New Generation Compact Linear Accelerator for Low-Current, Low-Energy Multiple Applications

Abstract

:1. Introduction

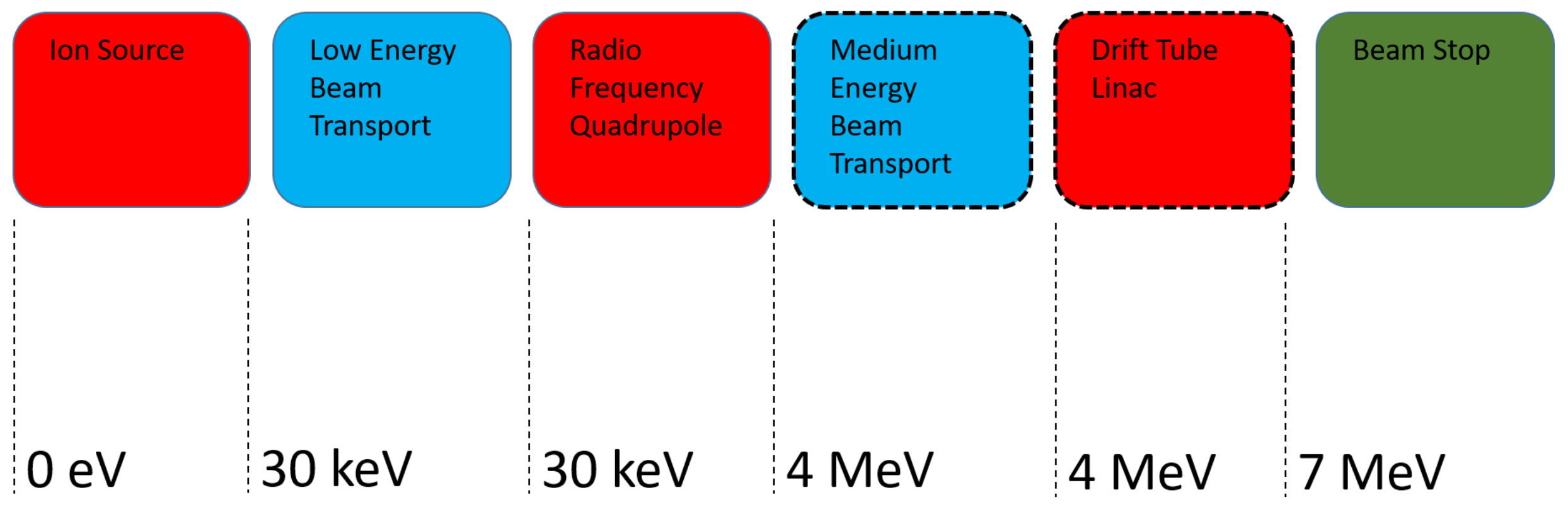

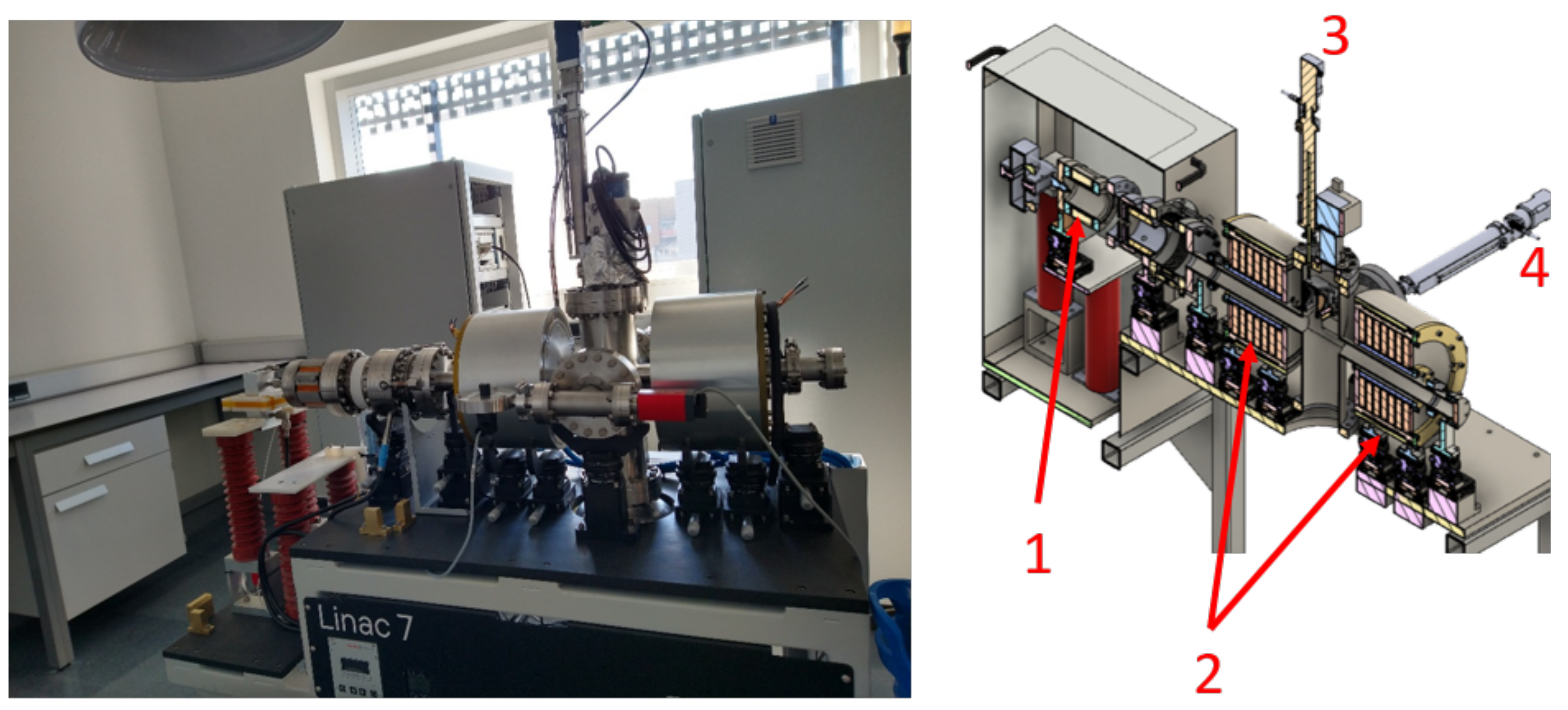

2. LINAC 7 Accelerator Component Descriptions

2.1. Ion Source

2.2. Low Energy Beam Transport

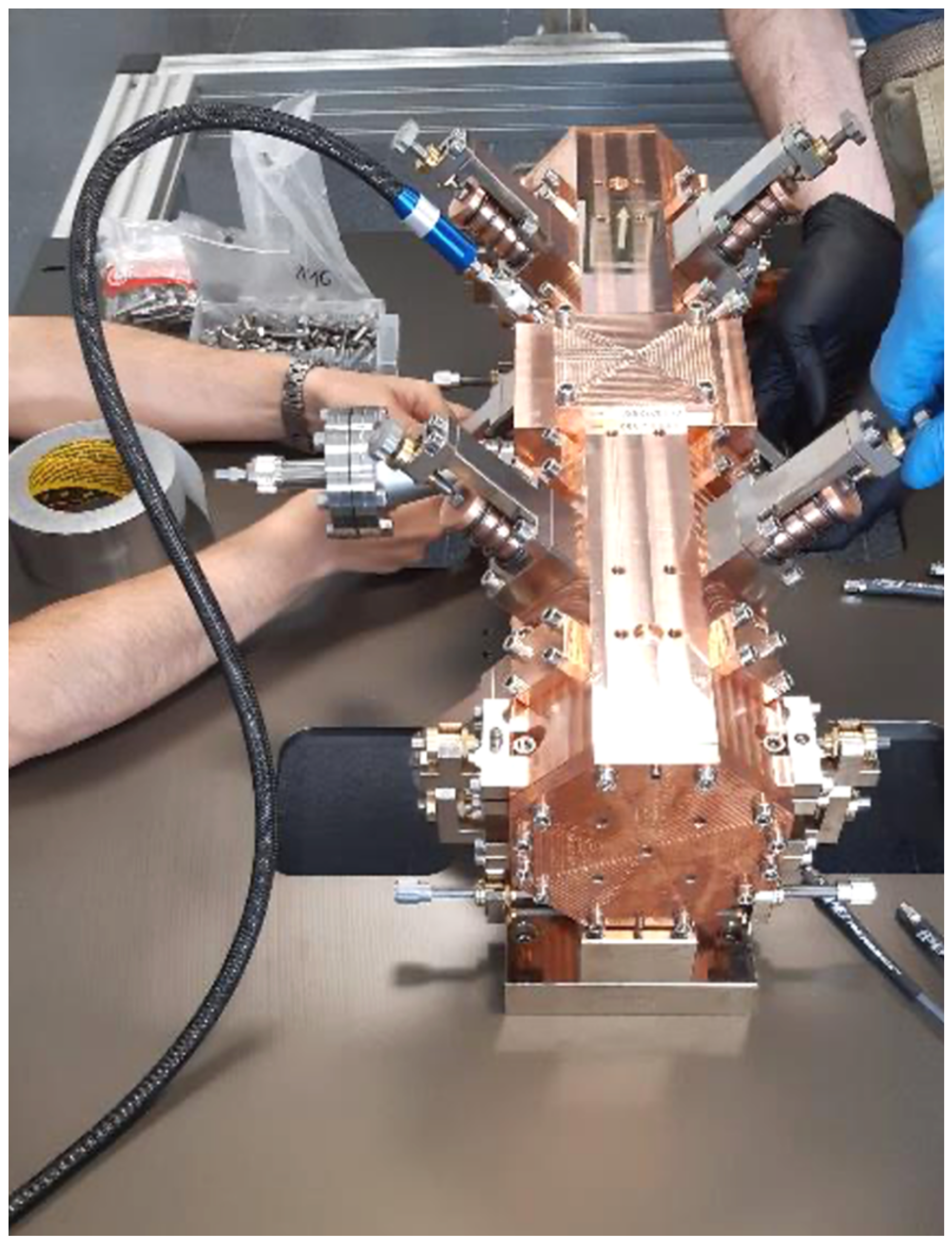

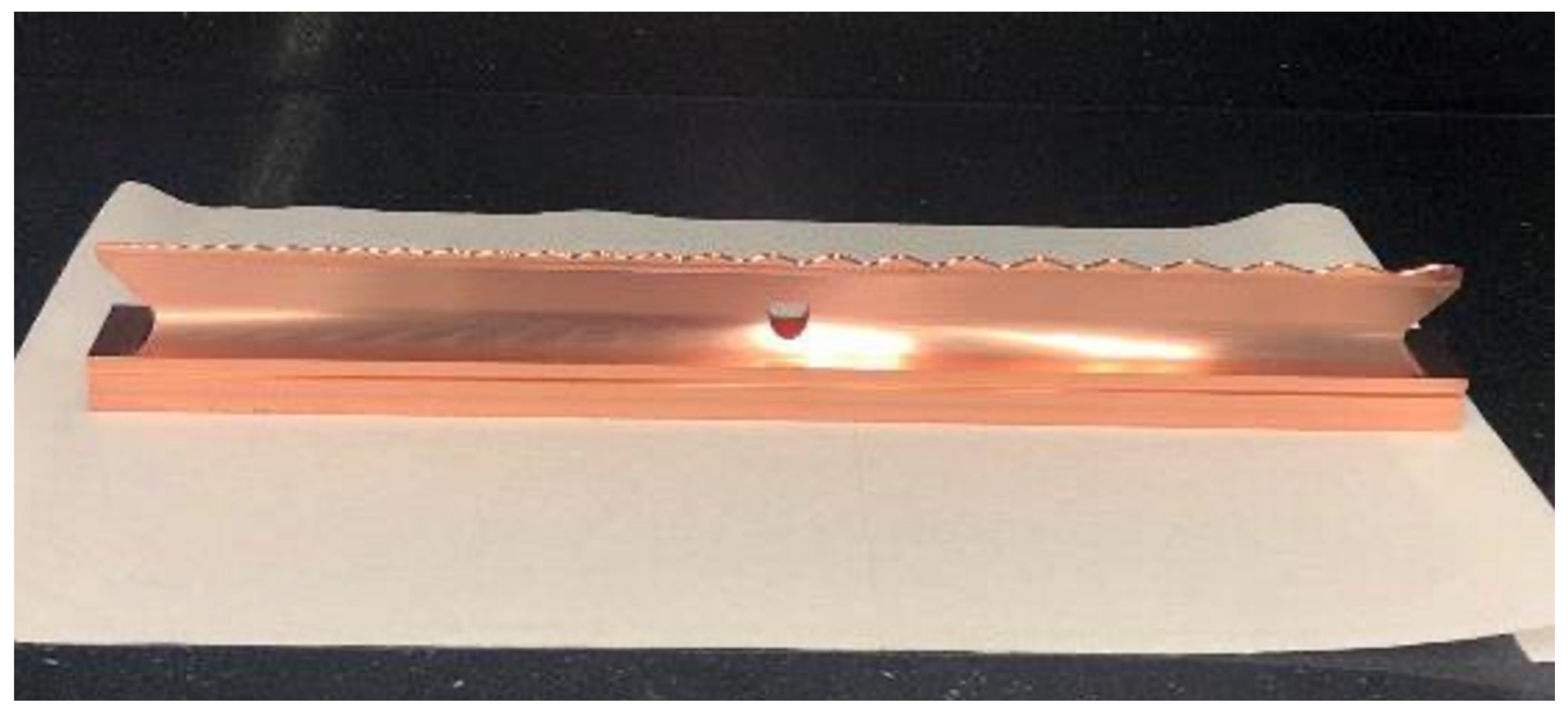

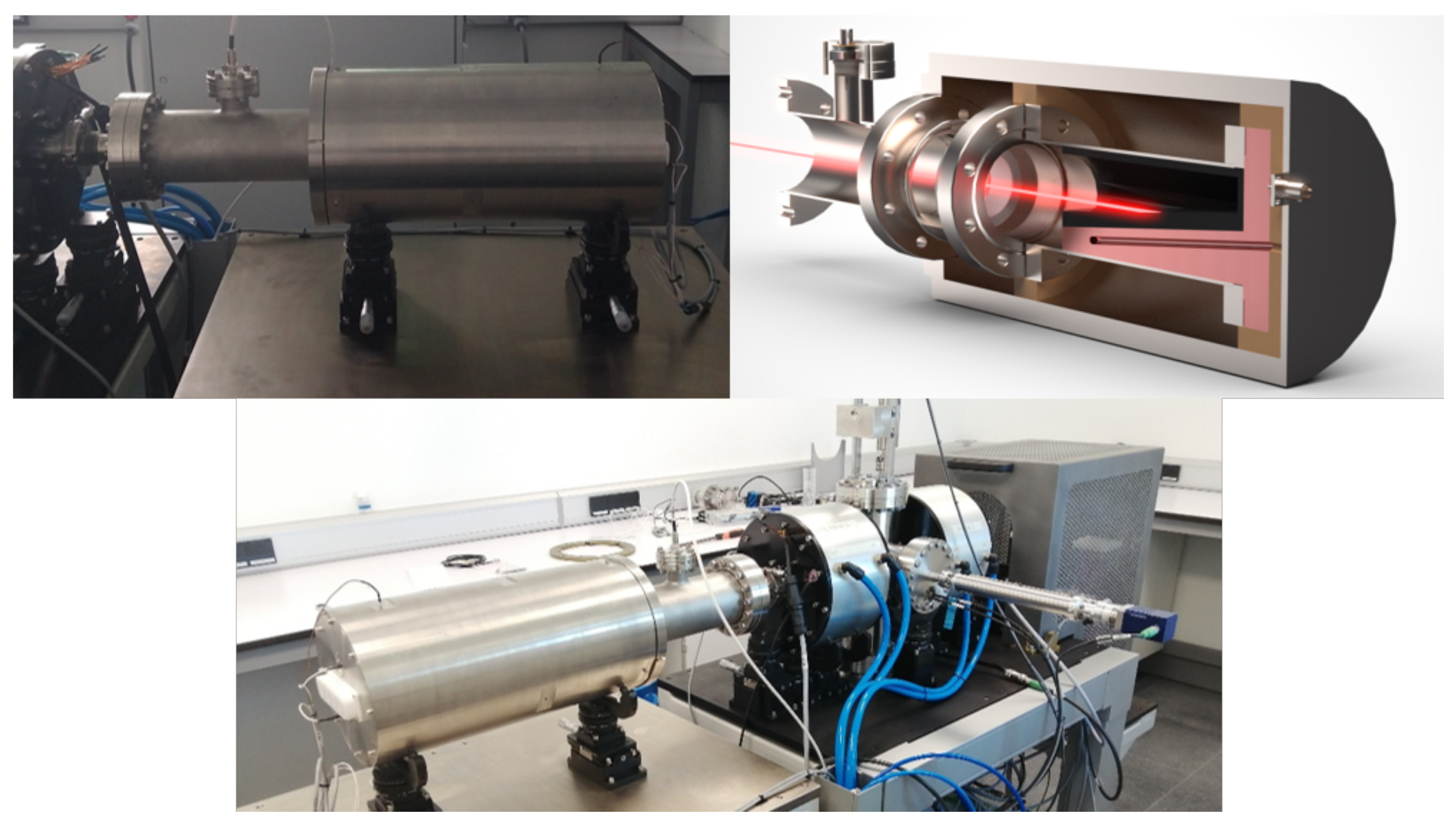

2.3. Radio Frequency Quadrupole (RFQ)

2.4. Medium Energy Beam Transport (MEBT)

2.5. Drift Tube Linac (DTL)

2.6. Beam Stop

2.7. Control Systems

3. Experiment and Simulations

3.1. Ion Source

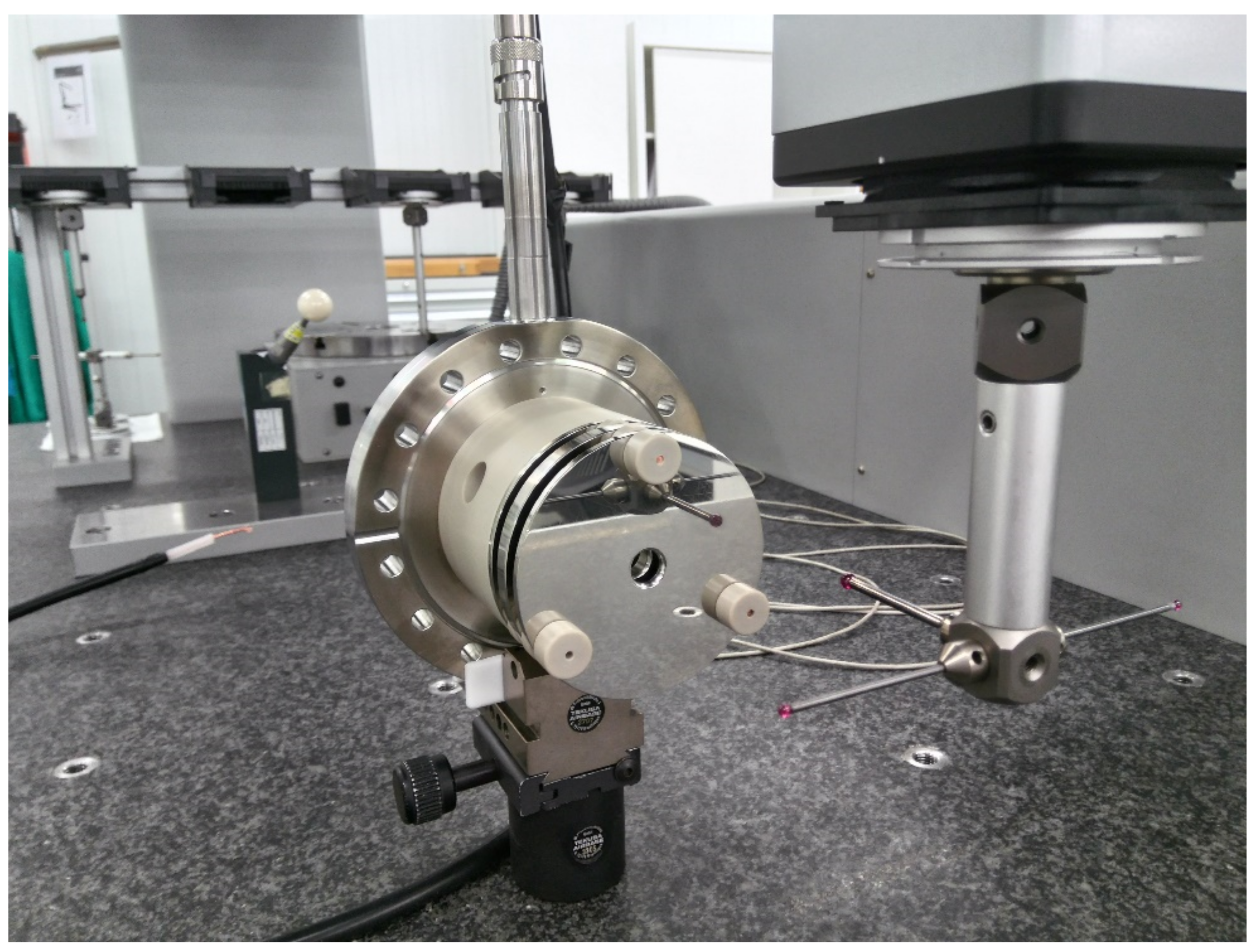

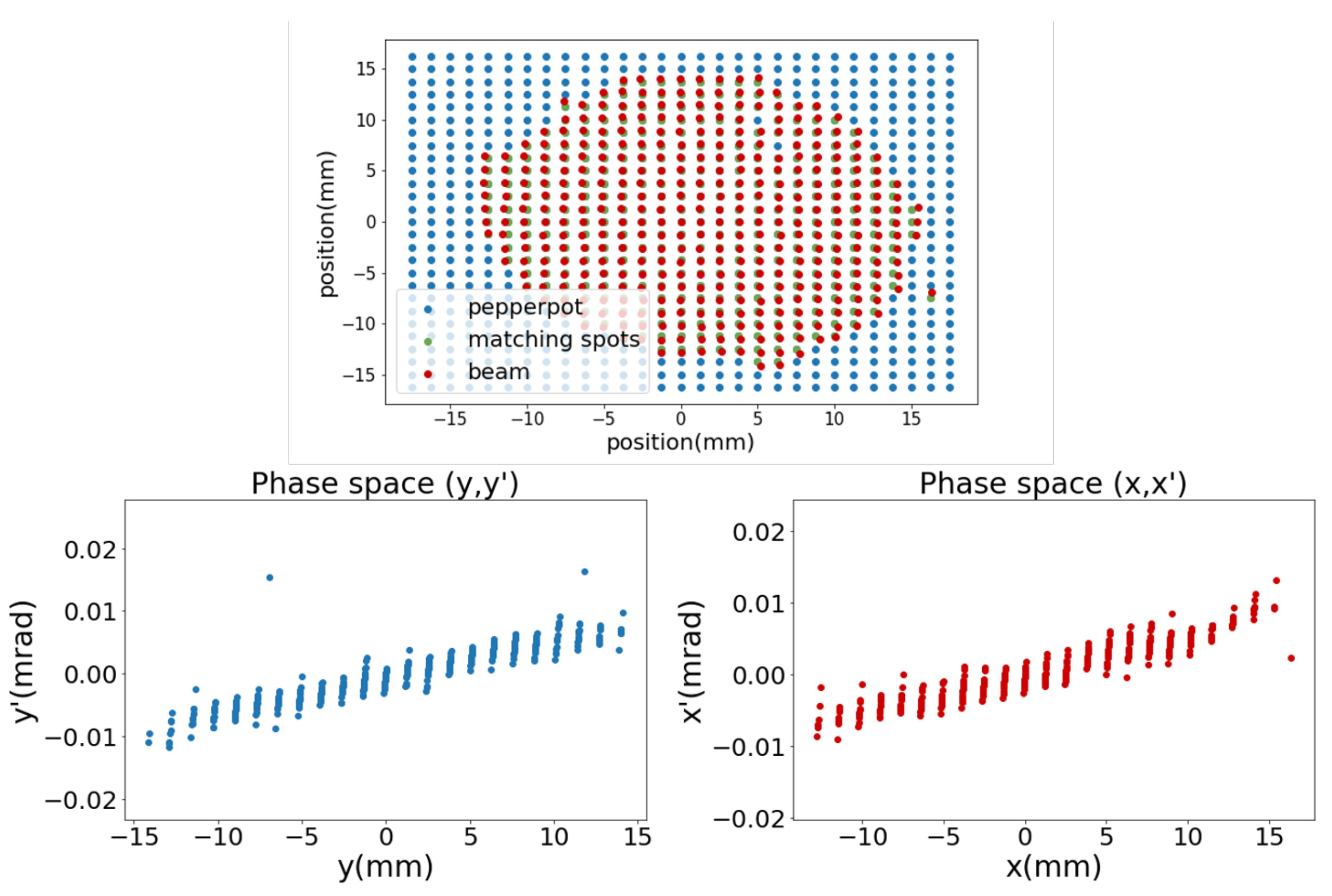

3.2. Low-Energy Beam Transport

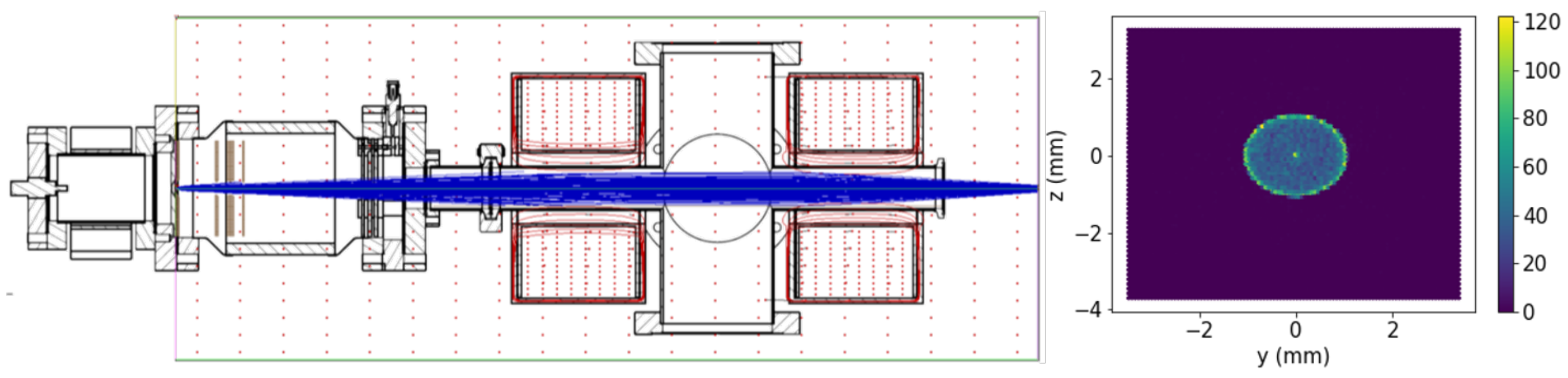

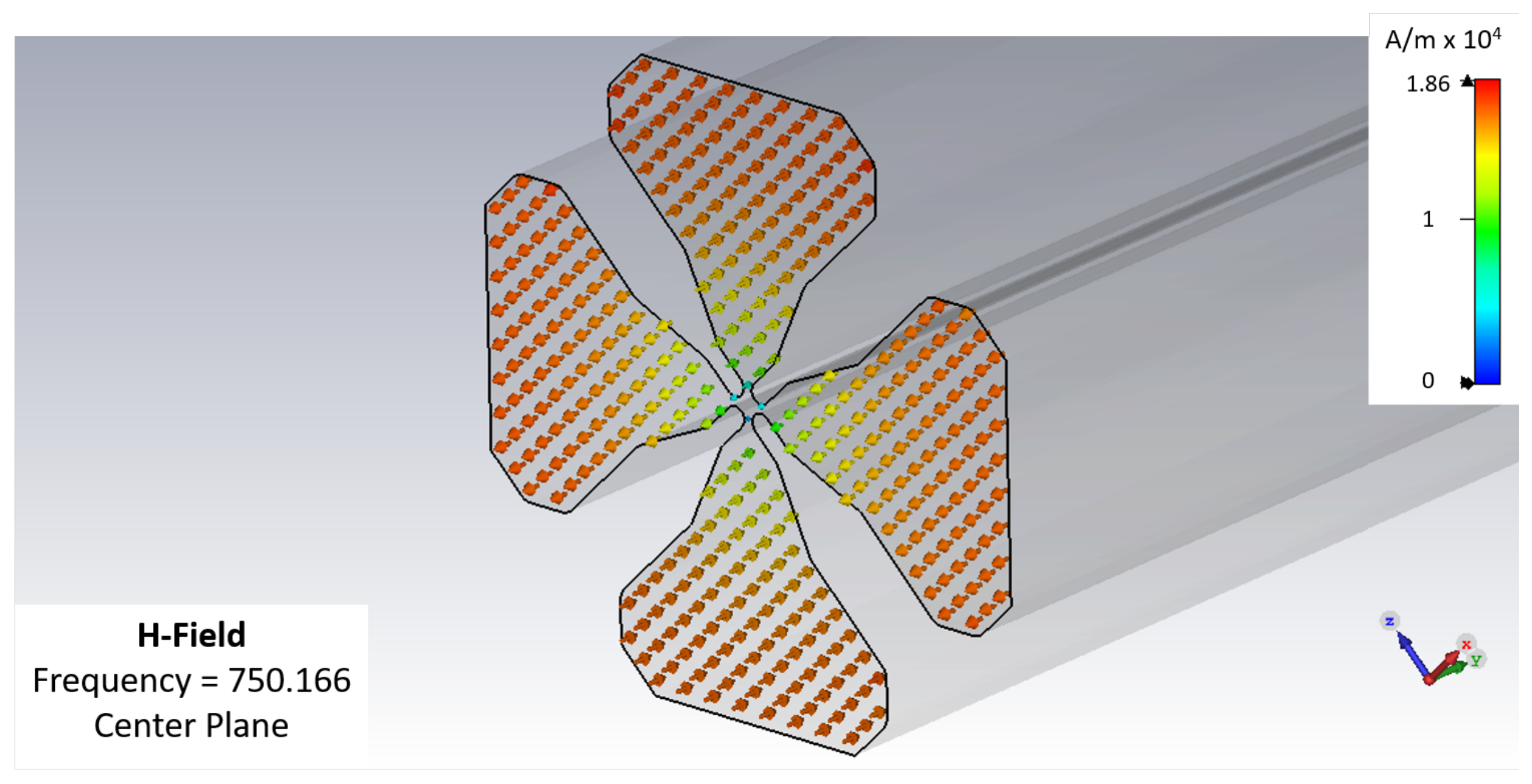

3.3. Radio Frequency Quadrupole

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Doyle, B.L.; McDaniel, F.D.; Hamm, R.W. The future of industrial accelerators and applications. Rev. Accel. Sci. Technol. 2019, 10, 93–116. [Google Scholar] [CrossRef]

- Hoang, S.M.T.; Tran, H.N.; Sun, G.M.; Le, N.T.; Ho, M.D.; Tran, T.A. The Innovative PIXE/PIGE facility at the 2-MV KIST tandem ion accelerator: Design and calculation. In Proceedings of the Fourth International Conference on Application of Radiotracers and Energetic Beams in Sciences, Kolkata, India, 11–17 November 2018. [Google Scholar]

- Mathot, S.; Anelli, G.; Atieh, S.; Bilton, A.; Bulat, B.; Callamand, T.; Calvo, S.; Favre, G.; Geisser, J.M.; Gerardin, A.; et al. The CERN PIXE-RFQ, a transportable proton accelerator for the machina project. Nucl. Inst. Methods Phys. Res. Sect. Beam Interact. Mater. Atoms. 2019, 459, 153–157. [Google Scholar] [CrossRef]

- Larson, L.A.; Williams, J.M.; Current, M.I. Ion implantation for semiconductor doping and materials modification. In Reviews of Accelerator Science and Technology: Volume 4: Accelerator Applications in Industry and the Environment; World Scientific Publishing Europe Ltd.: London, UK, 2011; pp. 11–40. [Google Scholar]

- Makuuchi, K.; Cheng, S. Radiation Processing of Polymer Materials and Its Industrial Applications; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Edgecock, R. REPORT: Comparison of Different Accelerator Options for 99 mTc and Therapeutic Isotope Production; Technical Report; ARIES: Accelerator Research and Innovation for European Science and Society. Ref. Aries3260480; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Etxebarria, V.; Feuchtwanger, J.; Portilla, J.; Jugo, J.; Arredondo, I.; Badillo, I.; Asua, E.; Enparantza, R.; Ariz, I.; Etxebeste, U.; et al. Manufacturing of Radiopharmaceutical Isotopes through the LINAC 7 Accelerator For Biomedical Applications. Dyna Acelerado 2022, 7. [Google Scholar] [CrossRef]

- Feuchtwanger, J.; Etxebarria, V.; Portilla, J.; Jugo, J.; Badillo, I.; Arredondo, I. Hydrogen electron cyclotron resonance ion sources plasma characterization based on simple optical emission spectroscopy. Nucl. Inst. Methods Phys. Res. Sect. 2018, 881, 44–47. [Google Scholar] [CrossRef]

- Feuchtwanger, J.; Etxebarria, V.; Portilla, J.; Jugo, J.; Badillo, I.; Arredondo, I. New compact ion source design and implementation for low current applications. Nucl. Inst. Methods Phys. Res. Sect. 2019, 929, 101–106. [Google Scholar] [CrossRef]

- Agostinelli, S.; Allison, J.; Amako, K.A.; Apostolakis, J.; Araujo, H.; Arce, P.; Asai, M.; Axen, D.; Banerjee, S.; Barrand, G.; et al. GEANT4—A simulation toolkit. Nucl. Inst. Methods Phys. Res. Sect. 2003, 506, 250–303. [Google Scholar] [CrossRef] [Green Version]

- Ansys. ANSYS Mechanical 2021 R1. Available online: https://www.ansys.com/academic/terms-and-conditions (accessed on 17 March 2022).

- Badillo, I.; Jugo, J.; Portilla, J.; Feuchtwanger, J.; San Vicente, C.; Etxebarria, V. Pxie-based llrf architecture and versatile test bench for heavy ion linear acceleration. IEEE Trans. Nucl. Sci. 2015, 62, 963–971. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M. Emittance Formula for Slits and Pepper-Pot Measurement; Technical Report; Fermi National Accelerator Lab.: Batavia, IL, USA, 1996. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feuchtwanger, J.; Etxebarria, V.; Portilla, J.; Jugo, J.; Arredondo, I.; Badillo, I.; Asua, E.; Vallis, N.; Elorza, M.; Alberdi, B.; et al. New Generation Compact Linear Accelerator for Low-Current, Low-Energy Multiple Applications. Appl. Sci. 2022, 12, 4118. https://doi.org/10.3390/app12094118

Feuchtwanger J, Etxebarria V, Portilla J, Jugo J, Arredondo I, Badillo I, Asua E, Vallis N, Elorza M, Alberdi B, et al. New Generation Compact Linear Accelerator for Low-Current, Low-Energy Multiple Applications. Applied Sciences. 2022; 12(9):4118. https://doi.org/10.3390/app12094118

Chicago/Turabian StyleFeuchtwanger, Jorge, Victor Etxebarria, Joaquin Portilla, Josu Jugo, Iñigo Arredondo, Inari Badillo, Estibaliz Asua, Nicolas Vallis, Mikel Elorza, Beñat Alberdi, and et al. 2022. "New Generation Compact Linear Accelerator for Low-Current, Low-Energy Multiple Applications" Applied Sciences 12, no. 9: 4118. https://doi.org/10.3390/app12094118

APA StyleFeuchtwanger, J., Etxebarria, V., Portilla, J., Jugo, J., Arredondo, I., Badillo, I., Asua, E., Vallis, N., Elorza, M., Alberdi, B., Enparantza, R., Ariz, I., Muñoz, I., Etxebeste, U., & Hernandez, I. (2022). New Generation Compact Linear Accelerator for Low-Current, Low-Energy Multiple Applications. Applied Sciences, 12(9), 4118. https://doi.org/10.3390/app12094118