Review of the Research on Soil Disturbance by Tools

Abstract

1. Introduction

2. Theoretical Analysis

2.1. Contact Model of Soil Particles

2.2. Research on the Bonds between Soil Particles

2.3. Energy Dissipation Analysis

3. Simulation Analysis

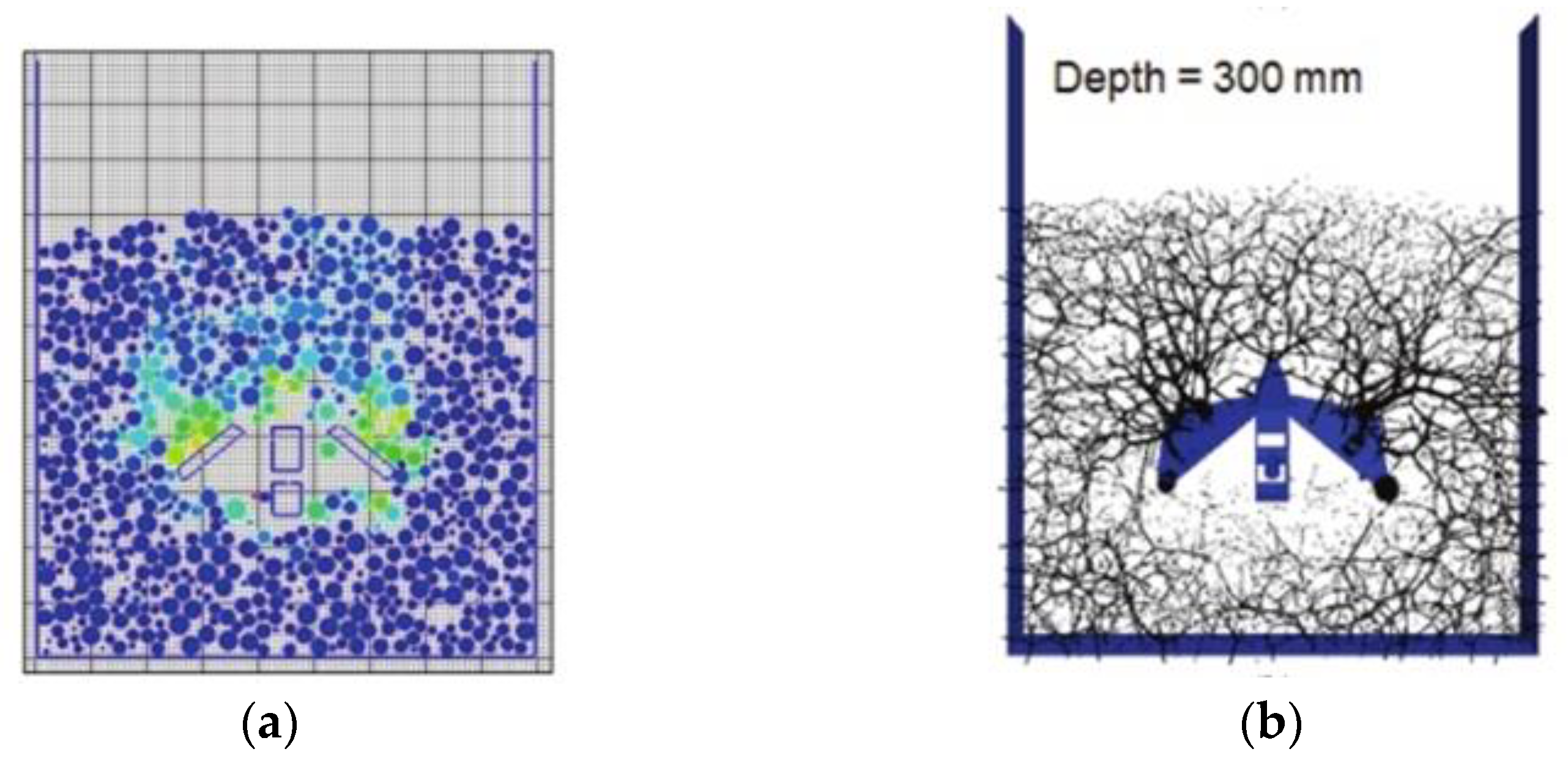

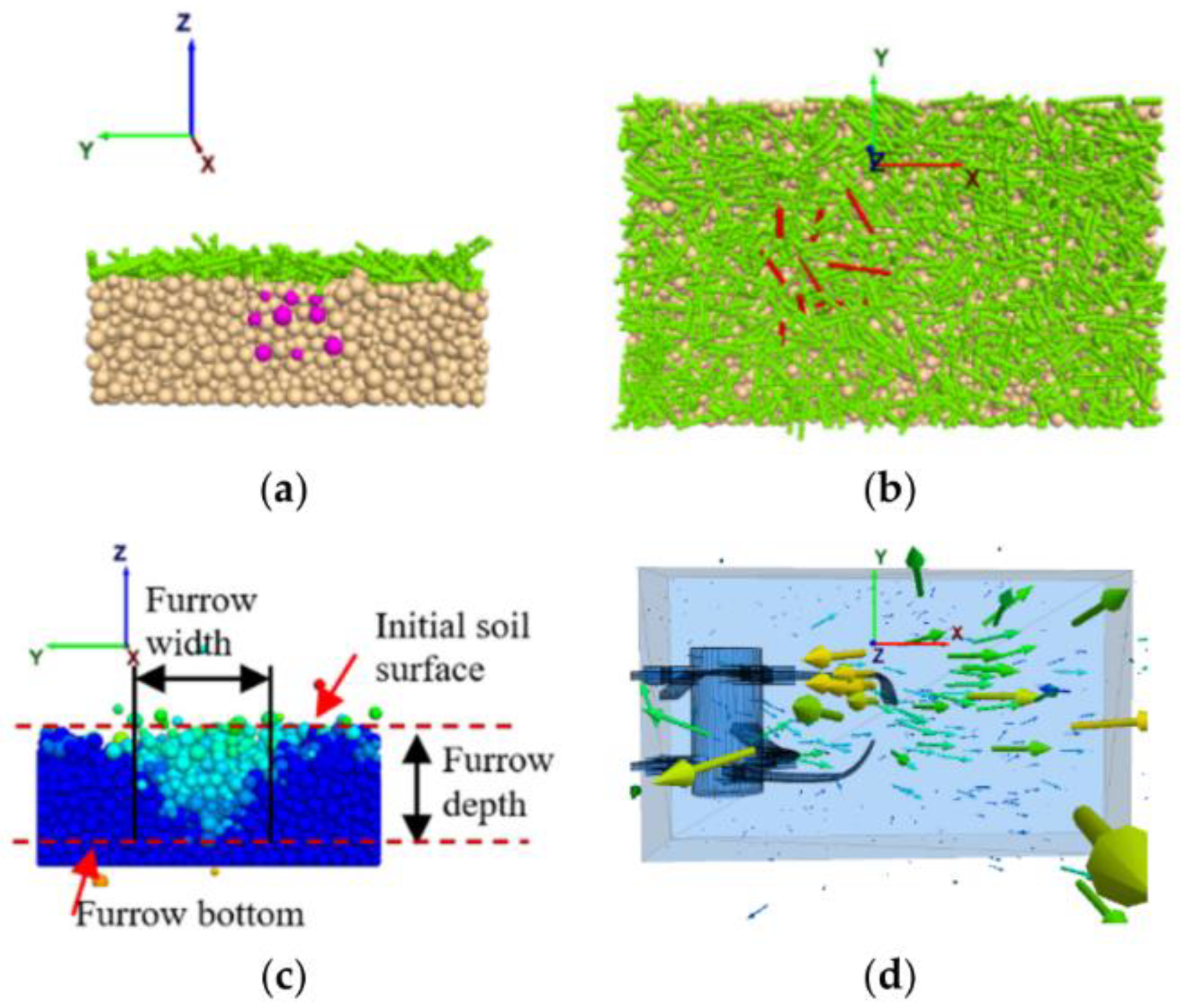

3.1. Movement Trajectories of Soil Particles

3.2. Analysis of Velocity Field

3.3. Soil Throwing and Accumulation

3.4. Disturbance Profile of Soil

3.5. Mixing of Soil Layers

3.6. Resistance Analysis

4. Test Analysis

4.1. Research on Disturbance Profile and Size of Soil

4.2. Analysis of the Influence of Implements on Soil and Residue Mixing

4.3. Soil Accumulation and Throwing

4.4. Analysis of Soil Disturbance Proportion

4.5. Traction Resistance

5. Discussion

5.1. Advantages of Current Research in This Field

5.2. Limitations of This Study

5.3. Prospects

- (1)

- The soil compaction degree before and after disturbance cannot be displayed and compared intuitively through simulation. Currently, the number of particles in the fixed area is used to represent the degree of compaction. The degree of compaction can reflect the compaction or loosening of the soil after the action of the tools. Condition is an important indicator to characterize the effect of tools. In the future, if a function that can intuitively represent particle compaction contours can be developed, soil disturbance analysis will be more intuitive and convenient.

- (2)

- The current measurement of the disturbance profile is based on a self-made profiler and requires hand-painting or image processing to obtain the soil profile after the measurement. The procedure is relatively complicated. It is good if it can be directly drawn into a map and stored in the field, which will make the field disturbance profile measurement more convenient and accurate.

- (3)

- At present, the soil mixing is mainly based on simulation analysis. In the test, the tracer is used as the tracking marker, but this is mainly to study the movement law of a small number of particles. Soil dyeing and other operations on the operation area in the flume test can more intuitively analyze the mixing of soil particles in different soil layers. This is convenient for comparative analysis of errors between simulation and experiment, so as to better verify the accuracy of simulation and soil movement trend.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ucgul, M.; Saunders, C.; Fielke, J.M. Comparison of the discrete element and finite element methods to model the interaction of soil and tool cutting edge. Biosyst. Eng. 2018, 169, 199–208. [Google Scholar] [CrossRef]

- Lysych, M.N.; IOP. Review of numerical methods for modeling the interaction of soil environments with the tools of soil tillage machines. In Proceedings of the International Scientific Conference on Applied Physics, Information Technologies and Engineering (APITECH)/2nd International Scientific and Practical Conference on Borisov’s Readings, Krasnoyarsk, Russia, 25–27 September 2019. [Google Scholar]

- Barr, J.B.; Ucgul, M.; Desbiolles, J.M.; Fielke, J.M. Simulating the effect of rake angle on narrow opener performance with the discrete element method. Biosyst. Eng. 2018, 171, 1–15. [Google Scholar] [CrossRef]

- Barr, J.B.; Desbiolles, J.M.A.; Fielke, J.M. Minimising soil disturbance and reaction forces for highspeed sowing using bentleg furrow openers. Biosyst. Eng. 2016, 151, 53–64. [Google Scholar] [CrossRef]

- Zeng, Z.; Chen, Y.; Zhang, X. Modelling the interaction of a deep tillage tool with heterogeneous soil. Comput. Electron. Agric. 2017, 143, 130–138. [Google Scholar] [CrossRef]

- Wang, Y.; Xue, W.; Ma, Y.; Tong, J.; Liu, X.; Sun, J. DEM and soil bin study on a biomimetic disc furrow opener. Comput. Electron. Agric. 2019, 156, 209–216. [Google Scholar] [CrossRef]

- Sun, J.Y.; Wang, Y.M.; Ma, Y.H.; Tong, J.; Zhang, Z.J. DEM simulation of bionic subsoilers (tillage depth >40 cm) with drag reduction and lower soil disturbance characteristics. Adv. Eng. Softw. 2018, 119, 30–37. [Google Scholar] [CrossRef]

- Li, J.; Jiang, X.; Ma, Y.; Tong, J.; Hu, B. Bionic Design of a Potato Digging Shovel with Drag Reduction Based on the Discrete Element Method (DEM) in Clay Soil. Appl. Sci. 2020, 10, 7096. [Google Scholar] [CrossRef]

- Sun, J.; Chen, H.; Wang, Z. Study on plowing performance of EDEM low-resistance animal bionic device based on red soil. Soil Tillage Res. 2020, 196, 104336. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, X.; Liu, D. Calibration of discrete element parameters and experimental verification for modelling subsurface soils. Biosyst. Eng. 2021, 212, 215–227. [Google Scholar] [CrossRef]

- Yang, Y.; Wen, B.; Ding, L.; Li, L.; Chen, X.; Li, J. Soil Particle Modeling and Parameter Calibration for Use with Discrete Element Method. Trans. Asabe 2021, 64, 2011–2023. [Google Scholar] [CrossRef]

- Shaikh, S.A.; Li, Y.; Ma, Z. Discrete element method (DEM) simulation of single grouser shoe-soil interaction at varied moisture contents. Comput. Electron. Agric. 2021, 191, 106538. [Google Scholar] [CrossRef]

- Lopez, B.E.; Tijskens, E.; Herrera, S.M.; Gonzalez, C.O.; Ramon, H. Prediction model for non-inversion soil tillage implemented on discrete element method. Comput. Electron. Agric. 2014, 106, 120–127. [Google Scholar]

- Ahmad, F.; Qiu, B.; Ding, Q. Discrete element method simulation of disc type furrow openers in paddy soil. Int. J. Agric. Biol. Eng. 2020, 13, 103–110. [Google Scholar] [CrossRef]

- Saunders, C.; Ucgul, M.; Godwin, R.J. Discrete element method (DEM) simulation to improve performance of a mouldboard skimmer. Soil Tillage Res. 2021, 205, 104764. [Google Scholar] [CrossRef]

- Ajmal, M.; Roessler, T.; Richter, C.; Katterfeld, A. Calibration of cohesive DEM parameters under rapid flow conditions and low consolidation stresses. Powder Technol. 2020, 374, 22–32. [Google Scholar] [CrossRef]

- Zeng, Z.; Ma, X.; Chen, Y.; Qi, L. Modelling residue incorporation of selected chisel ploughing tools using the discrete element method (DEM). Soil Tillage Res. 2020, 197, 104505. [Google Scholar] [CrossRef]

- Zhao, H.; Li, H.; Ma, S. The effect of various edge-curve types of plain-straight blades for strip tillage seeding on torque and soil disturbance using DEM. Soil Tillage Res. 2020, 202, 104674. [Google Scholar] [CrossRef]

- Shi, Z.; Yu, Z.; Yang, L.; Yang, M. On Simulation and experiment of Soil Disturbance Cause by Airfoil Subsoil Shovel Spacing. J. Southwest Norm. Univ. 2021, 46, 38–44. [Google Scholar]

- Zhao, S.; Gao, L.; Yuan, Y.; Hou, L.; Zhang, X.; Yang, Y. Maize straw motion law in subsoiling operation using discrete element method. Trans. Chin. Soc. Agric. Eng. 2021, 37, 53–62. [Google Scholar]

- Zeng, R.; Lin, Y.; Wan, Z.; Tu, M.; Jiao, J.; Zhang, G. An Investigation of Pull-Out Force of Semi-Buried Lotus Roots after Hydraulic Scouring. Agriculture 2021, 11, 706. [Google Scholar] [CrossRef]

- Li, B.; Chen, Y.; Chen, J. Comparison of Two Subsoiler Designs Using the Discrete Element Method (DEM). Trans. Asabe 2018, 61, 1529–1537. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, H.; Yang, C.; Yang, L.; Gao, L.; Yang, Y. Design and Discrete Element Simulation of Interactive Layered Subsoiler with Maize Straw Returned to Filed. Trans. Chin. Soc. Agric. Mach. 2021, 52, 75–87. [Google Scholar]

- Hoseinian, S.H.; Hemmat, A.; Esehaghbeygi, A.; Shahgoli, G.; Baghbanan, A. Development of a dual sideway-share subsurface tillage implement: Part 2. Effect of tool geometry on tillage forces and soil disturbance characteristics. Soil Tillage Res. 2022, 215, 105200. [Google Scholar] [CrossRef]

- Zhang, R.; Ji, Q.; Zhang, S.; Liu, F.; Li, J. Effect of Wheel Surface Curvature Radius on Sinkage Performance of Sand Rigid Wheel. Trans. Chin. Soc. Agric. Mach. 2016, 47, 341–349. [Google Scholar]

- Qi, L.; Chen, Y.; Sadek, M. Simulations of soil flow properties using the discrete element method (DEM). Comput. Electron. Agric. 2019, 157, 254–260. [Google Scholar] [CrossRef]

- Tamas, K. The role of bond and damping in the discrete element model of soil-sweep interaction. Biosyst. Eng. 2018, 169, 57–70. [Google Scholar] [CrossRef]

- Zhang, R.; Li, J.; Zhou, C.; Xu, S. Simulation of dynamic behavior of soil ahead of the bulldozing plates with different surface configurations by discrete element method. Trans. Chin. Soc. Agric. Eng. 2007, 23, 13–19. [Google Scholar]

- Li, Y.; Wu, T.; Lin, J.; Xu, Y. Influence of penetrating cone on motion characteristics of sandy soil particle using discrete element method. Trans. Chin. Soc. Agric. Eng. 2012, 28, 55–61. [Google Scholar]

- Zeng, Z.; Chen, Y. Simulation of straw movement by discrete element modelling of straw-sweep-soil interaction. Biosyst. Eng. 2019, 180, 25–35. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, J.; Chen, J.; Yang, Y.; Tan, H. Design and Experiment of Fitting Curve Subsoiler of Conservation Tillage. Trans. Chin. Soc. Agric. Mach. 2018, 49, 82–92. [Google Scholar]

- Zhao, S.; Liu, H.; Hou, L.; Zhang, X.; Yuan, Y.; Yang, Y. Development of deep fertilizing no-tillage segmented maize sowing opener using discrete element method. Trans. Chin. Soc. Agric. Eng. 2021, 37, 1–10. [Google Scholar]

- Bo, L.; Rui, X.; Liu, F.; Jun, C.; Han, W.; Bing, H. Determination of the draft force for different subsoiler points using discrete element method. Int. J. Agric. Biol. Eng. 2016, 9, 81–87. [Google Scholar]

- Gu, X.; Chen, Y.; Huang, M. Critical state shear behavior of the soil-structure interface determined by discrete element modeling. Particuology 2017, 35, 68–77. [Google Scholar] [CrossRef]

- Tamas, K.; Jori, I.J.; Mouazen, A.M. Modelling soil-sweep interaction with discrete element method. Soil Tillage Res. 2013, 134, 223–231. [Google Scholar] [CrossRef]

- Zhao, H.; Huang, Y.; Liu, Z.; Liu, W.; Zheng, Z. Applications of Discrete Element Method in the Research of Agricultural Machinery: A Review. Agriculture 2021, 11, 425. [Google Scholar] [CrossRef]

- Zeng, H.; Xu, W.; Zang, M.; Yang, P.; Guo, X. Calibration and validation of DEM-FEM model parameters using upscaled particles based on physical experiments and simulations. Adv. Powder Technol. 2020, 31, 3947–3959. [Google Scholar] [CrossRef]

- Ibrahim, A.N.; Sabarudin, S.S.; Fukuoka, Y. Effects of Wheel Grouser Angle of Attack on Simulated Robot Wheel Performance on Soft Sand with High Slip Condition. In Proceedings of the 4th IEEE International Conference on Advanced Robotics and Mechatronics (ICARM), Osaka, Japan, 3–5 July 2019. [Google Scholar]

- Han, D.; Zhang, R.; Zhang, H.; Hu, Z.; Li, J. Mechanical Performances of Typical Robot Feet Intruding into Sands. Energies 2020, 13, 1867. [Google Scholar] [CrossRef]

- Zeng, Z.W.; Chen, Y.; Qi, L. Simulation of cotyledon-soil dynamics using the discrete element method (DEM). Comput. Electron. Agric. 2020, 174, 105505. [Google Scholar] [CrossRef]

- Tian, L.; Cao, C.; Qin, K.; Fang, L.; Ge, J. Design and test of post-seat weeding machine for paddy. Int. J. Agric. Biol. Eng. 2021, 14, 112–122. [Google Scholar] [CrossRef]

- Aikins, K.A.; Barr, J.B.; Antille, D.L.; Ucgul, M.; Jensen, T.A.; Desbiolles, J.M.A. Analysis of effect of bentleg opener geometry on performance in cohesive soil using the discrete element method. Biosyst. Eng. 2021, 209, 106–124. [Google Scholar] [CrossRef]

- Zhao, H.; Jin, H.E.; Li, H.; Liu, C.; Zheng, K.; Zhang, Z. Design and Experiment of Strip Rotary-cut-throw Anti-blocking Implement. Trans. Chin. Soc. Agric. Mach. 2018, 49, 65–75. [Google Scholar]

- Han, D.; Zhang, R.; Cao, Q.; Jiang, L.; Li, J. Research in mechanical model of bionic foot intruding into sands with different physical characteristics. J. Terramechanics 2021, 98, 25–33. [Google Scholar] [CrossRef]

- Li, B.; Chen, Y.; Chen, J. Modeling of soil-claw interaction using the discrete element method (DEM). Soil Tillage Res. 2016, 158, 177–185. [Google Scholar] [CrossRef]

- Tekeste, M.Z.; Balvanz, L.R.; Hatfield, J.L.; Ghorbani, S. Discrete element modeling of cultivator sweep-to-soil interaction: Worn and hardened edges effects on soil-tool forces and soil flow. J. Terramechanics 2019, 82, 1–11. [Google Scholar] [CrossRef]

- Murray, S.E.; Chen, Y. Discrete Element Modeling of Soil Displacement Resulting from Hoe Openers. Trans. Asabe 2019, 62, 253–262. [Google Scholar] [CrossRef]

- Tsuji, T.; Matsui, Y.; Nakagawa, Y.; Kadono, Y.; Tanaka, T. DEM Study on the Interaction between Wet Cohesive Granular Materials and Tools. In Proceedings of the 7th International Conference on Micromechanics of Granular Media (Powders and Grains), Sydney, Australia, 8–12 July 2013. [Google Scholar]

- Ucgul, M.; Saunders, C.; Fielke, J.M. Discrete element modelling of top soil burial using a full scale mouldboard plough under field conditions. Biosyst. Eng. 2017, 160, 140–153. [Google Scholar] [CrossRef]

- Ucgul, M.; Fielke, J.M.; Saunders, C. 3D DEM tillage simulation: Validation of a hysteretic spring (plastic) contact model for a sweep tool operating in a cohesionless soil. Soil Tillage Res. 2014, 144, 220–227. [Google Scholar] [CrossRef]

- Xu, L.; Feng, T.; Song, Y.; Li, F.; Song, Z. Research on Drag Reduction Mechanism of Bionic Rib Subsoiling Shovel Based on Discrete Element Method. In Proceedings of the 3rd International Workshop on Renewable Energy and Development (IWRED), Guangzhou, China, 8–10 March 2019. [Google Scholar]

- Huang, Y.; Gao, P.; Zhang, Q.; Shen, H.; Zhu, R.; Shi, J. Design and Experiment of Grass-Soil Separation Device with Combination of Stubble Cutting and Grass Guiding Used for No-till Planter. Trans. Chin. Soc. Agric. Mach. 2020, 51, 67–78. [Google Scholar]

- Solhjou, A.; Desbiolles, J.M.A.; Fielke, J.M. Soil translocation by narrow openers with various blade face geometries. Biosyst. Eng. 2013, 114, 259–266. [Google Scholar] [CrossRef]

- Hoseinian, S.H.; Hemmat, A.; Esehaghbeygi, A.; Shahgoli, G.; Baghbanan, A. Development of a dual sideway-share subsurface tillage implement: Part 1. Modeling tool interaction with soil using DEM. Soil Tillage Res. 2022, 215, 105201. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, D.; Yang, L.; Cui, T.; Jing, H.; Zhong, X. Modeling the interaction of soil and a vibrating subsoiler using the discrete element method. Comput. Electron. Agric. 2020, 174, 105518. [Google Scholar] [CrossRef]

- Chen, Y.; Munkholm, L.J.; Nyord, T. A discrete element model for soil-sweep interaction in three different soils. Soil Tillage Res. 2013, 126, 34–41. [Google Scholar] [CrossRef]

- Zhang, X.; Zeng, W.; Liu, J.; Wu, P.; Dong, X.; Hu, H. Design and Experiment of Iateritic Soil Inclined Handle Folding Wing Subsoiling Shovel Based on Discrete Element Method. Trans. Chin. Soc. Agric. Mach. 2022, 53, 40–49. [Google Scholar]

- Ding, Q.; Li, Y.; Belal, E.A.; Liang, L.; He, R.; Wang, X. Subsoiler-induced Paddy Soil Disturbance and Effects Based on Video-assisted Multi-index Quantification. Trans. Chin. Soc. Agric. Mach. 2019, 50, 44–55. [Google Scholar]

- Du, J.; Heng, Y.; Zheng, K. Investigation of the burial and mixing performance of a rotary tiller using discrete element method. Soil Tillage Res. 2022, 220, 105349. [Google Scholar] [CrossRef]

- Ma, W.; You, Y.; Wang, D.; Hu, J.; Huan, X.; Zhu, L. Design and Experiment of Low-resistance Soil Loosening Shovel for Cutting Roots and Reseeding in Perennial Alfalfa Field. Trans. Chin. Soc. Agric. Mach. 2021, 52, 86–95, 144. [Google Scholar]

- Wang, Y.; Li, N.; Ma, Y.; Tong, J.; Pfleging, W.; Sun, J. Field experiments evaluating a biomimetic shark-inspired (BioS) subsoiler for tillage resistance reduction. Soil Tillage Res. 2020, 196, 104432. [Google Scholar] [CrossRef]

- Yang, Y.; Li, M.; Tong, J.; Ma, Y. Study on the Interaction between Soil and the Five-Claw Combination of a Mole Using the Discrete Element Method. Appl. Bionics Biomech. 2018, 2018, 7854052. [Google Scholar] [CrossRef]

- Zhang, Z.; Gan, S.; Zuo, G.; Tong, J. Bionic Design and Performance Experiment of Sandfish Head Inspired Subsoiler Tine. Trans. Chin. Soc. Agric. Mach. 2021, 52, 33–42. [Google Scholar]

- Fan, Y. Research on potato digging mechanism based on discrete element method and design of bionic shove. Shenyang Agric. Univ. 2020. [Google Scholar] [CrossRef]

- Barbosa, L.A.P. Modelling the aggregate structure of a bulk soil to quantify fragmentation properties and energy demand of soil tillage tools in the formation of seedbeds. Biosyst. Eng. 2020, 197, 203–215. [Google Scholar] [CrossRef]

- Hasimu, A.; Chen, Y. Soil disturbance and draft force of selected seed openers. Soil Tillage Res. 2014, 140, 48–54. [Google Scholar] [CrossRef]

- Aikins, K.A.; Barr, J.B.; Ucgul, M.; Jensen, T.A.; Antille, D.L.; Desbiolles, J.M.A. No-tillage furrow opener performance: A review of tool geometry, settings and interactions with soil and crop residue. Soil Res. 2020, 58, 603–621. [Google Scholar] [CrossRef]

- Milkevych, V.; Munkholm, L.J.; Chen, Y.; Nyord, T. Modelling approach for soil displacement in tillage using discrete element method. Soil Tillage Res. 2018, 183, 60–71. [Google Scholar] [CrossRef]

- Barr, J.; Desbiolles, J.; Ucgul, M.; Fielke, J.M. Bentleg furrow opener performance analysis using the discrete element method. Biosyst. Eng. 2020, 189, 99–115. [Google Scholar] [CrossRef]

- Keppler, I.; Hudoba, Z.; Oldal, I.; Csatar, A.; Fenyvesi, L. Discrete element modeling of vibrating tillage tools. Eng. Comput. 2015, 32, 308–328. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, X.; Yi, J.; Kong, D.; Yuan, Y.; Ma, M.; Ma, J.; Zhang, J. Design and research of an integrated operation machine for straw reactor. In Proceedings of the 2020 ASABE Annual International Virtual Meeting, St. Joseph, MI, USA, 13–15 July 2020. [Google Scholar]

- Ucgul, M.; Saunders, C. Simulation of tillage forces and furrow profile during soil-mouldboard plough interaction using discrete element modelling. Biosyst. Eng. 2020, 190, 58–70. [Google Scholar] [CrossRef]

- Aikins, K.A.; Jensen, T.A.; Antille, D.L. Three-dimensional scanning of soil surface and furrow profiles using a portable and affordable unit. Biosyst. Eng. 2020, 193, 279–289. [Google Scholar] [CrossRef]

- Hang, C.; Huang, Y.; Zhu, R. Analysis of the movement behaviour of soil between subsoilers based on the discrete element method. J. Terramechanics 2017, 74, 35–43. [Google Scholar] [CrossRef]

- Huang, Y.; Hang, C.; Yuan, M.; Wang, B.; Zhu, R. Discrete Element Simulation and Experiment on Disturbance Behavior of Subsoiling. Trans. Chin. Soc. Agric. Mach. 2016, 47, 80–88. [Google Scholar]

- Matin, M.A.; Fielke, J.M.; Desbiolles, J.M.A. Furrow parameters in rotary strip-tillage: Effect of blade geometry and rotary speed. Biosyst. Eng. 2014, 118, 7–15. [Google Scholar] [CrossRef]

- Wang, X.; Yue, B.; Gao, X.; Zheng, Z.; Zhu, R.; Huang, Y. Discrete Element Simulations and Experiments of Disturbance Behavior as Affected by Mounting Height of Subsoiler’s Wing. Trans. Chin. Soc. Agric. Mach. 2018, 49, 124–136. [Google Scholar]

- Wang, X.; Zhang, S.; Pan, H.; Zheng, Z.; Huang, Y.; Zhu, R. Effect of soil particle size on soil-subsoiler interactions using the discrete element method simulations. Biosyst. Eng. 2019, 182, 138–150. [Google Scholar] [CrossRef]

- Dong, X.; Su, C.; Zheng, H.; Han, R.; Li, Y.; Wan, L.; Song, J.; Wang, J. Analysis of soil disturbance process by vibrating subsoiling based on DEM-MBD coupling algorithm. Trans. Chin. Soc. Agric. Eng. 2022, 38, 34–43. [Google Scholar]

- Song, W.; Jiang, X.; Li, L.; Ren, L.; Tong, J. Increasing the width of disturbance of plough pan with bionic inspired subsoilers. Soil Tillage Res. 2022, 220, 105356. [Google Scholar] [CrossRef]

- Gursoy, S.; Chen, Y.; Li, B. Measurement and modelling of soil displacement from sweeps with different cutting widths. Biosyst. Eng. 2017, 161, 1–13. [Google Scholar] [CrossRef]

- Zhang, J.H.; Jia, L.Z.; Zhang, Z.H.; Wei, Y.H.; Wang, Y.; Su, Z.A. Effect of the soil-implement contact area on soil translocation under hoeing tillage. Soil Tillage Res. 2018, 183, 42–50. [Google Scholar] [CrossRef]

- Fang, H.M.; Ji, C.Y.; Zhang, Q.Y.; Guo, J. Force analysis of rotary blade based on distinct element method. Trans. CSAE 2016, 32, 54–59. [Google Scholar]

- Li, P.; Ucgul, M.; Lee, S.H.; Saunders, C. A new method to analyse the soil movement during tillage operations using a novel digital image processing algorithm. Comput. Electron. Agric. 2019, 156, 43–50. [Google Scholar] [CrossRef]

- Fang, H.; Ji, C.; Ahmed, A.T.; Zhang, Q.; Guo, J. Simulation Analysis of Straw Movement in Straw-Soil-Rotary Blade System. Trans. Chin. Soc. Agric. Mach. 2016, 47, 60–67. [Google Scholar]

- Wu, J.; Shen, Y.; Yang, S.; Feng, Z. Simulation of Track-Soft Soil Interactions Using a Discrete Element Method. Appl. Sci. 2022, 12, 2524. [Google Scholar] [CrossRef]

- Abdeldayem, M.A.A.; Mabrouk, M.H.; Abo-Elnor, M. Analytical and Numerical Modeling of Soil Cutting and Transportation During Auger Drilling Operation. In Proceedings of the ASME 2019 International Mechanical Engineering Congress and Exposition, Salt Lake City, UT, USA, 11–14 November 2019; Volume 7. [Google Scholar]

- Wang, W.; Zhu, C.; Chen, L.; Li, Z.; Huang, X.; Li, J. Design and experiment of active straw-removing anti-blocking device for maize no-tillage planter. Trans. Chin. Soc. Agric. Eng. 2017, 33, 10–17. [Google Scholar]

- Shi, Y.; Xin, S.; Wang, X.; Hu, Z.; Newman, D.; Ding, W. Numerical simulation and field tests of minimum-tillage planter with straw smashing and strip laying based on EDEM software. Comput. Electron. Agric. 2019, 166, 105021. [Google Scholar] [CrossRef]

- Lysych, M.N. Computer simulation of the process soil treatment by tillage tools of soil processing machines. Comput. Res. Modeling 2020, 12, 607–627. [Google Scholar] [CrossRef]

- Ani, O.A.; Uzoejinwa, B.B.; Ezeama, A.O.; Onwualu, A.P.; Ugwu, S.N.; Ohagwu, C.J. Overview of soil-machine interaction studies in soil bins. Soil Tillage Res. 2018, 175, 13–27. [Google Scholar] [CrossRef]

- Makange, N.R.; Ji, C.; Nyalala, I.; Sunusi, I.I.; Opiyo, S. Prediction of precise subsoiling based on analytical method, discrete element simulation and experimental data from soil bin. Sci. Rep. 2021, 11, 11082. [Google Scholar] [CrossRef]

- Zheng, K.; He, J.; Li, H.; Diao, P.; Wang, Q.; Zhao, H. Research on Polyline Soil breaking Blade Subsoiler Based on Subsoiling Soil Model Using Discrete Element Method. Trans. Chin. Soc. Agric. Mach. 2016, 47, 62–72. [Google Scholar]

- Makange, N.R.; Ji, C.; Torotwa, I. Prediction of cutting forces and soil behavior with discrete element simulation. Comput. Electron. Agric. 2020, 179, 105848. [Google Scholar] [CrossRef]

- Wang, X.; Gao, P.; Yue, B. Optimisation of installation parameters of subsoiler wing using the discrete element method. Comput. Electron. Agric. 2019, 12, 523–530. [Google Scholar] [CrossRef]

- Fang, W.; Wang, X.; Han, D.; Chen, X. Review of Material Parameter Calibration Method. Agriculture 2022, 12, 706. [Google Scholar] [CrossRef]

- Wang, X.; Wei, W.; He, J.; Huang, Y. Effect of soil particle-size distribution (PSD) on soil-subsoiler interactions in the discrete element model. Span. J. Agric. Res. 2021, 19, 205. [Google Scholar] [CrossRef]

- Liu, C.; Pan, L.; Wang, F.; Zhang, Z.; Cui, J.; Liu, H.; Duan, Z.; Ji, X. Three-Dimensional Discrete Element Analysis on Tunnel Face Instability in Cobbles Using Ellipsoidal Particles. Materials 2019, 12, 3347. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Tang, D.; Yue, H.; Jiang, S.; Deng, Z. Influence of friction on sampling disturbance of lunar surface in direct push sampling method based on DEM. Adv. Space Res. 2017, 59, 3036–3044. [Google Scholar] [CrossRef]

- Hang, C.; Gao, X.; Yuan, M.; Huang, Y.; Zhu, R. Discrete element simulations and experiments of soil disturbance as affected by the tine spacing of subsoiler. Biosyst. Eng. 2018, 168, 73–82. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, H.; Ji, J. Effect of Mounting Angle on Bending Subsoiling Tool-Soil Interactions Using DEM Simulations. Agriculture 2022, 12, 1830. [Google Scholar] [CrossRef]

- Tong, J.; Jiang, X.; Wang, Y.; Ma, Y.; Li, J.; Sun, J. Tillage force and disturbance characteristics of different geometric-shaped subsoilers via DEM. Adv. Manuf. 2020, 8, 392–404. [Google Scholar] [CrossRef]

- Aikins, K.A.; Antille, D.L.; Ucgul, M.; Barr, J.B.; Jensen, T.A.; Desbiolles, J.M.A. Analysis of effects of operating speed and depth on bentleg opener performance in cohesive soil using the discrete element method. Comput. Electron. Agric. 2021, 187, 106236. [Google Scholar] [CrossRef]

- Zhang, L.; Zhai, Y.; Chen, J.; Zhang, Z.; Huang, S. Optimization design and performance study of a subsoiler underlying the tea garden subsoiling mechanism based on bionics and EDEM. Soil Tillage Res. 2022, 220, 105375. [Google Scholar] [CrossRef]

| Order Number | Main Content | Details |

|---|---|---|

| 1 | The influence of the tools on the trajectory of soil particles at different depths. | Its motion trajectory is used as the feedback of the tools. When there is a relationship between the movement of particles or there is a certain mathematical relationship between the movement trajectory of the particles and the tools, mathematical models can be established to more effectively analyze particle-tools systems. |

| 2 | The influence of the tools on the disturbance range of the soil. | When the tools enter the particle system, the number of broken forces bonds between particles is compared with the total number of forces bonds, thereby quantifying the disturbance of the soil by the tools. In the actual test measurement process, the soil layer can be longitudinally and transversely sectioned, and the dimensions can be measured and converted into the soil disturbance range. |

| 3 | The influence of tools on soil disturbance profile. | During simulation, the particle system can be longitudinally and transversely profiled by using the section tool that comes with the simulation software post-processing. The disturbance shape can be observed in other ways. In the actual test, the profile shape of the soil system can be measured by the self-made profiler. |

| 4 | By studying the forces bonds of the particle system. | When studying the damage of agricultural machinery to the soil structure, the damage ratio and damage range of the forces bonds can intuitively display the disturbance of soil structure, and has a theoretical guiding role for the design of equipment that needs to limit the disturbance area. |

| 5 | The velocity field of the particle. | The simulation time disturbance contour takes the tools as the boundary between the disturbance area and the non-disturbance area. The analysis shows the intensity of the action of the tools on soil particles and residues, and the comparison of the velocity field can determine the design advantages and disadvantages of the tools. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Fang, W.; Han, D.; Chen, X. Review of the Research on Soil Disturbance by Tools. Appl. Sci. 2023, 13, 338. https://doi.org/10.3390/app13010338

Wang X, Fang W, Han D, Chen X. Review of the Research on Soil Disturbance by Tools. Applied Sciences. 2023; 13(1):338. https://doi.org/10.3390/app13010338

Chicago/Turabian StyleWang, Xinzhong, Weiquan Fang, Dianlei Han, and Xuegeng Chen. 2023. "Review of the Research on Soil Disturbance by Tools" Applied Sciences 13, no. 1: 338. https://doi.org/10.3390/app13010338

APA StyleWang, X., Fang, W., Han, D., & Chen, X. (2023). Review of the Research on Soil Disturbance by Tools. Applied Sciences, 13(1), 338. https://doi.org/10.3390/app13010338