Ergonomics Evaluation Using Motion Capture Technology—Literature Review

Abstract

1. Introduction

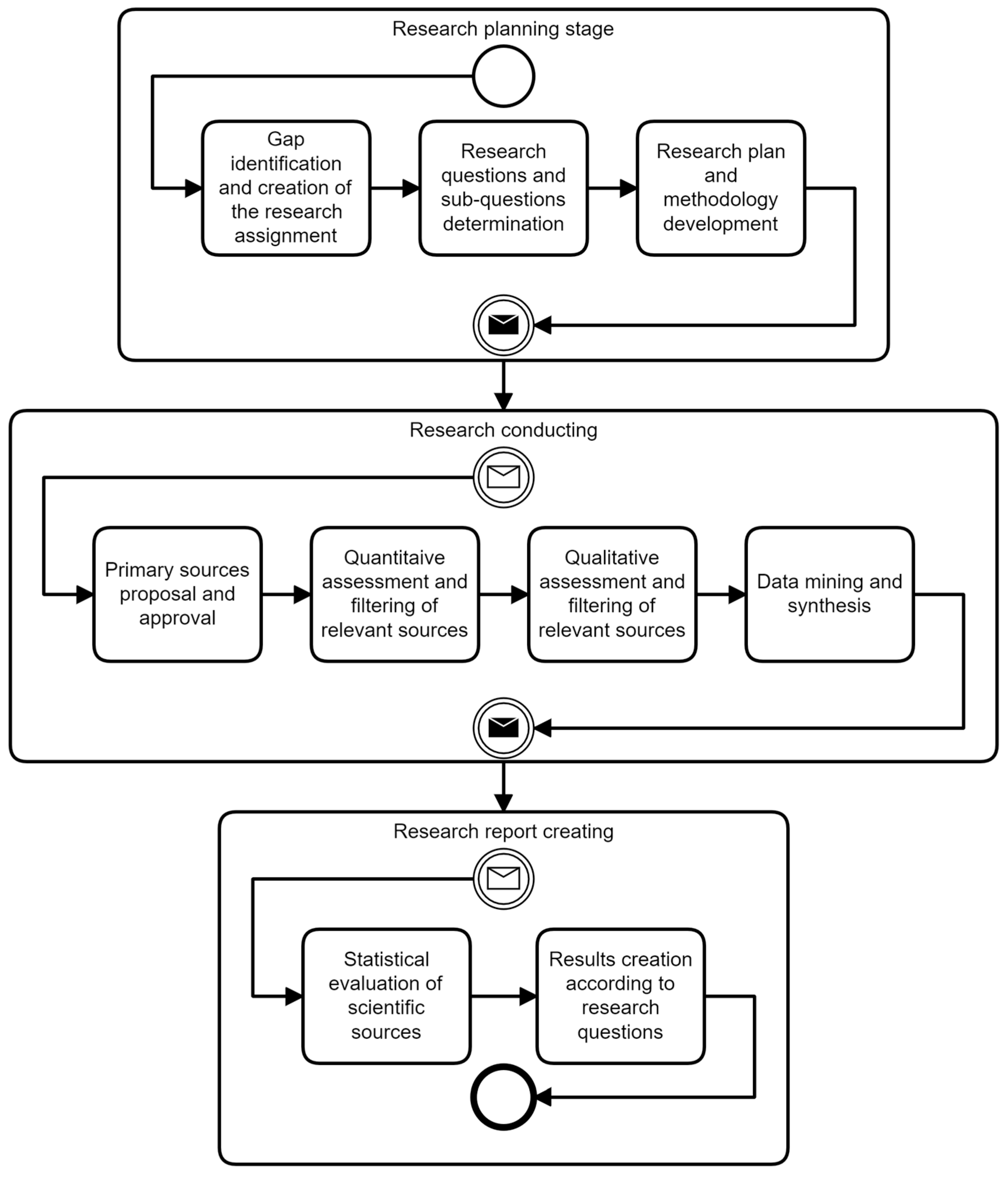

2. Literature Review Methodology

2.1. Research Procedure Selection

2.2. Defining the Research Queries

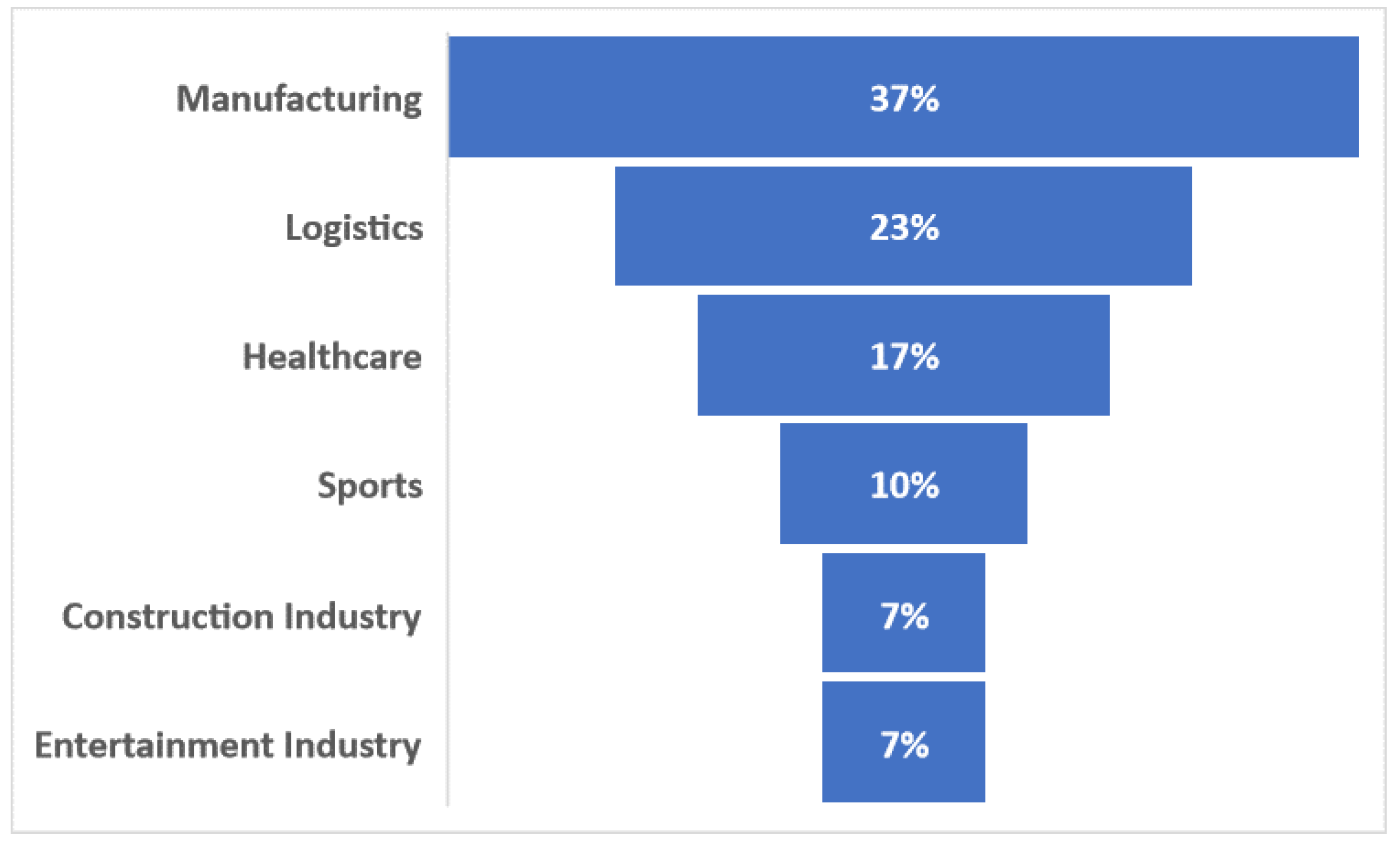

- What industries are using motion capture technology for ergonomics evaluation?

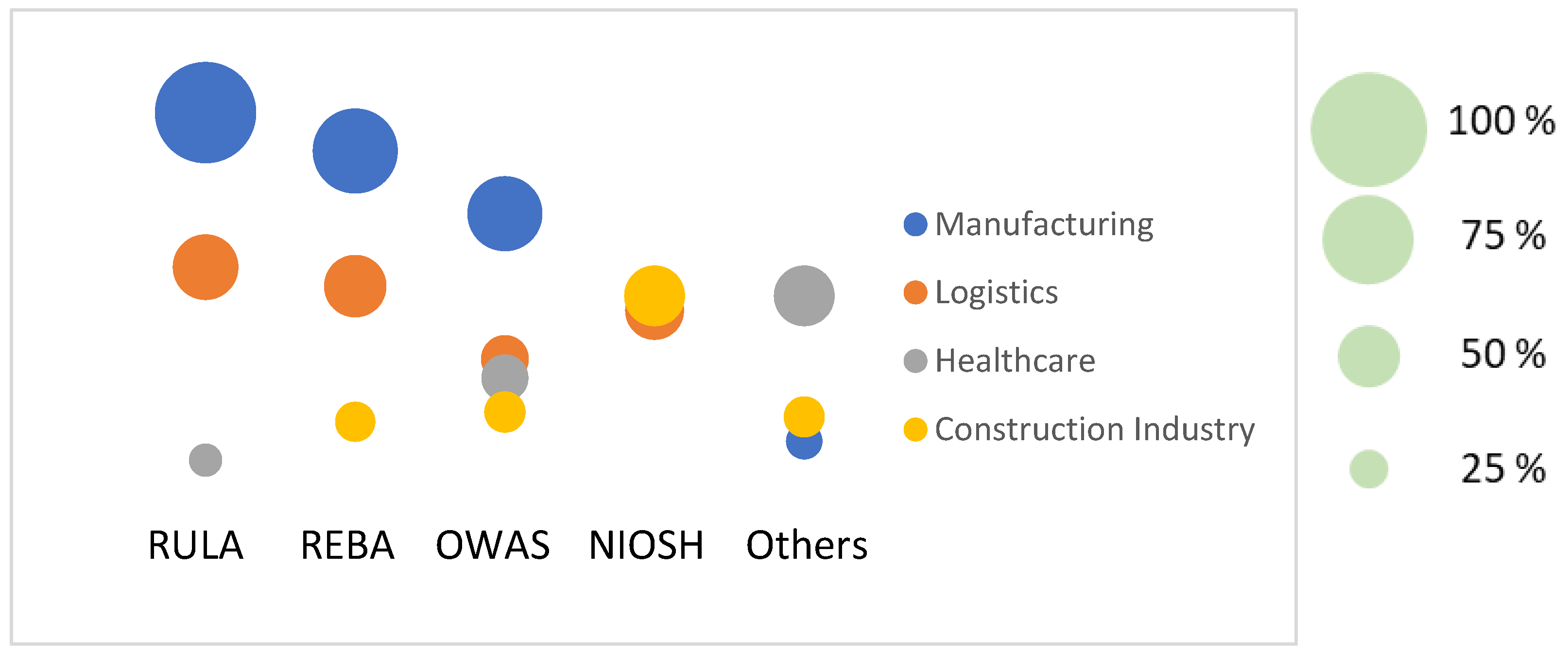

- What ergonomic evaluation methods can motion capture be applied to?

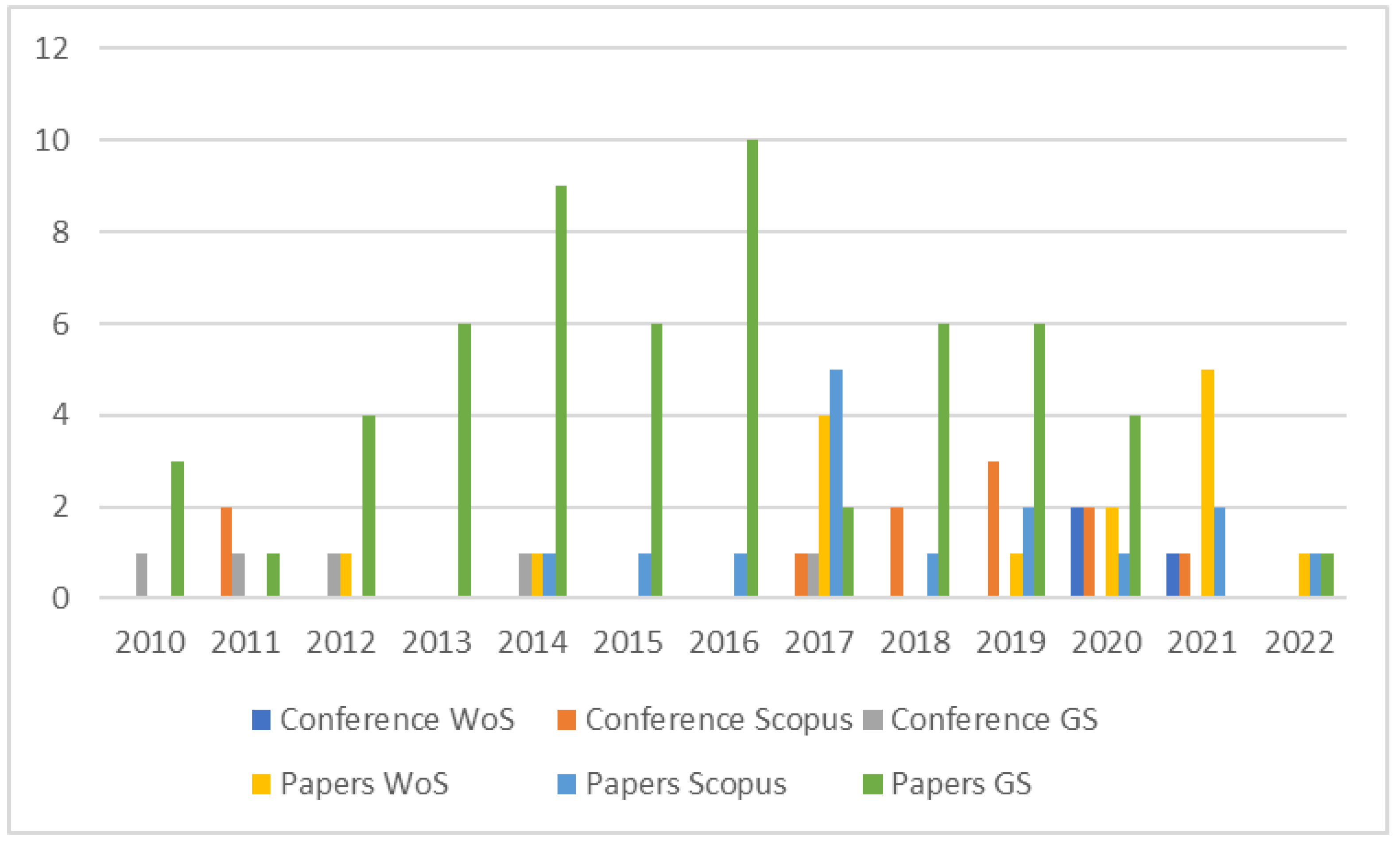

- How has the frequency and content of scientific publications on the topic of using motion capture for ergonomic evaluation changed over time?

- What problems do authors face when using the motion capture tool for ergonomics evaluation, and what responses do authors mention in their publications regarding these problems?

- What direction do the authors believe future research in combining ergonomics and MoCap technology will take?

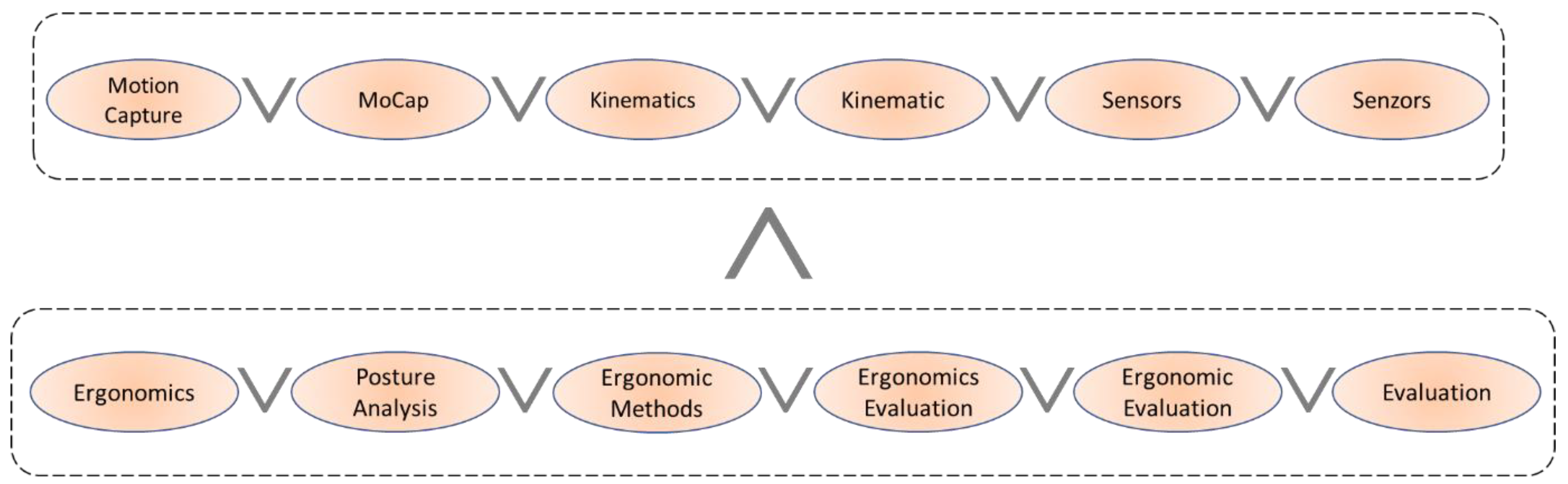

2.3. Search Query Formulation

- Restriction of the research—topic of the paper depending on the occurrence of keywords using the search query (publication title, abstract, keywords) according to the query: (Motion Capture OR MoCap OR Kinematics OR Kinematic suit OR Sensors OR Senzors) AND (Ergonomics OR Posture analysis OR Ergonomic methods OR Ergonomics evaluation OR Ergonomic evaluation OR Evaluation);

- Language—English;

- Year of publication: 2010–2022;

- Publication type—conference papers, conference proceedings, articles, books, book chapters, and research papers.

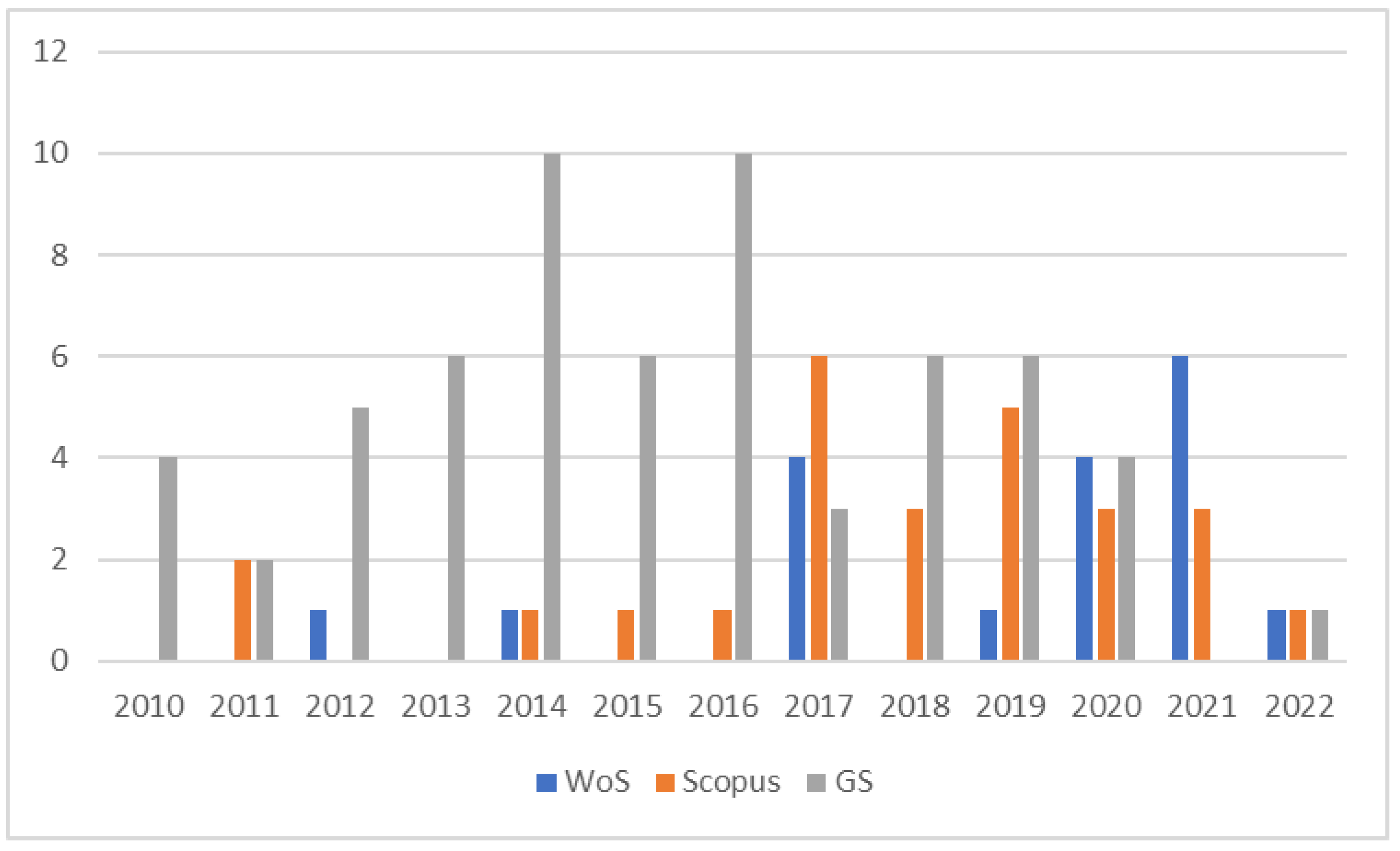

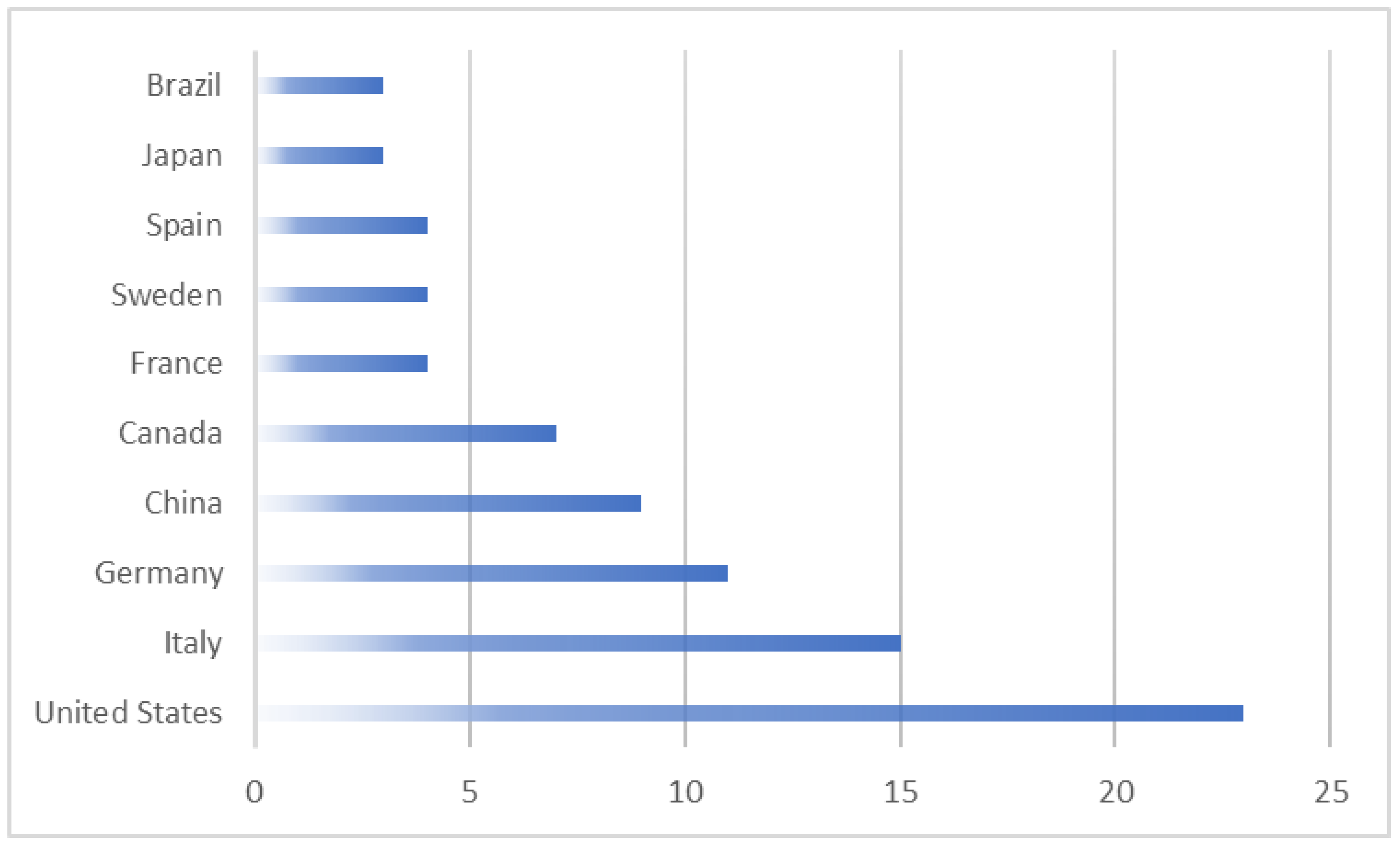

3. Research Results

- 40 publications from the Web of Science database;

- 81 publications from the Scopus database;

- 980 publications from Google Scholar.

- Web of Science: 36 publications;

- Scopus: 68 publications;

- Google Scholar: 119 publications.

- Web of Science: 27 publications;

- Scopus: 46 publications;

- Google Scholar: 112 publications.

- Web of Science: 18 publications;

- Scopus: 26 publications;

- Google Scholar: 63 publications.

4. Summary of Theoretical Knowledge

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bortolini, M.; Gamberi, M.; Pilati, F.; Regattieri, A. Automatic Assessment of the Ergonomic Risk for Manual Manufacturing and Assembly Activities through Optical Motion Capture Technology. In Proceedings of the 51st Cirp Conference on Manufacturing Systems, Stockholm, Sweden, 16–18 May 2018; Wang, L., Ed.; Elsevier Science Bv: Amsterdam, The Netherlands, 2018; Volume 72, pp. 81–86. [Google Scholar]

- Caserman, P.; Krug, C.; Goebel, S. Recognizing Full-Body Exercise Execution Errors Using the Teslasuit. Sensors 2021, 21, 8389. [Google Scholar] [CrossRef] [PubMed]

- Battini, D.; Berti, N.; Finco, S.; Guidolin, M.; Reggiani, M.; Tagliapietra, L. WEM-Platform: A Real-Time Platform for Full-Body Ergonomic Assessment and Feedback in Manufacturing and Logistics Systems. Comput. Ind. Eng. 2022, 164, 107881. [Google Scholar] [CrossRef]

- Dlugosz, Z. Population Ageing in Europe. In Proceedings of the 2nd International Geography Symposium-Mediterranean Environment 2010, Kemer-Antalya, Turkey, 2–5 June 2010; Efe, R., Ozturk, M., Eds.; Elsevier Science Bv: Amsterdam, The Netherlands, 2011; Volume 19, pp. 47–55. [Google Scholar]

- Strasser, H. The “Art of Aging” from an Ergonomics Point of View. In Proceedings of the Bridging Research and Good Practices towards Patient Welfare: Healthcare Systems Ergonomics and Patient Safety 2014, Taipei, Taiwan, 23–26 June 2014; Shih, Y.C., Liang, S.F.M., Eds.; CRC Press-Taylor & Francis Group: Boca Raton, FL, USA, 2015; pp. 3–16. [Google Scholar]

- Stedmon, A.W.; Howells, H.; Wilson, J.R.; Dianat, I. Ergonomics/Human Factors Needs of an Ageing Workforce in the Manufacturing Sector. Health Promot. Perspect. 2012, 2, 112–125. [Google Scholar] [CrossRef][Green Version]

- Navaratnarajah, A.; Jackson, S.H.D. The Physiology of Ageing. Medicine 2013, 41, 5–8. [Google Scholar] [CrossRef]

- Crettez, B.; Le Maitre, P. Optimal Age of Retirement and Population Growth. J. Popul. Econ. 2002, 15, 737–755. [Google Scholar] [CrossRef]

- Kumashiro, M. Ergonomics Strategies and Actions for Achieving Productive Use of an Ageing Work-Force. Ergonomics 2000, 43, 1007–1018. [Google Scholar] [CrossRef]

- Kristjuhan, U. Ergonomics as a Tool in Prolonging Youth and Postponing Ageing. Work 2012, 41, 380–382. [Google Scholar] [CrossRef]

- Brucker, E. Employment Population Age-Share Differences: An International Comparison of the Economic Impact of Population Aging. J. Aging Soc. Policy 2009, 21, 17–30. [Google Scholar] [CrossRef]

- Balachandran, A.; de Beer, J.; James, K.S.; van Wissen, L.; Janssen, F. Comparison of Population Aging in Europe and Asia Using a Time-Consistent and Comparative Aging Measure. J. Aging Health 2020, 32, 340–351. [Google Scholar] [CrossRef]

- Sidlo, L.; Sprocha, B.; Durcek, P. A Retrospective and Prospective View of Current and Future Population Ageing in the European Union 28 Countries. Morav. Geogr. Rep. 2020, 28, 187–207. [Google Scholar] [CrossRef]

- Dlugosz, Z.; Razniak, P. Risk of Population Aging in Asia. In Proceedings of the 3rd International Geography Symposium, Geomed 2013, Antalya, Turkey, 10–13 June 2013; Efe, R., Ozturk, M., Atalay, I., Eds.; Elsevier Science Bv: Amsterdam, The Netherlands, 2014; Volume 120, pp. 36–45. [Google Scholar]

- Maresova, P.; Mohelska, H.; Kuca, K. Economics Aspects of Ageing Population. In Proceedings of the 2nd Global Conference on Business, Economics, Management and Tourism, Prague, Czech Republic, 30–31 October 2014; Iacob, A.I., Ed.; Elsevier Science Bv: Amsterdam, The Netherlands, 2015; Volume 23, pp. 534–538. [Google Scholar]

- Broniatowska, P. Population Ageing and Inflation. J. Popul. Ageing 2019, 12, 179–193. [Google Scholar] [CrossRef]

- Langhamrova, J.; Fiala, T. Ageing of Population of Productive Age in the Czech Epublic. In Proceedings of the 7th International Days of Statistics and Economics, Prague, Czech Republic, 19–21 September 2013; Loster, T., Pavelka, T., Eds.; Melandrium: Slany, Czech Republic, 2013; pp. 748–757. [Google Scholar]

- Huang, W.-H.; Lin, Y.-J.; Lee, H.-F. Impact of Population and Workforce Aging on Economic Growth: Case Study of Taiwan. Sustainability 2019, 11, 6301. [Google Scholar] [CrossRef]

- Murata, A. Ergonomics and Cognitive Engineering for Robot-Human Cooperation. In Proceedings of the IEEE Ro-Man 2000: 9th IEEE International Workshop on Robot and Human Interactive Communication, Osaka, Japan, 27–29 September 2000; IEEE: New York, NY, USA, 2000; pp. 206–211. [Google Scholar]

- Stein, V.; Scholz, T.M. Manufacturing Revolution Boosts People Issues: The Evolutionary Need for ‘Human-Automation Resource Management’ in Smart Factories. Eur. Manag. Rev. 2020, 17, 391–406. [Google Scholar] [CrossRef]

- Gualtieri, L.; Rauch, E.; Vidoni, R. Emerging Research Fields in Safety and Ergonomics in Industrial Collaborative Robotics: A Systematic Literature Review. Robot. Comput.-Integr. Manuf. 2021, 67, 101998. [Google Scholar] [CrossRef]

- Dobra, Z.; Dhir, K.S. Technology Jump in the Industry: Human-Robot Cooperation in Production. Ind. Robot. 2020, 47, 757–775. [Google Scholar] [CrossRef]

- Morioka, M.; Adachi, S.; Sakakibara, S.; Tan, J.T.C.; Kato, R.; Arai, T. Cooperation Between a High-Power Robot and a Human by Functional Safety. J. Robot. Mechatron. 2011, 23, 926–938. [Google Scholar] [CrossRef]

- Hoecherl, J.; Wrede, B.; Schlegl, T. Motion Analysis of Human-Human and Human-Robot Cooperation During Industrial Assembly Tasks. In Proceedings of the 5th International Conference on Human Agent Interaction (Hai’17), Bielefeld, Germany, 17–20 October 2017; Assoc Computing Machinery: New York, NY, USA, 2017; pp. 425–429. [Google Scholar]

- van der Spaa, L.; Gienger, M.; Bates, T.; Kober, J. Predicting and Optimizing Ergonomics in Physical Human-Robot Cooperation Tasks. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; IEEE: New York, NY, USA, 2020; pp. 1799–1805. [Google Scholar]

- Barcellini, F. Conceptions of human-robot collaborative cooperation. A case of participation in a collaborative robot design process. Activities 2020, 17, 5007. [Google Scholar] [CrossRef]

- Quenehen, A.; Klement, N.; Abdeljaouad, A.M.; Roucoules, L.; Gibaru, O. Economic and Ergonomic Performance Enhancement in Assembly Process through Multiple Collaboration Modes between Human and Robot. Int. J. Prod. Res. 2022, 60. [Google Scholar] [CrossRef]

- Barcellini, F. Quelles conceptions de la coopération humains-robots collaboratifs? Activités 2020, 17-1, 73–100. [Google Scholar] [CrossRef]

- Maltry, L.; Holzgreve, F.; Maurer, C.; Wanke, E.M.; Ohlendorf, D. Improved ergonomic risk assessment through the combination of inertial sensors and observational methods exemplified by RULA. Zent. Arb. Arb. Ergon. 2020, 70, 236–239. [Google Scholar] [CrossRef]

- Humadi, A.; Nazarahari, M.; Ahmad, R.; Rouhani, H. In-Field Instrumented Ergonomic Risk Assessment: Inertial Measurement Units versus Kinect V2. Int. J. Ind. Ergon. 2021, 84, 103147. [Google Scholar] [CrossRef]

- Marin, J.; Marin, J.J. Forces: A Motion Capture-Based Ergonomic Method for the Today’s World. Sensors 2021, 21, 5139. [Google Scholar] [CrossRef] [PubMed]

- Baber, C.; Young, M.S. Making Ergonomics Accountable: Reliability, Validity and Utility in Ergonomics Methods. Appl. Ergon. 2022, 98, 103583. [Google Scholar] [CrossRef] [PubMed]

- Motion Analysis System (MAS) for Production and Ergonomics Assessment in the Manufacturing Processes-Web of Science Core Collection. Available online: https://www.webofscience.com/wos/woscc/full-record/WOS:000509784000095 (accessed on 7 April 2022).

- Jang, M.; Kim, J.S.; Kang, K.; Urn, S.H.; Yang, S.; Kim, J. Development of Wearable Motion Capture System Using Fiber Bragg Grating Sensors for Measuring Arm Motion. In Proceedings of the 2019 26th IEEE Conference on Virtual Reality and 3d User Interfaces (VR), Osaka, Japan, 23–27 March 2019; IEEE: New York, NY, USA, 2019; pp. 994–995. [Google Scholar]

- Iriondo Pascual, A.; Hogberg, D.; Syberfeldt, A.; Brolin, E.; Garcia Rivera, F.; Perez Luque, E.; Hanson, L. Implementation of Ergonomics Evaluation Methods in a Multi-Objective Optimization Framework. In Proceedings of the 6th International Digital Human Modeling Symposium (DHM2020), Skövde, Sweden, 31 August–2 September 2020; Hanson, L., Hogberg, D., Brolin, E., Eds.; IOS Press: Amsterdam, The Netherlands, 2020; Volume 11, pp. 361–371. [Google Scholar]

- Gregor, M.; Horejsi, P.; Simon, M. Case Study: Motion Capture for Ergonomics. In Innovation Vision 2020: From Regional Development Sustainability to Global Economic Growth, Proceedings of the 25th International Business Information Management Association Conference, Amsterdam, The Netherlands, 7–8 May 2015; Soliman, K.S., Ed.; Int Business Information Management Assoc-Ibima: Norristown, PA, USA, 2015; Volume I– Vi, pp. 468–476. [Google Scholar]

- Iosa, M.; Picerno, P.; Paolucci, S.; Morone, G. Wearable Inertial Sensors for Human Movement Analysis. Expert Rev. Med. Devices 2016, 13, 641–659. [Google Scholar] [CrossRef] [PubMed]

- Menolotto, M.; Komaris, D.-S.; Tedesco, S.; O’Flynn, B.; Walsh, M. Motion Capture Technology in Industrial Applications: A Systematic Review. Sensors 2020, 20, 5687. [Google Scholar] [CrossRef]

- Szczęsna, A.; Błaszczyszyn, M.; Pawlyta, M. Optical Motion Capture Dataset of Selected Techniques in Beginner and Advanced Kyokushin Karate Athletes. Sci. Data 2021, 8, 13. [Google Scholar] [CrossRef]

- Aughey, R.J.; Ball, K.; Robertson, S.J.; Duthie, G.M.; Serpiello, F.R.; Evans, N.; Spencer, B.; Ellens, S.; Cust, E.; Haycraft, J.; et al. Comparison of a Computer Vision System against Three-Dimensional Motion Capture for Tracking Football Movements in a Stadium Environment. Sports Eng. 2022, 25, 2. [Google Scholar] [CrossRef]

- Vicon. Award Winning Motion Capture Systems. Available online: https://www.vicon.com/ (accessed on 10 December 2022).

- Hu, Y.; He, X.; Zhang, Y.; Zeng, J.; Yang, H.; Zhou, S. Research and Application of Digital Collection Method of Human Movement. In Proceedings of the 2021 2nd International Conference on Artificial Intelligence and Information Systems, Chongqing, China, 28–30 May 2021; Association for Computing Machinery: New York, NY, USA, 2021; pp. 1–6. [Google Scholar]

- Guess, T.M.; Bliss, R.; Hall, J.B.; Kiselica, A.M. Comparison of Azure Kinect Overground Gait Spatiotemporal Parameters to Marker Based Optical Motion Capture. Gait Posture 2022, 96, 130–136. [Google Scholar] [CrossRef]

- Choo, C.Z.Y.; Chow, J.Y.; Komar, J. Validation of the Perception Neuron System for Full-Body Motion Capture. PLoS ONE 2022, 17, e0262730. [Google Scholar] [CrossRef]

- Rybnikár, F.; Šimon, M.; Vránek, P.; Kačerová, I. The Influence of Ergonomics as a Quality Parameter on the Evaluation of Manual Assembly Processes. Prod. Manag. Process Control 2022, 36, 82–90. [Google Scholar]

- Feldmann, F.; Seitz, R.; Kretschmer, V.; Bednorz, N.; ten Hompel, M. Ergonomic Evaluation of Body Postures in Order Picking Systems Using Motion Capturing. In Proceedings of the 2019 Prognostics and System Health Management Conference (PHM-Paris), Paris, France, 2–5 May 2019; Li, C., DeOliveira, J.V., Ding, P., Cabrera, D., Eds.; IEEE: New York, NY, USA, 2019; pp. 204–209. [Google Scholar]

- Dania, B.; Martina, C.; Alessandro, P.; Fabio, S.; Valentina, V.; Zennaro, I. Integrating Mocap System and Immersive Reality for Efficient Human-Centred Workstation Design. IFAC -Pap. 2018, 51, 188–193. [Google Scholar]

- Yunus, M.N.H.; Jaafar, M.H.; Mohamed, A.S.A.; Azraai, N.Z.; Hossain, M.S. Implementation of Kinetic and Kinematic Variables in Ergonomic Risk Assessment Using Motion Capture Simulation: A Review. Int. J. Environ. Res. Public Health 2021, 18, 8342. [Google Scholar] [CrossRef] [PubMed]

- Garousi, V.; Felderer, M.; Mantyla, M.V. Guidelines for Including Grey Literature and Conducting Multivocal Literature Reviews in Software Engineering. Inf. Softw. Technol. 2019, 106, 101–121. [Google Scholar] [CrossRef]

- Higgins, J.; Thomas, J. Cochrane Handbook for Systematic Reviews of Interventions. Available online: https://training.cochrane.org/handbook/current (accessed on 28 June 2022).

- Adams, R.J.; Smart, P.; Huff, A.S. Shades of Grey: Guidelines for Working with the Grey Literature in Systematic Reviews for Management and Organizational Studies. Int. J. Manag. Rev. 2017, 19, 432–454. [Google Scholar] [CrossRef]

- Okoli, C.; Schabram, K. A Guide to Conducting a Systematic Literature Review of Information Systems Research 2010; Sprouts: msterdam, The Netherlands, 2010. [Google Scholar]

- Eger, L.; Egerová, D. Základy Metodologie Výzkumu; Západočeská Univerzita v Plzni: Plzeň, Czech Republic, 2017; ISBN 978-80-261-0735-4. [Google Scholar]

- Foxon, T.J. Responding to the Financial Crisis: Need for a New Economics. Environ. Innov. Soc. Transit. 2013, 6, 126–128. [Google Scholar] [CrossRef]

- Xu, H.; Couch, K.A. The Business Cycle, Labor Market Transitions by Age, and the Great Recession. Appl. Econ. 2017, 49, 5370–5396. [Google Scholar] [CrossRef]

- Protecting Workplace Safety and Health in Difficult Economic Times—The Effect of the Financial Crisis and Economic Recession on Occupational Safety and Health; International Labour Organization: Geneva, Switzerland, 2013; ISBN 978-92-2-127090-4.

- Bauhardt, C. Solutions to the Crisis? The Green New Deal, Degrowth, and the Solidarity Economy: Alternatives to the Capitalist Growth Economy from an Ecofeminist Economics Perspective. Ecol. Econ. 2014, 102, 60–68. [Google Scholar] [CrossRef]

- Tienhaara, K. Varieties of Green Capitalism: Economy and Environment in the Wake of the Global Financial Crisis. Environ. Politics 2014, 23, 187–204. [Google Scholar] [CrossRef]

- Foresight on New and Emerging Risks in Green Jobs—Workshop for EU-OSHA Focal Points|Safety and Health at Work EU-OSHA. Available online: https://osha.europa.eu/en/tools-and-resources/seminars/foresight-new-and-emerging-risks-green-jobs-workshop-eu-osha-focal (accessed on 26 August 2022).

- Estrada, M.A.R.; Park, D.; Kim, J.S.; Khan, A. The Economic Impact of Terrorism: A New Model and Its Application to Pakistan. J. Policy Model. 2015, 37, 1065–1080. [Google Scholar] [CrossRef]

- Alija, A. La persistente crisis de los refugiados en Europa. El marco jurídico y de gestión de la Unión Europea. Rev. Estud. Segur. Int. 2020, 6, 37–56. [Google Scholar] [CrossRef]

- Chen, X.; Liao, B.; Cheng, L.; Peng, X.; Xu, X.; Li, Y.; Hu, T.; Li, J.; Zhou, X.; Ren, B. The Microbial Coinfection in COVID-19. Appl. Microbiol. Biotechnol. 2020, 104, 7777–7785. [Google Scholar] [CrossRef] [PubMed]

- Goodell, J.W. COVID-19 and Finance: Agendas for Future Research. Financ. Res. Lett. 2020, 35, 101512. [Google Scholar] [CrossRef] [PubMed]

- Pfister, A.; West, A.M.; Bronner, S.; Noah, J.A. Comparative Abilities of Microsoft Kinect and Vicon 3D Motion Capture for Gait Analysis. J. Med. Eng. Technol. 2014, 38, 274–280. [Google Scholar] [CrossRef]

- Dutta, T. Evaluation of the KinectTM Sensor for 3-D Kinematic Measurement in the Workplace. Appl. Ergon. 2012, 43, 645–649. [Google Scholar] [CrossRef] [PubMed]

- Millor, N.; Lecumberri, P.; Gómez, M.; Martínez-Ramírez, A.; Izquierdo, M. An Evaluation of the 30-s Chair Stand Test in Older Adults: Frailty Detection Based on Kinematic Parameters from a Single Inertial Unit. J. NeuroEng. Rehabil. 2013, 10, 86. [Google Scholar] [CrossRef] [PubMed]

- Greene, B.R.; McGrath, D.; O’Neill, R.; O’Donovan, K.J.; Burns, A.; Caulfield, B. An Adaptive Gyroscope-Based Algorithm for Temporal Gait Analysis. Med. Biol. Eng. Comput. 2010, 48, 1251–1260. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.C.; Nangia, V.; Bui, K.; Hammoor, B.; Kurt, M.; Hernandez, F.; Kuo, C.; Camarillo, D.B. In Vivo Evaluation of Wearable Head Impact Sensors. Ann. Biomed. Eng. 2016, 44, 1234–1245. [Google Scholar] [CrossRef]

- Cheng, T.; Migliaccio, G.C.; Teizer, J.; Gatti, U.C. Data Fusion of Real-Time Location Sensing and Physiological Status Monitoring for Ergonomics Analysis of Construction Workers. J. Comput. Civ. Eng. 2013, 27, 320–335. [Google Scholar] [CrossRef]

- Wang, D.; Dai, F.; Ning, X. Risk Assessment of Work-Related Musculoskeletal Disorders in Construction: State-of-the-Art Review. J. Constr. Eng. Manag. 2015, 141, 04015008. [Google Scholar] [CrossRef]

- Kim, S.; Nussbaum, M.A. Performance Evaluation of a Wearable Inertial Motion Capture System for Capturing Physical Exposures during Manual Material Handling Tasks. Ergonomics 2013, 56, 314–326. [Google Scholar] [CrossRef]

- Wang, Q.; Markopoulos, P.; Yu, B.; Chen, W.; Timmermans, A. Interactive Wearable Systems for Upper Body Rehabilitation: A Systematic Review. J. NeuroEng. Rehabil. 2017, 14, 20. [Google Scholar] [CrossRef]

- Cust, E.E.; Sweeting, A.J.; Ball, K.; Robertson, S. Machine and Deep Learning for Sport-Specific Movement Recognition: A Systematic Review of Model Development and Performance. J. Sport. Sci. 2019, 37, 568–600. [Google Scholar] [CrossRef]

- Oess, N.P.; Wanek, J.; Curt, A. Design and Evaluation of a Low-Cost Instrumented Glove for Hand Function Assessment. J. NeuroEng. Rehabil. 2012, 9, 2. [Google Scholar] [CrossRef] [PubMed]

- Manghisi, V.M.; Uva, A.E.; Fiorentino, M.; Bevilacqua, V.; Trotta, G.F.; Monno, G. Real Time RULA Assessment Using Kinect v2 Sensor. Appl. Ergon. 2017, 65, 481–491. [Google Scholar] [CrossRef] [PubMed]

- Schall, M.C.; Fethke, N.B.; Chen, H.; Oyama, S.; Douphrate, D.I. Accuracy and Repeatability of an Inertial Measurement Unit System for Field-Based Occupational Studies. Ergonomics 2016, 59, 591–602. [Google Scholar] [CrossRef] [PubMed]

- O’Reilly, M.; Caulfield, B.; Ward, T.; Johnston, W.; Doherty, C. Wearable Inertial Sensor Systems for Lower Limb Exercise Detection and Evaluation: A Systematic Review. Sports Med. 2018, 48, 1221–1246. [Google Scholar] [CrossRef]

- Schönauer, C.; Pintaric, T.; Kaufmann, H. Full Body Interaction for Serious Games in Motor Rehabilitation. In Proceedings of the 2nd Augmented Human International Conference, Tokyo, Japan, 13 March 2011; Association for Computing Machinery: New York, NY, USA, 2011; pp. 1–8. [Google Scholar]

- Ťupa, O.; Procházka, A.; Vyšata, O.; Schätz, M.; Mareš, J.; Vališ, M.; Mařík, V. Motion Tracking and Gait Feature Estimation for Recognising Parkinson’s Disease Using MS Kinect. BioMed. Eng. OnLine 2015, 14, 97. [Google Scholar] [CrossRef]

- Watanabe, T.; Saito, H.; Koike, E.; Nitta, K. A Preliminary Test of Measurement of Joint Angles and Stride Length with Wireless Inertial Sensors for Wearable Gait Evaluation System. Comput. Intell. Neurosci. 2011, 2011, e975193. [Google Scholar] [CrossRef]

- Golabchi, A.; Han, S.; Seo, J.; Han, S.; Lee, S.; Al-Hussein, M. An Automated Biomechanical Simulation Approach to Ergonomic Job Analysis for Workplace Design. J. Constr. Eng. Manag. 2015, 141, 04015020. [Google Scholar] [CrossRef]

- Rhodin, H.; Richardt, C.; Casas, D.; Insafutdinov, E.; Shafiei, M.; Seidel, H.-P.; Schiele, B.; Theobalt, C. EgoCap: Egocentric Marker-Less Motion Capture with Two Fisheye Cameras. ACM Trans. Graph. 2016, 35, 162. [Google Scholar] [CrossRef]

- Battini, D.; Persona, A.; Sgarbossa, F. Innovative Real-Time System to Integrate Ergonomic Evaluations into Warehouse Design and Management. Comput. Ind. Eng. 2014, 77, 1–10. [Google Scholar] [CrossRef]

- Golabchi, A.; Han, S.; Fayek, A.R.; AbouRizk, S. Stochastic Modeling for Assessment of Human Perception and Motion Sensing Errors in Ergonomic Analysis. J. Comput. Civ. Eng. 2017, 31, 04017010. [Google Scholar] [CrossRef]

- Han, S.; Lee, S.; Peña-Mora, F. Comparative Study of Motion Features for Similarity-Based Modeling and Classification of Unsafe Actions in Construction. J. Comput. Civ. Eng. 2014, 28, A4014005. [Google Scholar] [CrossRef]

- Alwasel, A.; Abdel-Rahman, E.M.; Haas, C.T.; Lee, S. Experience, Productivity, and Musculoskeletal Injury among Masonry Workers. J. Constr. Eng. Manag. 2017, 143, 05017003. [Google Scholar] [CrossRef]

- Mobini, A.; Behzadipour, S.; Saadat, M. Test–Retest Reliability of Kinect’s Measurements for the Evaluation of Upper Body Recovery of Stroke Patients. BioMed. Eng. OnLine 2015, 14, 75. [Google Scholar] [CrossRef]

- Ohlendorf, D.; Erbe, C.; Hauck, I.; Nowak, J.; Hermanns, I.; Ditchen, D.; Ellegast, R.; Groneberg, D.A. Kinematic Analysis of Work-Related Musculoskeletal Loading of Trunk among Dentists in Germany. BMC Musculoskelet. Disord. 2016, 17, 427. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J.; Zhao, H.; Qiu, S.; Li, J.; Gao, F.; Shi, X. Using Wearable Sensors to Capture Posture of the Human Lumbar Spine in Competitive Swimming. IEEE Trans. Hum.-Mach. Syst. 2019, 49, 194–205. [Google Scholar] [CrossRef]

- Liu, L.; Wang, H.-H.; Qiu, S.; Zhang, Y.-C.; Hao, Z.-D. Paddle Stroke Analysis for Kayakers Using Wearable Technologies. Sensors 2021, 21, 914. [Google Scholar] [CrossRef]

- Aristidou, A.; Stavrakis, E.; Charalambous, P.; Chrysanthou, Y.; Himona, S.L. Folk Dance Evaluation Using Laban Movement Analysis. J. Comput. Cult. Herit. 2015, 8, 20:1–20:19. [Google Scholar] [CrossRef]

- Bregler, C. Motion Capture Technology for Entertainment [In the Spotlight]. IEEE Signal Process. Mag. 2007, 24, 160-158. [Google Scholar] [CrossRef]

- Devika, P.S.; Vijay, C.H. Motion Capture Suit/Vest. Int. J. Res. Eng. Sci. (IJRES) 2022, 10, 5–11. [Google Scholar]

- El Mazgualdi, C.; Masrour, T.; El Hassani, I.; Khdoudi, A. Machine Learning for KPIs Prediction: A Case Study of the Overall Equipment Effectiveness within the Automotive Industry. Soft Comput. 2021, 25, 2891–2909. [Google Scholar] [CrossRef]

- Hara, T.; Li, Y.; Ota, J.; Arai, T. Automatic Risk Assessment Integrated with Activity Segmentation in the Order Picking Process to Support Health Management. CIRP Ann. 2020, 69, 17–20. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, W.; Fu, H.; Guo, Y.; Chablat, D.; Bennis, F.; Sawanoi, A.; Fugiwara, N. A Framework for Interactive Work Design Based on Motion Tracking, Simulation, and Analysis. Hum. Factors Ergon. Manuf. Serv. Ind. 2010, 20, 339–352. [Google Scholar] [CrossRef]

- Kačerová, I.; Kubr, J.; Hořejší, P.; Kleinová, J. Ergonomic Design of a Workplace Using Virtual Reality and a Motion Capture Suit. Appl. Sci. 2022, 12, 2150. [Google Scholar] [CrossRef]

- Vignais, N.; Bernard, F.; Touvenot, G.; Sagot, J.-C. Physical Risk Factors Identification Based on Body Sensor Network Combined to Videotaping. Appl. Ergon. 2017, 65, 410–417. [Google Scholar] [CrossRef]

- Conforti, I.; Mileti, I.; Del Prete, Z.; Palermo, E. Measuring Biomechanical Risk in Lifting Load Tasks through Wearable System and Machine-Learning Approach. Sensors 2020, 20, 1557. [Google Scholar] [CrossRef]

- Lunin, A.; Glock, C.H. Systematic Review of Kinect-Based Solutions for Physical Risk Assessment in Manual Materials Handling in Industrial and Laboratory Environments. Comput. Ind. Eng. 2021, 162, 107660. [Google Scholar] [CrossRef]

- Maurer-Grubinger, C.; Holzgreve, F.; Fraeulin, L.; Betz, W.; Erbe, C.; Brueggmann, D.; Wanke, E.M.; Nienhaus, A.; Groneberg, D.A.; Ohlendorf, D. Combining Ergonomic Risk Assessment (RULA) with Inertial Motion Capture Technology in Dentistry—Using the Benefits from Two Worlds. Sensors 2021, 21, 4077. [Google Scholar] [CrossRef]

- Giannini, P.; Bassani, G.; Avizzano, C.A.; Filippeschi, A. Wearable Sensor Network for Biomechanical Overload Assessment in Manual Material Handling. Sensors 2020, 20, 3877. [Google Scholar] [CrossRef]

- Igelmo, V.; Syberfeldt, A.; Högberg, D.; Rivera, F.; Luque, E. Aiding Observational Ergonomic Evaluation Methods Using MOCAP Systems Supported by AI-Based Posture Recognition. In DHM2020; IOS Press: Amsterdam, The Netherlands, 2020; pp. 419–429. [Google Scholar] [CrossRef]

- Plantard, P.; Shum, H.P.H.; Multon, F. Filtered Pose Graph for Efficient Kinect Pose Reconstruction. Multimed. Tools Appl. 2017, 76, 4291–4312. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Ahn, C.R.; Han, S. Detecting the Hazards of Lifting and Carrying in Construction through a Coupled 3D Sensing and IMUs Sensing System. In Proceedings of the 2014 International Conference on Computing in Civil and Building Engineering, Orlando, FL, USA, 23–25 June 2014; pp. 1110–1117. [Google Scholar] [CrossRef]

| Author | Number of Citations | Title of Publication | Year |

|---|---|---|---|

| A. Pfister | 442 | Comparative abilities of Microsoft Kinect and Vicon 3D motion capture for gait analysis [64] | 2014 |

| Tilak Dutta | 261 | Evaluation of the Kinect (TM) sensor for 3-D kinematic measurement in the workplace [65] | 2012 |

| N. Millor | 205 | An evaluation of the 30-s chair stand test in older adults: frailty detection based on kinematic parameters from a single inertial unit [66] | 2013 |

| B.R. Greene | 195 | An adaptive gyroscope-based algorithm for temporal gait analysis [67] | 2010 |

| L.C. Wu | 189 | In vivo evaluation of wearable head impact sensors [68] | 2016 |

| T. Cheng | 180 | Data fusion of real-time location sensing and physiological status monitoring for ergonomics analysis of construction workers [69] | 2013 |

| M. Iosa | 179 | Wearable inertial sensors for human movement analysis [37] | 2016 |

| D. Wang | 169 | Risk assessment of work-related musculoskeletal disorders in construction: State-of-the-art review [70] | 2015 |

| S. Kim | 165 | Performance evaluation of a wearable inertial motion capture system for capturing physical exposures during manual material handling tasks [71] | 2013 |

| Q. Wang | 144 | Interactive wearable systems for upper body rehabilitation: A systematic review [72] | 2017 |

| E.E. Cust | 136 | Machine and deep learning for sport-specific movement recognition: A systematic review of model development and performance [73] | 2019 |

| N.P. Oess | 110 | Design and evaluation of a low-cost instrumented glove for hand function assessment [74] | 2012 |

| V.M. Manghisi | 101 | Real time RULA assessment using Kinect v2 sensor [75] | 2017 |

| M.C. Schall Jr. | 97 | Accuracy and repeatability of an inertial measurement unit system for field-based occupational studies [76] | 2016 |

| M. O’Reilly | 95 | Wearable inertial sensor systems for lower limb exercise detection and evaluation: A systematic review [77] | 2018 |

| C. Schönauer | 93 | Full body interaction for serious games in motor rehabilitation [78] | 2011 |

| O. Ťupa | 88 | Motion tracking and gait feature estimation for recognising Parkinson’s disease using MS Kinect [79] | 2015 |

| T. Watanabe | 87 | A preliminary test of measurement of joint angles and stride length with wireless inertial sensors for wearable gait evaluation system [80] | 2011 |

| A. Golabchi | 87 | An automated biomechanical simulation approach to ergonomic job analysis for workplace design [81] | 2015 |

| H. Rhodin | 86 | Egocap: egocentric marker-less motion capture with two fisheye cameras [68] | 2016 |

| Periodical/Source | Number of Publications | Percentage Representation |

|---|---|---|

| Ergonomics | 8 | 7% |

| Journal of NeuroEngineering and Rehabilitation | 6 | 5% |

| Journal of Construction Engineering and Management | 6 | 5% |

| Applied Ergonomics | 4 | 4% |

| Sensors | 4 | 4% |

| Advantages | Disadvantages |

|---|---|

| Objectivity | Price |

| Reliability | Signal interference during data transmission in industry |

| Repeatability | Limited suit size |

| Combining of multiple ergonomic methods | Calibration required |

| Evaluation in pre-design stage | Large volume of transported data |

| Connectivity with AI | Requirement for high-powered PC |

| Real-time automatic data acquisition |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rybnikár, F.; Kačerová, I.; Hořejší, P.; Šimon, M. Ergonomics Evaluation Using Motion Capture Technology—Literature Review. Appl. Sci. 2023, 13, 162. https://doi.org/10.3390/app13010162

Rybnikár F, Kačerová I, Hořejší P, Šimon M. Ergonomics Evaluation Using Motion Capture Technology—Literature Review. Applied Sciences. 2023; 13(1):162. https://doi.org/10.3390/app13010162

Chicago/Turabian StyleRybnikár, Filip, Ilona Kačerová, Petr Hořejší, and Michal Šimon. 2023. "Ergonomics Evaluation Using Motion Capture Technology—Literature Review" Applied Sciences 13, no. 1: 162. https://doi.org/10.3390/app13010162

APA StyleRybnikár, F., Kačerová, I., Hořejší, P., & Šimon, M. (2023). Ergonomics Evaluation Using Motion Capture Technology—Literature Review. Applied Sciences, 13(1), 162. https://doi.org/10.3390/app13010162