Design of a Parallel Quadruped Robot Based on a Novel Intelligent Control System

Abstract

1. Introduction

2. Materials and Methods

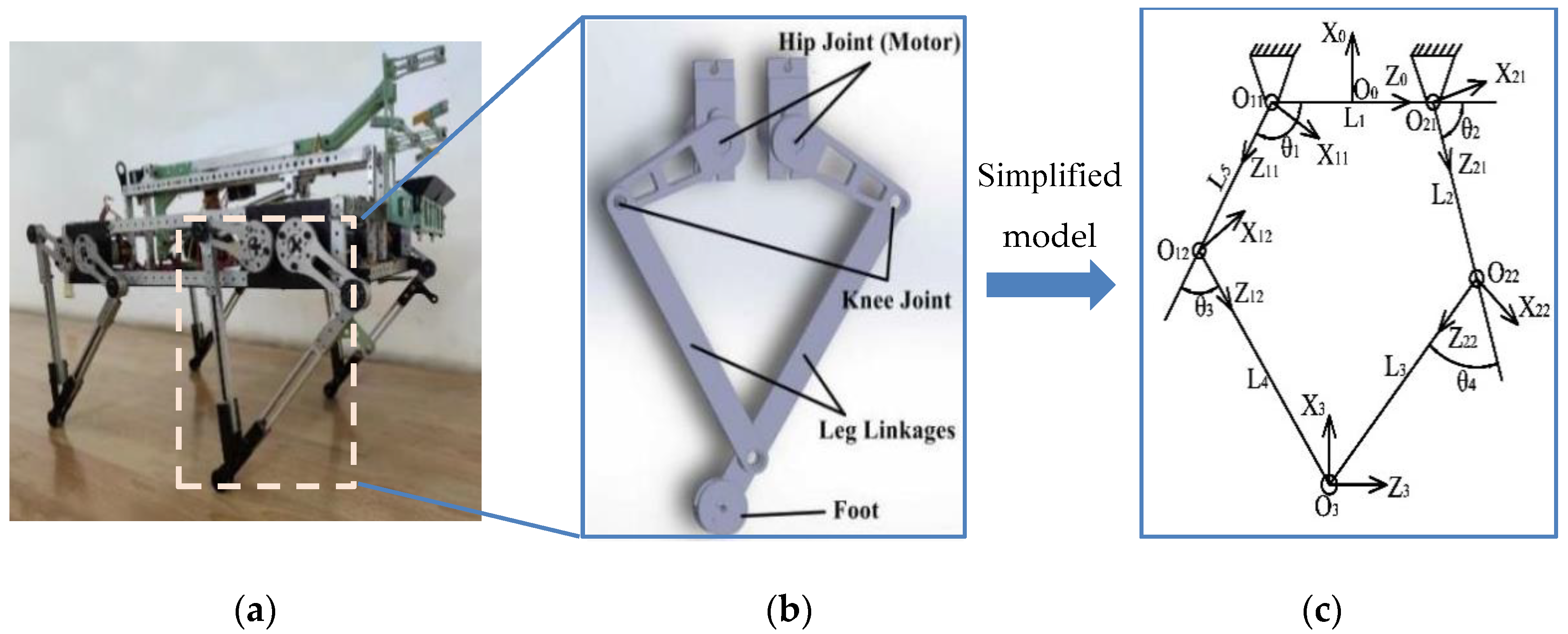

2.1. The Mechanical Structure and Kinematics Analysis

2.1.1. The Mechanical Structure

2.1.2. Kinematics Analysis

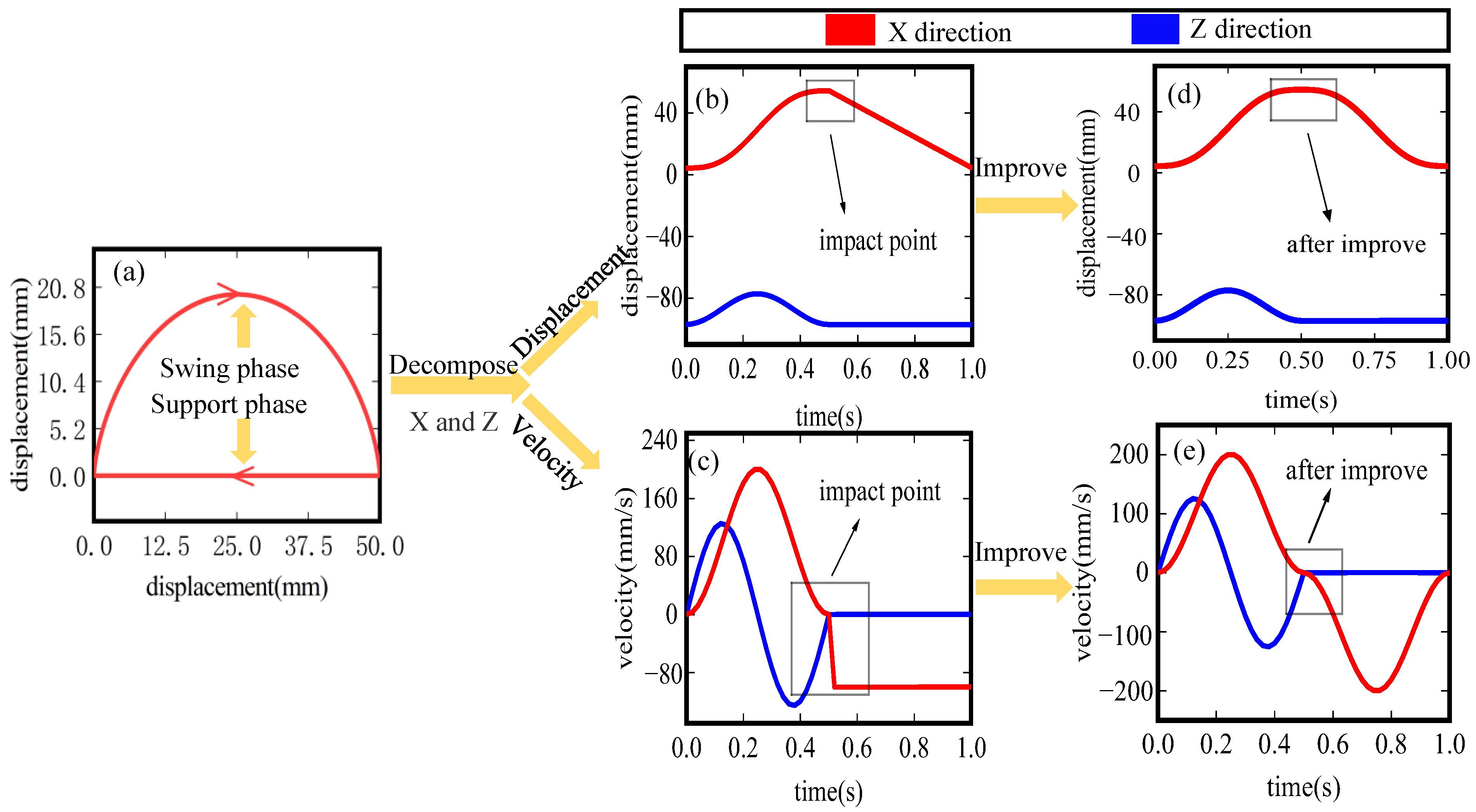

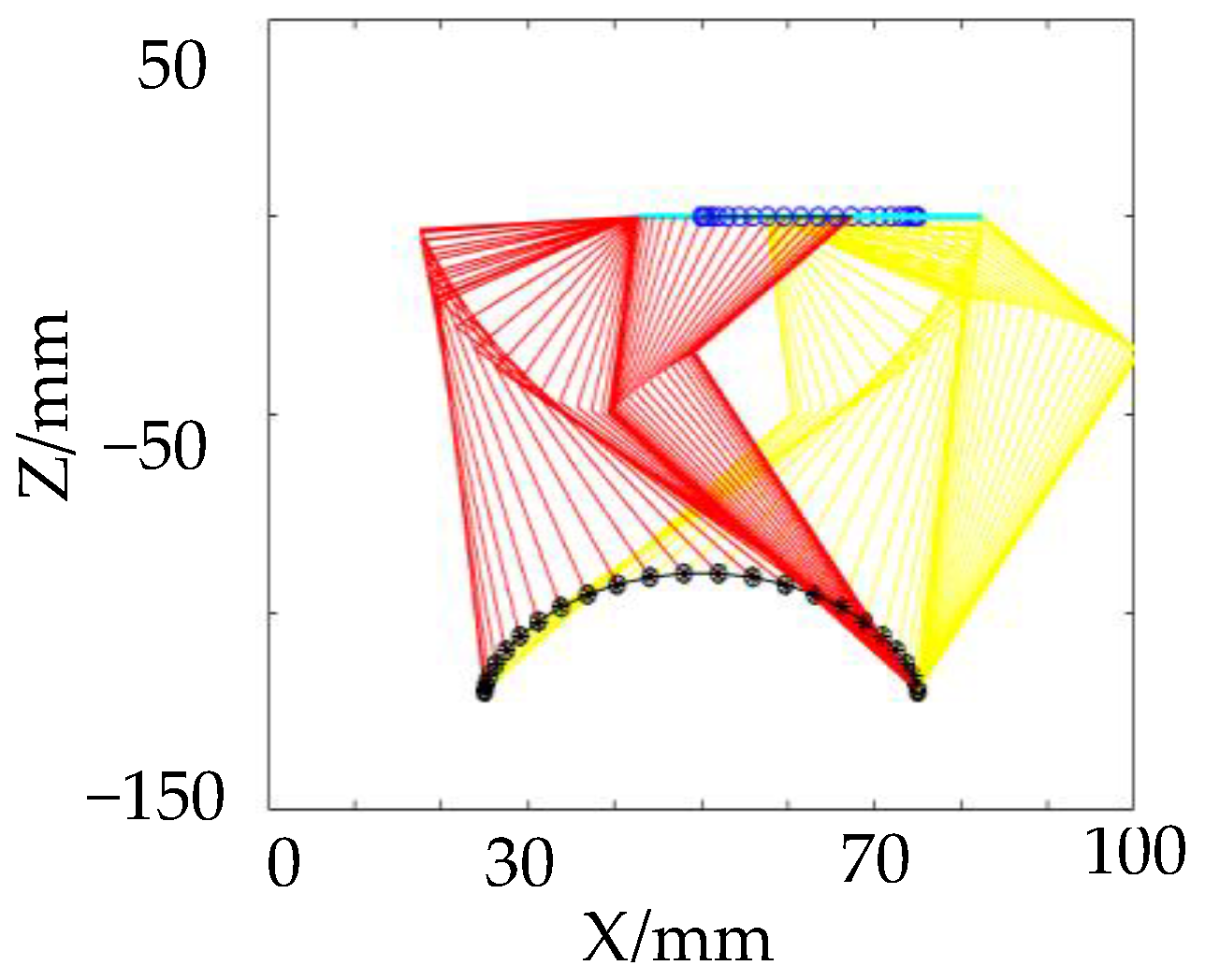

2.2. Planning and Improvement of Foot Trajectory

2.2.1. Foot Trajectory Planning

2.2.2. Improved Trajectory Planning Based on Bézier Curve

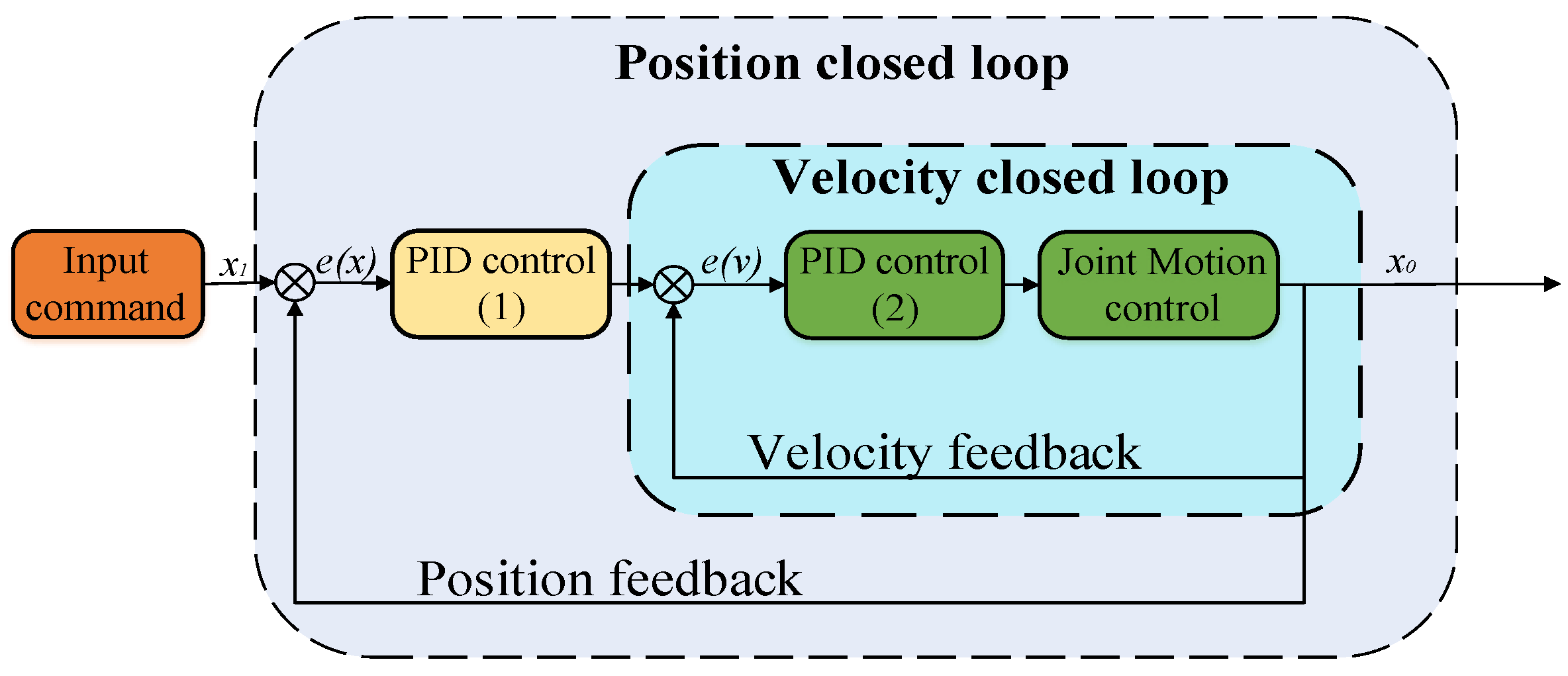

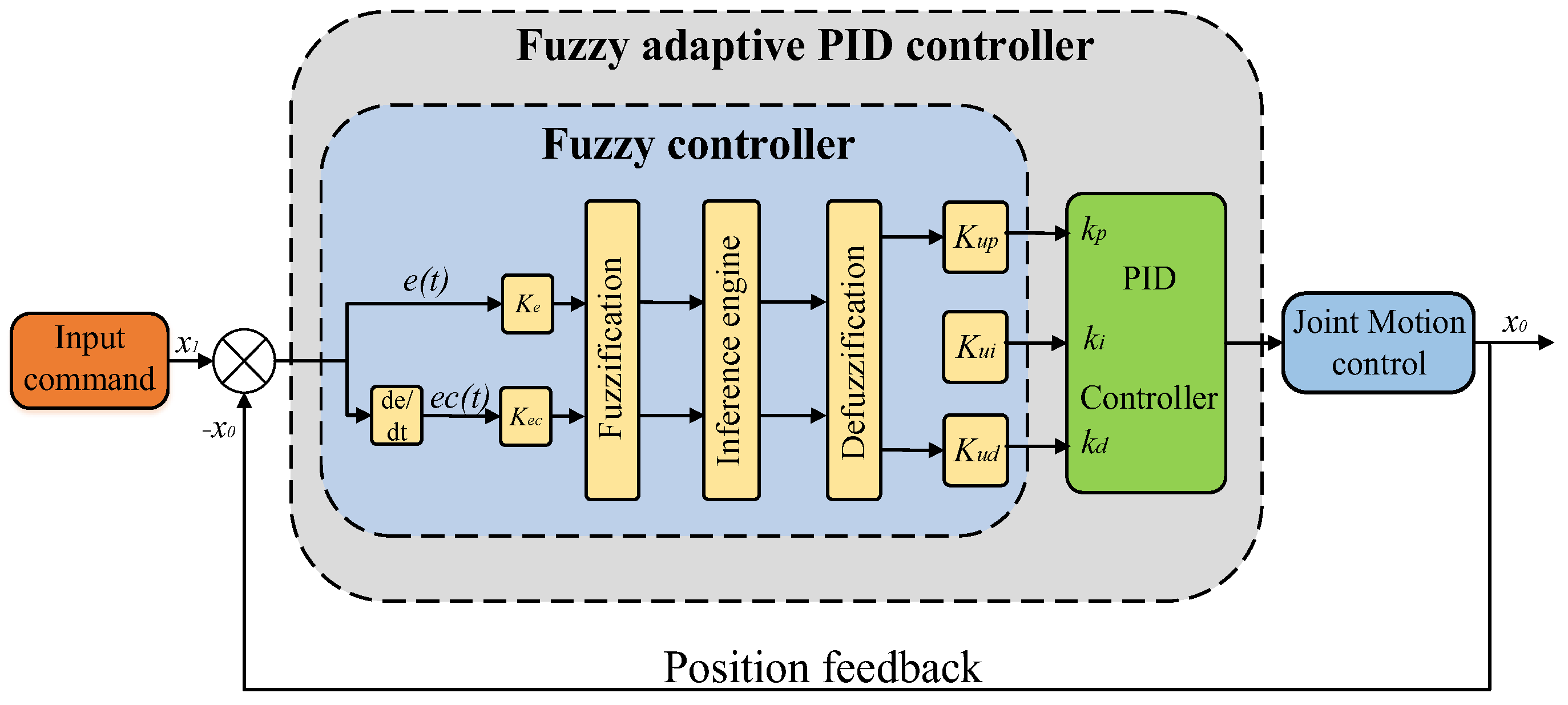

2.3. Control System

2.3.1. Cascade PID Controller

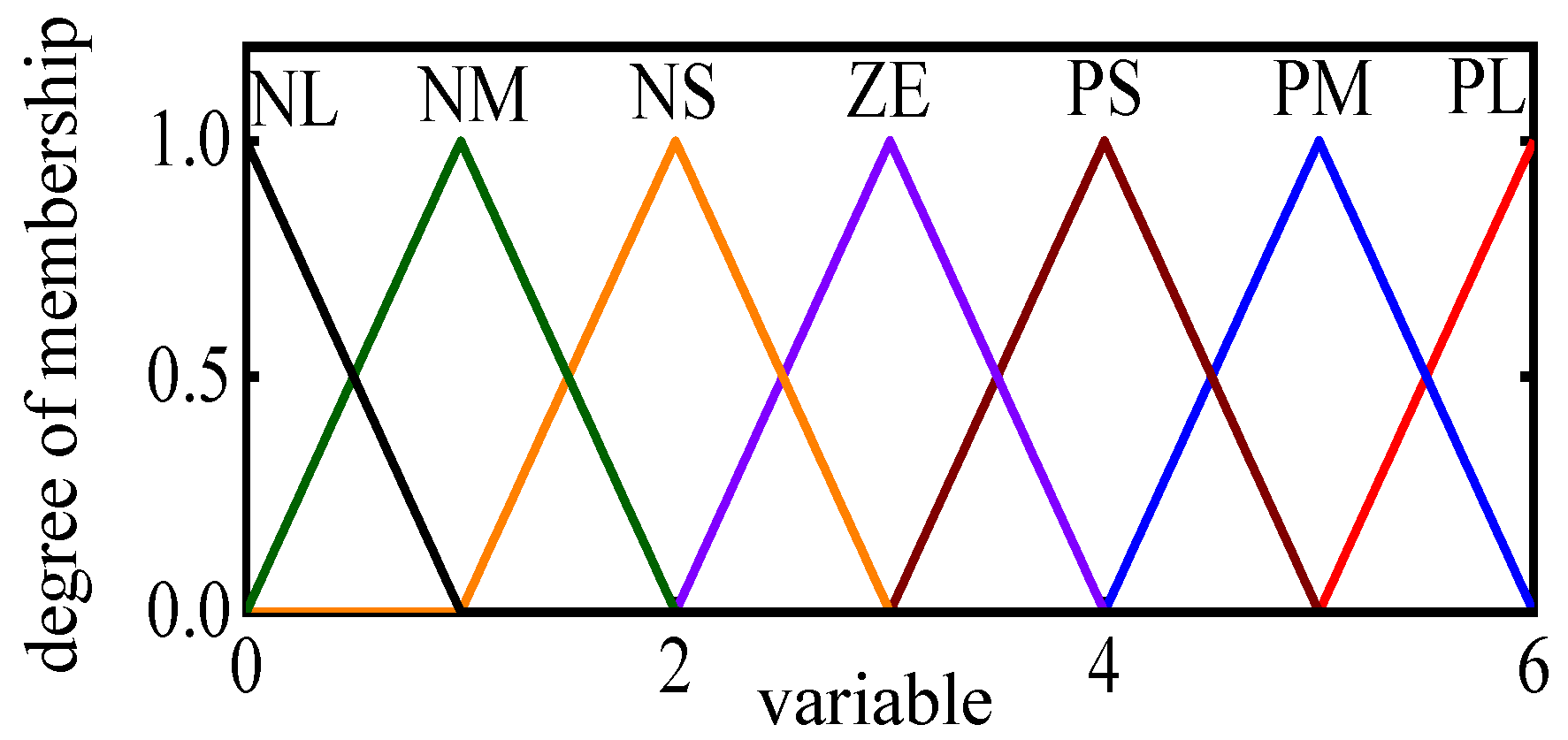

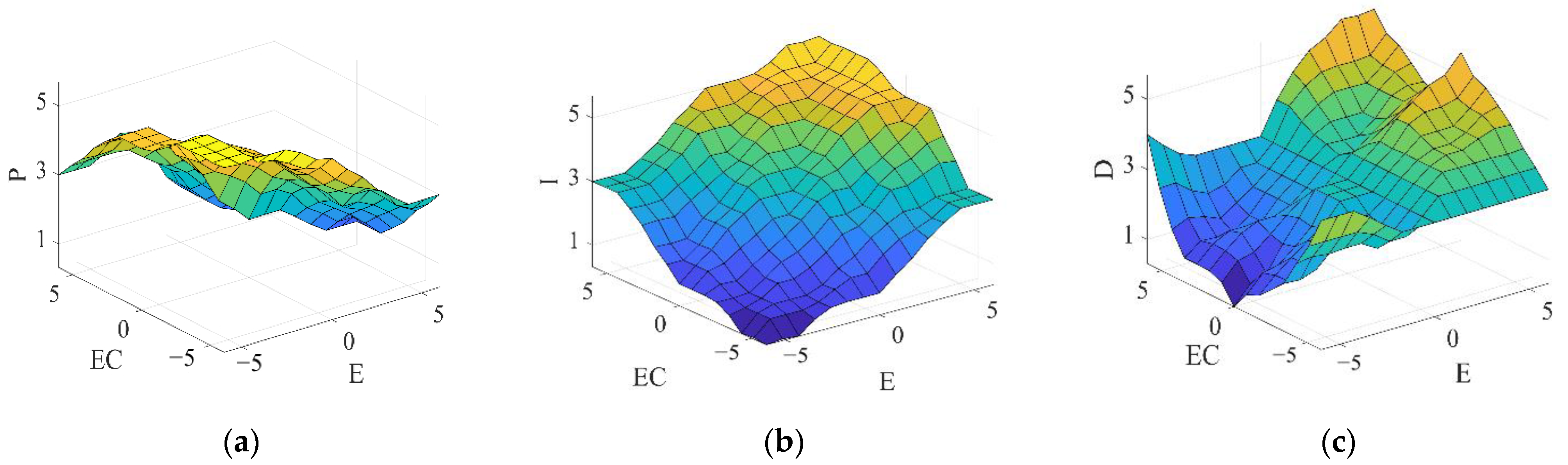

2.3.2. Fuzzy Adaptive PID Controller

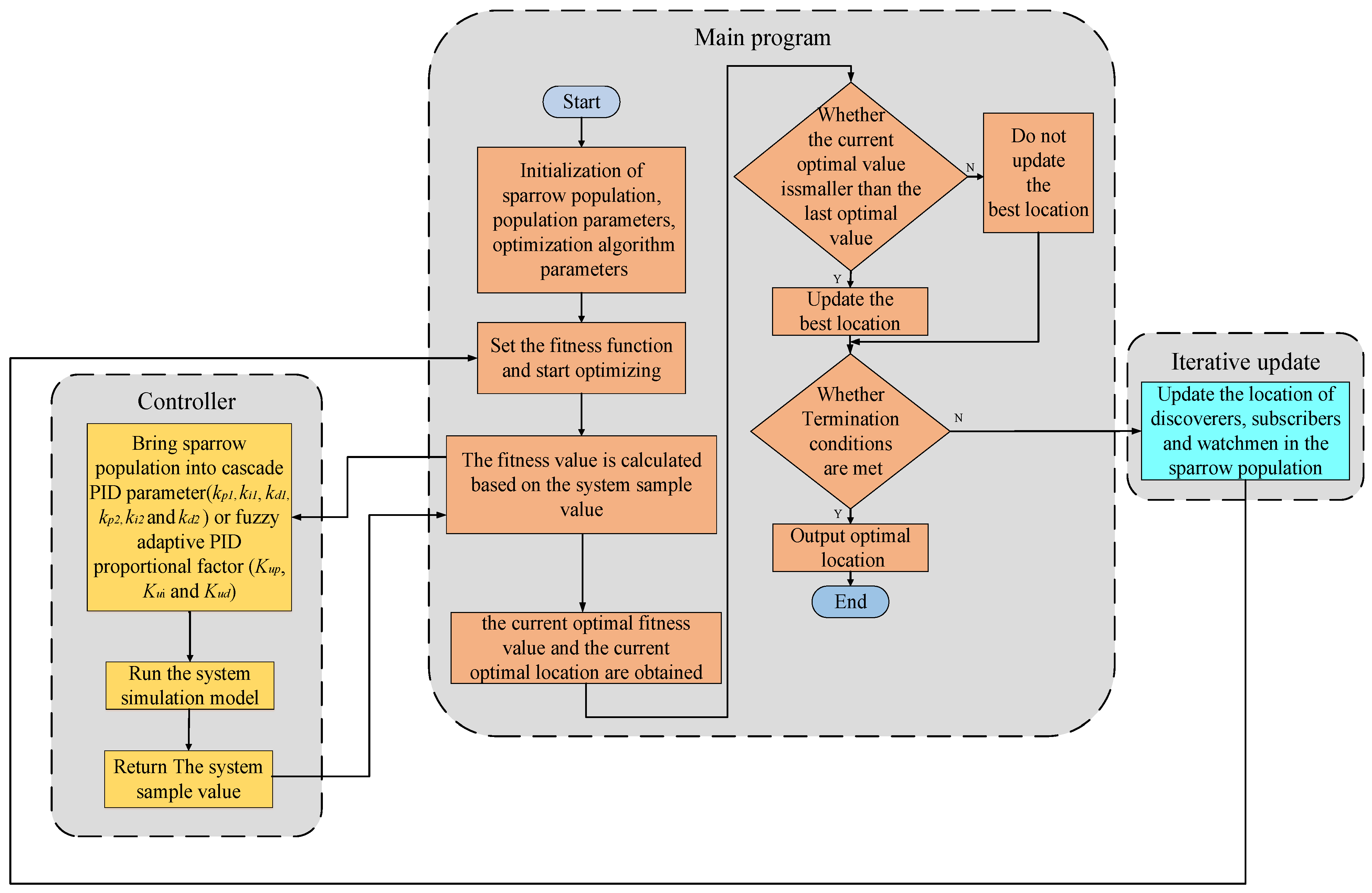

2.3.3. The Optimization of the Controller

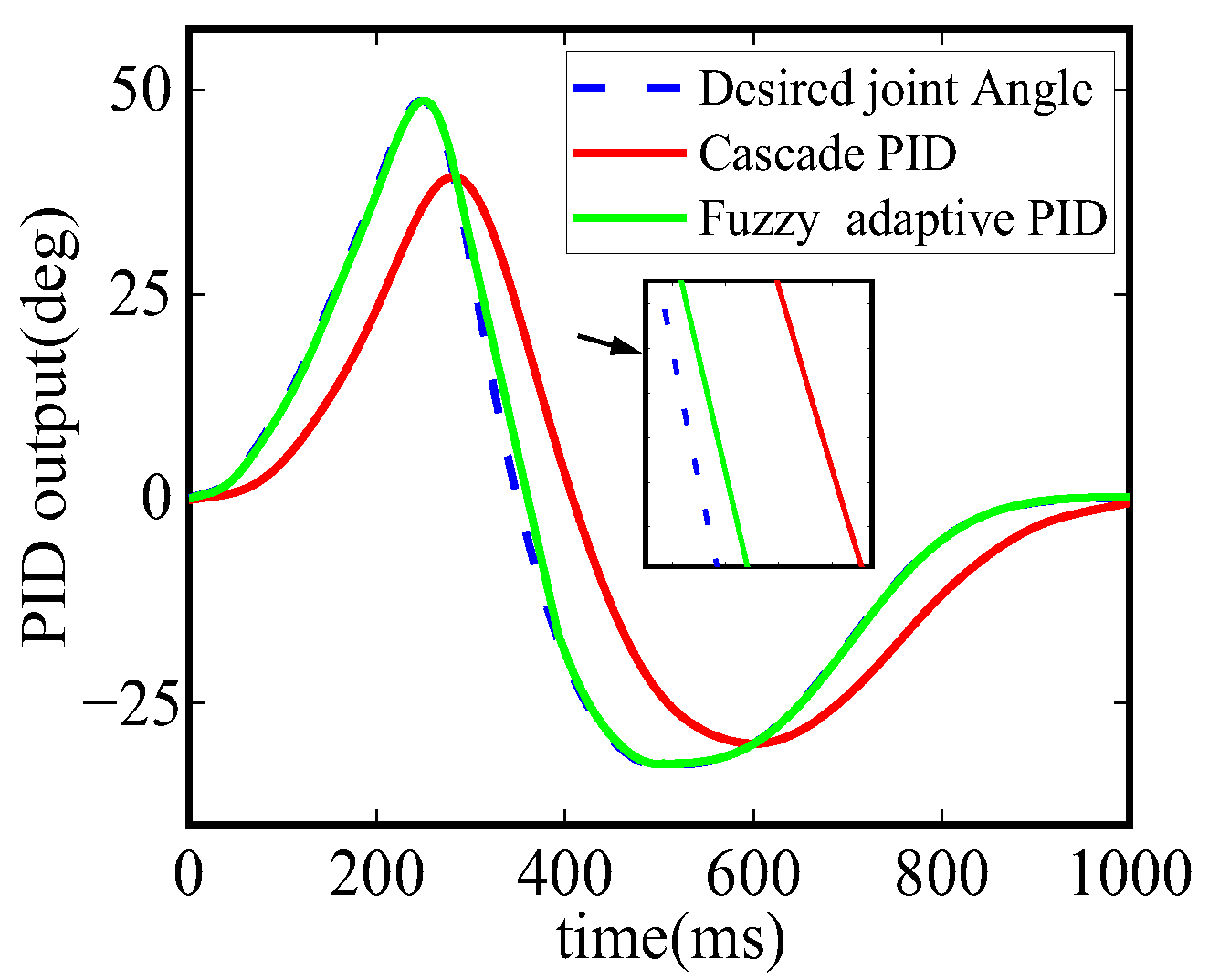

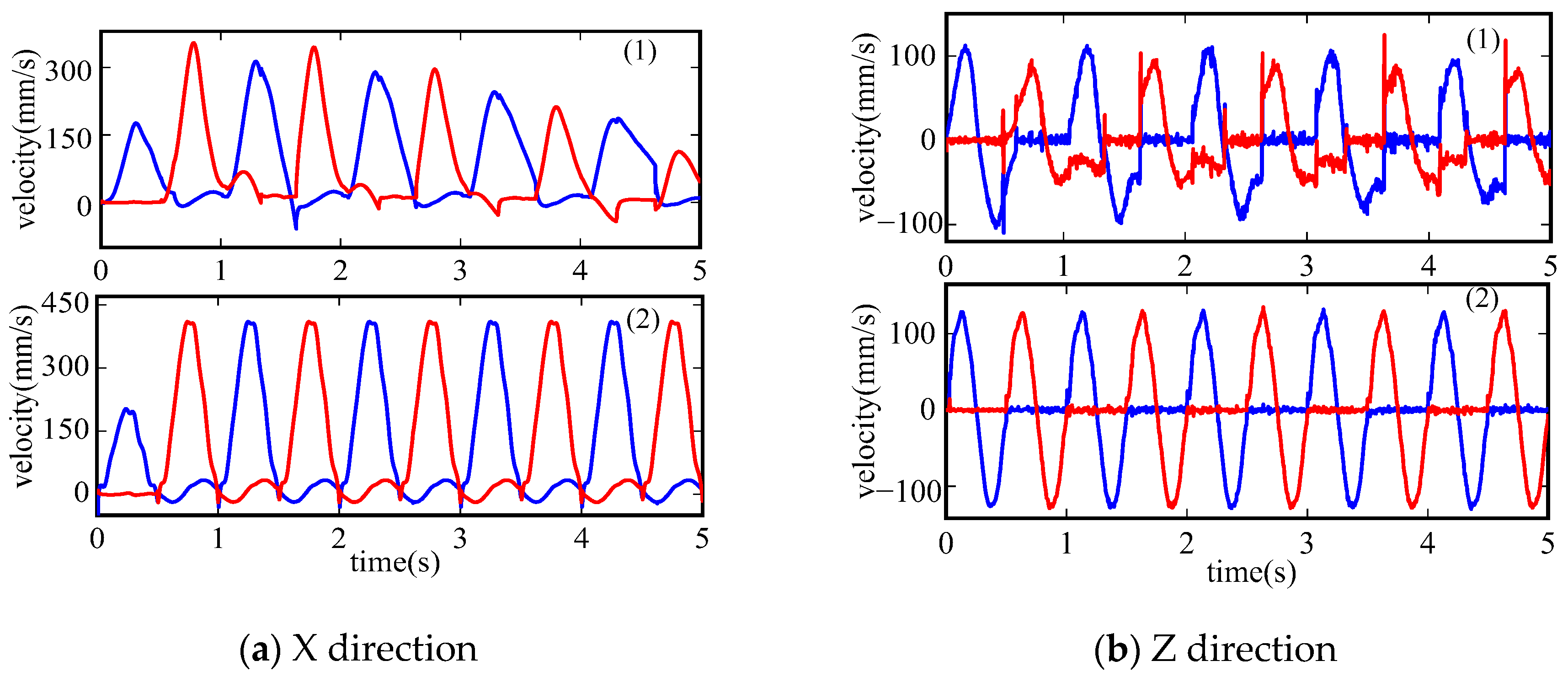

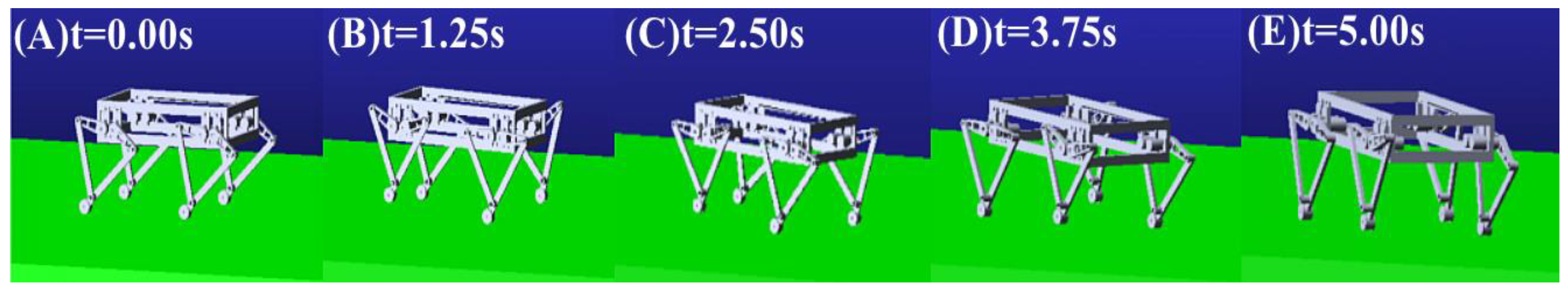

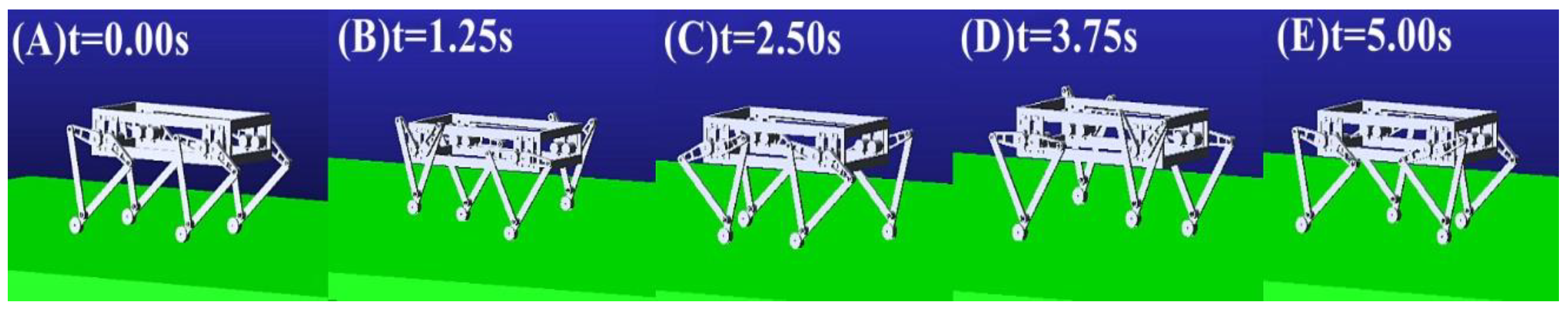

3. Results and Discussions

4. Conclusions

- (1)

- The mechanical structure of the robot’s leg was designed using a parallel five link with two degrees of freedom. The angle function of the leg joint was obtained using the D-H method for kinematics analysis. Moreover, the phase switch with minimum impact during the entire movement process was realized and verified.

- (2)

- The cascade PID control system optimized based on the sparrow search algorithm and the fuzzy adaptive PID control system optimized based on the sparrow search algorithm are used to drive the quadruped robot, and the overall performance of the two control strategies are compared in the simulation. The convergence speed and accuracy of the sparrow search algorithm are verified by comparing with the moth flame optimization algorithm and particle swarm optimization algorithm.

- (3)

- The fuzzy adaptive PID optimized based on the sparrow search algorithm has higher precision and more stable control effect compared with the cascade PID control optimized based on the sparrow search algorithm, which was demonstrated by co-simulation using MATLAB and ADAMS. The simulation results also simultaneously verified that the parallel five link with eight degrees of freedom quadruped robot and its control system provided a reliable solution for the operation of a quadruped robot and provided a reference for other related researchers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raibert, M.; Blankespoor, K.; Nelson, G.; Playter, R. Bigdog, the Rough-Terrain Quadruped Robot. IFAC Proc. 2008, 41, 10822–10825. [Google Scholar] [CrossRef]

- Wang, L.; Du, W.; Mu, X.; Wang, X.; Xie, G.; Wang, C. A geometric approach to solving the stable workspace of quadruped bionic robot with hand-foot-integrated function. Robot. Comput.-Integr. Manuf. 2016, 37, 68–78. [Google Scholar] [CrossRef]

- Tian, X.; Gao, F.; Qi, C.; Chen, X.; Zhang, D. External disturbance identification of a quadruped robot with parallel–serial leg structure. Int. J. Mech. Mater. Des. 2016, 12, 109–120. [Google Scholar] [CrossRef]

- Zhang, L.; Li, A.; Gao, Z. Modeling and Analysis of Flexible Foot Vibration of Multi-Foot Bionic Robot. In Proceedings of the 2019 IEEE International Conference on Robotics and Biomimetics (ROBIO), Dali, China, 6–8 December 2019; pp. 136–141. [Google Scholar]

- Hirose, S.; Kato, K. Study on quadruped walking robot in Tokyo Institute of Technology-past, present and future. Proc. IEEE Int. Conf. Robot. Autom. 2000, 1, 414–419. [Google Scholar]

- Ioannis, P.; James, A.S.; Martin, B. Modeling and Experiments of Untethered Quadrupedal Running with a Bounding Gait: The Scout II Robot. Int. J. Robot. Res. 2005, 24, 239–256. [Google Scholar]

- Patrick, M.W.; Albert, W.; Sangok, S.; David, O.; Jeffrey, L.; Sangbae, K. Proprioceptive Actuator Design in the MIT Cheetah: Impact Mitigation and High-Bandwidth Physical Interaction for Dynamic Legged Robots. IEEE Trans. Robot. 2017, 33, 509–522. [Google Scholar]

- Rong, X.; Li, Y.; Meng, J. Design for several hydraulic parameters of a quadruped robot. Appl. Math. Inform. Sci. 2014, 8, 2465–2470. [Google Scholar] [CrossRef][Green Version]

- Nathan, K.; Aaron, S.; Natalie, F.; Patrick, S. Stanford Doggo: An Open-Source, Quasi-Direct-Drive Quadruped. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 6309–6315. [Google Scholar]

- Hao, L.; Chen, B.; Liu, Y.; Lu, Y. Guardian Map Approach to Feasible Range of Static Stability Margin of Hypersonic Flight Vehicles with Input Saturation. Int. J. Aerosp. Eng. 2020, 2020, 8895324. [Google Scholar]

- Yu, H.; Gao, H.; Ding, L.; Li, M.; Deng, Z.; Liu, G. Gait Generation With Smooth Transition Using CPG-Based Locomotion Control for Hexapod Walking Robot. IEEE Trans. Ind. Electron. 2016, 63, 5488–5500. [Google Scholar] [CrossRef]

- Xu, H.; Gan, S.; Ren, J.; Wang, B.; Jin, Y. Gait CPG Adjustment for a Quadruped Robot Based on Hopf Oscillator. J. Syst. Simul. 2017, 29, 3092–3099. [Google Scholar]

- Liu, W.; Zhang, C.; Chen, J.; Qi, J. Survey of locomotion control of legged robots inspired by biological concept. Sci. China Ser. F Inf. Sci. 2009, 52, 1715–1729. [Google Scholar]

- Zhong, G.; Chen, L.; Jiao, Z.; Li, J.; Deng, H. Locomotion Control and Gait Planning of a Novel Hexapod Robot Using Biomimetic Neurons. IEEE Trans. Control Syst. Technol. 2018, 26, 624–636. [Google Scholar] [CrossRef]

- Liu, C.; Wang, D.; Chen, Q. Adaptive walking control of biped robots using online trajectory generation method based on neural oscillators. J. Bionic. Eng. 2016, 13, 572–584. [Google Scholar] [CrossRef]

- Alexander, R.M. The Gaits of Bipedal and Quadrupedal Animals. Int. J. Robot. Res. 1984, 33, 49–59. [Google Scholar] [CrossRef]

- Gor, M.M.; Pathak, P.M.; Samantaray, A.K.; Yang, J.M.; Kwak, S.W. Control of compliant legged quadruped robots in the workspace. Simulation 2015, 91, 103–125. [Google Scholar] [CrossRef]

- Zhao, M.; Liu, L.; Wang, J.; Chen, K.; Zhao, J.; Xu, K. Control system design of THBIP-I humanoid robot. In Proceedings of the 2002 IEEE International Conference on Robotics and Automation (Cat. No.02CH37292), Washington, DC, USA, 11–15 May 2002; Volume 3, pp. 2253–2258. [Google Scholar]

- Meinard, C.A.; Manuel, C.R. Bipedal robot locomotion using multivariable control. In Proceedings of the TENCON 2009–2009 IEEE Region 10 Conference, Singapore, 23–26 January 2009; pp. 1–6. [Google Scholar]

- Moosavian, S.A.A.; Khorram, M.; Zamani, A.; Abedini, H. PD regulated sliding mode control of a quadruped robot. In Proceedings of the 2011 IEEE International Conference on Mechatronics and Automation, Beijing, China, 7–10 August 2011; pp. 2061–2066. [Google Scholar]

- Shabnam, S.; Mohammad, F. Fuzzy-backstepping control of quadruped robots. Intel. Serv. Robot. 2020, 13, 13191–13206. [Google Scholar]

- Wu, H.M.; Karkoub, M.; Hwang, C.L. Mixed Fuzzy Sliding-Mode Tracking with Backstepping Formation Control for Multi-Nonholonomic Mobile Robots Subject to Uncertainties. J. Intell. Robot. Syst. 2015, 79, 73–86. [Google Scholar] [CrossRef]

- Wang, D.; Tan, D.; Liu, L. Particle swarm optimization algorithm: An overview. Soft Comput. 2018, 22, 387–408. [Google Scholar] [CrossRef]

- Rahul, B.; Dharani, J. Genetic Algorithm tuned PID Controller for Aircraft Pitch Control. IJREAM 2019, 4, 303–307. [Google Scholar]

- Bezdan, T.; Stoean, C.; Naamany, A.A.; Bacanin, N.; Rashid, T.A.; Zivkovic, M.; Venkatachalam, K. Hybrid Fruit-Fly Optimization Algorithm with K-Means for Text Document Clustering. Mathematics 2021, 9, 1929. [Google Scholar] [CrossRef]

- Xue, J. Research and Application of A Novel Swarm Intelligence Optimization Technique: Sparrow Search Algorithm. Master’s Thesis, College of information science and Technology, Donghua University, Shanghai, China, 2020. [Google Scholar]

- Liao, W.; Ross, C.; Jonathan, R. An Analytic Approach to Converting POE Parameters into D-H Parameters for Serial-Link Robots. IEEE Robot. Autom. Lett. 2019, 2, 217. [Google Scholar]

| Joint (O1i) | αi−1/° | Li/mm | di/mm | θi/° |

|---|---|---|---|---|

| 1 (O21) | 0 | −L1/2 | 0 | θ2 |

| 2 (O22) | 0 | L5 | 0 | θ4 |

| 3 (O3) | 0 | L4 | 0 | −θ2–θ4 |

| Joint (O1i) | αi−1/° | Li/mm | di/mm | θi/° |

|---|---|---|---|---|

| 1 (O11) | 0 | L1/2 | 0 | θ1 |

| 2 (O12) | 0 | L2 | 0 | θ3 |

| 3 (O3) | 0 | L3 | 0 | −θ2–θ4 |

| Parameter Names | Parameter Values |

|---|---|

| population | 100 |

| number of iterations | 100 |

| proportion of discoverers | 0.6 |

| proportion of subscribers | 0.4 |

| proportion of watchmen | 0.1 |

| Algorithm | kp1 | ki1 | kd1 | kp2 | ki2 |

|---|---|---|---|---|---|

| SSA | 20.0000 | 1.2977 | 19.8444 | 5.7473 | 19.4983 |

| MFO | 20.0000 | 0.0245 | 20.0000 | 19.5924 | 20.0000 |

| PSO | 20.0000 | 0.0000 | 20.0000 | 19.2943 | 0.0149 |

| Algorithm | Kup | Kui | Kud |

|---|---|---|---|

| SSA | 19.9936 | 20.0000 | 20.0000 |

| MFO | 19.5910 | 0.0000 | 20.0000 |

| PSO | 19.6313 | 0.0000 | 20.0000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Liu, Z.; Wang, M.; Pang, G.; Zhang, H. Design of a Parallel Quadruped Robot Based on a Novel Intelligent Control System. Appl. Sci. 2022, 12, 4358. https://doi.org/10.3390/app12094358

Li M, Liu Z, Wang M, Pang G, Zhang H. Design of a Parallel Quadruped Robot Based on a Novel Intelligent Control System. Applied Sciences. 2022; 12(9):4358. https://doi.org/10.3390/app12094358

Chicago/Turabian StyleLi, Mingying, Zhilei Liu, Manfu Wang, Guibing Pang, and Hui Zhang. 2022. "Design of a Parallel Quadruped Robot Based on a Novel Intelligent Control System" Applied Sciences 12, no. 9: 4358. https://doi.org/10.3390/app12094358

APA StyleLi, M., Liu, Z., Wang, M., Pang, G., & Zhang, H. (2022). Design of a Parallel Quadruped Robot Based on a Novel Intelligent Control System. Applied Sciences, 12(9), 4358. https://doi.org/10.3390/app12094358