Planar Laser Induced Fluorescence of OH for Thermometry in a Flow Field Based on Two Temperature Point Calibration Method

Abstract

:1. Introduction

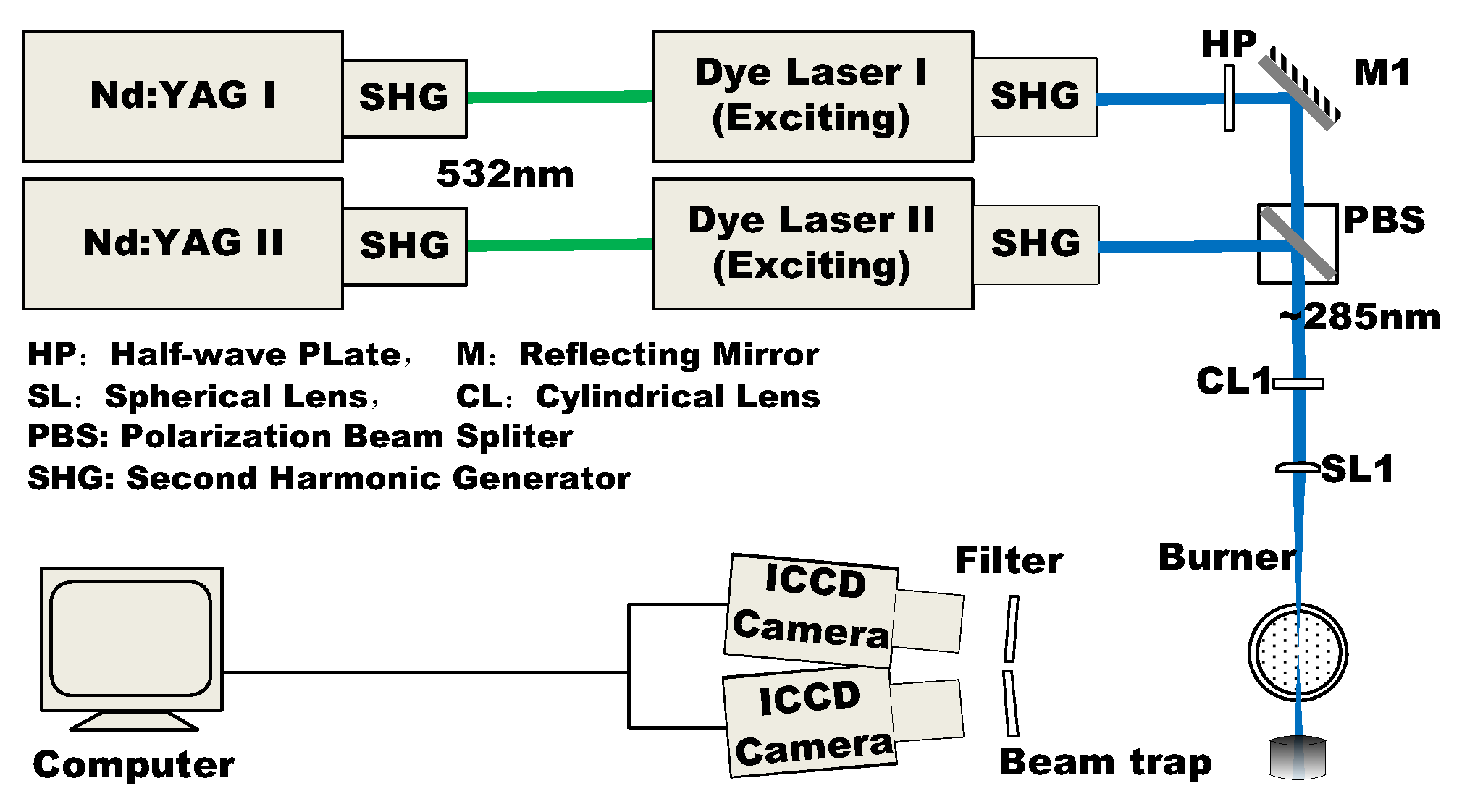

2. Principles of PLIF Thermometry

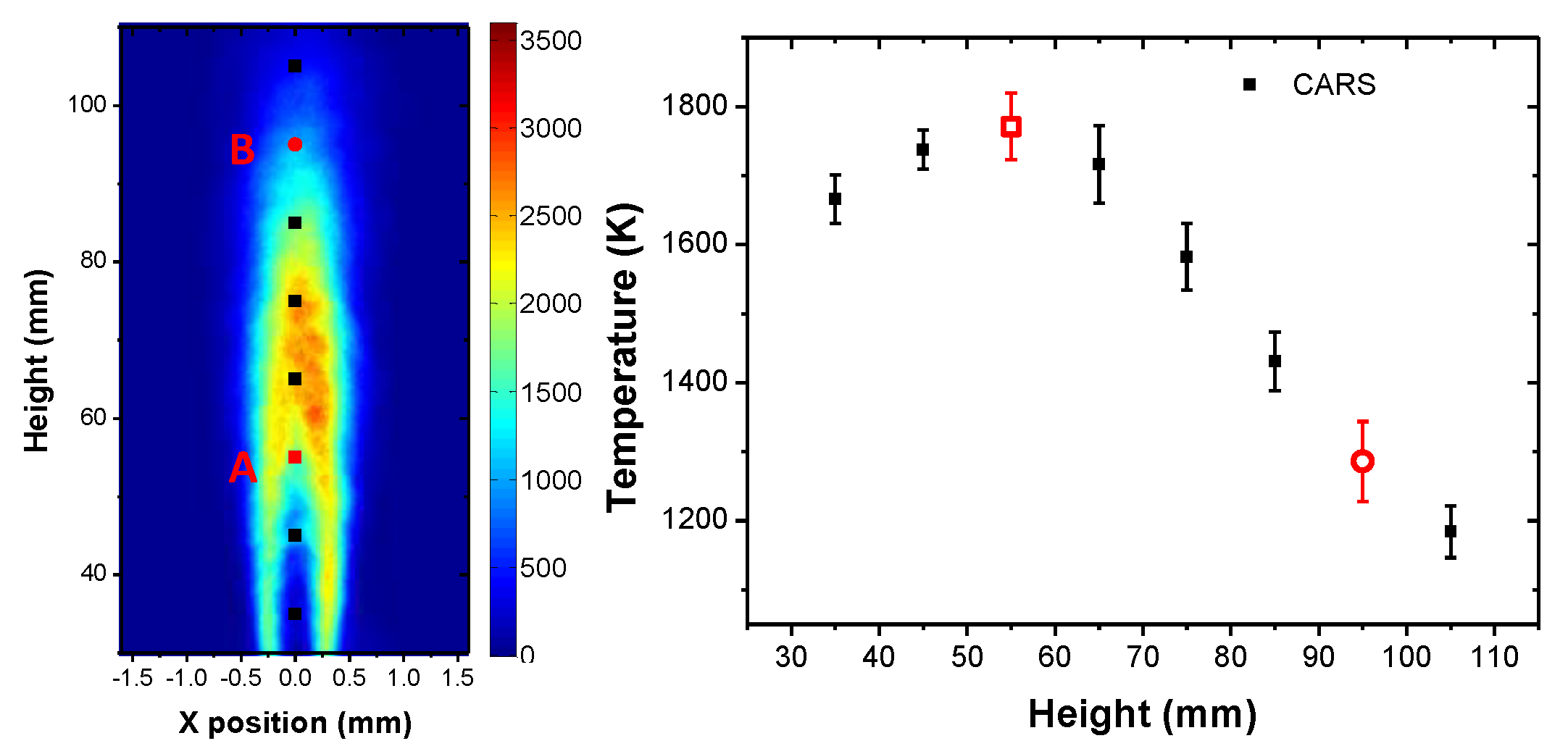

3. Experimental Setting

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Eckbreth, A.C. Laser Diagnostics for Combustion Temperature Species, 2nd ed.; CRC Press: Boca Raton, FL, USA, 1996. [Google Scholar]

- Kohse-Höinghaus, K.R.; Barlow, S.; Aldén, M.; Wolfrum, J. Combustion at the focus: Laser diagnostics and control. Proc. Combust. Inst. 2005, 30, 89–123. [Google Scholar] [CrossRef]

- Alden, M.; Bengtsson, P.; Edner, H. Rotational CARS generation through a multiple four-color interaction. Appl. Opt. 1986, 25, 4493–4500. [Google Scholar] [CrossRef] [Green Version]

- Bohlin, A.; Kliewer, C.J. Communication: Two-dimensional gas-phase coherent anti-Stokes Raman spectroscopy (2D-CARS): Simultaneous planar imaging and multiplex spectroscopy in a single laser shot. J. Chem. Phys. 2013, 138, 110–122. [Google Scholar] [CrossRef]

- Laurendeau, N.M. Temperature measurements by light-scattering methods. Prog. Energ. Combust. 1988, 14, 147–170. [Google Scholar] [CrossRef]

- Wang, S.; Si, J.H.; Shao, J.; Hu, Z.Y.; Ye, J.F.; Liu, J.R. Two-dimensional interferometric Rayleigh scattering velocimetry using multibeam probe laser. Opt. Eng. 2017, 56, 111705. [Google Scholar]

- Alden, M.; Grafstroom, P.; Lundberg, H.; Svanberg, S. Spatially resolved temperature measurements in a flame using laser-excited two-line atomic fluorescence and diode-array detection. Opt. Lett. 1983, 8, 241–243. [Google Scholar] [CrossRef]

- Boxx, I.; Stöhr, M.; Carter, C.; Meier, W. Temporally resolved planar measurements of transient phenomena in a partially pre-mixed swirl flame in a gas turbine model combustor. Combust. Flame 2010, 157, 1510–1525. [Google Scholar] [CrossRef] [Green Version]

- Zhou, B.; Kiefer, J.; Zetterberg, J.; Li, Z.S.; Alden, M. Strategy for PLIF single-shot HCO imaging in turbulent methane/air flames. Combust. Flame 2014, 161, 1566–1574. [Google Scholar] [CrossRef]

- Feroughi, O.M.; Kronemayer, H.; Dreier, T.; Schulz, C. Effect of fluctuations on time-averaged multi-line NO-LIF thermometry measurements of the gas-phase temperature. Appl. Phys. B 2015, 120, 429–440. [Google Scholar] [CrossRef]

- Chan, C.; Daily, J.W. Measurement of temperature in flames using laser induced fluorescence spectroscopy of OH. Appl. Opt. 1980, 19, 1963–1968. [Google Scholar] [CrossRef]

- Cattolica, R. OH rotational temperature from two-line laser-excited fluorescence. Appl. Opt. 1981, 20, 1156–1166. [Google Scholar] [CrossRef]

- Seitzman, J.M.; Hanson, R.K.; Debarber, P.A.; Hess, C.F. Application of quantitative two-line OH planar laser-induced fluorescence for temporally resolved planar thermometry in reacting flows. Appl. Opt. 1994, 33, 4000–4012. [Google Scholar] [CrossRef]

- Luque, J.; Crosley, D.R. LIFBASE: Database and Spectral Simulation Program (Version 1.5); SRI International: Menlo Park, CA, USA, 1999. [Google Scholar]

- Dunn, M.J.; Masri, A.R. A comprehensive model for the quantification of linear and nonlinear regime laser-induced fluorescence of OH under A2Σ+←X2Π(1,0) excitation. Appl. Phys. B 2010, 101, 445–463. [Google Scholar] [CrossRef]

- Sharipov, G.L.; Tukhbatullin, A.A.; Abdrakhmanov, A.M. Detection of OH radical and O atom during triboluminescence of hydrated cerium/terbium sulfates. J. Lumin. 2012, 132, 175–177. [Google Scholar] [CrossRef]

- Li, L.; Nikiforov, A.; Xiong, Q.; Britun, N.; Snyders, R.; Lu, X.; Leys, C. OH radicals distribution in an Ar-H2O atmospheric plasma jet. Phys. Plasmas 2013, 20, 093502. [Google Scholar] [CrossRef] [Green Version]

- Kienle, R.; Lee, M.P.; Kohse-Höinghaus, K. A detailed rate equation model for the simulation of energy transfer in OH laser-induced fluorescence. Appl. Phys. B 1996, 62, 583–599. [Google Scholar] [CrossRef]

- Devillers, R.; Bruneaux, G.; Schulz, C. Development of a two-line OH-laser-induced fluorescence thermometry diagnostics strategy for gas-phase temperature measurements in engines. Appl. Opt. 2008, 47, 5871–5885. [Google Scholar] [CrossRef]

- Seitzman, J.M.; Hanson, R.K. Two-line planar fluorescence for temporally resolved temperature imaging in a reacting supersonic flow over a body. Appl. Phys. B 1993, 57, 385–391. [Google Scholar] [CrossRef]

- Cattolica, R.J.; Mataga, T.G. Rotational-level-dependent quenching of OH by collisions with H2O in a low-pressure flame. Chem. Phys. Lett. 1991, 182, 623–631. [Google Scholar] [CrossRef]

- Copeland, R.A.; Dyer, M.J.; Crosley, D.R. Rotational-level dependent quenching of OH and OD. J. Chem Phys. 1985, 82, 4022–4032. [Google Scholar] [CrossRef]

- Li, G.H.; Hu, Z.Y.; Wang, S. 2D scanning CARS for temperature distribution measurement. Optics Precis. Eng. 2016, 24, 14–19. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Zhang, Z.; Ye, J.; Wang, S.; Shao, J.; Wu, H.; Wang, Y.; Hu, Z.; Wang, J.; Huang, Z. Planar Laser Induced Fluorescence of OH for Thermometry in a Flow Field Based on Two Temperature Point Calibration Method. Appl. Sci. 2023, 13, 176. https://doi.org/10.3390/app13010176

Li G, Zhang Z, Ye J, Wang S, Shao J, Wu H, Wang Y, Hu Z, Wang J, Huang Z. Planar Laser Induced Fluorescence of OH for Thermometry in a Flow Field Based on Two Temperature Point Calibration Method. Applied Sciences. 2023; 13(1):176. https://doi.org/10.3390/app13010176

Chicago/Turabian StyleLi, Guohua, Zhenrong Zhang, Jingfeng Ye, Sheng Wang, Jun Shao, Haolong Wu, Yamin Wang, Zhiyun Hu, Jinhua Wang, and Zuohua Huang. 2023. "Planar Laser Induced Fluorescence of OH for Thermometry in a Flow Field Based on Two Temperature Point Calibration Method" Applied Sciences 13, no. 1: 176. https://doi.org/10.3390/app13010176