Comparison of Dual-Combustion Ramjet and Scramjet Performances Considering Combustion Efficiency

Abstract

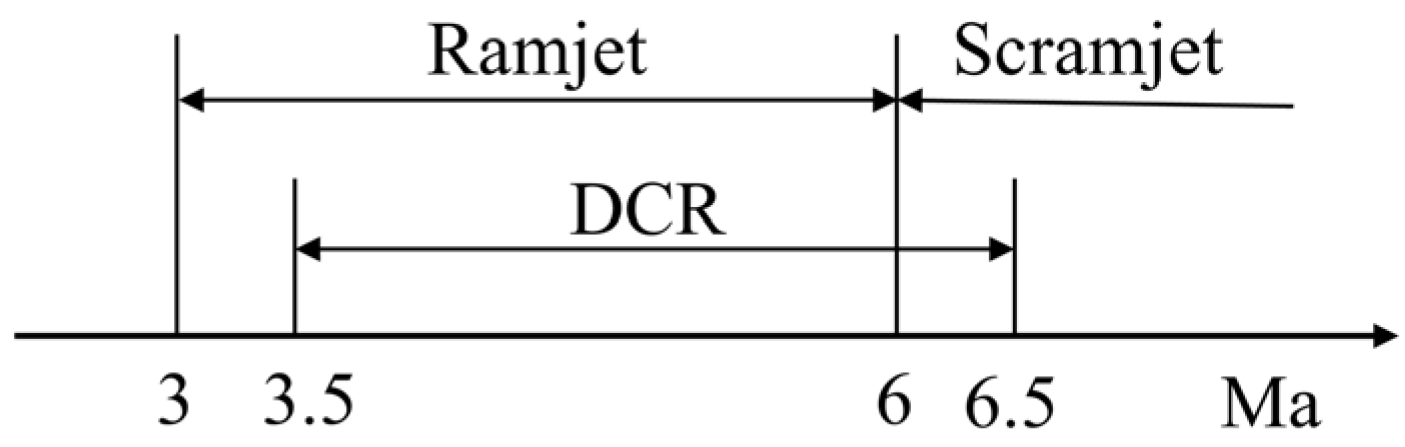

:1. Introduction

2. Materials and Methods

2.1. Mathematical Model

2.1.1. Flow Control Equations

2.1.2. Turbulence Model

2.1.3. Turbulent Combustion Model

2.1.4. Chemical Kinetic Model

2.2. Physical Model

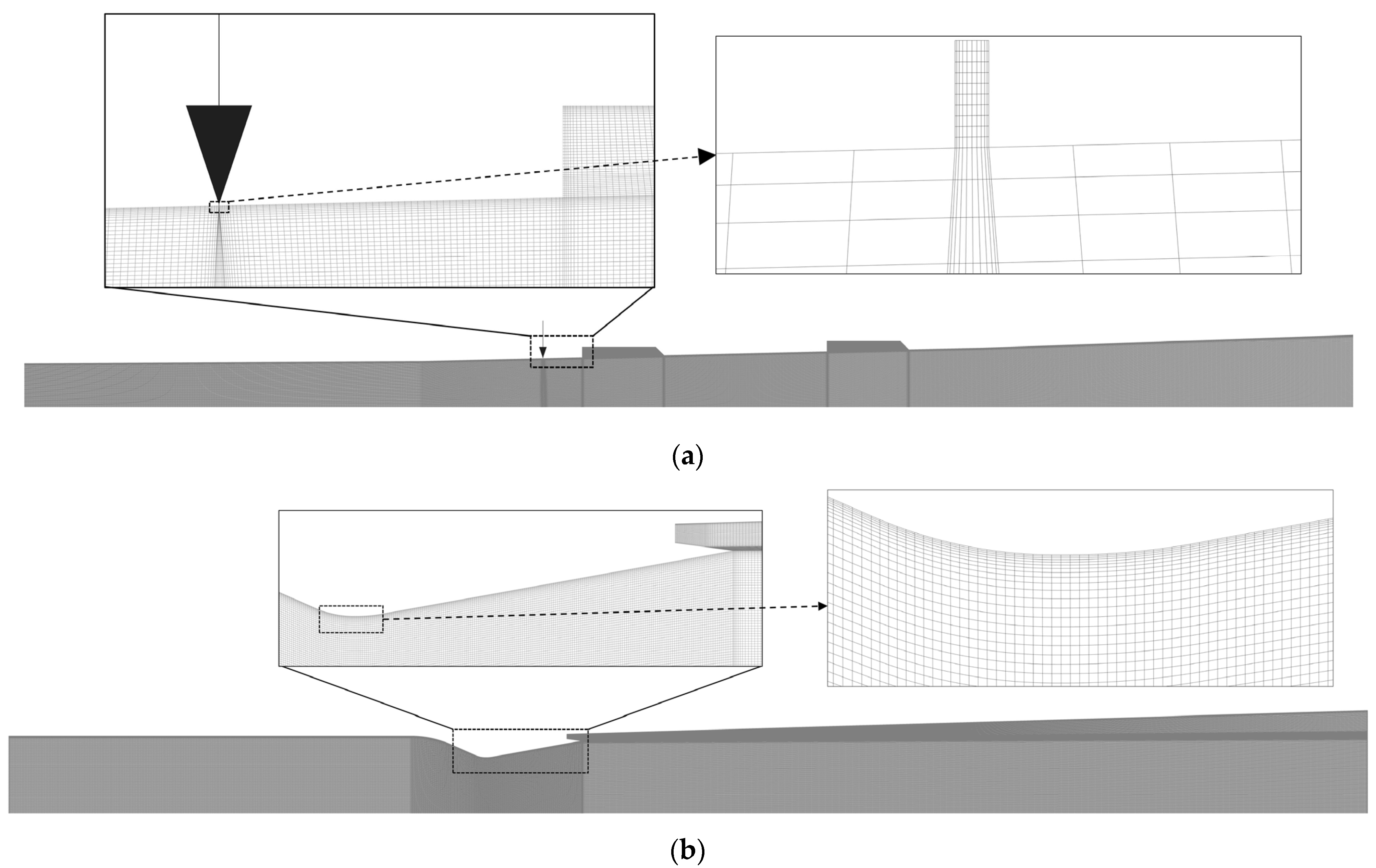

2.2.1. Geometric Model

2.2.2. Boundary Conditions

2.3. Algorithm Verification

2.3.1. Algorithm Validation of Scramjet

2.3.2. Algorithm Validation of DCR

3. Results and Discussion

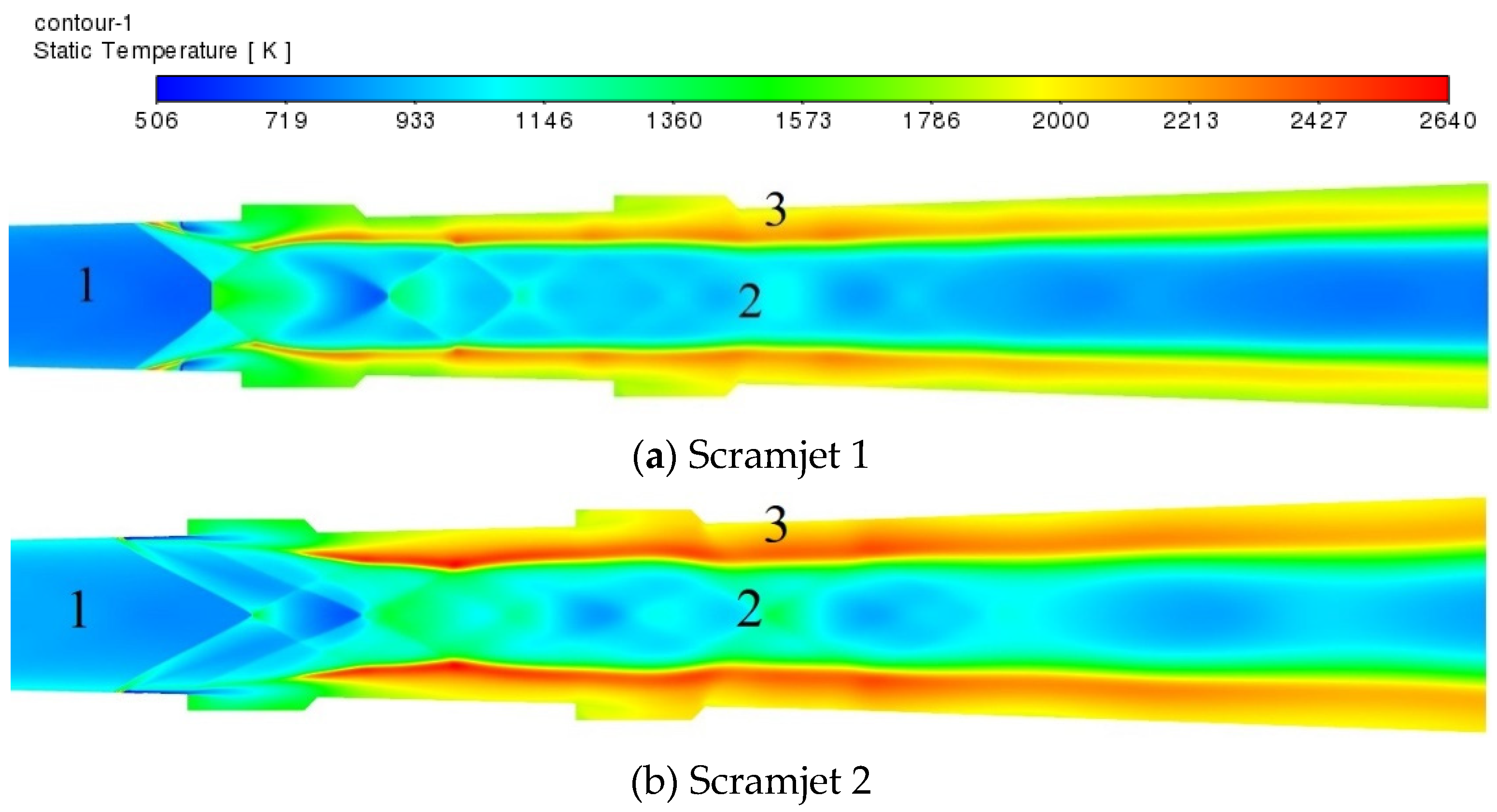

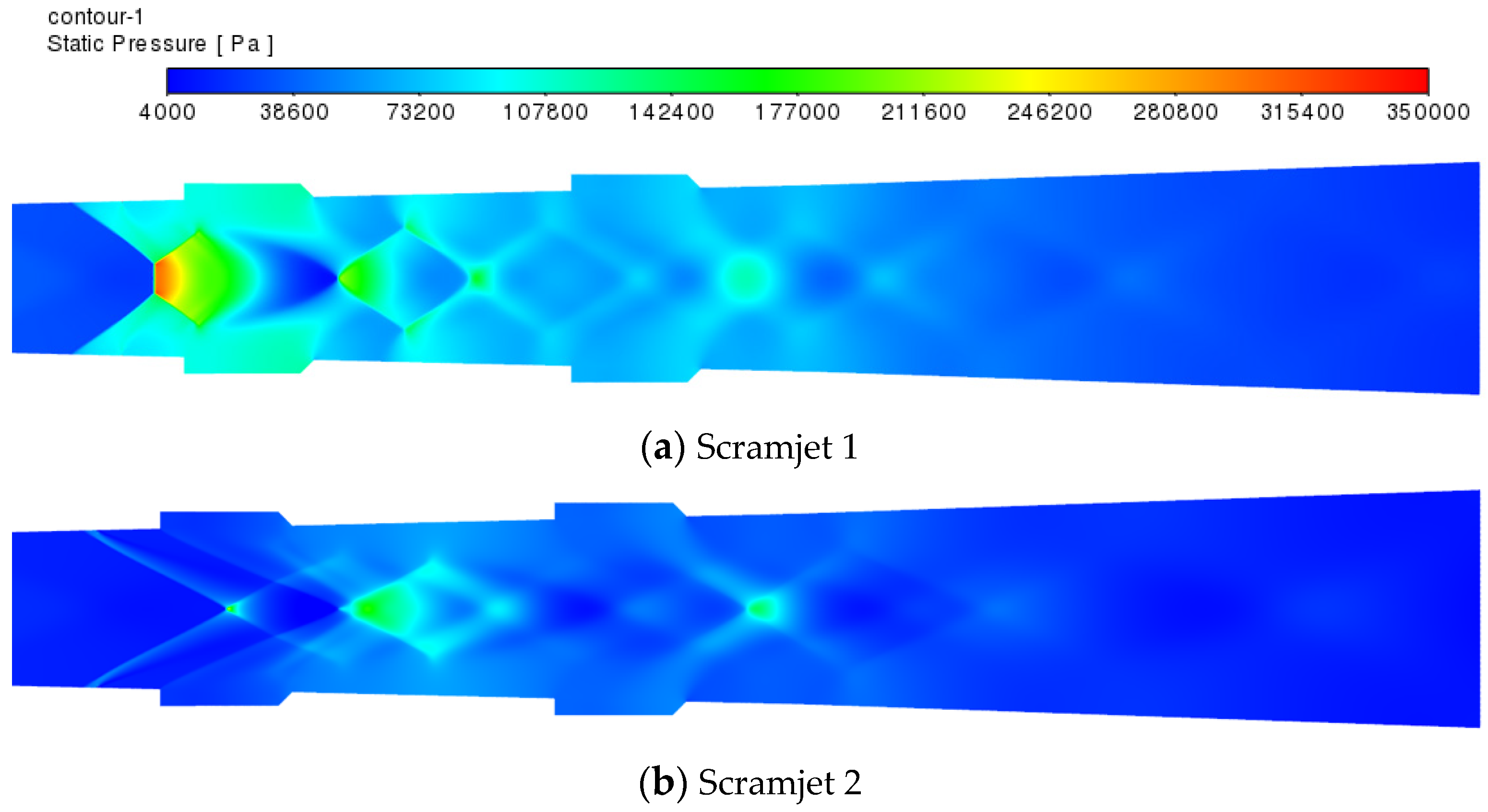

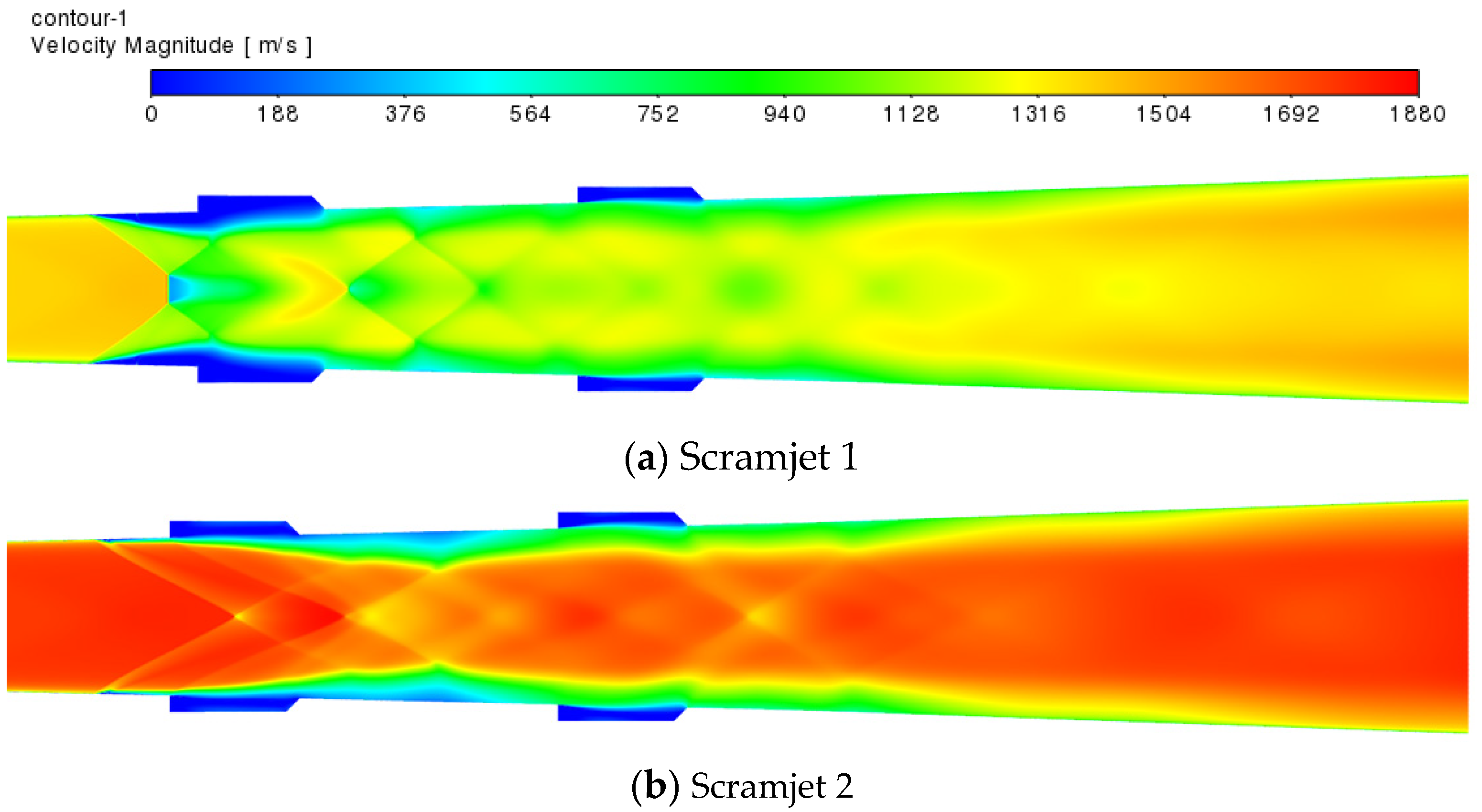

3.1. Combustion Flow Characteristics of the Scramjet

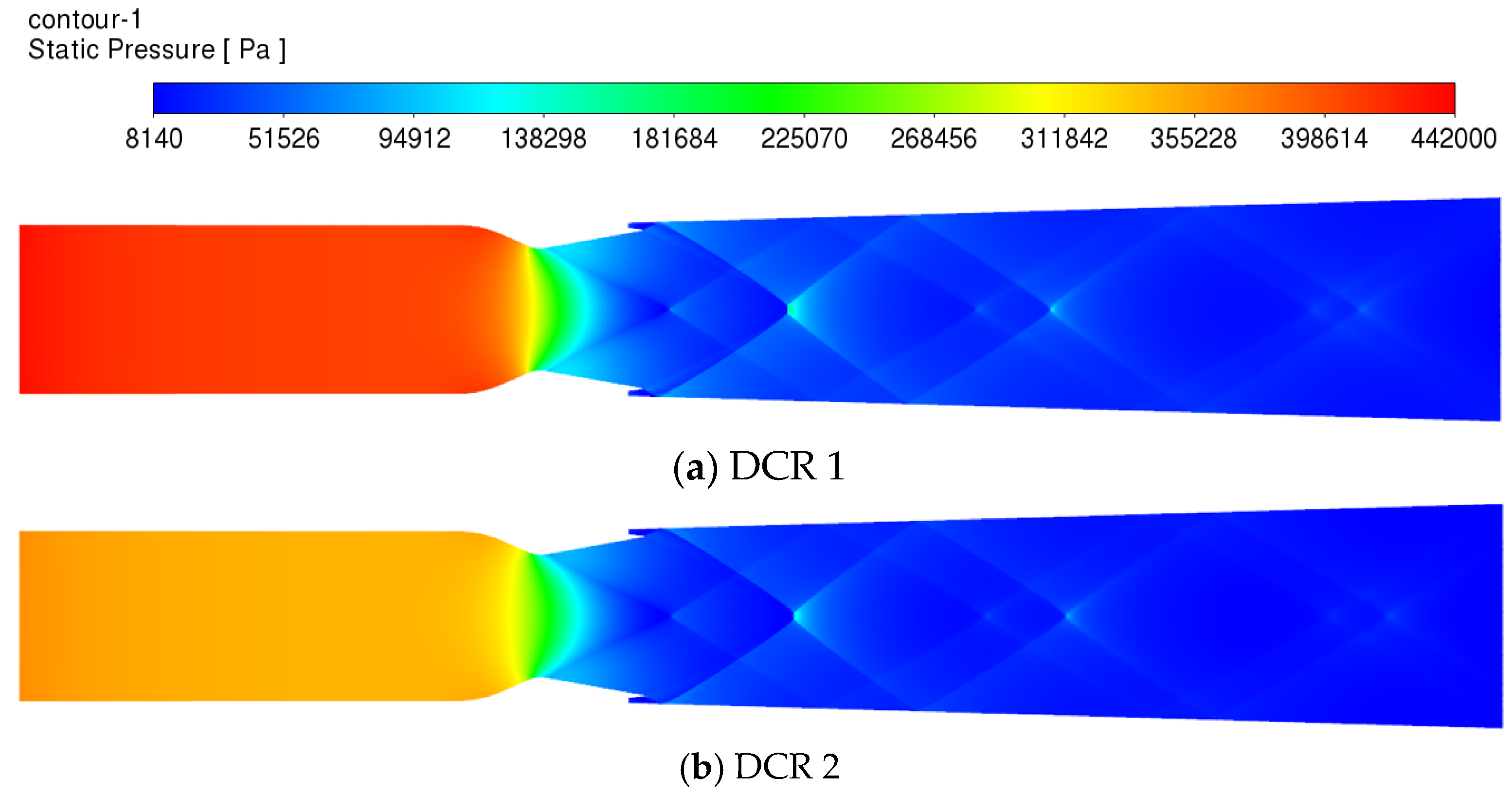

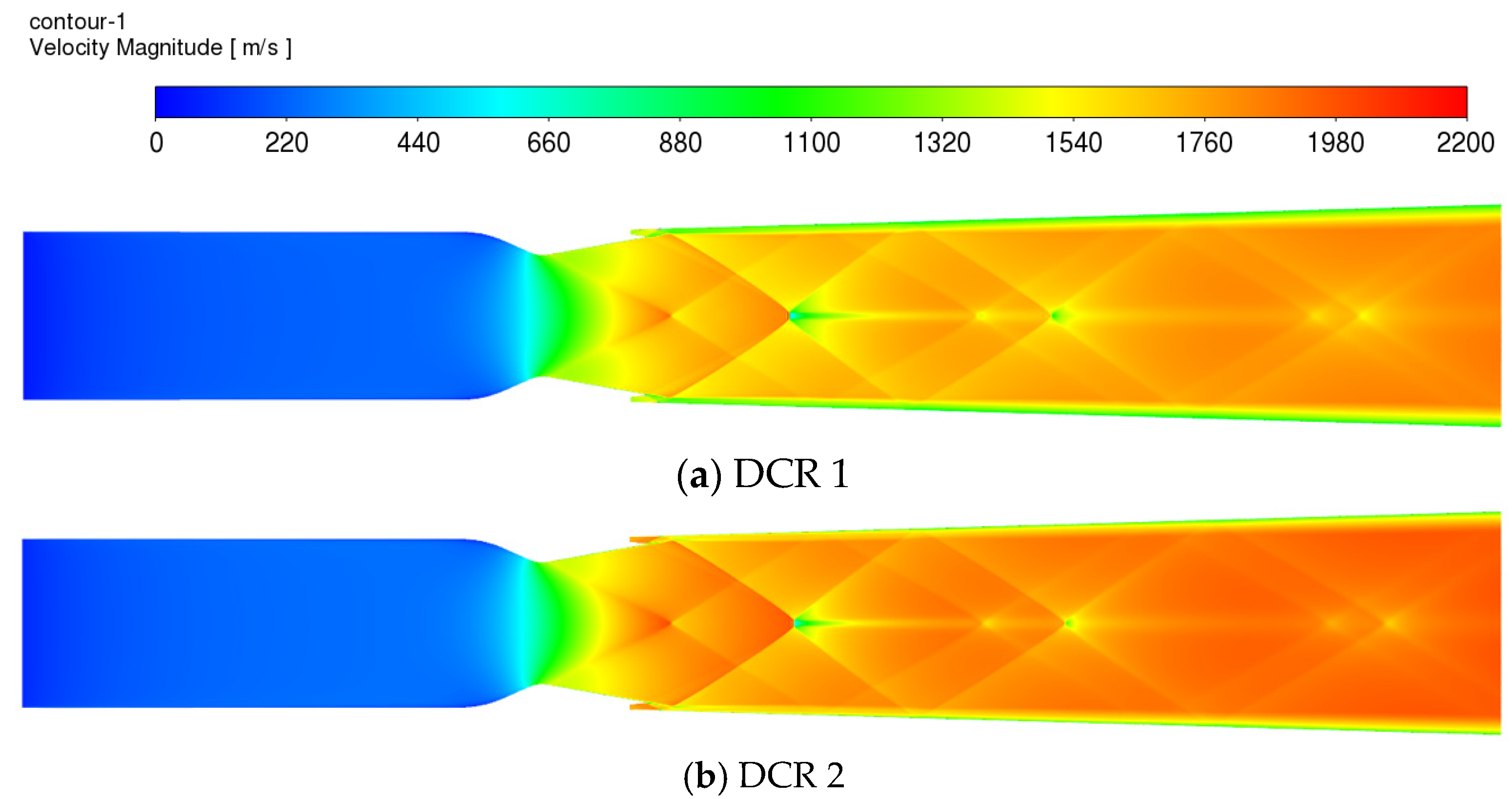

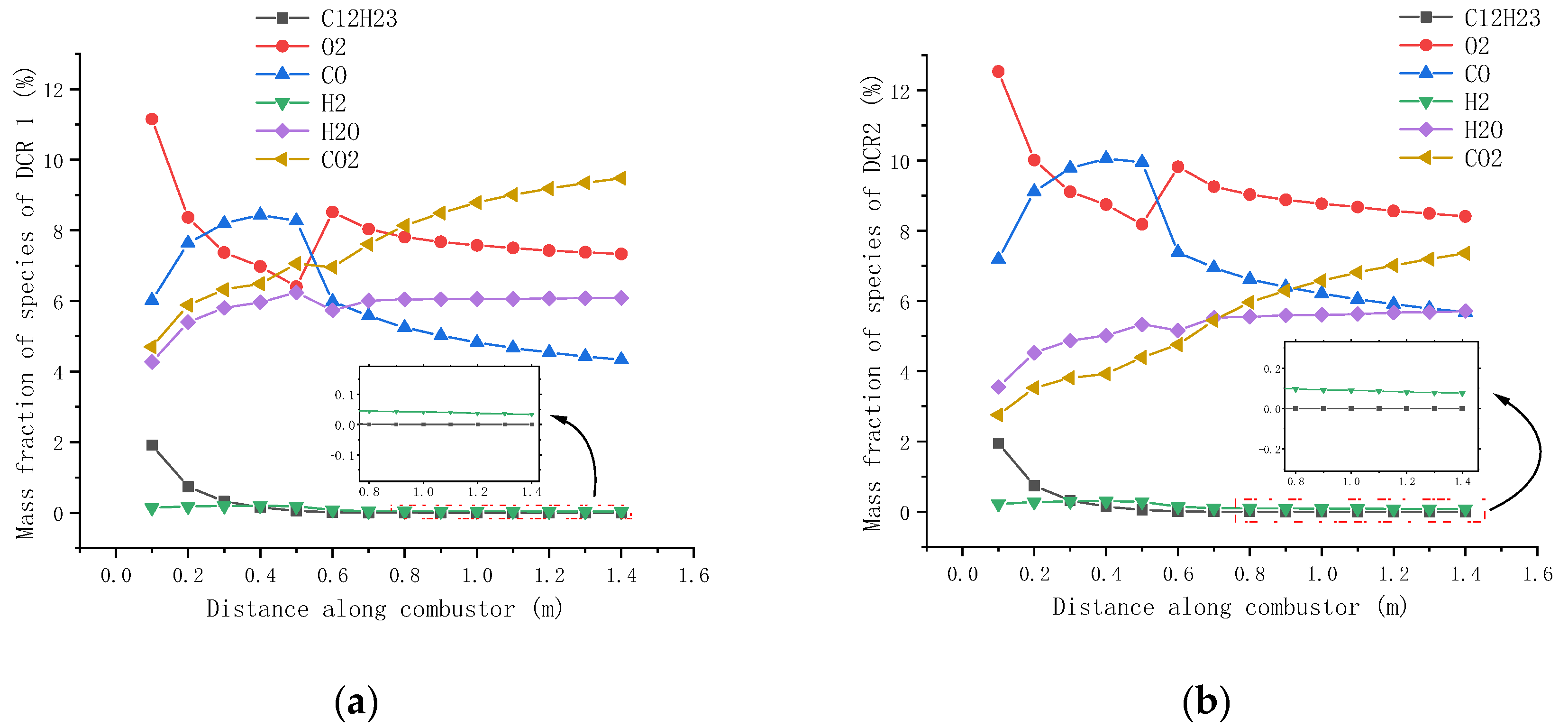

3.2. Combustion Flow Characteristics of DCR

3.3. Comparison of Overall Performances of the Scramjet and DCR

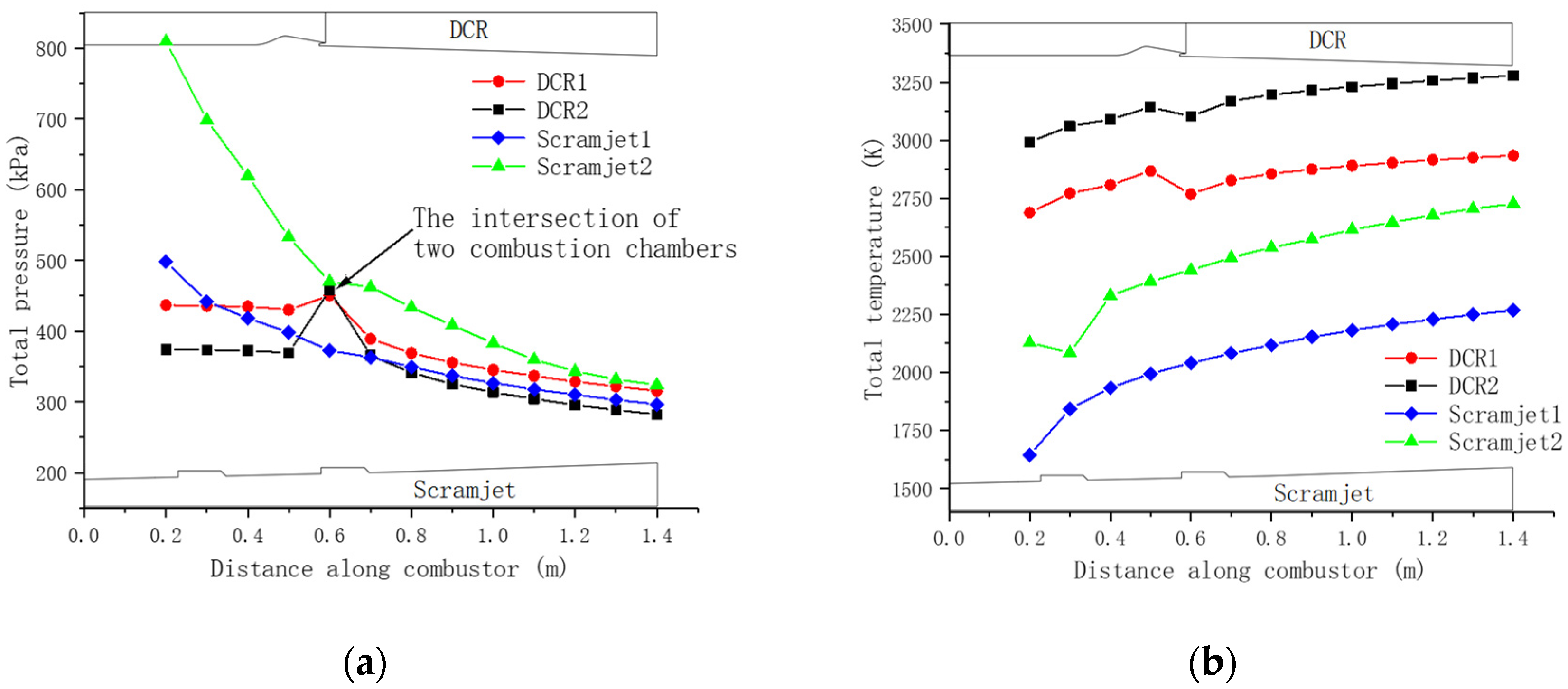

3.3.1. Comparison of Total Pressures, Total Temperatures, and Combustion Efficiencies

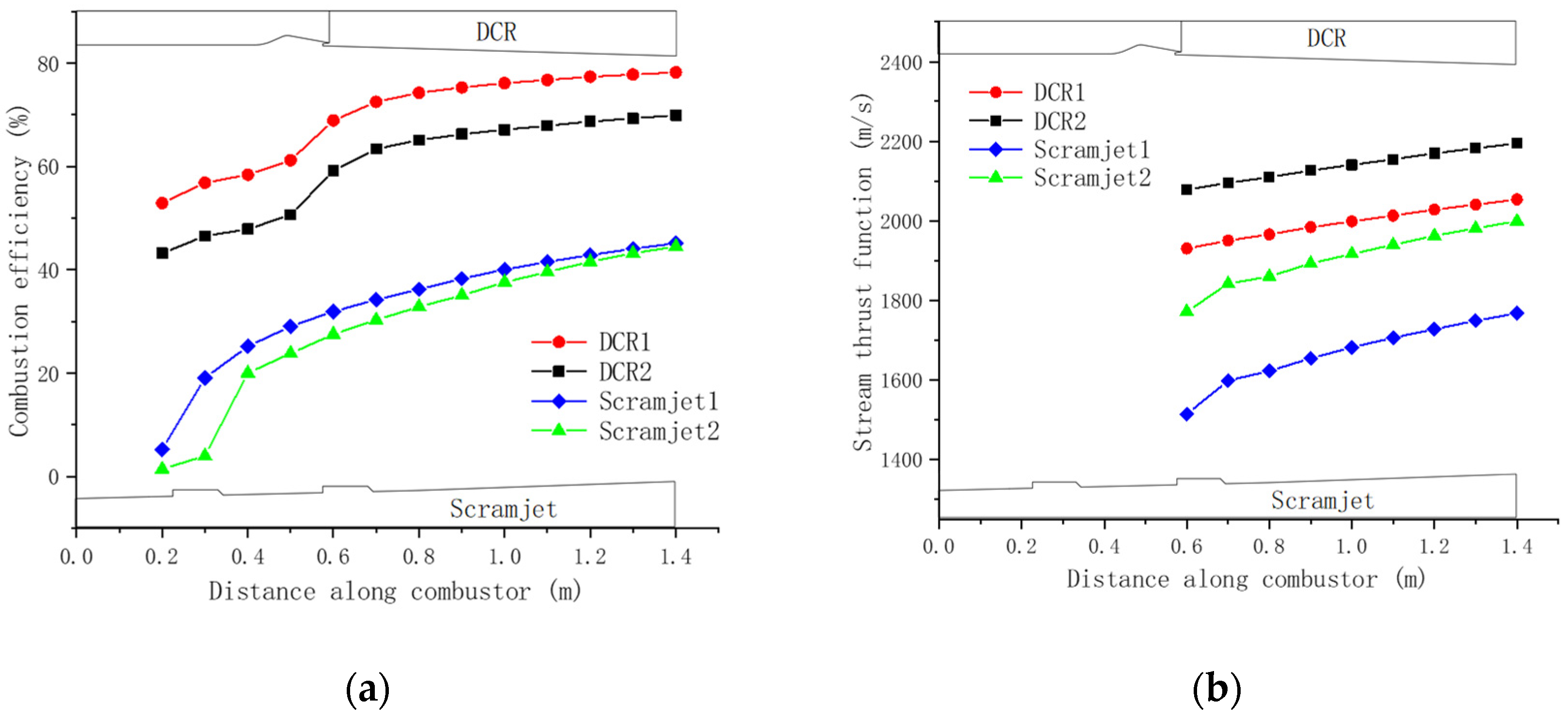

3.3.2. Comparison of Stream Thrust Functions

3.3.3. Comparison of the Overall Performances

4. Conclusions

- (1)

- The two types of engines had different combustion modes. The scramjet was a near wall combustion mode, while the DCR was a central combustion mode, which had small pressure fluctuation, small temperature gradient, good heat release uniformity, and high combustion stability.

- (2)

- When the Mach number increased, the total pressure recovery capability of scramjet was superior to that of DCR. Specifically, the total pressure recovery coefficient of scramjet was 0.9% lower than that of DCR under the Ma6 condition, but 5.6% higher than that of DCR under the Ma7 condition.

- (3)

- The combustion efficiency of DCR was 35.6% and 25.4% higher than that of scramjet under Ma6 and Ma7 conditions, respectively. When the Mach number increased from 6 to 7, the combustion efficiency of the scramjet remained almost unchanged, and that of DCR decreased by 10%. This was because the dissociation rate of CO2 into CO increased with increasing temperature.

- (4)

- The performance of DCR was better than that of scramjet under both conditions. However, the performance advantage of DCR decreased as the Mach number increased. Specifically, under the conditions of Ma6 and Ma7, the specific impulse or specific thrust of DCR was 2.67 times and 1.51 times of scramjet, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Mass of flow per unit time, kg/s. | |

| M | Molar mass, kg/mol. |

| Formation enthalpy, J/mol. | |

| T | Temperature, K. |

| P | Pressure, kPa. |

| Ma | Mach number. |

| Combustion efficiency. | |

| Kp | Total pressure recovery coefficient. |

| F | Thrust, which is the thrust gain in the paper, N. |

| I | Specific impulse, m/s. |

| Specific thrust, m/s. | |

| Stream thrust function, m/s. | |

| Axial velocity of air flow, m/s. | |

| The average gas constant of the flow, J/(kg·k). | |

| Heat released per unit mass of complete combustion, J/kg. | |

| Subscripts | |

| A_tot | Sum of the air mass of the subsonic combustor and supersonic combustor. |

| fuel | Fuel, i.e., kerosene. |

| hot | Operating conditions when the fuel is burned. |

| cold | Operating conditions when the fuel is not burned. |

| net | Net increase value. |

| c_in | Inlet of combustor. |

| 0 | The state of a stagnant air flow. |

| 1 | Operating condition 1, which is 30 km flight altitude and Mach 6. |

| 2 | Operating condition 2, which is 30 km flight altitude and Mach 7. |

References

- Sziroczak, D.; Smith, H. A review of design issues specific to hypersonic flight vehicles. Prog. Aeosp. Sci. 2016, 84, 1–28. [Google Scholar] [CrossRef] [Green Version]

- Urzay, J. Supersonic Combustion in Air-Breathing Propulsion Systems for Hypersonic Flight. Annu. Rev. Fluid Mech. 2018, 50, 593–627. [Google Scholar] [CrossRef]

- Liu, Q.; Baccarella, D.; Lee, T. Review of combustion stabilization for hypersonic airbreathing propulsion. Prog. Aeosp. Sci. 2020, 119, 100636. [Google Scholar] [CrossRef]

- Billig, F.S.; Waltrup, P.J.; Stockbridge, R.D. Integral-Rocket Dual-Combustion Ramjets: A New Propulsion Concept. J. Spacecr. Rockets 1980, 17, 416–424. [Google Scholar] [CrossRef]

- Waltrup, P.J. The dual combustor ramjet: A versatile propulsion system for hypersonic tactical missile applications. In AGARD, Airbreathing Propulsion for Missiles and Projectiles 11 p (SEE N93-17607 05-20); AGARD: Villepreux, France, 1992. [Google Scholar]

- Tan, J.; Wang, Y. Freejet Experimental Investigation on Performance of Dual-Combustion Ramjet. J. Propul. Power 2015, 31, 478–482. [Google Scholar] [CrossRef]

- Segal, C. The Scramjet Engine: Processes and Characteristics; Cambridge University Press: Cambridge, NY, USA, 2009. [Google Scholar]

- Choubey, G.; Devarajan, Y.; Huang, W.; Mehar, K.; Tiwari, M.; Pandey, K.M. Recent advances in cavity-based scramjet engine- a brief review. Int. J. Hydrogen Energy 2019, 44, 13895–13909. [Google Scholar] [CrossRef]

- Chang, J.; Zhang, J.; Bao, W.; Yu, D. Research progress on strut-equipped supersonic combustors for scramjet application. Prog. Aeosp. Sci. 2018, 103, 1–30. [Google Scholar] [CrossRef]

- Gerdroodbary, M.B. Injection and Mixing of Single Fuel Jet in SCRAMJET Engine; Butterworth-Heinemann: Kidlington, UK, 2020. [Google Scholar]

- Wadwankar, N.; Kandasamy, G.; Ananthkrishnan, N.; Renganathan, V.S.; Park, I.; Hwang, K. Dual combustor ramjet engine dynamics modeling and simulation for design analysis. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2019, 233, 1307–1322. [Google Scholar] [CrossRef]

- Jiang, Y.; Abu-Hamdeh, N.H.; Bantan, R.A.R.; Moradi, R. Mixing efficiency of hydrogen and air co-flow jets via wedge shock generator in dual-combustor ramjet. Aerosp. Sci. Technol. 2021, 116, 106846. [Google Scholar] [CrossRef]

- Fry, R.S. A Century of Ramjet Propulsion Technology Evolution. J. Propul. Power 2004, 20, 27–58. [Google Scholar] [CrossRef]

- Yang, Z.; Shan, P.; Guo, D.; Zhao, L.; Jie, K.; Liu, J. Design Improvement and Validation of Subsonic Combustor Pilot Burner for Dual Combustor Ramjet. J. Propuls. Technol. 2013, 34, 69–75. [Google Scholar]

- Zhang, L.; Sung, H.; Yang, V. Flow and Flame Dynamics in a Hydrocarbon-fueled Dual-Combustion Ramjet Engine; AIAA SciTech Forum: Orlando, FL, USA, 2020. [Google Scholar]

- Stockbridge, R.D.; Schetz, J.A.; Waltrup, P.J.; Billig, F.S. Combustor/Inlet Interactions and Modeling of Hypersonic Dual Combustor Ramjet Engines; Air Force Office of Scientific Research: Washington, WA, USA, 1984. [Google Scholar]

- Stockbridge, R.D. Experimental investigation of shock wave/boundary-layer interactionsin an annular duct. J. Propul. Power 1989, 5, 346–352. [Google Scholar] [CrossRef]

- Raghavendra Rao, M.; Amba Prasad Rao, G.; Charyulu, B.V.N.; Singh, H. Numerical studies and validation of combustor and annular isolator interactions of hydrocarbon based axisymmetric dual combustion ramjet. Aerosp. Sci. Technol. 2020, 106, 106185. [Google Scholar] [CrossRef]

- Situ, M.; Wang, C.; Lu, H. Investigation on supersonic combustion of fuel-rich hot gas as reacting jets in ramjet scramjet combustor. J. Propuls. Technol. 2001, 22, 237–240. [Google Scholar]

- Vaught, C.; Witt, M.; Netzer, D.; Gany, A. Investigation of solid-fuel, dual-mode combustion ramjets. J. Propul. Power 1992, 8, 1004–1011. [Google Scholar] [CrossRef]

- Raghavendra Rao, M.; Amba Prasad Rao, G.; Kumar, A. Experimental validation of liquid hydrocarbon based fuel rich gas generator for high speed propulsion systems. Acta Astronaut. 2020, 174, 180–188. [Google Scholar] [CrossRef]

- Tan, J.; Wu, J.; Wang, Z. Experimental and numerical investigations on flow fields and performance of dual combustion ramjet. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2014, 228, 920–929. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef] [Green Version]

- Cai, G.; Li, C.; Tian, H. Numerical and experimental analysis of heat transfer in injector plate of hydrogen peroxide hybrid rocket motor. Acta Astronaut. 2016, 128, 286–294. [Google Scholar] [CrossRef]

- Yan, D.; He, G.; Qin, F.; Zhang, D.; Shi, L. Effect of the heat release on the component coordination in the rocket-based combined cycle engine. Acta Astronaut. 2018, 151, 942–952. [Google Scholar] [CrossRef]

- Hjertager, L.K.; Hjertager, B.H.; Solberg, T. CFD modelling of fast chemical reactions in turbulent liquid flows. Comput. Chem. Eng. 2002, 26, 507–515. [Google Scholar] [CrossRef]

- Jones, W.P.; Lindstedt, R.P. Global reaction schemes for hydrocarbon combustion. Combust. Flame 1988, 73, 233–249. [Google Scholar] [CrossRef]

- Yao, W.; Yuan, Y.; Li, X.; Wang, J.; Wu, K.; Fan, X. Comparative Study of Elliptic and Round Scramjet Combustors Fueled by RP-3. J. Propul. Power 2018, 34, 772–786. [Google Scholar] [CrossRef]

- Bonfiglioli, A.; Paciorri, R. Convergence Analysis of Shock-Capturing and Shock-Fitting Solutions on Unstructured Grids. AIAA J. 2014, 52, 1404–1416. [Google Scholar] [CrossRef]

- Byun, J.; Park, C.; Kwon, O.J.; Ahn, J. Experimental Study of Combustor-Isolator Interactions in a Dual-Combustion Ramjet. J. Propul. Power 2015, 31, 592–603. [Google Scholar] [CrossRef]

- Heiser, W.H. Hypersonic Airbreathing Propulsion; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 1994. [Google Scholar]

- Liu, Y.; Gao, Y.; Chai, Z.; Dong, Z.; Hu, C.; Yu, X. Mixing and heat release characteristics in the combustor of solid-fuel rocket scramjet based on DES. Aerosp. Sci. Technol. 2019, 94, 105391. [Google Scholar] [CrossRef]

- Wu, K.; Zhang, P.; Fan, X. On jet-wake flame stabilization in scramjet: A LES/RANS study from chemical kinetic and fluid-dynamical perspectives. Aerosp. Sci. Technol. 2022, 120, 107255. [Google Scholar] [CrossRef]

| Initial Temperature, K | Flame Temperature | Ignition Delay | |||

|---|---|---|---|---|---|

| 2185 Species, K | Six-Species, K | 2185 Species, s | Six-Species, s | ||

| Condition 1 | 1600 | 2780 | 2721 | 3 × 105 | 2.6 × 107 |

| Condition 2 | 2200 | 2948 | 2898 | 3.5 × 106 | 4.6 × 108 |

| kg/s | T0, K | P0, kPa | Mac_in | |

|---|---|---|---|---|

| Scramjet 1 | 3.72 | 1694 | 889 | 2.4 |

| Scramjet 2 | 2.74 | 2224 | 1241 | 2.8 |

| DCR 1 | 3.72 | 1694 | 889 (448) | 2.4 (0.3) |

| DCR 2 | 3.03 | 2224 | 1241 (383) | 2.8 (0.3) |

| ηc | Kp | F, N | Sp, m/s | I, m/s | |

|---|---|---|---|---|---|

| Scramjet 1 | 44.4 | 0.371 | 1019 | 274 | 5009 |

| Scramjet 2 | 44.6 | 0.298 | 799 | 292 | 5338 |

| DCR 1 | 80 | 0.38 | 2719 | 731 | 13,364 |

| DCR 2 | 70 | 0.242 | 1339 | 442 | 8087 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Wei, Z. Comparison of Dual-Combustion Ramjet and Scramjet Performances Considering Combustion Efficiency. Appl. Sci. 2023, 13, 480. https://doi.org/10.3390/app13010480

Wu X, Wei Z. Comparison of Dual-Combustion Ramjet and Scramjet Performances Considering Combustion Efficiency. Applied Sciences. 2023; 13(1):480. https://doi.org/10.3390/app13010480

Chicago/Turabian StyleWu, Xianju, and Zhijun Wei. 2023. "Comparison of Dual-Combustion Ramjet and Scramjet Performances Considering Combustion Efficiency" Applied Sciences 13, no. 1: 480. https://doi.org/10.3390/app13010480

APA StyleWu, X., & Wei, Z. (2023). Comparison of Dual-Combustion Ramjet and Scramjet Performances Considering Combustion Efficiency. Applied Sciences, 13(1), 480. https://doi.org/10.3390/app13010480