Automotive Seat Comfort and Vibration Performance Evaluation in Dynamic Settings

Abstract

:1. Introduction

2. Materials and Methods

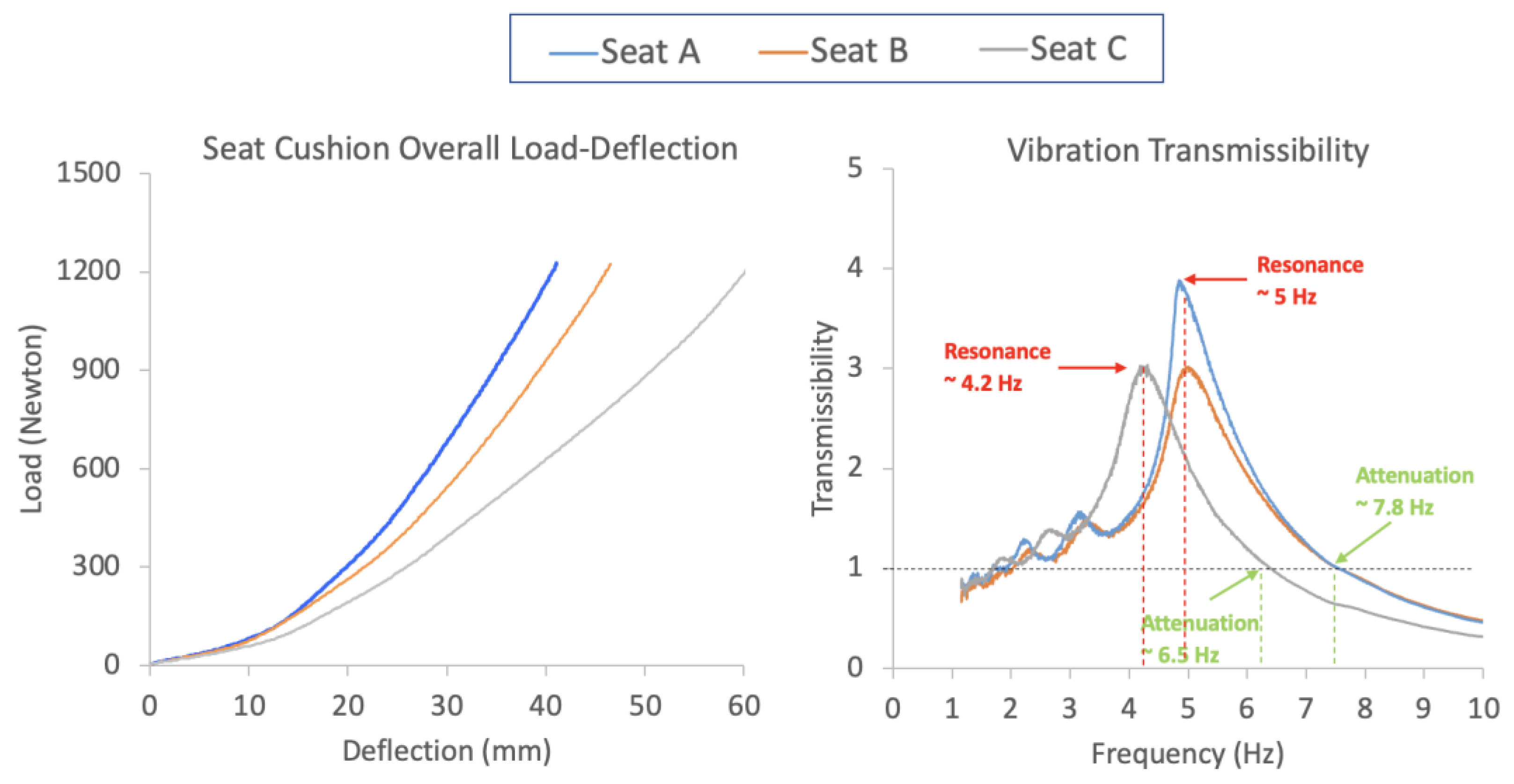

2.1. Seat Sample Preparation

- −

- Foam Firmness was evaluated by the indentation force (load) deflection test and summarized as 50% indentation load in newtons.

- −

- Support factor (also known as compression modulus) indicates foam’s ability to support weight. The support factor was calculated by the ratio of 65% to 25% indentation loads obtained from the indentation force deflection test. The greater support factor measurements indicate that the foam can better sustain the weight while the lower support factor indicates that the foam more easily bottoms out.

- −

- Hysteresis loss was also evaluated by the indentation force deflection test and defined as the difference between loading and unloading portion (energy) of the load-deflection curve expressed as a percentage of the loading energy. As hysteresis loss indicates how much energy the foam can absorb, the foam with the higher hysteresis loss can better absorb vibration.

2.2. Laboratory Evaluation

2.2.1. Participants

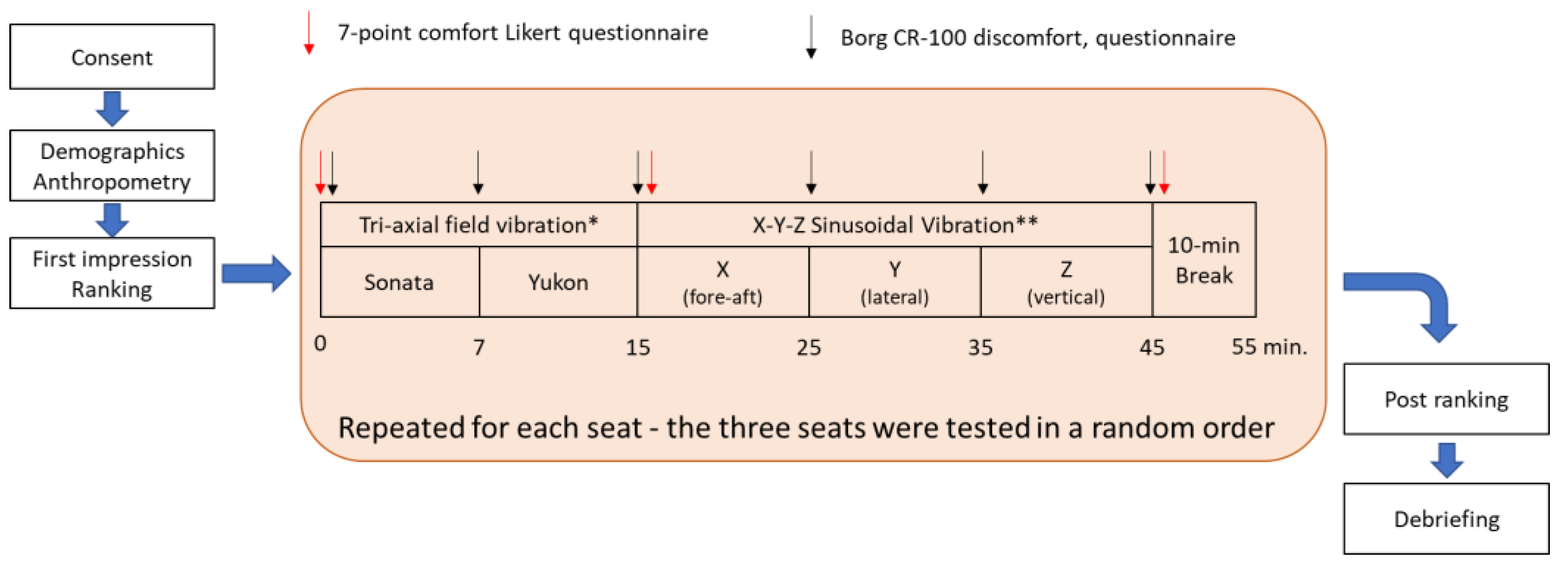

2.2.2. Lab Test Protocols

2.2.3. Laboratory Vibration Exposures

2.2.4. Measures

WBV

Self-Reported Measures

2.2.5. Statistical Analyses

2.3. Field Evaluation

2.3.1. Participants

2.3.2. Field Test Protocols

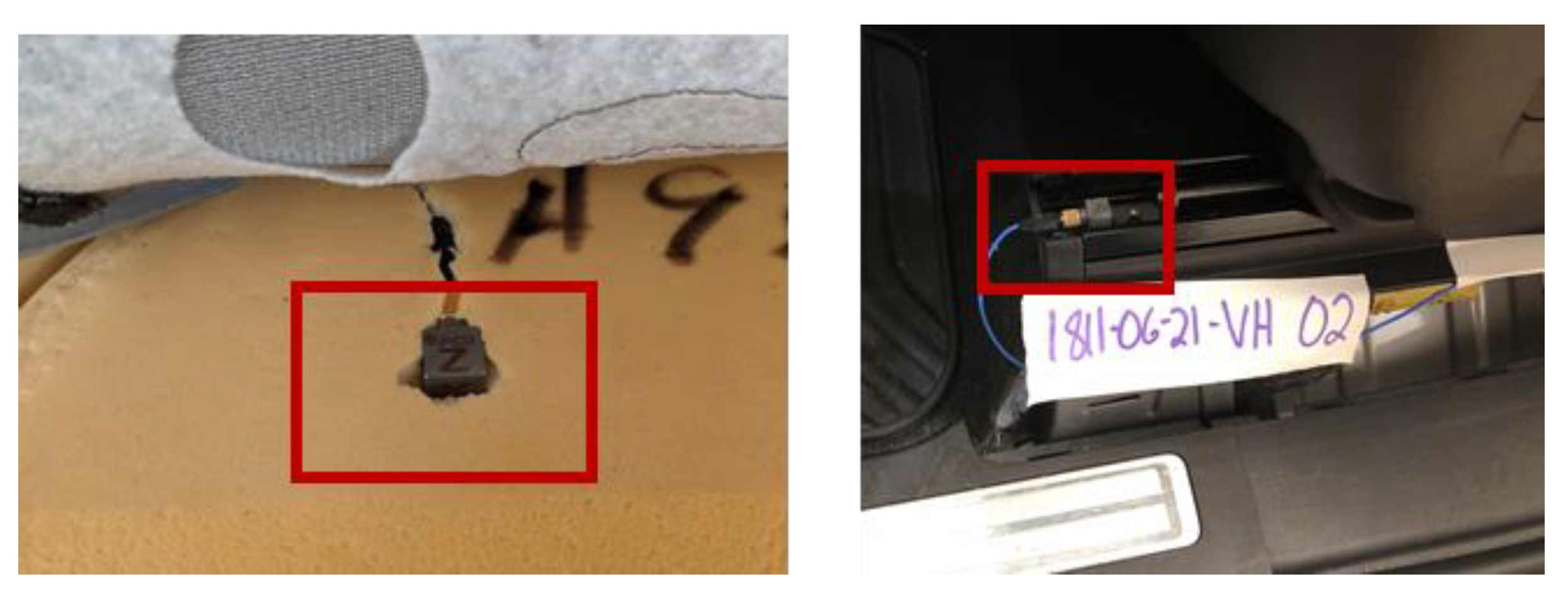

2.3.3. Measures

WBV

Self-Reported Seating Comfort

2.3.4. Statistical Analyses

3. Results

3.1. Laboratory Vibration Exposures

3.1.1. Simulation of Field-Measured Vibration Exposures

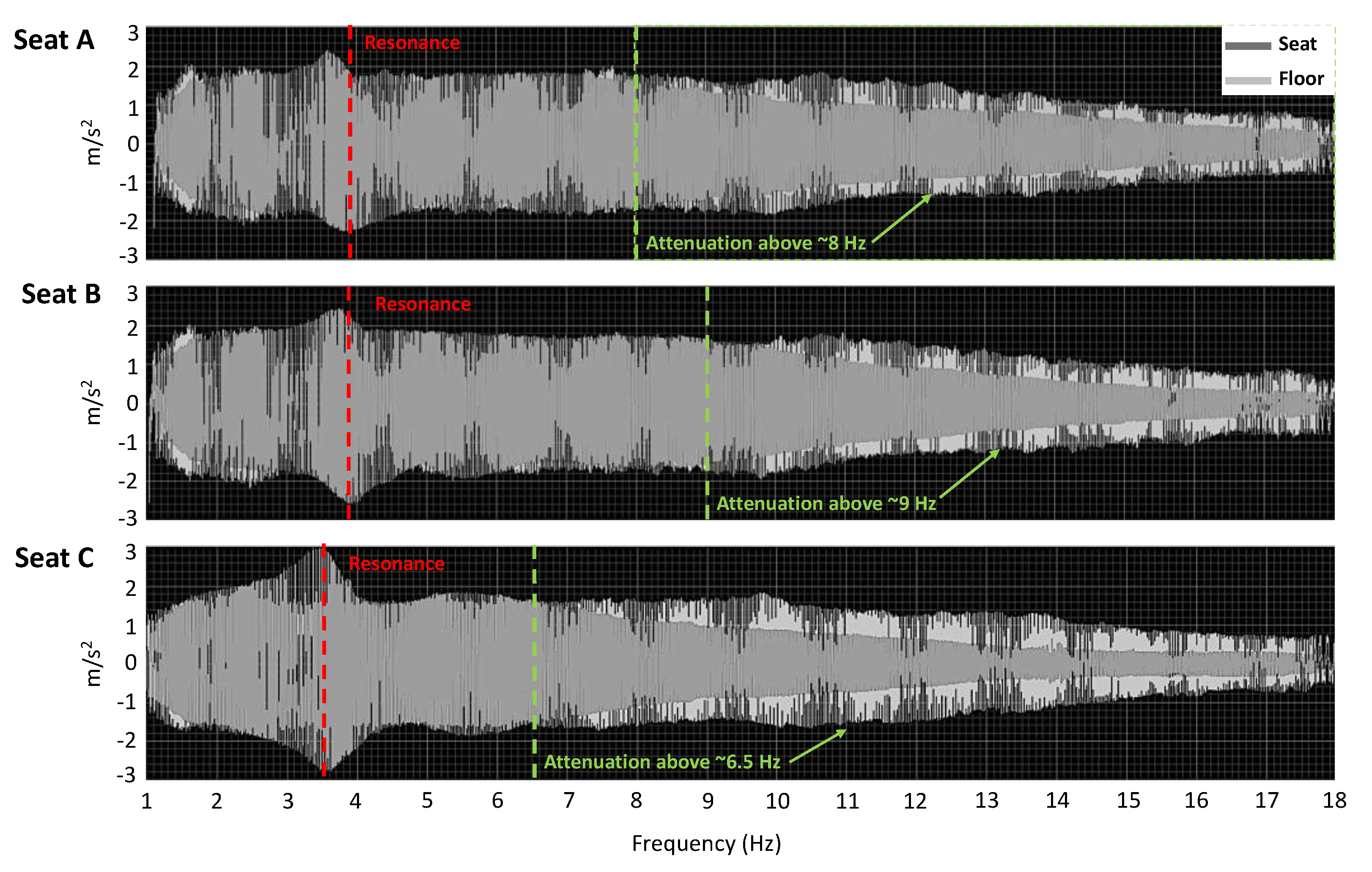

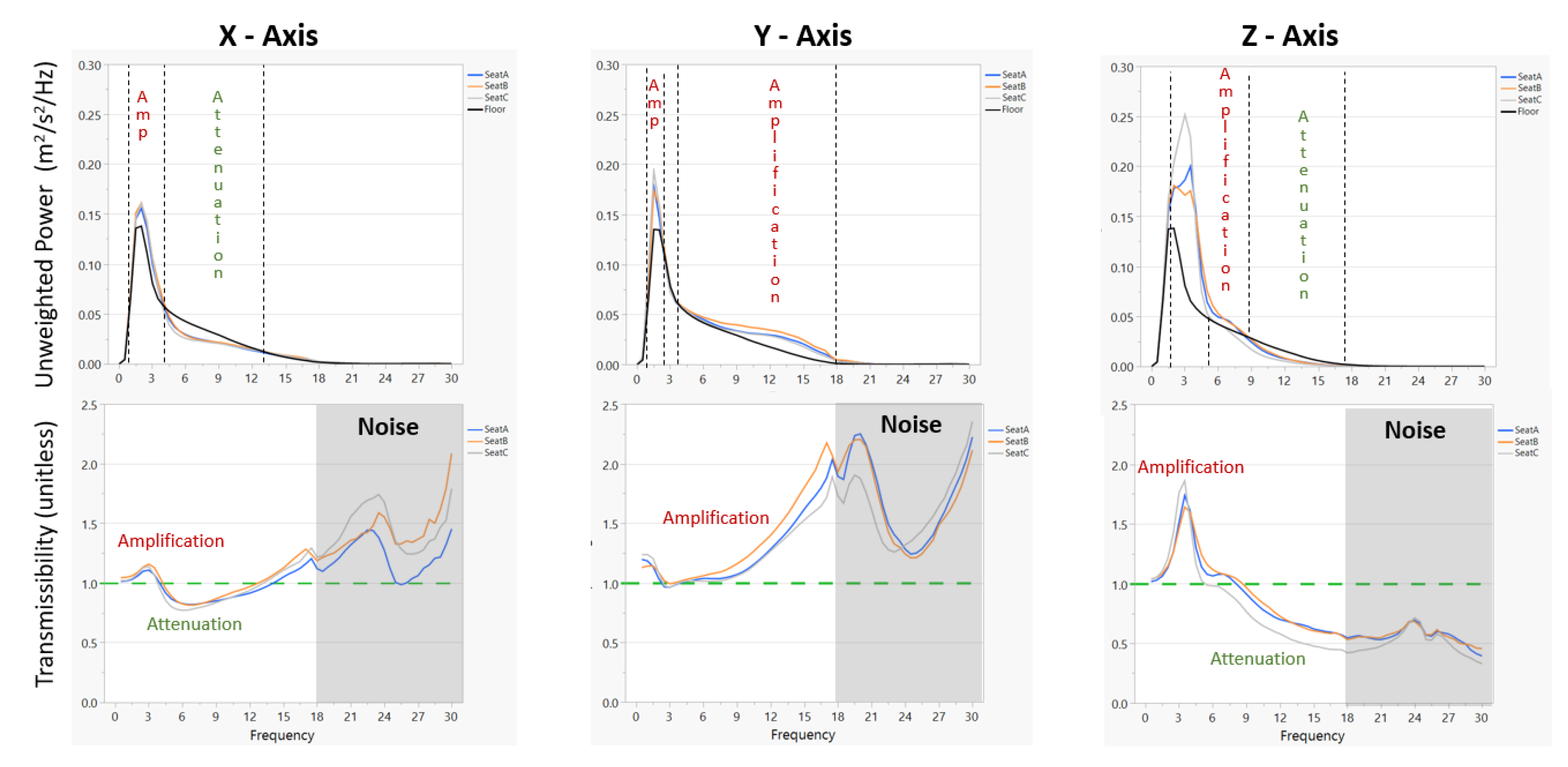

3.1.2. X-Y-Z Axis Continuous Sine Sweep Vibration

3.1.3. Subjective Vibration Comfort

3.2. Field Vibration Exposures

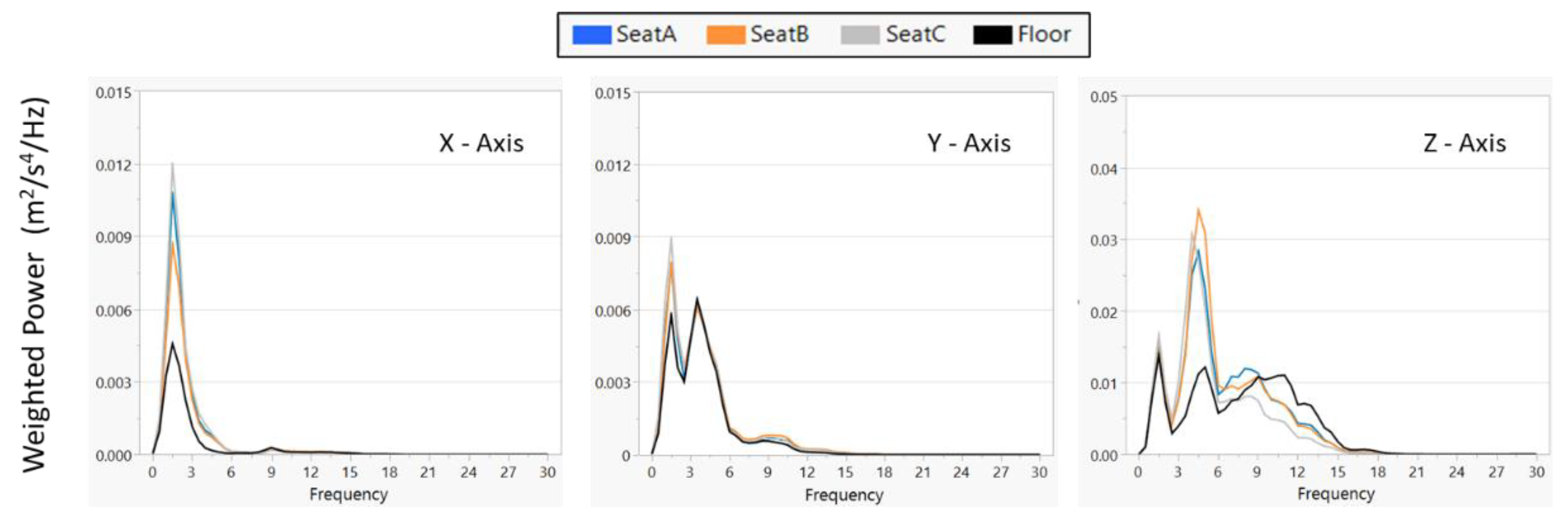

3.2.1. Vibration Measures

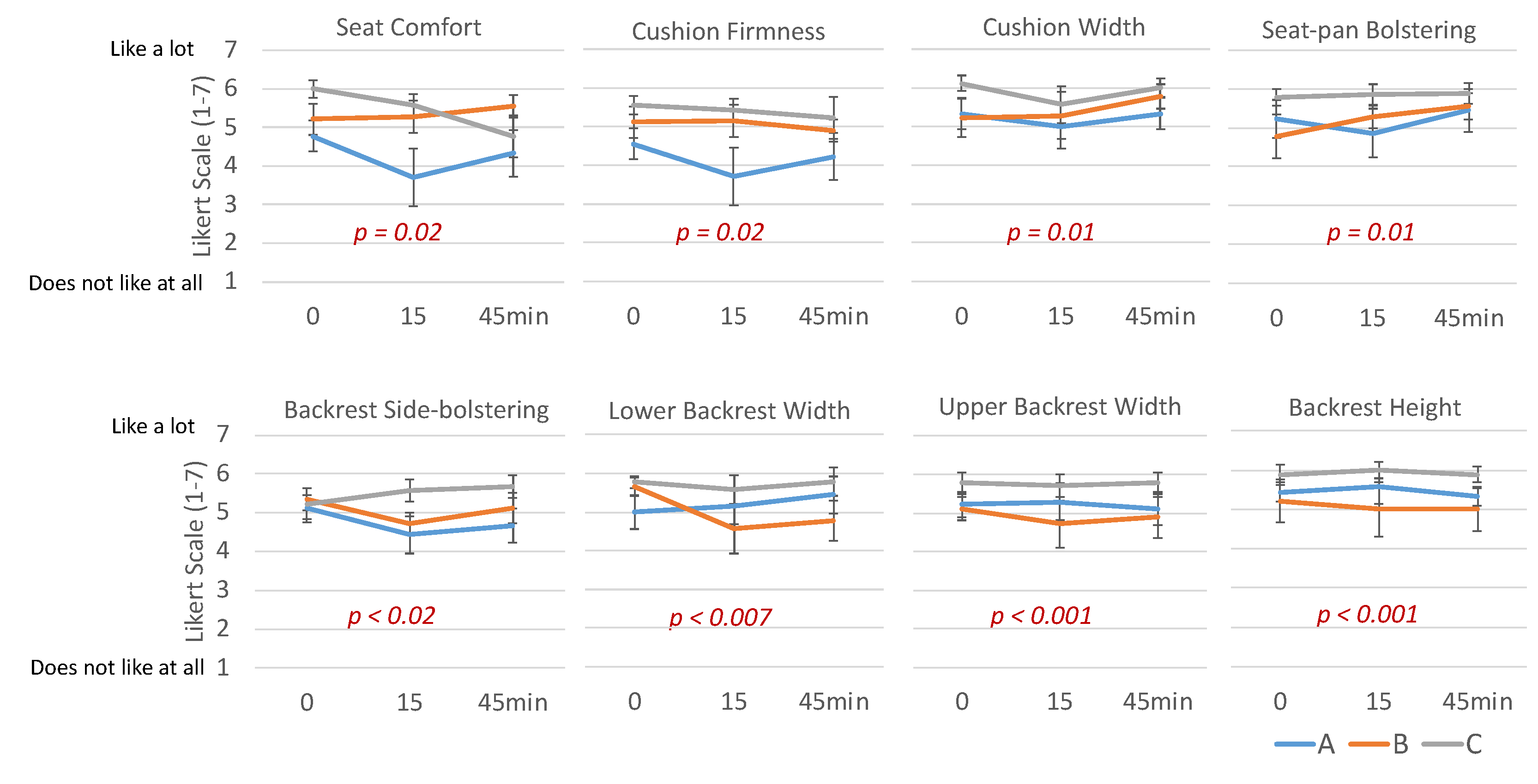

3.2.2. Subjective Measures

4. Discussion and Conclusions

4.1. Seat Vibration Performance

4.2. Seating Comfort and Body Discomfort

4.3. Conclusions, Limitations, and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Blair, G.R.; Milivojevich, A.; Pageau, J.-G.; van Heumen, J.D. Automotive Seating Comfort; Defining ComfortProperties in Polyurethane Foam. SAE Trans. 1999, 108, 504–514. [Google Scholar]

- Ishii, N.; Matsumoto, T.; Ao, T. Development of High-Performance PUF and Organoleptic Evaluation of Polyurethane Foam for Car Seat. Honda R&D Technical Review. 2014, 26, 139–149. [Google Scholar]

- Murakami, S.; Saiki, K.; Hayashi, M.; Satou, T.; Fukami, T. A Newly Developed Mdi-Based Polyurethane Flexible Foam for Automotive Seat Cushion Having Both Superior Static and Dynamic Properties. J. Cell. Plast. 2001, 37, 249–261. [Google Scholar] [CrossRef]

- Ebe, K.; Griffin, M.J. Qualitative Models of Seat Discomfort Including Static and Dynamic Factors. Ergonomics 2000, 43, 771–790. [Google Scholar] [CrossRef]

- Ebe, K.; Griffin, M.J. Factors Affecting Static Seat Cushion Comfort. Ergonomics 2001, 44, 901–921. [Google Scholar] [CrossRef]

- Mehta, C.R.; Tewari, V.K. Vibrational Characteristics of Tractor Seat Cushion Materials and Ride Comfort. J. Low Freq. Noise Vib. Act. Control 2002, 21, 77–85. [Google Scholar] [CrossRef]

- Joshi, G.; Bajaj, A.K.; Davies, P. Whole-Body Vibratory Response Study Using a Nonlinear Multi-Body Model of Seat-Occupant System with Viscoelastic Flexible Polyurethane Foam. Ind. Health 2010, 48, 663–674. [Google Scholar] [CrossRef] [Green Version]

- Mansfield, N.; Sammonds, G.; Nguyen, L. Driver Discomfort in Vehicle Seats – Effect of Changing Road Conditions and Seat Foam Composition. Appl. Ergon. 2015, 50, 153–159. [Google Scholar] [CrossRef] [Green Version]

- Patten, W.N.; Sha, S.; Mo, C. A Vibrational Model of Open Celled Polyurethane Foam Automotive Cushions. J. Sound Vib. 1998, 217, 145–161. [Google Scholar] [CrossRef]

- Zhang, X.; Qiu, Y.; Griffin, M.J. Transmission of Vertical Vibration through a Seat: Effect of Thickness of Foam Cushions at the Seat Pan and the Backrest. Int. J. Ind. Ergon. 2015, 48, 36–45. [Google Scholar] [CrossRef]

- SAE J2896; Motor Vehicle Seat Comfort Performance Measures; SAE International: Warrendale, PA, USA, 2012; Available online: https://www.sae.org/standards/content/j2896_201201/ (accessed on 17 March 2022).

- ASTM D3574-17; Standard Test Methods for Flexible Cellular Materials-Slab, Bonded, and Molded Urethane Foams; ASTM International: West Conshohocken, PA, USA, 2017.

- Sammonds, G.M.; Fray, M.; Mansfield, N.J. Effect of Long Term Driving on Driver Discomfort and Its Relationship with Seat Fidgets and Movements (SFMs). Appl. Ergon. 2017, 58, 119–127. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mansfield, N.J.; Mackrill, J.; Rimell, A.N.; MacMull, S.J. Combined Effects of Long-Term Sitting and Whole-Body Vibration on Discomfort Onset for Vehicle Occupants. ISRN Automot. Eng. 2014, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Na, S.; Lim, S.; Choi, H.-S.; Chung, M.K. Evaluation of Driver’s Discomfort and Postural Change Using Dynamic Body Pressure Distribution. Int. J. Ind. Ergon. 2005, 35, 1085–1096. [Google Scholar] [CrossRef]

- Kim, D.Y.; Bang, J.H.; Lee, C.A.; Kim, H.Y.; Choi, K.Y.; Lim, B.G. Numerical Evaluation of Time-Dependent Sagging for Low Density Polyurethane Foams to Apply the Long-Term Driving Comfort on the Seat Cushion Design. Int. J. Ind. Ergon. 2018, 64, 178–187. [Google Scholar] [CrossRef]

- ISO 2631-1: Mechanical Vibration and Shock-Evaluation of Human Exposure to Whole-Body Vibration-Par1-General Requirements; International Organization for Standardization: Geneva, Switzerland, 1997; Available online: https://www.iso.org/standard/7612.html (accessed on 17 March 2022).

- Burström, L.; Nilsson, T.; Wahlström, J. Whole-Body Vibration and the Risk of Low Back Pain and Sciatica: A Systematic Review and Meta-Analysis. Int. Arch. Occup. Environ. Health 2015, 88, 403–418. [Google Scholar] [CrossRef] [PubMed]

- Bovenzi, M.; Hulshof, C.T.J. An Updated Review of Epidemiologic Studies on the Relationship between Exposure to Whole-Body Vibration and Low Back Pain (1986-1997). Int. Arch. Occup. Environ. Health 1999, 72, 351–365. [Google Scholar] [CrossRef]

- Troup, J.D.G. Clinical Effects of Shock and Vibration on the Spine. Clin. Biomech. 1988, 3, 232–235. [Google Scholar] [CrossRef]

- Kim, J.H.; Zigman, M.; Aulck, L.S.; Ibbotson, J.A.; Dennerlein, J.T.; Johnson, P.W. Whole Body Vibration Exposures and Health Status among Professional Truck Drivers: A Cross-Sectional Analysis. Ann. Occup. Hyg. 2016, 60, 936–948. [Google Scholar] [CrossRef]

- Johnson, D.A.; Nève, M. Analysis of Possible Lower Lumbar Strains Caused by the Structural Properties of Automobile Seats: A Review of Some Recent Technical Literature. J. Manip. Physiol. Ther. 2001, 24, 582–588. [Google Scholar] [CrossRef]

- Park, S.J.; Subramaniyam, M. Evaluating Methods of Vibration Exposure and Ride Comfort in Car. J. Ergon. Soc. Korea 2013, 32, 381–387. [Google Scholar] [CrossRef] [Green Version]

- Blood, R.P.; Ploger, J.D.; Johnson, P.W. Whole Body Vibration Exposures in Forklift Operators: Comparison of a Mechanical and Air Suspension Seat. Ergonomics 2010, 53, 1385–1394. [Google Scholar] [CrossRef] [PubMed]

- Johnson, P.W.; Zigman, M.; Ibbotson, J.; Dennerlein, J.T.; Kim, J.H. A Randomized Controlled Trial of a Truck Seat Intervention: Part 1—Assessment of Whole Body Vibration Exposures. Ann. Work. Expo. Health 2018, 62, 990–999. [Google Scholar] [CrossRef] [PubMed]

- Pan-Zagorski, W.; Pereny, M.A. Quantitative Investigation on Dynamic Comfort in Automotive Seats: A Ride and Drive Study. In Proceedings of the 2019 International Comfort Congress, Delft, Netherland, 29–30 August 2019. [Google Scholar]

- DeShaw, J. New Methodologies for Evaluating Human Biodynamic Response and Discomfort during Seated Whole-Body Vibration Considering Multiple Postures; University of Iowa: Iowa City, IA, USA, 2013. [Google Scholar]

- Mulder, M.; Abbink, D.A. Subjective Perception of Discomfort Due to Vehicle Vibrations in the Sagittal Plane. IFAC-PapersOnLine 2016, 49, 494–499. [Google Scholar] [CrossRef]

- Naddeo, A.; Cappetti, N.; Vallone, M.; Califano, R. New Trend Line of Research about Comfort Evaluation: Proposal of a Framework for Weighing and Evaluating Contributes Coming from Cognitive, Postural and Physiologic Comfort Perceptions. In Proceedings of the 5th International Conference on Applied Human Factors and Ergonomics AHFE 2014, Kraków, Poland, 19–23 July 2014. [Google Scholar]

- SAE J826: Devices for Use in Defining and Measuring Vehicle Seating Accommodation; SAE International: Warrendale, PA, USA, 2021; Available online: https://www.sae.org/standards/content/j826_202106 (accessed on 17 March 2022).

- Kim, J.H.; Dennerlein, J.T.; Johnson, P.W. The Effect of a Multi-Axis Suspension on Whole Body Vibration Exposures and Physical Stress in the Neck and Low Back in Agricultural Tractor Applications. Appl. Ergon. 2018, 68, 80–89. [Google Scholar] [CrossRef] [PubMed]

- Marin, L.S.; Rodriguez, A.C.; Rey-Becerra, E.; Piedrahita, H.; Barrero, L.H.; Dennerlein, J.T.; Johnson, P.W. Assessment of Whole-Body Vibration Exposure in Mining Earth-Moving Equipment and Other Vehicles Used in Surface Mining. Ann. Work Expo. Health 2017, 61, 669–680. [Google Scholar] [CrossRef] [Green Version]

- Kia, K.; Fitch, S.M.; Newsom, S.A.; Kim, J.H. Effect of Whole-Body Vibration Exposures on Physiological Stresses: Mining Heavy Equipment Applications. Appl. Ergon. 2020, 85, 103065. [Google Scholar] [CrossRef]

- European Union Directive 2002/44/EC of the European Parliament and of the Council of 25 June 2002 on the Minimum Health and Safety Requirements Regarding the Exposure of Workers to the Risks Arising from Physical Agents (Vibration). Off. J. Eur. Communities 2002, 177, 13–19.

- Mansfield, N.J. Human Response to Vibration; CRC Press: Boca Raton, FL, USA, 2005; ISBN 978-0-203-48722-8. [Google Scholar]

- Pelmear, P.L.; Leong, D.K.N. EU Directive on Physical Agents—Vibration. J. Low Freq. Noise Vib. Act. Control 2002, 21, 131–139. [Google Scholar] [CrossRef]

- Kim, J.H.; Pan-Zagorski, W.; Pereny, M.A.; Johnson, P.W. The Evaluation of Seat-Comfort, Body Discomfort and Seat Vibration Performance in a Dynamic Testing Environment. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, Online, 5–9 October 2020; SAGE Publications Sage CA: Los Angeles, CA, USA, 2020; Volume 64, pp. 1530–1531. [Google Scholar]

- Pan-Zagorski, W.; Kim, J.H.; Pereny, M.A.; Collins, J.G.; Johnson, P.W. Dynamic Comfort Testing of Automotive Seats in a Laboratory Setting. In Proceedings of the 2021 International Comfort Congress, Online, 2–3 September 2021. [Google Scholar]

- Porter, J.M.; Gyi, D.E.; Tait, H.A. Interface Pressure Data and the Prediction of Driver Discomfort in Road Trials. Appl. Ergon. 2003, 34, 207–214. [Google Scholar] [CrossRef] [Green Version]

| Seat ID | 50% Indentation Load (N) | Support Factor 1 | Hysteresis Loss (%) | Thickness (mm) |

|---|---|---|---|---|

| A | 698.4 | 3.30 | 20.3 | 84.0 |

| B | 386.6 | 3.27 | 26.5 | 82.7 |

| C | 333.8 | 3.24 | 19.7 | 82.2 |

| Mean ± SD | Range | |

|---|---|---|

| Age (years) | 27.3 ± 6.7 | 19–40 |

| Height (cm) | 169.6 ± 11.2 | 154–185 |

| Weight (kg) | 67.5 ± 9.8 | 52–80 |

| BMI (kg/m2) | 23.7 ± 3.0 | 19.6–29.6 |

| Driving Experience (years) | 10.0 ± 6.9 | 3.5–24 |

| Mean ± SD | Range | |

|---|---|---|

| Height (cm) | 171.7 ± 8.8 | 152.4–185.4 |

| Weight (kg) | 76.4 ± 23.9 | 49.8–135.0 |

| BMI (kg/m2) | 25.7 ± 7.0 | 17.7–43.9 |

| Daily Commute Time 1 (mins) | 27.5 ± 11.0 | 15.0–50.0 |

| Personal Vehicle Age (years) | 5.4 ± 7.3 | 0.0–20.0 |

| Axis | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X | Y | Z | ||||||||||

| Seat A | Seat B | Seat C | p-Value | Seat A | Seat B | Seat C | p-Value | Seat A | Seat B | Seat C | p-Value | |

| Speed | 0.142 | 0.136 | 0.147 | <0.0001 | 0.148 | 0.152 | 0.151 | 0.03 | 0.621 | 0.624 | 0.569 | <0.0001 |

| Bunps | (0.002) | (0.002) | (0.002) | (0.001) | (0.001) | (0.001) | (0.009) | (0.01) | (0.007) | |||

| Speed | 0.208 | 0.194 | 0.217 | <0.0001 | 0.157 | 0.158 | 0.157 | 0.69 | 0.582 | 0.592 | 0.559 | <0.0001 |

| Hunps | (0.005) | (0.004) | (0.003) | (0.002) | (0.002) | (0.001) | (0.007) | (0.006) | (0.006) | |||

| Expansion | 0.096 | 0.076 | 0.101 | <0.0001 | 0.06 | 0.062 | 0.062 | 0.44 | 0.392 | 0.396 | 0.363 | <0.0001 |

| Joints | (0.006) | (0.004) | (0.003) | (0.001) | (0.001) | (0.001) | (0.006) | (0.005) | (0.005) | |||

| Cobblestone | 0.208 | 0.194 | 0.217 | <0.0001 | 0.157 | 0.158 | 0.157 | 0.02 | 0.582 | 0.592 | 0.559 | <0.0001 |

| Road | (0.005) | (0.004) | (0.003) | (0.002) | (0.002) | (0.001) | (0.007) | (0.006) | (0.006) | |||

| City | 0.096 | 0.087 | 0.101 | <0.0001 | 0.123 | 0.124 | 0.124 | 0.54 | 0.411 | 0.416 | 0.395 | 0.0006 |

| Streets | (0.003) | (0.002) | (0.002) | (0.001) | (0.001) | (0.001) | (0.003) | (0.005) | (0.005) | |||

| Freeway | 0.073 | 0.056 | 0.077 | <0.0001 | 0.063 | 0.063 | 0.064 | 0.82 | 0.273 | 0.276 | 0.263 | <0.0001 |

| (0.005) | (0.004) | (0.003) | (0.001) | (0.001) | (0.001) | (0.002) | (0.002) | (0.001) |

| Body Parts | Seat | Tri-Axial Field Vibration | Sinusoidal Vibration | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 min | 7 min | 15 min | X | Y | Z | |||||

| Pre | Post | Pre | Post | Pre | Post | |||||

| Ankles /Feet | A | 3.9 (2.4) | 2.7 (1.5) | 5.2 (6.3) | 5.2 (3.5) | 2.4 (1.1) | 2.6 (1.1) | 2.5 (1.1) | 1.9 (1.1) | 1.8 (0.7) |

| B | 2.8 (1.5) | 1.2 (0.7) | 2.4 (2.3) | 1.1 (0.4) | 1.1 (0.4) | 1.1 (0.4) | 1.2 (0.4) | 1.8 (0.5) | 1.3 (0.5) | |

| C | 0.7 (0.4) | 0.8 (0.4) | 0.9 (1.1) | 3.2 (1.8) | 2.2 (1.1) | 2.4 (1.1) | 2.2 (1.1) | 0.8 (0.4) | 3.4 1.6) | |

| Knees | A | 3.9 (1.8) | 5.1 (3.1) | 8.8 (6.3) | 9.7 (7.0) | 6.2 (3.5) | 6.4 (3.6) | 10.2 (5.2) | 6.9 (4.8) | 6.6 (3.5) |

| B | 6.1 (2.0) | 6.5 (1.9) | 7.0 (2.3) | 6.4 (2.4) | 5.9 (2.1) | 5.4 (2.2) | 7.1 (3.1) | 6.4 (2.8) | 6.8 (2.8) | |

| C | 3.1 (0.9) | 1.9 (0.6) | 3.3 (1.1) | 3.9 (1.6) | 4.6 (1.8) | 5.3 (2.2) | 6.4 (3.2) | 3.7 (1.2) | 5.7 (2.1) | |

| Thighs | A | 3.1 (1.3) | 2.6 (1.3) | 3.1 (1.1) | 3.2 (1.5) | 5.9 (3.2) | 5.9 (3.3) | 4.6 (2.0) | 3.1 (1.1) | 3.3 (1.3) |

| B | 1.5 (0.9) | 3.1 (1.4) | 2.6 (0.9) | 1.3 (0.4) | 2.8 (1.6) | 3.1 (1.7) | 1.4 (0.5) | 2.0 (0.5) | 1.9 (0.8) | |

| C | 1.0 (0.5) | 1.2 (0.5) | 1.2 (0.6) | 1.7 (0.7) | 2.3 (1.1) | 3.0 (1.4) | 2.6 (1.2) | 1.2 (0.6) | 2.4 (1.2) | |

| Tailbones | A | 1.2 (0.5) | 2.4 (0.6) | 3.3 (1.1) | 7.2 (4.2) | 7.3 (4.1) | 5.7 (2.7) | 8.9 (4.5) | 3.4 (1.1) | 5.7 (2.7) |

| B | 2.9 (2.0) | 1.7 (0.6) | 2.7 (0.9) | 1.6 (0.6) | 2.5 (0.6) | 2.9 (0.6) | 3.8 (1.6) | 2.0 (0.7) | 2.4 (0.6) | |

| C | 1.3 (0.6) | 1.8 (0.7) | 1.4 (0.5) | 2.7 (1.0) | 3.4 (1.0) | 2.7 (0.9) | 7.1 (2.9) | 3.8 (1.8) | 5.0 (2.1) | |

| Lower Back | A | 1.1 (0.4) | 3.0 (1.3) | 4.2 (1.6) | 3.6 (1.5) | 4.3 (1.8) | 3.7 (1.5) | 4.7 (1.6) | 4.9 (1.7) | 4.2 (1.3) |

| B | 0.9 (0.5) | 1.7 (0.7) | 2.5 (1.0) | 2.3 (1.1) | 2.7 (0.6) | 2.9 (0.8) | 2.0 (0.7) | 2.3 (0.7) | 4.2 (1.1) | |

| C | 2.1 (0.9) | 2.5 (0.9) | 2.3 (0.9) | 2.5 (1.1) | 2.6 (1.0) | 2.9 (1.0) | 5.1 (2.1) | 4.8 (2.1) | 5.2 (2.1) | |

| Upper Back | A | 4.7 (2.9) | 2.9 (0.9) | 6.6 (3.1) | 7.9 (3.3) | 6.7 (1.6) | 5.8 (2.2) | 6.1 (1.4) | 5.3 (1.1) | 5.9 (1.5) |

| B | 5.4 (2.4) | 4.4 (1.7) | 4.7 (1.6) | 3.8 (1.7) | 5.2 (2.3) | 4.7 (2.4) | 5.2 (2.3) | 6.3 (2.2) | 6.3 (2.7) | |

| C | 2.9 (1.1) | 3.4 (0.9) | 3.1 (0.9) | 4.3 (1.4) | 4.7 (1.2) | 4.3 (1.4) | 4.7 (1.6) | 3.3 (1.0) | 5.3 (1.6) | |

| Shoulders | A | 2.2 (0.8) | 4.2 (1.6) | 5.9 (2.9) | 6.7 (3.1) | 5.7 (2.1) | 5.4 (2.4) | 8.9 (3.4) | 6.9 (3.5) | 5.7 (2.1) |

| B | 5.8 (3.2) | 5.6 (2.2) | 5.0 (2.2) | 5.2 (2.3) | 5.4 (2.5) | 4.4 (2.6) | 5.8 (2.9) | 6.4 (2.8) | 6.4 (2.8) | |

| C | 1.8 (0.8) | 1.8 (0.6) | 3.0 (1.0) | 4.1 (2.1) | 5.1 (2.1) | 5.2 (2.2) | 6.1 (3.2) | 2.8 (1.1) | 4.9 (2.2) | |

| Neck | A | 6.9 (4.8) | 7.9 (5.3) | 9.7 (6.2) | 10.4 (6.9) | 7.6 (3.9) | 7.5 (3.9) | 10.5 (4.7) | 8.7 (4.8) | 7.5 (3.6) |

| B | 7.8 (4.4) | 6.7 (2.6) | 6.1 (2.4) | 5.8 (2.7) | 9.4 (3.3) | 7.3 (2.7) | 7.3 (2.8) | 8.6 (3.5) | 7.5 (3.3) | |

| C | 4.2 (1.7) | 3.7 (1.4) | 4.4 (1.7) | 5.4 (2.2) | 5.2 (1.6) | 6.0 (1.8) | 6.5 (1.8) | 4.3 (1.3) | 5.1 (1.5) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan-Zagorski, W.; Johnson, P.W.; Pereny, M.; Kim, J.H. Automotive Seat Comfort and Vibration Performance Evaluation in Dynamic Settings. Appl. Sci. 2022, 12, 4033. https://doi.org/10.3390/app12084033

Pan-Zagorski W, Johnson PW, Pereny M, Kim JH. Automotive Seat Comfort and Vibration Performance Evaluation in Dynamic Settings. Applied Sciences. 2022; 12(8):4033. https://doi.org/10.3390/app12084033

Chicago/Turabian StylePan-Zagorski, Wu, Peter W. Johnson, Missy Pereny, and Jeong Ho Kim. 2022. "Automotive Seat Comfort and Vibration Performance Evaluation in Dynamic Settings" Applied Sciences 12, no. 8: 4033. https://doi.org/10.3390/app12084033

APA StylePan-Zagorski, W., Johnson, P. W., Pereny, M., & Kim, J. H. (2022). Automotive Seat Comfort and Vibration Performance Evaluation in Dynamic Settings. Applied Sciences, 12(8), 4033. https://doi.org/10.3390/app12084033