Formation of ZnO/CuO Heterostructures Based on Quasi-One-Dimensional Nanomaterials

Abstract

1. Introduction

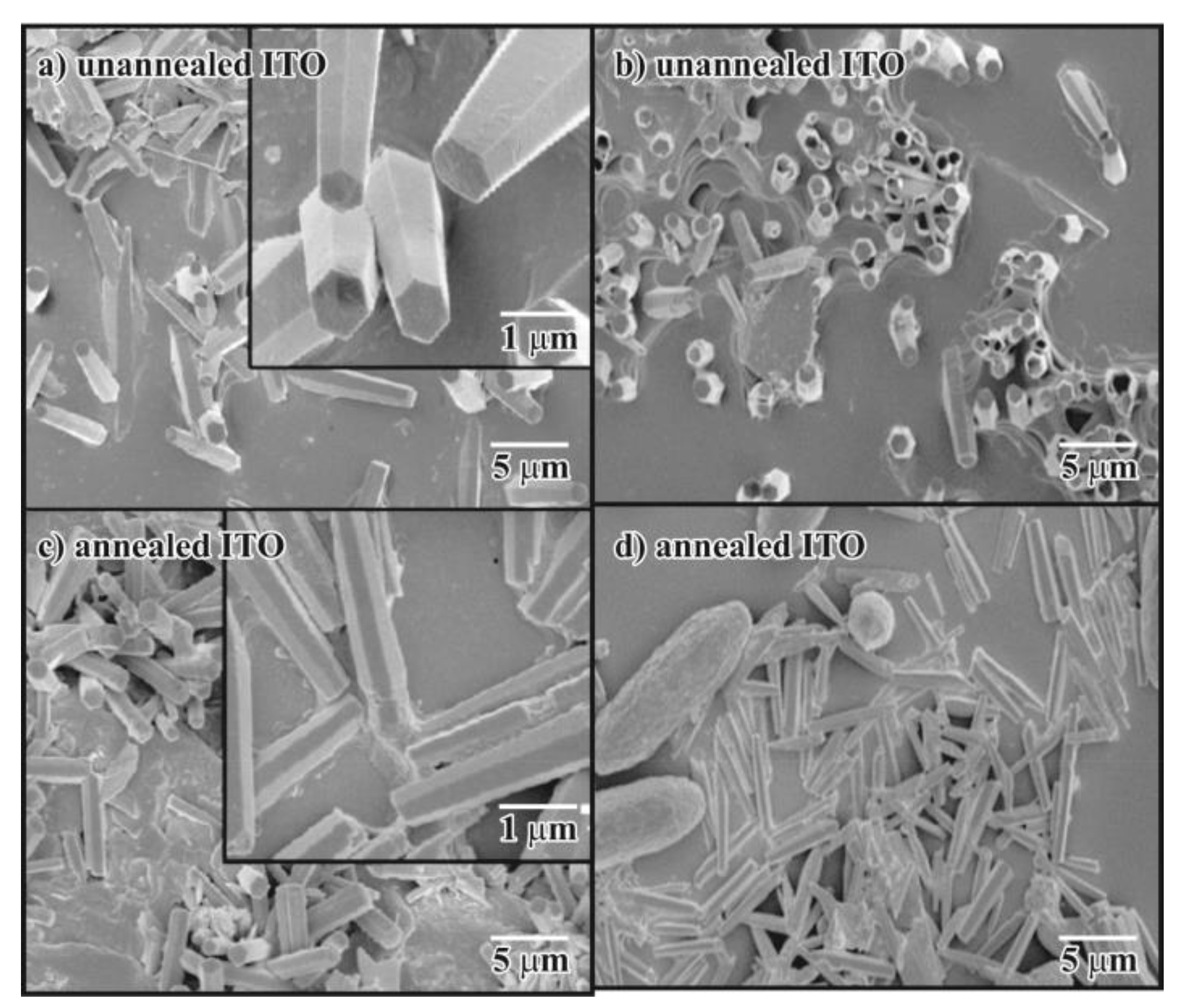

2. CuO Nanowires: Fabrication Methods, Areas of Application

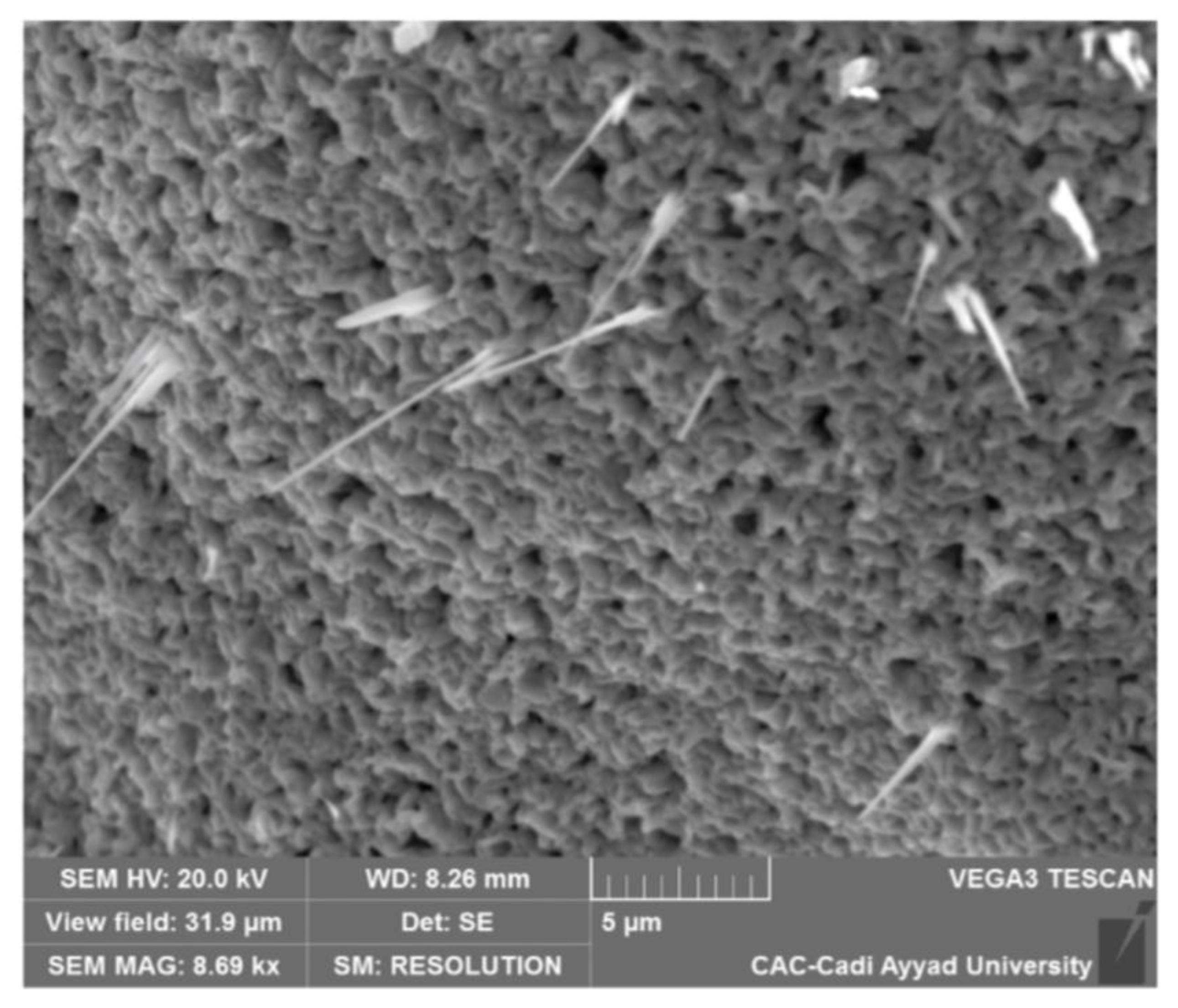

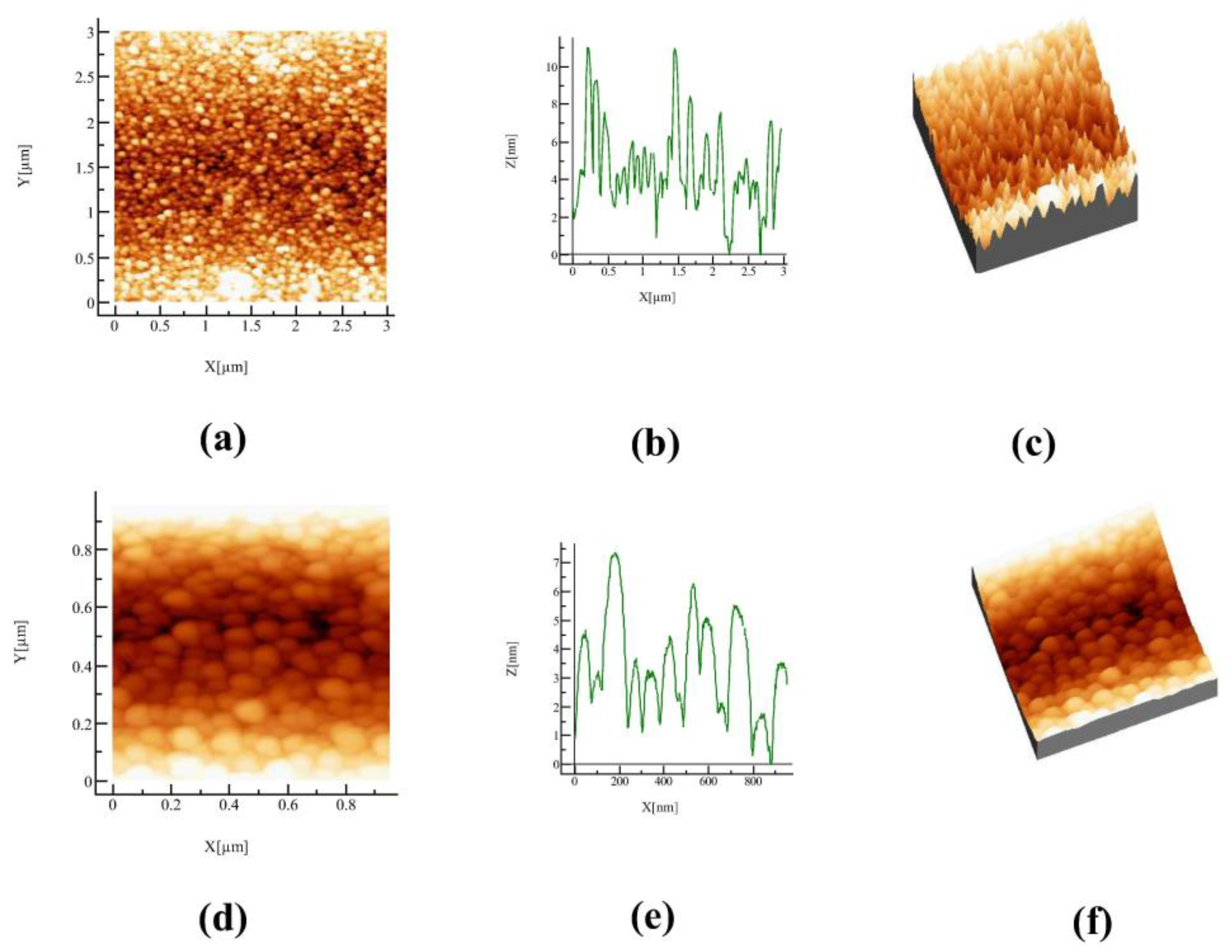

3. Applications and Peculiarities of Synthesis of ZnO-Based Quasi-One-Dimensional Nanostructures

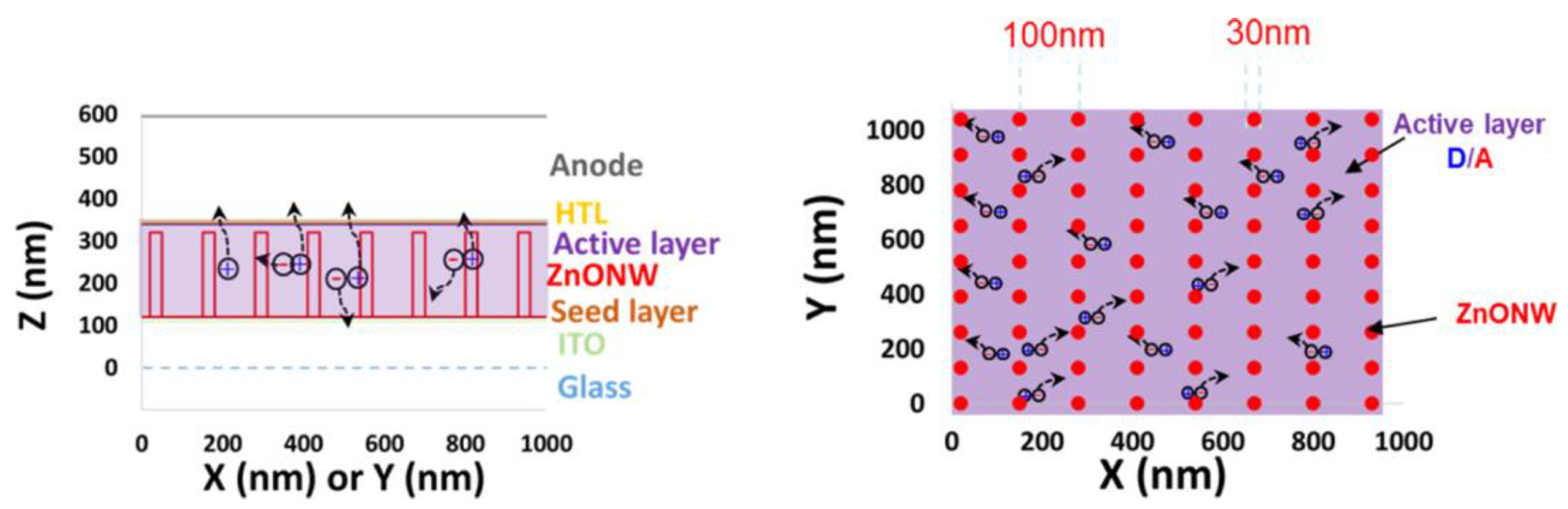

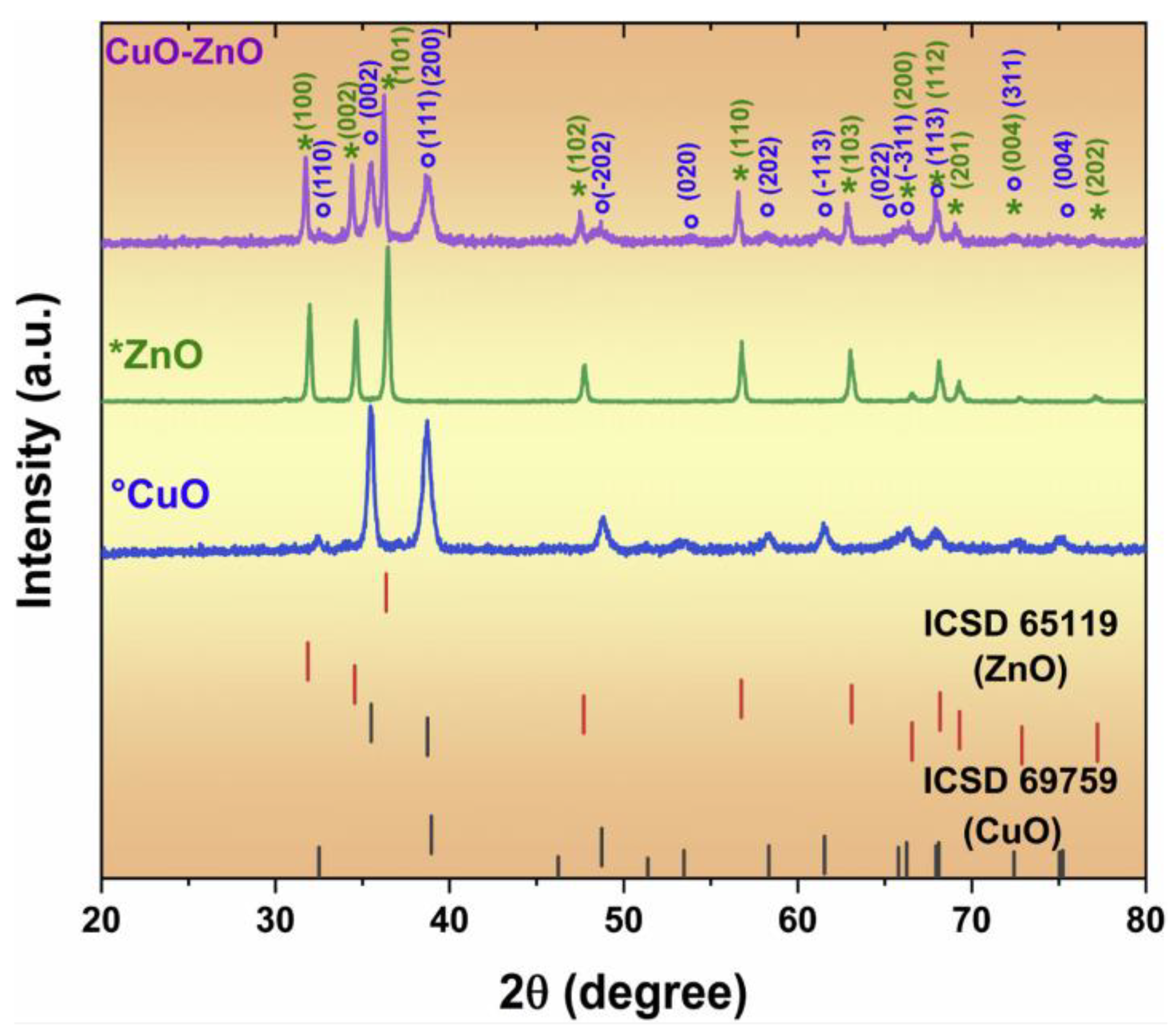

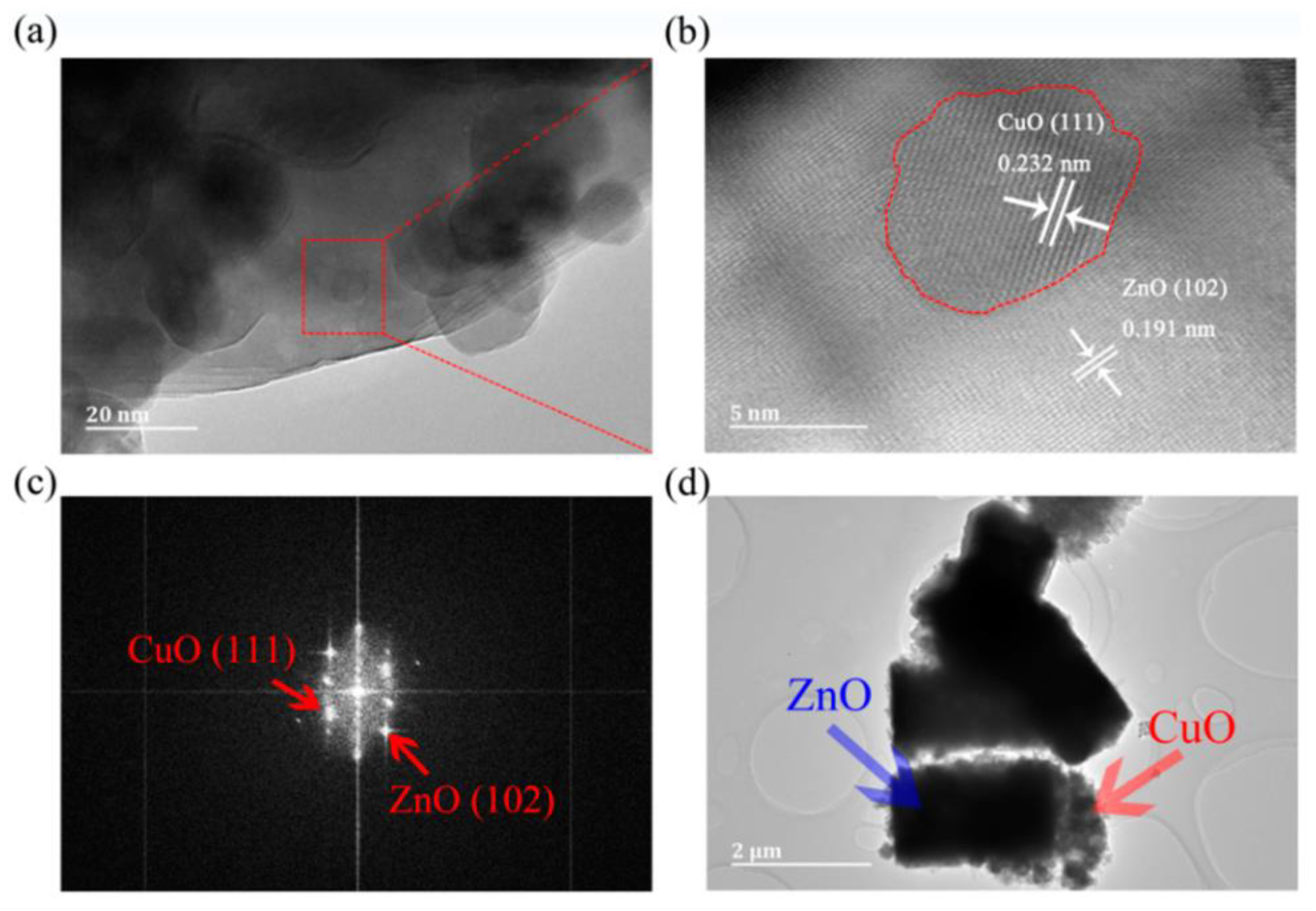

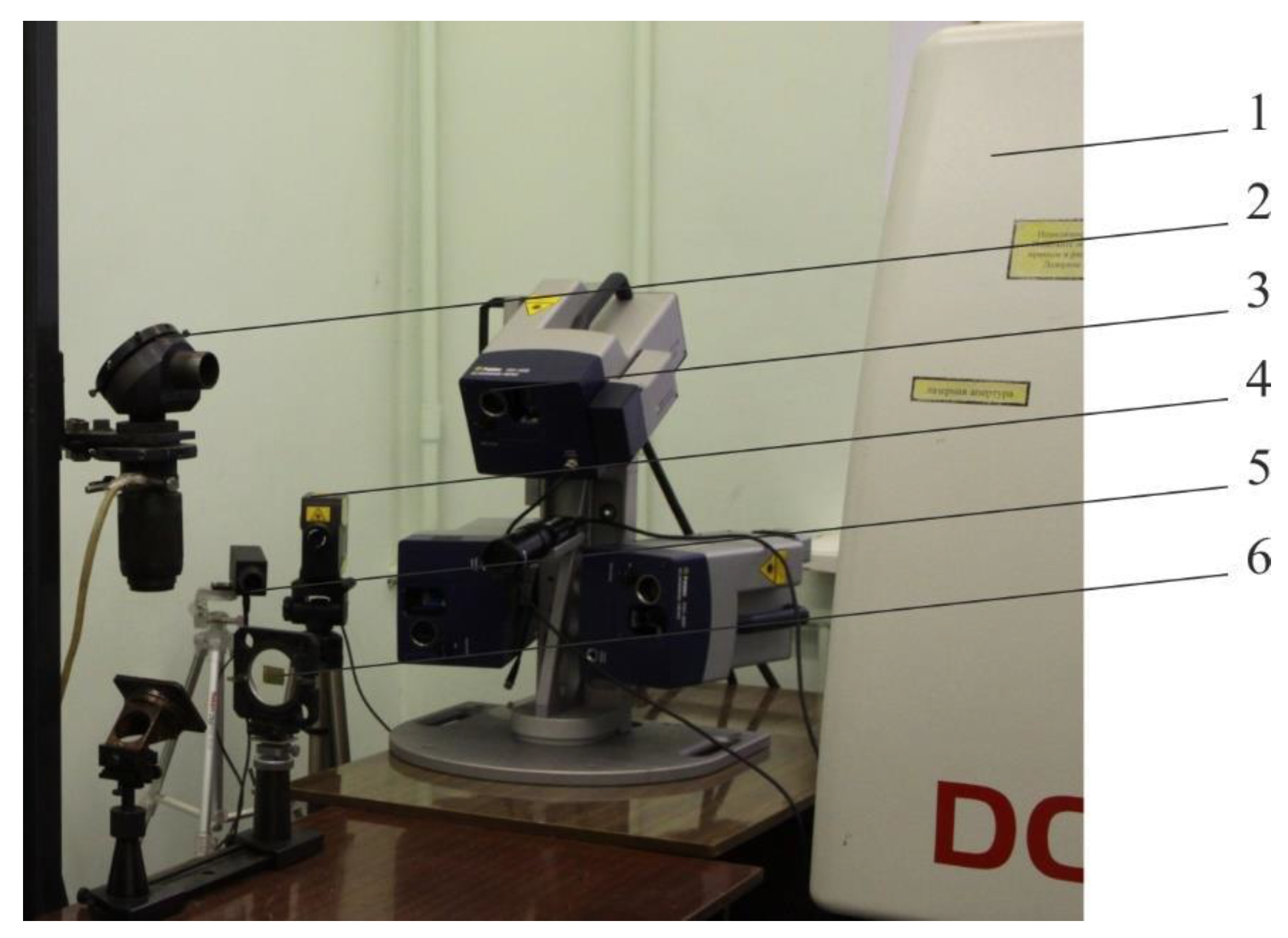

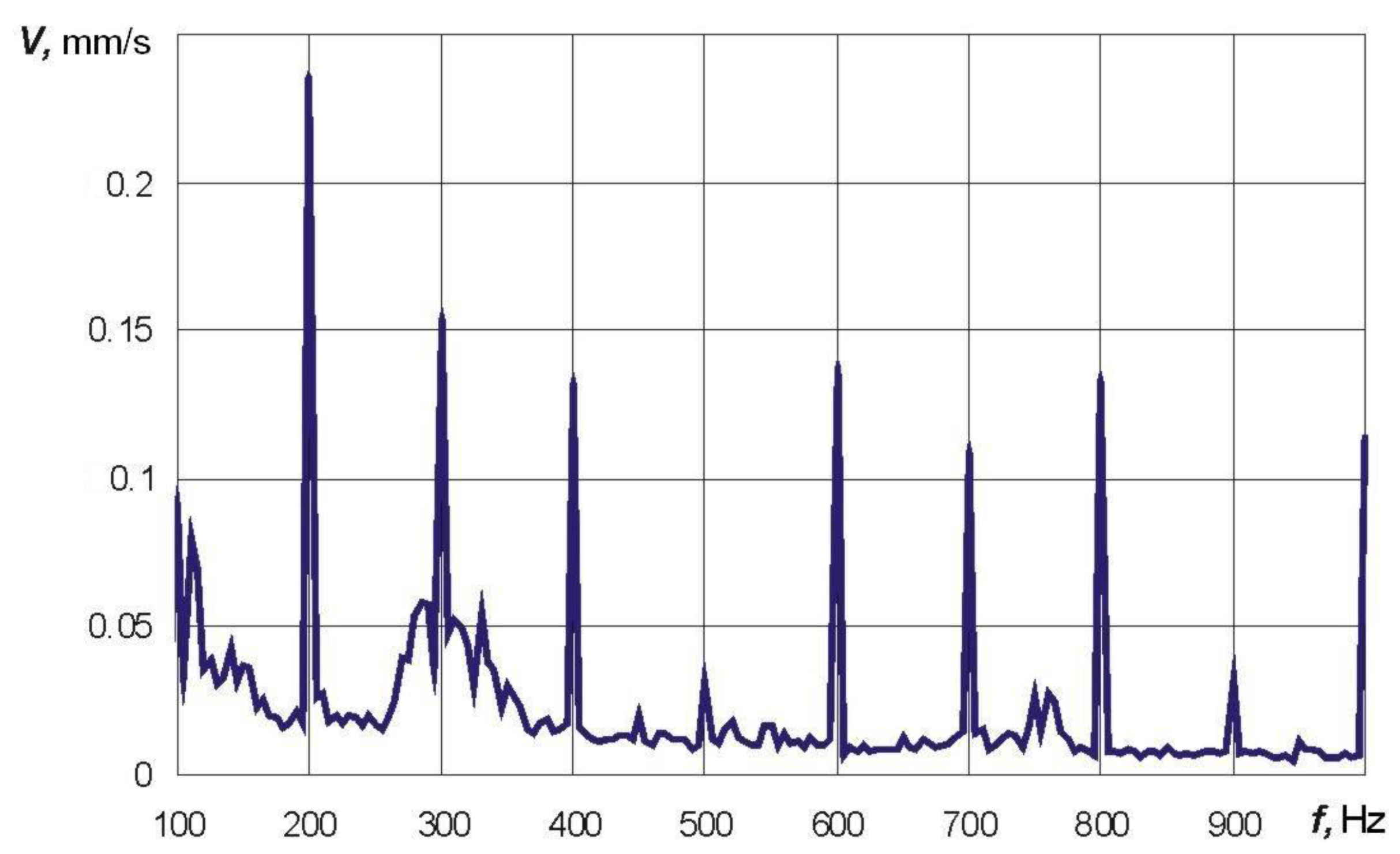

4. Synthesis of ZnO/CuO Heterostructures Based on Quasi-Dimensional Nanomaterials

5. Discussion of the Presented Results

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kolahalam, L.A.; Kasi Viswanath, I.V.; Diwakar, B.S.; Govindh, B.; Reddy, V.; Murthy, Y.L.N. Review on nanomaterials: Synthesis and applications. Mater. Today Proc. 2019, 18, 2182–2190. [Google Scholar] [CrossRef]

- Zappi, D.; Ramma, M.M.; Scognamiglio, V.; Antonacci, A.; Varani, G.; Giardi, M.T. High-tech and nature-made nanocomposites and their applications in the field of sensors and biosensors for gas detection. Biosensors 2020, 10, 176. [Google Scholar] [CrossRef]

- Diao, F.; Wang, Y. Transition metal oxide nanostructures: Premeditated fabrication and applications in electronic and photonic devices. J. Mater. Sci. 2018, 53, 4334–4359. [Google Scholar] [CrossRef]

- Nazemi, H.; Joseph, A.; Park, J.; Emadi, A. Advanced micro- and nano-gas sensor technology: A review. Sensors 2019, 19, 1285. [Google Scholar] [CrossRef] [PubMed]

- Malik, R.; Tomer, V.K.; Mishra, Y.K.; Lin, L. Functional gas sensing nanomaterials: A panoramic view. Appl. Phys. Rev. 2020, 7, 21301. [Google Scholar] [CrossRef]

- Védrine, J.C. (Ed.) Metal Oxides in Heterogeneous Catalysis; Elsevier: Oxford, UK; Cambridge, MA, USA, 2018; 596p. [Google Scholar]

- Rothenberg, G. Catalysis: Concepts and Green Applications, 2nd ed.; Wiley-VCH: Weinheim, Germany, 2017; 320p. [Google Scholar]

- Králik, M. Adsorption, chemisorption, and catalysis. Chem. Pap. 2014, 68, 1625–1638. [Google Scholar] [CrossRef]

- Védrine, J.C. Metal oxides in heterogeneous oxidation catalysis: State of the art and challenges for a more sustainable world. ChemSusChem 2019, 12, 577–588. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, H.-Y.; Jia, X.; Liu, B.; Yang, Y. One-dimensional metal oxide nanostructures for heterogeneous catalysis. Nanoscale 2013, 5, 7175–7183. [Google Scholar] [CrossRef]

- Song, H.C.; Lee, G.R.; Jeon, K.; Lee, H.; Lee, S.W.; Jung, Y.S.; Park, J.Y. Engineering nanoscale interfaces of metal/oxide nanowires to control catalytic activity. ACS Nano 2020, 14, 8335–8342. [Google Scholar] [CrossRef]

- Xu, Y.; Cao, M.; Zhang, Q. Recent advances and perspective on heterogeneous catalysis using metals and oxide nanocrystals. Mater. Chem. Front. 2021, 5, 151–222. [Google Scholar] [CrossRef]

- Fàbrega, C.; Casals, O.; Hernández-Ramírez, F.; Prades, J.D. A review on efficient self-heating in nanowire sensors: Prospects for very-low power devices. Sens. Actuators B Chem. 2018, 256, 797–811. [Google Scholar] [CrossRef]

- Korotcenkov, G. Current trends in nanomaterials for metal oxide-based conductometric gas sensors: Advantages and limitations. Part 1: 1D and 2D nanostructures. Nanomaterials 2020, 10, 1392. [Google Scholar] [CrossRef] [PubMed]

- Majhi, S.M.; Mirzaei, A.; Kim, H.W.; Kim, S.S.; Kim, T.W. Recent advances in energy-saving chemiresistive gas sensors: A review. Nano Energy 2021, 79, 105369. [Google Scholar] [CrossRef]

- Carpenter, M.A.; Mathur, S.; Kolmakov, A. Metal Oxide Nanomaterials for Chemical Sensors; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; 548p. [Google Scholar]

- Deng, Y. Semiconducting Metal Oxides for Gas Sensors; Springer: Singapore, 2019; 246p. [Google Scholar]

- Mirzaei, A.; Lee, J.-H.; Majhi, S.M.; Weber, M.; Bechelany, M.; Kim, H.W.; Kim, S.S. Resistive gas sensors based on metal-oxide nanowires. J. Appl. Phys. 2019, 126, 241102. [Google Scholar] [CrossRef]

- Mirzaei, A.; Kim, H.W.; Kim, S.S.; Neri, G. Nanostructured semiconducting metal oxide gas sensors for acetaldehyde detection. Chemosensors 2019, 7, 56. [Google Scholar] [CrossRef]

- Amiri, V.; Roshan, H.; Mirzaei, A.; Neri, G.; Ayesh, A.I. Nanostructured metal oxide-based acetone gas sensors: A review. Sensors 2020, 20, 3096. [Google Scholar] [CrossRef]

- Hung, C.M.; Le, D.T.T.; Van Hieu, N. On-chip growth of semiconductor metal oxide nanowires for gas sensors: A review. J. Sci. Adv. Mater. Devices 2017, 2, 263–285. [Google Scholar] [CrossRef]

- Comini, E. Metal oxides nanowires chemical/gas sensors: Recent advances. Mater. Today Adv. 2020, 7, 100099. [Google Scholar] [CrossRef]

- Nunes, D.; Pimentel, A.; Goncalves, A.; Pereira, S.; Branquinho, R.; Barquinha, P.; Fortunato, E.; Martins, R. Metal oxide nanostructures for sensor applications. Semicond. Sci. Technol. 2019, 34, 43001. [Google Scholar] [CrossRef]

- Kim, J.-H.; Mirzaei, A.; Kim, H.W.; Kim, S.S. Variation of shell thickness in ZnO-SnO2 core-shell nanowires for optimizing sensing behaviors to CO, C6H6, and C7H8 gases. Sens. Actuators B Chem. 2020, 302, 127150. [Google Scholar] [CrossRef]

- Wang, Y.; Duan, L.; Deng, Z.; Liao, J. Electrically transduced gas sensors based on semiconducting metal oxide nanowires. Sensors 2020, 20, 6781. [Google Scholar] [CrossRef] [PubMed]

- Chehadi, Z.; Bouabdellaoui, M.; Modaresialam, M.; Bottein, T.; Salvalaglio, M.; Bollani, M.; Grosso, D.; Abbarchi, M. Scalable disordered hyperuniform architectures via nanoimprint lithography of metal oxides. ACS Appl. Mater. Interfaces 2021, 13, 37761–37774. [Google Scholar] [CrossRef]

- Jeon, S.; Sung, S.-K.; Jang, E.-H.; Jeong, J.; Surabhi, S.; Choi, J.-H.; Jeong, J.-R. Multilayer metal-oxide-metal nanopatterns via nanoimprint and strip-off for multispectral resonance. Appl. Surf. Sci. 2018, 428, 280–288. [Google Scholar] [CrossRef]

- Wang, Y.; Kiang, K.S.; Abb, M.; Muskens, O.L.; De Groot, C.H. Electron beam lithography tri-layer lift-off to create ultracompact metal/metal oxide 2D patterns on CaF2 substrate for surface-enhanced infrared spectroscopy. Microelectron. Eng. 2015, 141, 87–91. [Google Scholar] [CrossRef]

- Kumar, R.; Chauhan, M.; Moinuddin, M.G.; Sharma, S.K.; Gonsalves, K.E. Development of nickel-based negative tone metal oxide cluster resists for sub-10 nm electron beam and helium ion beam lithography. ACS Appl. Mater. Interfaces 2020, 12, 19616–19624. [Google Scholar] [CrossRef]

- Mei, H.; Koch, A.; Wan, C.; Rensberg, J.; Zhang, Z.; Salman, J.; Hafermann, M.; Schaal, M.; Xiao, Y.; Wambold, R.; et al. Tuning carrier density and phase transitions in oxide semiconductors using focused ion beams. Nanophotonics 2022, 11, 3923–3932. [Google Scholar] [CrossRef]

- Zhao, P.; Wang, R.; Lien, D.-H.; Zhao, Y.; Kim, H.; Cho, J.; Ahn, G.H.; Javey, A. Scanning probe lithography patterning of monolayer semiconductors and application in quantifying edge recombination. Adv. Mater. 2019, 31, 1900136. [Google Scholar] [CrossRef]

- Alameri, D.; Ocola, L.E.; Kuljanshvili, I. Controlled selective CVD growth of ZnO nanowires enabled by mask-free fabrication approach using aqueous Fe catalytic inks. Adv. Mater. Interfaces 2017, 4, 1700950. [Google Scholar] [CrossRef]

- Qi, Z.; Li, S.; Sun, S.; Zhang, W.; Ye, W.; Fang, Y.; Tian, Y.; Dai, J.; Chen, C. Large-scale growth of density-tunable aligned ZnO nanorods arrays on GaN QDs. Nanotechnology 2015, 26, 415601. [Google Scholar] [CrossRef]

- Sachenko, A.V.; Kryuchenko, Y.V.; Bobyl’, A.V.; Kostylyov, V.P.; Terukov, E.I.; Bogdanov, D.A.; Panaiotti, I.E.; Sokolovskyi, I.O.; Orekhov, D.L. Analysis of the possibility of high-efficiency photovoltaic conversion in tandem heterojunction thin-layer solar cells. Tech. Phys. Lett. 2015, 41, 482–485. [Google Scholar] [CrossRef]

- Lisitski, O.L.; Kumekov, M.E.; Kumekov, S.E.; Terukov, E.I. Thin-film polycrystalline n-ZnO/p-CuO heterojunction. Semiconductors 2009, 43, 765–767. [Google Scholar] [CrossRef]

- Bobkov, A.A.; Maximov, A.I.; Moshnikov, V.A.; Somov, P.A.; Terukov, E.I. Zinc-oxide-based nanostructured materials for heterostructure solar cells. Semiconductors 2015, 49, 1357–1360. [Google Scholar] [CrossRef]

- Murzin, S.P. Laser irradiation for enhancing mass transfer in the solid phase of metallic materials. Metals 2021, 11, 1359. [Google Scholar] [CrossRef]

- Murzin, S.P.; Kryuchkov, A.N. Formation of ZnO/CuO heterostructure caused by laser-induced vibration action. Procedia Eng. 2017, 176, 546–551. [Google Scholar] [CrossRef]

- Murzin, S.P.; Kazanskiy, N.L.; Stiglbrunner, C. Analysis of the advantages of laser processing of aerospace materials using diffractive optics. Metals 2021, 11, 963. [Google Scholar] [CrossRef]

- He, C.; Cai, X.; Wei, S.-H.; Janotti, A.; Teplyakov, A.V. Self-catalyzed sensitization of CuO nanowires via a solvent-free click reaction. Langmuir 2020, 36, 14539–14545. [Google Scholar] [CrossRef]

- Konar, S.; Kalita, H.; Puvvada, N.; Tantubay, S.; Mahto, M.K.; Biswas, S.; Pathak, A. Shape-dependent catalytic activity of CuO nanostructures. J. Catal. 2016, 336, 11–22. [Google Scholar] [CrossRef]

- Zhang, D.; Wei, Y.; Zhao, M.; Wang, H.; Xia, Q.; Fang, Y. Facile two-step electrodeposition synthesis of CuO nanowires for ultrasensitive non-enzymatic sensing of glucose. Int. J. Electrochem. Sci. 2019, 14, 10835–10847. [Google Scholar] [CrossRef]

- Filipič, G.; Cvelbar, U. Copper oxide nanowires: A review of growth. Nanotechnology 2012, 23, 194001. [Google Scholar] [CrossRef]

- Wang, C.; Yang, F.; Cao, Y.; He, X.; Tang, Y.; Li, Y. Cupric oxide nanowires on three-dimensional copper foam for application in click reaction. RSC Adv. 2017, 7, 9567–9572. [Google Scholar] [CrossRef]

- Xiang, L.; Guo, J.; Wu, C.; Cai, M.; Zhou, X.; Zhang, N. A brief review on the growth mechanism of CuO nanowires via thermal oxidation. J. Mater. Res. 2018, 33, 2264–2280. [Google Scholar] [CrossRef]

- Shapouri, S.; Rajabi Kalvani, P.; Jahangiri, A.R.; Elahi, S.M. Physical characterization of copper oxide nanowire fabricated via magnetic-field assisted thermal oxidation. J. Magn. Magn. Mater. 2021, 524, 167633. [Google Scholar] [CrossRef]

- Criado, D.; Zúñiga, A. Influence of an electric current on the growth kinetics of CuO nanowires produced by oxidation. Mater. Today Commun. 2019, 19, 18–22. [Google Scholar] [CrossRef]

- Espro, C.; Donato, N.; Galvagno, S.; Aloisio, D.; Leonardi, S.G.; Neri, G. CuO nanowires-based electrodes for glucose sensors. Chem. Eng. Trans. 2014, 41, 415–420. [Google Scholar]

- Lupan, O.; Postica, V.; Cretu, V.; Wolff, N.; Duppel, V.; Kienle, L.; Adelung, R. Single and networked CuO nanowires for highly sensitive p-type semiconductor gas sensor applications. Phys. Status Solidi—Rapid Res. Lett. 2016, 10, 260–266. [Google Scholar] [CrossRef]

- Krawczyk, S.; Kozłowski, M.; Wronka, H.; Czerwosz, E. CuO nanowires sensor of gases. Proc. SPIE 2018, 10808, 108084K. [Google Scholar]

- Nkhaili, L.; Narjis, A.; Agdad, A.; Tchenka, A.; El Kissani, A.; Outzourhit, A.; Oueriagli, A. A simple method to control the growth of copper oxide nanowires for solar cells and catalytic applications. Adv. Condens. Matter Phys. 2020, 2020, 5470817. [Google Scholar] [CrossRef]

- Jasulaneca, L.; Livshits, A.I.; Meija, R.; Kosmaca, J.; Sondors, R.; Ramma, M.M.; Jevdokimovs, D.; Prikulis, J.; Erts, D. Fabrication and characterization of double-and single-clamped CuO nanowire based nanoelectromechanical switches. Nanomaterials 2021, 11, 117. [Google Scholar] [CrossRef]

- Zuo, Y.; Liu, Y.; Li, J.; Du, R.; Han, X.; Zhang, T.; Arbiol, J.; Divins, N.J.; Llorca, J.; Guijarro, N.; et al. In situ electrochemical oxidation of Cu2S into CuO nanowires as a durable and efficient electrocatalyst for oxygen evolution reaction. Chem. Mater. 2019, 31, 7732–7743. [Google Scholar] [CrossRef]

- Su, Y.; Liu, T.; Zhang, P.; Zheng, P. CuO nanowire arrays synthesized at room temperature as a high-performance anode material for Li/Na-ion batteries. Thin Solid Films 2019, 690, 137522. [Google Scholar] [CrossRef]

- Azenha, C.; Mateos-Pedrero, C.; Alvarez-Guerra, M.; Irabien, A.; Mendes, A. Enhancement of the electrochemical reduction of CO2 to methanol and suppression of H2 evolution over CuO nanowires. Electrochim. Acta 2020, 363, 137207. [Google Scholar] [CrossRef]

- Kana, N.; Kaviyarasu, K.; Khamliche, T.; Magdalane, C.M.; Maaza, M. Stability and thermal conductivity of CuO nanowire for catalytic applications. J. Environ. Chem. Eng. 2019, 7, 103255. [Google Scholar] [CrossRef]

- Yu, J.; Liao, B.; Zhang, X.; Zhou, F.; Fu, K.; Wu, X. Fabrication of CuO nanowires on copper foams by thermal oxidation and investigation of their photocatalytic properties. Xiyou Jinshu Chin. J. Rare Met. 2016, 40, 1021–1028. [Google Scholar]

- Yan, H.; Chen, Z.; He, X.; Zhang, K.; Shen, S.; Wang, Z.; Zhou, R. Fabrication and photocalytic performance of CuO nanowires on copper foam based on laser texturing. Sci. Sin. Phys. Mech. Astron. 2019, 49, 34209. [Google Scholar]

- Tran, T.H.; Nguyen, M.H.; Nguyen, T.H.T.; Dao, V.P.T.; Nguyen, P.M.; Nguyen, V.T.; Pham, N.H.; Le, V.V.; Sai, C.D.; Nguyen, Q.H.; et al. Effect of annealing temperature on morphology and structure of CuO nanowires grown by thermal oxidation method. J. Cryst. Growth 2019, 505, 33–37. [Google Scholar] [CrossRef]

- Shi, J.; Qiao, L.; Zhao, Y.; Sun, Z.; Feng, W.; Zhang, Z.; Wang, J.; Men, X. Synergistic effects on thermal growth of CuO nanowires. J. Alloys Compd. 2020, 815, 152355. [Google Scholar] [CrossRef]

- Wang, X.; Cho, H.J. Morphologies and electrical properties of multiple CuO nanowire-based device controlled by electroplating and thermal oxidation process. Microsyst. Technol. 2018, 24, 2719–2726. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, D.; Ni, X.; Meng, X.; Zhou, Y.; Sun, Z.; Kuang, Y. Better charge separation in CuO nanowire array photocathodes: Micro-/nanostructure regulation for photoelectrochemical reaction. ACS Appl. Energy Mater. 2020, 3, 6334–6343. [Google Scholar] [CrossRef]

- Yan, H.; Xiao, X.; Chen, Z.; Chen, Y.; Zhou, R.; Wang, Z.; Hong, M. Realization of adhesion enhancement of CuO nanowires growth on copper substrate by laser texturing. Opt. Laser Technol. 2019, 119, 105612. [Google Scholar] [CrossRef]

- Fritz-Popovski, G.; Sosada-Ludwikowska, F.; Köck, A.; Keckes, J.; Maier, G.A. Study of CuO nanowire growth on different copper surfaces. Sci. Rep. 2019, 9, 807. [Google Scholar] [CrossRef]

- Goel, S.; Kumar, B. A review on piezo-/ferro-electric properties of morphologically diverse ZnO nanostructures. J. Alloys Compd. 2020, 816, 152491. [Google Scholar] [CrossRef]

- Borysiewicz, M.A. ZnO as a functional material, a review. Crystals 2019, 9, 505. [Google Scholar] [CrossRef]

- Theerthagiri, J.; Salla, S.; Senthil, R.A.; Nithyadharseni, P.; Madankumar, A.; Arunachalam, P.; Maiyalagan, T.; Kim, H.-S. A review on ZnO nanostructured materials: Energy, environmental and biological applications. Nanotechnology 2019, 30, 392001. [Google Scholar] [CrossRef]

- Hadis, M.; Ümit, Ö. Zinc Oxide: Fundamentals, Materials and Device Technology; Wiley-VCH Verlag GmbH & Co.: Weinheim, Germany, 2009; 477p. [Google Scholar]

- Aisida, S.O.; Obodo, R.M.; Arshad, M.; Mahmood, I.; Ahmad, I.; Ezema, F.I.; Zhao, T.-K.; Malik, M. Irradiation-induced structural changes in ZnO nanowires. Nucl. Instrum. Methods Phys. Res. B 2019, 458, 61–71. [Google Scholar] [CrossRef]

- Al-Ruqeishi, M.S.; Mohiuddin, T.; Al-Habsi, B.; Al-Ruqeishi, F.; Al-Fahdi, A.; Al-Khusaibi, A. Piezoelectric nanogenerator based on ZnO nanorods. Arab. J. Chem. 2019, 12, 5173–5179. [Google Scholar] [CrossRef]

- Di Mauro, A.; Zimbone, M.; Fragala, M.E.; Impellizzeri, G. Synthesis of ZnO nanofibers by the electrospinning process. Mater. Sci. Semicond. 2016, 42, 98–101. [Google Scholar] [CrossRef]

- Hamzaoui, N.; Boukhachem, A.; Ghamnia, M.; Fauquet, C. Investigation of some physical properties of ZnO nanofilms synthesized by micro-droplet technique. Results Phys. 2017, 7, 1950–1958. [Google Scholar] [CrossRef]

- Bano, N.; Hussain, I.; Sawaf, S.; Alshammari, A.; Saleemi, F. Enhancement of external quantum efficiency and quality of heterojunction white LEDs by varying the size of ZnO nanorods. Nanotechnology 2017, 28, 245203. [Google Scholar] [CrossRef]

- Yun, S.; Guo, T.; Li, Y.; Gao, X.; Huang, A.; Kang, L. Well-ordered vertically aligned ZnO nanorods arrays for high-performance perovskite solar cells. Mater. Res. Bull. 2020, 130, 110935. [Google Scholar] [CrossRef]

- Galdámez-Martinez, A.; Santana, G.; Güell, F.; Martínez-Alanis, P.R.; Dutt, A. Photoluminescence of zno nanowires: A review. Nanomaterials 2020, 10, 857. [Google Scholar] [CrossRef]

- Angub, M.C.M.; Vergara, C.J.T.; Husay, H.A.F.; Salvador, A.A.; Empizo, M.J.F.; Kawano, K.; Minami, Y.; Shimizu, T.; Sarukura, N.; Somintac, A.S. Hydrothermal growth of vertically aligned ZnO nanorods as potential scintillator materials for radiation detectors. J. Lumin. 2018, 203, 427–435. [Google Scholar] [CrossRef]

- Yang, D.; Qiu, Y.; Jiang, Q.; Guo, Z.; Song, W.; Xu, J.; Zong, Y.; Feng, Q.; Sun, X. Patterned growth of ZnO nanowires on flexible substrates for enhanced performance of flexible piezoelectric nanogenerators. Appl. Phys. Lett. 2017, 110, 63901. [Google Scholar] [CrossRef]

- Consonni, V.; Briscoe, J.; Kärber, E.; Li, X.; Cossuet, T. ZnO nanowires for solar cells: A comprehensive review. Nanotechnology 2019, 30, 362001. [Google Scholar] [CrossRef]

- Nourdine, A.; Abdelli, M.; Charvin, N.; Flandin, L. Custom synthesis of ZnO nanowires for efficient ambient air-processed solar cells. ACS Omega 2021, 6, 32365–32378. [Google Scholar] [CrossRef]

- Wei, Y.; Nakamura, M.; Ding, C.; Liu, D.; Li, H.; Li, Y.; Yang, Y.; Wang, D.; Wang, R.; Hayase, S.; et al. Unraveling the organic and inorganic passivation mechanism of ZnO nanowires for construction of efficient bulk heterojunction quantum dot solar cells. ACS Appl. Mater. Interfaces 2022, 14, 36268–36276. [Google Scholar] [CrossRef]

- Saleem, M.; Farooq, W.A.; Khan, M.I.; Akhtar, M.N.; Rehman, S.U.; Ahmad, N.; Khalid, M.; Atif, M.; AlMutairi, M.A.; Irfan, M. Effect of ZnO nanoparticles coating layers on top of ZnO nanowires for morphological, optical, and photovoltaic properties of dye-sensitized solar cells. Micromachines 2019, 10, 819. [Google Scholar] [CrossRef]

- Nicaise, S.M.; Cheng, J.J.; Kiani, A.; Gradečak, S.; Berggren, K.K. Control of zinc oxide nanowire array properties with electron-beam lithography templating for photovoltaic applications. Nanotechnology 2015, 26, 75303. [Google Scholar] [CrossRef]

- Serairi, L.; Leprince-Wang, Y. ZnO nanowire-based piezoelectric nanogenerator device performance tests. Crystals 2022, 12, 1023. [Google Scholar] [CrossRef]

- Sun, L.; Sun, N.; Liu, Y.; Jiang, C. A High-sensitivity knock sensor based on zno nanowires array as piezoelectric nanogenerator. Chem. Lett. 2021, 50, 1118–1122. [Google Scholar] [CrossRef]

- Ahmad, M.; Ahmad, M.K.; Mamat, M.H.; Mohamed, A.; Suriani, A.B.; Ismail, N.M.A.N.; Soon, C.F.; Nafarizal, N. Effects of group-I elements on output voltage generation of ZnO nanowires based nanogenerator; degradation of screening effects by oxidation of nanowires. Micromachines 2022, 13, 1450. [Google Scholar] [CrossRef]

- Mohd Adnan, M.A.; Julkapli, N.M.; Abd Hamid, S.B. Review on ZnO hybrid photocatalyst: Impact on photocatalytic activities of water pollutant degradation. Rev. Inorg. Chem. 2016, 36, 77–104. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, X.; Yeom, J. A floatable piezo-photocatalytic platform based on semi-embedded ZnO nanowire array for high-performance water decontamination. Nano-Micro Lett. 2019, 11, 11. [Google Scholar] [CrossRef]

- Gaffuri, P.; Dedova, T.; Appert, E.; Danilson, M.; Baillard, A.; Chaix-Pluchery, O.; Güell, F.; Oja-Acik, I.; Consonni, V. Enhanced photocatalytic activity of chemically deposited ZnO nanowires using doping and annealing strategies for water remediation. Appl. Surf. Sci. 2022, 582, 152323. [Google Scholar] [CrossRef]

- Leprince-Wang, Y.; Martin, N.; Habba, Y.G.; Le Pivert, M.; Capochichi-Gnambodoe, M. ZnO nanostructure based photocatalysis for water purification. NanoWorld J. 2020, 6, 1–6. [Google Scholar] [CrossRef]

- Lam, S.-M.; Sin, J.-C. A green and facile hydrothermal synthesis of ZnO nanorods for photocatalytic application. JOJ Mater. Sci. 2018, 4, 555629. [Google Scholar]

- Cao, H.; Li, D.; Zhou, K.; Chen, Y. Demonstration of a ZnO-nanowire-based nanograting temperature sensor. Photonic Sens. 2023, 13, 230123. [Google Scholar] [CrossRef]

- Zhu, L.-Y.; Yuan, K.-P.; Yang, J.-H.; Hang, C.-Z.; Ma, H.-P.; Ji, X.-M.; Devi, A.; Lu, H.-L.; Zhang, D.W. Hierarchical highly ordered SnO2 nanobowl branched ZnO nanowires for ultrasensitive and selective hydrogen sulfide gas sensing. Microsyst. Nanoeng. 2020, 6, 30. [Google Scholar] [CrossRef]

- Chowdhury, P.; Roy, S.; Banerjee, N.; Dutta, K.; Gangopadhaya, U.; Biswas, U. Facile synthesis of ZnO nanofoam on ZnO nanowire for hydrogen gas detection. Nanosci. Nanotechnol.—Asia 2020, 10, 86–92. [Google Scholar] [CrossRef]

- Jabeen, M.; Ashraf, M.W.; Tayyaba, S.; Manzoor, S.; Javed, M.T.; Kumar, R.V.; Ahmed, M. Hydrogen gas sensing OF ZnO nanowires synthesis by hydrothermal technique. Dig. J. Nanomater. Biostructures 2018, 13, 263–269. [Google Scholar]

- Navarrete, E.; Güell, F.; Martínez-Alanis, P.R.; Llobet, E. Chemical vapour deposited ZnO nanowires for detecting ethanol and NO2. J. Alloys Compd. 2022, 890, 161923. [Google Scholar] [CrossRef]

- Bertuna, A.; Faglia, G.; Ferroni, M.; Kaur, N.; Arachchige, H.M.M.M.; Sberveglieri, G.; Comini, E. Metal oxide nanowire preparation and their integration into chemical sensing devices at the SENSOR lab in Brescia. Sensors 2017, 17, 1000. [Google Scholar] [CrossRef]

- Quy, C.T.; Hung, C.M.; Van Duy, N.; Hoa, N.D.; Jiao, M.; Nguyen, H. Ethanol-sensing characteristics of nanostructured ZnO: Nanorods, nanowires, and porous nanoparticles. J. Electron. Mater. 2017, 46, 3406–3411. [Google Scholar] [CrossRef]

- Kim, J.-H.; Lee, J.-H.; Park, Y.; Kim, J.-Y.; Mirzaei, A.; Kim, H.W.; Kim, S.S. Toluene- and benzene-selective gas sensors based on Pt- and Pd-functionalized ZnO nanowires in self-heating mode. Sens. Actuators B Chem. 2019, 294, 78–88. [Google Scholar] [CrossRef]

- Bhati, V.S.; Hojamberdiev, M.; Kumar, M. Enhanced sensing performance of ZnO nanostructures-based gas sensors: A review. Energy Rep. 2020, 6, 46–62. [Google Scholar] [CrossRef]

- Campos, A.C.; Paes, S.C.; Correa, B.S.; Cabrera-Pasca, G.A.; Costa, M.S.; Costa, C.S.; Otubo, L.; Carbonari, A.W. Growth of long ZnO nanowires with high density on the ZnO surface for gas sensors. ACS Appl. Nano Mater. 2020, 3, 175–185. [Google Scholar] [CrossRef]

- Bai, Z.; Xu, W.; Xie, C.; Dong, M.; Zhang, S.; Xu, J.; Xiao, S. Preparation and gas-sensing property of parallel-aligned ZnO nanofibrous films. Bull. Mater. Sci. 2013, 36, 505–511. [Google Scholar] [CrossRef][Green Version]

- Kang, Y.; Yu, F.; Zhang, L.; Wang, W.; Chen, L.; Li, Y. Review of ZnO-based nanomaterials in gas sensors. Solid State Ion. 2021, 360, 115544. [Google Scholar] [CrossRef]

- Drmosh, Q.A.; Olanrewaju Alade, I.; Qamar, M.; Akbar, S. Zinc oxide-based acetone gas sensors for breath analysis: A review. Chem. Asian J. 2021, 16, 1519–1538. [Google Scholar] [CrossRef]

- Yuan, Z.; Yin, L.; Ding, H.; Huang, W.; Shuai, C.; Deng, J. One-step synthesis of single-crystalline ZnO nanowires for the application of gas sensor. J. Mater. Sci. Mater. Electron. 2018, 29, 11559–11565. [Google Scholar] [CrossRef]

- Tamvakos, A.; Calestani, D.; Tamvakos, D.; Pullini, D.; Sgroi, M.; Pruna, A. Low concentration CO gas sensing properties of hybrid ZnO architecture. Microelectron. Eng. 2016, 160, 12–17. [Google Scholar] [CrossRef]

- Konstantinova, M.; Koprinarov, N.; Tzacheva, T.Z. Arc discharge assisted synthesis of ZnO whiskers and nanowires. Optoelectron. Adv. Mater. Rapid Commun. 2010, 4, 1709–1712. [Google Scholar]

- Koprinarov, N.; Marinov, M.; Konstantinova, M. An arc discharge by closely situated electrodes for synthesis of nanostructures. Solid State Phenom. 2010, 159, 181–184. [Google Scholar] [CrossRef]

- Kane, A.; Hinkov, I.; Brinza, O.; Hosni, M.; Barry, A.H.; Cherif, S.M.; Farhat, S. One-step synthesis of graphene, copper and zinc oxide graphene hybrids via arc discharge: Experiments and modeling. Coatings 2020, 10, 308. [Google Scholar] [CrossRef]

- Ahmad, R.; Majhi, S.M.; Zhang, X.; Swager, T.M.; Salama, K.N. Recent progress and perspectives of gas sensors based on vertically oriented ZnO nanomaterials. Adv. Colloid Interface Sci. 2019, 270, 1–27. [Google Scholar] [CrossRef]

- Huang, Y.M.; Ma, Q.-L.; Zhai, B.-G. Controlled morphology of ZnO nanostructures by adjusting the zinc foil heating temperature in an air-filled box furnace. Mater. Chem. Phys. 2014, 147, 788–795. [Google Scholar] [CrossRef]

- Cossuet, T.; Roussel, H.; Chauveau, J.-M.; Chaix-Pluchery, O.; Thomassin, J.-L.; Appert, E.; Consonni, V. Well-ordered ZnO nanowires with controllable inclination on semipolar ZnO surfaces by chemical bath deposition. Nanotechnology 2018, 29, 475601. [Google Scholar] [CrossRef]

- Paiman, S.; Hui Ling, T.; Husham, M.; Sagadevan, S. Significant effect on annealing temperature and enhancement on structural, optical and electrical properties of zinc oxide nanowires. Results Phys. 2020, 17, 103185. [Google Scholar] [CrossRef]

- Mateen Tantray, A.; Shah, M.A. Photo electrochemical ability of dense and aligned ZnO nanowire arrays fabricated through electrochemical anodization. Chem. Phys. Lett. 2020, 747, 137346. [Google Scholar] [CrossRef]

- Kasap, S.; Koughia, C.; Ruda, H.; Johanson, R. Electrical Conduction in Metals and Semiconductors. In Springer Handbook of Electronic and Photonic Materials; Kasap, S., Capper, P., Eds.; Springer: Boston, MA, USA, 2006; pp. 19–45. [Google Scholar]

- Janotti, A.; Van De Walle, C.G. Fundamentals of zinc oxide as a semiconductor. Rep. Prog. Phys. 2009, 72, 126501. [Google Scholar] [CrossRef]

- Saha, R.; Saha, N.R.; Karmakar, A.; Dalapati, G.K.; Chattopadhyay, S. Generation of oxygen interstitials with excess in situ Ga doping in chemical bath deposition process for the growth of p-type ZnO nanowires. J. Mater. Sci. Mater. Electron. 2019, 30, 8796–8804. [Google Scholar] [CrossRef]

- Tsay, C.-Y.; Hsiao, I.-P.; Chang, F.-Y.; Hsu, C.-L. Improving the photoelectrical characteristics of self-powered p-GaN film/n-ZnO nanowires heterojunction ultraviolet photodetectors through gallium and indium co-doping. Mater. Sci. Semicond. 2021, 121, 105295. [Google Scholar] [CrossRef]

- Kumari, V.; Yadav, S.; Jindal, J.; Sharma, S.; Kumari, K.; Kumar, N. Synthesis and characterization of heterogeneous ZnO/CuO hierarchical nanostructures for photocatalytic degradation of organic pollutant. Adv. Powder Technol. 2020, 31, 2658–2668. [Google Scholar] [CrossRef]

- Tan, H.; Huang, Z.; Wang, Y.; Sang, L.; Wang, L.; Jia, F.; Sun, F.; Wang, X. One-step fabrication and photocatalytic performance of sea urchin-like CuO/ZnO heterostructures. New J. Chem. 2022, 46, 16078–16089. [Google Scholar] [CrossRef]

- Lashkova, N.A.; Maximov, A.I.; Ryabko, A.A.; Bobkov, A.A.; Moshnikov, V.A.; Terukov, E.I. Synthesis of ZnO-based nanostructures for heterostructure photovoltaic cells. Semiconductors 2016, 50, 1254–1260. [Google Scholar] [CrossRef]

- Li, Z.; Jia, M.; Abraham, B.; Blake, J.C.; Bodine, D.; Newberg, J.T.; Gundlach, L. Synthesis and characterization of ZnO/CuO vertically aligned hierarchical tree-like nanostructure. Langmuir 2018, 34, 961–969. [Google Scholar] [CrossRef]

- Upadhaya, D.; Dhar Purkayastha, D. Self-cleaning activity of CuO/ZnO heterostructure: A synergy of photocatalysis and hydrophilicity. J. Taiwan Inst. Chem. Eng. 2022, 132, 104216. [Google Scholar] [CrossRef]

- Meng, Q.; Liu, W.; Jiang, J.; Zhang, X. Fabrication of novel p-CuO/n-ZnO heterojunction nanofibers by electrospinning for enhanced photocatalytic performance in the denitrification of fuel oil. Ceram. Int. 2021, 47, 19402–19413. [Google Scholar] [CrossRef]

- Karimi Shamsabadi, M.; Behpour, M. Fabricated CuO–ZnO/nanozeolite X heterostructure with enhanced photocatalytic performance: Mechanism investigation and degradation pathway. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2021, 269, 115170. [Google Scholar] [CrossRef]

- Oliveira, M.C.; Fonseca, V.S.; Andrade Neto, N.F.; Ribeiro, R.A.P.; Longo, E.; de Lazaro, S.R.; Motta, F.V.; Bomio, M.R.D. Connecting theory with experiment to understand the photocatalytic activity of CuO–ZnO heterostructure. Ceram. Int. 2020, 46, 9446–9454. [Google Scholar] [CrossRef]

- Bajiri, M.A.; Hezam, A.; Namratha, K.; Viswanath, R.; Drmosh, Q.A.; Bhojya Naik, H.S.; Byrappa, K. CuO/ZnO/g-C3N4 heterostructures as efficient visible light-driven photocatalysts. J. Environ. Chem. Eng. 2019, 7, 103412. [Google Scholar] [CrossRef]

- Peshkova, T.V.; Dimitrov, D.T.; Nalimova, S.S.; Kononova, I.E.; Nikolaev, N.K.; Papazova, K.I.; Bozhinova, A.S.; Moshnikov, V.A.; Terukov, E.I. Structures of nanowires with Zn-ZnO:CuO junctions for detecting ethanol vapors. Tech. Phys. 2014, 59, 771–776. [Google Scholar] [CrossRef]

- Daimary, S.; Dhar, J.C. Ultrafast photoresponse using axial n-ZnO/p-CuO heterostructure nanowires array-based photodetectors. IEEE Trans. Electron Devices 2022, 69, 3768–3774. [Google Scholar] [CrossRef]

- Daimary, S.; Chetri, P.; Dhar, J.C. High performance UV-A detector using axial n-ZnO/p-CuO p-n junction heterostructure nanowire arrays. IEEE Electron Device Lett. 2022, 43, 898–901. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Y.; Zhang, H. Study of highly sensitive formaldehyde sensors based on ZnO/CuO heterostructure via the sol-gel method. Sensors 2021, 21, 4685. [Google Scholar] [CrossRef]

- Cai, L.; Li, H.; Zhang, H.; Fan, W.; Wang, J.; Wang, Y.; Wang, X.; Tang, Y.; Song, Y. High performance gas sensor based on ZnO/CuO heterostructures. Lect. Notes Electr. Eng. 2021, 726, 191–198. [Google Scholar]

- Miao, Y.; Pan, G.; Sun, C.; He, P.; Cao, G.; Luo, C.; Zhang, L.; Li, H. Enhanced photoelectric responses induced by visible light of acetone gas sensors based on CuO-ZnO nanocomposites at about room temperature. Sens. Rev. 2018, 38, 311–320. [Google Scholar] [CrossRef]

- Khan, M.A.; Nayan, N.; Ahmad, M.K.; Fhong, S.C.; Mohamed Ali, M.S.; Mustafa, M.K.; Tahir, M. Interface study of hybrid CuO nanoparticles embedded ZnO nanowires heterojunction synthesized by controlled vapor deposition approach for optoelectronic devices. Opt. Mater. 2021, 117, 111132. [Google Scholar] [CrossRef]

- Ren, S.; Fan, X.; Shang, Z.; Shoemaker, W.R.; Ma, L.; Wu, T.; Li, S.; Klinghoffer, N.B.; Yu, M.; Liang, X. Enhanced catalytic performance of Zr modified CuO/ZnO/Al2O3 catalyst for methanol and DME synthesis via CO2 hydrogenation. J. CO2 Util. 2020, 36, 82–95. [Google Scholar] [CrossRef]

- Wang, G.; Mao, D.; Guo, X.; Yu, J. Enhanced performance of the CuO-ZnO-ZrO2 catalyst for CO2 hydrogenation to methanol by WO3 modification. Appl. Surf. Sci. 2018, 456, 403–409. [Google Scholar] [CrossRef]

- Tangcharoen, T.; Klysubun, W.; Kongmark, C. Synthesis and characterization of nanocrystalline CuO/ZnO composite powders with enhanced photodegradation performance under sunlight irradiation. J. Mater. Sci. Mater. Electron. 2020, 31, 12807–12822. [Google Scholar] [CrossRef]

- Xu, L.; Su, J.; Zheng, G.; Zhang, L. Enhanced photocatalytic performance of porous ZnO thin films by CuO nanoparticles surface modification. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2019, 248, 114405. [Google Scholar] [CrossRef]

- Costas, A.; Florica, C.; Preda, N.; Besleaga, C.; Kuncser, A.; Enculescu, I. Self-connected CuO–ZnO radial core–shell heterojunction nanowire arrays grown on interdigitated electrodes for visible-light photodetectors. Sci. Rep. 2022, 12, 6834. [Google Scholar] [CrossRef]

- Arafat, M.M.; Haseeb, A.S.M.A.; Rozali, S.; Brabazon, D.; Rahman, B.M.A.; Grattan, K.T.V.; Naher, S. Synthesis of ZnO and CuO nanowires by thermal oxidation on metallic substrates. Key Eng. Mater. 2022, 926, 1703–1712. [Google Scholar] [CrossRef]

- Cai, L.; Li, H.; Zhang, H.; Fan, W.; Wang, J.; Wang, Y.; Wang, X.; Tang, Y.; Song, Y. Enhanced performance of the tangerines-like CuO-based gas sensor using ZnO nanowire arrays. Mater. Sci. Semicond. Process. 2020, 118, 105196. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.; Kheel, H.; Hyun, S.K.; Jin, C.; Lee, C. Enhanced H2S gas sensing performance of networked CuO-ZnO composite nanoparticle sensor. Mater. Res. Bull. 2016, 82, 130–135. [Google Scholar] [CrossRef]

- Thu, P.T.; Thinh, V.D.; Lam, V.D.; Bach, T.N.; Phong, L.T.H.; Tung, D.H.; Manh, D.H.; Van Khien, N.; Anh, T.X.; Le, N.T.H. Decorating of Ag and CuO on ZnO nanowires by plasma electrolyte oxidation method for enhanced photocatalytic efficiency. Catalysts 2022, 12, 801. [Google Scholar] [CrossRef]

- Guo, X.; Diao, P.; Xu, D.; Huang, S.; Yang, Y.; Jin, T.; Wu, Q.; Xiang, M.; Zhang, M. CuO/Pd composite photocathodes for photoelectrochemical hydrogen evolution reaction. Int. J. Hydrog. Energy 2014, 39, 7686–7696. [Google Scholar] [CrossRef]

- Rahmati, A.; Zakeri-Afshar, S. Heteroepitaxial ZnO/CuO thin film and nanorods array: Photoconductivity and field emission effect. J. Mater. Sci. Mater. Electron. 2017, 28, 13032–13040. [Google Scholar] [CrossRef]

- Bobkov, A.A.; Lashkova, N.A.; Maximov, A.I.; Moshnikov, V.A.; Nalimova, S.S. Fabrication of oxide heterostructures for promising solar cells of a new generation. Semiconductors 2017, 51, 61–65. [Google Scholar] [CrossRef]

- Rackauskas, S. (Ed.) Nanowires—Synthesis, Properties and Applications; IntechOpen: London, UK, 2019; 122p. [Google Scholar]

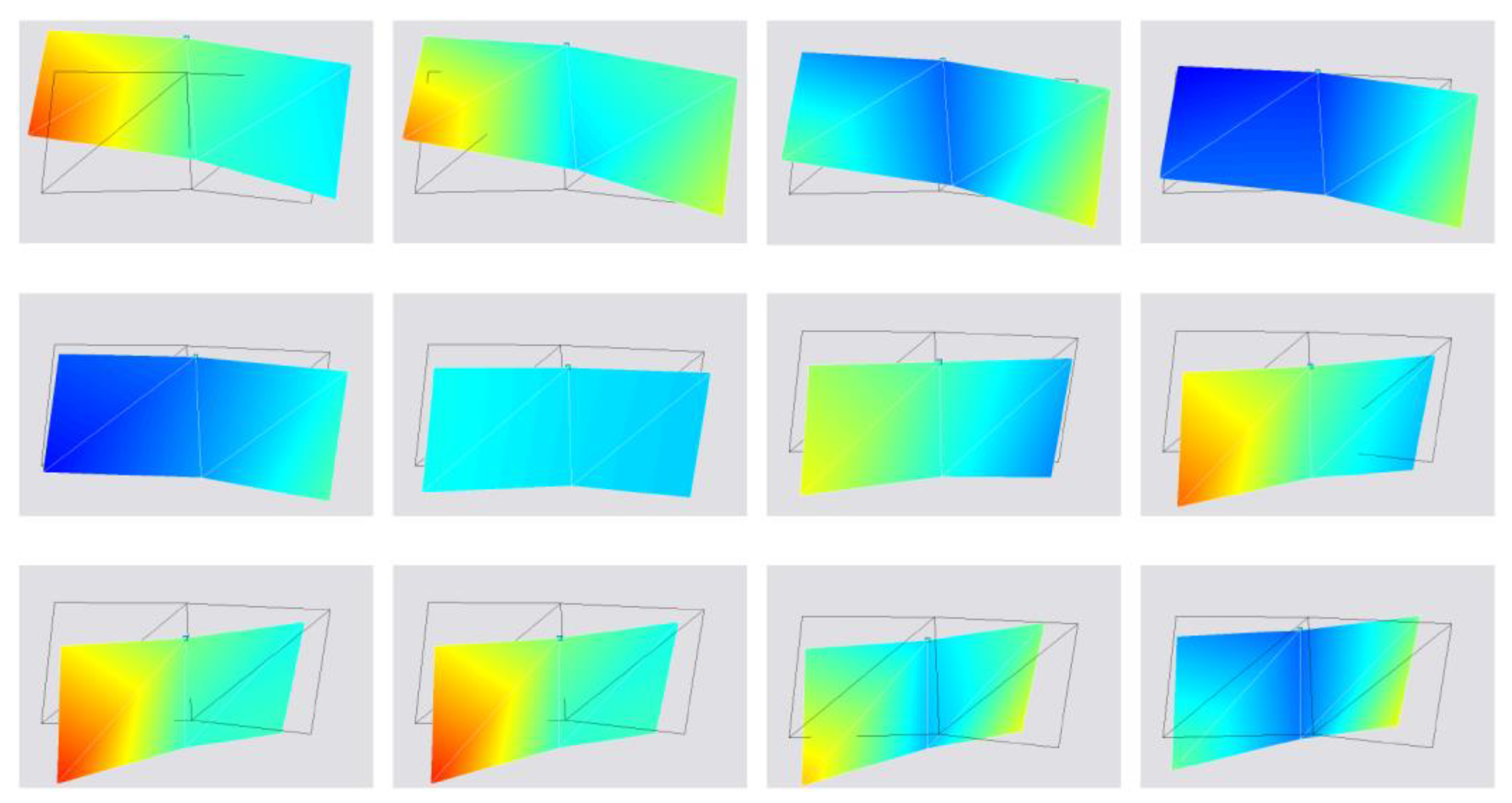

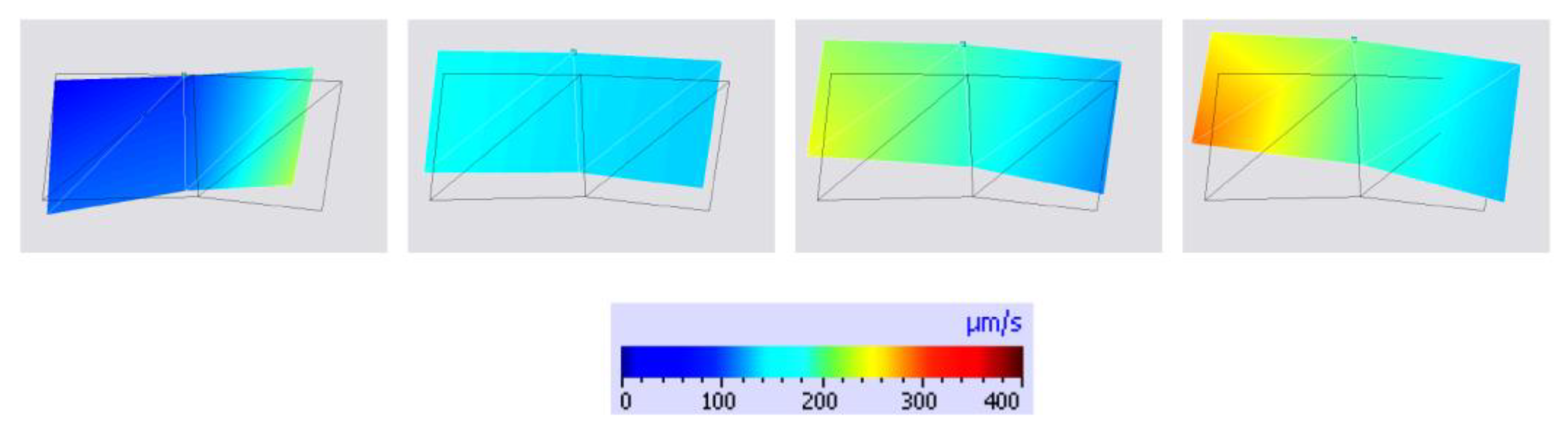

- Lausecker, C.; Salem, B.; Baillin, X.; Consonni, V. Implementing the reactor geometry in the modeling of chemical bath deposition of ZnO nanowires. Nanomaterials 2022, 12, 1069. [Google Scholar] [CrossRef]

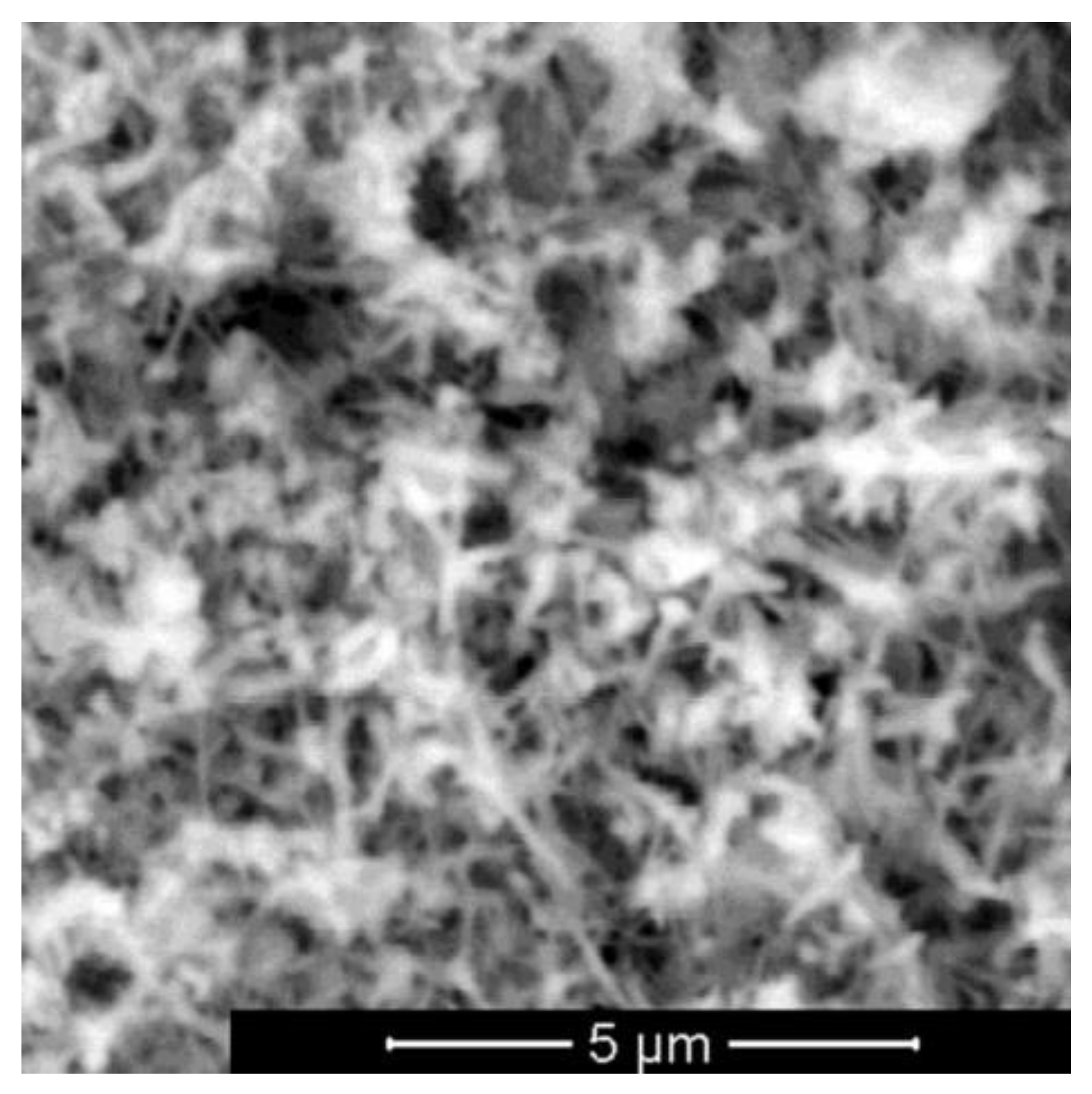

- Kazanskiy, N.L.; Murzin, S.P.; Osetrov, Y.L.; Tregub, V.I. Synthesis of nanoporous structures in metallic materials under laser action. Opt. Lasers Eng. 2011, 49, 1264–1267. [Google Scholar] [CrossRef]

- Murzin, S.P. Exposure to laser radiation for creation of metal materials nanoporous structures. Opt. Laser Technol. 2013, 48, 509–512. [Google Scholar] [CrossRef]

- Murzin, S.P. Formation of nanoporous structures in metallic materials by pulse-periodic laser treatment. Opt. Laser Technol. 2015, 72, 48–52. [Google Scholar] [CrossRef]

- Murzin, S.P. Improvement of thermochemical processes of laser-matter interaction and optical systems for wavefront shaping. Appl. Sci. 2022, 12, 12133. [Google Scholar] [CrossRef]

- Murzin, S.P.; Kazanskiy, N.L. Arrays formation of zinc oxide nano-objects with varying morphology for sensor applications. Sensors 2020, 20, 5575. [Google Scholar] [CrossRef]

- Murzin, S.P.; Afanasiev, S.A.; Blokhin, M.V. Pulse-periodic laser action to create an ordered heterogeneous structure based on copper and zinc oxides. J. Phys. Conf. Ser. 2018, 1096, 12139. [Google Scholar] [CrossRef]

- Adilov, S.R.; Kumekov, M.E.; Kumekov, S.E.; Terukov, E.I. Model of the formation of a polycrystalline n-ZnO/p-CuO heterojunction. Semiconductors 2013, 47, 655–656. [Google Scholar] [CrossRef]

- Kampara, R.K.; Sonia, T.; Jeyaprakash, B.G. CuO/ZnO heterojunction nanograins: Methanol vapour detection. J. Electron. Mater. 2021, 50, 2482–2495. [Google Scholar] [CrossRef]

- Wang, P.; Jia, C.; Huang, Y.; Duan, X. Van der Waals heterostructures by design: From 1D and 2D to 3D. Matter 2021, 4, 552–581. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Xu, K.; Yao, Q.; Jannat, A.; Ren, G.; Field, M.R.; Wen, X.; Zhou, C.; Zavabeti, A.; Ou, J.Z. Hexagonal metal oxide monolayers derived from the metal–gas interface. Nat. Mater. 2021, 20, 1073–1078. [Google Scholar] [CrossRef]

- Parkinson, G.S. Adding oxides to the 2D toolkit. Nat. Mater. 2021, 20, 1041–1042. [Google Scholar] [CrossRef]

- Doskolovich, L.L.; Mingazov, A.A.; Byzov, E.V.; Skidanov, R.; Ganchevskaya, S.; Bykov, D.A.; Bezus, E.A.; Podlipnov, V.V.; Porfirev, A.P.; Kazanskiy, N.L. Hybrid design of diffractive optical elements for optical beam shaping. Opt. Express 2021, 29, 31875–31890. [Google Scholar] [CrossRef]

- Kharitonov, S.I.; Doskolovich, L.L.; Kazanskiy, N.L. Solving the inverse problem of focusing laser radiation in a plane region using geometrical optics. Comput. Opt. 2016, 40, 439–450. [Google Scholar] [CrossRef]

- Murzin, S.P.; Kazanskiy, N.L. Use of diffractive optical elements for beam intensity redistribution. Proc. SPIE 2020, 11516, 115160H. [Google Scholar]

- Murzin, S.P.; Kazanskiy, N.L. Study of the beam intensity redistribution in the focal plane of diffractive optical element. Proc. SPIE 2019, 11146, 111460V. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murzin, S.P. Formation of ZnO/CuO Heterostructures Based on Quasi-One-Dimensional Nanomaterials. Appl. Sci. 2023, 13, 488. https://doi.org/10.3390/app13010488

Murzin SP. Formation of ZnO/CuO Heterostructures Based on Quasi-One-Dimensional Nanomaterials. Applied Sciences. 2023; 13(1):488. https://doi.org/10.3390/app13010488

Chicago/Turabian StyleMurzin, Serguei P. 2023. "Formation of ZnO/CuO Heterostructures Based on Quasi-One-Dimensional Nanomaterials" Applied Sciences 13, no. 1: 488. https://doi.org/10.3390/app13010488

APA StyleMurzin, S. P. (2023). Formation of ZnO/CuO Heterostructures Based on Quasi-One-Dimensional Nanomaterials. Applied Sciences, 13(1), 488. https://doi.org/10.3390/app13010488