Development of a High-Power Surface Grating Tunable Distributed-Feedback Bragg Semiconductor Laser Based on Gain-Coupling Effect

Abstract

:1. Introduction

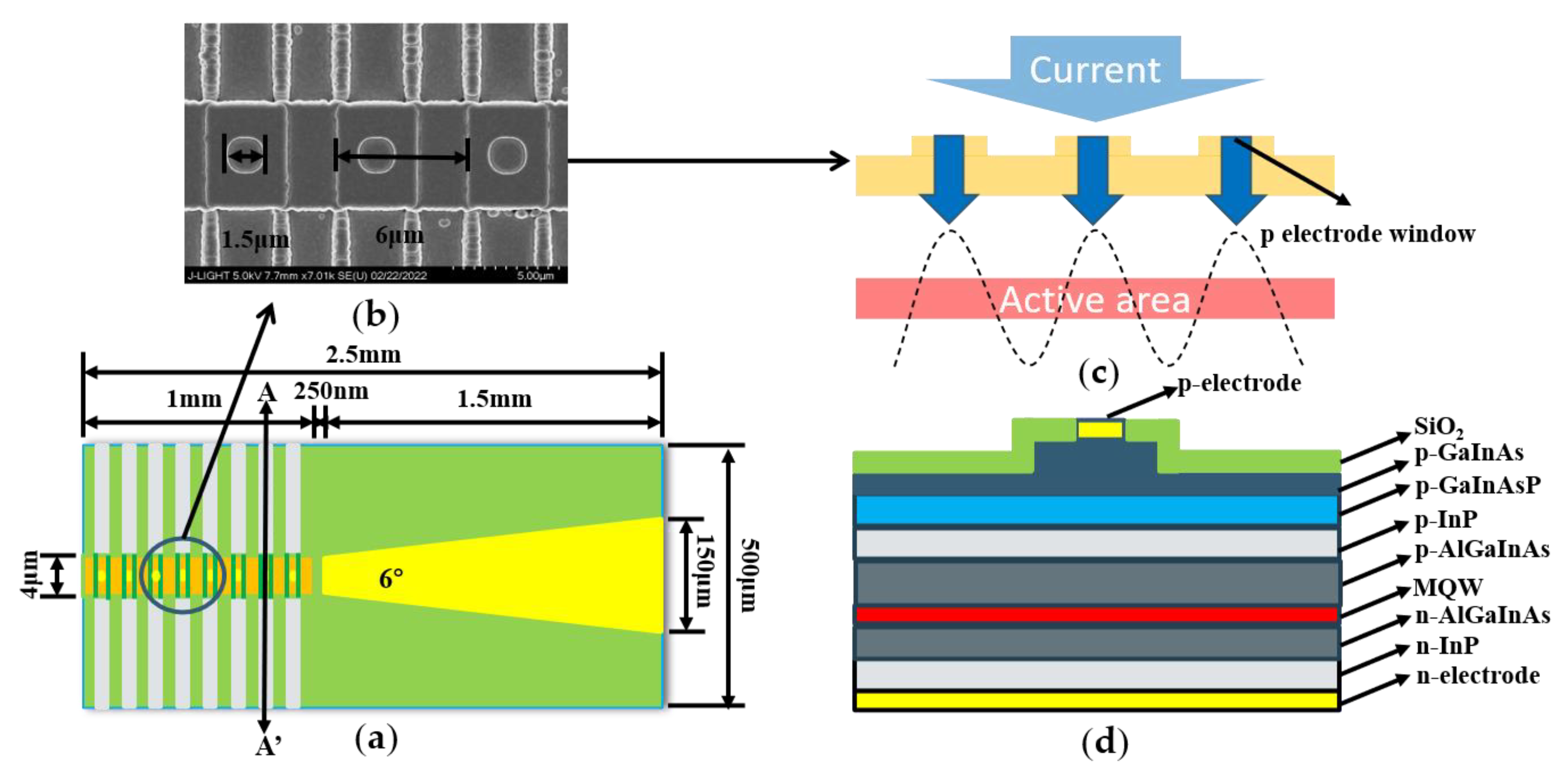

2. Materials and Methods

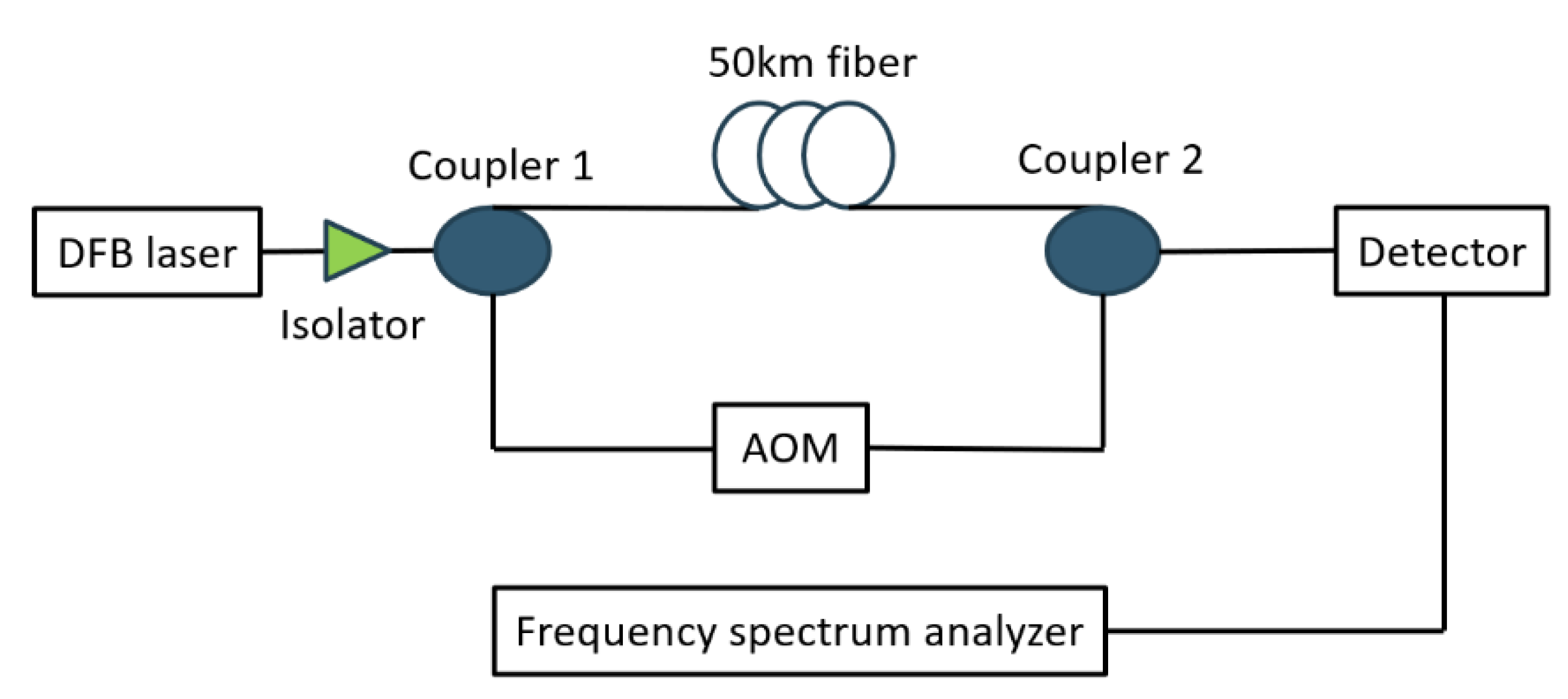

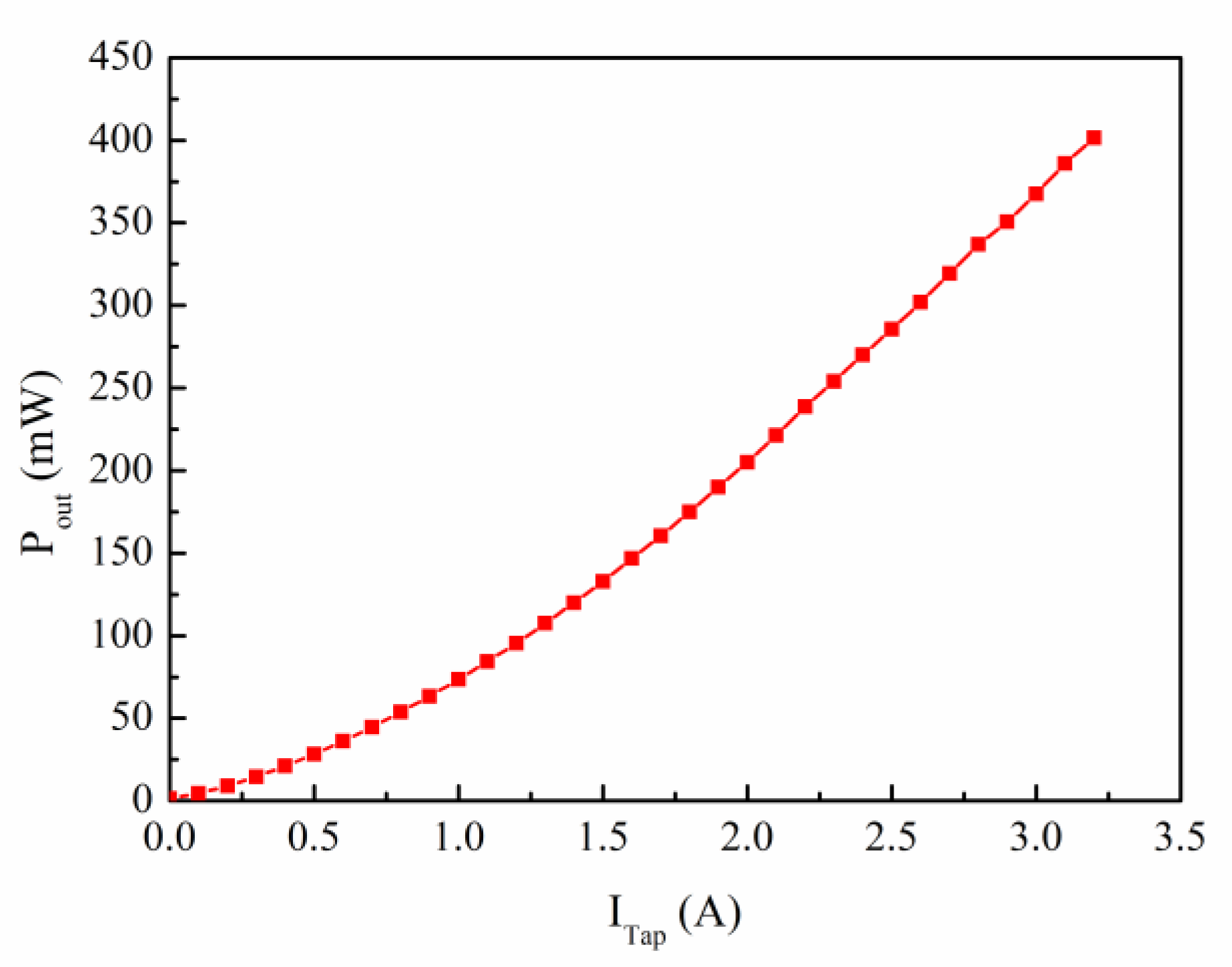

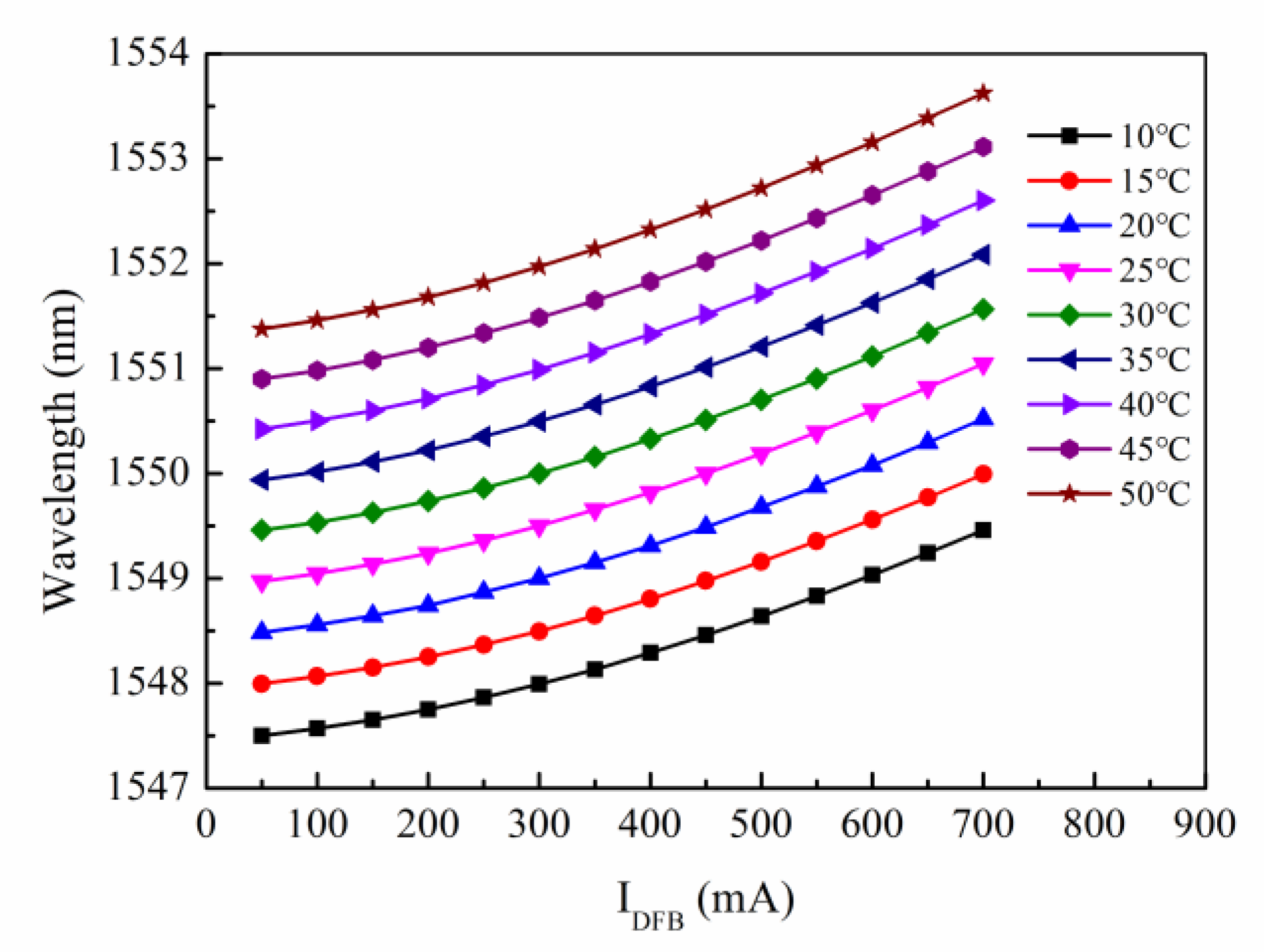

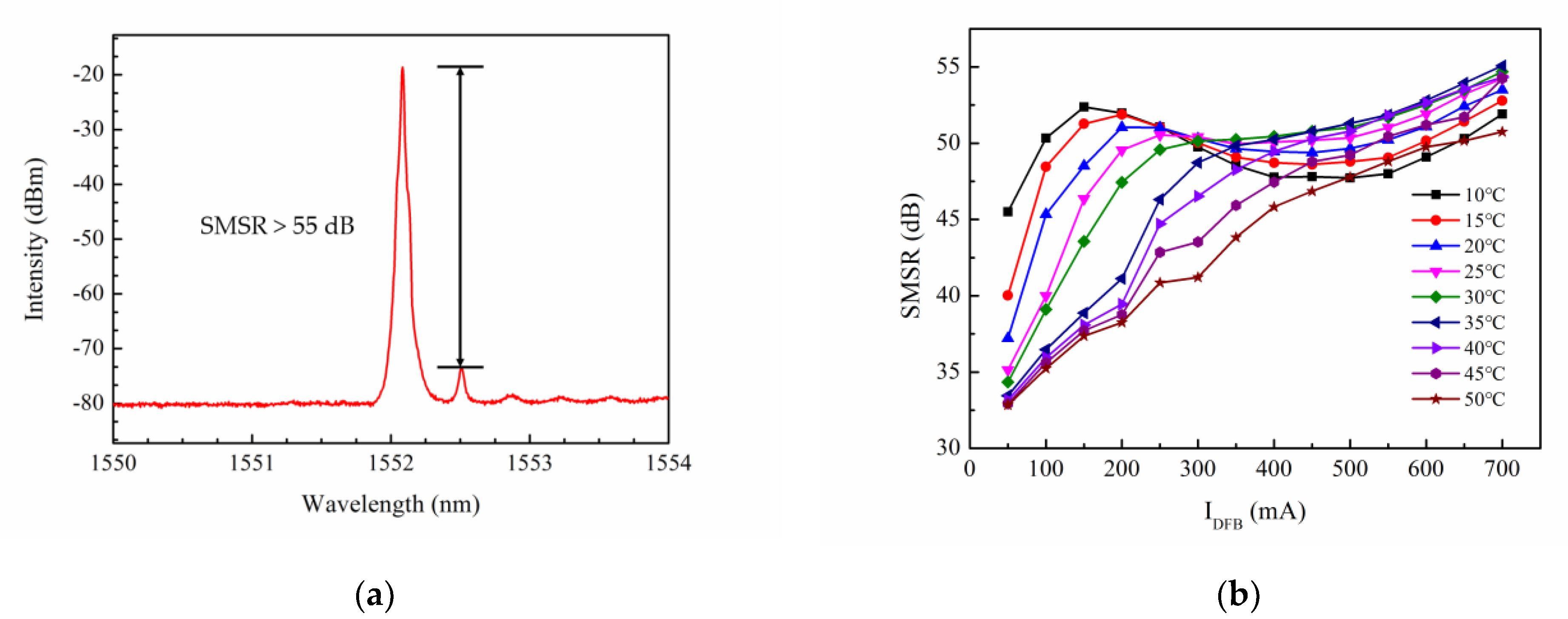

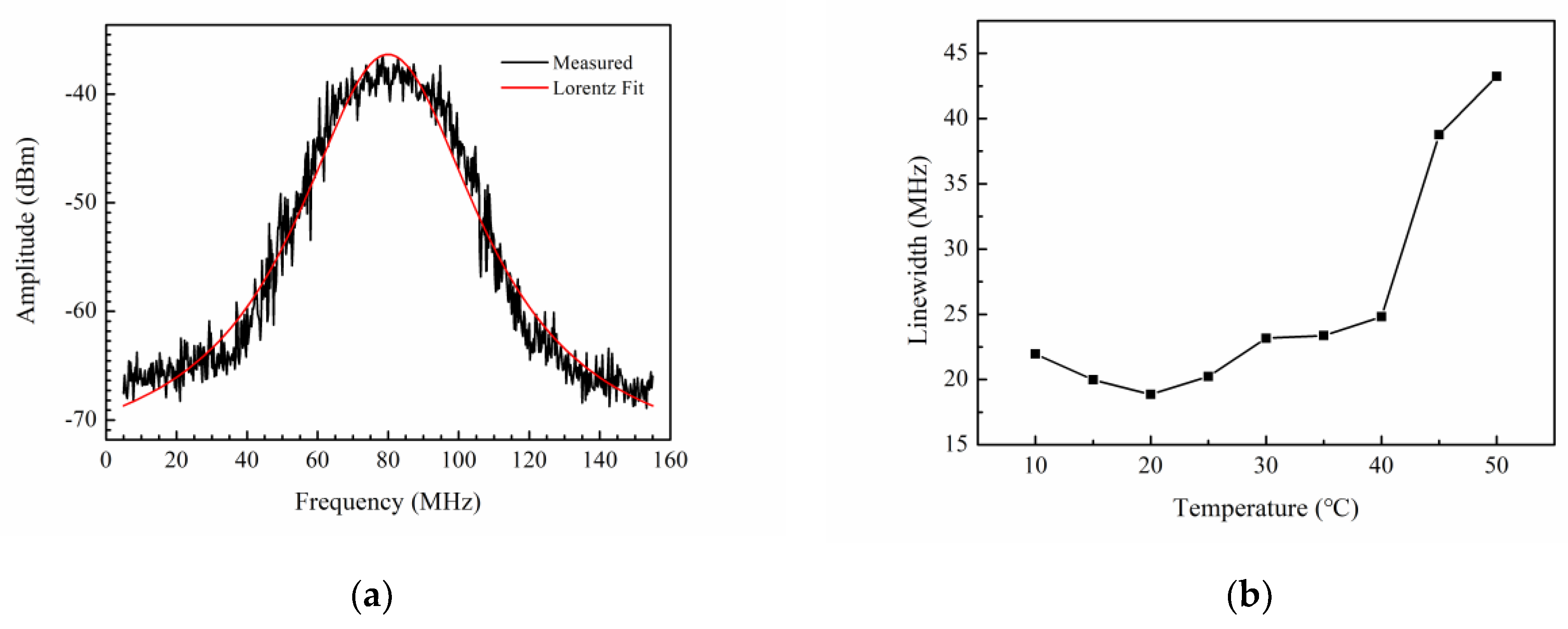

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Toyoshima, M.; Takayama, Y.; Takahashi, T.; Suzuki, K.; Kimura, S.; Takizawa, K.; Kuri, T.; Klaus, W.; Toyoda, M.; Kunimori, H.; et al. Ground-to-satellite laser communication experiments. IEEE Aerosp. Electron. Syst. Mag. 2008, 23, 10–18. [Google Scholar] [CrossRef]

- Müller, G.J.; Berlien, P.; Scholz, C. The medical laser. Med. Laser Appl. 2006, 21, 99–108. [Google Scholar] [CrossRef]

- Schulz, W.; Poprawe, R. Manufacturing with novel high-power diode lasers. IEEE J. Sel. Top. Quantum Electron. 2000, 6, 696–705. [Google Scholar] [CrossRef]

- Zhou, Z.; Yin, B.; Michel, J. On-chip light sources for silicon photonics. Light-Sci. Appl. 2015, 4, e358. [Google Scholar] [CrossRef]

- Warburton, R.E.; McCarthy, A.; Wallace, A.M.; Hernandez-Marin, S.; Hadfield, R.H.; Nam, S.W.; Buller, G.S. Subcentimeter depth resolution using a single-photon counting time-of-flight laser ranging system at 1550 nm wavelength. Opt. Lett. 2007, 32, 2266–2268. [Google Scholar] [CrossRef]

- Strickland, B.R.; Lavan, M.J.; Woodbridge, E.; Chan, V. Effects of fog on the bit-error rate of a free-space laser communication system. Appl. Opt. 1999, 38, 424–431. [Google Scholar] [CrossRef]

- Ma, W.; Tan, S.; Wang, K.; Guo, W.; Liu, Y.; Liao, L.; Zhou, L.; Zhou, J.; Li, X.; Liang, L.; et al. Practical two-dimensional beam steering system using an integrated tunable laser and an optical phased array. Appl. Opt. 2020, 59, 9985–9994. [Google Scholar] [CrossRef]

- Luo, Y.; Nakano, Y.; Tada, K.; Inoue, T.; Hosomatsu, H.; Iwaoka, H. Purely gain-coupled distributed feedback semiconductor lasers. Appl. Phys. Lett. 1990, 56, 1620–1622. [Google Scholar] [CrossRef]

- Kogelnik, H.; Shank, C.V. Coupled-Wave Theory of Distributed Feedback Lasers. J. Appl. Phys. 1972, 43, 2327–2335. [Google Scholar] [CrossRef]

- Soda, H.; Kotaki, Y.; Sudo, H.; Ishikawa, H.; Yamakoshi, S.; Imai, H. Stability in single longitudinal mode operation in GaInAsP/InP phase-adjusted DFB lasers. IEEE J. Quantum Electron. 1987, 23, 804–814. [Google Scholar] [CrossRef]

- Nilsson, S.; Kjellberg, T. Improved spectral characteristics of MQW-DFB lasers by incorporation of multiple phase-shifts. J. Lightwave Technol. 1995, 13, 434–441. [Google Scholar] [CrossRef]

- Orth, A.; Reithmaier, J.P.; Zeh, R.; Doleschel, H.; Forchel, A. First order gain-coupled GaInAs/GaAs distributed feedback laser diodes patterned by focused ion beam implantation. Appl. Phys. Lett. 1996, 69, 1906–1908. [Google Scholar] [CrossRef]

- Li, G.P.; Makino, T. Single-mode yield analysis of partly gain-coupled multiquantum-well DFB lasers. IEEE Photonics Technol. Lett. 1993, 5, 1282–1284. [Google Scholar] [CrossRef]

- Lowery, A.J.; Novak, D. Enhanced maximum intrinsic modulation bandwidth of complex-coupled DFB semiconductor lasers. Electron. Lett. 1993, 29, 461–463. [Google Scholar] [CrossRef]

- Luo, Y.; Nakano, Y. Fabrication and characteristics of gain-coupled distributed feedback semiconductor lasers with a corrugated active layer. IEEE J. Quantum Electron. 1991, 27, 1724–1731. [Google Scholar] [CrossRef]

- Okai, M.; Tsuchiya, T. Tunable DFB lasers with ultra-narrow spectral linewidth. Electron. Lett. 1993, 29, 349–351. [Google Scholar] [CrossRef]

- Ruan, C.; Chen, Y.; Qin, L.; Ma, D.; Jia, P.; Liu, X.; Liang, L.; Lei, Y.; Zeng, Y.; Song, Y.; et al. Purely gain-coupled distributed feedback Bragg semiconductor laser emitting at 795 nm with a wide tunable range. IEEE Photonics J. 2021, 13, 1500908. [Google Scholar] [CrossRef]

- Liu, X.; Chen, Y.; Zeng, Y.; Qin, L.; Lei, L.; Jia, P.; Wu, H.; Ma, D.; Ruan, C.; Ning, Y.; et al. Tunable DFB laser diode based on high-order surface isolation grooves working at 905 nm. Opt. Commun. 2021, 481, 126528. [Google Scholar] [CrossRef]

- Lei, Y.-X.; Chen, Y.-Y.; Gao, F.; Ma, D.-Z.; Jia, P.; Cheng, Q.; Wu, H.; Ruan, C.-K.; Liang, L.; Chen, C.; et al. 990 nm High-Power High-Beam-Quality DFB Laser with Narrow Linewidth Controlled by Gain-Coupled Effect. IEEE Photonics J. 2019, 11, 1500609. [Google Scholar] [CrossRef]

- Ma, D.Z.; Chen, Y.Y.; Lei, Y.X.; Jia, P.; Gao, F.; Zeng, Y.G.; Liang, L.; Song, Y.; Ruan, C.K.; Liu, X.; et al. 1045 nm purely gain coupled semiconductor laser based on periodic electric injection. J. Lumin. 2020, 225, 117372. [Google Scholar] [CrossRef]

- Corbett, B.; Mcdonald, D. Single longitudinal mode ridge waveguide 1.3 μm Fabry-Perot laser by modal perturbation. Electron. Lett. 1995, 31, 2181–2182. [Google Scholar] [CrossRef]

- Gao, F.; Qin, L.; Jia, P.; Chen, C.; Cheng, L.; Chen, H.; Liang, L.; Zhang, X.; Chen, Y.; Zeng, Y.; et al. Narrow-Strip Single-Longitudinal-Mode Laser Based on Periodic Anodes Defined by i-Line Lithography. IEEE Photonics J. 2018, 10, 1–10. [Google Scholar] [CrossRef]

- Liu, L.; Qu, H.; Wang, Y.; Liu, Y.; Zhang, Y.; Zheng, W. High-brightness single-mode double-tapered laser diodes with laterally coupled high-order surface grating. Opt. Lett. 2014, 39, 3231–3234. [Google Scholar] [CrossRef] [PubMed]

- Johannes, T.; Rast, A.; Rieger, J.; Harth, W. Gain-coupled DFB lasers with a titanium surface Bragg grating. Electron. Lett. 2002, 31, 370–371. [Google Scholar] [CrossRef]

- Chen, Y.; Jia, P.; Zhang, J.; Qin, L.; Chen, H.; Gao, F.; Zhang, X.; Shan, X.; Ning, Y.; Wang, L. Gain-coupled distributed feedback laser based on periodic surface anode canals. Appl. Opt. 2015, 54, 8863–8866. [Google Scholar] [CrossRef]

- Gao, F.; Qin, L.; Chen, Y.; Jia, P.; Chen, C.; Cheng, L.; Chen, H.; Liang, L.; Zeng, Y.; Zhang, X.; et al. Study of gain-coupled distributed feedback laser based on high order surface gain-coupled gratings. Opt. Commun. 2018, 410, 936–994. [Google Scholar] [CrossRef]

- Henry, C. Theory of the linewidth of semiconductor lasers. IEEE J. Quantum Electron. 1982, 18, 259–264. [Google Scholar] [CrossRef]

- Davies, S.C.; Whitbread, N.D.; Ward, A.J.; Arnold, M.; Griffin, R.A.; Wale, M.J. Reduced Lorentzian linewidth for monolithic widely tunable C-band lasers utilising InGaAlAs/InP active region. In Proceedings of the 2011 Conference on Lasers and Electro-Optics Europe and 12th European Quantum Electronics Conference (CLEO EUROPE/EQEC), Munich, Germany, 22–26 May 2011; IEEE: Piscataway, NJ, USA, 2011. [Google Scholar]

- Zhao, Y.G.; Nikolov, A.; Dutt, R. 1550 nm DFB semiconductor lasers with high power and low noise. Proc. SPIE—Int. Soc. Opt. Eng. 2011, 7933, 838–839. [Google Scholar]

- Chen, Q.; Jiang, C.; Wang, K.; Zhang, M.; Ma, X.; Liu, Y.; Lu, Q.; Guo, W. Narrow-linewidth thermally tuned multi-channel interference widely tunable semiconductor laser with thermal tuning power below 50 mW. Photonics Res. 2020, 8, 47–52. [Google Scholar] [CrossRef]

- Li, X.; Liang, L.; Wang, L.J.; Qin, L.; Chen, Y.Y.; Wang, Y.B.; Song, Y.; Lei, Y.X.; Jia, P.; Zeng, Y.G.; et al. Monolithic Integrated Semiconductor Optical Amplifier with Broad Spectrum, High Power, and Small Linewidth Expansion. IEEE Access 2021, 9, 98863–98873. [Google Scholar] [CrossRef]

- Hou, L.; Haji, M.; Akbar, J.; Marsh, J.H. Narrow linewidth laterally coupled 1.55μm AlGaInAs/InP distributed feedback lasers integrated with a curved tapered semiconductor optical amplifier. Opt. Lett. 2012, 37, 4525–4527. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Chen, X.; Zhou, Y.; Li, S.; Lu, L.; Liu, R.; Feng, Y. Experimental demonstration of eight-wavelength distributed feedback semiconductor laser array using equivalent phase shift. Opt. Lett. 2012, 37, 3315–3317. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Li, S.; Li, L.; Guo, R.; Zhang, T.; Rui, L.; Li, W.; Lu, L.; Song, T.; Zhou, Y.; et al. Study of the Multiwavelength DFB Semiconductor Laser Array Based on the Reconstruction-Equivalent-Chirp Technique. J. Lightwave Technol. 2013, 31, 3243–3250. [Google Scholar] [CrossRef]

- Dridi, K.; Benhsaien, A.; Zhang, J.; Hinzer, K.; Hall, T.J. Narrow linewidth two-electrode 1560 nm laterally coupled distributed feedback lasers with third-order surface etched gratings. Opt. Express 2014, 22, 19087–19097. [Google Scholar] [CrossRef] [PubMed]

- Dridi, K.; Benhsaien, A.; Zhang, J.; Hall, T.J. Narrow Linewidth 1550 nm Corrugated Ridge Waveguide DFB Lasers. Photonics Technol. Lett. IEEE 2014, 26, 1192–1195. [Google Scholar] [CrossRef]

- Li, L.; Tang, S.; Huang, L.; Zhang, T.; Li, S.; Shi, Y.; Chen, X. Experimental demonstration of a low-cost tunable semiconductor DFB laser for access networks. Semicond. Sci. Technol. 2014, 29, 95002. [Google Scholar] [CrossRef]

- Lu, J.; Liu, S.; Tang, Q.; Xu, H.; Chen, Y.; Chen, X. Multi-wavelength distributed feedback laser array with very high wavelength-spacing precision. Opt. Lett. 2015, 40, 5136–5139. [Google Scholar] [CrossRef]

- Tang, S.; Lu, J.; Li, L.; Xu, H.; Tang, Q.; Chen, X. A Matrix-Grating Equivalent Phase Shifted Laser Array With 25-nm Wavelength Tuning Range. Photonics Technol. Lett. IEEE 2015, 27, 530–533. [Google Scholar] [CrossRef]

- Zhao, Y.; Shi, Y.; Li, J.; Liu, S.; Xiao, R.; Li, L.; Lu, J.; Chen, X. A Cascaded Tunable DFB Semiconductor Laser With Compact Structure. IEEE J. Quantum Electron. 2018, 54, 2200111. [Google Scholar] [CrossRef]

- Su, Z.; Xiao, R.; Sun, Z.; Yang, Z.; Du, Y.; Chen, Z.; Zheng, J.; Zhang, Y.; Lu, J.; Shi, Y.; et al. 48 channels 100-GHz tunable laser by integrating 16 DFB lasers with high wavelength-spacing uniformity. arXiv 2020, arXiv:2001.01178. [Google Scholar]

- Sun, Z.; Xiao, R.; Su, Z.; Liu, K.; Hu, Z.; Dai, P.; Lu, J.; Zheng, J.; Zhang, Y.; Shi, Y.; et al. High Single-Mode Stability Tunable In-Series Laser Array With High Wavelength-spacing Uniformity. J. Lightwave Technol. 2020, 38, 6038–6046. [Google Scholar] [CrossRef]

- Sun, Z.; Xiao, R.; Su, Z.; Liu, K.; Lv, G.; Xu, K.; Fang, T.; Shi, Y.; Chiu, Y.-J.; Chen, X. Experimental Demonstration of Wavelength-tunable In-series DFB Laser Array with 100-GHz Spacing. IEEE J. Sel. Top. Quantum Electron. 2021, 28, 1500308. [Google Scholar] [CrossRef]

| Year | Pout | Tunable Range | SMSR | Linewidth |

|---|---|---|---|---|

| 2012 [32] | 210 mW | - | >45 dB | 64 kHz (3 dB) |

| 2012 [33] | >15 mW | >15 nm | >40 dB | - |

| 2013 [34] | >13 mW | 5.88 nm | >45 dB | - |

| 2014 [35] | 6 mW | 3.37 nm | >52 dB | <170 kHz (3 dB) |

| 2014 [36] | 7 mW | <4 nm | >50 dB | <185 kHz (3 dB) |

| 2014 [37] | >3 mW | 9 nm | >42 dB | 1.67 MHz (3 dB) |

| 2015 [38] | >4 mW | 30 nm | >40 dB | - |

| 2015 [39] | >1.5 mW | 25 nm | >40 dB | - |

| 2018 [40] | >15 mW | >9 nm | >35 dB | - |

| 2020 [41] | >4 mW | 40 nm | >45 dB | 0.68 nm (20 dB) |

| 2020 [42] | >25 mW | 10 nm | >60 dB | - |

| 2021 [43] | >10 mW | >3.5 nm | >55 dB | - |

| This paper | 400 mW | 6.156 nm | >55 dB | 18.86 MHz (3 dB) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Liang, L.; Qin, L.; Lei, Y.; Jia, P.; Tang, H.; Yang, C.; Chen, Y.; Wang, Y.; Song, Y.; et al. Development of a High-Power Surface Grating Tunable Distributed-Feedback Bragg Semiconductor Laser Based on Gain-Coupling Effect. Appl. Sci. 2022, 12, 4498. https://doi.org/10.3390/app12094498

Li X, Liang L, Qin L, Lei Y, Jia P, Tang H, Yang C, Chen Y, Wang Y, Song Y, et al. Development of a High-Power Surface Grating Tunable Distributed-Feedback Bragg Semiconductor Laser Based on Gain-Coupling Effect. Applied Sciences. 2022; 12(9):4498. https://doi.org/10.3390/app12094498

Chicago/Turabian StyleLi, Xin, Lei Liang, Li Qin, Yuxin Lei, Peng Jia, Hui Tang, Changjin Yang, Yongyi Chen, Yubing Wang, Yu Song, and et al. 2022. "Development of a High-Power Surface Grating Tunable Distributed-Feedback Bragg Semiconductor Laser Based on Gain-Coupling Effect" Applied Sciences 12, no. 9: 4498. https://doi.org/10.3390/app12094498

APA StyleLi, X., Liang, L., Qin, L., Lei, Y., Jia, P., Tang, H., Yang, C., Chen, Y., Wang, Y., Song, Y., Qiu, C., Zheng, C., & Wang, L. (2022). Development of a High-Power Surface Grating Tunable Distributed-Feedback Bragg Semiconductor Laser Based on Gain-Coupling Effect. Applied Sciences, 12(9), 4498. https://doi.org/10.3390/app12094498