A GAN-Augmented Corrosion Prediction Model for Uncoated Steel Plates

Abstract

1. Introduction

- Predicting the surface corrosion of steel structures can save time for monitoring and observation.

- Predicting the surface corrosion of steel structures can facilitate the modeling of corroded surfaces.

- Predicting the surface corrosion of steel structures can predict the lifetime of the steel structure, and provide early warning for facility maintenance.

- Low prediction accuracy. The current prediction methods have low accuracy, which is not enough for corrosion simulation.

- The specificity of the environment and steel. Many methods are not generally applicable. They usually target specific environments and specific steels.

- We propose a method for predicting the corrosion surface of uncoated steel plates.

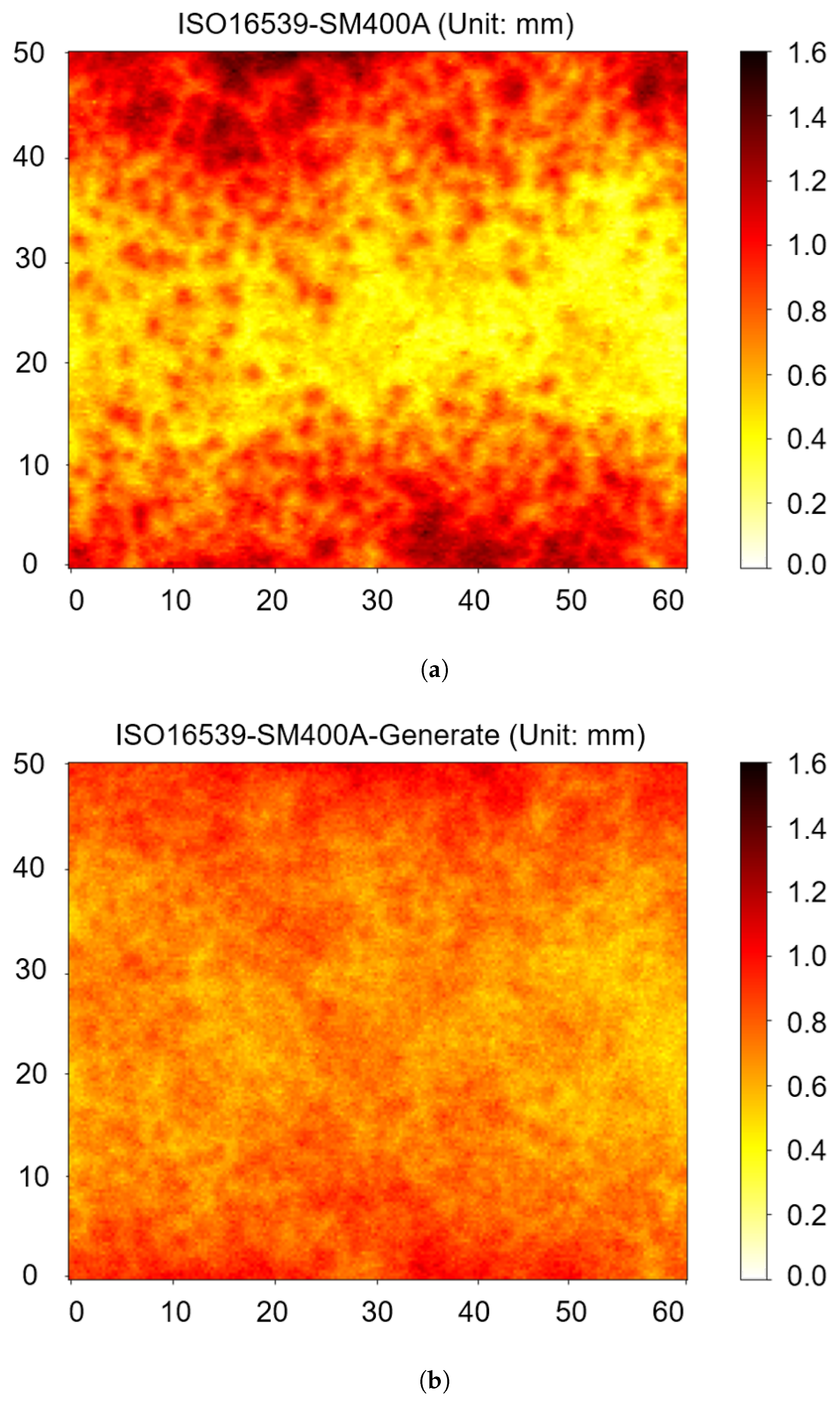

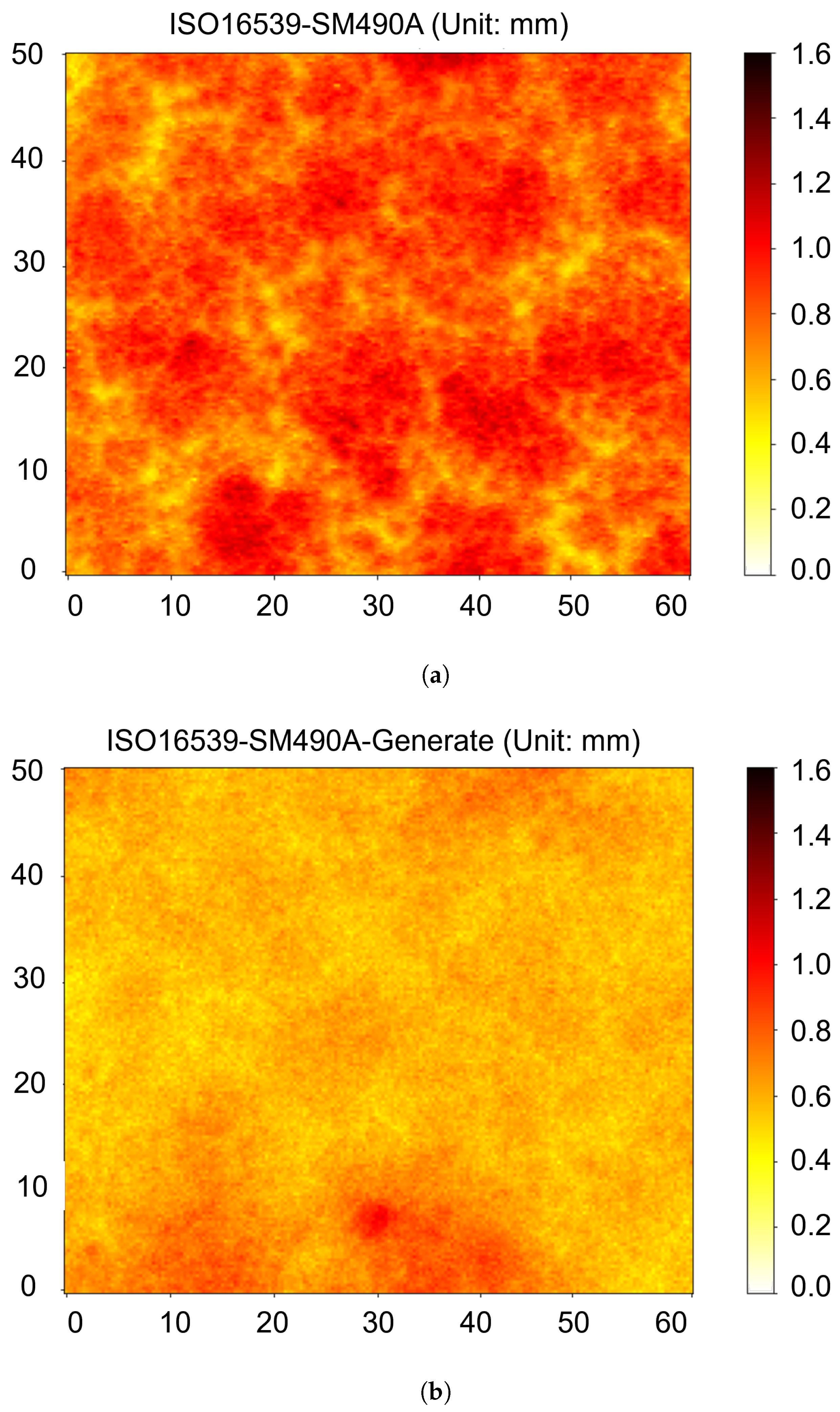

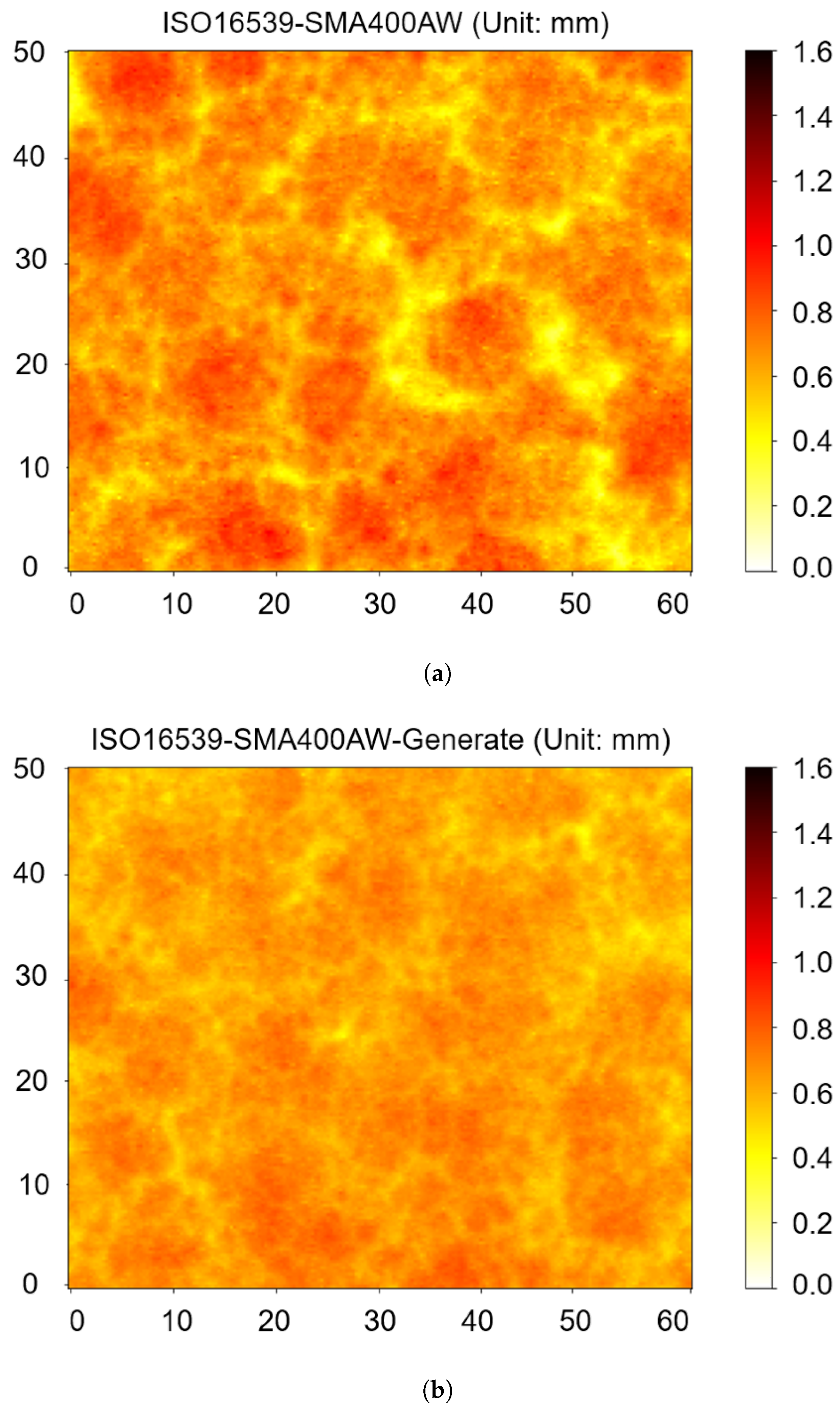

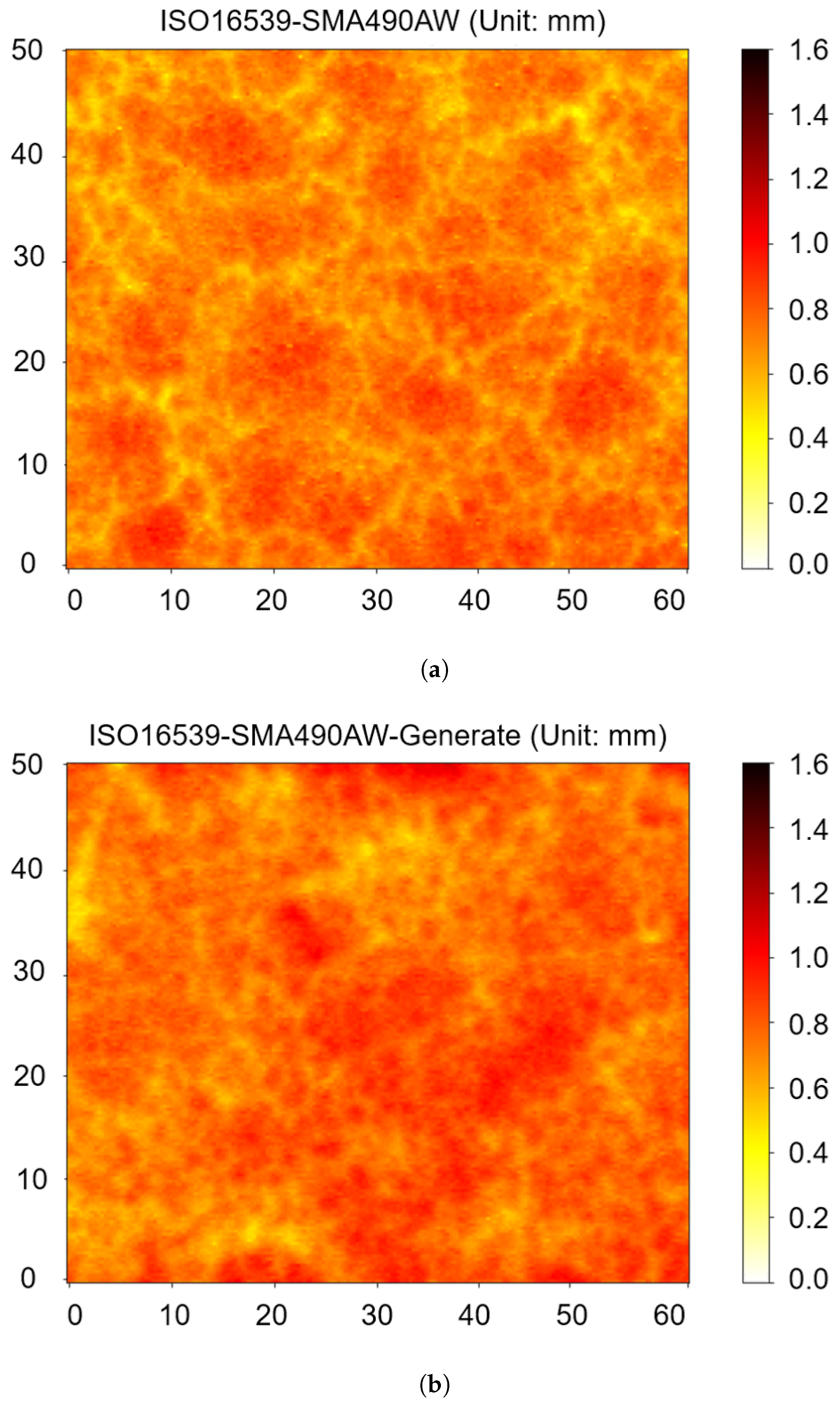

- We use Unet to simulate the corrosion surface, and verify its reliability for the simulation.

- Our system can also predict the stage of corrosion and days of the stage based on the current corrosive status.

2. Related Work

2.1. Challenges in the Maintenance and Management of Steel Structure Corrosion

2.2. Methods and Limitations of Steel Structure Corrosion Prediction

2.3. Deep Learning Methods

3. Materials and Methods

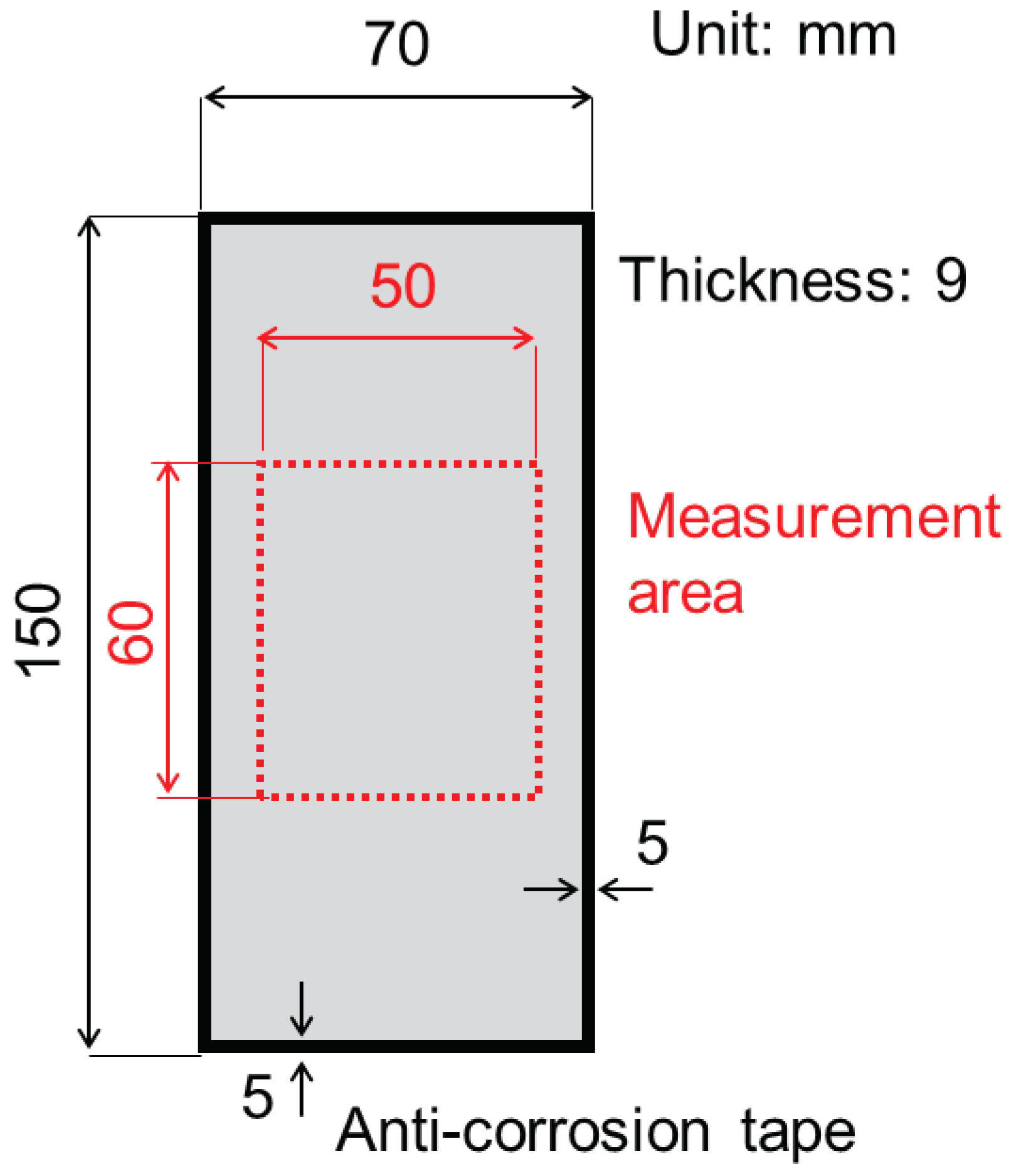

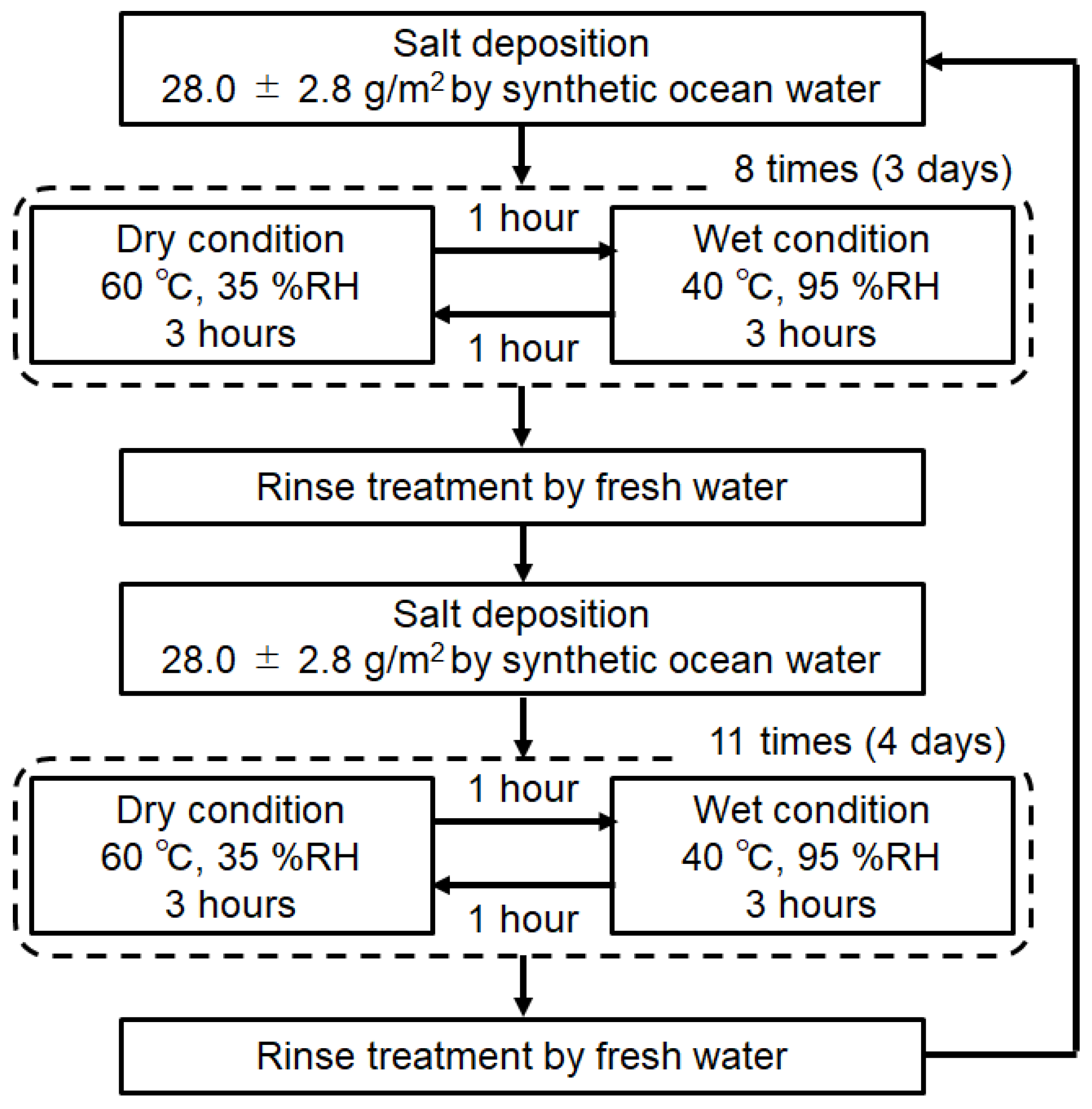

3.1. Dataset

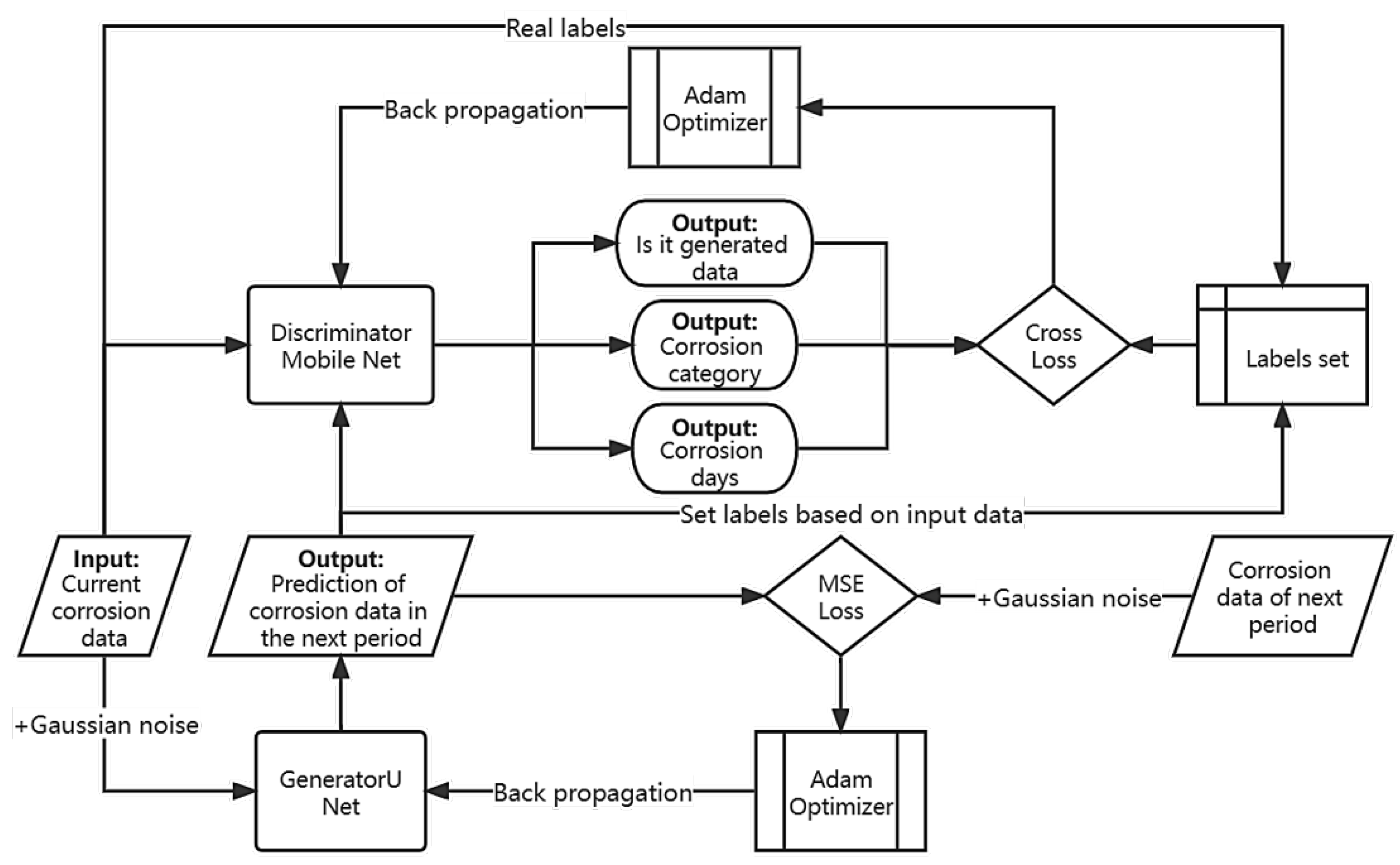

3.2. System Architecture

3.3. GAN

3.4. UNet: The Generator

3.5. MobileNetV2: The Discriminator

4. Experiments and Results

4.1. Experiment Settings

4.2. Model Training

- We use GaussNoise and previous stage data as the input for UNet, and the next stage data is the target.

- Use MobileNet to determine whether the input image is generated by Unet or the real image, and each Step is Trained based on the GAN model.

- At the end of each Epoch, only Unet will be Trained (fine-tuning the gap between the generated data and the real data).

4.3. Evaluation Metrics

4.4. Baseline Model

4.5. Comparative Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chang, K.; Kim, C. Modal-parameter identification and vibration-based damage detection of a damaged steel truss bridge. Eng. Struct. 2016, 122, 156–173. [Google Scholar] [CrossRef]

- Farhey, D.N.; Thakur, A.M.; Buchanan, R.C.; Aktan, A.E.; Jayaraman, N. Structural deterioration assessment for steel bridges. J. Bridge Eng. 1997, 2, 116–124. [Google Scholar] [CrossRef]

- Pidaparti, R.M.; Fang, L.; Palakal, M.J. Computational simulation of multi-pit corrosion process in materials. Comput. Mater. Sci. 2008, 41, 255–265. [Google Scholar] [CrossRef]

- Secer, M.; Uzun, E.T. Corrosion damage analysis of steel frames considering lateral torsional buckling. Procedia Eng. 2017, 171, 1234–1241. [Google Scholar] [CrossRef]

- Bonopera, M.; Chang, K.; Chen, C.; Lin, T.; Tullini, N. Compressive column load identification in steel space frames using second-order deflection-based methods. Int. J. Struct. Stab. Dyn. 2018, 18, 1850092. [Google Scholar] [CrossRef]

- Awad, M.K.; Mustafa, M.R.; Elnga, M.M.A. Computational simulation of the molecular structure of some triazoles as inhibitors for the corrosion of metal surface. J. Mol. Struct. Theochem 2010, 959, 66–74. [Google Scholar] [CrossRef]

- Popoola, L.T.; Grema, A.S.; Latinwo, G.K.; Gutti, B.; Balogun, A.S. Corrosion problems during oil and gas production and its mitigation. Int. J. Ind. Chem. 2013, 4, 1–15. [Google Scholar] [CrossRef]

- Fujii, K.; Kaita, T.; Hirai, K.; Okumura, M. Applicability of spatial auto-correlation model for corroded surface modeling in corroded steel plate. J. Struct. Eng. 2002, 48, 1031–1038. [Google Scholar]

- Alamilla, J.L.; Sosa, E. Stochastic modelling of corrosion damage propagation in active sites from field inspection data. Corros. Sci. 2008, 50, 1811–1819. [Google Scholar] [CrossRef]

- Engelhardt, G.; Macdonald, D.D. Unification of the deterministic and statistical approaches for predicting localized corrosion damage. I. Theoretical foundation. Corros. Sci. 2004, 46, 2755–2780. [Google Scholar] [CrossRef]

- Kainuma, S.; Young, S.J.; Utsunomiya, K.; Jin, H.A. Numerical simulations for time-dependent corrosion surfaces of unpainted carbon steel plates in atmospheric corrosive environments using spatial statistical techniques. Corros. Eng. 2012, 61, 203. [Google Scholar] [CrossRef]

- Kainuma, S.; Hosomi, N. Numerical stimulation of time-dependent corroded surface of structural steel members in boundary with concrete. Doboku Gakkai Ronbunshuu 2006, 62, 440–453. [Google Scholar] [CrossRef][Green Version]

- Ronneberger, O.; Philipp, F.; Thomas, B. U-Net: Convolutional Networks for Biomedical Image Segmentation. arXiv 2015, arXiv:1505.04597. [Google Scholar]

- Sandler, M.; Howard, A.; Zhu, M.; Zhmoginov, A.; Chen, L.C. MobileNetV2: Inverted Residuals and Linear Bottlenecks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Salt Lake City, UT, USA, 18–23 June 2018; pp. 4510–4520. [Google Scholar]

- Thompson, N.G.; Yunovich, M.; Dunmire, D. Cost of corrosion and corrosion maintenance strategies. Corros. Rev. 2007, 25, 247–262. [Google Scholar] [CrossRef]

- Abbas, M.; Shafiee, M. An overview of maintenance management strategies for corroded steel structures in extreme marine environments. Mar. Struct. 2020, 71, 102718. [Google Scholar] [CrossRef]

- Kiefner, J.F.; Kolovich, K.M. Calculation of a corrosion rate using Monte Carlo simulation. In Proceedings of the CORROSION 2007, Nashville, TN, USA, 11–15 March 2007. [Google Scholar]

- Kainuma, S.; Yang, M.; Xie, J.; Jeong, Y.S. Time-Dependent Prediction on the Localized Corrosion of Steel Structure Using Spatial Statistical Simulation. Int. J. Steel Struct. 2021, 21, 987–1003. [Google Scholar] [CrossRef]

- Kim, K.; Lee, G.; Park, K.; Park, S.; Lee, W.B. Adaptive approach for estimation of pipeline corrosion defects via Bayesian inference. Reliab. Eng. Syst. Saf. 2021, 216, 107998. [Google Scholar] [CrossRef]

- Melchers, R.E. The effect of corrosion on the structural reliability of steel offshore structures. Corros. Sci. 2005, 47, 2391–2410. [Google Scholar] [CrossRef]

- Shibata, T. Statistical and stochastic approaches to localized corrosion. Corrosion 1996, 52. [Google Scholar] [CrossRef]

- Alamilla, J.L.; Oliveros, J.; García-Vargas, J. Probabilistic modelling of a corroded pressurized pipeline at inspection time. Struct. Infrastruct. Eng. 2009, 5, 91–104. [Google Scholar] [CrossRef]

- Caleyo, F.; Velázquez, J.C.; Valor, A.; Hallen, J.M. Probability distribution of pitting corrosion depth and rate in underground pipelines: A Monte Carlo study. Corros. Sci. 2009, 51, 1925–1934. [Google Scholar] [CrossRef]

- Ganz, R.; Elad, M. Improved Image Generation via Sparse Modeling. arXiv 2021, arXiv:2104.00464. [Google Scholar]

- Chen, X.; Yin, B.; Chen, S.; Li, H. Generating Multi-scale Maps from Remote Sensing Images via Series Generative Adversarial Networks. arXiv 2015, arXiv:2103.16909. [Google Scholar]

- Saseendran, A.; Skubch, K.; Keuper, M. Multi-Class Multi-Instance Count Conditioned Adversarial Image Generation. arXiv 2021, arXiv:2103.16795. [Google Scholar]

- Yu, N.; Liu, G.; Dundar, A.; Tao, A.; Catanzaro, B.; Davis, L.; Fritz, M. Dual Contrastive Loss and Attention for GANs. arXiv 2021, arXiv:2103.16748. [Google Scholar]

- Yan, B.; Goto, S.; Miyamoto, A.; Zhao, H. Imaging-based rating for corrosion states of weathering steel using wavelet transform and PSO-SVM techniques. J. Comput. Civ. Eng. 2014, 28, 04014008. [Google Scholar] [CrossRef]

- Corrosion of Metals and Alloys—Accelerated Cyclic Corrosion Tests with Exposure to Synthetic Ocean Water Salt-Deposition Process—“Dry” and “Wet” Conditions at Constant Absolute Humidity. Available online: https://www.iso.org/obp/ui/#iso:std:iso:16539:ed-1:v1:en (accessed on 4 April 2022).

- Fujii, K.; Ohashi, K.; Kajiyama, H. Corrosion aspect of electrical appliances–development of new accelerated corrosion Test simulating appliances environment (1). Zairyo-to-Kankyo 2006, 55, 349–355. [Google Scholar] [CrossRef]

- Jiang, F.; Hirohata, M.; Liu, J.; Ojima, K. Application of accelerated cyclic Test with synthetic ocean water salt-deposition process to the evaluation on corrosion characteristics of weathering steel. Corros. Eng. Sci. Technol. 2022, 57, 1–10. [Google Scholar] [CrossRef]

- Chen, X.; Duan, Y.; Houthooft, R.; Schulman, J.; Sutskever, I.; Abbeel, P. Infogan: Interpretable representation learning by information maximizing generative adversarial nets. In Proceedings of the 30th International Conference on Neural Information Processing Systems, Kyoto, Japan, 16–21 October 2016; pp. 2180–2188. [Google Scholar]

- Mirza, M.; Osindero, S. Conditional generative adversarial nets. arXiv 2014, arXiv:1411.1784. [Google Scholar]

- Chollet, F. Xception: Deep Learning with Depthwise Separable Convolutions. arXiv 2016, arXiv:1610.02357. [Google Scholar]

- Zhang, J.; Zhuang, Y.; Ji, H.; Teng, G. Pig Weight and Body Size Estimation Using a Multiple Output Regression Convolutional Neural Network: A Fast and Fully Automatic Method. Sensors 2021, 21, 3218. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Yang, C.; Hou, T. Spine Landmark Localization with combining of Heatmap Regression and Direct Coordinate Regression. arXiv 2020, arXiv:2007.05355. [Google Scholar]

| Subsets | ISO16539 | PWRI | Atmospheric Exposure I | Atmospheric Exposure II | Total |

|---|---|---|---|---|---|

| Number of samples | 36 | 16 | 12 | 12 | 76 |

| Chemical Compositions (Mass %) | Mechanical Properties | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cu | Ni | Cr | Yield Stress (MPa) | Tensile Strength (MPa) | Elongation (%) | |

| SM400A | 0.18 | 0.17 | 0.5 | 0.015 | 0.006 | - | - | - | 279 | 442 | 29 |

| SM490A | 0.16 | 0.02 | 1.04 | 0.011 | 0.005 | - | - | - | 426 | 542 | 20 |

| SMA400AW | 0.12 | 0.2 | 0.67 | 0.015 | 0.004 | 0.31 | 0.09 | 0.49 | 305 | 445 | 33 |

| SMA490AW | 0.12 | 0.22 | 1.14 | 0.015 | 0.002 | 0.31 | 0.09 | 0.49 | 391 | 514 | 30 |

| Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | Scenario 5 | Scenario 6 | |

|---|---|---|---|---|---|---|

| Training set | ds1 | ds1 | ds2 | ds2 | ds1 + ds2 | ds1 + ds2 |

| Testing set | ds3 | ds4 | ds3 | ds4 | ds3 | ds4 |

| Train: ds1; Test: ds3 | Train: ds1; Test: ds4 | Train: ds2; Test: ds3 | Train: ds2; Test: ds4 | Train: ds1 + ds2; Test: ds3 | Train: ds1 + ds2; Test: ds4 | |

|---|---|---|---|---|---|---|

| GAN | 0.3917 | 0.423 | 0.4619 | 0.3373 | 0.1976 | 0.2442 |

| InfoGAN | 0.3684 | 0.455 | 0.4328 | 0.363 | 0.2331 | 0.3468 |

| cGAN | 0.4663 | 0.4698 | 0.4385 | 0.4523 | 0.3132 | 0.2987 |

| Baseline model: Xception | 0.9524 | 1.4923 | 0.882 | 0.5873 | 0.9015 | 0.8837 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, F.; Hirohata, M. A GAN-Augmented Corrosion Prediction Model for Uncoated Steel Plates. Appl. Sci. 2022, 12, 4706. https://doi.org/10.3390/app12094706

Jiang F, Hirohata M. A GAN-Augmented Corrosion Prediction Model for Uncoated Steel Plates. Applied Sciences. 2022; 12(9):4706. https://doi.org/10.3390/app12094706

Chicago/Turabian StyleJiang, Feng, and Mikihito Hirohata. 2022. "A GAN-Augmented Corrosion Prediction Model for Uncoated Steel Plates" Applied Sciences 12, no. 9: 4706. https://doi.org/10.3390/app12094706

APA StyleJiang, F., & Hirohata, M. (2022). A GAN-Augmented Corrosion Prediction Model for Uncoated Steel Plates. Applied Sciences, 12(9), 4706. https://doi.org/10.3390/app12094706