Abstract

This paper presents a thermal performance evaluation of a novel particle-to-air heat exchanger. The heat exchanger has a patented design with a shell-and-tube configuration. Solid particles move as a dense packed-bed inside the vertical tubes of the heat exchanger whereas air flows on the shell-side. This design avoids a number of limitations associated with the state-of-the-art heat exchangers in the same category, such as the stagnant/void zones and the prolonged residence time. The heat exchanger has a 50-kW thermal duty; it has been integrated into the particle-based concentrating solar power facility located at the campus of King Saud University in Riyadh, Saudi Arabia. The detailed description of the heat exchanger and the integration process is introduced. The recuperated air of the facility’s power cycle is used to heat the solid particles being circulated inside the facility. The solid particles used in this study are engineered particles called Carbobead CP with 0.3 mm mean diameter. The effect of particle flow rate on the thermal performance of the heat exchanger is investigated. The results show that as the particle flow rate increases, the overall heat transfer coefficient (U) increases; a maximum value was measured to be 150 W/m2-°C based on LMTD calculations. The measurement accuracy was verified by repeating several tests; a slight variation was observed in the measured U. The results also show that only a small air pressure drop (~5 kPa) was measured across the heat exchanger. Furthermore, it was found that a significant part of the heat exchange occurred at the bottom section of the heat exchanger.

1. Introduction

Particle-Based Concentrating Solar Power (PBCSP) is one of the promising technologies that has the potential to minimize the dependency on fossil fuels. This technology offers several advantages over those in the same category. A PBCSP system can operate at higher temperatures than other CSP systems [1], permitting the integration with high-efficiency power cycles. Moreover, PBCSP systems can provide a cost-effective energy storage [2], which other CSP systems and solar photovoltaic (PV) systems currently lack. PBCSP systems do not have issues like freezing, corrosion, or flux limits. Additionally, the US Department of Energy (DOE) has selected the solid-particle pathway, over the other CSP competitors, as a way to develop highly efficient CSP plants which can achieve a levelized cost of electricity of $0.05/kWh [3]. The first pilot PBCSP plant was built at the campus of King Saud University (KSU), Riyadh, Saudi Arabia [4,5]. A typical PBCSP plant is composed of a heliostat field, a particle heating receiver (PHR), a thermal energy storage (TES), a particle-based heat exchanger (PBHX), and a power block. Solid particles serve as an energy carrier, transferring and storing heat medium; the particles are allowed to freely fall in the PHR to become irradiated by sunlight reflected from the heliostat field. The hot particles are then stored in a high-temperature TES bin that continuously feeds the PBHX which, in turn, transfers the thermal energy from the hot particles to the working fluid of a power cycle to generate electricity. The cooled particles are then collected in a low-temperature TES bin to be circulated, thus completing the particle loop.

The PBHX stands as one of the most critical components that requires extensive experimental and theoretical investigations towards commercializing the PBCSP technology. Developing an effective PBHX will greatly improve the overall efficiency of the plant and reduce the fuel consumption. Various designs (mainly categorized as direct and indirect-contact) are being investigated, including, but not limited to, moving packed-bed, fluidized-bed, and falling cloud direct-contact PBHXs [6]. To date, the indirect-contact moving packed-bed heat exchangers (ICMPBHXs), either the shell-and-tube or the shell-and-plate design, are attractive options to transfer thermal energy from solar-heated particles to the working fluid of the power cycle. ICMPBHXs offer several advantages, compared to the other designs, such as no parasitic load requirements, simpler in design, gravity-driven, no risk of contaminating the working fluid, and commercial availability. Although these heat exchangers have inherently low overall heat transfer coefficients and are costly because of the large amounts of expensive alloys needed, research is going on to develop designs that mitigate such limitations.

Several studies have been conducted to investigate the particle flow kinematics and performance of a shell-and-tube design in which particles move around tubes on a shell-side. Takeuchi [7] used X-ray video films to visualize the flow of particles around a circular tube of several types of tube arrangements including a single tube, a single row of tubes, two rows of tubes, and three rows of tubes; staggered formation was used in the last two cases. The author found that the flow pattern and, thus, the local heat transfer coefficient depends greatly on the tube arrangement. Three zones were observed around the tube of staggered banks, namely, a stagnant zone on top of the tube, a void zone below the tube, and a moving bed region along both sides of the tube. The size of stagnant zone is affected by the tube pitch, as the pitch increases the stagnant zone flattens; on the other hand, the particle velocity has no effect on the stagnant zone. The existence of stagnant and void zones has a negative effect on the heat exchange process. The local heat transfer coefficient was found to be between 25 and 120 W/m2-K for the two-row arrangement when particles velocities range from 0.4 to 6.7 mm/s. Baumann and Zunft [8] conducted a study on a moving packed-bed shell-and-tube heat exchanger to be used for power tower CSP plants with a particle-based storage. The authors studied two designs for the heat exchanger, differing from each other by the tube bundle arrangement. In the first design (called the reference design), the tube bundle is arranged with a horizontal tube pitch ratio of 2.5 in a 60° staggered formation, while in the adapted design is 1.5 in a 72° staggered formation. The particles used were sintered bauxite and quartz sand with a mean particle size of 0.5 mm and 0.8 mm. The particles flow inside the shell with superficial inlet velocities up to 5.0 mm/s and a maximum temperature of ~500 °C; and thermal oil flows through the tubes as heat sink. The authors found that the stagnant zones for the adapted design are thinner, but somewhat higher than those of the reference design. The velocity profile shape and the dimensions of the stagnant and void zone are not affected by the superficial velocity of the bulk. Additionally, the authors found that the effectiveness of the adapted design improved substantially due to the higher integral particle velocity (lower tube pitch and lower flow area) and the shorter contact time between the particles and the tube walls.

Al-Ansary et al. [9] studied the heat transfer characteristics of sand bulk flow in a sand–air heat exchanger. The tested heat exchanger was made of a transparent polymer box which included a tube bank consisting of eight tubes arranged in three rows in a staggered formation. The tubes, either bare or finned, were made out of carbon steel and electrically heated by heater cartridges. Experiments were conducted on silica sand and olivine sand with two parameters being changed, namely, the power input (100 W to 350 W) and sand velocities (1 and 3 mm/s). The authors found that heat transfer coefficient was slightly affected by the sand type, with olivine a little higher than silica. The sand velocity was found to have a positive and significant effect on the heat transfer coefficient, and the reported values for bare and finned tubes were found in the range of 80–160 W/m2-K, with bare tubes higher than finned tubes. Negyen et al. [10] continued the previous work by testing five particulate materials: fracking sand, Atlanta industrial sand, Riyadh white sand, and small and large proppants. The authors investigated the effect of higher particles velocities on the heat transfer coefficient; the velocities used were 3, 5, and 10 mm/s. The results showed that the particles velocity had a great effect on enhancing the heat transfer coefficient.

The reduced contact area (induced by stagnant zones on top of the tubes and void zones on the tubes’ bottom) between particles and tubes’ walls was one of the main obstacles towards a highly-effective thermal performance. By looking closely at the stagnant/void zones around circular tubes, an approximate diamond shape can be noticed. This might suggest that a sharp-edge tube profile (following the particles streamline) could eliminate/reduce the extent of such zones and promote the heat transfer. Therefore, the KSU-CSP team collaborated with Grenzbach company to fabricate a heat exchanger with a design that replaced circular tubes by diamond-shaped tubes; in this way, the extent of the stagnant zones and void zones are to be minimized, which will improve the contact between particles and tubes’ walls. The Grenzbach heat exchanger was incorporated in the KSU PBCSP facility; it linked the particle thermal system to the recuperated microturbine [11]. The thermal capacity of the heat exchanger is about 100 kW, and it has six passes of diamond-shaped tubes (894 tubes) with a heat transfer area of approximately 90 m2. The heat exchanger was tested using Riyadh red sand; the recuperated air of the microturbine, flowing inside the tubes, was used to heat the red sand. The results showed that the particle velocity greatly affects the overall heat transfer coefficient (U). An increase in sand velocity by less than 20% can cause an increase in the U by more than 300%. The maximum value of ~30 W/m2-°C is obtained at maximum particle velocity of 0.71 mm/s, which corresponds to 0.97 kg/s. This value was considered low compared to the value targeted by Department of Energy (100 W/m2-K) [12]. The downside of such design was the prolonged residence time of particles, which resulted in a reduced thermal gradient between particles (slowly flowing) and tubes’ walls and, thus, reduced heat transfer.

According to the above literature, the state-of-the-art designs of the shell-and-tube PBHX have some limitations impacting their performance, including the reduced contact area and the prolonged residence time of particles. It is, therefore, desirable to have a design that can overcome such problems to improve the overall performance. In this study, another configuration of a shell-and-tube PBHX is investigated. A patented design [13], by Solex Thermal Science Inc., has been fabricated to be tested at the KSU-PBCSP facility. In this design, particles flow inside vertical tubes while the working fluid flows on the shell-side. The flow of particles on the tube-side eliminates the problem of stagnation and void zones, and allows the particle speed to increase, thereby reduced residence time. In the following sections, the description and the integration of the heat exchanger are introduced, and the effect of particle flow rate on the thermal performance of this design is presented as well.

2. Experimental Setup

2.1. The Moving Packed-Bed Shell-and-Tube Particle-to-Air Heat Exchanger

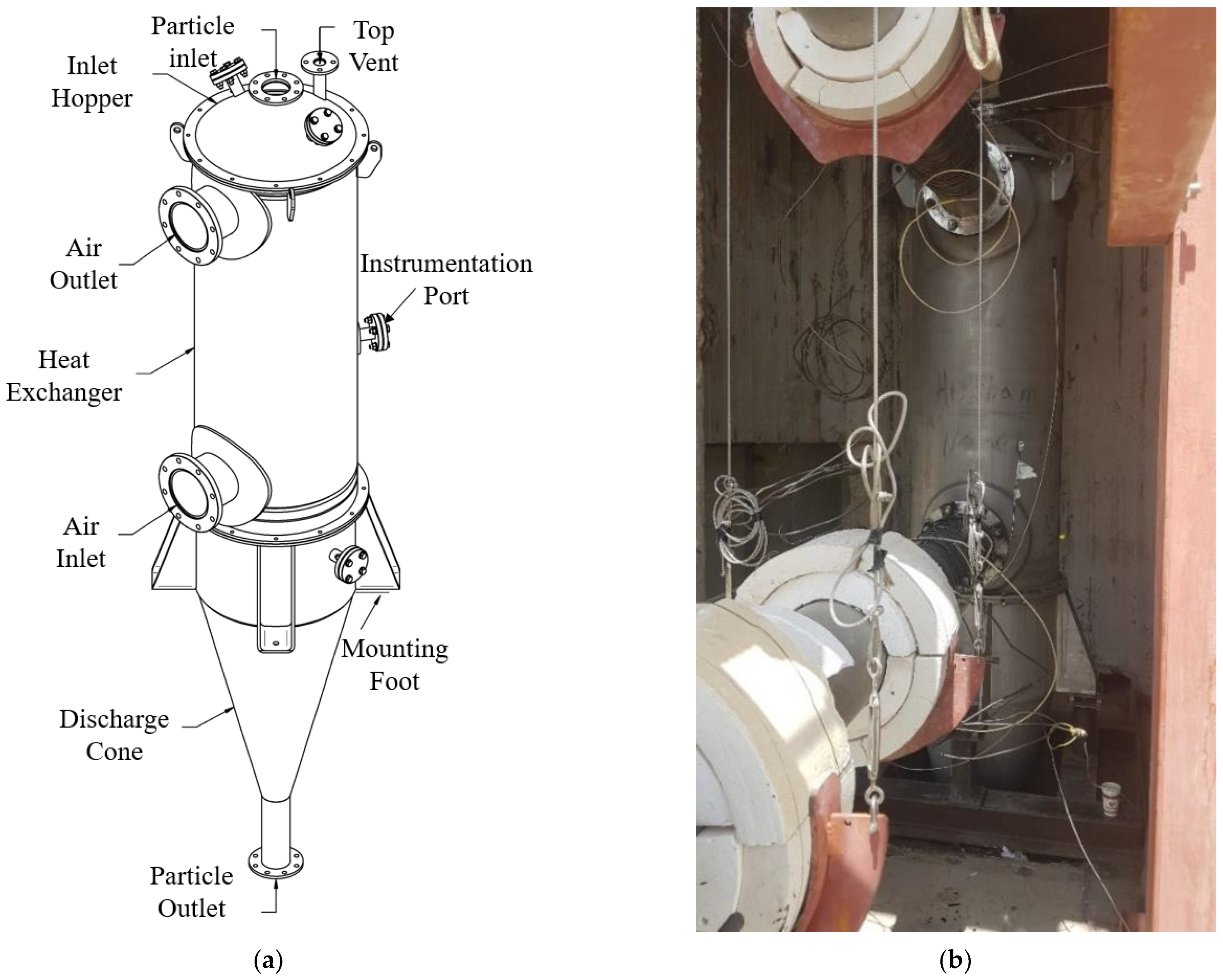

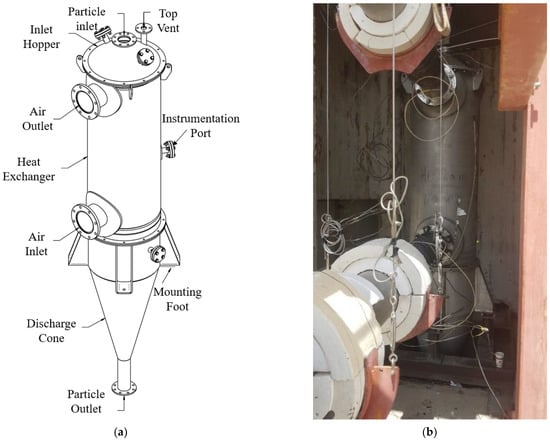

Figure 1 shows an illustration of the moving packed-bed shell-and-tube heat exchanger fabricated by Solex Thermal Science Inc. The heat exchanger has a 50-kW thermal duty, and it is made of a stainless-steel alloy (SS316/321). The heat exchanger is intended to exchange heat between solid particles and a pressurized air; the solid particles flow inside the exchanger’s vertical tubes by gravity whereas air flows on the shell side. Several baffles are used to support the tubes, distribute the air inside the shell, and increase air velocity. The total heat transfer area of the heat exchanger is 16.59 m2 on the particle side (i.e., the total inside surface of all tubes); more details about the design concept can be found in [13]. The heat exchanger is provided with an inlet hopper at the top; its function is to always ensure that the upper tube sheet is covered with solid particles, and all tubes are receiving particles.

Figure 1.

(a) Schematic of the Solex vertical tube heat exchanger, and (b) a photograph showing the installed exchanger with the air pipes.

Furthermore, the heat exchanger is also equipped with a mass-flow discharge cone attached at its bottom. This cone plays a key role towards effective operation of the exchanger. To control particle residence time, the tubes must be full of particles at their packing limit all the time during operation, and the gravity-driven dense granular flow inside the tubes must have the same velocity. This is achieved by installing a mass-flow cone, which is always kept full of particles. The cone is designed according to Jenike & Johanson theory. Particles move inside the cone in a mass-flow pattern, which supposedly maintains a uniform flow inside all tubes. The heat exchanger along with inlet hopper and the discharge cone can accommodate around 800 kg of particles. The heat exchanger is provided with several ports for maintenance and instrumentation. Those ports are located at the shell, the inlet hopper and the discharge cone.

This type of heat exchanger exhibits several advantages and de-risking measures. First, the flow of particles on the tube side allows the particle speed to be significantly high, thereby reduced residence time. Second, particle flow control occurs through a valve at the bottom. Therefore, the heat exchanger is not prone to clogging. Third, the current design is amenable to easy maintenance since it does not contain air plenums that make access to the tube bank difficult. The design conditions of the heat exchanger are listed in Table 1.

Table 1.

Heat exchanger design conditions.

2.2. Integration of the Heat Exchanger into the KSU CSP Test Facility

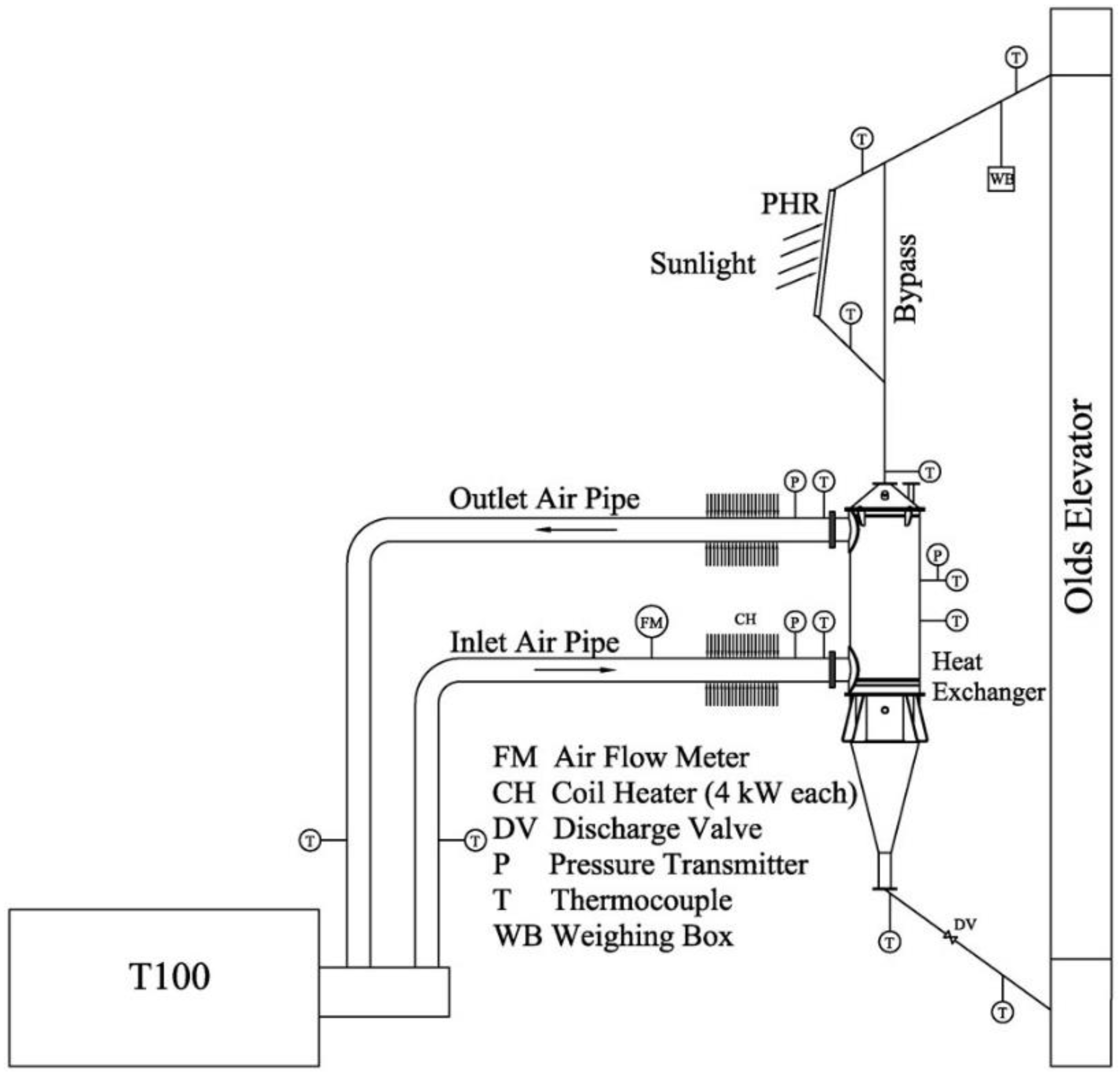

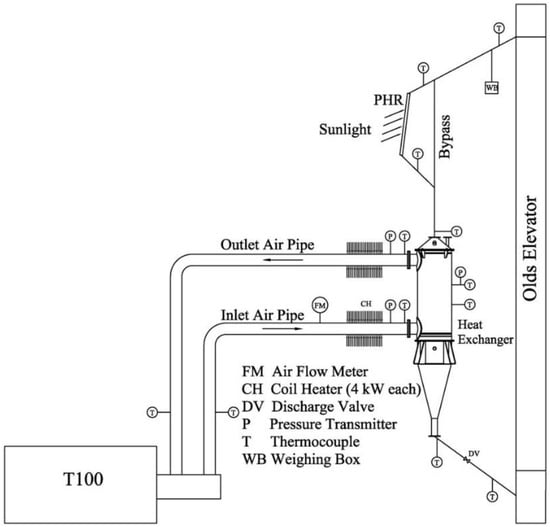

In order to evaluate the thermal performance of the heat exchanger, it has been integrated with the particle-based power tower CSP test facility located at the campus of KSU. The facility consists of a heliostat field (66 heliostats with 8 m2 reflector area and 300 kW peak thermal power), a PHR on top of a tower, a particle lift (Olds Elevator), a PBHX, and a power block; more details about the facility can be found in [4,5]. It is noteworthy that the main purpose of this research facility is to demonstrate the applicability of using solar energy to decrease the dependency on fossil fuels; additionally, it provides an opportunity to evaluate the performance of each component in order to achieve the optimal operation, and to examine their durability as well. Figure 2 shows how the heat exchanger is connected to the components of the facility.

Figure 2.

Process diagram of particle and air loops.

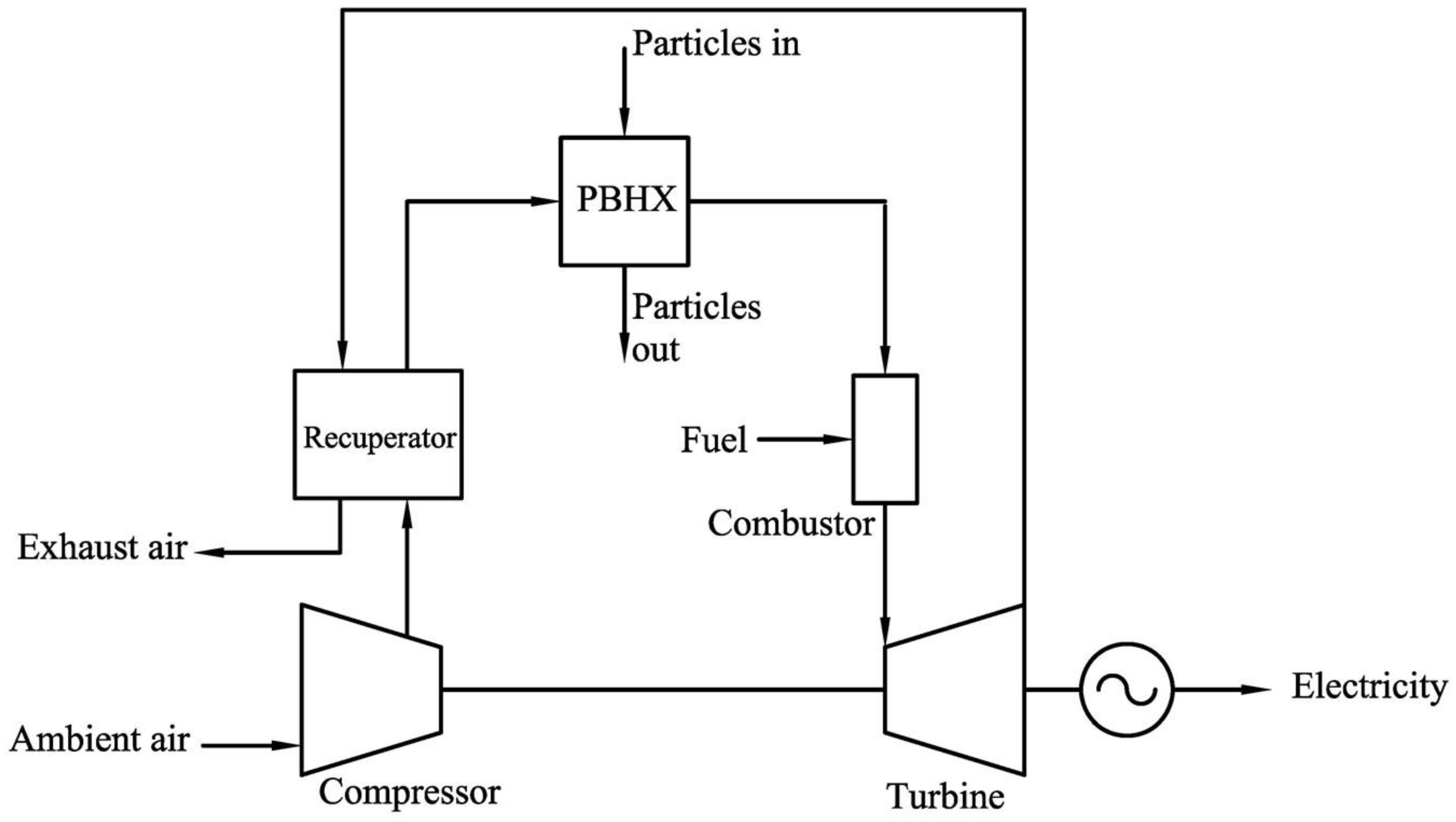

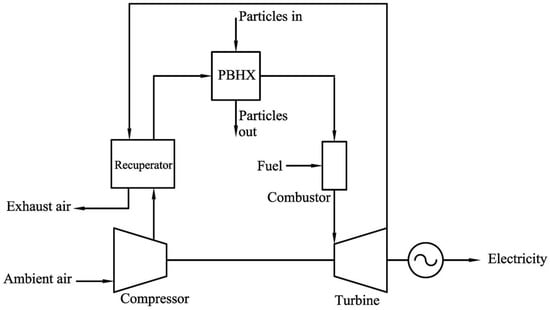

The power block is a recuperated gas microturbine (air-Brayton cycle) with a nominal electrical power of 100 kW (it is called the T100). It has an external combustion chamber which is modified to admit hot compressed air from the PBHX in addition to burning diesel fuel. The heat exchanger is connected to the T100 through two air/power pipes (8 inch, sch 10) and the first pipe is connected to the recuperator’s outlet, while the second is connected to the inlet of the combustion chamber (Figure 3) such that, the air leaving the recuperator enters the heat exchanger from the bottom, exchanges heat with particles flowing inside the tubes, leaves the heat exchanger from the top through the second air pipe, and then enters the combustion chamber. Each air pipe incorporates three expansion joints/bellows to accommodate for thermal expansion and absorb the lateral deflection; a counterweight system is installed to hold the air pipes.

Figure 3.

Schematic of the T100 unit.

The particle inlet hopper of the heat exchanger is connected to the outlets of the PHR and the bypass line, such that two particle flow loops are achieved, namely the PHR loop and the bypass loop. The inlets of the PHR and the bypass line are connected to the outlet of the Olds Elevator, so particles can either go to the PHR and then to the heat exchanger or they can bypass the PHR and go directly to the heat exchanger. The process diagram of the particle and air loops is shown in Figure 2. The heat exchanger’s particle outlet is connected to the Olds Elevator’s inlet through the discharge cone. A 4-inch pipe is used to connect the discharge cone to the bottom hopper of the Olds Elevator. A knife valve is installed on this pipe to isolate the heat exchanger when needed.

In order to minimize the heat loss, the components of the facility are heavily insulated; ceramic wool (1-inch thick), rock wool (3-inch thick), and glass wool (1-inch thick) have been used as insulation materials. The ceramic wool has a thermal conductivity of 0.152 W/m-K and an operating temperature of 1260 °C, while the rock wool is of 0.034 W/m-K thermal conductivity and 600 °C operating temperature. Each component is first wrapped with ceramic wool, and then rock wool and glass wool, respectively. Table 2 shows the number of layers used to insulate the facility components.

Table 2.

Thermal insulation layers.

2.3. Instrumentation

Performance evaluation requires the measurement of several quantities such as air temperature, air pressure, air flow rate, particle temperature, and particle flow rate. Several instruments are installed at different locations of the facility; the heat exchanger’s instrumentation is presented in detail in this section. The particle inlet temperature of the heat exchanger is measured just before the particle inlet hopper using four thermocouples, while the particle outlet temperature is measured just after the discharge cone using three thermocouples. To ensure accurate measurement of bulk particle temperatures, the thermocouples are always kept immersed inside moving particle beds. Two thermocouples are installed at the inlet air pipe just before the heat exchanger’s entrance to measure the air inlet temperature, and another two at the outlet air pipe to measure the air outlet temperature. Type-K Thermocouples (KMQIN-062U-24 and KMQIN-125U-24, Omega Engineering Inc., Norwalk, CT, USA) are used for the temperature measurement. The air pressure drop across the heat exchanger can be determined by measuring the air pressures at the inlet and outlet of the heat exchanger. Three Omega pressure transmitters (PXM309-007AI) are used to measure the air pressure at the inlet, the middle, and at the outlet of the heat exchanger. The air flow rate is measured using SDF flow meter made by SKI. It uses an averaging pitot tube installed at the inlet air pipe near the entrance of the heat exchanger; the flow meter has a bias error of 0.001 kg/s. All instruments are wired into a data acquisition unit (Keysight 34972A). The particle mass flow rate is measured upstream of the heat exchanger where a box with a diverting gate is installed at the bypass line. The measurement is conducted using a simple weight and time measurements; the bias error of the weighing scale is 0.005 kg.

2.4. Test Procedure

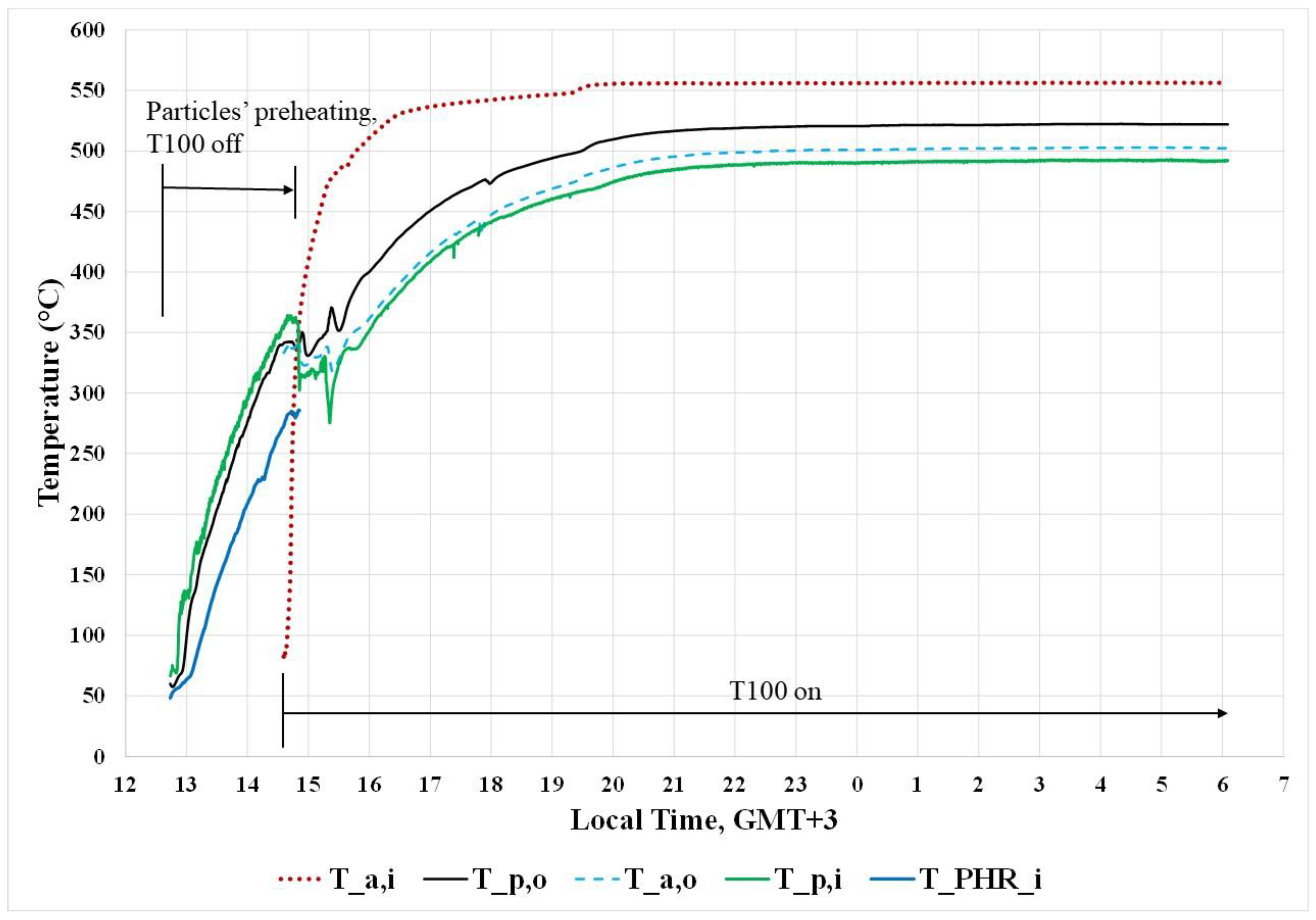

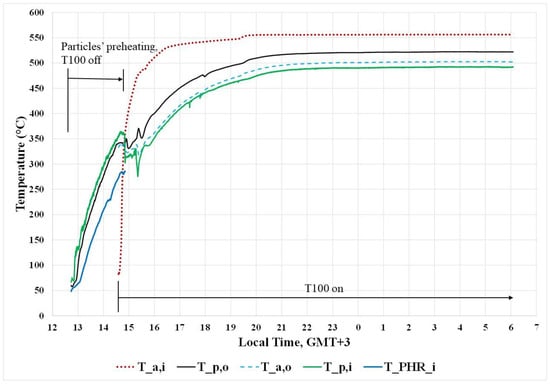

Following the successful integration of the heat exchanger into the facility, the heat exchanger performance can be evaluated by means of two types of tests, namely, the steady-state test and the on-sun test. In the steady-state test, the T100 unit serves as a heat source since once the T100 has started it can be operated independently, without any help from the heliostat field, by burning diesel fuel. However, to start up the T100 unit, the temperature of air entering the combustion chamber must be around 300 °C to sustain the combustor flame. To achieve that, the particle temperature inside the heat exchanger must be above 300 °C to preheat the air. The particle temperature is brought to such temperature by running the facility through a process called the startup/preheating process where particles are circulated through the PHR loop. The particles are allowed to fall through the PHR and get irradiated by the concentrated sunlight reflected from the heliostat field. The particle preheating process continues until the particle temperature inside the heat exchanger gets higher than 300 °C. By then, the T100 unit can be started. During the T100′s startup, the air leaving the recuperator has a temperature less than a 100 °C, so to reduce the possibility of the heat exchanger thermal shock, the air inlet pipe is wrapped with an electric coil heater (4 kW) to preheat air before entering the heat exchanger. In the same way, the air outlet pipe is wrapped with another coil heater (4 kW) to further heat the air before entering the T100′s combustor. Once the T100 unit succeeds to run, the heliostat field and the coil heaters are turned off. The particles are then diverted to the bypass line and kept circulated through the bypass loop. Figure 4 shows the air and particle temperatures at the inlet and outlet of the heat exchanger, in addition to the particle temperature at the PHR’s inlet, during the preheating/startup process until steady-state condition is reached. As shown in the figure, the preheating process takes around two hours.

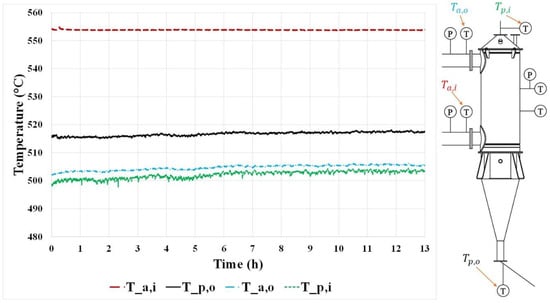

Figure 4.

Temperature variation during the startup/preheating process.

The control system of the T100 unit allows the turbine outlet (flue gases) to be maintained at a fixed temperature. Consequently, the compressed air leaving the T100′s recuperator goes to the heat exchanger with constant conditions (i.e., constant temperature, constant pressure, and constant flow rate). The temperature of the recuperated air can go up to 550 °C. This hot air is used to heat the particles circulated in the heat exchanger’s tubes. The particle heating process in the heat exchanger continues until the whole facility reaches a steady-state situation, where the air and particle temperatures reach a plateau as seen in Figure 4. Several hours (around 8 h, as seen in Figure 4) are needed to reach the steady state due to the large thermal inertia of the facility. The steady-state experimental data are then collected to evaluate the heat exchanger performance.

In the on-sun test, the hot particles (with a temperature usually around 500 °C) are diverted to the PHR, get irradiated by the heliostat field. The further-heated particles then flow inside the PBHX’s tubes to heat the compressed air needed to operate the T100 unit. The test is usually conducted after the facility reaches a steady-state condition. The test really depends on the weather conditions and cannot be performed unless the direct normal irradiance (DNI) is suitable (usually above 700 W/m2). This test is intended to investigate the percentage of the captured solar energy (in the PHR) which can be transferred to the compressed air of the T100 unit. This percentage is called the solar contribution. The solar contribution depends on the effectiveness of the heat exchanger. The higher the effectiveness, the more thermal energy is transferred from particles to the air of the T100 unit. More elaboration on the on-sun operation can be found in [14].

3. Experimental Results

The solid particles used in this study are called Carbobead CP (also known as ACCUCAST ID); they are engineered ceramic particles manufactured by CARBO Industrial Technologies. The chemical composition of Carbobead CP particles is listed in Table 3.

Table 3.

The chemical composition of Carbobead CP particles [15].

Several tests were conducted to identify the relevant kinematic, optical, and thermophysical properties of the Carbobead CP particles. For instance, the angle of repose was measured using different methods including the hollow cylinder, fixed funnel, and revolving cylinder methods. The packed-bed reflectivity was measured using ASD FieldSpe3 Portable Spectroradiometer. The absorptance was estimated using the measured reflectivity. Some of the measured properties, and those provided by the manufacturer, are listed in Table 4. Moreover, the particles did not show any sign of agglomeration while being tested in the PHR and inside an electrical oven at high temperatures.

Table 4.

Carbobead CP properties.

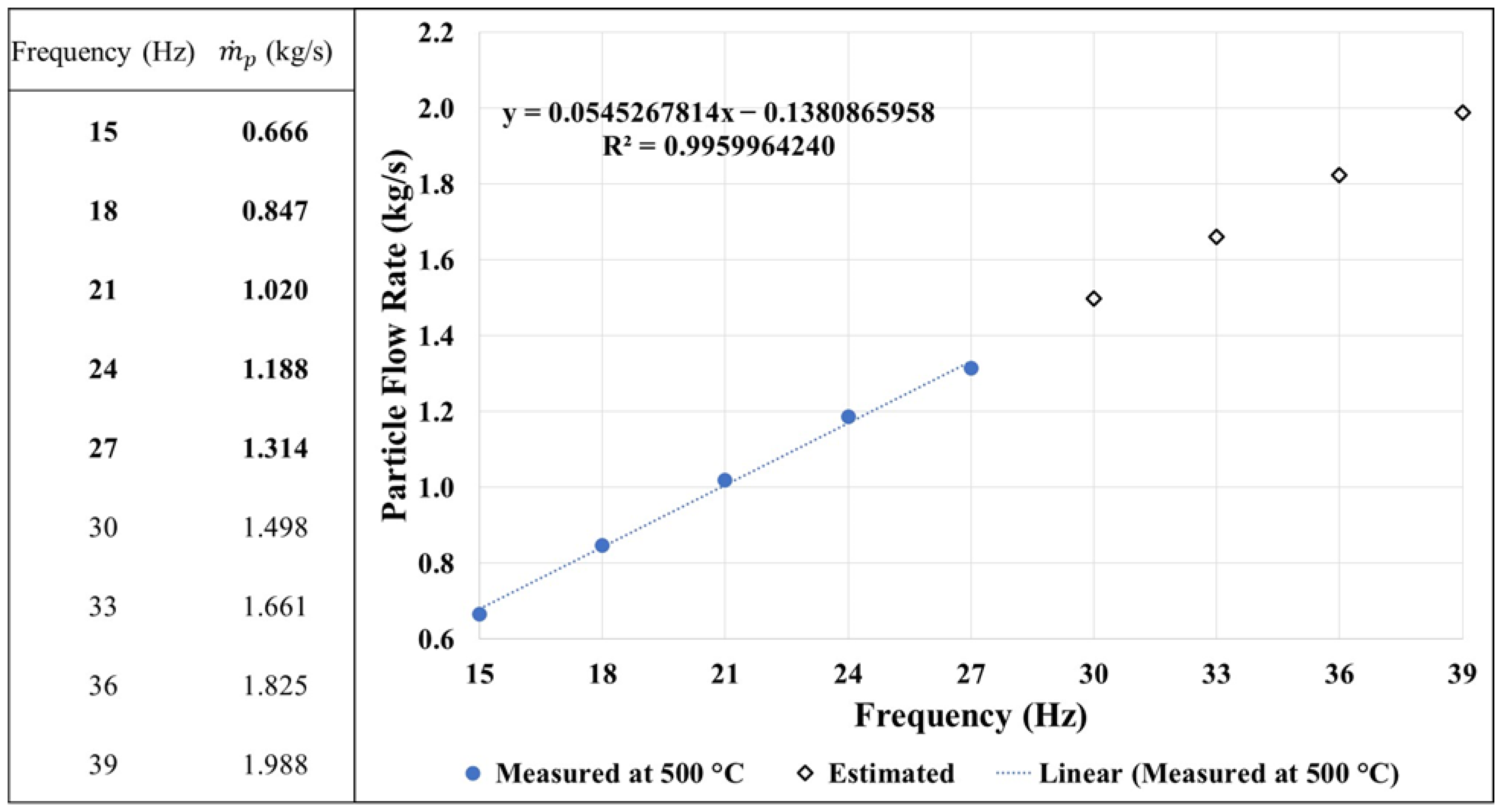

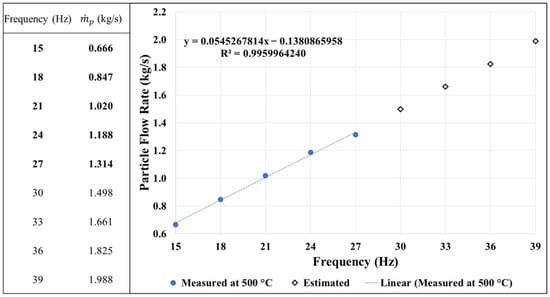

A series of on-sun and steady-state tests were performed to investigate the thermal performance of the heat exchanger. The recuperated air of the T100 unit was used as the heat source in the steady-state tests while the solar energy was the heat source in the on-sun (unsteady) tests. Several mass flow rates of particles were used to investigate the effect of flow rate (velocity) variation on the thermal performance of the heat exchanger. As mentioned earlier, the particle flow rate can be controlled by controlling the rotational speed of the Olds Elevator. The Olds Elevator has a variable frequency drive that controls the motor speed of the Olds Elevator; each speed/frequency gives a certain particle flow rate. Figure 5 shows how the particle flow rate changes with the speed/frequency of the elevator; five flow rates were measured while the particles were maintained at around 500 °C; it was found that the flow rate changes linearly with the speed. Another four flow rates have been extrapolated using such linear relationship as can be seen in Figure 5. The recuperated air of the T100 unit always enters the heat exchanger with constant conditions, i.e., constant flow rate, constant temperature, and constant pressure. The air and particle temperatures, air pressure, and air flow rate are continuously measured and recorded during the tests.

Figure 5.

Variation of particle flow rate with elevator VFD frequency (Hz).

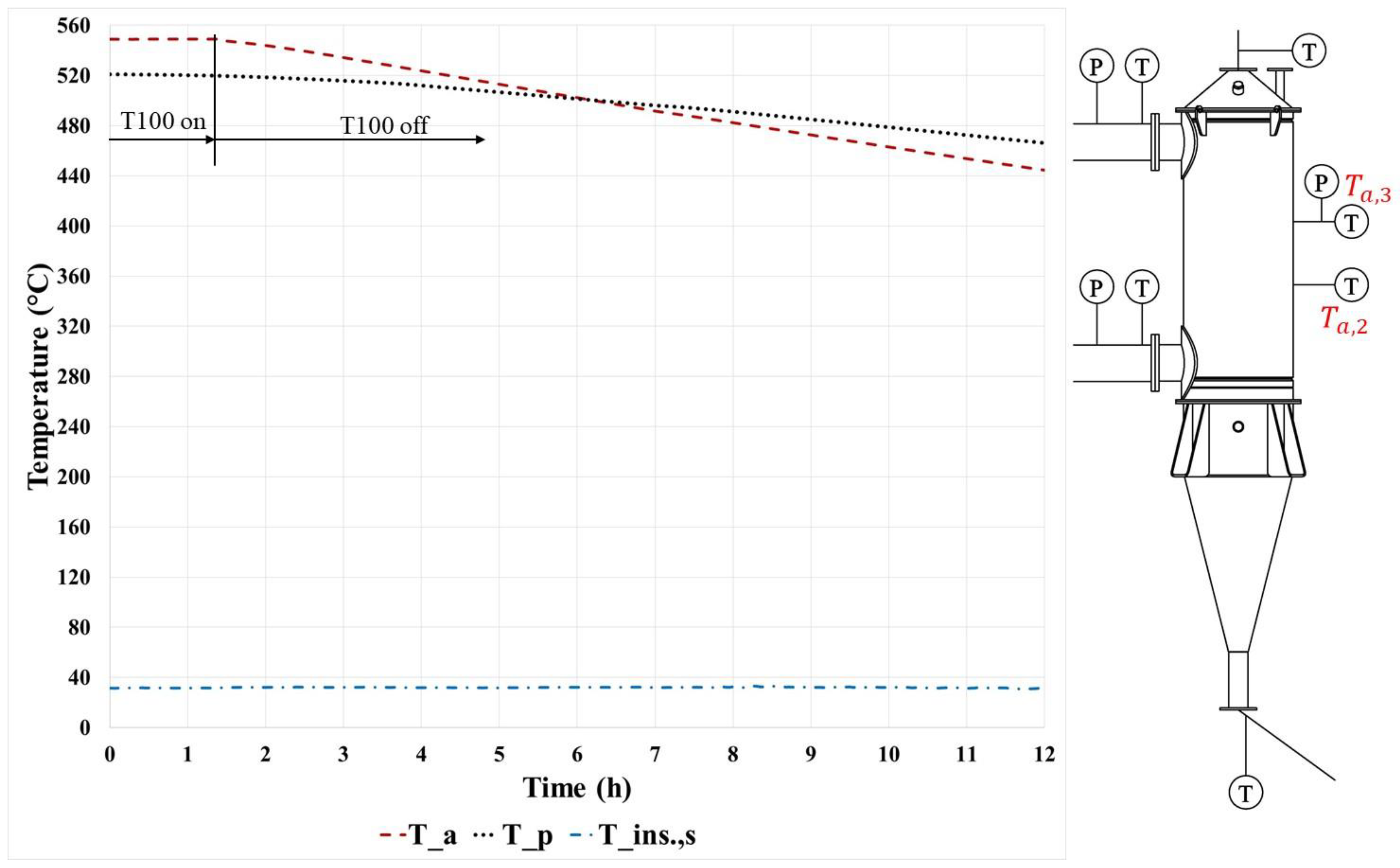

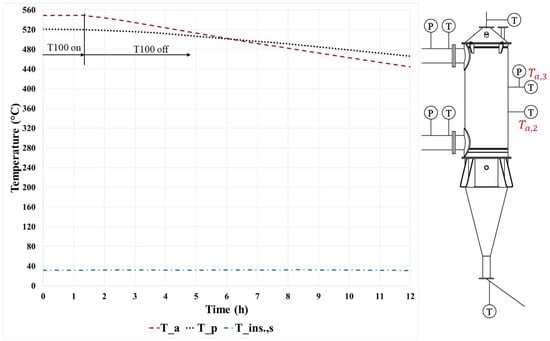

The quality of the thermal insulation of the heat exchanger was tested by keeping the particles inside the heat exchanger without being circulated. Meanwhile the T100 unit was kept running in order for the heat exchanger to reach a thermal equilibrium. Once this was conducted, the T100 unit was shut down, and air and particle temperatures were continuously recorded for several hours in order to examine the temperature decay process. Figure 6 shows the results of this test; the air temperature is the arithmetic mean of the readings of the thermocouples installed below and above the middle of the heat exchanger, i.e., and , respectively. The particle temperature refers to the temperature of particles inside the mass-flow cone, and is the temperature of the outer surface of the thermal insulation.

Figure 6.

Temperature decay inside the heat exchanger when T100 unit is off.

The heat loss from the heat exchanger to the surrounding through the thermal insulation can be estimated using the thermal resistance concept by knowing the temperatures and thermal resistance across the thermal insulation. The inner temperature of the insulation is equal to the temperature of the outer surface of the heat exchanger’s shell if the thermal contact resistance is neglected. The shell’s outer surface temperature is assumed to be the average of the maximum temperatures of both media across the heat exchanger, i.e., the average of air inlet and particles outlet temperatures, as shown in Equation (1). This approach represents the upper limit for the shell’s outer surface temperature; hence, the worst-case scenario for the heat loss.

where and are the air inlet and particle outlet temperatures, respectively, ∆T is the temperature difference between the inner and outer surfaces of the insulation, and is the total thermal resistance of the insulation.

The heat losses associated with the conducted steady-state tests are listed in Table 5. Those tests will be presented shortly in detail. It can be noticed that the loss represents a small percentage of the total heat supplied by the air, less than 3%. This implies that the heat exchanger is well insulated.

Table 5.

Heat loss through thermal insulation.

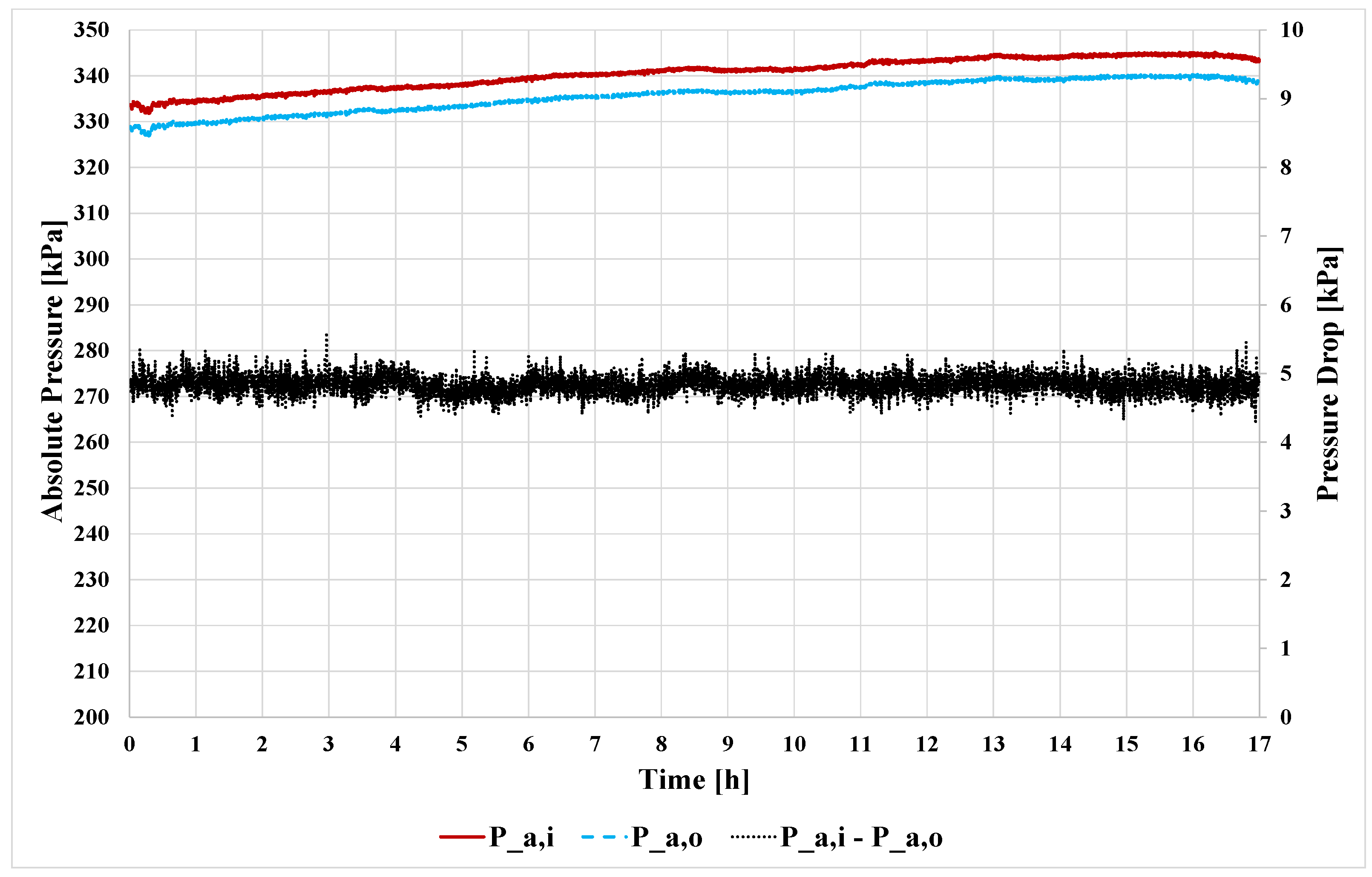

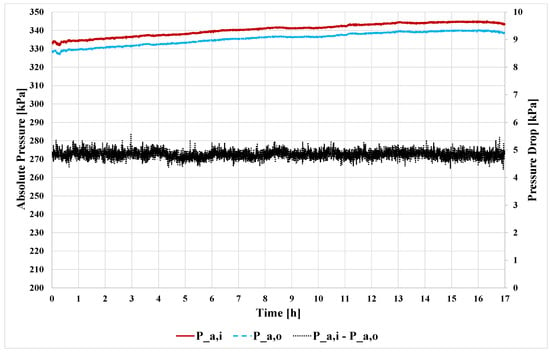

The air pressure at the inlet () and outlet () of the heat exchanger is continuously measured. It was found that the pressure drop () across the heat exchanger is around 5 kPa. Figure 7 shows the air pressure measurements and the pressure drop.

Figure 7.

Air pressure across the heat exchanger.

3.1. On-Sun Tests

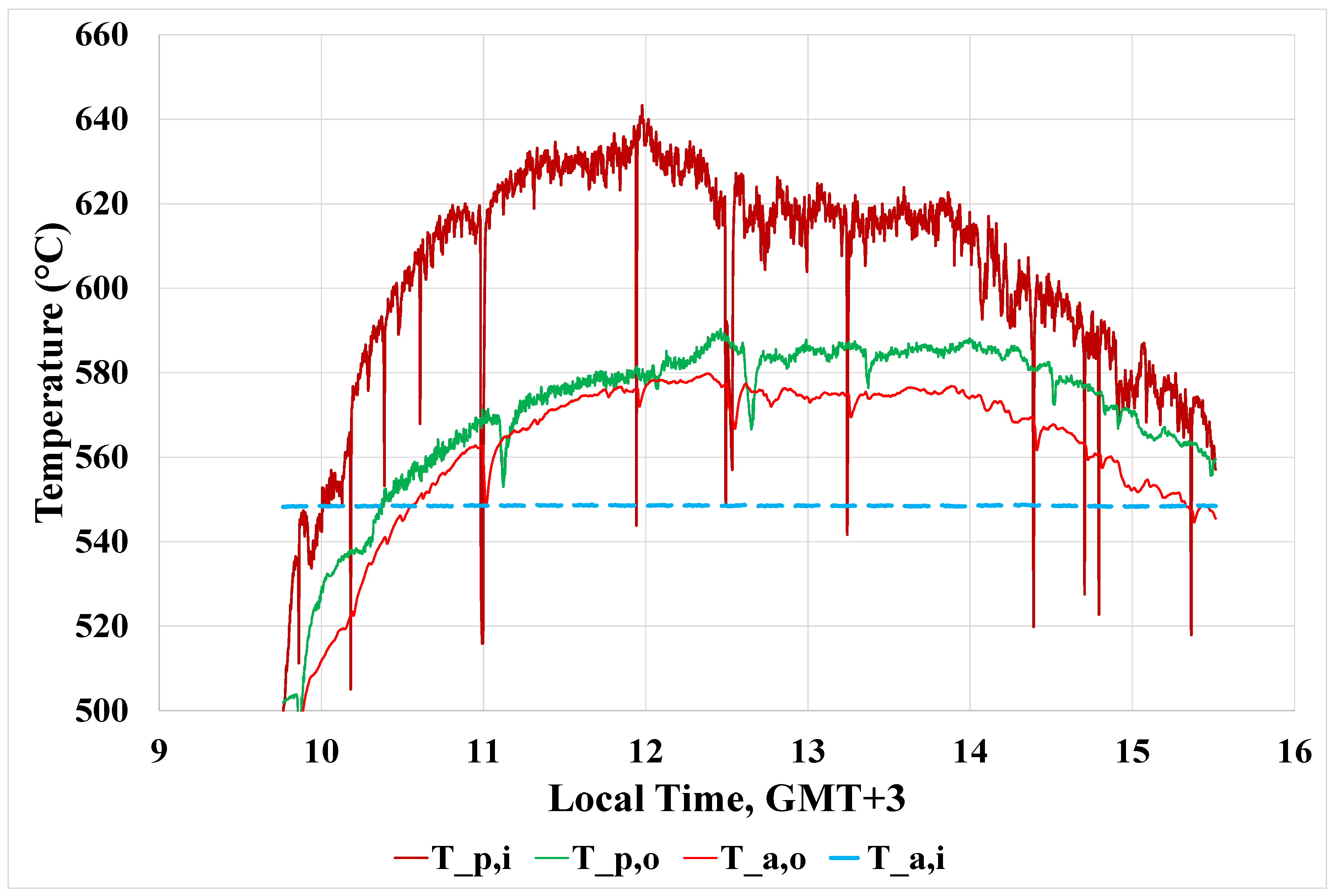

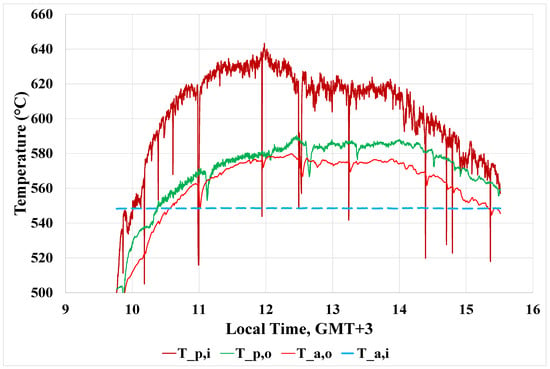

Several on-sun tests have been conducted in order to investigate the thermal performance of the heat exchanger at high temperatures, i.e., higher than those that can be obtained in the steady-state tests. In the on-sun tests, the heat exchanger uses hot particles to further heat up the recuperated air of the T100 unit. The particles, whose temperatures are higher than 500 °C, are allowed to flow through the PHR, where they are irradiated by the heliostat field, thus, raising their temperature to around 650 °C. The hot particles then transfer some of the collected thermal energy to the T100′s air while flowing through the heat exchanger. Figure 8 shows a typical example of such tests. The heat exchanger kept supplying thermal energy to the T100′s air for around five hours. However, it is obvious that the temperature of particles entering the heat exchanger keeps changing with time as a result of the variable incident solar flux on the PHR during the test period. Due to such variation of air and particle temperatures, it is not possible to assess the heat exchanger performance. The thermal mass of the heat exchanger needs a certain amount of time to reach a thermal equilibrium which gets more complicated when the particle inlet temperature varies with time. For the particle inlet temperature to get steady, a buffer tank needs to be installed upstream of the heat exchanger, just after the PHR to receive the hot particles leaving the PHR. Along with that, the incident solar flux on the PHR and/or the particle flow rate should be adjusted/controlled. The incident solar flux can be controlled by adjusting the number of running heliostats, and a particle mass flow control system can be installed upstream the PHR. Nevertheless, it is evident that the heat exchanger is able to transfer some of the collected solar energy to the T100′s air. The area enclosed by the air lines (shown in Figure 8) qualitatively represents the amount of energy added during this test, i.e., solar contribution.

Figure 8.

Air and particles temperatures across the heat exchanger during an on-sun test.

3.2. Steady-State Tests

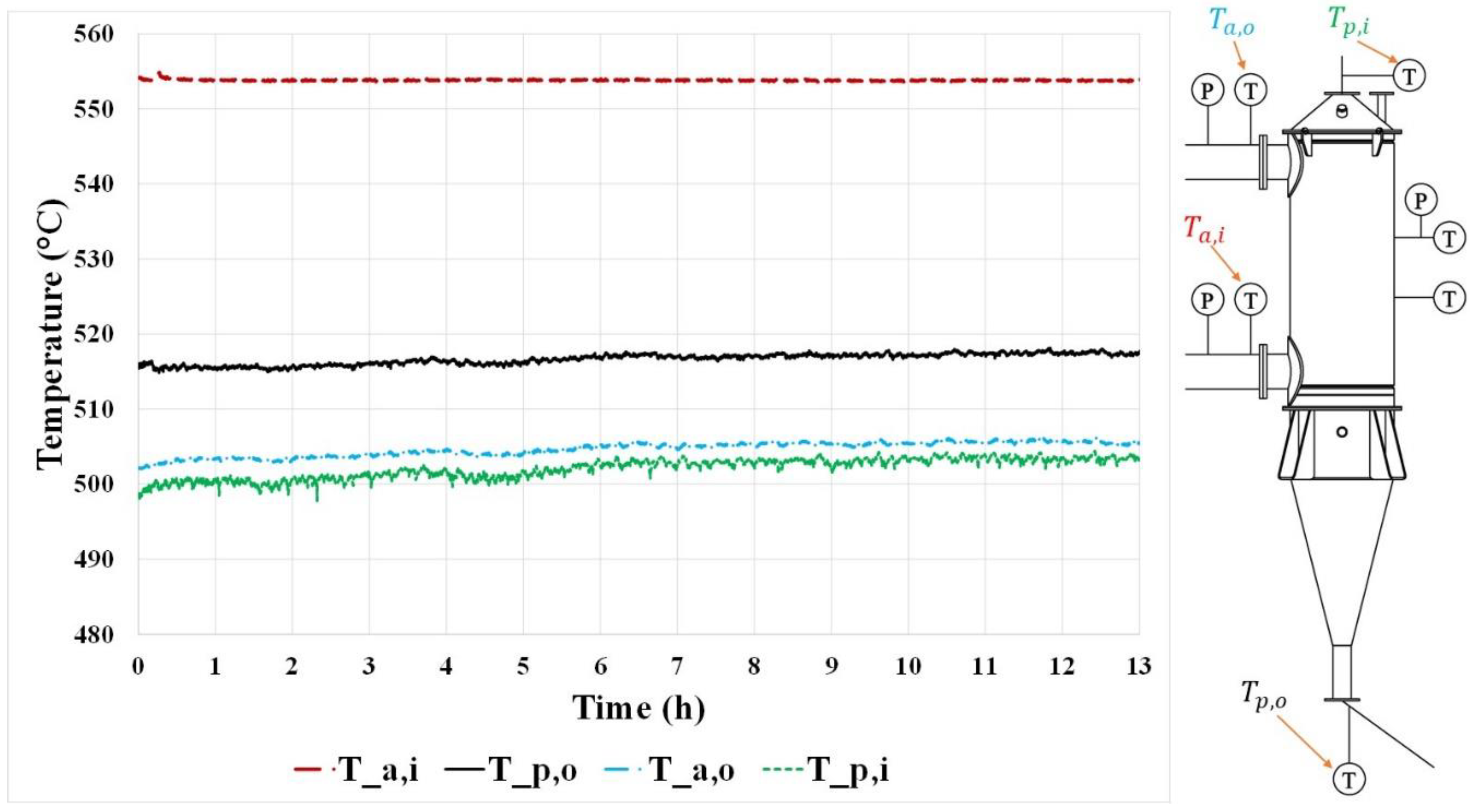

In the steady-state tests, the hot recuperated air (above 500 °C) of the T100 unit is used to heat the particles. In such tests, the particles are circulated through the bypass loop, i.e., no solar energy is being added. It is important to emphasize that the T100′s air always enters the heat exchanger with steady-state conditions, i.e., constant flow rate, constant temperature, and constant pressure. Table 6 summarizes some of the conducted tests in which the particle flow rate was varied. These experimental data were collected when air and particles temperatures along the heat exchanger and the whole facility reach steady-state conditions for a sufficient period. The temperatures were obtained by averaging the readings of the thermocouples installed at the corresponding locations. Figure 9 shows the air and particle temperatures at the inlet and outlet of the heat exchanger during one of the conducted steady-state tests.

Table 6.

Steady-state tests measurements.

Figure 9.

Air and particle temperatures at the inlet and outlet of the heat exchanger, Test no. 8.

The thermal performance of the heat exchanger can be represented by the overall heat transfer coefficient and the effectiveness. These parameters can be estimated using the following equations:

where is the heat transfer rate, is the overall heat transfer coefficient, is the total heat transfer area, is the log mean temperature difference, is the heat exchanger effectiveness, and is the maximum possible heat transfer rate.

The heat supplied by the air and that captured by the particles, inside the heat exchanger, can be estimated by incorporating a control volume on each medium and applying energy balance

where is the mass flow rate, ∆h is the specific enthalpy difference between the inlet and outlet, is the specific heat, and ∆T is the temperature difference.

The specific heat of the Carbobead CP particles, according to [6], can be obtained from

The log mean temperature difference and the maximum possible heat transfer rate are obtained as

where and are the inlet and outlet temperatures of air, respectively, and are the inlet and outlet temperatures of particles, respectively, and is the minimum heat capacity rate.

The particle superficial velocity inside the tubes is calculated as

where is the number of tubes, is the material density of particles, and is the cross-sectional area of each tube.

Table 7 shows the results of the conducted tests. The results include the heat transfer rates, the LMTD, the heat exchanger effectiveness, the particle velocity inside each tube, and the overall heat transfer coefficient. It should be noted that the overall heat transfer coefficient was calculated based on the heat transfer area of the particle side. The propagation of the bias error of the measured variables into the calculated quantities was estimated using the Engineering Equation Solver (EES) software package as

where refers to the bias uncertainty, is the dependent variable, and are the independent variables.

Table 7.

Results of the steady-state tests.

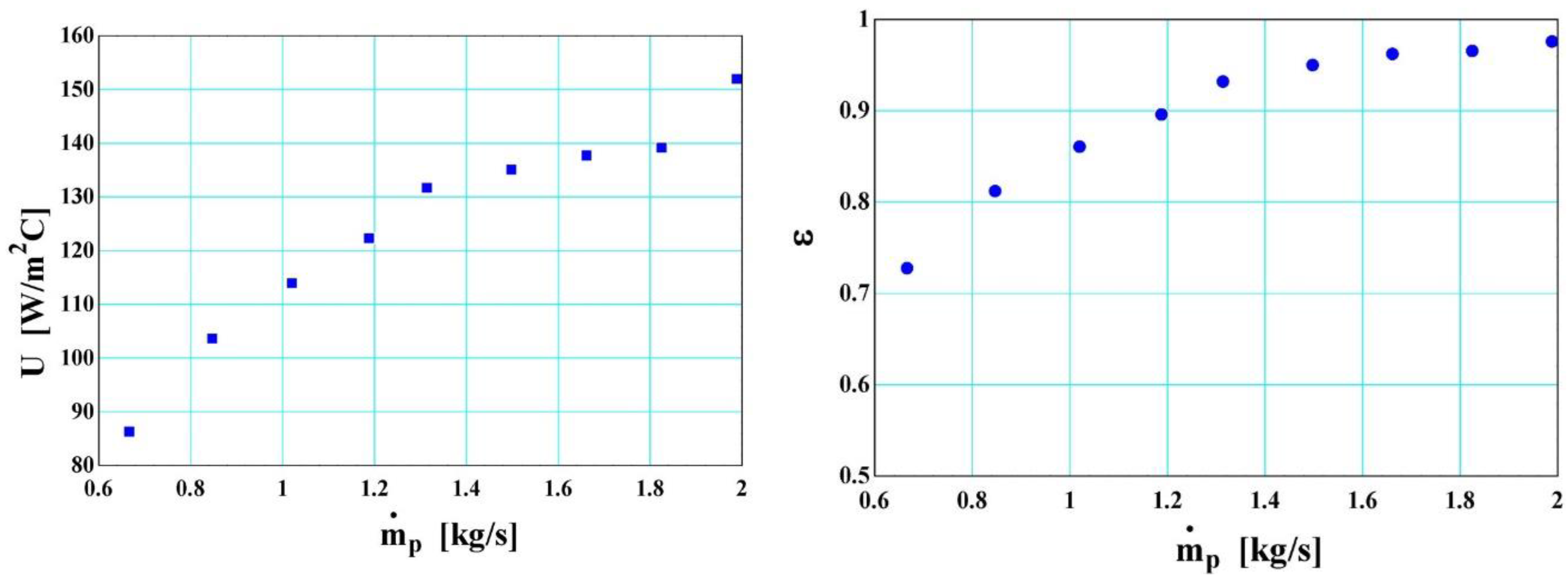

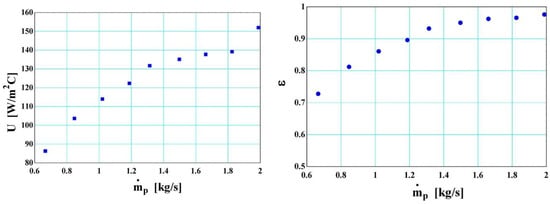

Figure 10 shows a graphical representation of the variation of the overall heat transfer coefficient and effectiveness with the particle mass flow rate. It can be seen that as the particle mass flow rate increases, the and increase. By observing the amount of collected heat () compared to the supplied heat (), it is noticeable that the approaches at higher flow rates. This might be the main reason of such increase in the values of and . Moreover, as can be seen from Figure 10, when the mass flow rate increases, both and approach a plateau, i.e., a constant value, since gets almost equal to .

Figure 10.

The variation of the overall heat transfer coefficient and the effectiveness with particle flow rate.

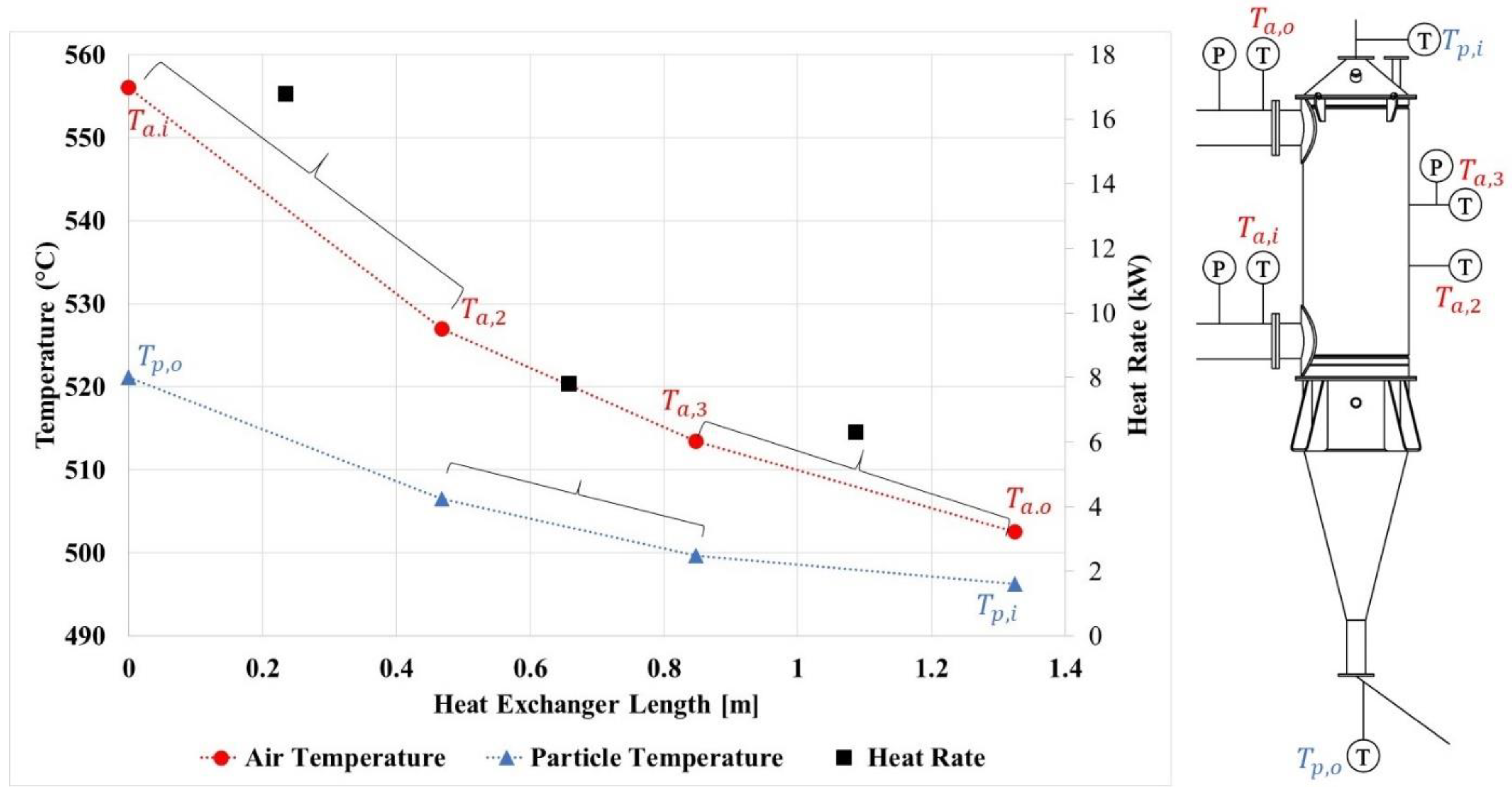

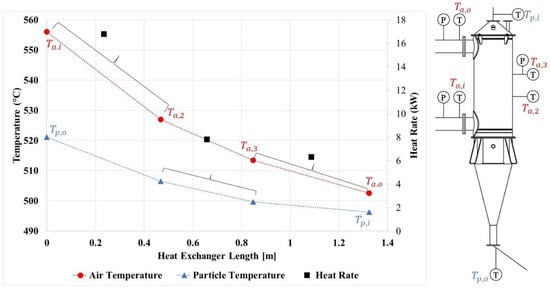

The temperature distributions of air and particles across the heat exchanger are shown in Figure 11. It should be noted that the particles temperatures, other than the inlet and outlet, have been estimated by applying a heat balance between air and particles. It is evident from Figure 11 that more than half of the heat transfer occurred at the lower section of the heat exchanger where the temperature difference is the largest. It could also be noted that these results are based on test conditions under a particle heating scenario, and it could be better in a particle cooling situation especially if the particle flow rate is balanced with the air flow rate so that the approach temperature is maximized throughout the exchanger instead of having a pinch point at the top of the exchanger, thereby, enhancing the overall heat transfer coefficient.

Figure 11.

Temperature distributions of air and particles across the heat exchanger, Test no. 3.

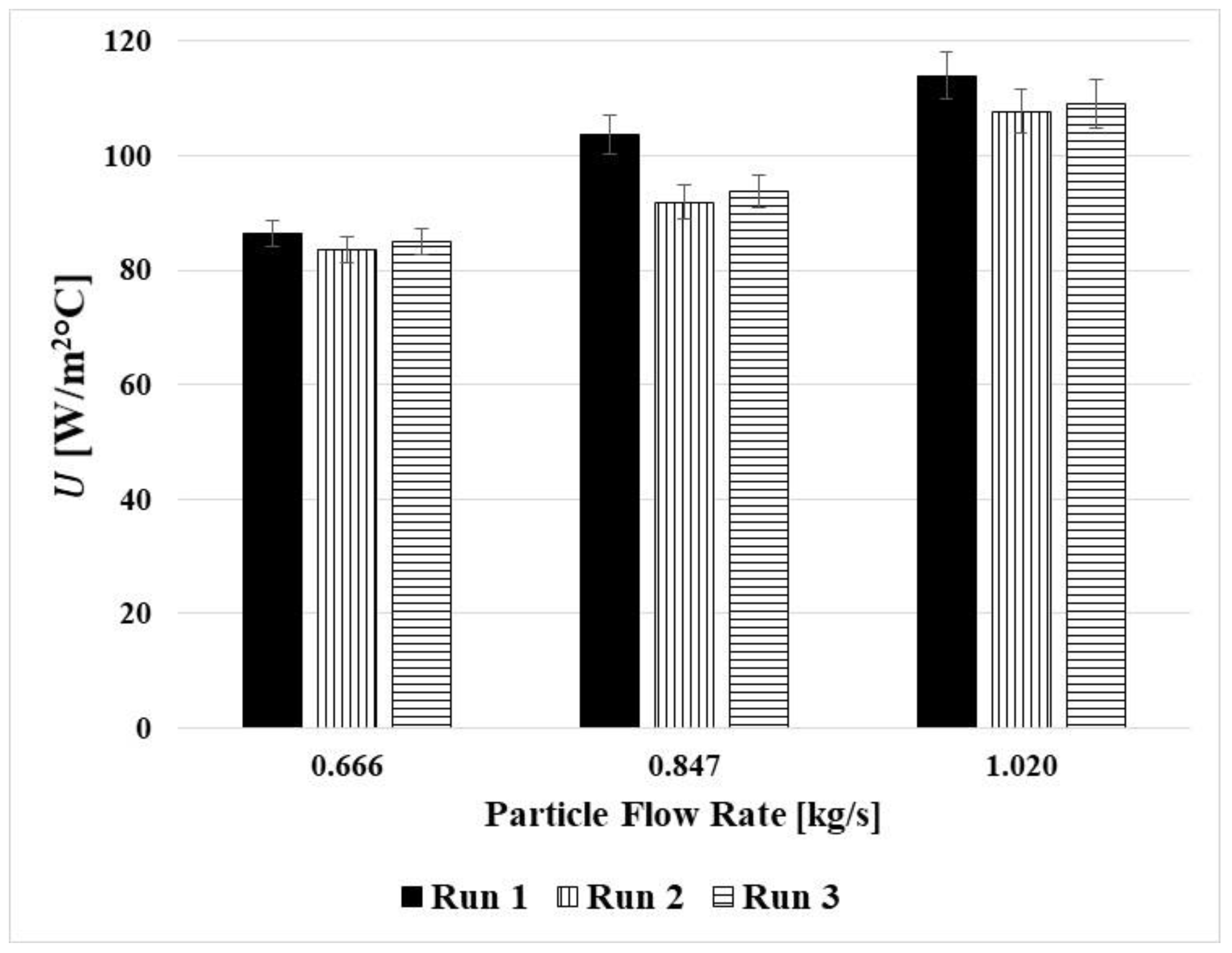

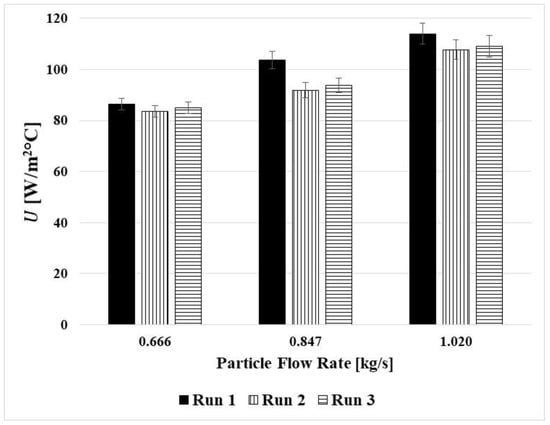

Some tests have been repeated to assess the accuracy of measurements. Figure 12 shows three separate runs for three tests conducted in different testing campaigns. The results slightly differ; the standard deviations of the measured U for particle flow rates of 0.666, 0.847 and 1.020 kg/s are 1.4, 6.3 and 3.3 W/m2-°C, respectively, which correspond to relative standard deviations of 1.6, 6.6 and 3.3%. This implies that the measured overall heat transfer coefficient is quite accurate.

Figure 12.

Repeatability analysis of steady-state tests.

4. Conclusions

A 50 kWth moving packed-bed particle-to-air heat exchanger, fabricated by Solex Thermal Science Inc., has been integrated into the PBCSP test facility located at KSU in Riyadh, Saudi Arabia. The heat exchanger incorporates a shell-and-tube configuration in which solid particles move downward inside vertical tubes while air flows on a shell-side. Particles, called Carbobead CP, with 0.3 mm mean diameter were used in this investigation. The thermal performance of the heat exchanger was evaluated using the recuperated air of the T100 unit as the heat source. The effect of particle flow rate variation on the overall heat transfer coefficient and effectiveness was studied. Based on LMTD calculations, the measured overall heat transfer coefficient, in the steady-state tests, was found to be in a range that meets the value targeted by the DOE (100 W/m2-°C). The accuracy of measurement was investigated by repeating some tests; a slight difference was noted in the measured U. The results revealed that a significant portion of the heat exchange took place at the bottom section of the heat exchanger. In addition, a small pressure drop (5 kPa) was recorded on the air side of the heat exchanger. Achieving a steady-state condition during on-sun operation currently is not possible. In the future, the amount of solar energy is to be controlled. By controlling the number of operating heliostats, the PHR’s outlet, thus, the exchanger’s inlet temperature, can be held constant during the test. Going with such measures allows for steady-state operation to be reached, i.e., the performance of the exchanger can be evaluated at elevated temperature (>650 °C).

Author Contributions

Conceptualization, S.A., H.A.-A., S.J., Z.A.-S., A.B., N.J. and D.M.; data curation, N.S.S.; formal analysis, N.S.S. and S.A.; funding acquisition, H.A.-A.; investigation, N.S.S., S.A. and E.D.; methodology, N.S.S., S.A., H.A.-A., Z.A.-S., O.Z. and S.J.; project administration, S.A. and H.A.-A.; resources, H.A.-A.; supervision, Z.A.-S., O.Z. and H.A.-A.; validation, N.S.S., S.A., Z.A.-S. and O.Z.; visualization, N.S.S.; writing—original draft, N.S.S.; writing—review & editing, N.S.S., S.A., E.D., R.S.S., Z.A.-S., O.Z., A.A., A.E.-L., S.D., A.B. and N.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by “The Deanship of Scientific Research at King Saud University, through research group no. RG-1440-087”, which is truly appreciated.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors extend their appreciation to the Deanship of Scientific Research at King Saud University for funding this work through research group no. RG-1440-087.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Benoit, H.; Spreafico, L.; Gauthier, D.; Flamant, G. Review of heat transfer fluids in tube-receivers used in concentrating solar thermal systems: Properties and heat transfer coefficients. Renew. Sustain. Energy Rev. 2016, 55, 298–315. [Google Scholar] [CrossRef]

- El-Leathy, A.; Jeter, S.; Al-Ansary, H.; Danish, S.N.; Saeed, R.; Abdel-Khalik, S.; Golob, M.; Djajadiwinata, E.; Al-Suhaibani, Z. Thermal performance evaluation of lining materials used in thermal energy storage for a falling particle receiver based CSP system. Sol. Energy 2019, 178, 268–277. [Google Scholar] [CrossRef]

- “Generation 3 Concentrating Solar Power Systems (Gen3 CSP) Phase 3 Project Selection”. Energy.gov, Solar Energy Technologies Office. Available online: https://www.energy.gov/eere/solar/generation-3-concentrating-solar-power-systems-gen3-csp-phase-3-project-selection (accessed on 8 April 2022).

- Al-Ansary, H.; El-Leathy, A.; Jeter, S.; Djajadiwinata, E.; Alaqel, S.; Golob, M.; Nguyen, C.; Saad, R.; Shafiq, T.; Danish, S. On-sun experiments on a particle heating receiver with red sand as the working medium. AIP Conf. Proc. 2018, 2033, 040002. [Google Scholar]

- El-Leathy, A.; Al-Ansary, H.; Jeter, S.; Djajadiwinata, E.; Alaqel, S.; Golob, M.; Nguyen, C.; Saad, R.; Shafiq, T.; Danish, S. Preliminary tests of an integrated gas turbine-solar particle heating and energy storage system. AIP Conf. Proc. 2018, 2033, 040013. [Google Scholar]

- Ho, C.K.; Carlson, M.; Albrecht, K.J.; Ma, Z.; Jeter, S.; Nguyen, C.M. Evaluation of alternative designs for a high temperature particle-to-sCO2 heat exchanger. J. Sol. Energy Eng. 2019, 141, 021001. [Google Scholar] [CrossRef]

- Takeuchi, H. Particles flow pattern and local heat transfer around tube in moving bed. AIChE J. 1996, 42, 1621–1626. [Google Scholar] [CrossRef]

- Baumann, T.; Zunft, S. Development and performance assessment of a moving bed heat exchanger for solar central receiver power plants. Energy Procedia 2015, 69, 748–757. [Google Scholar] [CrossRef] [Green Version]

- Al-Ansary, H.; El-Leathy, A.; Al-Suhaibani, Z.; Jeter, S.; Sadowski, D.; Alrished, A.; Golob, M. Experimental study of a sand–air heat exchanger for use with a high-temperature solar gas turbine system. J. Sol. Energy Eng. 2012, 134, 041017. [Google Scholar] [CrossRef]

- Nguyen, C.; Sadowski, D.; Alrished, A.; Al-Ansary, H.; Jeter, S.; Abdel-Khalik, S. Study on solid particles as a thermal medium. Energy Procedia 2014, 49, 637–646. [Google Scholar] [CrossRef] [Green Version]

- Alaqel, S.; El-Leathy, A.; Al-Ansary, H.; Djajadiwinata, E.; Saleh, N.; Danish, S.; Saeed, R.; Alswaiyd, A.; Al-Suhaibani, Z.; Jeter, S. Experimental investigation of the performance of a shell-and-tube particle-to-air heat exchanger. Sol. Energy 2020, 204, 561–568. [Google Scholar] [CrossRef]

- Mehos, M.; Turchi, C.; Vidal, J.; Wagner, M.; Ma, Z.; Ho, C.; Kolb, W.; Andraka, C.; Kruizenga, A. Concentrating Solar Power Gen3 Demonstration Roadmap; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2017.

- Byman, A.D.; Huang, X.; Mcgillivray, R. Heat Exchanger for Heating or Cooling Bulk Solids. U.S. Patent 15/633,365, 27 December 2018. [Google Scholar]

- Alaqel, S.; Djajadiwinata, E.; Saleh, N.S.; Saeed, R.; Alswaiyd, A.; Al-Ansary, H.; El-Leathy, A.; Jeter, S.; Danish, S.; Al-Suhaibani, Z.; et al. On-Sun Experiments on the World’s First Deployed Gas-Turbine Particle-Based Power Tower Facility at King Saud University. In Proceedings of the SolarPACES Conference, Online Event, 28 September–2 October 2020. [Google Scholar]

- Ho, C.K.; Christian, J.M.; Romano, D.; Yellowhair, J.; Siegel, N.; Savoldi, L.; Zanino, R. Characterization of particle flow in a free-falling solar particle receiver. J. Sol. Energy Eng. 2017, 139, 021011. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).