Correlation of Acoustic Emissions with Electrical Signals in the Vicinity of Fracture in Cement Mortars Subjected to Uniaxial Compressive Loading

Abstract

:1. Introduction

2. Theoretical Preliminaries

2.1. PSC Technique

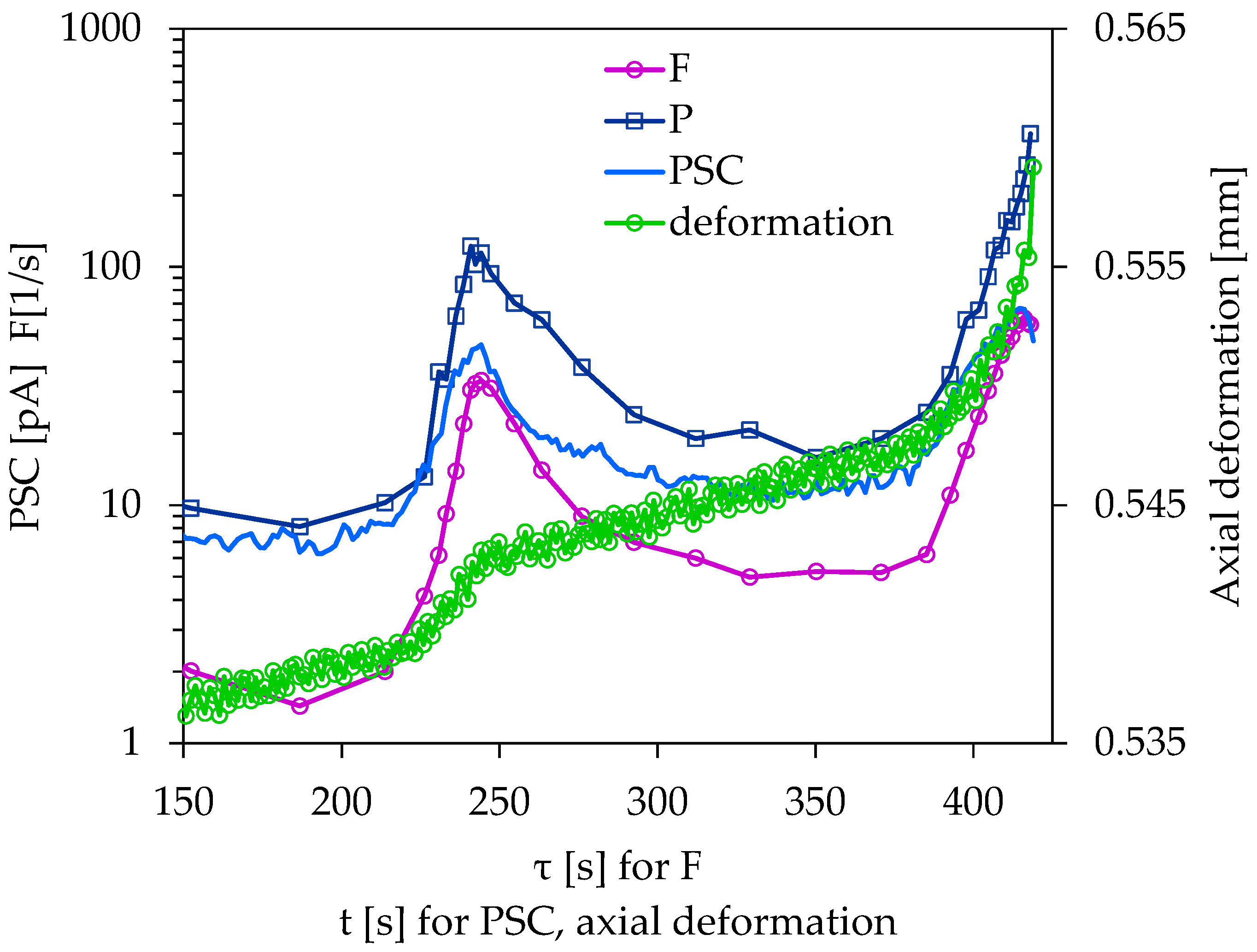

2.2. F-Function

2.3. P-Function

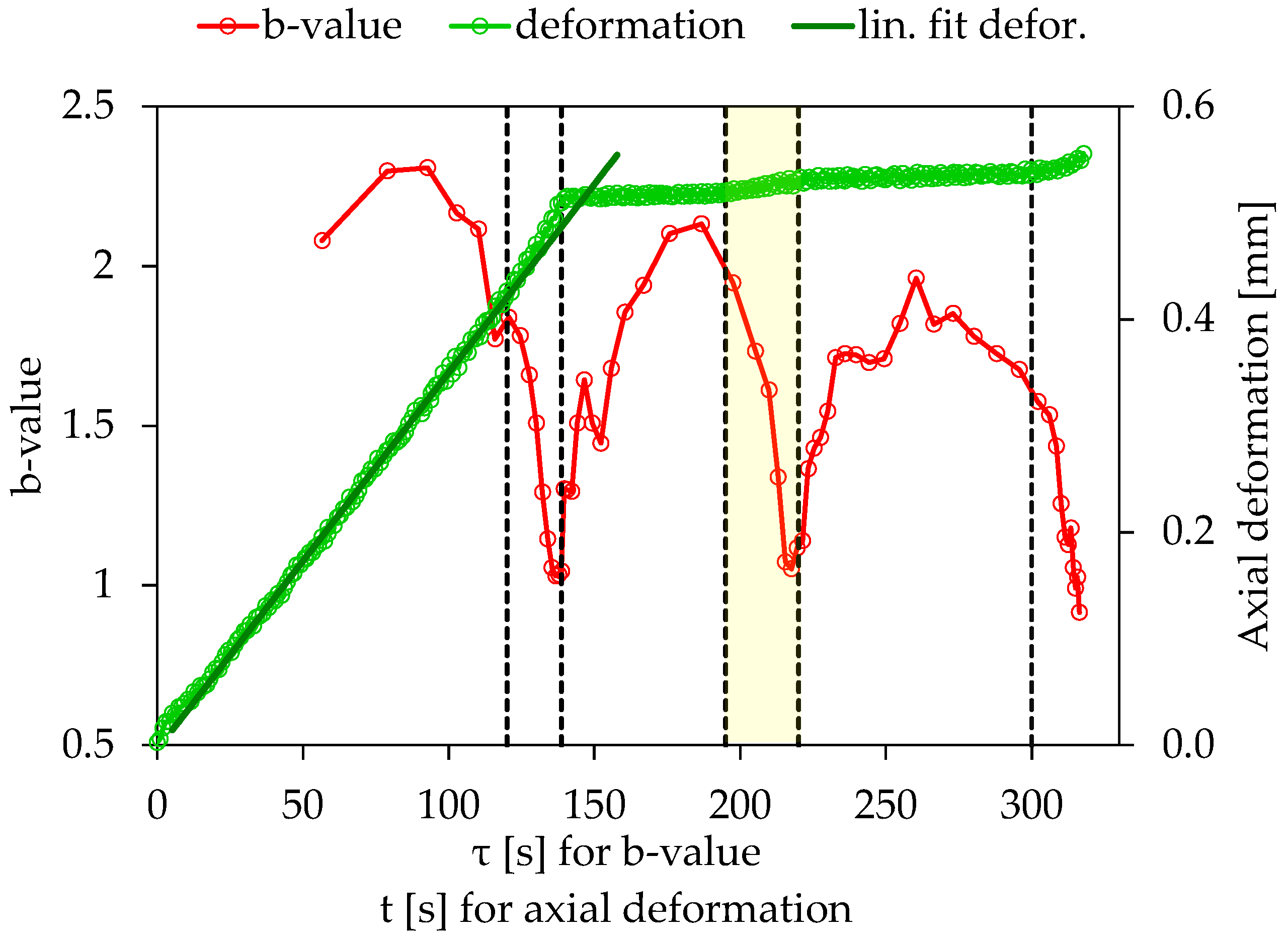

2.4. b-Value

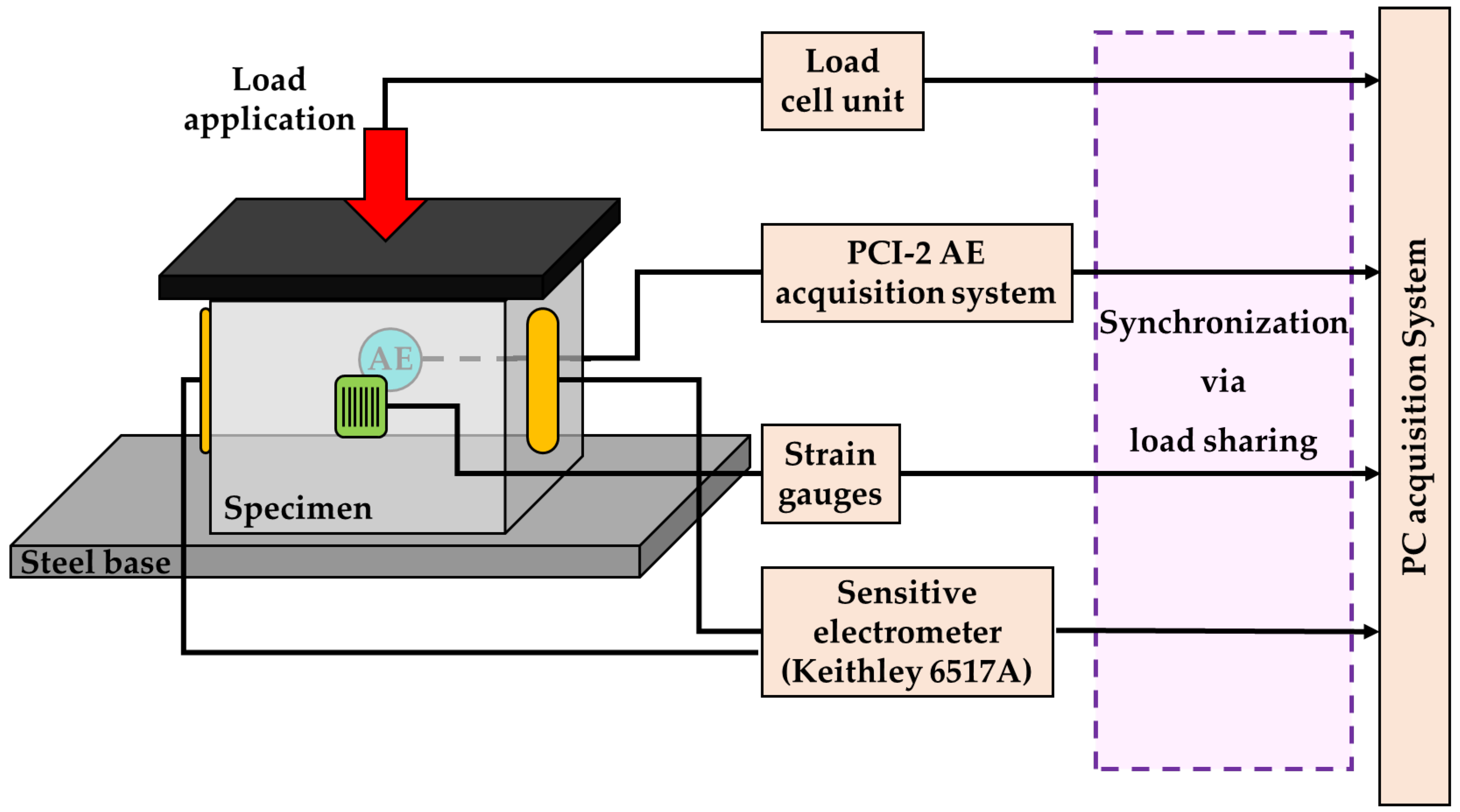

3. Materials and Experimental Apparatus

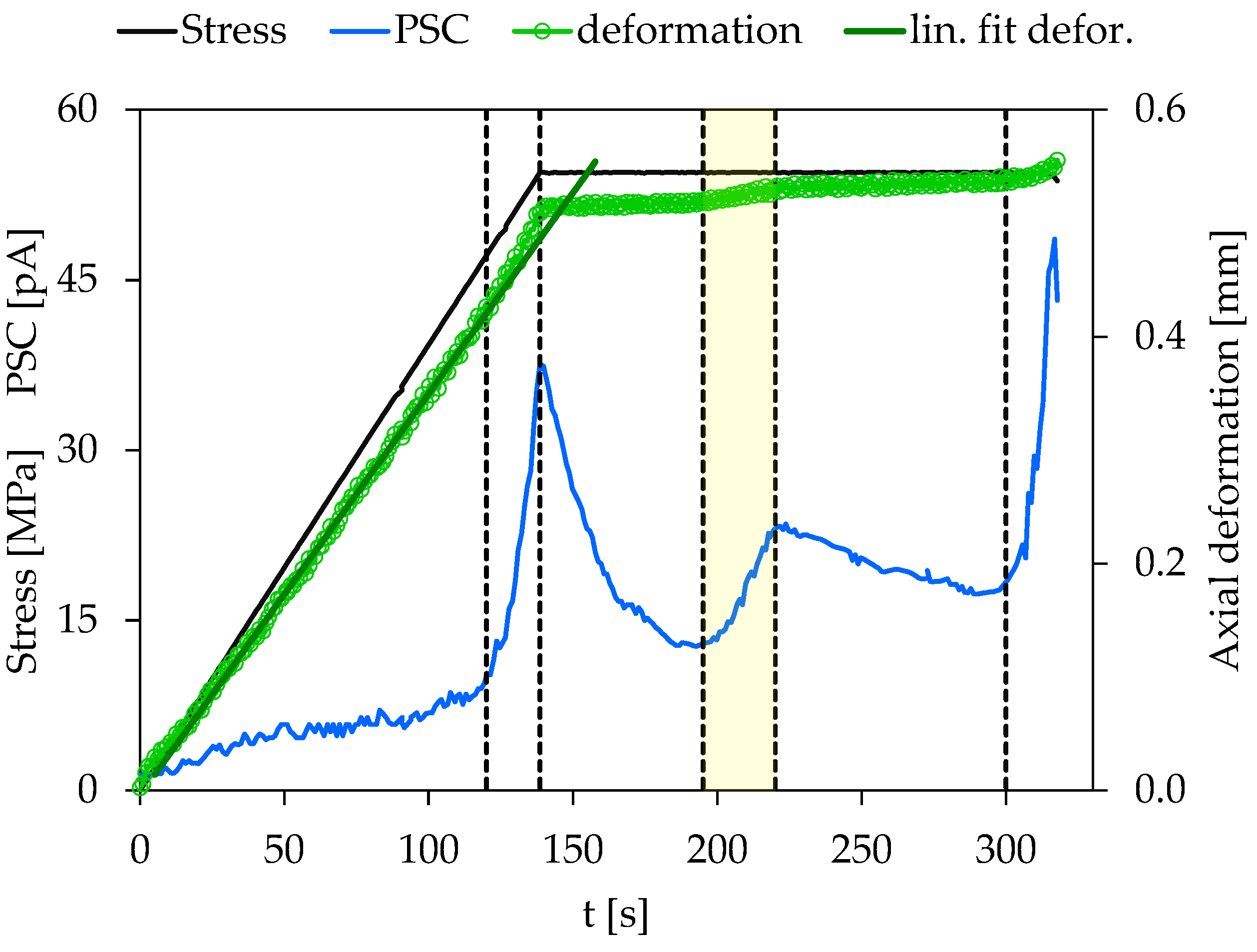

4. Experimental Results and Discussion

5. Conclusions

- Identical qualitative behaviors between the acoustic activity and the PSC signal emerged in all stages of the loading experiment.

- The peaks of the produced AE hit rates and energy rates are concurrent with the PSC peaks and with the local minima of the b-values, which converge on the value 1.0.

- Especially the appearance of the PSC signal, F- and P-function peaks during the constant axial compressive stress application at a level near the total strength of the specimen in combination with the b-values that descend close to 1.0, is an indication that the final collapse of the specimen is imminent.

- The appearance of above-described behaviors is combined with an increased axial deformation rate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hanks, T.C. Small Earthquakes, Tectonic Forces. Science 1992, 256, 1430–1432. [Google Scholar] [CrossRef] [PubMed]

- Zang, A.C.; Wagner, F.; Stanchits, S.; Dresen, G.; Andresen, R.; Haidekker, M.A. Source analysis of acoustic emissions in Aue granite cores under symmetric and asymmetric compressive loads. Geophys. J. Int. 1998, 135, 1113–1130. [Google Scholar] [CrossRef] [Green Version]

- Grosse, C.U.; Ohtsu, M.; Aggelis, D.G.; Shiotani, T. History and Fundamentals. In Acoustic Emission Testing, Basics for Research—Applications in Civil Engineering; Grosse, C., Ohtsu, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 11–18. [Google Scholar]

- He, W.; Hao, W.; Meng, X.; Zhang, P.; Sun, X.; Shen, Y. Influence of Graphite Powder on the Mechanical and Acoustic Emission Characteristics of Concrete. Buildings 2022, 12, 18. [Google Scholar] [CrossRef]

- Deresse, N.E.; Van Steen, C.; Sarem, M.; François, S.; Verstrynge, E. Acoustic Emission Analysis of Fracture and Size Effect in Cementitious Mortars. Appl. Sci. 2022, 12, 3489. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, H.; Li, J.; Zheng, J.; Ren, J. Effect of loading rate on failure characteristics of asphalt mixtures using acoustic emission technique. Constr. Build. Mater. 2023, 364, 129835. [Google Scholar] [CrossRef]

- Shiotani, T. Evaluation of progressive failure using AE sources and improved b-value on slope model tests. Prog. Acoust. Emiss. JSNDI 1994, 7, 529–534. [Google Scholar]

- Colombo, I.S.; Main, I.G.; Forde, M.C. Assessing Damage of Reinforced Concrete Beam Using “b-value” Analysis of Acoustic Emission Signals. J. Mater. Civ. Eng. 2003, 15, 280–286. [Google Scholar] [CrossRef] [Green Version]

- Rao, A.K. Acoustic Emission and Signal Analysis. Def. Sci. J. 2013, 40, 55–70. [Google Scholar] [CrossRef] [Green Version]

- Triantis, D.; Stavrakas, I.; Loukidis, A.; Pasiou, E.D.; Kourkoulis, S.K. Exploring the acoustic activity in brittle materials in terms of the position of the acoustic sources and the power of the acoustic signals—Part I: Founding the approach. Forces Mech. 2022, 7, 100088. [Google Scholar] [CrossRef]

- Yamada, I.; Masuda, K.; Mizutani, H. Electromagnetic and acoustic emission associated with rock fracture. Phys. Earth Planet. Inter. 1989, 57, 157–168. [Google Scholar] [CrossRef]

- Frid, V. Rockburst hazard forecast by electromagnetic radiation excited by rock fracture. Rock Mech. Rock Eng. 1997, 30, 229–236. [Google Scholar] [CrossRef]

- Sharma, S.K.; Kumar, A.; Chauhan, V.S.; Kiran, R.; Kumar, R. Electromagnetic radiation detection from cubical mortar sample and its theoretical model. Mater. Sci. Eng. B 2020, 260, 114638. [Google Scholar] [CrossRef]

- Lou, Q.; Wan, X.; Jia, B.; Song, D.; Qiu, L.; Yin, S. Application Study of Empirical Wavelet Transform in Time-Frequency Analysis of Electromagnetic Radiation Induced by Rock Fracture. Minerals 2022, 12, 1307. [Google Scholar] [CrossRef]

- Stavrakas, I.; Anastasiadis, C.; Triantis, D.; Vallianatos, F. Piezo stimulated currents in marble samples: Precursory and concurrent-with-failure signals. Nat. Hazards Earth Syst. Sci. 2003, 3, 243–247. [Google Scholar] [CrossRef] [Green Version]

- Kyriazopoulos, A.; Anastasiadis, C.; Triantis, D.; Brown, C.J. Non-destructive evaluation of cement-based materials from pressure-stimulated electrical emission—Preliminary results. Constr. Build. Mater. 2011, 25, 1980–1990. [Google Scholar] [CrossRef] [Green Version]

- Archer, J.W.; Dobbs, M.R.; Aydin, A.; Reeves, H.J.; Prance, R.J. Measurement and correlation of acoustic emissions and pressure stimulated voltages in rock using an electric potential sensor. Int. J. Rock Mech. Min. 2016, 89, 26–33. [Google Scholar] [CrossRef] [Green Version]

- Cartwright-Taylor, A.; Vallianatos, F.; Sammonds, P. Superstatistical view of stress-induced electric current fluctuations in rocks. Phys. A Stat. Mech. Appl. 2014, 414, 368–377. [Google Scholar] [CrossRef]

- Stavrakas, I.; Triantis, D.; Agioutantis, Z.; Maurigiannakis, S.; Saltas, V.; Vallianatos, F.; Clarke, M. Pressure stimulated currents in rocks and their correlation with mechanical properties. Nat. Hazards Earth Syst. Sci. 2004, 4, 563–567. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Li, Z.; Wang, E.; Li, B.; Song, J.; Niu, Y. Experimental investigation of pressure stimulated currents and acoustic emissions from sandstone and gabbro samples subjected to multi-stage uniaxial loading. Bull. Eng. Geol. Environ. 2021, 80, 7683–7700. [Google Scholar] [CrossRef]

- Li, D.; Wang, E.; Li, Z.; Ju, Y.; Wang, D.; Wang, X. Experimental investigations of pressure stimulated currents from stressed sandstone used as precursors to rock fracture. Int. J. Rock Mech. Min. 2021, 145, 104841. [Google Scholar] [CrossRef]

- Li, D.; Wang, E.; Ju, Y.; Wang, D. Laboratory Investigations of a New Method Using Pressure Stimulated Currents to Monitor Concentrated Stress Variations in Coal. Nat. Resour. Res. 2021, 30, 707–724. [Google Scholar] [CrossRef]

- Triantis, D.; Pasiou, E.D.; Stavrakas, I.; Kourkoulis, S.K. Hidden Affinities Between Electric and Acoustic Activities in Brittle Materials at Near-Fracture Load Levels. Rock Mech. Rock Eng. 2022, 55, 1325–1342. [Google Scholar] [CrossRef]

- Mao, W.; Wu, L.; Xu, Y.; Yao, R.; Lu, J.; Sun, L.; Qi, Y. Pressure-Stimulated Rock Current as Loading Diorite to Failure: Particular Variation and Holistic Mechanisms. J. Geophys. Res. Solid Earth 2022, 127, e2022JB024931. [Google Scholar] [CrossRef]

- Varotsos, P.; Sarlis, N.V.; Lazaridou, M.; Kapiris, P. Transmission of stress induced electric signals in dielectric media. J. Appl. Phys. 1998, 83, 60–70. [Google Scholar] [CrossRef]

- Triantis, D.; Stavrakas, I.; Kyriazopoulos, A.; Hloupis, G.; Agioutantis, Z. Pressure stimulated electrical emissions from cement mortar used as failure predictors. Int. J. Fract. 2012, 175, 53–61. [Google Scholar] [CrossRef]

- Varotsos, P.; Sarlis, N.V.; Skordas, E.S. Long-range correlations in the electric signals that precede rupture. Phys. Rev. E 2002, 66, 011902. [Google Scholar] [CrossRef] [Green Version]

- Slifkin, L. Seismic electric signals from displacement of charged dislocations. Tectonophysics 1993, 224, 149–152. [Google Scholar] [CrossRef]

- Vallianatos, F.; Tzanis, A. Electric current generation associated with the deformation rate of a solid: Preseismic and coseismic signals. Phys. Chem. Earth 1998, 23, 933–938. [Google Scholar] [CrossRef]

- Vallianatos, F.; Tzanis, A. A model for the generation of precursory electric and magnetic fields associated with the deformation rate of the earthquake focus. In Atmospheric and Ionospheric Electromagnetic Phenomena Associated with Earthquakes; Hayakawa, M., Ed.; TERRAPUB: Tokyo, Japan, 1999; pp. 287–305. [Google Scholar]

- Vallianatos, F.; Triantis, D.; Tzanis, A.; Anastasiadis, C.; Stavrakas, I. Electric earthquake precursors: From laboratory results to field observations. Phys. Chem. Earth Parts A/B/C 2004, 29, 339–351. [Google Scholar] [CrossRef]

- Anastasiadis, C.; Stavrakas, I.; Triantis, D.; Vallianatos, F. Correlation of Pressure Stimulated Currents in rocks with the damage parameter. Ann. Geophys. 2007, 50, 1–6. [Google Scholar] [CrossRef]

- Kourkoulis, S.K.; Pasiou, E.D.; Loukidis, A.; Stavrakas, I.; Triantis, D. Comparative Assessment of Criticality Indices Extracted from Acoustic and Electrical Signals Detected in Marble Specimens. Infrastructures 2022, 7, 15. [Google Scholar] [CrossRef]

- Fursa, T.V.; Petrov, M.; Dann, D.D.; Reutov, Y.A. Evaluating damage of reinforced concrete structures subjected to bending using the parameters of electric response to mechanical impact. Compos. B. Eng. 2019, 158, 34–45. [Google Scholar] [CrossRef]

- Sun, M.; Liu, Q.; Li, Z.; Wang, E. Electrical emission in mortar under low compressive loading. Cem. Concr. Res. 2002, 32, 47–50. [Google Scholar] [CrossRef]

- Kourkoulis, S.K.; Pasiou, E.D.; Dakanali, I.; Stavrakas, I.; Triantis, D. Notched marble plates under tension: Detecting prefailure indicators and predicting entrance to the “critical stage”. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 776–786. [Google Scholar] [CrossRef]

- Pasiou, E.D.; Triantis, D. Correlation between the electric and acoustic signals emitted during compression of brittle materials. Frat. Integrità Strutt. 2017, 11, 41–51. [Google Scholar] [CrossRef] [Green Version]

- Triantis, D.; Kourkoulis, S.K. An Alternative Approach for Representing the Data Provided by the Acoustic Emission Technique. Rock Mech. Rock Eng. 2018, 51, 2433–2438. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Zhou, X.P.; Zhou, L.S.; Berto, F. Progressive failure of brittle rocks with non-isometric flaws: Insights from acousto-optic-mechanical (AOM) data. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1787–1802. [Google Scholar] [CrossRef]

- Wang, X.; Wang, E.; Liu, X. Damage characterization of concrete under multi-step loading by integrated ultrasonic and acoustic emission techniques. Constr. Build. Mater. 2019, 221, 678–690. [Google Scholar] [CrossRef]

- Ju, Y.; Wu, X. Acoustic Emission Characteristics and Failure Prediction of the Granite with Orthogonal Cracks under Compressive Loading. Adv. Civ. Eng. 2020, 2020, 8846290. [Google Scholar] [CrossRef]

- Ge, Z.; Sun, Q. Acoustic emission characteristics of gabbro after microwave heating. Int. J. Rock Mech. Min. 2021, 138, 104616. [Google Scholar] [CrossRef]

- Main, I.G. Damage mechanics with long-range interactions: Correlation between the seismic b-value and the fractal two-point correlation dimension. Geophys. J. Int. 1992, 111, 531–541. [Google Scholar] [CrossRef]

- Rao, M.V.M.S.; Lakshmi, K.J.P. Analysis of b-value and improved b-value of acoustic emissions accompanying rock fracture. Curr. Sci. 2005, 89, 1577–1582. [Google Scholar]

- Aggelis, D.G.; Soulioti, D.V.; Sapouridis, N.; Barkoula, N.M.; Paipetis, A.S.; Matikas, T.E. Acoustic emission characterization of the fracture process in fibre reinforced concrete. Constr. Build. Mater. 2011, 25, 4126–4131. [Google Scholar] [CrossRef]

- Rouchier, S.; Foray, G.; Godin, N.; Woloszyn, M.; Roux, J.J. Damage monitoring in fibre reinforced mortar by combined digital image correlation and acoustic emission. Constr. Build. Mater. 2013, 38, 371–380. [Google Scholar] [CrossRef] [Green Version]

- Loukidis, A.; Triantis, D.; Stavrakas, I.; Pasiou, E.D.; Kourkoulis, S.K. Comparative Ib-value and F-function analysis of Acoustic Emissions from elementary and structural tests with marble specimens. Mater. Des. Process. Commun. 2021, 3, e176. [Google Scholar] [CrossRef] [Green Version]

- Behnia, A.; Chai, H.K.; Shiotani, T. Advanced structural health monitoring of concrete structures with the aid of acoustic emission. Constr. Build. Mater. 2014, 65, 282–302. [Google Scholar] [CrossRef]

- Loukidis, A.; Stavrakas, I.; Triantis, D. The relaxation processes of Pressure Stimulated Currents under the concept of Non-extensive statistical physics. Procedia Struct. Integr. 2020, 26, 277–284. [Google Scholar] [CrossRef]

- Triantis, D.; Vallianatos, F.; Stavrakas, I.; Hloupis, G. Relaxation phenomena of electrical signal emissions from rock following application of abrupt mechanical stress. Ann. Geophys. 2012, 55, 207–212. [Google Scholar] [CrossRef]

- Triantis, D.; Loukidis, A.; Stavrakas, I.; Pasiou, E.D.; Kourkoulis, S.K. Attenuation of the Acoustic Activity in Cement Beams under Constant Bending Load Closely Approaching the Fracture Load. Foundations 2022, 2, 590–606. [Google Scholar] [CrossRef]

- Triantis, D.; Kourkoulis, S. Fracture precursor phenomena in marble specimens under uniaxial compression by means of Acoustic Emission data. Frat. Integrità Strutt. 2019, 13, 537–547. [Google Scholar] [CrossRef] [Green Version]

- Triantis, D.; Stavrakas, I.; Pasiou, E.D.; Kourkoulis, S.K. Assessing the acoustic activity in marble specimens under stepwise compressive loading. Mater. Des. Process. Commun. 2020, 2, e100. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loukidis, A.; Tzagkarakis, D.; Kyriazopoulos, A.; Stavrakas, I.; Triantis, D. Correlation of Acoustic Emissions with Electrical Signals in the Vicinity of Fracture in Cement Mortars Subjected to Uniaxial Compressive Loading. Appl. Sci. 2023, 13, 365. https://doi.org/10.3390/app13010365

Loukidis A, Tzagkarakis D, Kyriazopoulos A, Stavrakas I, Triantis D. Correlation of Acoustic Emissions with Electrical Signals in the Vicinity of Fracture in Cement Mortars Subjected to Uniaxial Compressive Loading. Applied Sciences. 2023; 13(1):365. https://doi.org/10.3390/app13010365

Chicago/Turabian StyleLoukidis, Andronikos, Dimitrios Tzagkarakis, Antonios Kyriazopoulos, Ilias Stavrakas, and Dimos Triantis. 2023. "Correlation of Acoustic Emissions with Electrical Signals in the Vicinity of Fracture in Cement Mortars Subjected to Uniaxial Compressive Loading" Applied Sciences 13, no. 1: 365. https://doi.org/10.3390/app13010365