossRef]

- Hermawati, S.; Lawson, G. User-centred design of virtual training for automotive industries. In Proceedings of the International Conference on Ergonomics & Human Factors 2013, Cambridge, UK, 15–18 April 2013; pp. 267–274. [Google Scholar]

- Stockinger, C.; Stuke, F.; Subtil, I. User-centered development of a worker guidance system for a flexible production line. Hum. Factors Ergon. Manuf. Serv. Ind. 2021, 31, 532–545. [Google Scholar] [CrossRef]

- Müller, R.; Kessler, F.; Humphrey, D.W.; Rahm, J. Data in Context: How Digital Transformation Can Support Human Reasoning in Cyber-Physical Production Systems. Future Internet 2021, 13, 156. [Google Scholar] [CrossRef]

- Chatti, S.; Laperrière, L.; Reinhart, G.; Tolio, T. CIRP Encyclopedia of Production Engineering; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 978-3-642-35950-7. [Google Scholar]

- Lotter, B.; Wiendahl, H.-P. Changeable and Reconfigurable Assembly Systems. In Changeable and Reconfigurable Manufacturing Systems; El Maraghy, H.A., Ed.; Springer: London, UK, 2009; pp. 127–142. [Google Scholar]

- Heilala, J.; Voho, P. Modular reconfigurable flexible final assembly system. Assem. Autom. 2001, 21, 20–30. [Google Scholar] [CrossRef]

- Gorlach, I.; Wessel, O. Optimal Level of Automation in the Automotive Industry. Eng. Lett. 2008, 16, 141–149. [Google Scholar]

- Yoshimura, M.; Yoshida, S.; KonishI, K.; Izui, S.; Nishiwaki, Y.; Inamori, A.; Nomura, K.; Mitsuyuki, Y.; Kawaguchi, Y.; Inagaki, T. A rapid analysis method for production line design. Int. J. Product. Res. 2006, 44, 1171–1192. [Google Scholar] [CrossRef]

- Swift, K.G.; Booker, J.D. Chapter 10—Assembly Systems. In Manufacturing Process Selection Handbook; Swift, K.G., Booker, J.D., Eds.; Butterworth-Heinemann: Oxford, UK, 2013; pp. 281–289. [Google Scholar]

- Schleich, H.; Schaffer, L.; Scavarda, F. Managing complexity in automotive production. In Proceedings of the 19th international Conference on Production Research, Valparaiso, Chile, 29 July–2 August 2007. [Google Scholar]

- Matondang, M.Z.; Jambak, M.I. Soft computing in optimizing assembly lines balancing. J. Comput. Sci. 2010, 6, 141–162. [Google Scholar] [CrossRef] [Green Version]

- Urbanic, R.J.; El Maraghy, H.A. Modeling of Manufacturing Process Complexity. In Springer Series in Advanced Manufacturing; Springer: London, UK, 2006; pp. 425–436. [Google Scholar] [CrossRef]

- Doerr, K.H.; Arreola-Risa, A. A worker-based approach for modeling variability in task completion times. IIE Trans. 2007, 32, 625–636. [Google Scholar] [CrossRef]

- Gullander, P.; Davidsson, A.; Dencker, K.; Fasth, Å.; Fässberg, T.; Harlin, U.; Stahre, J. Towards a production complexity model that supports operation, re-balancing and man-hour planning. In Proceedings of the 4th Swedish Production Symposium (SPS), Lund, Sweden, 3–5 May 2011. [Google Scholar]

- Fast-Berglund, Å.; Fässberg, T.; Hellman, F.; Davidsson, A.; Stahre, J. Relations between complexity, quality and cognitive automation in mixed-model assembly. J. Manuf. Syst. 2013, 32, 449–455. [Google Scholar] [CrossRef] [Green Version]

- Bol, L.; Hacker, D.J.; Mattarella-Micke, A.; Beilock, S.L.; Seel, N.M.; Rosenstand, C.A.F.; Ell, S. Cognitive Tasks and Learning. Encyclopedia of the Sciences of Learning; Springer Science & Business Media: Boston, MA, USA, 2012; pp. 619–622. [Google Scholar] [CrossRef]

- Rasmussen, J.; Pejtersen, A.M.; Schmidt, K. Taxonomy for Cognitive Work Analysis; Grafisk Service: Roskilde, Denmark, 1990. [Google Scholar]

- Kahneman, D. A perspective on judgment and choice: Mapping bounded rationality. Am. Psychol. 2003, 58, 697–720. [Google Scholar] [CrossRef] [Green Version]

- Endsley, M.R. Toward a theory of situation awareness in dynamic systems. Hum. Factors J. 1995, 37, 32–64. [Google Scholar] [CrossRef]

- Wickens, C.D.; Hollands, J.G. Engineering Psychology and Human Performance, 5th ed.; Prentice-Hall Inc.: Upper Saddle River, NJ, USA, 2000. [Google Scholar]

- Yang, X.; Plewe, D.A. Assistance Systems in Manufacturing: A Systematic Review. In Advances in Ergonomics of Manufacturing: Managing the Enterprise of the Future, Proceedings of the AHFE 2016 International Conference on Human Aspects of Advanced Manufacturing, Orlando, FL, USA, 27–31 July 2016; Schlick, C., Trzcielinski, S., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 279–289. [Google Scholar]

- Li, D.; Fast-Berglund, Å.; Salunkhe, O.; Fast-Berglund, Å.; Skoogh, A.; Broberg, J. Effects of Information Content in Work Instructions for Operator Performance. Procedia Manuf. 2018, 25, 628–635. [Google Scholar] [CrossRef]

- Longo, F.; Nicoletti, L.; Padovano, A. Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Comput. Ind. Eng. 2017, 113, 144–159. [Google Scholar] [CrossRef]

- Bellgran, M.; Säfsten, K. Production Development—Design and Operation of Production Systems, 1st ed.; Springer: London, UK, 2010. [Google Scholar]

- Lusic, M.; Fischer, C.; Bonig, J.; Hornfeck, R.; Franke, J. Worker information systems: State of the art and guideline for selection under consideration of company specific boundary conditions. Procedia CIRP 2016, 44, 1113–1118. [Google Scholar] [CrossRef] [Green Version]

- Rainer, R.K.; Cegielski, C.G. Introduction to Information Systems; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Teubner, S.; Rimpau, C.; Reinhart, G. Approaching Dynamic and Individual Worker Information Systems. Procedia CIRP 2020, 93, 795–801. [Google Scholar] [CrossRef]

- Stair, R.M.; Reynolds, G.W. Fundamentals of Information Systems. A Managerial Approach; Thomson Course Technology: Boston, MA, USA, 2010. [Google Scholar]

- Hinrichsen, S.; Bornewasser, M. How to Design Assembly Assistance Systems. In Intelligent Human Systems Integration 2019; Springer: San Diego, CA, USA, 2019; pp. 286–292. [Google Scholar] [CrossRef]

- Schlick, C.; Ziefle, M.; Park, M.; Luczak, H. Visual Displays. In The Human-Computer Interaction Handbook: Fundamentals, Evolving Technologies, and Emerging Applications, 2nd ed.; Sears, A., Jacko, J.A., Eds.; Lawrence Erlbaum Associates: New York, NY, USA, 2008; pp. 201–229. [Google Scholar]

- Schmidt, A.; Gellersen, H.; Beigl, M.; Thate, O. Developing user interfaces for wearable computers: Don’t stop to point and click. In International Workshop on Interactive Applications of Mobile Computing (IMC2000); University of Karlsruhe: Karlsruhe, Germany, 2000. [Google Scholar]

- Mourtzis, D.; Zogopoulos, V. Augmented reality application to support the assembly of highly customized products and to adapt to production re-scheduling. Int. J. Adv. Manuf. Technol. 2019, 105, 1–12. [Google Scholar] [CrossRef]

- Frohm, J.; Lindström, V.; Winroth, M.; Stahre, J. Levels of Automation in Manufacturing. Int. J. Ergon. Hum. Factors 2008, 30, 181–207. Available online: https://core.ac.uk/download/pdf/70575908.pdf (accessed on 12 February 2022).

- Akao, Y. Quality Function Deployment: Integration Customer Requirements into Product Design; Mazur, G.H., Ed.; Productivity Press: Cambridge, MA, USA, 1990. [Google Scholar]

- Cristiano, J.J.; Liker, J.K.; White, C.C., III. Key factors in the successful application of quality function deployment. IEEE Trans. Eng. Manag. 2001, 48, 81–95. [Google Scholar] [CrossRef]

- Sorli, M.; Stokic, D. Innovating in Product/Process Development: Gaining Pace in New Product Development; Springer: London, UK; New York, NY, USA, 2009. [Google Scholar]

- Cohen, L. Quality Function Deployment: How to Make QFD Work for You; Addison-Wesley: Boston, MA, USA, 1995. [Google Scholar]

- Terninko, J. Step-by-Step QFD: Customer-Driven Product Design, 2nd ed.; Routledge: New York, NY, USA, 1997. [Google Scholar]

- Clausing, D.P. Total Quality Development: A Step by Step Guide to World-Class Concurrent Engineering; ASME Press: New York, NY, USA, 1994. [Google Scholar]

- Erdil, N.O.; Arani, O.M. Quality function deployment: More than a design tool. Int. J. Qual. Serv. Sci. 2018, 11, 142–166. [Google Scholar] [CrossRef]

- Delgado-Hernandez, D.J.; Bampton, K.E.; Aspinwall, E. Quality function deployment in construction. Constr. Manag. Econ. 2007, 25, 597–609. [Google Scholar] [CrossRef]

- Raharjo, H.; Brombacher, A.C.; Xie, M. Dealing with Subjectivity in Early Product Design Phase: A Systematic Approach to Exploit Quality Function Deployment Potentials. Comput. Ind. Eng. 2008, 55, 253–278. [Google Scholar] [CrossRef]

- Chan, L.K.; Wu, M.-L. Quality function deployment: A literature review. Eur. J. Oper. Res. 2002, 143, 463–497. [Google Scholar] [CrossRef]

- Sivasamy, K.; Arumugam, C.; Devadasan, S.R.; Murugesh, R.; Thilak, V.M.M. Advanced models of quality function deployment: A literature review. Qual. Quant. 2016, 50, 1399–1414. [Google Scholar] [CrossRef]

- Mochamad, S.; Ismoyo, R.; Agung, F.P.; Sarjana, P.; Manajemen, M.; Mercubana, M.; Selatan, J.M. Employee Expectation Analysis using Quality Function Deployment Method. Int. J. Innov. Sci. Res. Technol. 2018, 3, 228–237. [Google Scholar]

- Hernández-Rangel, F.J.; Saavedra-Leos, M.Z.; Morales-Morales, J.; Bautista-Santos, H.; Reyes-Herrera, V.A.; Rodríguez-Lelis, J.M.; Cruz-Alcantar, P. Continuous Improvement Process in the Development of a Low-Cost Rotational Rheometer. Processes 2020, 8, 935. [Google Scholar] [CrossRef]

- Crowe, T.J.; Cheng, C. Using quality function deployment in manufacturing strategic planning. Int. J. Oper. Prod. Manag. 1996, 16, 35–48. [Google Scholar] [CrossRef]

- Olewnik, A.; Lewis, K. Limitations of the House of Quality to provide quantitative design information. Int. Qual. Reliab. Manag. 2008, 25, 125–146. [Google Scholar] [CrossRef] [Green Version]

- Hevner, A.R.; March, S.T.; Park, J.; Ram, S. Design Science in Information Systems Research. Manag. Inf. Syst. Q. 2004, 28, 6. [Google Scholar] [CrossRef] [Green Version]

- Peffers, K.; Tuunanen, T.; Rothenberger, M.A.; Chatterjee, S. A Design Science Research Methodology for Information Systems Research. J. Manag. Inf. Syst. 2007, 24, 45–77. [Google Scholar] [CrossRef]

- Åkerman, M. Implementing Shop Floor IT for Industry 4.0; Chalmers Tekniska Högskola: Gothenburg, Sweden, 2018. [Google Scholar]

- March, S.T.; Smith, G.F. Design and natural science research on information technology. Decis. Support Syst. 1995, 15, 251–266. [Google Scholar] [CrossRef]

- Rahman Abdul Rahim, A.; Shariff Nabi Baksh, M. Application of quality function deployment (QFD) method for pultrusion machine design planning. Ind. Manag. Data Syst. 2003, 103, 373–387. [Google Scholar] [CrossRef]

- Eringa, K.; Boer, I.L.J. Integrating Quality Function Deployment and Service Blueprinting. In Proceedings of the Tenth Symposium on Quality Function Deployment, Novi, MI, USA, 14–16 June 1998; pp. 289–304. [Google Scholar]

- Ekdahl, F.; Gustafsson, A.; Norling, P. QFD for Service Development—A Case Study from Telia Mobitel. In Proceedings of the Third Annual International QFD Symposium, Linköping, Sweden, 1–2 October 1997; pp. 189–207. [Google Scholar]

- Kaneko, N. QFD Implementation in Hotel Service. In Proceedings of the Fifth Annual International QFD Symposium, Belo Horizonte, Brazil, 24–25 August 1999; pp. 119–136. [Google Scholar]

- Herzwurm, G.; Schockert, S.; Mellis, W. Higher customer satisfaction with prioritizing and focused software quality function deployment. In Proceedings of the Sixth European Conference on Software Quality, Vienna, Austria, 12–16 April 1999. [Google Scholar]

- Karlsson, J. Managing software requirements using quality function deployment. Software Qual. J. 1997, 6, 311–326. [Google Scholar] [CrossRef]

- Herzwurm, G.; Schockert, S. The leading edge in QFD for software and electronic business. Int. Qual. Reliab. Manag. 2003, 20, 36–55. [Google Scholar] [CrossRef] [Green Version]

- Pokorni, B. Human-Centered Design of Digital Assistance Systems in Smart Factories Based on Quality Function Deployment. In Proceedings of the AHFE 2021 Virtual Conference on Human Factors and Systems Interaction, New York, NY, USA, 25–29 July 2021; pp. 155–161. [Google Scholar]

- Fasth, Å.; Stahre, J.; Dencker, K. Measuring and analyzing Levels of Automation in an assembly system. In Proceedings of the 41st CIRP International Conference on Manufacturing Systems (ICMS), Tokyo, Japan, 26–28 May 2008. [Google Scholar]

- Hinrichsen, S.; Riedieger, D.; Unrau, A. Assistance Systems in Manual Assembly. In Proceedings of the 6th International conference on Production Engineering and Management, Villmer Lemgo, Germany, 29 September 2016; pp. 3–14. [Google Scholar]

- Kovacs, K.; Ansari, F.; Geisert, C.; Uhlmann, E.; Glawar, R.; Sihn, W. A Process Model for Enhancing Digital Assistance in Knowledge-Based Maintenance. In Technologien Für Die Intelligente Automation; Springer: Lemgo, Germany, 2018; pp. 87–96. [Google Scholar] [CrossRef] [Green Version]

- Keller, T.; Bayer, C.; Bausch, P.; Metternich, J. Benefit evaluation of digital assistance systems for assembly workstations. Procedia CIRP 2016, 81, 441–446. [Google Scholar] [CrossRef]

- Augstein, M.; Neumayr, T. A Human-Centered Taxonomy of Interaction Modalities and Devices. Interact. Comput. 2019, 31, 27–58. [Google Scholar] [CrossRef]

- Ginn, D.; Zairi, M. Best practice QFD application: An internal/external benchmarking approach based on Ford Motors’ experience. Int. J. Qual. Reliab. Manag. 2005, 1, 256–275. [Google Scholar] [CrossRef]

- Bouchereau, V.; Rowlands, H. Quality function deployment: The unused tool. Eng. Manag. J. 2000, 10, 45–52. [Google Scholar] [CrossRef]

- Howell, D. Making wishes come true. Prof. Eng. 2000, 13, 39. [Google Scholar]

- Zairi, M. Quality function deployment—A main pillar for successful total quality management and product development. Int. J. Qual. Reliab. Manag. 2000, 12, 9–23. [Google Scholar] [CrossRef]

- Papic, L. Deployment Customer Requirements via Four-Stage Team Approach in Business Planning. Int. J. Reliab. Qual. Saf. Eng. 2007, 14, 263–274. [Google Scholar] [CrossRef]

- Franceschini, F.; Rossetto, S. QFD: The Problem of Comparing Technical/Engineering Design Requirements. Res. Eng. Des. 1995, 7, 270–278. [Google Scholar] [CrossRef]

- Kazemzadeh, R.B.; Behzadian, M.; Aghdasi, M.; Albadvi, A. Integration of Marketing Research Techniques into House of Quality and Product Family Design. Int. J. Adv. Manuf. Technol. 2009, 41, 1019–1033. [Google Scholar] [CrossRef]

- Van de Poel, I. Methodological Problems in QFD and Directions for Future Development. Res. Eng. Des. 2007, 18, 21–36. [Google Scholar] [CrossRef] [Green Version]

- Dahlgaard, J.; Kanji, G. Break down barriers between departments, Advances in Total Quality Management. Taylor Fr. 1995, 5, 81–89. [Google Scholar]

- Bødker, K.; Kensing, F.; Simonsen, J. Participatory IT Design: Designing for Business and Workplace Realities; MIT Press: Cambridge, MA, USA, 1987. [Google Scholar]

- Buur, J.; Larsen, H. Crossing intentions in participatory innovation. In Proceedings of the 11th Biennial Participatory Design Conference on—PDC’10, Sydney, Australia, 29 November–3 December 2010; Robertson, T., Bødker, K., Bratteteig, T., Loi, D., Eds.; ACM Press: New York, NY, USA; p. 251. [Google Scholar]

- Buur, J.; Matthews, B. Participatory Innovation. Int. J. Innov. Manag. 2008, 12, 255–273. [Google Scholar] [CrossRef]

- Muller, M.J.; Kuhn, S. Participatory design. Commun. ACM 1993, 36, 24–28. [Google Scholar] [CrossRef]

- Ho, W.; Bennett, D.J.; Mak, K.L.; Chuah, K.B.; Lee, C.K.M.; Hall, M. Strategic Logistics Outsourcing: An Integrated QFD and AHP Approach. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management (IEEM 2009), Singapore, 8–11 December 2009. [Google Scholar]

- Askin, R.G.; Dawson, D.W. Maximizing Customer Satisfaction by Optimal Specification of Engineering Characteristics. IIE Trans. 2010, 32, 9–20. [Google Scholar] [CrossRef]

- Park, T.; Kim, K.J. Determination of an Optimal Set of Design Requirements Using House of Quality. J. Oper. Manag. 1998, 16, 569–581. [Google Scholar] [CrossRef]

- Pokorni, B. Participatory Visual Process Analysis of Manual Assembly Processes to Identify User Requirements for Digital Assistance Systems. In Ahram, T.: Human Interaction, Emerging Technologies and Future Systems 2021; Springer Nature: Cham, Switzerland, 2022; pp. 207–214. [Google Scholar]

- Pokorni, B.; Constantinescu, C. Design and Configuration of Digital Assistance Systems in Manual Assembly of Variant-rich Products based on Customer Journey Mapping. Procedia CIRP 2021, 104, 1777–1782. [Google Scholar] [CrossRef]

- Ahram, T.Z.; Karwowski, W. Engineering sustainable complex systems. Manag. Prod. Eng. Rev. 2013, 4, 4–14. [Google Scholar] [CrossRef] [Green Version]

- Marquez, A.C. Dynamic Modelling for Supply Chain Management: Dealing with Front-End, Back-End and Integration Issues; Springer: London, UK, 2010. [Google Scholar]

- Fässberg, T.; Fasth, Å.; Stahre, J. Classification of Carrier and Content of Information. In Proceedings of the 4th CIRP Conference on Assembly Technologies and Systems (CATS), Ann Arbor, MI, USA, 21–22 May 2012. [Google Scholar]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. A Framework for Automatic Generation of Augmented Reality Maintenance & Repair Instructions based on Convolutional Neural Networks. Procedia CIRP 2020, 93, 977–982. [Google Scholar]

- Neb, A. Review on Approaches to Generate Assembly Sequences by Extraction of Assembly Features from 3D Models. Procedia CIRP 2019, 81, 856–861. [Google Scholar] [CrossRef]

| Levels | Cognitive | Example for Cognitive Assistance Functions in Assembly Processes |

|---|---|---|

| 1 | Totally manual The user creates his/her own understanding of the situation and develops his/her course of action based on his/her earlier experience and knowledge, e.g., the user’s earlier experience and knowledge | No assistance provided. |

| 2 | Decision-giving The user receives information about what to do or a proposal for how the task can be achieved, e.g., work order | Transparency assistance System provides transparent overview about orders or tasks. |

| 3 | Teaching The user receives instructions about how the task can be achieved, e.g., checklists, manuals | Coaching assistance System provides (step-by-step) instruction for work task by using text, video, picture, etc. |

| 4 | Questioning The technology questions the execution if the execution deviates from what the technology considers suitable, e.g., verification before action | Orientation assistance System monitors the execution of work tasks and provides help to solve problems or shows impacts. |

| 5 | Supervision The technology calls for the users’ attention and directs it to the present task, e.g., alarms | Feedback assistance System detects deviating operations and actively informs workers. |

| 6 | Intervene The technology takes over and corrects the action if the executions deviate from what the technology considers suitable, e.g., thermostat | Informed execution assistance System takes over task or parts of a task automatically and informs the worker about it, e.g., execution and documentation of tests. |

| 7 | Totally automatic All information and control are handled by the technology. The user is never involved, e.g., autonomous systems | Takeover assistance System takes over task completely without the worker being involved, e.g., artificial-intelligence-based failure management in closed-loop-assembly stations. |

| Step | Methods and Results |

|---|---|

| Problem identification and motivation |

|

| |

| Definition of the objectives of a solution |

|

| |

| Design and Development |

|

| Demonstration |

|

| Evaluation Communication |

|

| Category | Methods and Techniques |

|---|---|

| Observational | Case study: In-depth study in a suitable environment. |

| Field study: Monitor use in different projects. | |

| Analytical | Static analysis: Examine the structure of artefact for static qualities. |

| Architecture analysis: Study fit of artefact in technical architecture. | |

| Optimization: Demonstrate inherent optimal properties of the artefact or provide optimality bounds on artifact behavior. | |

| Dynamic analysis: Study artefact in use for dynamic qualities. | |

| Experimental | Controlled experiment: Study artefact in controlled environment. Simulation: Study artefact with artificial data. |

| Testing | Functional testing: Black box testing. Look for failures. Structural testing: White box testing. Test holistically by some metric. |

| Descriptive | Informed argument: Use knowledge base to build a convincing argument. Scenarios: Construct detailed scenarios around the argument and demonstrate its usefulness. |

| Symbol | Definition | Value |

|---|---|---|

| ◯ | weak influence | 1 |

| ⊙ | medium influence | 5 |

| ✹ | strong influence | 9 |

| Requirement (W: Worker Perspective; E: Engineering Perspective) | Qualitative Feedback from Engineers and Workers | Impact on Business Performance |

|---|---|---|

| W: Order transparency: overview of orders and shift-based overview |

|

|

| E: Clear monitoring of all assembly steps (not realized in prototyping phase) and picking steps |

|

|

| Push information regarding changes or special notes |

|

|

| Clear work instructions for assembly steps, configuration and test procedures |

|

|

| Easy access to additional information |

|

|

| Automatic documentation |

|

|

| Integrated testing |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pokorni, B.; Popescu, D.; Constantinescu, C. Design of Cognitive Assistance Systems in Manual Assembly Based on Quality Function Deployment. Appl. Sci. 2022, 12, 3887. https://doi.org/10.3390/app12083887

Pokorni B, Popescu D, Constantinescu C. Design of Cognitive Assistance Systems in Manual Assembly Based on Quality Function Deployment. Applied Sciences. 2022; 12(8):3887. https://doi.org/10.3390/app12083887

Chicago/Turabian StylePokorni, Bastian, Daniela Popescu, and Carmen Constantinescu. 2022. "Design of Cognitive Assistance Systems in Manual Assembly Based on Quality Function Deployment" Applied Sciences 12, no. 8: 3887. https://doi.org/10.3390/app12083887