ROS-Based Condition Monitoring Architecture Enabling Automatic Faults Detection in Industrial Collaborative Robots

Abstract

Featured Application

Abstract

1. Introduction

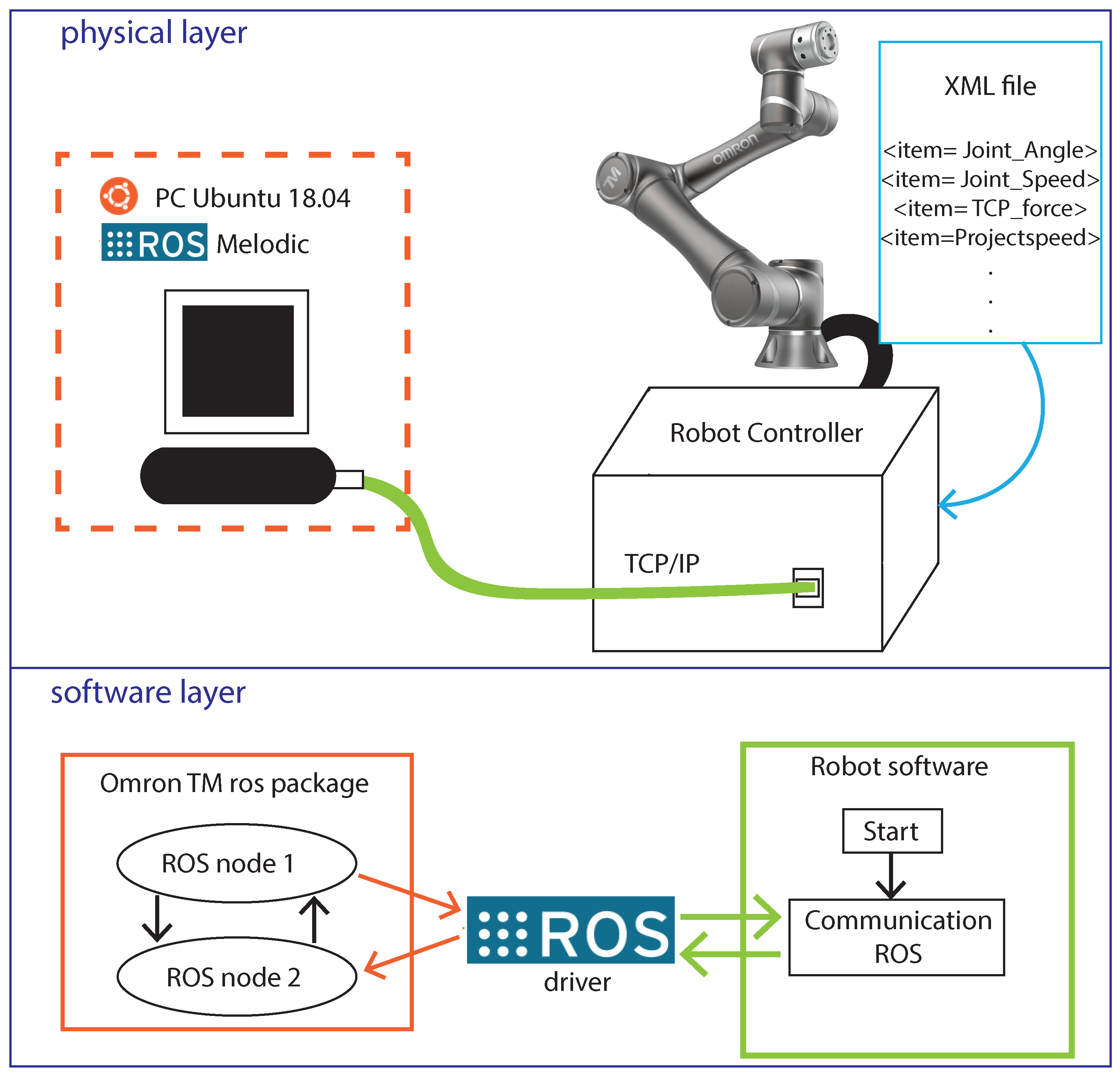

- Obtain system data. In order to choose which data to monitor to evaluate the health of cobot components, there is the need to answer precise questions: which data are useful for healthily evaluating the system? Which components do we need to monitor in order to avoid production stops and how do we obtain that information? The answers to these questions can fundamentally lead to two possibilities, the use of sensors already installed into the system or the use of external sensors. In the first case, there is a need to establish a connection with the industrial controllers to access sensing data (for instance, motor currents, joint positions, speeds, torques etc.). In the second case, however, there is a need to use a device to manage the acquisition of data from extra sensing units installed on the robot (for instance, the accelerometer, and the acoustic and laser sensors). As is easy to imagine, in the industry, the choice falls on the first solution as less expensive, given that it does not require other external components. Moreover, using the controller’s data allows for the definition of a common strategy valid in all systems which use that controller. Finally, the communication protocols used to exchange information with controllers are robust, and thus with a lesser possibility of losing data. Based upon these considerations, this work presents in Section 3.1 an ROS-based CM architecture running in a Linux system which enables the possibility of obtaining signals from industrial controllers.

- Acquire, collect and store data. The common questions that we need to answer to obtain a consistent dataset from which to extract information for further analysis are the following: How to manage the data acquisition phase? Which rules do we need to use to collect, organize and store data? To answer these questions, there is a need to go deeper into the details of a cobot application; however, it is easy to understand that it is not trivial to decide on a strategy to acquire data in a system that performs different combinations of movements, reaching many different positions at different speeds, sometimes carrying different payloads, all in the same program. In fact, those systems are thought of for flexible production and may be used for many different tasks contemporary. Therefore, in Section 3.3, we propose a methodology to solve these issues and we test its validity in a case study application common in Industrial scenarios in Section 4.

- Analyze and detect abnormal data. This area is the one that affects the reliability of a CM system, and the related question is: Which method do we need to use to automatically extract information on the system’s health? Furthermore, answering this question is not straightforward since there lots of valid techniques have been proposed in the literature. Generally, these are divided into model-based, signal-based and data-driven and they have proven their validity in many different scenarios. Fundamentally, we need to keep in mind that the methodology chosen should be the one that decreases the number of missed and false fault detection. However, this also depends on the kind of failure in the system we want to detect. In this paper, regarding the case study, we proposed a solution based on common health indicators (HIs) that are well-known in this area, considering that the purpose of this paper is to define a general CM architecture which can be applied to different collaborative robots involved in flexible manufacturing. For this reason, this work is not going to be focused on defining the best strategy for detecting failures but on how to automate this process.

2. Related Work

Joint Health Assessment via Torque Analysis

3. Presenting a ROS-Based Condition Monitoring Architecture

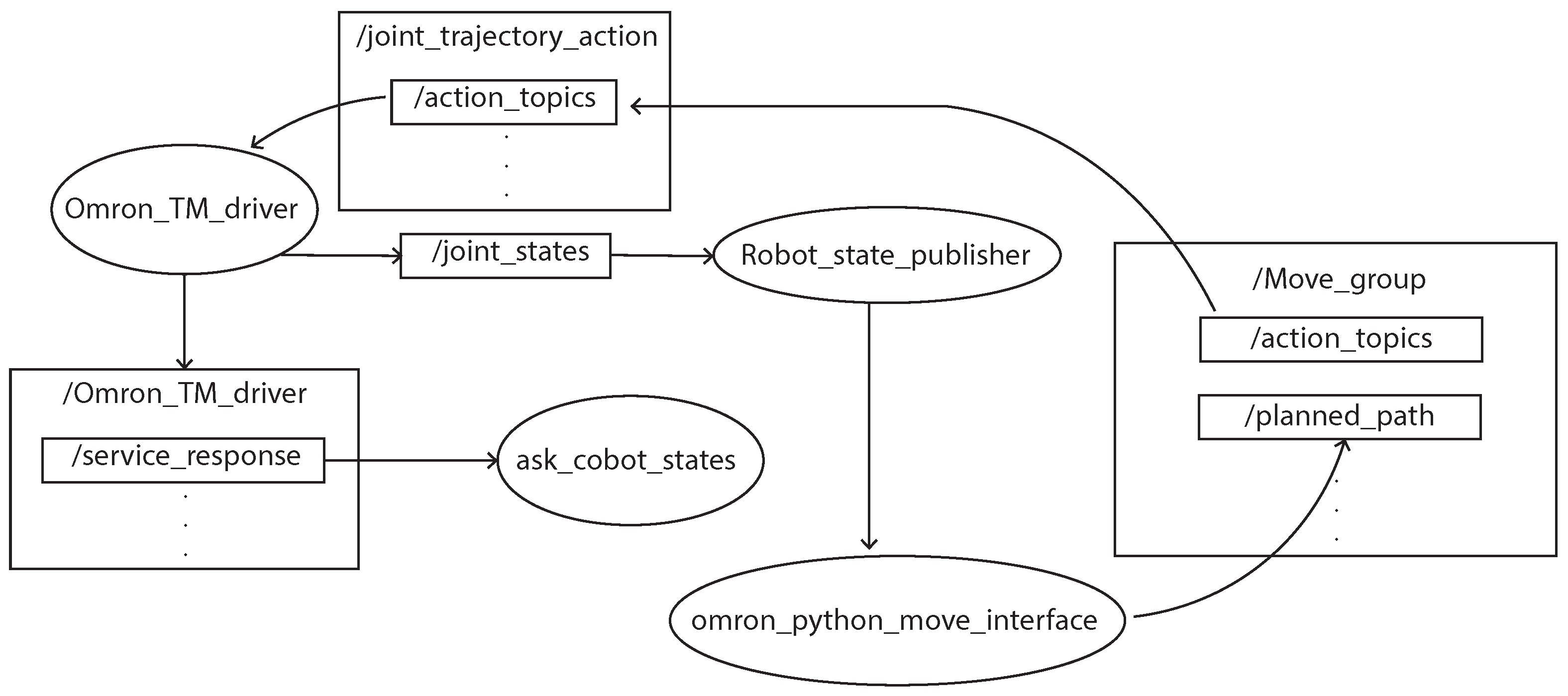

- Enable communication between the Omron TM controller and a Linux system in which the ROS master is running.

- Send motion commands through a Python Application Programming Interface (API) which uses open source trajectory planners.

- Enable the use of grippers and the possibility of simulating robotics applications using Gazebo.

- Read and storing controller data using Python libraries to manage the acquisition (i.e., rospy, pickle)

3.1. Omron TM Robots ROS Package

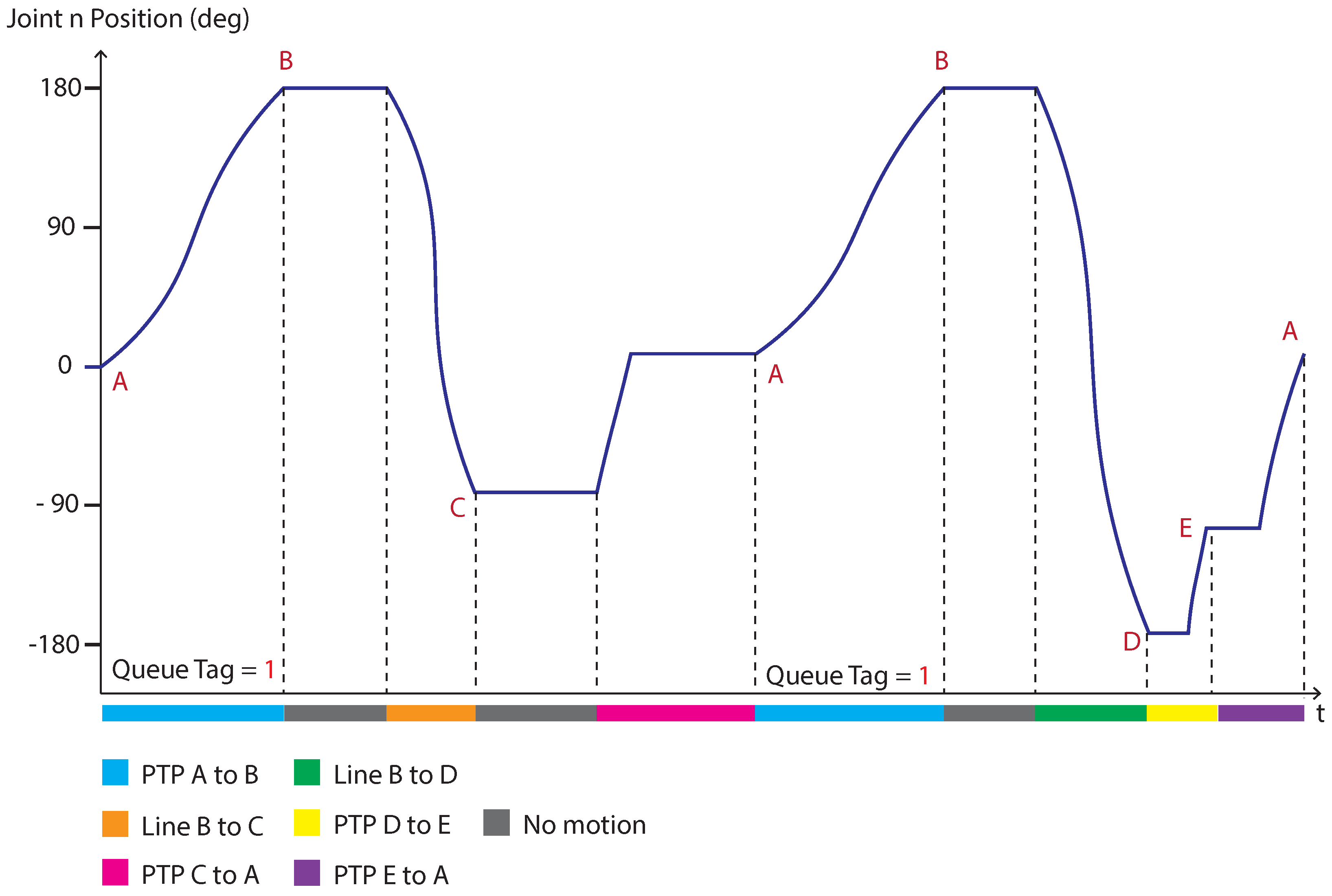

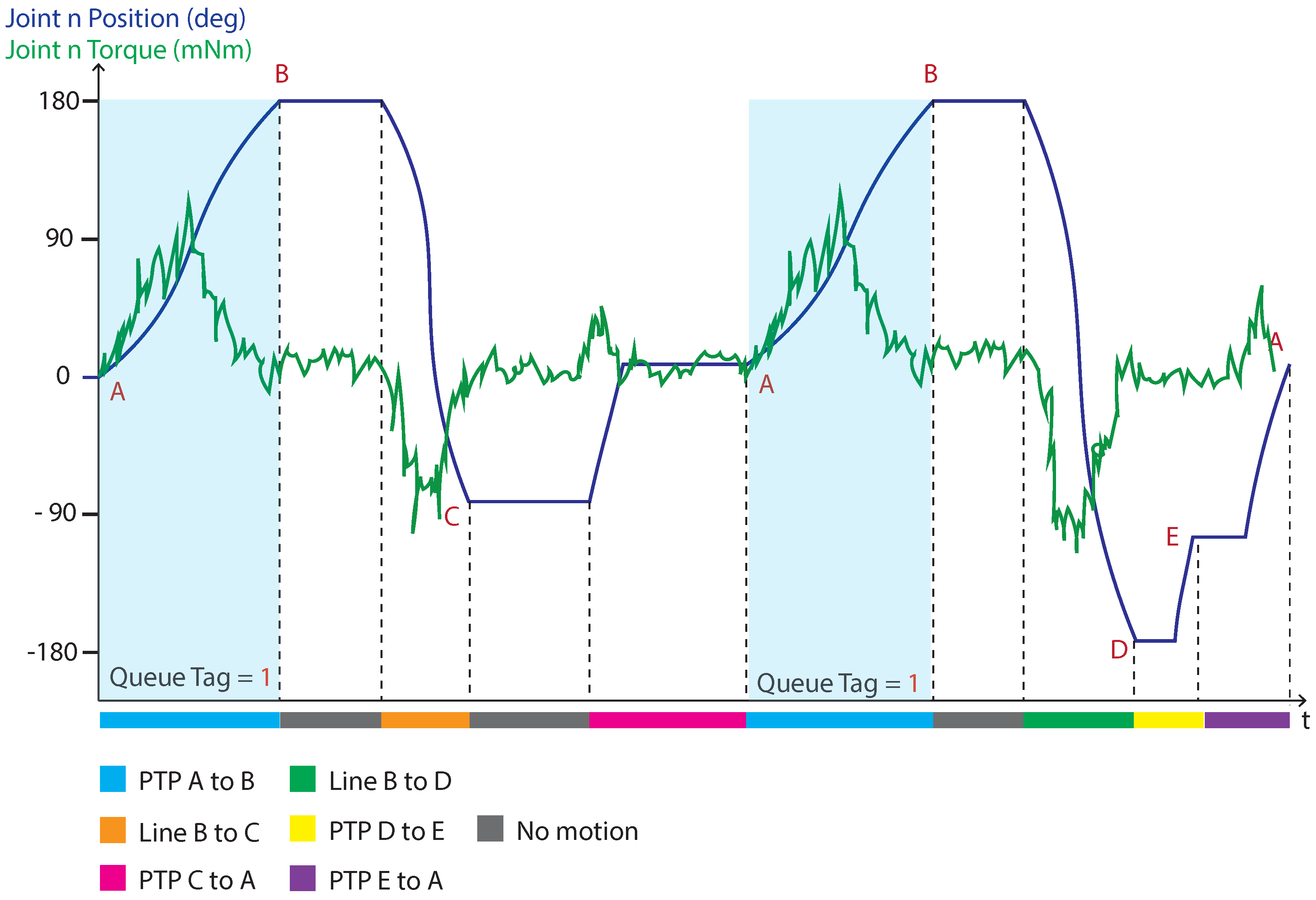

3.2. Conceptual Idea

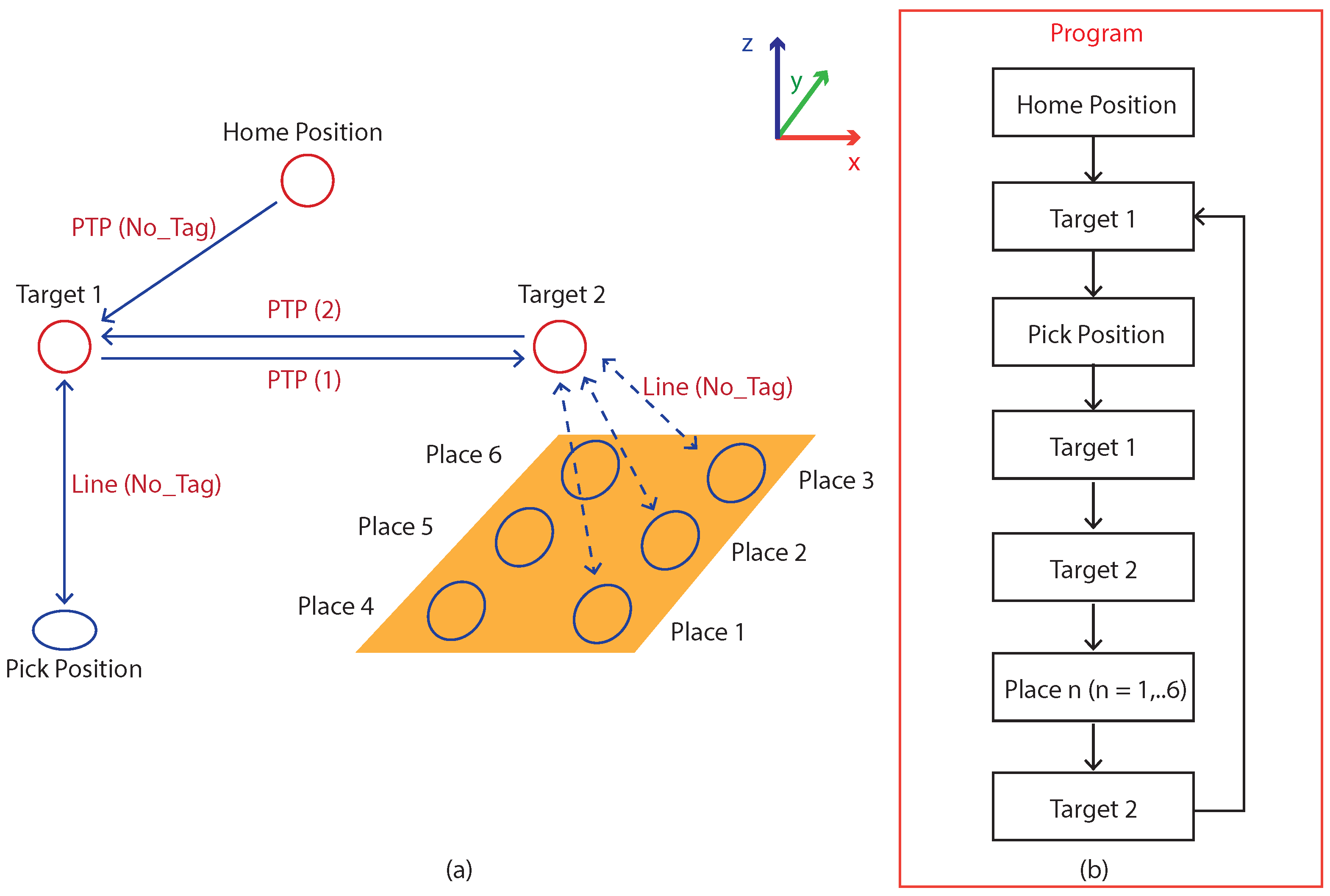

- Point-to-point (PTP) motion from A to B;

- Line move from B to C;

- PTP motion from C to A;

- PTP motion from A to B;

- Line move from B to D;

- PTP motion from D to E;

- PTP motion from E to A;

- ... etc.

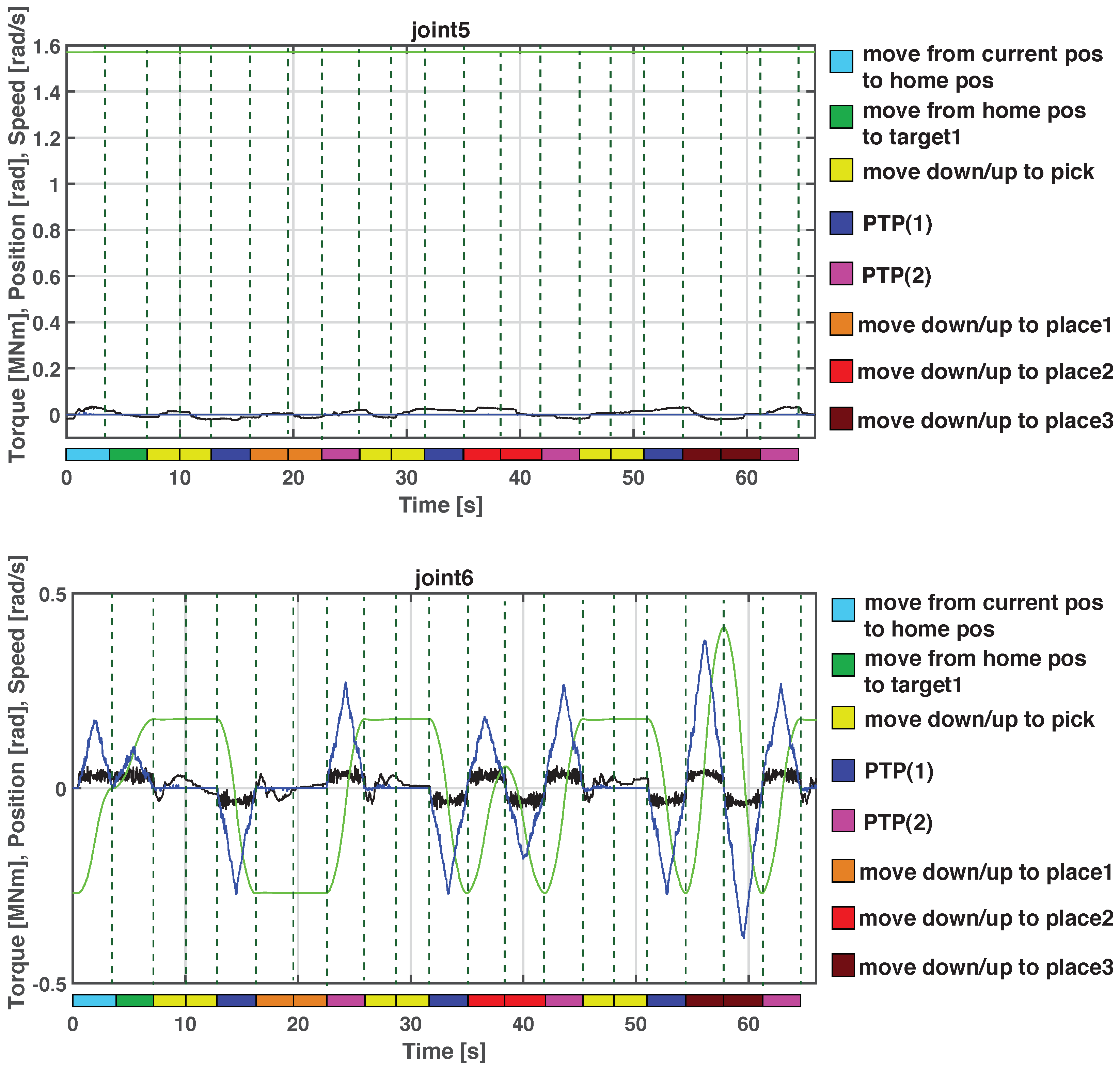

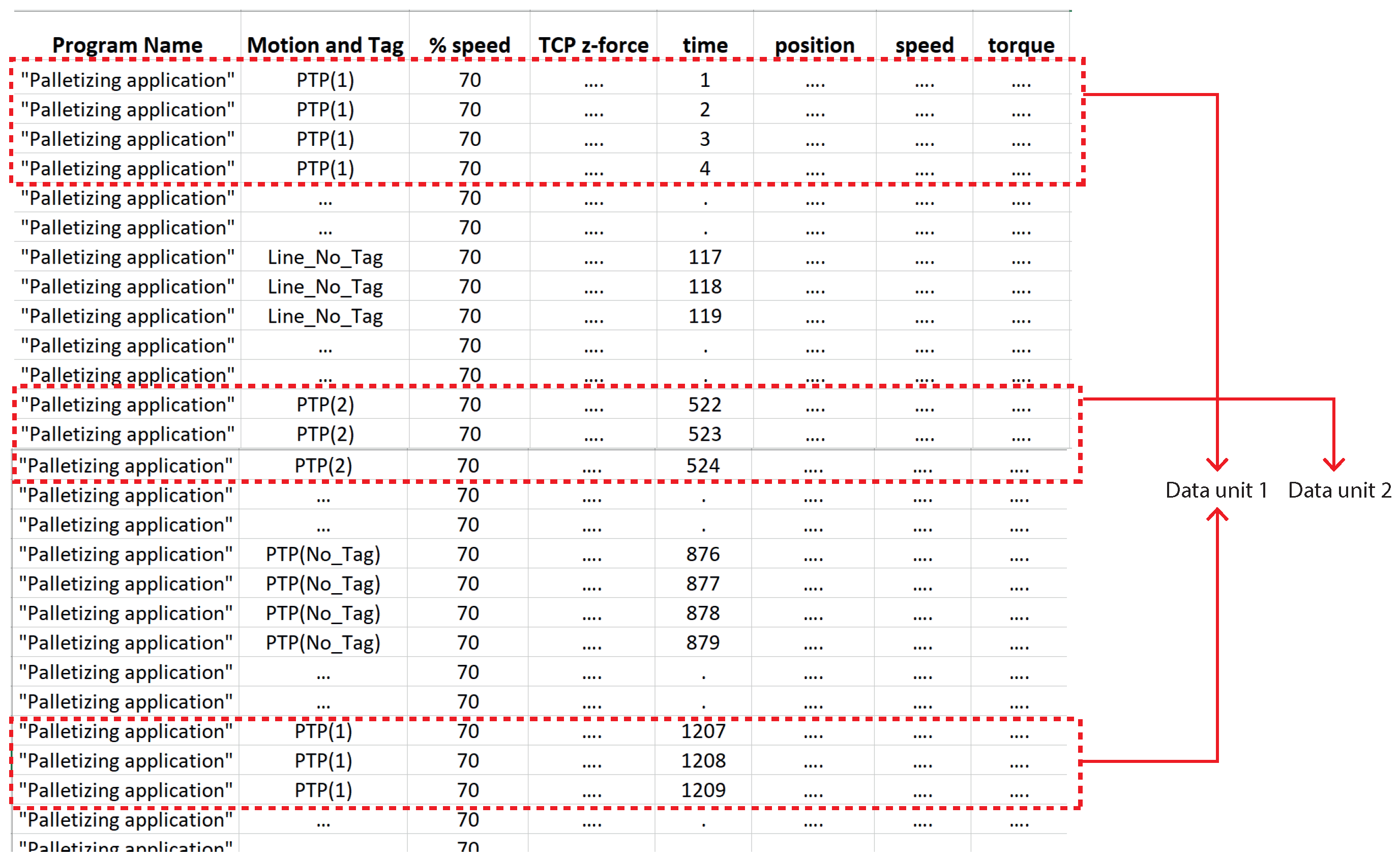

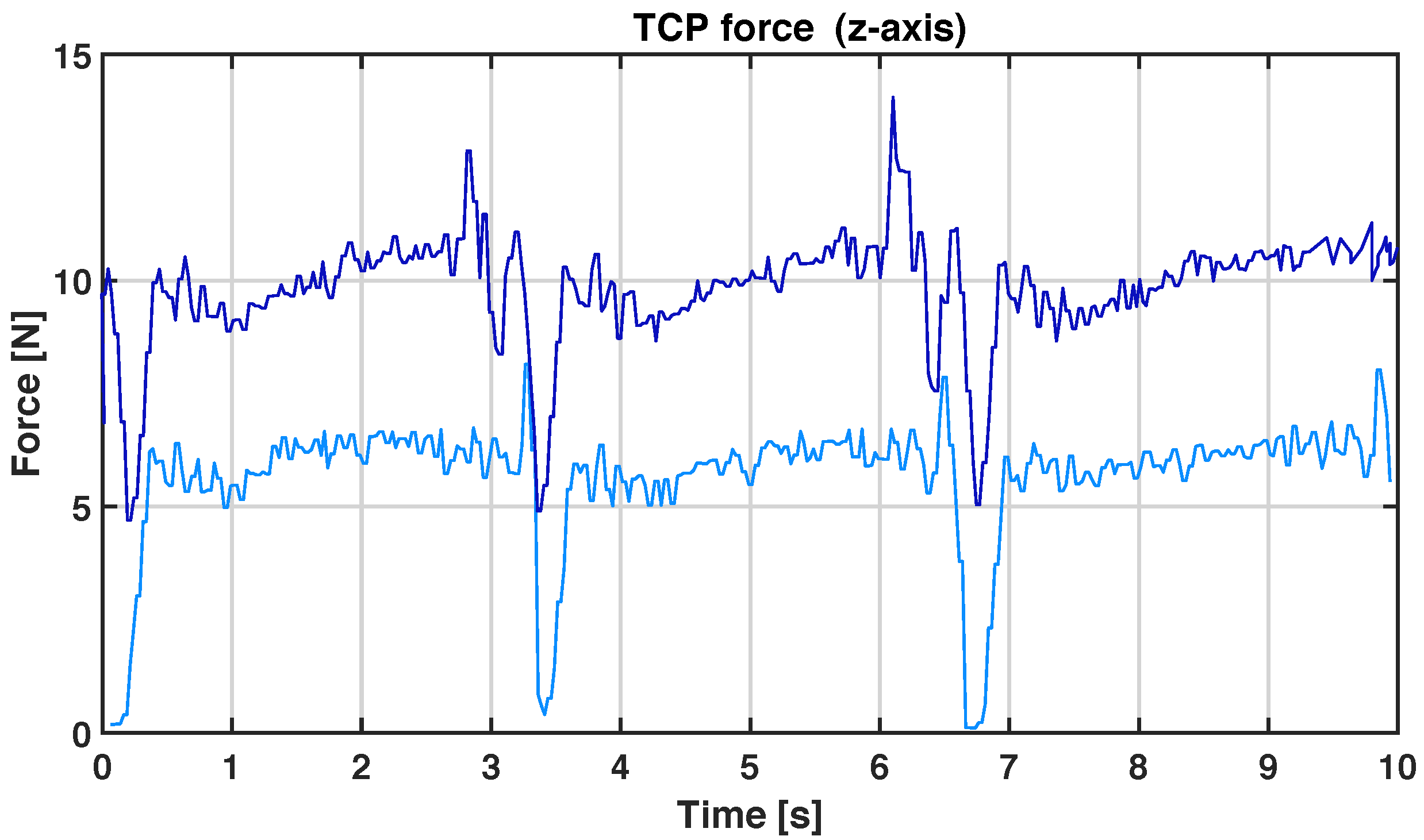

3.3. Data Labeling and Indexing Method

- Name of the running program;

- Type of motion and tag;

- Program percentual speed execution;

- Estimated tool center point (TCP) force along Z.

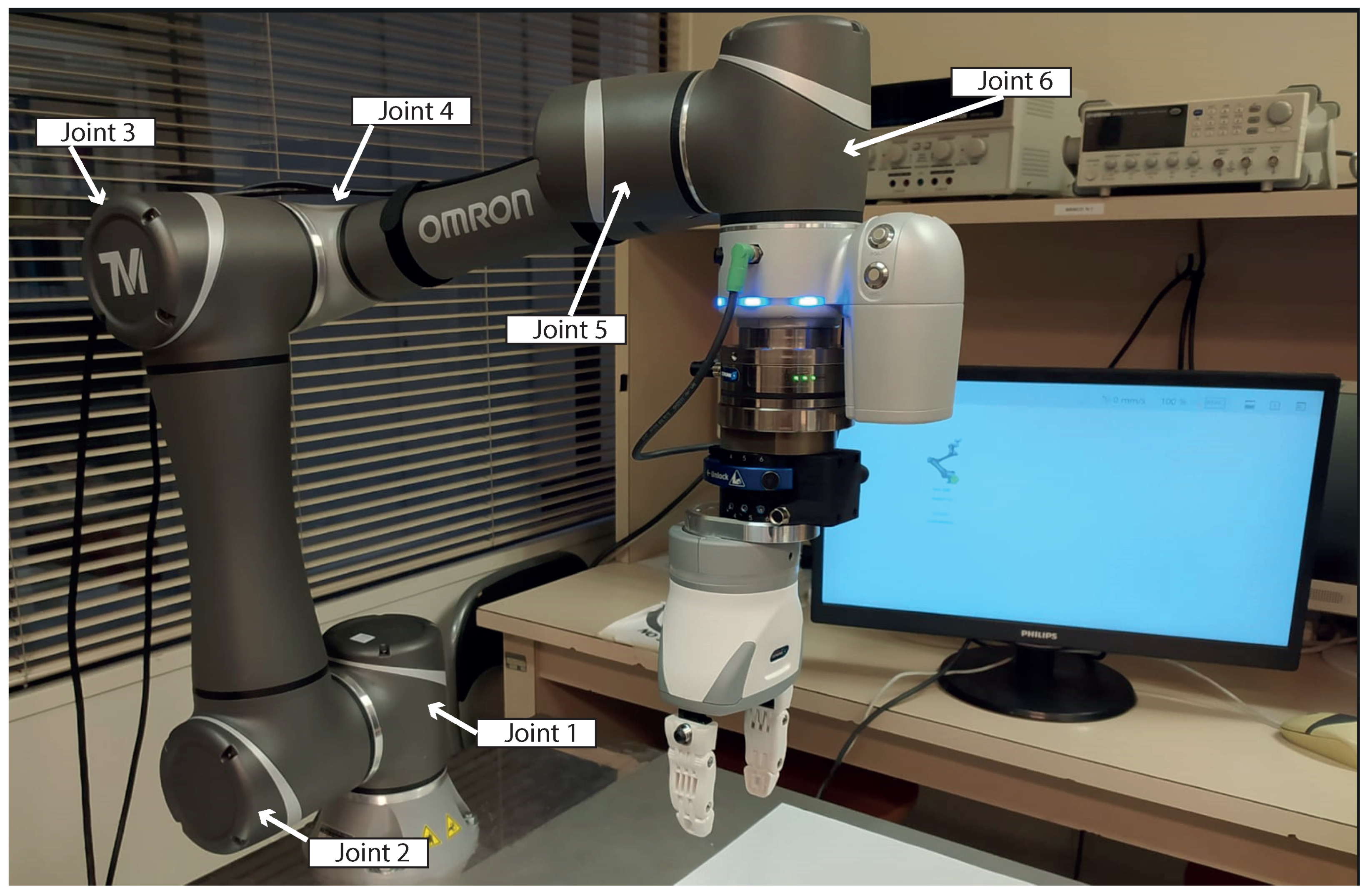

4. Applying the CM Framework to a Case Study

- Joint torques;

- Joint positions;

- Joint speeds.

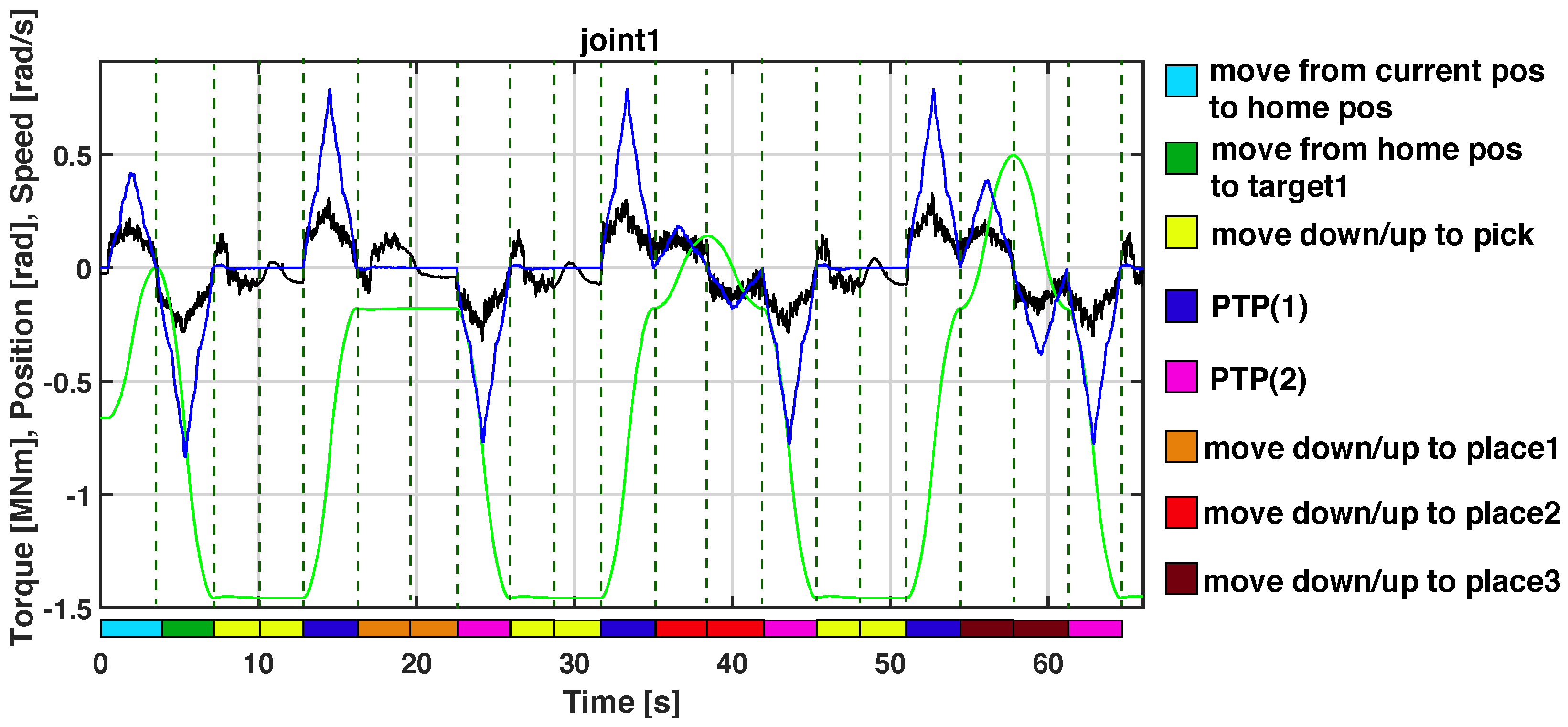

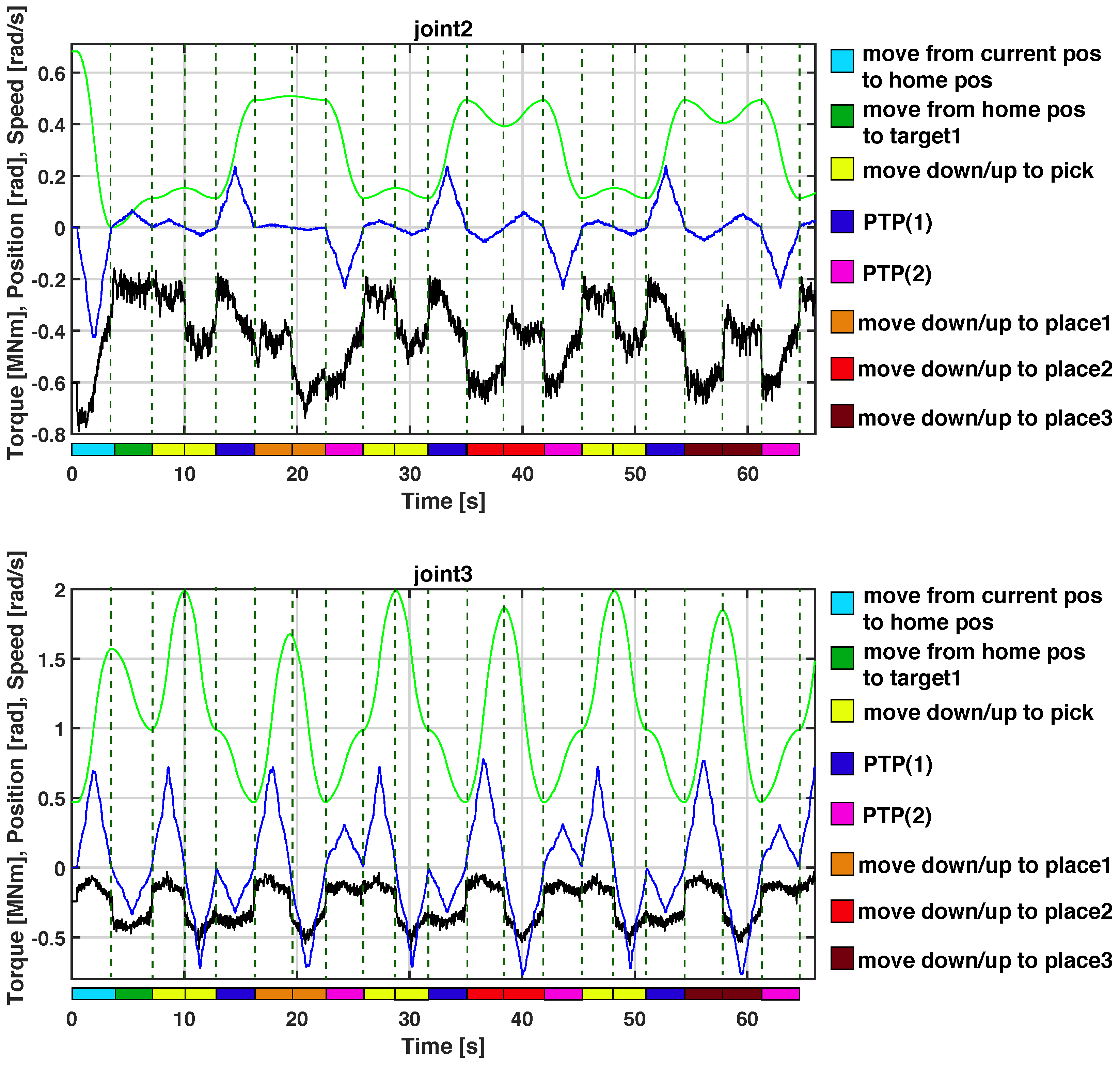

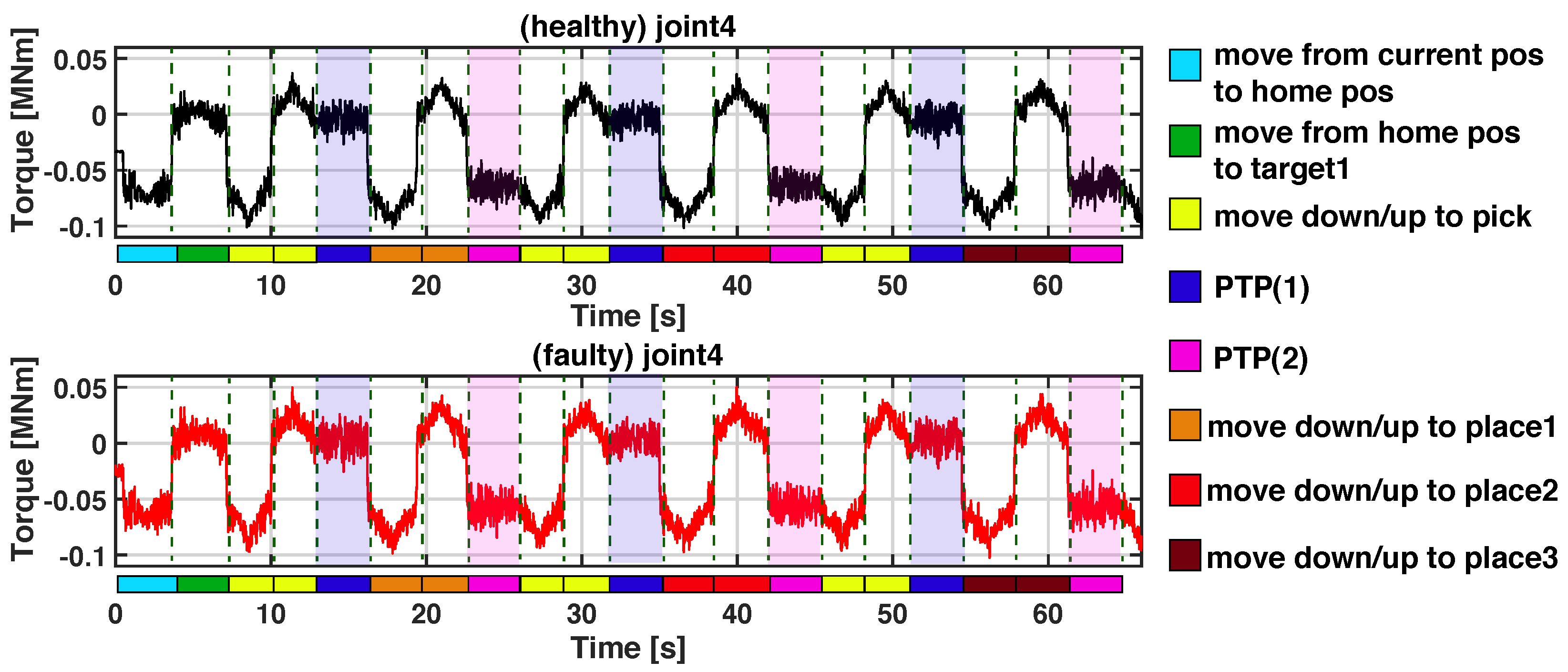

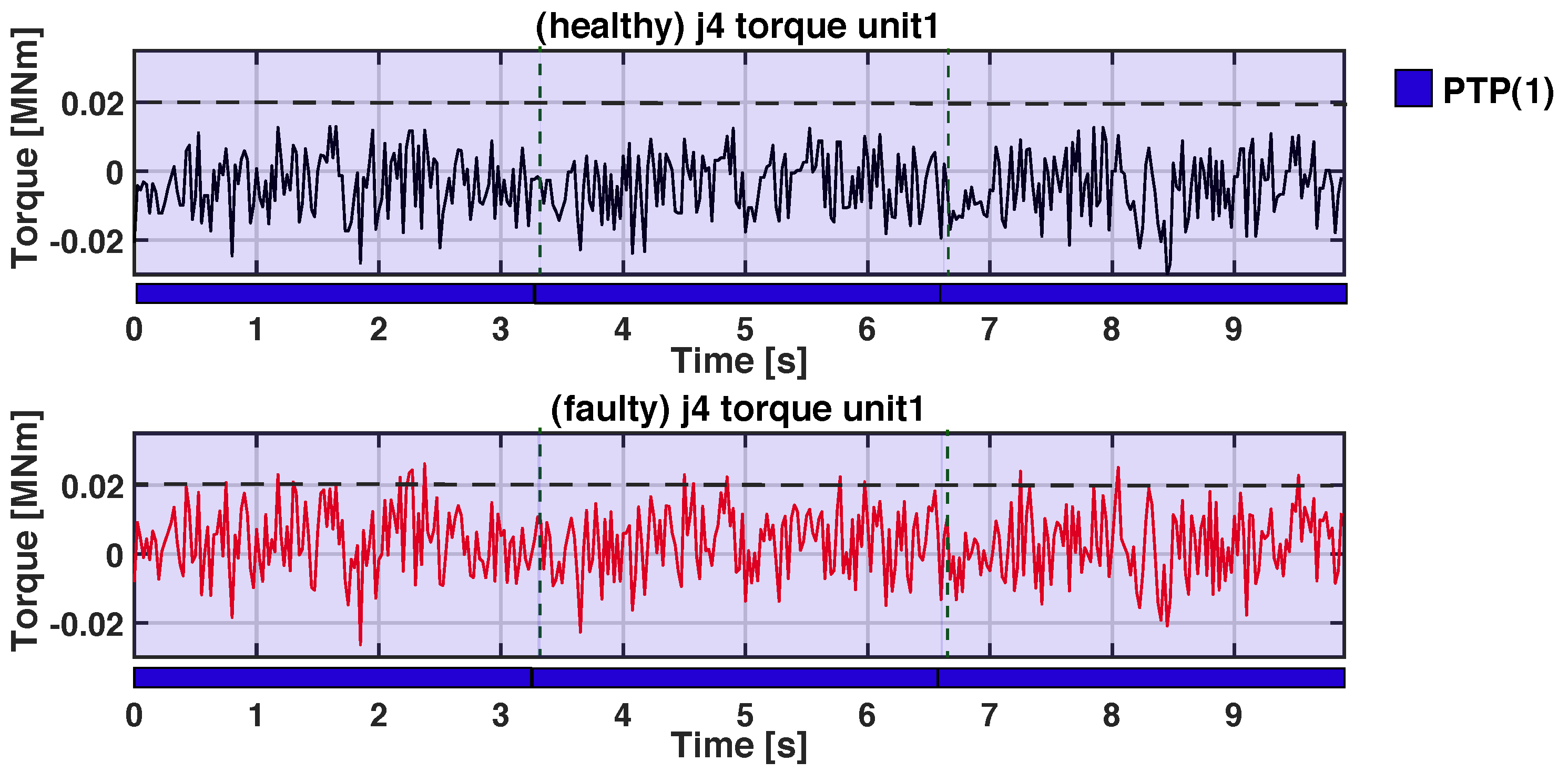

4.1. Definition of Data Analysis Methodology

4.2. Results

- Program Name = “Palletizing application”;

- Motion and Tag = PTP(1) and PTP(2);

- % speed = 70.

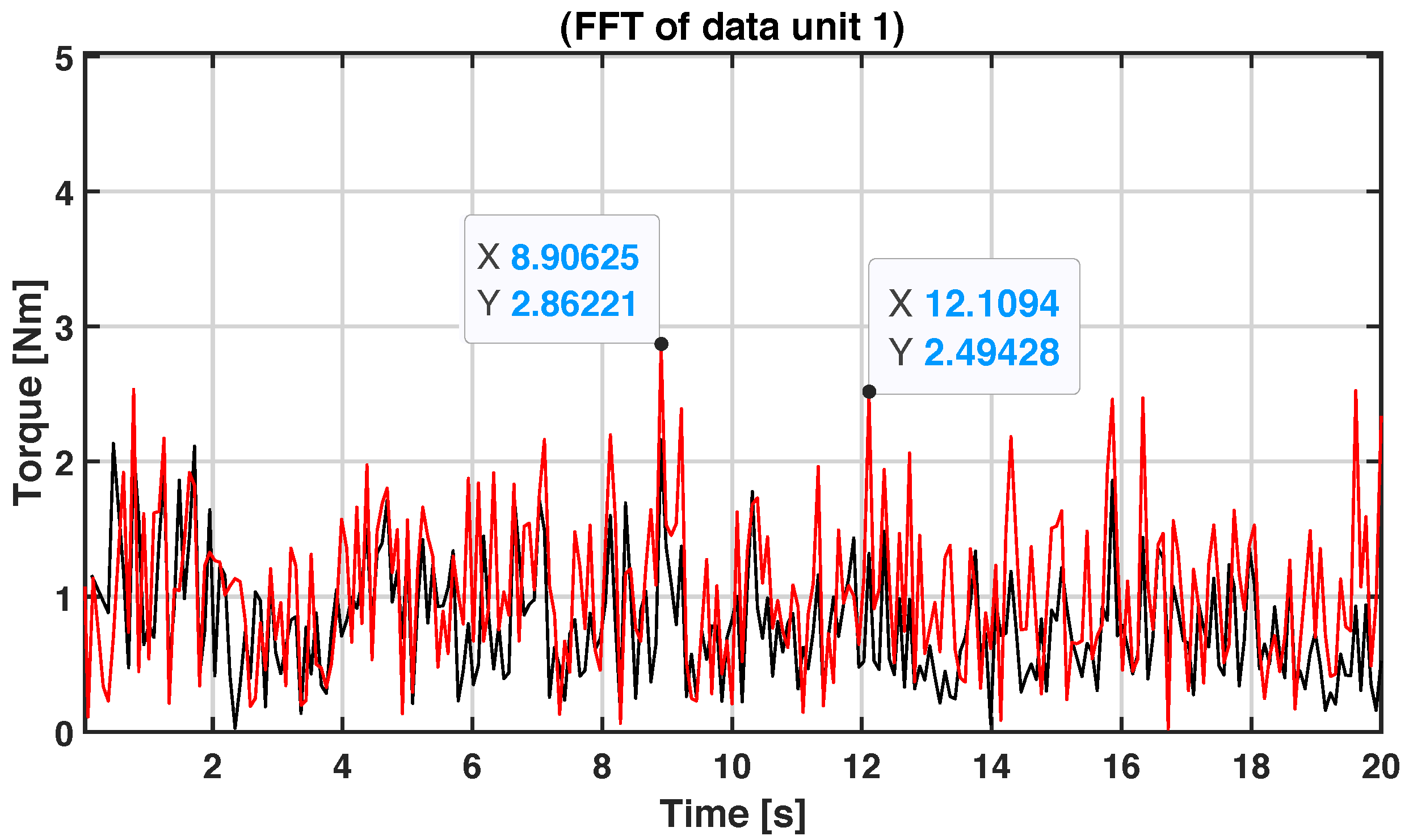

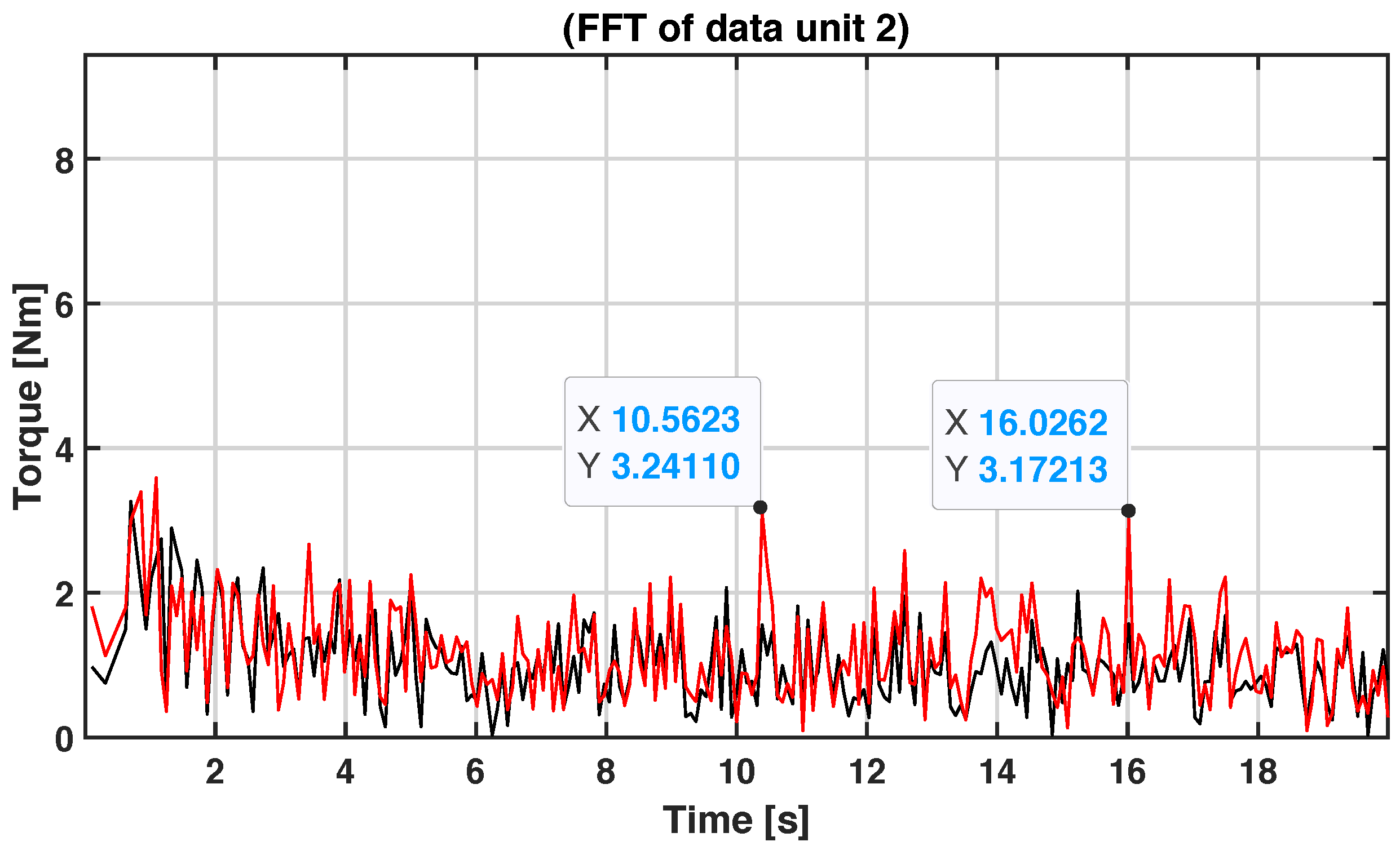

Automatic Detection of a Joint Malfunction

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Inkulu, A.K.; Bahubalendruni, M.R.; Dara, A.; SankaranarayanaSamy, K. Challenges and opportunities in human robot collaboration context of Industry 4.0—A state of the art review. Ind. Robot Int. J. Robot. Res. Appl. 2021, 49, 226–239. [Google Scholar] [CrossRef]

- Eswaran, M.; Bahubalendruni, M.R. Challenges and opportunities on AR/VR technologies for manufacturing systems in the context of industry 4.0: A state of the art review. J. Manuf. Syst. 2022, 65, 260–278. [Google Scholar] [CrossRef]

- Nabissi, G. Omron TM Robots—ROS. 2022. Available online: https://github.com/GiakNab/Omron_TM_robots-ROS (accessed on 9 December 2022).

- Khalastchi, E.; Kalech, M. Fault detection and diagnosis in multi-robot systems: A survey. Sensors 2019, 19, 4019. [Google Scholar] [CrossRef] [PubMed]

- Visinsky, M.L.; Cavallaro, J.R.; Walker, I.D. Robotic fault detection and fault tolerance: A survey. Reliab. Eng. Syst. Saf. 1994, 46, 139–158. [Google Scholar] [CrossRef]

- Alobaidy, M.A.A.; Abdul-Jabbar, J.M.; Al-khayyt, S.Z. Faults Diagnosis in Robot Systems: A Review. Al-Rafidain Eng. J. 2020, 25, 164–175. [Google Scholar] [CrossRef]

- Jaber, A.A.; Bicker, R. Development of a Condition Monitoring Algorithm for Industrial Robots based on Artificial Intelligence and Signal Processing Techniques. Int. J. Electr. Comput. Eng. 2018, 8, 996–1009. [Google Scholar] [CrossRef][Green Version]

- Xu, K.; Wu, X.; Wang, D.; Liu, X. Electromechanical coupling modeling and motor current signature analysis of bolt loosening of industrial robot joint. Mech. Syst. Signal Process. 2023, 184, 109681. [Google Scholar] [CrossRef]

- Raouf, I.; Lee, H.; Kim, H.S. Mechanical fault detection based on machine learning for robotic RV reducer using electrical current signature analysis: A data-driven approach. J. Comput. Des. Eng. 2022, 9, 417–433. [Google Scholar] [CrossRef]

- Nentwich, C.; Reinhart, G. A Method for Health Indicator Evaluation for Condition Monitoring of Industrial Robot Gears. Robotics 2021, 10, 80. [Google Scholar] [CrossRef]

- Graabæk, S.G.; Ancker, E.V.; Christensen, A.L.; Fugl, A.R. An Experimental Comparison of Anomaly Detection Methods for Collaborative Robot Manipulators. IEEE Trans. Autom. Sci. Eng. 2022, 1, 1–14. [Google Scholar] [CrossRef]

- Izagirre, U.; Andonegui, I.; Egea, A.; Zurutuza, U. A methodology and experimental implementation for industrial robot health assessment via torque signature analysis. Appl. Sci. 2020, 10, 7883. [Google Scholar] [CrossRef]

- Cheng, F.; Raghavan, A.; Jung, D.; Sasaki, Y.; Tajika, Y. High-Accuracy Unsupervised Fault Detection of Industrial Robots Using Current Signal Analysis. In Proceedings of the 2019 IEEE International Conference on Prognostics and Health Management (ICPHM), San Francisco, CA, USA, 17–20 June 2019; pp. 1–8. [Google Scholar] [CrossRef]

- Vallachira, S.; Orkisz, M.; Norrlöf, M.; Butail, S. Data-driven gearbox failure detection in industrial robots. IEEE Trans. Ind. Inform. 2019, 16, 193–201. [Google Scholar] [CrossRef]

- Ohno, M.; Takeda, Y. Design of target trajectories for the detection of joint clearances in parallel robot based on the actuation torque measurement. Mech. Mach. Theory 2021, 155, 104081. [Google Scholar] [CrossRef]

- Bonci, A.; Kermenov, R.; Longhi, S.; Nabissi, G. Motor Torque Analysis for diagnosis in PMSMs under non-stationary conditions. In Proceedings of the 2021 26th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vasteras, Sweden, 7–10 September 2021; pp. 1–6. [Google Scholar]

- Bonci, A.; Indri, M.; Kermenov, R.; Longhi, S.; Nabissi, G. Comparison of PMSMs Motor Current Signature Analysis and Motor Torque Analysis Under Transient Conditions. In Proceedings of the 2021 IEEE 19th International Conference on Industrial Informatics (INDIN), Palma de Mallorca, Spain, 21–23 July 2021; pp. 1–6. [Google Scholar]

- Han, Z.Y.; Liu, Y.L.; Jin, H.Y.; Fu, H.Y. A review of methodologies used for fault diagnosis of gearbox. Appl. Mech. Mater. 2013, 415, 510–514. [Google Scholar] [CrossRef]

- Peshkin, M.; Colgate, J.E. Cobots. Ind. Robot Int. J. 1999, 26, 335–341. [Google Scholar] [CrossRef]

- Vicentini, F. Collaborative robotics: A survey. J. Mech. Des. 2021, 143, 040802. [Google Scholar] [CrossRef]

- Bonci, A.; Cen Cheng, P.D.; Indri, M.; Nabissi, G.; Sibona, F. Human–robot perception in industrial environments: A survey. Sensors 2021, 21, 1571. [Google Scholar] [CrossRef]

- Bittencourt, A.C.; Saarinen, K.; Sander-Tavallaey, S.; Gunnarsson, S.; Norrlöf, M. A data-driven approach to diagnostics of repetitive processes in the distribution domain–applications to gearbox diagnostics in industrial robots and rotating machines. Mechatronics 2014, 24, 1032–1041. [Google Scholar] [CrossRef]

- Huan-Kun, H.; Hsiang-Yuan, T.; Huang, M.B.; Huang, H.P. Intelligent Fault Detection, Diagnosis and Health Evaluation for Industrial Robots. Mechanics 2021, 27, 70–79. [Google Scholar]

- Jaber, A.A.; Bicker, R. Fault diagnosis of industrial robot gears based on discrete wavelet transform and artificial neural network. Insight-Non Test. Cond. Monit. 2016, 58, 179–186. [Google Scholar] [CrossRef]

- Bonci, A.; Longhi, S.; Nabissi, G.; Verdini, F. Predictive Maintenance System using motor current signal analysis for Industrial Robot. In Proceedings of the 2019 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; pp. 1453–1456. [Google Scholar]

- Park, Y.S.; Yoo, D.Y.; Lee, J.W. Programmable Motion-Fault Detection for a Collaborative Robot. IEEE Access 2021, 9, 133123–133142. [Google Scholar] [CrossRef]

- Blodt, M.; Chabert, M.; Regnier, J.; Faucher, J. Mechanical load fault detection in induction motors by stator current time-frequency analysis. IEEE Trans. Ind. Appl. 2006, 42, 1454–1463. [Google Scholar] [CrossRef]

- Caesarendra, W.; Tjahjowidodo, T. A review of feature extraction methods in vibration-based condition monitoring and its application for degradation trend estimation of low-speed slew bearing. Machines 2017, 5, 21. [Google Scholar] [CrossRef]

- Zhu, J.; Nostrand, T.; Spiegel, C.; Morton, B. Survey of condition indicators for condition monitoring systems. In Proceedings of the Annual Conference of the PHM Society, Fort Worth, TX, USA, 29 September–2 October 2014; Volume 6. [Google Scholar]

- Phong, L.D.; Choi, J.; Kang, S. External force estimation using joint torque sensors for a robot manipulator. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012; pp. 4507–4512. [Google Scholar]

- Datta, A.; Mavroidis, C.; Krishnasamy, J.; Hosek, M. Neural netowrk based fault diagnostics of industrial robots using wavelt multi-resolution analysis. In Proceedings of the 2007 American Control Conference, New York, NY, USA, 9–13 July 2007; pp. 1858–1863. [Google Scholar]

- Oh, Y.; Kim, Y.; Na, K.; Youn, B.D. A deep transferable motion-adaptive fault detection method for industrial robots using a residual–convolutional neural network. ISA Trans. 2022, 128, 521–534. [Google Scholar] [CrossRef]

| Field | Data |

|---|---|

| Reach (mm) | 900 |

| Maximum payload (Kg) | 4 |

| Typical speed (m/s) | 1.4 |

| Angle of the joint 1, 6 (degree) | ±270 |

| Angle of the joint 2, 4, 5 (degree) | ±180 |

| Angle of the joint 3 (degree) | ±155 |

| Data Unit | Dominant Frequencies (Hz) | Wavelet Entropy | Kurtosis |

|---|---|---|---|

| Data unit 1 | 8.9, 12.1 | −1.9 × (h), −2.4 × (f) | 2.38 (h), 2.78 (f) |

| Data unit 2 | 10.5, 16.0 | −1.3 × (h), −1.6 × (f) | 2.65 (h), 2.81 (f) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nabissi, G.; Longhi, S.; Bonci, A. ROS-Based Condition Monitoring Architecture Enabling Automatic Faults Detection in Industrial Collaborative Robots. Appl. Sci. 2023, 13, 143. https://doi.org/10.3390/app13010143

Nabissi G, Longhi S, Bonci A. ROS-Based Condition Monitoring Architecture Enabling Automatic Faults Detection in Industrial Collaborative Robots. Applied Sciences. 2023; 13(1):143. https://doi.org/10.3390/app13010143

Chicago/Turabian StyleNabissi, Giacomo, Sauro Longhi, and Andrea Bonci. 2023. "ROS-Based Condition Monitoring Architecture Enabling Automatic Faults Detection in Industrial Collaborative Robots" Applied Sciences 13, no. 1: 143. https://doi.org/10.3390/app13010143

APA StyleNabissi, G., Longhi, S., & Bonci, A. (2023). ROS-Based Condition Monitoring Architecture Enabling Automatic Faults Detection in Industrial Collaborative Robots. Applied Sciences, 13(1), 143. https://doi.org/10.3390/app13010143