Mechanical Behavior and Excavation Optimization of a Small Clear-Distance Tunnel in an Urban Super Large and Complex Underground Interchange Hub

Abstract

1. Introduction

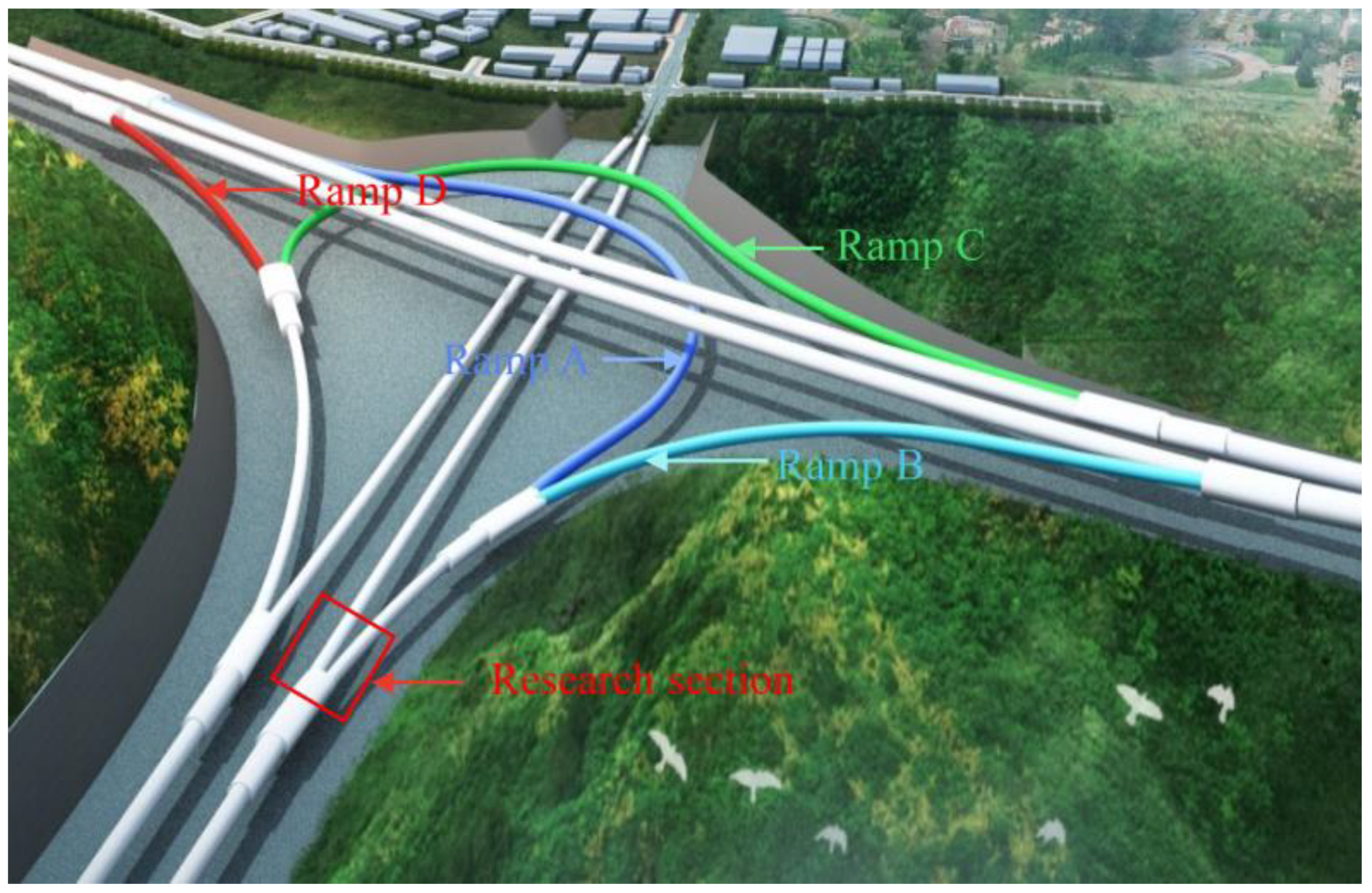

2. Research Section Project Overview

3. Numerical Model

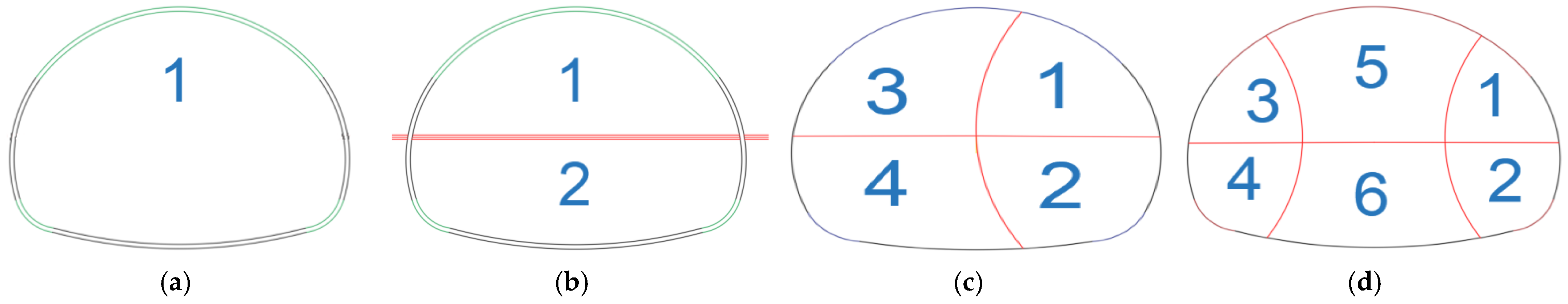

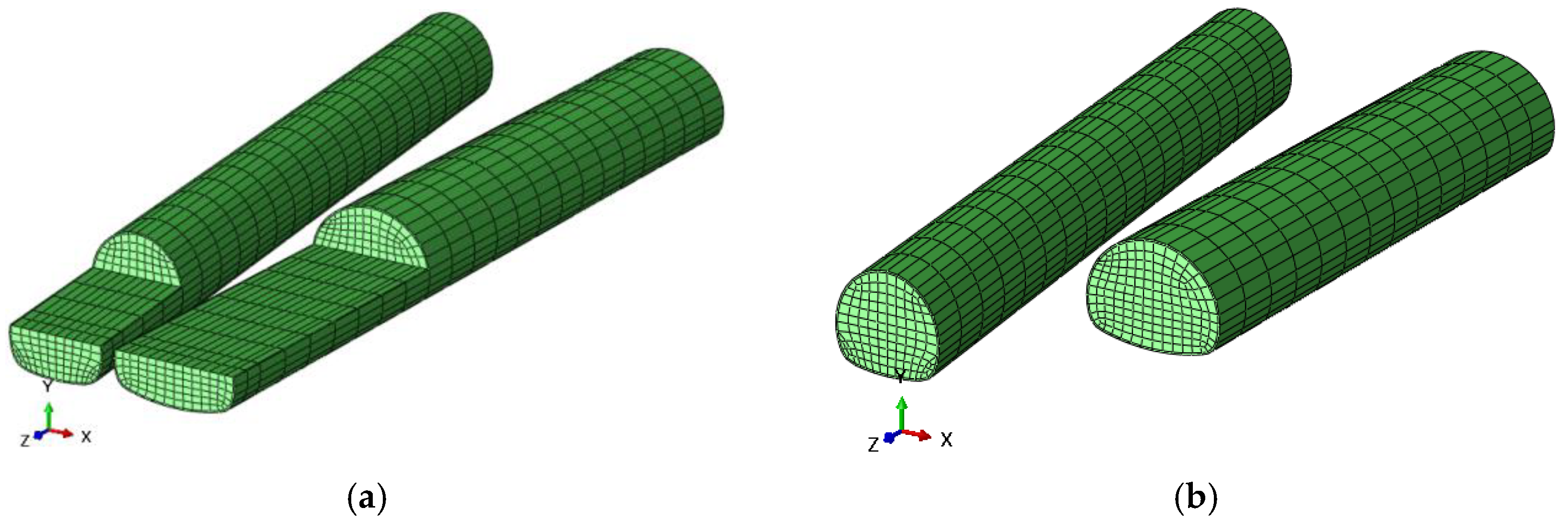

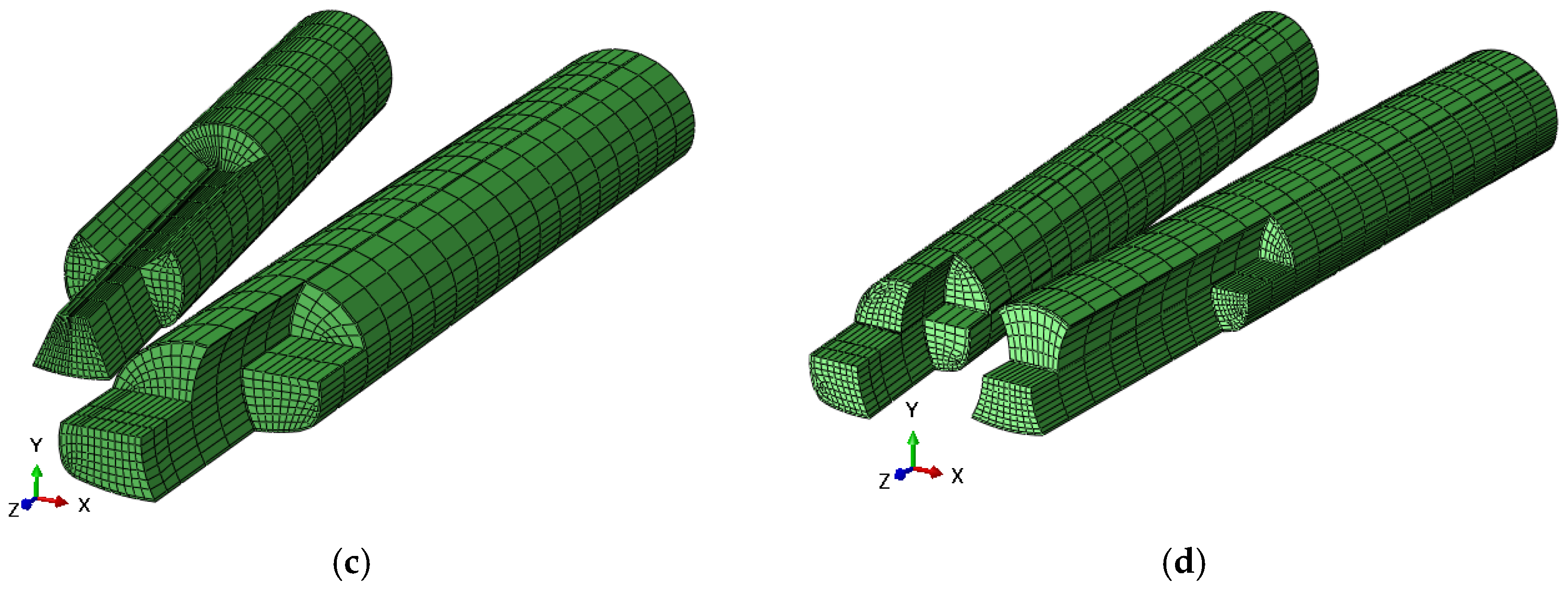

3.1. Establishment of a 3D Numerical Model

3.2. Numerical Model Parameters

4. Numerical Results and Discussion

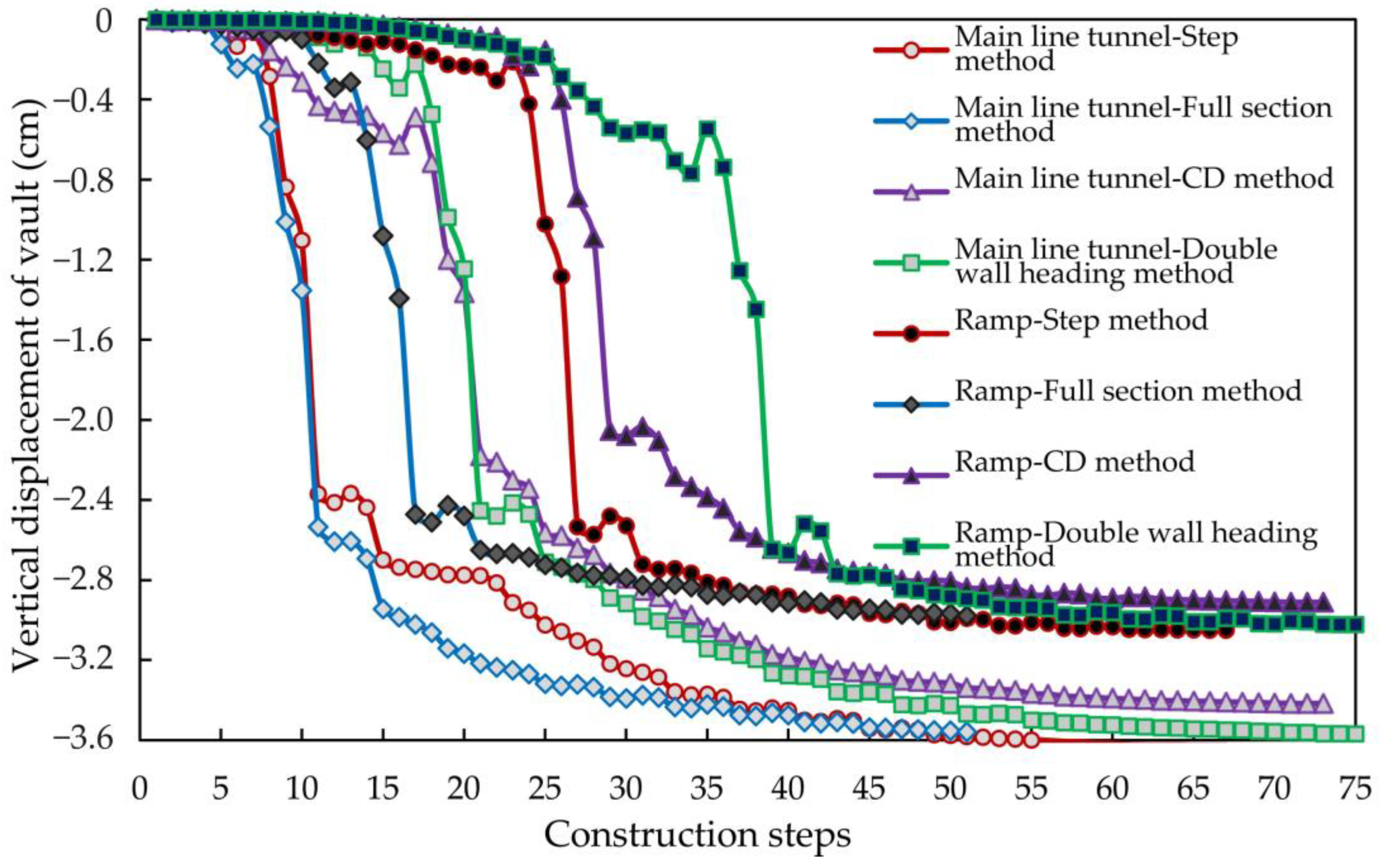

4.1. Stability Analysis of Small Clear-Distance Tunnels under Different Excavation Schemes

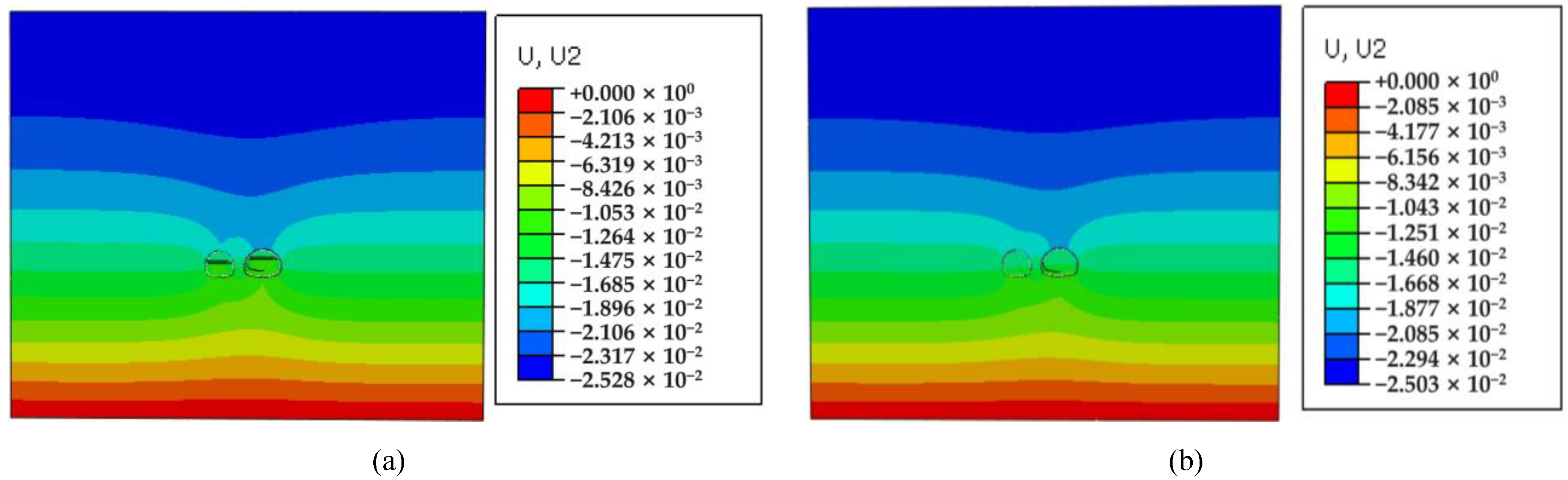

4.1.1. Analysis of Surface and Surrounding Rock Deformation

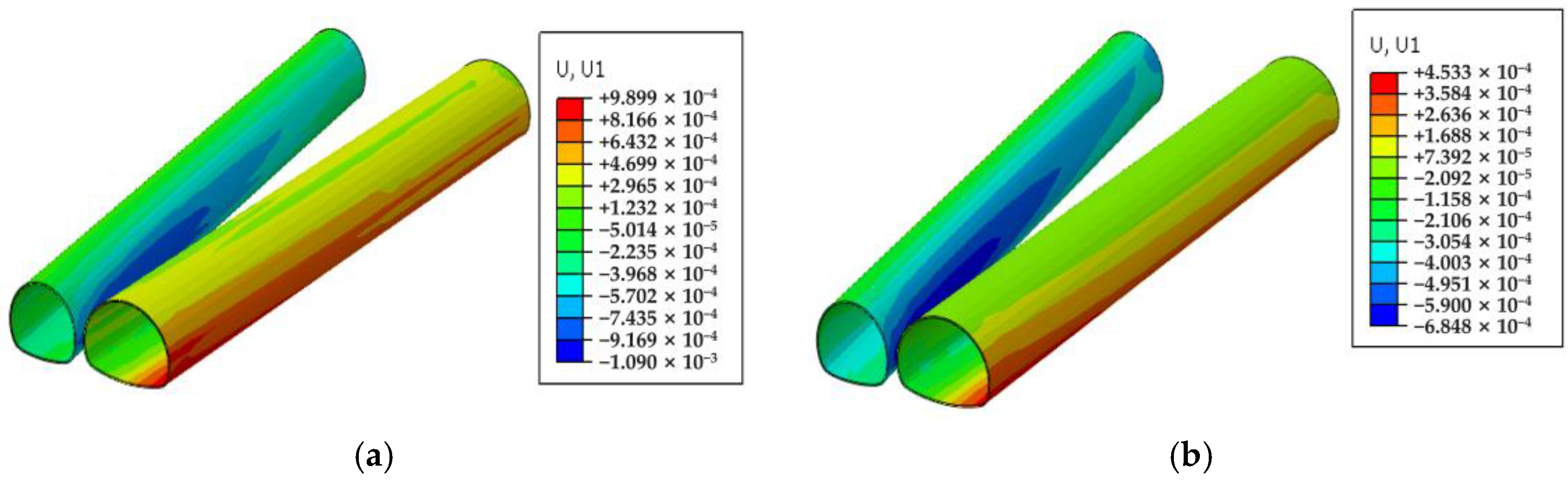

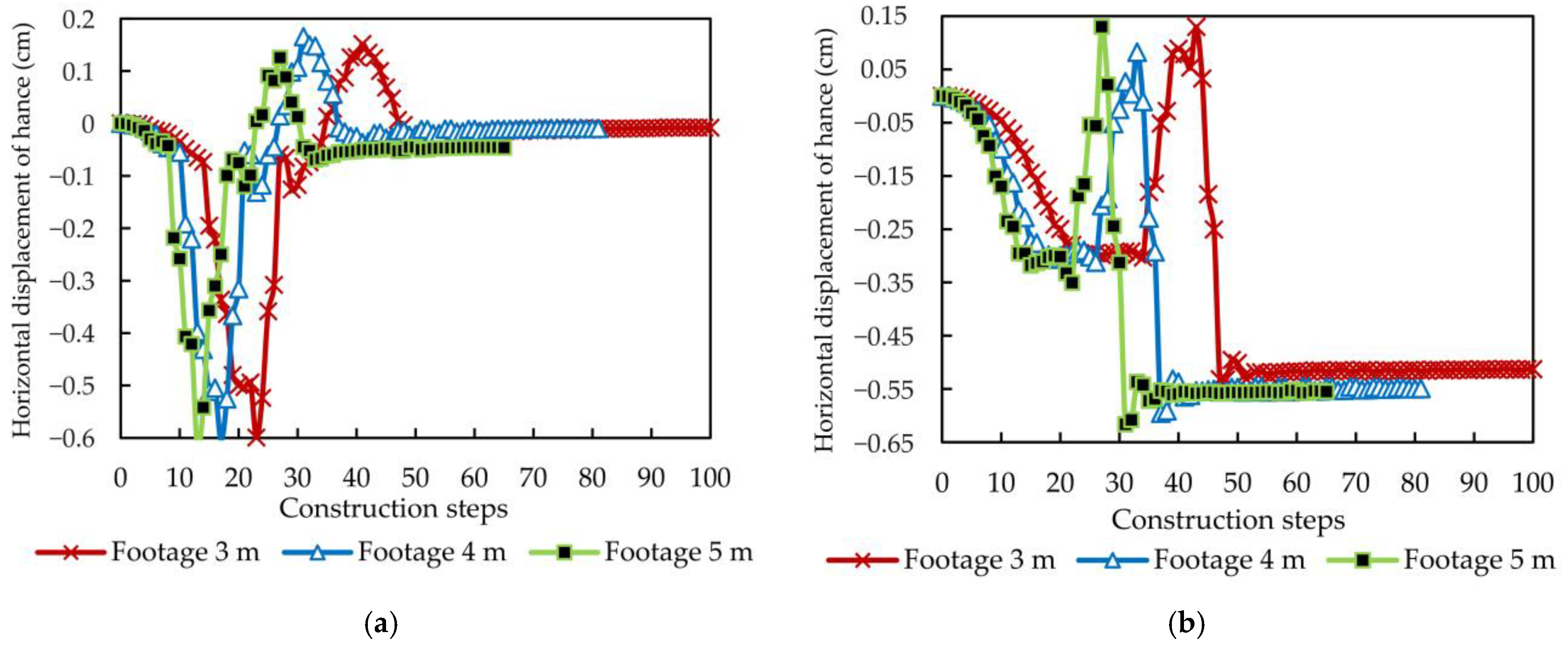

4.1.2. Deformation Analysis of the Surrounding Rock and Lining

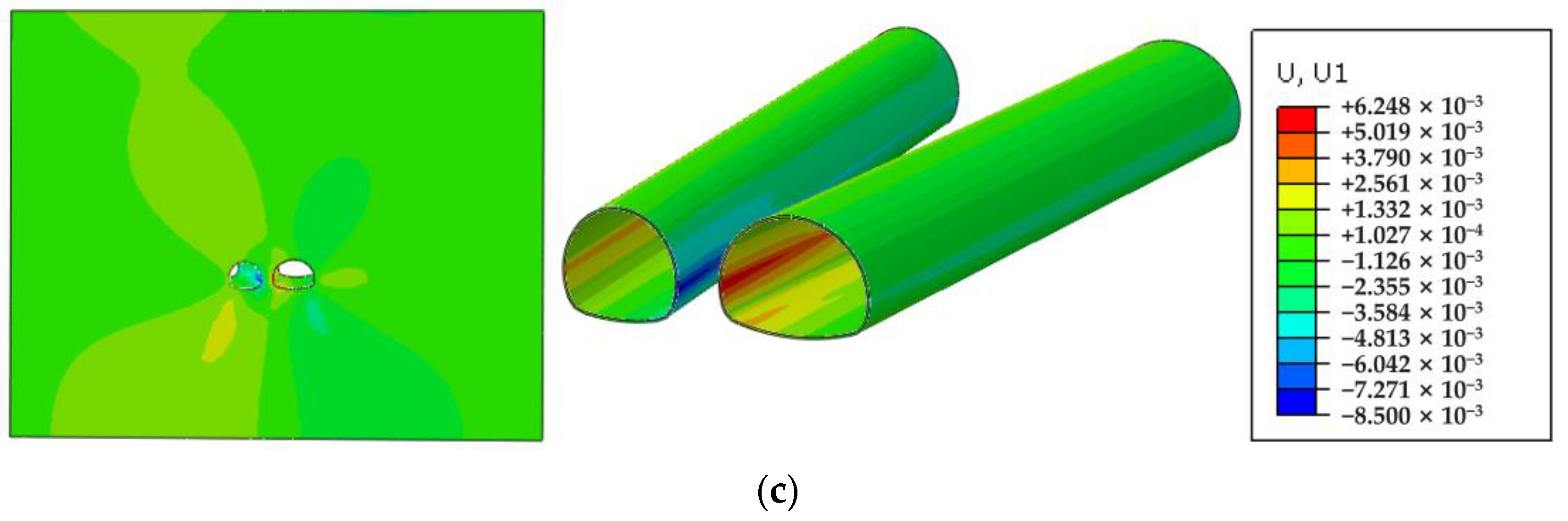

4.1.3. Stress Analysis of the Supporting Structure

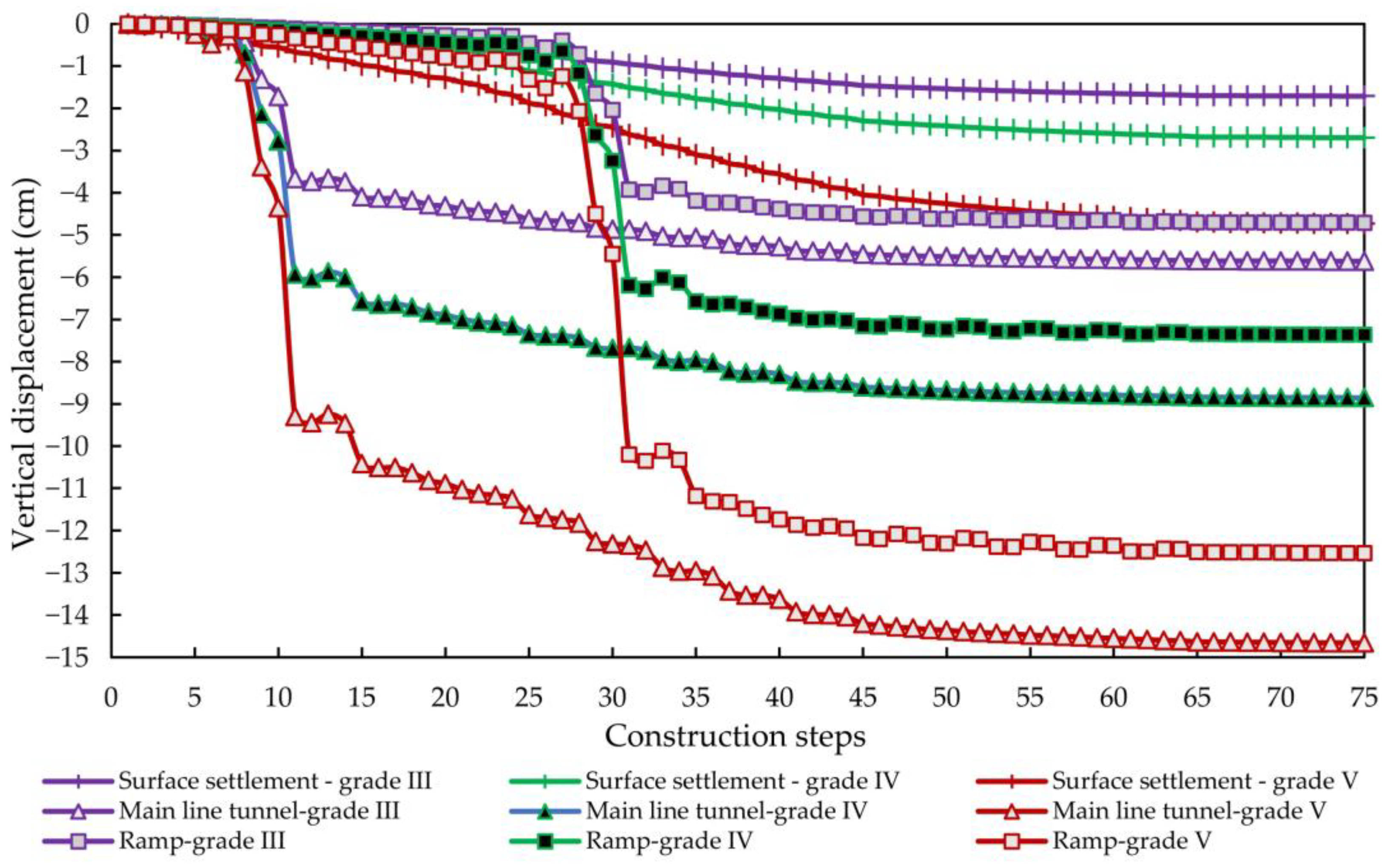

4.2. Analysis of the Construction Behaviour of the Small Clear-Distance Tunnel under Different Lithology Grades

4.2.1. Deformation Analysis of the Surrounding Rocks and Lining

4.2.2. Stress Analysis of Supporting Structure

4.3. Analysis of the Construction Behaviour of Small Clear-Distance Tunnels under Different Footage Lengths

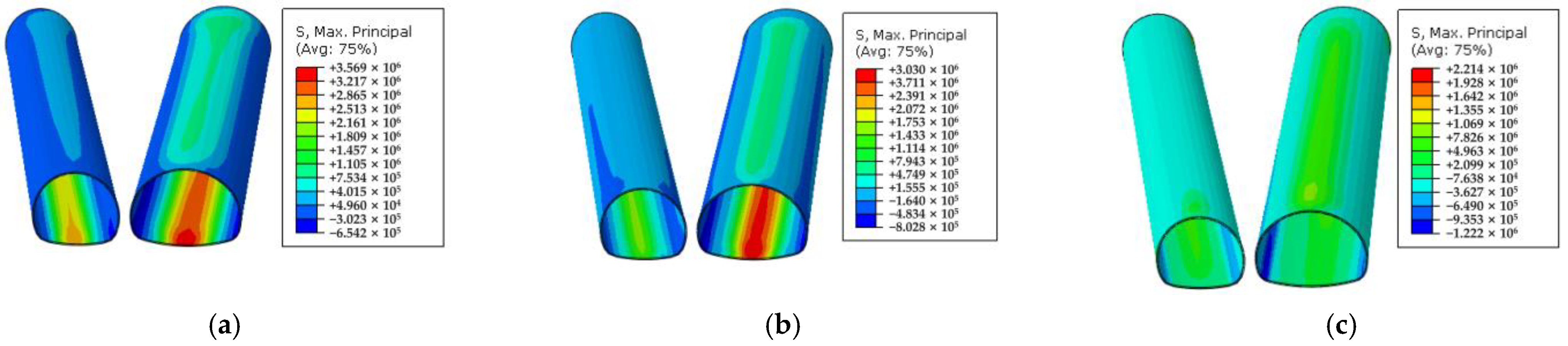

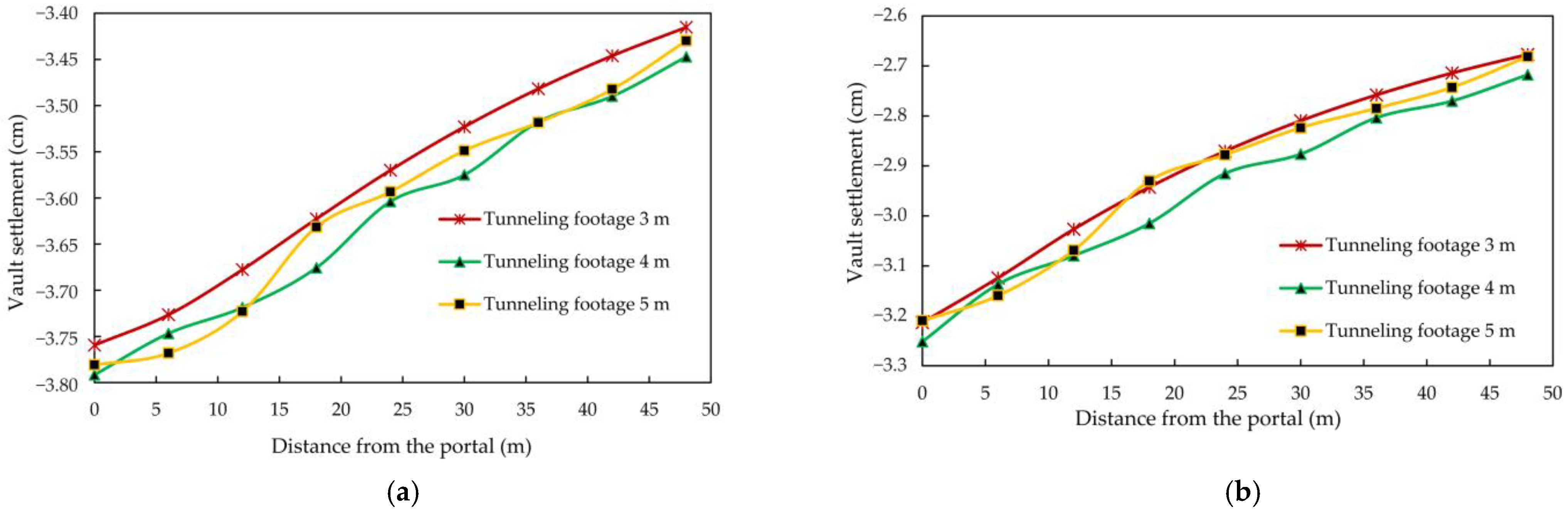

4.3.1. Deformation Analysis of the Surrounding Rocks and Lining

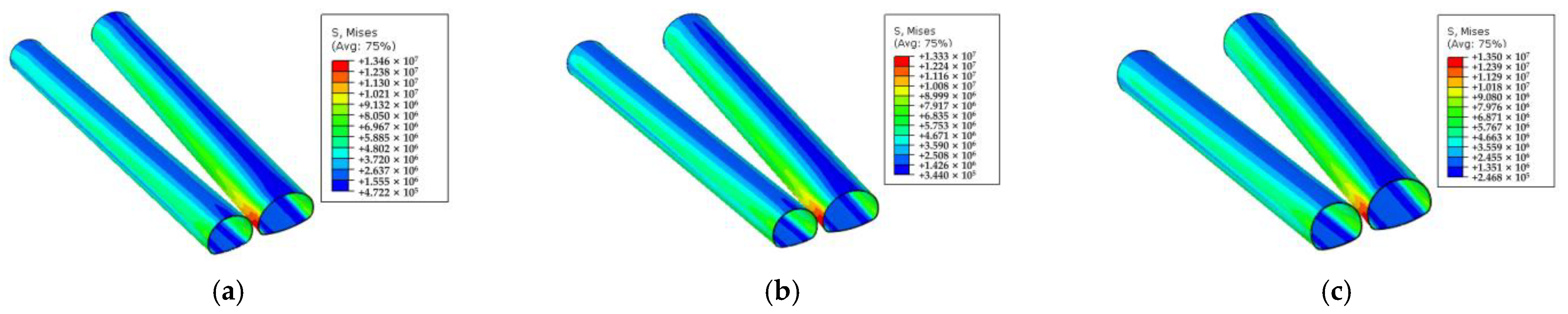

4.3.2. Stress Analysis of the Supporting Structure

5. Conclusions

- (1)

- For an urban super large and complex underground interchange hub, main line, and ramps were all constructed underground. Complex adjacent tunnels form complex small clear-distance tunnels whose construction mechanical behaviour of the small clear-distance tunnels was vital for the underground engineering system.

- (2)

- When the CD method was used for the excavation of the small clear-distance tunnel, the vertical displacement of the main line and ramp tunnel vaults was the smallest. The double wall heading method could effectively control the horizontal displacement of the tunnel arch waist. The overall stress state of the tunnel lining in the CD and double sidewall pilot pit methods was reasonable, whereas the tunnel lining in the full section and step methods had a large range of tensile stress.

- (3)

- In the CD method, the vertical displacement of the main line and ramp tunnel vault of the small clear-distance tunnel was the smallest. The double wall heading method could effectively control the horizontal displacement of the tunnel hance. The overall stress of the tunnel lining in the CD and double wall heading methods was reasonable, but a large range of tensile stress in the tunnel lining was observed in the full section and step methods.

- (4)

- The vertical displacement of the surface, main line tunnel vault, and ramp vault increased with the increase in the elastic modulus of the rock mass. In the rock mass with grades III and IV, the horizontal displacement of the main line tunnel hance was smaller than that of the ramp, and the area from the hance to the arch foot was prone to large deformation when no temporary support was available in the grade V rock mass.

- (5)

- Compared with the excavation scheme and lithology grade, the excavation footage length of the small clear-distance tunnel had less influence on the surrounding rock deformation and lining stress/deformation.

- (6)

- Reducing the tunnel excavation footage was conducive to reducing the deformation of the vault and hance. Therefore, when the geological conditions are good, a large footage can be selected for rapid excavation. Meanwhile, when crossing special sections, the footage should be reduced to control deformation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, Q.; Song, S.G.; Li, T.; Wang, K.; Gu, R.H. Study on Surrounding Rock Stability of Small Clear-Distance Twin Highway Tunnel with Eight Lanes. Geotech. Geol. Eng. 2019, 37, 593–598. [Google Scholar] [CrossRef]

- Gong, J.W.; Xia, C.C.; Lei, X.W. Analysis of filed measurement and theoretical calculation on rock pressure in shallow buried twin tunnels with small spacing. Chin. J. Rock Mech. Eng. 2010, 29 (Suppl. 2), 4139–4145. [Google Scholar]

- Zhang, W.G.; Anthony, T.C. Numerical study of pillar stresses and interaction effects for twin rock caverns. Int. J. Numer. Anal. Met. 2014, 39, 193–206. [Google Scholar] [CrossRef]

- Yamaguchi, I.; Yamazaki, I.; Kiritani, Y. Study of ground tunnel interactions of four shield tunnels driven in close proximity, in relation to design and construction of parallel shield tunnels. Tunn. Undergr. Space Technol. 1998, 13, 289–304. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhao, M.H.; Zhang, R.; Zhao, H.; Peng, W.Z. Stability of a circular tunnel in cohesive-frictional soil subjected to surcharge loading. Comput. Geotech. 2019, 38, 504–514. [Google Scholar] [CrossRef]

- Sahoo, J.P.; Kumar, J. Stability of long unsupported twin circular tunnels in soils. Tunn. Undergr. Space Technol. 2013, 38, 326–335. [Google Scholar] [CrossRef]

- Fu, J.; Yang, J.; Yan, L.; Abbas, S.M. An analytical solution for deforming twin-parallel tunnels in an elastic half plane. Int. J. Numer. Anal. Met. 2014, 39, 524–538. [Google Scholar] [CrossRef]

- Kooi, C.B.; Verruijt, A. Interaction of circular holes in an infinite elastic medium. Tunn. Undergr. Space Technol. 2001, 16, 59–62. [Google Scholar] [CrossRef]

- Yan, L.; Yang, J.S.; Liu, B.C. Stress and displacement of surrounding rock with shallow-twin-parallel tunnels. Chin. J. Geotech. Eng. 2011, 33, 413–419. [Google Scholar]

- Li, G.J.; Qu, Y.; Lu, G.S.; Liu, J.S. Surrounding Rock Pressure of Tunnel with Small Clear Distance under Complex Unsymmetrical Loading: Calculation and Parameter Impacts. J. Yangtze River Sci. Res. Inst. 2020, 37, 133–138. [Google Scholar] [CrossRef]

- Sun, Z.Y.; Zhang, D.L.; Fang, Q.; Su, W. Distribution of Surrounding Rock Pressure of Shallow Highway Tunnels with Small Spacing. China J. Highw. Transp. 2018, 31, 84–94. [Google Scholar] [CrossRef]

- Lei, M.; Lin, D.; Yang, W.; Shi, C.; Peng, L.; Huang, J. Model test to investigate failure mechanism and loading characteristics of shallow-bias tunnels with small clear distance. J. Cent. South. Univ. 2016, 23, 3312–3321. [Google Scholar] [CrossRef]

- Jiang, X.L.; Wang, F.F.; Yang, H.; Lian, P.Y.; Niu, J.Y. Study on Seismic Lining Strain Law of Shallow-buried Bias Tunnel with Small Clear Distance. Chin. J. Undergr. Space Eng. 2017, 13, 506–516. [Google Scholar]

- Kuriyama, H.; Koga, T.; Ogata, T. The design and construction of pillar reinforcement at horizontal twin tunnels. J. Tunn. Eng. JSCE 2011, 10, 125–130. [Google Scholar]

- Ng, C.W.; Lee, K.M.; Tang, D. Three-dimensional numerical investigations of new Austrian tunnelling method (NATM) twin tunnel interactions. Can. Geotech. J. 2004, 41, 523–539. [Google Scholar] [CrossRef]

- Yao, Y.; He, C. Analysis of blasting vibration response of parallel set small clear-distance tunnels and blasting control measures. Rock Soil Mech. 2008, 30, 2815–2822. [Google Scholar] [CrossRef]

- Xu, Q.E.; Xu, W.M.; Li, P.S.; Liu, Y. A Hybrid Construction Method for Shallow Buried Urban Tunnel with Ultra-Small Clear Distance. IOP Conf. Ser. Mater. Sci. Eng. 2020, 960, 032007. [Google Scholar] [CrossRef]

- Yu, L.Y.; Li, S.C.; Guo, X.H.; Shi, S.B. Study of Stability of Transition Segment for Fork Tunnel. China J. Highw. Transp. 2011, 24, 89. [Google Scholar] [CrossRef]

- Zhao, Y.D.; Liu, S.H.; Yang, J.S.; Fu, J.Y.; Yang, A.M.; Liu, W. Interaction mechanisms and control measures of shallow-buried shield tunnels with small clear distance. J. Beijing Jiaotong Univ. 2020, 44, 120–128. [Google Scholar] [CrossRef]

- Hage Chehade, F.; Shahrour, I. Numerical analysis of the interaction between twin tunnels: Influence of the relative position and construction procedure. Tunn. Undergr. Space Technol. 2008, 23, 210–214. [Google Scholar] [CrossRef]

- Fang, Q.; Tai, Q.M.; Zhang, D.L.; Louis, N.Y.W. Ground surface settlements due to construction of closely-spaced twin tunnels with different geometric arrangements. Tunn. Undergr. Space Technol. 2016, 51, 144–151. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Fu, X.K.; Liu, H.L.; Zheng, Y.Y. Study on the reasonable excavation sequence of shallow-embedded bias tunnels with small clear distance. J. Rail Way Sci. Eng. 2013, 10, 57–63. [Google Scholar] [CrossRef]

- Li, S.B.; Zhang, Y.G.; Cao, M.Y.; Wang, Z.N. Study on Excavation Sequence of Pilot Tunnels for a Rectangular Tunnel Using Numerical Simulation and Field Monitoring Method. Rock Mech. Rock Eng. 2022, 55, 3507–3523. [Google Scholar] [CrossRef]

- Naseem, A.; Schotte, K.; De, P.B.; De, B.H. Ground settlements due to construction of triplet tunnels with different construction arrangements. Adv. Civ. Eng. 2019, 2019, 8637837. [Google Scholar] [CrossRef]

- Deng, X.W.; Fu, H.L.; Wang, H.T.; Peng, W.X. Analysis and comparison of disturbance effect of shallow buried excavation tunnel construction method. Electron. J. Geotech. Eng. 2019, 24, 225–236. [Google Scholar]

- Yong, Z.; He, H.W.; Li, P.F. Key Techniques for the Construction of High-Speed Railway Large-Section Loess Tunnels. Engineering 2018, 4, 254–259. [Google Scholar] [CrossRef]

- Wang, H.N.; Utili, S.; Jiang, M.J. An analytical approach for the sequential excavation of axisymmetric lined tunnels in viscoelastic rock. Int. J. Rock Mech. Min. Sci. 2014, 68, 85–106. [Google Scholar] [CrossRef]

- Daraei, A.; Zare, S.; Ghorbani, M. A new multi-graph approach for selecting the sequential excavation method of civil tunnels. Tunn. Undergr. Space Technol. 2019, 91, 102999. [Google Scholar] [CrossRef]

- Liu, C.; Li, S.C.; Zhou, Z.Q.; Li, L.P.; Wang, K.; Hou, F.J.; Qin, C.S.; Gao, C.L. Model test on mechanical characteristics of surrounding rock during construction process of super-large section tunnel in complex strata. Rock Soil Mech. 2018, 39, 3495. [Google Scholar] [CrossRef]

- Zhou, Z.; Tan, Z.; Zhao, J.; Liang, H. Development and Research on the Vertical Center Diaphragm Method Applied in Shallow Tunnel Construction. Symmetry 2020, 12, 855. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, W.J.; Cai, Y.Q.; Xu, B.; Fu, Y.; Wei, G. Analysis of ground surface settlement induced by the construction of a large-diameter shallow-buried twin-tunnel in soft ground. Tunn. Undergr. Space. Technol. 2019, 83, 520–532. [Google Scholar] [CrossRef]

- Jin, A.B.; Li, L.F.; Deng, F.G.; Zhang, M.Z. Study on the Method of Construction of Large Section Tunnel Crossing the Ancient Great Wall. Appl. Mech. Mater. 2012, 226–228, 1504–1508. [Google Scholar] [CrossRef]

- Xu, P.; Yang, X.Z.; Li, Y.S.; Zou, X.S. Study on Adaptability of Double Side Drift Method in Construction of Large-section Tunnels in Accumulation Strata. Mod. Tunn. Technol. 2022, 59 (Suppl. 1), 803–810. [Google Scholar] [CrossRef]

- Industrial Standard of the People’s Republic of China. Specifications for Design of Highway Tunnels Section 1 Civil Engineering: JTG 3370. 1-2018; China Communications Press: Beijing, China, 2018. [Google Scholar]

- Wu, M.J.; Huang, L.H. Research on Dynamic Construction Mechanics of four-Lane Highway Tunnel. Chin. J. Rock Mech. Eng. 2006, 2006 (Suppl. 1), 3057–3062. [Google Scholar]

- Sun, Z.J. Numerical Analysis of Construction Method in Shallow-Buried Large-Section Loess Tunnel. Adv. Civ. Ind. Eng. IV 2014, 580–583, 997–1000. [Google Scholar] [CrossRef]

- Wang, C.H.; Zhang, A.J.; Fan, X.F.; Li, Y.P.; Niu, J.P.; Zeng, Z.N.; Sun, G.T. Study of Numerical Test on Surrounding Rock of Super Large Section Tunnel under Excavation by Bench Cut Method and CRD Method. Highway 2018, 63, 313–317. [Google Scholar]

- Cai, J.; Ye, H.W.; Lei, T.; He, H.J. Optimization of tunnel excavation footage in jointed rock mass considering dilatancy angle. Rock Soil Mech. 2016, 37 (Suppl. 1), 639–644. [Google Scholar] [CrossRef]

| Name of the Supporting | Support Method | |

|---|---|---|

| Main tunnel | ||

| Primary lining support | Concrete spraying layer | C25 shotcrete 20 cm |

| Rock bolt | Φ22 mortar bolt L300 cm | |

| Reinforcing mesh | Φ8 reinforcing mesh 25 cm × 25 cm | |

| Temporary support | I-steel truss | I18 I steel frame, longitudinal spacing 50 cm |

| Concrete spray layer | C25 concrete spray layer 22 cm | |

| Reinforcing mesh | Φ8 reinforcing mesh 20 cm × 20 cm | |

| Secondary lining support | Arch wall | C30 Waterproof reinforced concrete 40 cm thick |

| Inverted arch | C30 Waterproof reinforced concrete 40 cm thick | |

| Ramp section | ||

| Primary lining support | Concrete spraying layer | C25 shotcrete 20 cm |

| Rock bolt | Φ22 mortar bolt L2500 cm | |

| Reinforcing mesh | Φ8 reinforcing mesh 25 cm × 25 cm | |

| Temporary support | I-steel truss | I18 I steel frame, longitudinal spacing 50 cm |

| Concrete spray layer | C25 concrete spray layer 22 cm | |

| Reinforcing mesh | Φ8 reinforcing mesh 20 cm × 20 cm | |

| Secondary lining support | Arch wall | C30 Waterproof reinforced concrete 40 cm thick |

| Inverted arch | C30 Waterproof reinforced concrete 40 cm thick | |

| Materials | Density (kg/m3) | Elastic Modulus (GPa) | Poisson’s Ratio | Cohesion (MPa) | Friction Angle (°) |

|---|---|---|---|---|---|

| Surrounding rock | 2200–2300 | 6–10 | 0.25–0.3 | 2.0 | 39–50 |

| Primary lining support | 2500 | 30 | 0.20 | / | / |

| Secondary lining support | 2500 | 32.5 | 0.15 | / | / |

| Temporary support | 7900 | 200 | 0.30 | / | / |

| Materials | Density (kg/m3) | Elastic Modulus (GPa) | Poisson’s Ratio | Cohesion (MPa) | Friction Angle (°) |

|---|---|---|---|---|---|

| Grade III rock mass | 2200 | 6 | 0.25 | 2.1 | 50 |

| Grade IV rock mass | 1900 | 3 | 0.30 | 1.4 | 30 |

| Grade V rock mass | 1600 | 1.5 | 0.35 | 0.7 | 10 |

| Lithologic Grades | Ground Settlement (cm) | Displacement of Main Tunnel Vault (cm) | Ramp Vault Displacement (cm) | Mean Difference between Surface and Vault Settlement (cm) | Ground Settlement/Vault Displacement |

|---|---|---|---|---|---|

| III | 1.71 | 5.62 | 4.71 | +3.45 | 8.28% |

| IV | 2.70 | 8.85 | 7.36 | +5.41 | 8.31% |

| V | 4.73 | 14.66 | 12.54 | +8.87 | 8.69% |

| Excavation Effect | Excavation Methods | Lithology Grades | Footage Lengths (m) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Full-Section Method | Step Method | CD Method | Double Wall Heading Method | III | IV | V | 3 | 4 | 5 | |

| Displacement | (1) The influence range of vertical displacement of surrounding rock above the ramp from small to large was the full section, CD, double wall heading and step method. (2) In step and full section methods, the horizontal displacement range of surrounding rock around the tunnel was large. (3) In the CD and double wall heading methods, the overall horizontal displacement was relatively average. (4) In the CD method and double wall heading methods, the overall horizontal displacement of the lining structure was mainly concentrated on the temporary structural deformation. (5) The double wall heading method could maintain the integrity of the primary lining displacement, and the horizontal displacement of the primary lining at the hance was small. | The worse the rock mass quality was and the lower the grade was, the greater the displacement was. | The displacement of the vault at the section with footage of 3 m was smaller than that with footage of 4 and 5 m. | |||||||

| Stress | The overall stress of the lining was reasonable in the CD and double wall heading methods, but a large range of tensile stress was observed in the full section and step methods. | (1) The peak tensile stress of grade III was the largest, followed by grade IV and grade V. (2) The peak compressive stress of grade III was the smallest, and that of grade V was the largest. | The stress of the 4 m footage was the least, followed by that of the 5 m footage. The stress of the 3 m footage was the largest. | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Cao, A.; Li, Z.; Wu, Z.; Lin, L.; Liu, X.; Li, H.; Sun, Y. Mechanical Behavior and Excavation Optimization of a Small Clear-Distance Tunnel in an Urban Super Large and Complex Underground Interchange Hub. Appl. Sci. 2023, 13, 254. https://doi.org/10.3390/app13010254

Wang J, Cao A, Li Z, Wu Z, Lin L, Liu X, Li H, Sun Y. Mechanical Behavior and Excavation Optimization of a Small Clear-Distance Tunnel in an Urban Super Large and Complex Underground Interchange Hub. Applied Sciences. 2023; 13(1):254. https://doi.org/10.3390/app13010254

Chicago/Turabian StyleWang, Jianxiu, Ansheng Cao, Zonghai Li, Zhao Wu, Lihua Lin, Xiaotian Liu, Huboqiang Li, and Yuanwei Sun. 2023. "Mechanical Behavior and Excavation Optimization of a Small Clear-Distance Tunnel in an Urban Super Large and Complex Underground Interchange Hub" Applied Sciences 13, no. 1: 254. https://doi.org/10.3390/app13010254

APA StyleWang, J., Cao, A., Li, Z., Wu, Z., Lin, L., Liu, X., Li, H., & Sun, Y. (2023). Mechanical Behavior and Excavation Optimization of a Small Clear-Distance Tunnel in an Urban Super Large and Complex Underground Interchange Hub. Applied Sciences, 13(1), 254. https://doi.org/10.3390/app13010254