Research and Progress on Truing and Sharpening Process of Diamond Abrasive Grinding Tools

Abstract

:1. Introduction

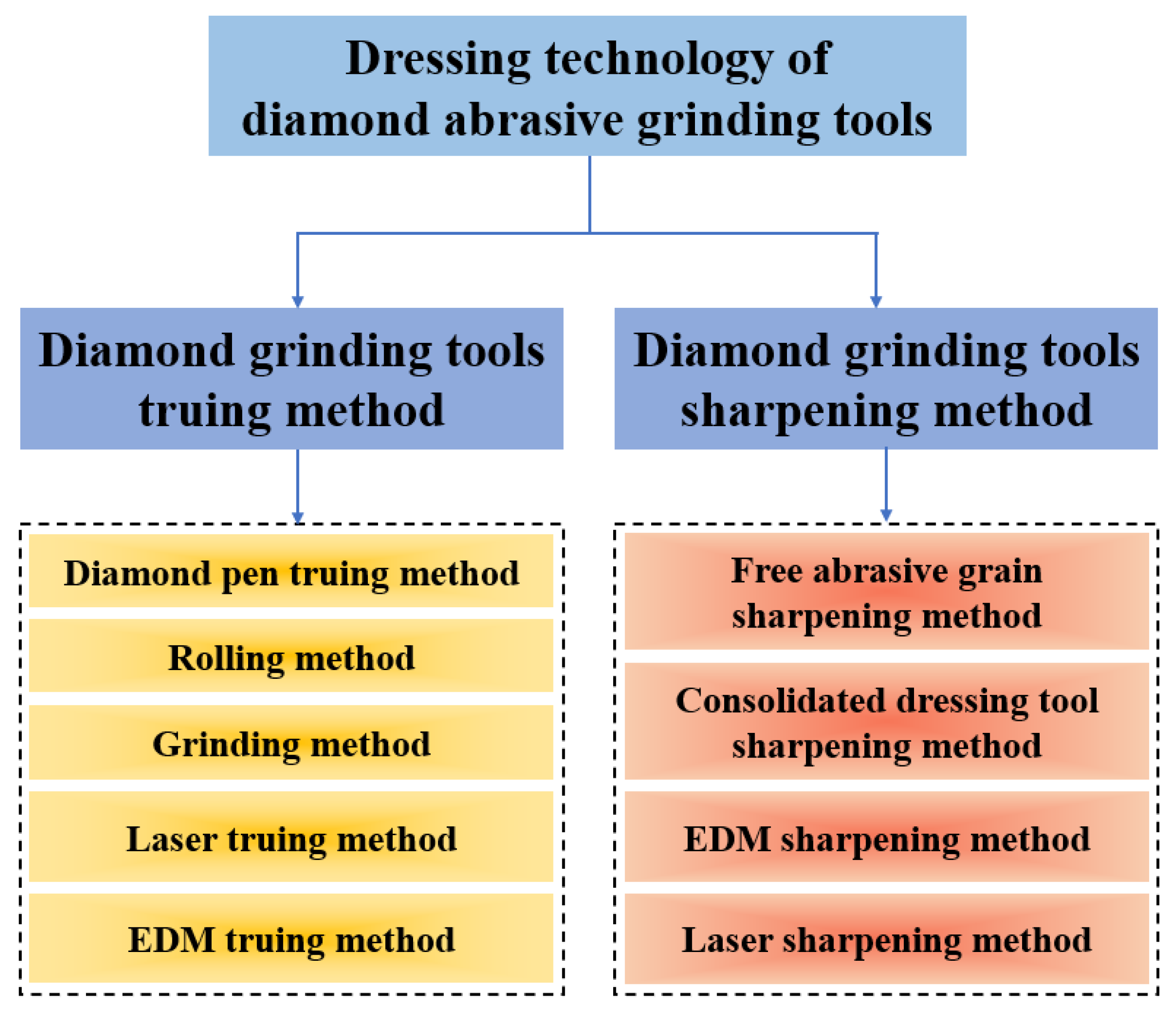

2. Dressing Status of Diamond Abrasive Grinding Tools

3. Dressing Method of Diamond Abrasive Grinding Tools

3.1. Truing Technology of Diamond Abrasive Grinding Tools

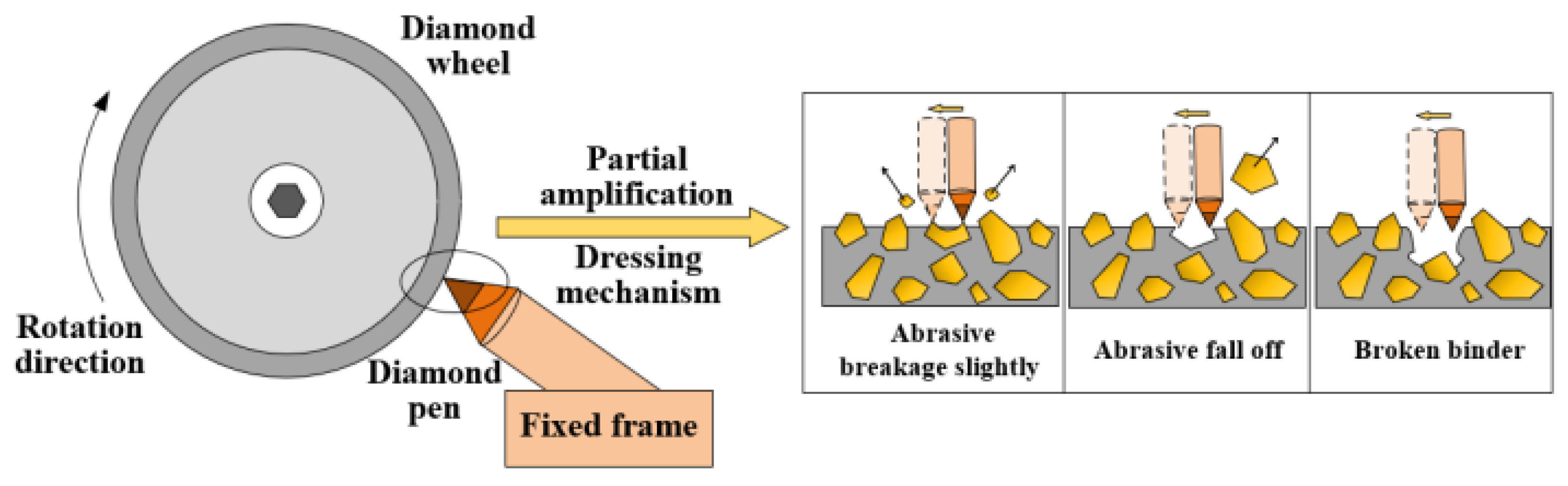

3.1.1. Diamond Pen Truing Method

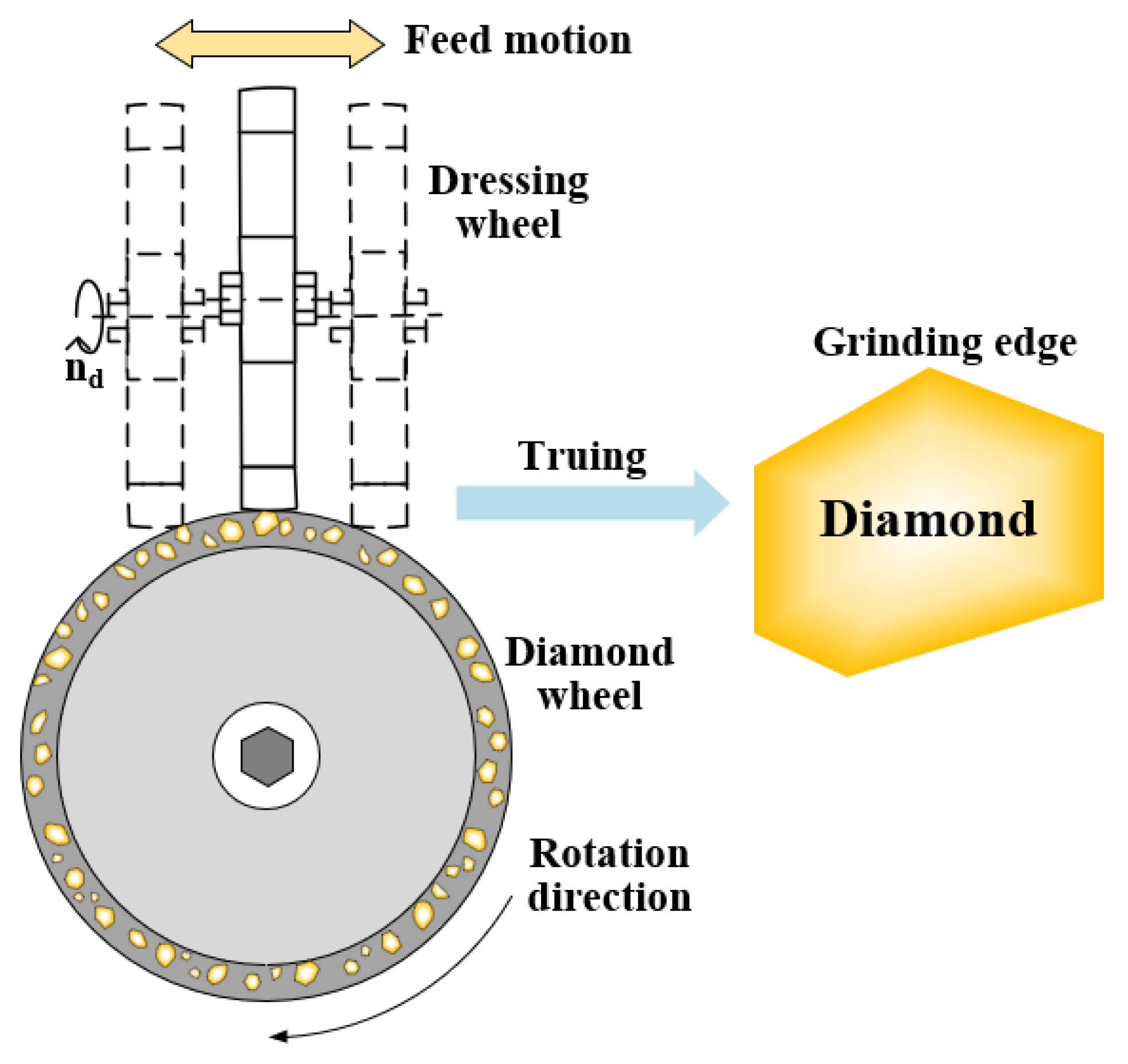

3.1.2. Rolling Method

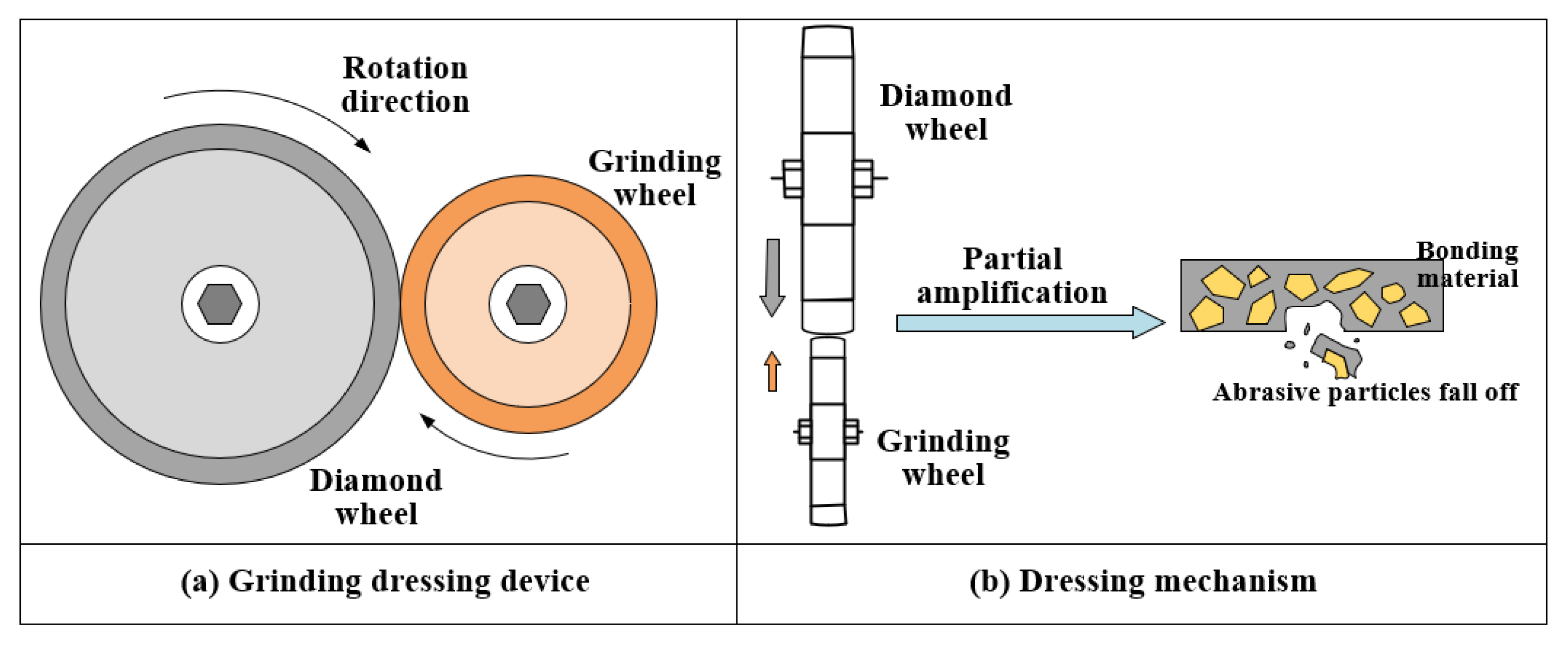

3.1.3. Grinding Method

3.1.4. Electric Discharge Machining (EDM) Truing Method

3.1.5. Laser Truing Method

3.2. Sharpening Technology of Diamond Abrasive Grinding Tools

3.2.1. Free Abrasive Grain Sharpening Method

3.2.2. Consolidated Dressing Tool Sharpening Method

3.2.3. Electric Discharge Machining (EDM) Sharpening Method

3.2.4. Laser Sharpening Method

4. Numerical Simulation and Experimental Research on Laser Dressing Bronze Diamond Abrasive Grinding Wheels

5. Conclusions

- (1)

- From the perspective of the truing and sharpening of diamond abrasive grinding tools, traditional processing methods, such as the diamond pen dressing method, grinding method, and rolling method, and new dressing methods, such as the EDM dressing method and laser dressing method, were described in detail. In comparison, it was pointed out that the laser dressing of diamond abrasive grinding tools was a green processing method with high efficiency and no environmental pollution.

- (2)

- Considering the superposition accumulation effect of the serial energy QC and coupling of the Fourier heat transfer model, the energy accumulation heat transfer model for laser dressing was established, and numerical simulation of pulsed fiber laser dressing of the bronze-bonded diamond abrasive grinding wheel was carried out. The temperature evolution law of the bronze bond and diamond abrasive grains dressed by pulsed fiber laser was obtained by using the numerical analysis of the model. The numerical analysis showed that, when the laser power density was greater than 1.68 × 108 W/cm2, the bronze-bonded diamond abrasive grinding wheel could be sharpened. When the laser power density was greater than 2.52 × 108 W/cm2, the truing effect of the diamond abrasive grinding tools was achieved.

- (3)

- An experiment on the laser dressing of a bronze-bonded diamond abrasive grinding wheel was carried out. The surface topography of the bronze-bonded diamond abrasive grinding wheel was photographed by a three-dimensional ultra-depth-of-field microscope. The results showed that, when the laser power density was 2.52 × 108 W/cm2∼3.36 × 108 W/cm2, it could not only properly remove the bronze bond, but also better sharpen the diamond abrasive grains. It was confirmed that the laser dressing method could achieve the combination of truing and sharpening of the diamond abrasive grinding tools. The experiment not only demonstrated the correctness and feasibility of the theoretical model but also provided process optimization for research into the pulsed laser dressing of diamond abrasive grinding tools.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, Z.M.; He, Q.S.; Feng, C.J.; Wang, X. Study on dressing technology of super abrasive products. Diam. Abras. Eng. 2016, 36, 43–49. [Google Scholar] [CrossRef]

- Zhou, Z.X.; Deng, Z.H.; Chen, G.Y.; Fu, H.Q. Development and Key Technology of Grinding. China Mech. Eng. 2000, 11, 195–198. [Google Scholar]

- Cai, S.; Xiong, B.; Chen, G.Y.; Wu, J.P. Laser truing and sharpening of bronze-bond diamond grinding wheel. Infrared Laser Eng. 2017, 46, 66–75. [Google Scholar] [CrossRef]

- Chen, G.Y. The Research on Mechanism and Technology for Laser Truing and Dressing of Bronze-Bonded Diamond Grinding Wheels by Acoustic-Optic Q-Switched Nd: YAG Pulsed Laser; Hunan University: Changsha, China, 2006; pp. 55–58. [Google Scholar]

- Lei, G.; Duan, W.; Li, H.; Wu, Z.; Jia, J.; Wen, K.; Bai, Q.; Zhao, S. Method for Dressing Diamond Grinding Wheels before Roll Grinding, Involves Changing Grinding Sound from Sharp to Thick, Meeting Roll Surface Grinding Requirements after Waste Roll Is Trimmed, and Completing Trimming. CN111716252-A, 29 September 2020. [Google Scholar]

- Zhao, J.Z.; Feng, K.M.; Xing, B. Present situation analysis and development trend of single-point diamond dresser. Manuf. Technol. Mach. Tool 2018, 10, 39–42. [Google Scholar] [CrossRef]

- Zhao, J.; Gao, G.F. Progress in ultrasonic dressing technologies of superabrasives grinding wheels. Diam. Abras. Eng. 2010, 30, 79–82. [Google Scholar] [CrossRef]

- Liu, R.Y. The Technology Research on Ultrasonic Dressing Diamond Grinding Wheel; Shenyang University of Technology: Shenyang, China, 2020; pp. 23–35. [Google Scholar]

- Radovan, D.; Jeffrey, B.; Uta, K.; Krajnik, P. Truing of diamond wheels—Geometry, kinematics and removal mechanisms. CIRP Ann. 2018, 67, 345–348. [Google Scholar] [CrossRef]

- Liang, Z.Q.; Wu, L.F.; Zhou, T.F.; Zhang, S.Y.; Wang, Q.Y.; Jiao, L.; Wang, X.B. Experimental Study on Diamond Wheel V-tip Truing Using a Tangential Grinding Truing Method. J. Mech. Eng. 2018, 54, 196–202. [Google Scholar] [CrossRef] [Green Version]

- Zhou, L.; Wei, Q.C.; Zheng, N.; Chen, X.H.; Zhang, Q.H.; Wang, J. Dressing technology of arc diamond wheel by roll abrading in aspheric parallel grinding. Int. J. Adv. Manuf. Technol. 2019, 105, 2699–2706. [Google Scholar] [CrossRef]

- Wada, Y.; Cai, J.Q. Dressing Device for Performing Planarization and Dressing of Grinding Surface, Which Comprises Ultrasonic Vibrating Device that Vibrates Ultrasonic Waves, and Dressing Device Has Dresser Assembly for Dressing Surface of Polishing Pad. JP2020168677-A, 15 October 2020. [Google Scholar]

- Chen, S.T.; Chen, Y.Y. Microgroove grinding of monocrystalline diamond using medium-frequency vibration-assisted grinding with self-sensing grinding force technique. J. Mater. Process. Technol. 2020, 282, 116686. [Google Scholar] [CrossRef]

- Lin, J. Dressing Method of Diamond Grinding Wheel, Involves Driving High-Speed Rotating Diamond Grinding WHEEL Dressing Grinding Wheel, and Moving Dressing Wheel Back and Forth until Outer Circle of Diamond Wheel Is Rounded. CN111168572-A, 19 May 2020. [Google Scholar]

- Zhang, Z.Z.; Yao, P.; Zhang, Z.Y.; Xue, D.L.; Wang, C.; Huang, C.Z. A novel technique for dressing metal-bonded diamond grinding wheel with abrasive waterjet and touch truing. Int. J. Adv. Manuf. Technol. 2017, 93, 3063–3073. [Google Scholar] [CrossRef]

- Zheng, F.F.; Dong, Z.G.; Zhang, J.T.; Liu, J.T.; Kang, R.K. Influence of Ultrasonic Vibration on Material Removal of Scratching on RB-SiC with Single Diamond Tool. J. Mech. Eng. 2019, 55, 225–232. [Google Scholar] [CrossRef]

- Cui, Z.M.; Feng, C.C.; Zhuang, Z.P.; Wang, X.; He, Q.S. Precision grinding technology of diamond abrasive tools based on grinding method. Diam. Abras. Eng. 2021, 41, 5–11. [Google Scholar] [CrossRef]

- Wu, Q.P.; Ouyang, Z.Y.; Wang, Y.; Yang, H.; Song, K. Precision grinding of engineering ceramic based on the electrolytic dressing of a multi-layer brazed diamond wheel. Diam. Relat. Mater. 2019, 100, 107552. [Google Scholar] [CrossRef]

- Wang, X.Z.; Yi, S.; Easton, M.; Ding, S.L. Active gap capacitance electrical discharge machining of polycrystalline diamond. J. Mater. Process. Technol. 2020, 280, 116598. [Google Scholar] [CrossRef]

- Borisov, M.L.; Yanyushkin, A. Investigation of the Process of Automatic Control of Current Polarity Reversal in the Conditions of Hybrid Technology of Electrochemical Processing of Corrosion-Resistant Steels. Metall. Metall. Eng. 2020, 22, 6–15. [Google Scholar] [CrossRef]

- He, Q.P.; Xie, J.; Lu, K.; Yang, H. Study on in-air electro-contact discharge (ECD) truncating of coarse diamond grinding wheel for the dry smooth grinding of hardened steel. J. Mater. Process. Technol. 2020, 276, 116402. [Google Scholar] [CrossRef]

- Zhou, D.D.; Qiu, Z.J. Metal-Bonded Diamond Grinding Wheel Topography Generated with Electrical Discharge Dressing (EDD). Nanotechnol. Precis. Eng. 2017, 15, 254–260. [Google Scholar] [CrossRef]

- Wang, T.Z.; Wu, C.Y.; Liu, H.N.; Chen, M.J.; Cheng, J.; Su, D.N. On-machine electric discharge truing of small ball-end fine diamond grinding wheels. J. Mater. Process. Technol. 2020, 277, 116472. [Google Scholar] [CrossRef]

- Guan, J.L.; Pan, Y.J.; Dai, Z.P.; Zhang, Z.G.; Wang, J.J. Experimental study on precision grinding technology of aluminum—Based diamond. Manuf. Technol. Mach. Tool 2021, 09, 75–79. [Google Scholar] [CrossRef]

- Cao, F.G. Laser Beam Machining; Chemical Industry Press: Beijing, China, 2014; pp. 75–92. [Google Scholar]

- Liu, J.P.; Chen, G.Y.; Zhou, C.; Wang, Y.Y.; Peng, Y.B.; Xiong, B. Experimental Study on Pulsed Laser Dressing Bronze Diamond Wheel V-shaped Concave Surfaces. Appl. Laser 2017, 37, 557–562. [Google Scholar] [CrossRef]

- Zhou, X.; Chen, G.Y.; Zhou, C.; He, J.; Liu, J.P.; Xiong, B. An Experimental Study of Dressing Electroplated Diamond Wheels with Pulsed Ultraviolet Laser. Appl. Laser 2016, 36, 521–526. [Google Scholar] [CrossRef]

- Chen, G.Y.; Wei, Y.; Peng, Y.B.; Wang, Y.Y. Fiber laser CNC tangential truing V-shaped concave diamond grinding wheel system based on machine vision technology. Int. J. Adv. Manuf. Technol. 2019, 104, 4077–4099. [Google Scholar] [CrossRef]

- Cai, S.; Xiong, W.; Zeng, X.; Yao, Y.; Wang, F.; Duan, J.; Guo, L.; Li, X.; Tao, Y. Grinding Wheel Double Laser Trimming Device Comprises e.g., Nanosecond Pulse Laser, Femtosecond Pulse Laser, Laser Beam Expander, First Focusing Lens, Second Focusing LENS and Pulse Liquid Column Generator. CN108032222-A, 15 May 2018. [Google Scholar]

- Deng, H.; Chen, G.Y.; Zhou, C.; Zhou, X.C. Pulsed Laser Tangential Profiling and Radial Sharpening of Bronze—Bonded Diamond Grinding Wheels. Chin. J. Lasers 2014, 41, 66–74. [Google Scholar] [CrossRef]

- Cui, Z.M.; Wang, X.; He, Q.S.; Zhou, B.C. A Method for Extruding Grinding Dressing Super-abrasive Grinding Wheels Using Free Grains under Constraint of Diamond Abrasive Surface. China Mech. Eng. 2020, 31, 2959–2965. [Google Scholar] [CrossRef]

- Soleimanimehr, H. Analysis of the cutting ratio and investigating its influence on the workpiece’s diametrical error in ultrasonic-vibration assisted turning. Proc. Inst. Mech. Eng. 2021, 235, 640–649. [Google Scholar] [CrossRef]

- Yang, Z.B.; Zhang, S.Y.; Hu, J.C.; Zhang, Z.; Li, K.Q.; Zhao, B. Study of Material Removal Behavior During Laser-Assisted Ultrasonic Dressing of Diamond Wheel. Int. J. Precis. Eng. Manuf. Green Technol. 2020, 7, 173–184. [Google Scholar] [CrossRef]

- Li, S.H.; Han, T.; Wang, W.D.; Sun, J.; Han, G.T. Design and Grinding Wheel Dressing of Vertical Super-hard Grinding Wheel Arc Dressers. China Mech. Eng. 2020, 31, 513–518. [Google Scholar] [CrossRef]

- Klink, U.; Sihling, B. Method for Dressing Honing Stone by Using Internally Cooled Honing Tool for Mechanical Finishing of Inner Surfaces of Cylinders of Internal Combustion Engines, Involves Dressing Honing Stone by Using Electro-Erosive Process. DE102018122682-A1, 19 March 2020. [Google Scholar]

- Zhou, L.; Wei, Q.; Li, J.; Chen, X.; Zhang, Q.; Wang, J.; Liu, M.; Xu, Q. Circular Arc-Shaped Diamond Grinding Wheel Off-Line Repairing Device, Has X Axis Ball Screw Connected with X Axial Numerical Control Servo Motor, Where X Axial Numerical Control Servo Motor Drives Coupling End of X Axial Shaft. CN108908124-A, 15 August 2018. [Google Scholar]

- Chen, B.; Jiao, H.; Luo, L.; Zhao, Q. Device for Precise Dressing of Resin-Based V-Shaped Diamond Grinding Wheels, Has Diamond Grinding Wheel that Is Arranged at Lower End of Vertical Grinding Spindle, and Carbide Grinding Rod Whose End Is in Contact with Grinding Wheel. CN111571445-A, 25 August 2020. [Google Scholar]

- Xue, M. Dressing Diamond Roller Grinding Wheel Twist Drilling Device, Has Axial Straight Angle Edge Formed with Circular Groove And Provided with Arc Main Body, Where Outer Circumferential Surface of Arc Main Body Is Fixed with Ring Roller. CN207387444-U, 22 May 2018. [Google Scholar]

- Liu, Q.; Wang, H.; Gong, Q. Trimming Device for Diamond Grinding Wheel Structure, Has Trimming Arm Whose Lower End Is Equipped with Oilstone, And Oilstone Seat Installed on Outer Ring of Oilstone, Where Oilstone Seat Is Provided with Screw for Fixing Whetstone to Prevent Oil Stone Base. CN110802517-A, 1 August 2020. [Google Scholar]

- Suzuki, K.; Uematsu, T.; Nakagawa, T. On-machine truing/dressing of metal bond diamond grinding wheels by electro-discharge machining. Ann. CIRP 1987, 36, 115–118. [Google Scholar] [CrossRef]

- Yu, J.W.; He, L.H.; Shang, Z.T.; Luo, H.; Liang, Q.H. Experimental Investigation on Precision Electrical Discharge Dressing of Small-diameter Bronze-bonded Fine Grain Grinding Wheel. J. Mech. Eng. 2019, 55, 199–207. [Google Scholar] [CrossRef]

- Chen, F.; Mei, G.J.; Zhao, B.; Bie, W.B.; Li, G.X. Mechanism of online dressing for micro-diamond grinding wheel during the ultrasound-aided electrolytic in-process dressing grinding. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2020, 234, 263–274. [Google Scholar] [CrossRef]

- Kundrák, J.; Fedorovich, V.; Pyzhov, I.; Markopoulos, A.P. Improving the effectiveness of combined grinding processes for processing superhard materials. J. Manuf. Process. 2019, 43, 270–275. [Google Scholar] [CrossRef]

- Wang, X.L.; Zhu, K. Influence of Discharge Parameters on Efficiency of EDM Dressing Diamond Grinding Wheel. Mach. Tool Hydraul. 2018, 46, 98–101. [Google Scholar] [CrossRef]

- Westkämper, E. Grinding Assisted by Nd:YAG Lasers. CIRP Ann.-Manuf. Technol. 1995, 44, 317–320. [Google Scholar] [CrossRef]

- Deng, H.; Xu, Z. Laser dressing of arc shaped resin-bonded diamond grinding wheels. J. Mater. Process. Technol. 2021, 288, 116884. [Google Scholar] [CrossRef]

- Witt, T. Method for Preparing Fine Machining Tool for Machining Workpiece Surfaces, Involves Resetting Bond Relative to Cutting Grains through Selective Laser Ablation by Irradiating Working Surface with Pulsed Laser Radiation. DE102019202533-A1, 27 August 2020. [Google Scholar]

- Cai, S.; Xiong, W.; Wang, F.; Tao, Y.F.; Ming, X.Z.; Sun, X.; Zeng, X.Y. Expansion property of plasma plume for laser ablation of materials. J. Alloys Compd. 2019, 773, 1075–1088. [Google Scholar] [CrossRef]

- Cai, S.; Chen, G.Y.; Zhou, C.; Ming, X.Z. Multi-Pulsed Laser Truing and Dressing of Deterioration Layer on Bronze-Bonded Diamond Grinding Wheel Surface. China J. Lasers 2017, 44, 51–61. [Google Scholar] [CrossRef]

- Cai, S.; Liu, W.H.; Long, S.Q.; Zhang, Y.; Ming, R.; Ming, X.Z.; Xu, J.F. Research on the mechanism of particle deposit effects and process optimization of nanosecond pulsed laser truing and dressing of materials. RSC Adv. 2021, 11, 28295–28312. [Google Scholar] [CrossRef]

- Liu, W.P.; Lv, Y.W.; Wu, L.X.; Wei, C.H.; Wang, J.W.; Han, Y.C.; Zhang, S. Numerical simulation of ablation and carbonization of GFRP irradiated by laser induced microwave transmission decay. Infrared Laser Eng. 2021, 50, 279–285. [Google Scholar] [CrossRef]

- Yuan, H.; Hao, M.L.; Li, F.X.; Shi, Q.Y. Attenuation properties of 1.06 μm laser radiation in water fog. Infrared Laser Eng. 2018, 47, 181–187. [Google Scholar] [CrossRef]

| Material | Name | Symbol | Unit | Numerical Value |

|---|---|---|---|---|

| Bronze | Atomic mass | m | kg | 1.038 × 10−25 |

| Density | ρs | kg·m−3 | 8620 | |

| Melting temperature | Tm | K | 1173 | |

| Gasification temperature | Tl | K | 2770 | |

| Thermal diffusivity | k | cm2·s−1 | 0.14 | |

| Thermal conductivity | ks | W·m−1·K−1 | 41.9 | |

| Specific heat capacity | cs | J·kg−1·K−1 | 352 | |

| Absorption rate | β | — | 0.38 | |

| Diamond | Density | ρs | kg·m−3 | 3.52 |

| Melting temperature | Tm | K | 3550 | |

| Gasification temperature | Tl | K | 4830 | |

| Refractive index | n | — | 2.42 | |

| Thermal diffusivity | k | cm2·s−1 | 3.11 | |

| Thermal conductivity | ks | W·m−1·K−1 | 2000 | |

| Specific heat capacity | cs | kg−1·K−1 | 1827 | |

| Absorption rate | β | — | 0.25 |

| Name | Symbol | Unit | Numerical Value |

|---|---|---|---|

| Laser wavelength | λ | nm | 1064 |

| Electron mass | me | kg | 9.1 × 10−31 |

| Average ionization energy | U | eV | 7.63 |

| Pulse repetition rate | f | kHz | 50 |

| Energy accumulation coefficient | s | — | 0.85 |

| Spot diameter | D | μm | 38 |

| Pulse width | τ | ns | 210 |

| Absorption coefficient | b | m−1 | 4.76 × 106 |

| Boltzmann constant | kb | J·K−1 | 1.38 × 10−23 |

| Grinding machine speed | rv | r·min−1 | 300 |

| Name | Unit | Numerical Value | |

|---|---|---|---|

| Bronze | Diamond | ||

| Laser ablation time | min | 6 | 6 |

| Number of cycles | times | 3 | 3 |

| Pulse width | ns | 210 | 210 |

| Distance in the X-direction | μm | 16 | 4.8 |

| Time step | ns | 0.21 | 0.021 |

| Spatial step | μm | 1 | 0.12 |

| kΔt/(ρc(Δx)2) | — | 0.0029 | 0.4541 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, S.; Liu, W.; Song, J.; Deng, K.; Tang, Y. Research and Progress on Truing and Sharpening Process of Diamond Abrasive Grinding Tools. Appl. Sci. 2022, 12, 4683. https://doi.org/10.3390/app12094683

Cai S, Liu W, Song J, Deng K, Tang Y. Research and Progress on Truing and Sharpening Process of Diamond Abrasive Grinding Tools. Applied Sciences. 2022; 12(9):4683. https://doi.org/10.3390/app12094683

Chicago/Turabian StyleCai, Song, Wenhao Liu, Jinchao Song, Kai Deng, and Yinghong Tang. 2022. "Research and Progress on Truing and Sharpening Process of Diamond Abrasive Grinding Tools" Applied Sciences 12, no. 9: 4683. https://doi.org/10.3390/app12094683

APA StyleCai, S., Liu, W., Song, J., Deng, K., & Tang, Y. (2022). Research and Progress on Truing and Sharpening Process of Diamond Abrasive Grinding Tools. Applied Sciences, 12(9), 4683. https://doi.org/10.3390/app12094683