Abstract

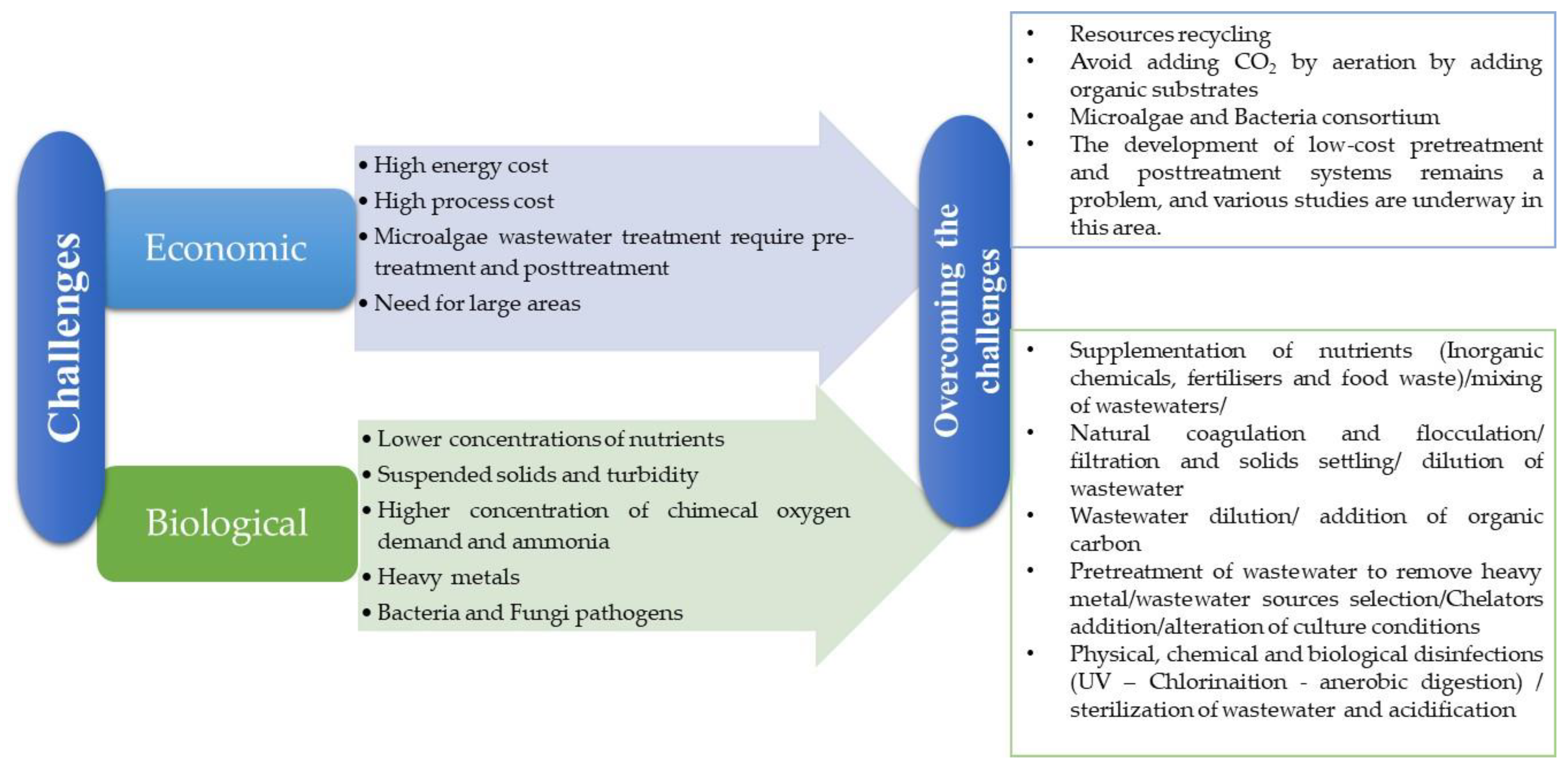

In addition to producing bioenergy and molecules with high added value, microalgae have been recognized as an efficient microorganism for wastewater treatment. However, a major obstacle preventing its widespread use is the high energy cost of pretreatment, cultivation and downstream processes. Different types of wastewaters have been tested as culture mediums for microalgal biorefinery system. This review gives a summary of the most used microalgae strains for wastewater treatment, as well as information on the physical and chemical characteristics of domestic, agricultural, and industrial wastewaters. It also discusses wastewater pretreatment techniques, nutrient uptake and removal, biomass production and biomolecules productivities. There is also discussion on how microalgae remove contaminants from wastewater. Additionally, the problems and restrictions of microalgae-based wastewater treatment are explored, and recommendations are made for additional study and advancement. This literature review demonstrates that microalgae monoculture systems have proven to be beneficial as an innovative wastewater treatment technology, due to its high efficiencies in pollutant removals and biomolecule production; however, the upstream and downstream treatment pose a limit to industrialize the process. Until now, there has been no conventional design of the wastewater treatment process using microalgae in the biorefinery system, which constitutes a huge gap to assess a real life cycle assessment (LCA) and techno economic analysis (TEA).

1. Introduction

Nowadays, planet earth is dealing with two significant issues: energy and water crises. According to [1], between 2015 and 2040, the global energy consumption is expected to rise by 28%, while the global use of petroleum-based fossil fuels would rise from 190 to 230 quadrillion British thermal unit. Additionally, excessive fossil fuel use not only depletes natural resources but causes continual increases in the carbon dioxide emissions, which contributes toward global warming [2]. Biodiesel from microalgae has been proposed as an alternative renewable fuel source [3], but the cost of production (160–480 USD BBL−1) is more than the cost of crude oil and over 50% of the overall price is often attributed to the price of freshwater, fertilizers and the harvesting procedure [4].

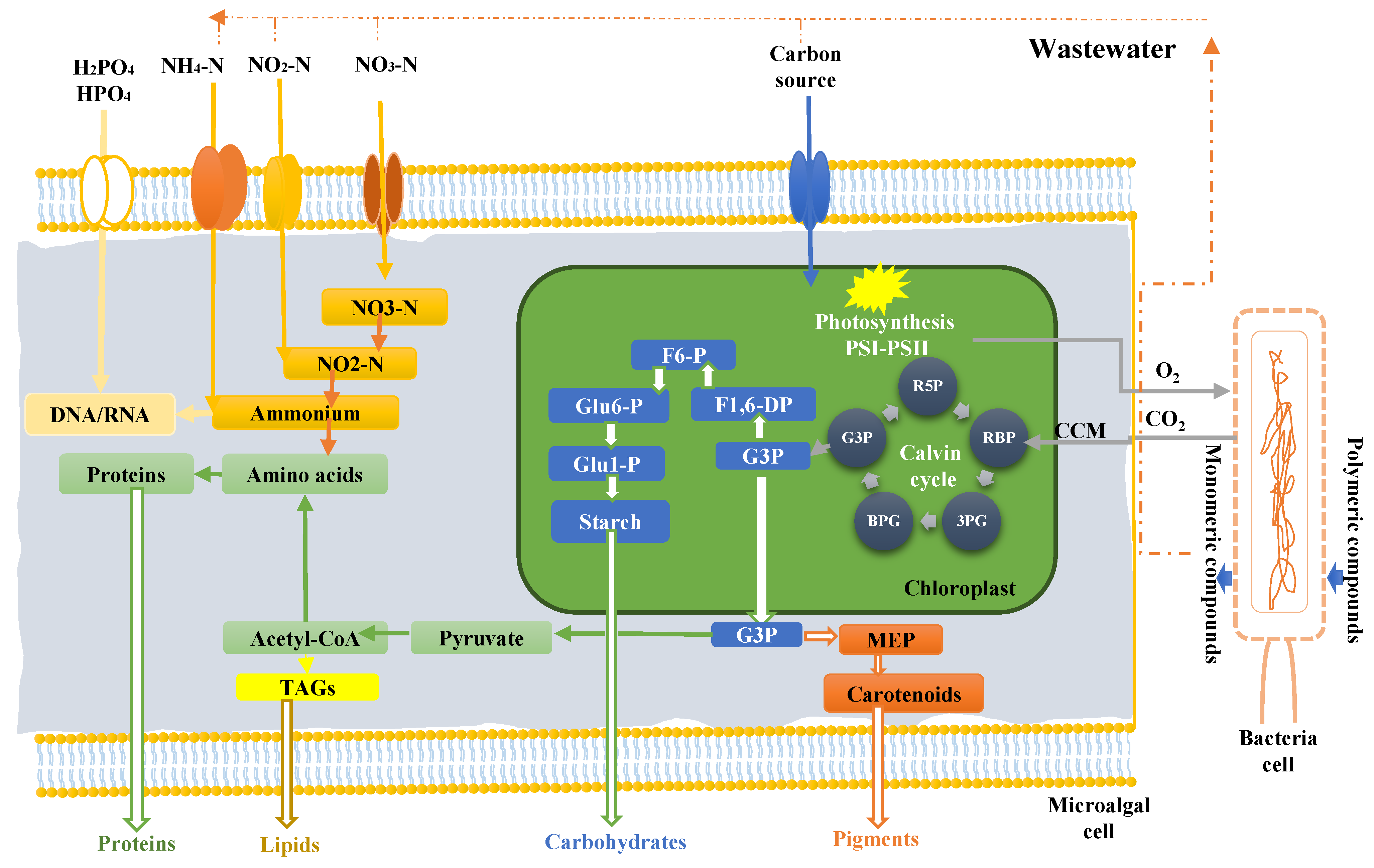

Freshwater represents only 0.5% of the global water on planet earth, and its consumption increases with the increasing population and industrial activity, which generate 380 trillion L y−1 of wastewater in the world [5]. In addition, by 2050, more than 50% of the planet’s population is projected to face chronic water shortages, hence the need for wastewater recycling [6]. As reported in this review, domestic, agricultural and industrial wastewaters contain significant concentrations of nutrients, including phosphorus, carbon and nitrogen, which are required for the growth of microalgae. Microalgae-based biorefineries for biofuels and wastewaters treatment have received a lot of interest to tackle the energy and water scarcity [1,5,7]. Consequently, researchers have frequently used wastewater from different sources for microalgae cultivation, in order to determine the potential of microalgae for simultaneous wastewater treatment. Recently, Chlorella pyrenoidosa (No. FACHB-863) was employed for its wastewater treatment ability to eliminate contaminants from synthetic tobacco wastewater [8]. The study’s findings demonstrated that Chlorella pyrenoidosa may grow in this kind of effluent, with a maximum biomass of 540.24 mg L−1. Arthrospira has been cultivated in seawater with the addition of anaerobic animal waste effluent to produce biofuels (biogas, biodiesel and biohydrogen) and high added value materials [7]. Although it has been widely studied in previous research, the use of wastewater for a biorefinery system at a low cost is rare on an industrial scale, because this cultivation method still has challenges that limit its application; however, several pieces of research are now underway for its implementation in the future.

In order to identify prospective directions for future research on microalgae-based bioremediation, this review intends to highlight the advances and existing work concerning the use of microalgae in wastewater treatment for a biorefinery system.

Following these guidelines, the available literature was assessed to accomplish the purpose of this review:

- Wastewater treatment by microalgae: In this section we present the physicochemical properties of domestic wastewater that have been used in domestic wastewater treatment by microalgae, followed by the pretreatment of domestic wastewater before microalgae cultivation, as well as pollutant removals such as chemical oxygen demand (COD), total nitrate (TN) and total phosphate (TP) removals, biomass generation and the productivity of biomolecules after microalgae cultivation, using different species that have been tested in the literature. The same parameters have been explored for both agricultural wastewater and industrial wastewater.

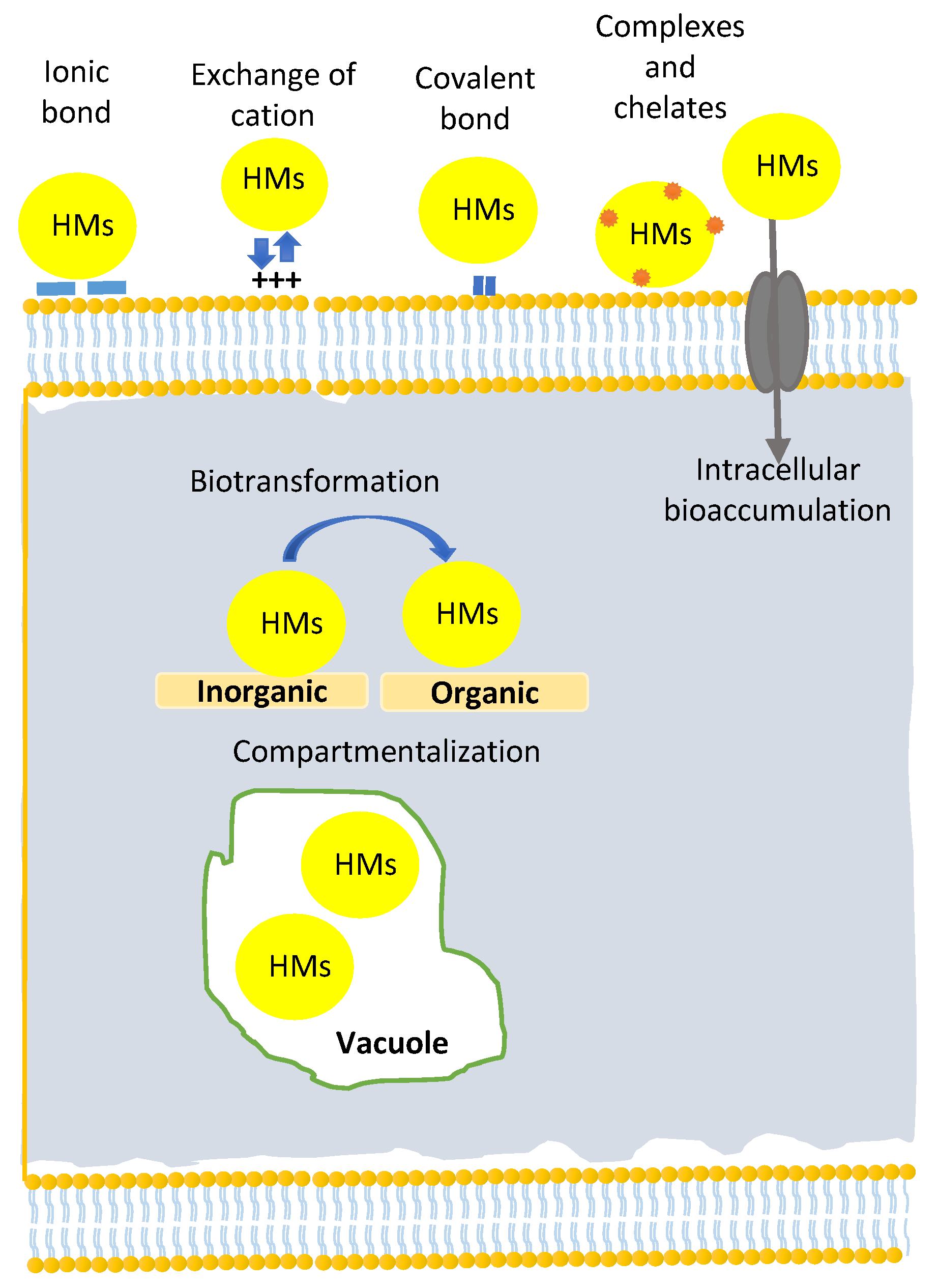

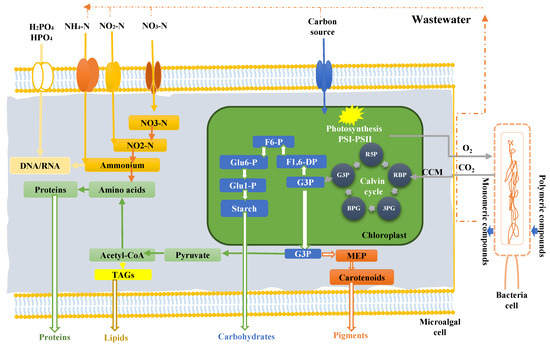

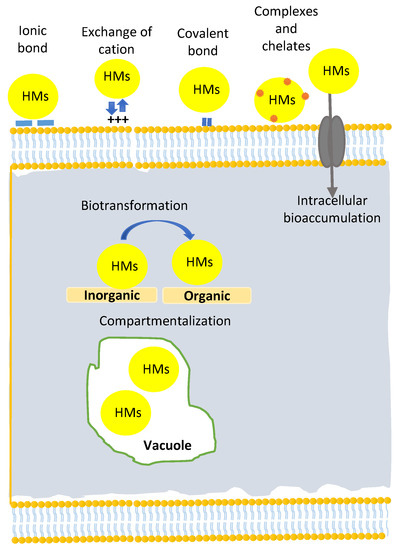

- Microalgal mechanisms for wastewater bioremediation: As the biodegradation response of microalgae to contaminants varies from one pollutant to another, we focus on the following mechanisms in this section: CO2 fixation, nitrogen sources assimilation, phosphate sources assimilation and heavy metals biodegradation mechanisms.

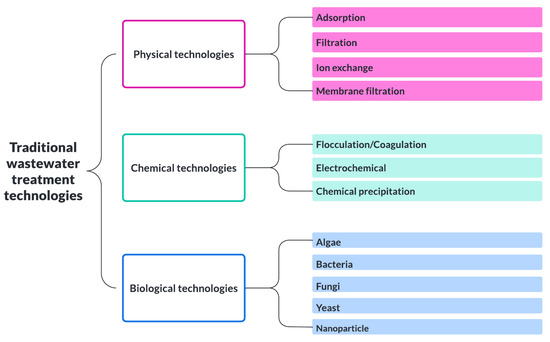

- Economic analysis of microalgae wastewater treatment technologies: In this section we compared microalgae wastewater treatment technologies with co-culture technologies such as microalgae-bacteria, microalgae-fungi, microalgae-yeast and microalgae-Nanoparticle. Furthermore, we discussed a life cycle assessment (LCA) and a techno economic assessment (TEA) of microalgae-based wastewater treatment process.

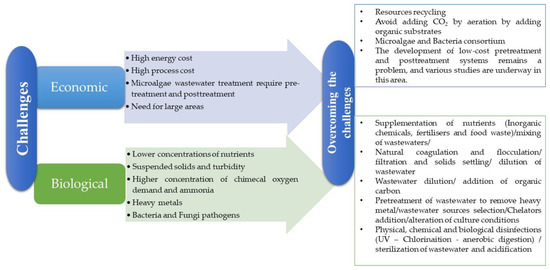

- Challenges and prospects: We have proposed strategies to overcome the challenges that the microalgae-based wastewater treatment process is facing.

2. Wastewater Treatment by Microalgae

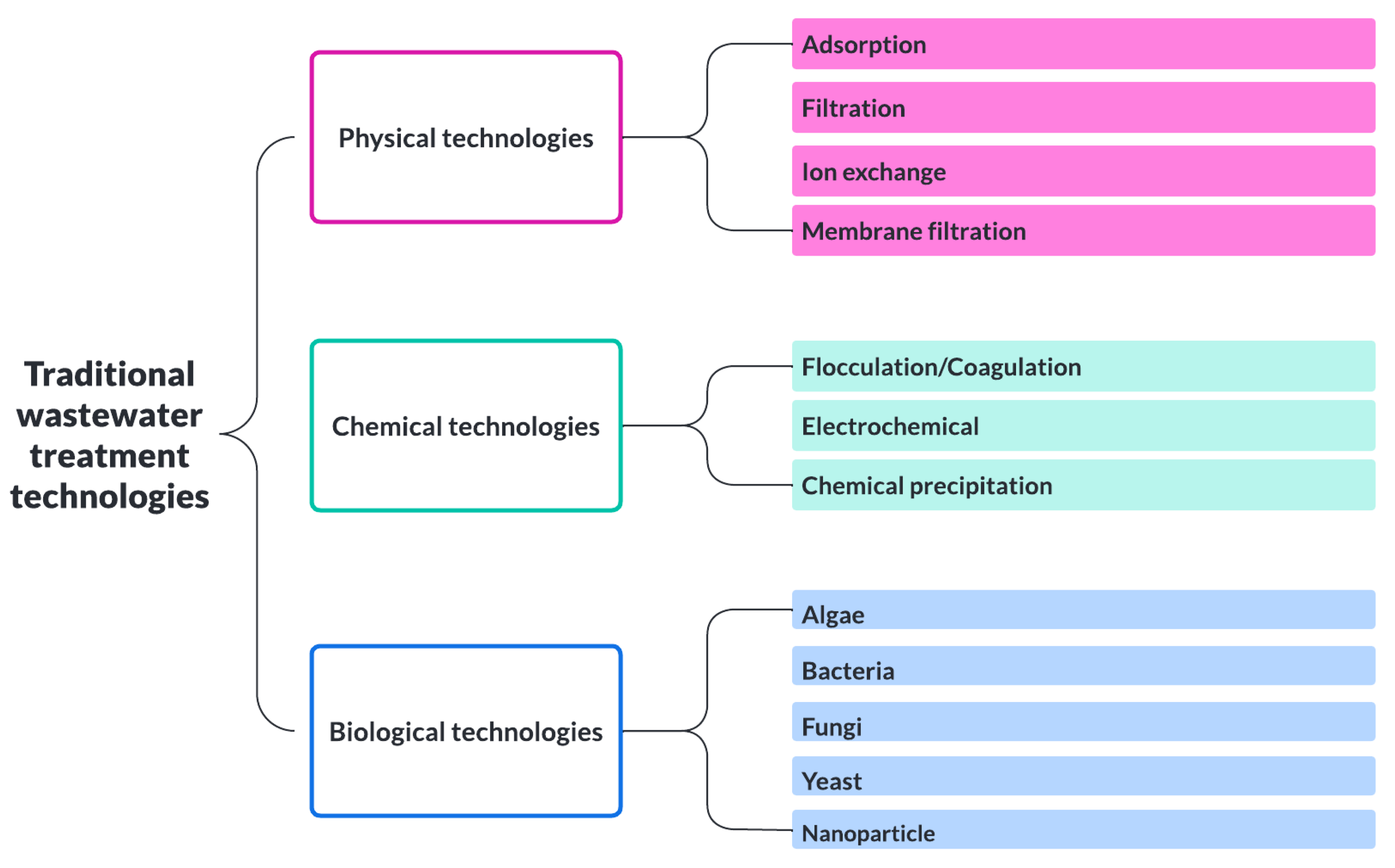

Different species of microalgae have been used to remediate various types of wastewaters in recent times. In terms of the wastewater employed, Table 1, Table 2, Table 3, Table 4, Table 5, Table 6, Table 7, Table 8, Table 9, Table 10, Table 11 and Table 12 describe the culture conditions, treatment efficiency, final biomass generated and its biochemical composition.

2.1. Domestic Wastewater

2.1.1. Physicochemical Properties

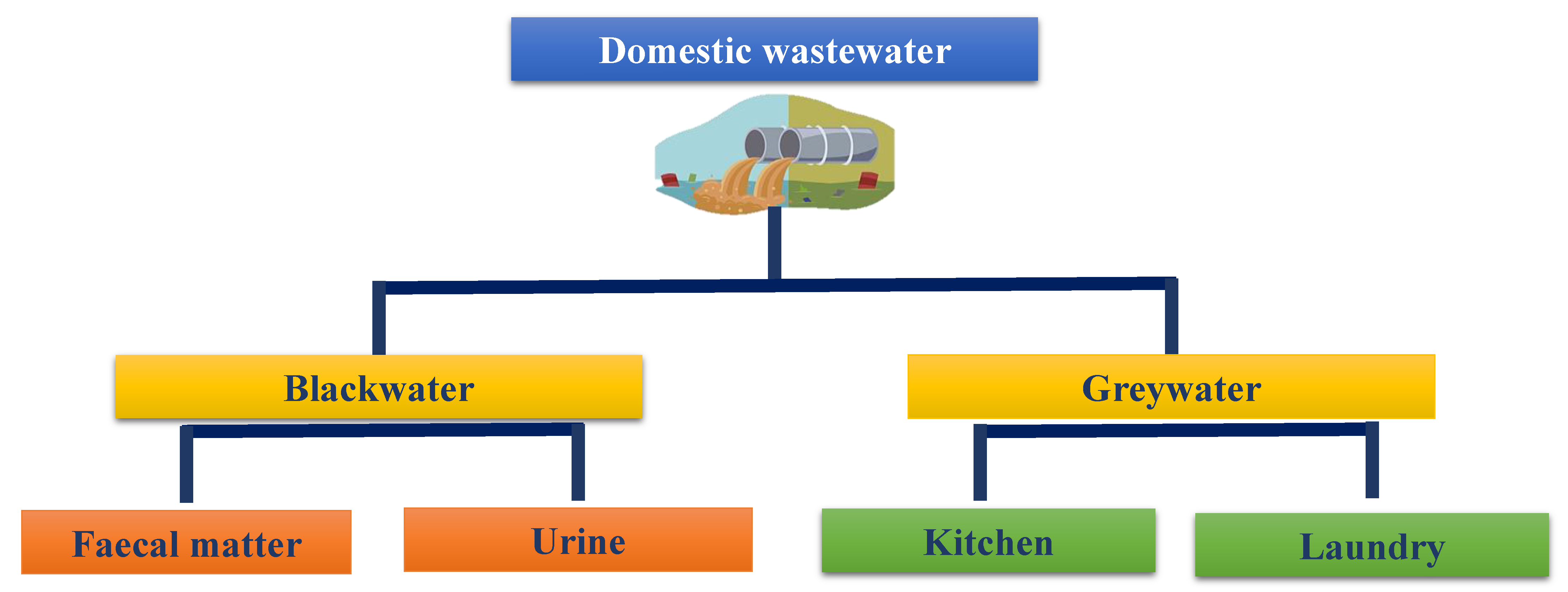

Domestic effluent is defined as water that has been used by a population and contains all the materials that have been added to it throughout its usage [9]. It is generally classified into two types (Figure 1): black-water and grey-water, and is mostly made up of discharge from domestic and home activities [10]. In some part of the world, this type of wastewater is disposed into drainage systems, lakes and rivers without any previous treatment, posing challenges to the enhancement of the community’s living conditions, because untreated wastewater has a significant negative impact on the environment and human health [9,11]. Black-water may consist of urine, flash water, fecal matter, toilet paper and others water, such as water from cleaning activities [10], and grey-water is wastewater that comes from kitchen sinks, laundromats and showers, or any other domestic activity other than toilet waste [11]. Kitchen wastewater is a type of wastewater that includes a lot of ammonium due to food protein degradation, and its excessive thickness supplements a terrible odor signal that must be treated. The treatment of kitchen wastewater by microalgae has been explored and it appeared that the collected kitchen wastewater had a high organic content due to the existence of oil, grease and food products and was acidic, with chemical oxygen demand (COD) levels ranging from 800 mg L−1 to 1400 mg L−1, compared to raw sewage wastewater which has COD levels ranging from 250 mg L−1 to 800 mg L−1 [12]. To solve this problem and make the kitchen wastewater acceptable for microalgal development, it should be diluted by about 1:1 with water [12].

Figure 1.

Domestic wastewater types.

The composition of different domestic wastewaters, which have been used in the literature for microalgae culture, is given in Table 1. As described in this table, sewage effluent has a pH of 6.6 to 8.81, a chemical oxygen demand (COD) of 97 mg L−1 to 1100 mg L−1, a total nitrate content (TN) of 0.22 mg L−1 to 265 mg L−1, a total phosphate concentration (TP) of 0.6 mg L−1 to 170 mg L−1 and other constituents such as chloride and potassium. Kitchen wastewater has a COD content of 560 mg L−1, whereas toilet wastewater has a COD value of 506.8 mg L−1, with TN and TP levels of 203.6 mg L−1 and 22.3 mg L−1, respectively. As a reason, using domestic wastewater for microalgae growth is a suitable choice for both wastewater treatment and the generation of biodiesel and other chemicals from the produced biomass.

Table 1.

Domestic wastewater composition.

Table 1.

Domestic wastewater composition.

| Type | pH | TSS (mg L−1) | TOC (mg L−1) | COD (mg L−1) | NO3-N (mg L−1) | NO2-N (mg L−1) | NH4-N (mg L−1) | NH3-N (mg L−1) | PO4-P (mg L−1) | TN (mg L−1) | TP (mg L−1) | References |

| Secondarily Treated Sewage | 7.63 | - | 5.5 | - | 7.67 | 0.01 | 0.17 | - | 0.02 | 8.9 | 0.04 | [13] |

| 7.2 | 352 | - | 328 | - | - | - | - | - | 18 | 7 | [14] | |

| Raw Sewage | 8.77 | 740 | - | 784 | 30.25 | - | - | - | 1.7 | - | - | [12] |

| - | - | 310–560 | 1000–1100 | - | - | - | - | - | 230–260 | 15 | [15] | |

| 7.80 | - | - | 702 | 10.72 | - | - | 33.1 | 2.25 | - | - | [16] | |

| 7.1 | - | - | 252 | - | - | 205 | - | - | 265 | 17.1 | [17] | |

| 7.8 | - | - | 104 | - | - | 26.3 | - | - | 33 | 0.6 | [18] | |

| 6.6–7.6 | - | - | 190–230 | - | - | - | 20–35 | - | 40–60 | 4.5–5.6 | [19] | |

| 7.82 | - | - | 426 | 1.156 | - | 46.2 | - | - | - | 3.22 | [20] | |

| 7.7 | 3500 | - | 286 | 197 | - | 992 | - | - | - | 286 | [21] | |

| 7.86 | - | - | 618 | - | - | 54 | - | - | 80 | 4.2 | [22] | |

| 7.56 | - | 154 | 496 | 2.45 | - | 12.5 | - | 7.1 | 24.45 | 9.6 | [23] | |

| - | - | 208.15 | 446.25 | 16.58 | - | 37.64 | - | - | 61.47 | 7.42 | [24] | |

| 6.9–7.5 | - | - | - | 2–5 | - | 36–47 | - | - | - | 12–19 | [25] | |

| 7.9–8.2 | - | - | 296–858 | 1.5–5.6 | - | 58.2–136.9 | - | - | - | 7.9–27.7 | [26] | |

| 8.81 | - | 20.58 | - | 0.07 | - | 30.02 | - | - | 30.46 | 2.6 | [27] | |

| 7.2 | - | - | 129 | - | - | - | 37 | - | 48 | 9 | [28] | |

| 7.4–7.6 | 95.8 | 201–311 | 190–310 | - | - | 45.6 | - | - | 57.9 | 4.4 | [29] | |

| 8.2 | 32 | 22.1 | 97 | 10 | - | 136 | - | 62 | 146 | - | [30] | |

| - | - | - | - | - | - | - | - | - | 315 | 10.15 | [31] | |

| 8.55 | - | 343.07 | - | - | - | - | - | - | 0.22 | 2.28 | [32] | |

| Kitchen | 6.85 | 980 | - | 560 | 52.962 | - | - | - | 2.037 | - | - | [12] |

| Toilet | 7.1 | - | - | 506.8 | - | - | 157.5 | - | 16.4 | 203.6 | 22.3 | [33] |

| Type | Chloride (mg L−1) | Na (mg L−1) | F (mg L−1) | Fe (mg L−1) | Cu (mg L−1) | Zn (mg L−1) | Mg (mg L−1) | Ca (mg L−1) | K (mg L−1) | Pb (mg L−1) | Turbidity NTU | References |

| Secondarily Treated Sewage | - | 65 | - | - | - | 0.05 | 3 | - | 27 | - | - | [14] |

| Sewage | 58.25 | 110 | - | - | - | - | - | 160 | 135 | - | - | [12] |

| 1200 | - | - | - | <0.005 | - | 14.8 | - | - | - | - | [17] | |

| 268 | - | - | - | - | - | - | - | - | - | 379 | [21] | |

| - | - | - | - | - | - | - | - | - | - | 182 | [23] | |

| 173–190 | - | - | - | - | - | 108–144 | 300–400 | - | - | - | [25] | |

| 410–435 | 222.5–312.1 | - | - | - | 0.1–0.18 | 52.1–65.7 | 31.1–31.9 | 8.4–9.8 | - | - | [26] | |

| - | - | - | - | - | - | - | - | - | - | - | [27] | |

| - | - | - | - | - | - | - | - | - | - | - | [28] | |

| - | - | - | - | - | - | - | - | - | - | 140–160 | [29] | |

| - | - | - | 0.098 | 0.0321 | 0.0218 | - | 52.2 | 12.16 | 0.1707 | - | [31] | |

| Kitchen | 92.08 | 130 | - | - | - | - | - | 180 | 148 | - | - | [12] |

| Toilet | - | - | - | - | - | - | 8.6 | 23.8 | 98.2 | - | - | [33] |

TSS (total suspended solids), TOC (total organic carbon), COD (chemical oxygen demand), NO3-N (nitrate-nitrogen), NO2-N (nitrite-nitrogen), NH4-N (ammonium-nitrogen), NH3-N (ammonia-nitrogen), PO4-P (orthophosphate phosphate), TN (total nitrogen), TP (total phosphate), Na (sodium), F (fluorine), Fe (iron), Cu (copper), Zn (zinc), Mg (magnesium), Ca (calcium), K (potassium), Pb (lead), NTU (nephelometric turbidity units) and nr (not reported).

2.1.2. Pretreatment

Table 2 shows three pretreatment procedures that have been mostly used for domestic wastewater: filtration, autoclaving and centrifugation. These pretreatments can remove suspended solids, debris and colloidal particles, which can limit light penetration and microbial contamination from wastewater. According to [33], all of their wastewater samples included significant levels of suspended particles, which might limit photosynthetic performance. As a result, they centrifuged them for 15 min at 5000 rpm before filtering the liquids through 0.45 µm polyester filters. They further sterilized the filtrated samples in an autoclave for 20 min at 121 °C to guarantee that they were axenic [33]. Other authors have filtered and sterilized the wastewater by autoclaving at 15 psi for 30 min to remove particles and microorganisms such as bacteria, fungi and microalgae [34]. The autoclaving has reduced the biological oxygen demand from 159.63 mg L−1 to 93 mg L−1 and the ammonium concentration from 31.38 mg L−1 to 17.19 mg L−1. In contrast, the total phosphate concentration increased from 9.24 mg L−1 to 12.8 mg L−1 and the nitrate concentration increased from 40.02 mg L−1 to 45.1 mg L−1 [34]. Even if the centrifugation and sterilization of wastewater is feasible for microalgae culture in the laboratory, it would be impossible to use it on a massive scale due to the increased costs of production, and the most significant barriers being the energy usage and time consumed [1].

Table 2.

Pretreatment methods of domestic wastewater before microalgae cultivation.

Table 2.

Pretreatment methods of domestic wastewater before microalgae cultivation.

| Wastewater | Pretreatment Method | Microalgae | References |

|---|---|---|---|

| Domestic | Filtered (Whatman filter paper, grade 1), autoclaved | Chaetoceros sp. and Isochrysis sp. | [35] |

| Municipal | Settled in flask for two hours and pretreated by passing Whatman filter paper | Chlorella minutissima | [23] |

| Domestic | Filtered using a 0.2 μm nylon membrane filter | Scenedesmus sp. | [36] |

| Domestic | Filtered through a mesh sieve (100 µm) | Chlorella sp. and Scenedesmus sp. | [24] |

| Domestic | Pre-filtered using filter cloth (nylon monofilament, pore size 25 μm) and autoclaved at 121 °C for 20 min | Chlorella variabilis TH03 | [37] |

| Septic tank | Centrifuged at 5000 rpm for 15 min, filtered by 0.45 μm polyester filters and sterilized by an autoclave for 20 min at 121 °C | Chlorella pyrenoidosa (FACHB-9) | [33] |

| Municipal | Filtered using LLG-filter papers (pore size 5 µm to 13 µm) | Chlorella sorokiniana (UTEX 1230) | [22] |

| Municipal | Filtered with a 2 μm filter | Phaeodactylum tricornutum | [28] |

| Domestic | Filtered using nylon mesh with pore size ∼50 μm | Botryococcus sp. | [14] |

| Domestic | Filtered | Chlorella sp. | [12] |

| Domestic | Autoclaved at 121 °C for 30 min | Chlorella pyrenoidosa | [19] |

| Municipal | Filtered and autoclaved at 121 °C for 20 min | Chlorella zofingiensis | [31] |

| Municipal | Filtered through glass microfiber filters with 0.6-μm pores and autoclaved at 121 °C under 15 psi for 20 min | Dunaliella salina | [38] |

| Domestic | Autoclaved at 121 °C for 30 min | Chlorella pyrenoidosa | [20] |

| Municipal | Filtered and sterilized using vacuum filtration unit and autoclaved at 121 °C for 15 min | Nannochloropsis oceanica | [32] |

| Domestic | Filtered and sterilized by autoclaving at 15 psi for 30 min | Chlorella vulgaris and Nannochloropsis oculata | [34] |

2.1.3. Microalgae Treatment of Domestic Wastewater

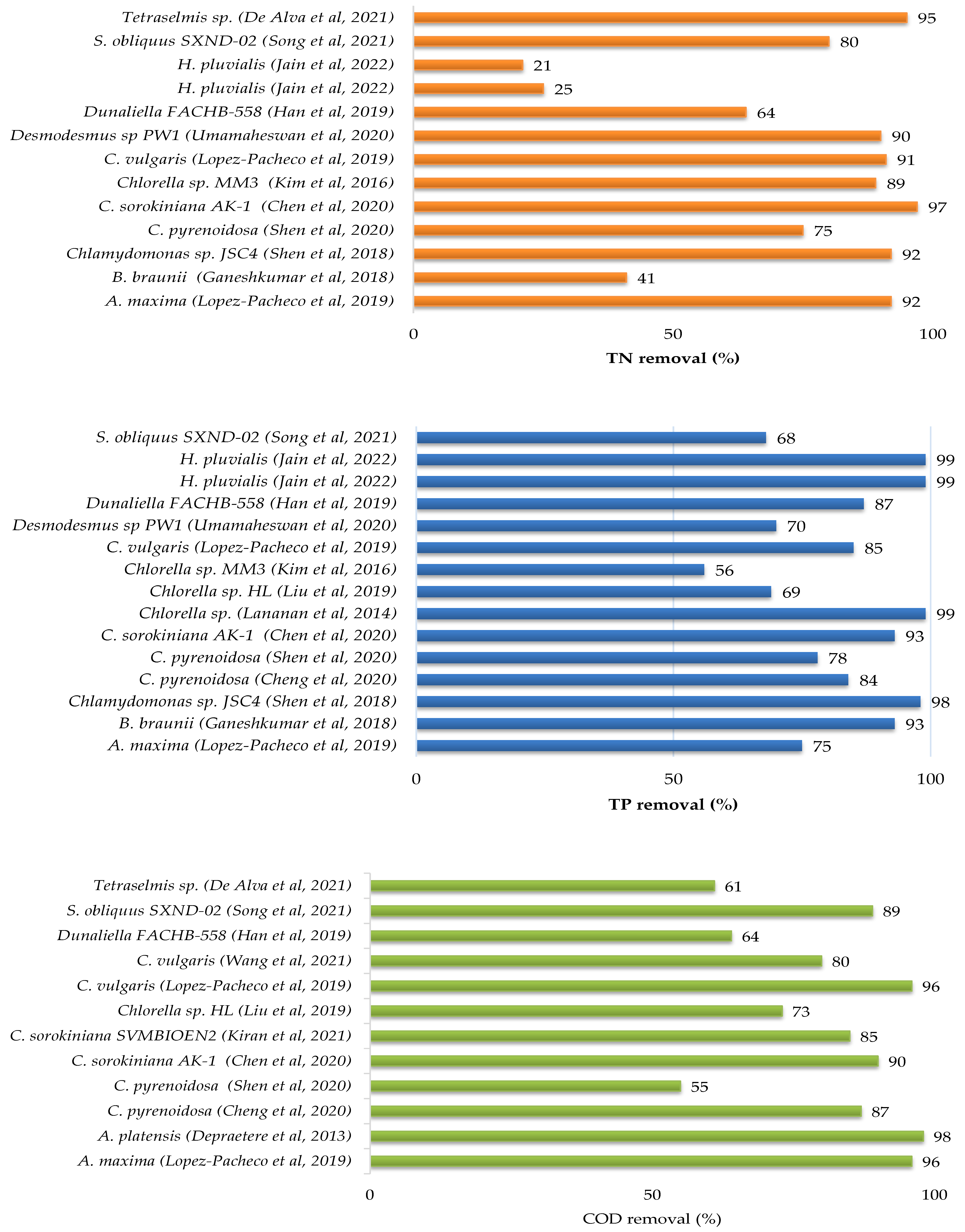

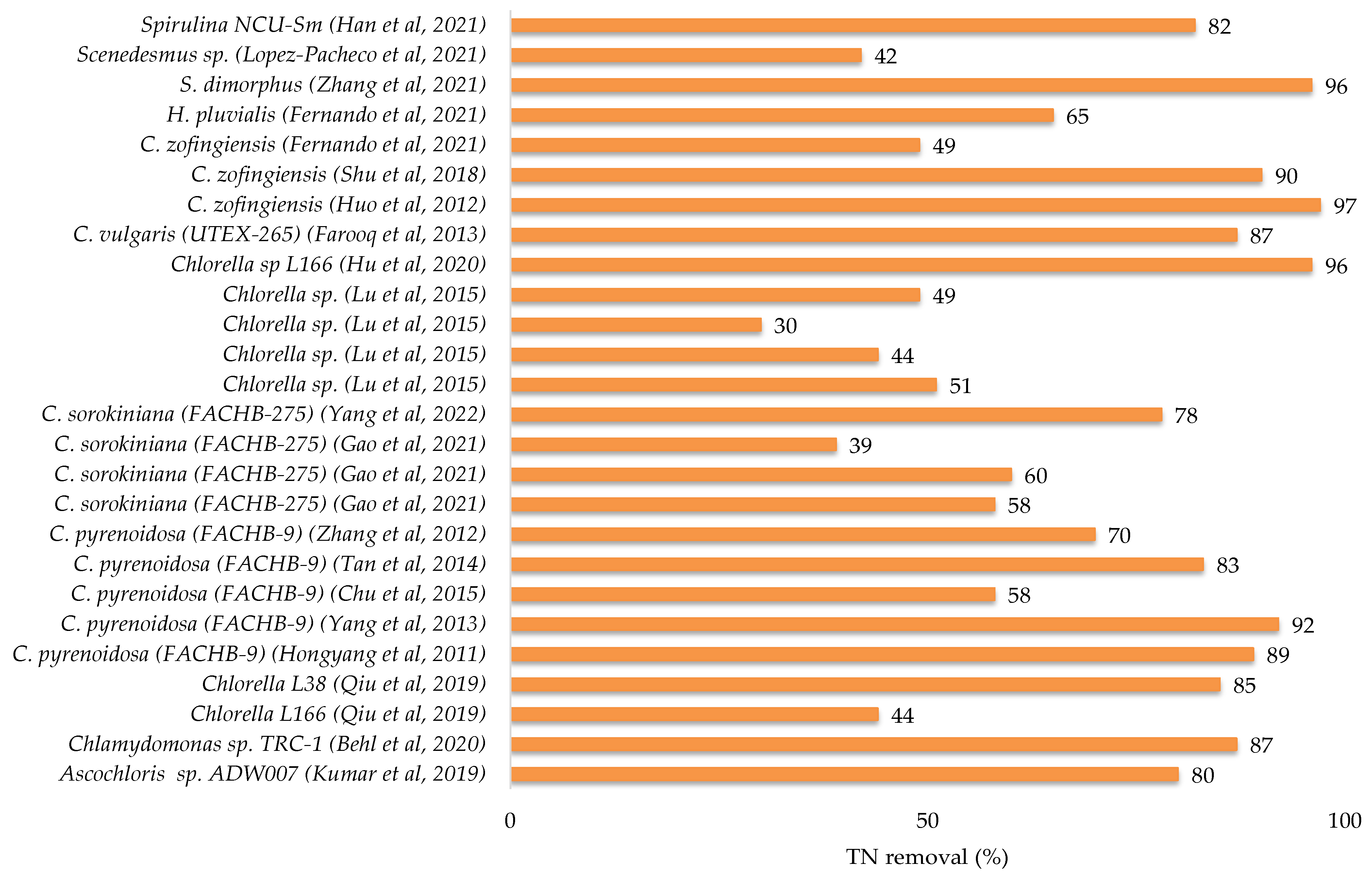

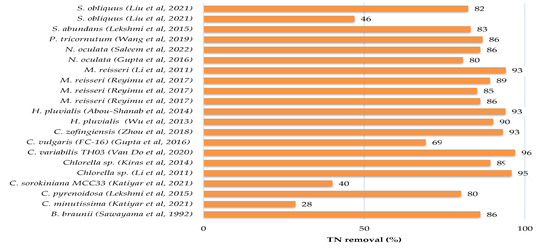

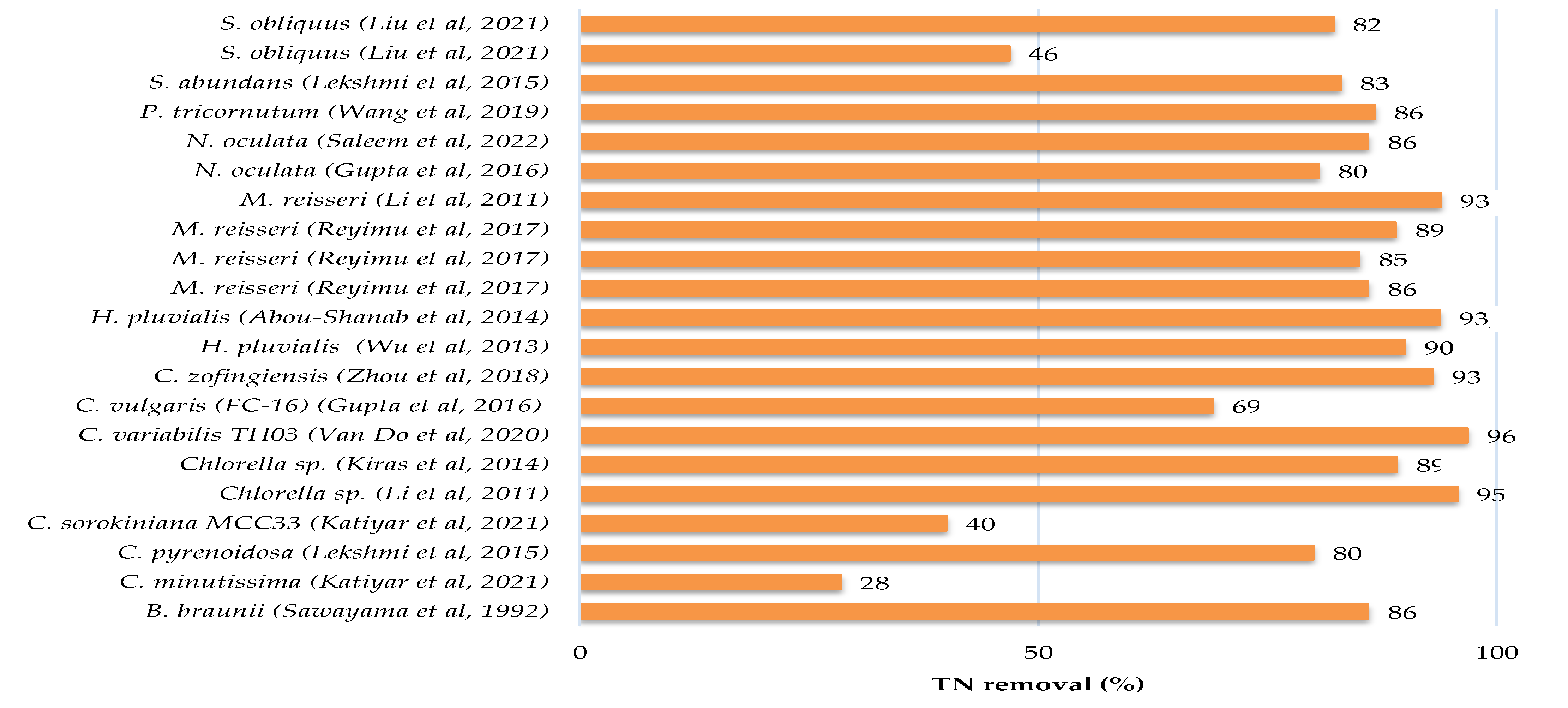

There have been several pieces of research published in the literature that have investigated the feasibility of treating sewage, kitchen and toilet wastewaters with or without dilution using microalgae. Culture conditions, initial nutrients concentrations and removal rates have been gathered in Table 3 for different microalgae and domestic wastewater treatments, while the growth parameters and metabolites production of microalgae culture in domestic wastewater are provided in Table 4. Figure 2 showed that each species of microalgae has a different capacity to reduce pollutants from domestic wastewater, and this ability varies from one wastewater to another.

The maximum potential for total nitrogen (TN) and total phosphate (TP) removals from municipal wastewater were found for Chlorella variabilis TH03 at a 96.8% and 100% removal rate [37]. The other microalgae removed between 28% and 95% of total nitrogen and between 12% and 99% of total phosphate. The removal efficiency of chemical oxygen demand was not assessed in the majority of these studies.

Recently, Kumar et al. 2019 [12] explored the treatment of kitchen wastewater (Phosphates: 2.037 mg L−1; Nitrates: 52.962 mg L−1; COD: 560 mg L−1) and sewage wastewater (Phosphates: 1.7 mg L−1; Nitrates: 30.25 mg L−1; COD: 784 mg L−1) by the species Chlorella sp. in culture flasks in the laboratory. The nitrate and phosphate removals were 38% and 75%, respectively, for kitchen wastewater, and 67% and 88% for sewage wastewater. The COD content in kitchen wastewater was gradually reduced in the first four days, after which it was kept around the same value and varied in a modest range throughout the culture period. COD reduction efficiency was 32.14% on the final day of culture [12]. In this study, the color of the kitchen wastewater was black during microalgal culture, and they supposed that it was due to the high concentration of ammonia and high turbidity and then concluded that these conditions were not conducive to microalgal development. To solve this problem and make the kitchen wastewater acceptable for microalgal development, they diluted it by about 1:1 with water [12]. Tan et al. 2021 [33] reported that septic tank wastewater can be utilized for microalgae cultivation. They tested diverse types of wastewaters for Chlorella pyrenoidosa (FACHB-9) cultivation and demonstrated that the toilet wastewater (TN: 203.6 mg L−1; NH4-N: 157.5 mg L−1; TP: 22.3 mg L−1; COD: 5200 mg L−1) was the great medium for biomass (1.68 g L−1) and nutrient removal efficiencies (NH4-N: 90.8%; TP: 62.9%; COD: 61.3%). According to the same study, discharging kitchen or laundry wastewater decreased the biomass production by 50.5–79%, and should be isolated from toilet wastewater. Kumar et al. 2021 [35] compared the remediation capability of the marine diatom Chaetoceros with the haptophyte Isochrysis microalgae when grown in urban wastewater. Their results demonstrated that the two strains can successfully remediate NO2-N of 0.63% from 10% of domestic wastewater by Chaetoceros and 5.57% from 30% of domestic wastewater by Isochrysis, as well as a total phosphorus removal of 83–84 and 84–94% by Chaetoceros and Isochrysis, respectively. Chemical oxygen demand was reduced more efficiently in 40% of domestic wastewater by Chaetoceros (157 mg L−1) and in 100% of domestic wastewater by Isochrysis (93%). According to [35], the use of domestic wastewater as a culture medium for Chaetoceros sp. and Isochrysis sp. has shown their effectiveness as a sustainable food source and a source of biofuels due to their production of total polyunsaturated fatty acids (PUFAs) from 33.5% to 71.6% in the case of Chaetoceros and from 20% to 63.4% in Isochrysis.

The effectiveness of autotrophic and heterotrophic metabolisms in different microalgae species for wastewater bioremediation and the generation of sustainable microalgal products/coproducts was also evaluated using various culture regimes [27,34,39,40]. For example, Leong et al. 2022 [39] assessed the photoperiod-induced mixotrophic metabolism in Chlorella vulgaris. They measured cell biomass growth and lipid content of Chlorella vulgaris and conducted organic nutrient removals from municipal wastewater (COD: 145 mg L−1; NH4-N: 48 mg L−1) with distinct light: dark photoperiod cycles. In their results, the 16:8 (light: dark) photoperiod was shown to be appropriate for producing high biomass (0.89 g L−1) and lipid production (0.16 g L−1), while also removing chemical oxygen demand and ammonium-nitrogen from municipal wastewater with near–complete removal (>94%).

The removal of nutrients from municipal wastewater by Chlorella vulgaris and Nannochloropsis oculata was examined utilizing mixotrophic culture with glycerol (0 g L−1 to 5 g L−1) [34]. The addition of 2 g L−1 of glycerol in the municipal wastewater as a medium for Chlorella vulgaris enhanced the biomass production to 56 mg L−1 d−1 and had a total nitrate removal of 64%. However, for N. oculata, the best nitrogen removal (80.62%) was obtained with 3 g L−1 of glycerol, with COD and TP removals of 96.3 and 60.72%, respectively, using 1 g L−1 and 5 g L−1 of glycerol. C. vulgaris had the highest lipid content (15.11%) when municipal wastewater was supplemented with 5 g L−1 of glycerol compared to wastewater without glycerol (7.72%). In the same way, N. oculata had a high lipid content (8.91%) with 2 g L−1 of glycerol compared to the culture without glycerol (4.59%) [34].

Similar to this finding, [40] demonstrated that combining a municipal wastewater with glycerol for boosting the mixotrophic culture of C. vulgaris Wu-G22 was a viable option for integrating wastewater treatment with energy production from algal biomass. They found that this microalga had the highest removals for COD, TN and PO4-P from 6195.6 mg L−1 to 448.47 mg L−1, from 46.78 mg L−1 to 3.39 mg L−1 and from 9.79 mg L−1 to 0.75 mg L−1, respectively, when domestic wastewater was supplemented with 50 mM of glycerol [40]. In addition, C. vulgaris Wu-G22 produced a high lipid content of 15.7% and produced contents of other compounds such as carbohydrates and proteins by about 7.3% and 70%, respectively [40].

A recent study used sodium acetate (NaAc) to enhance the removal efficiency of nutrients from municipal wastewater [27]. S. obliquus cultivated in the municipal wastewater grew faster and accumulated more lipids than those cultivated in the BG11 synthetic medium, indicating that the domestic wastewater might be used to replace the synthetic medium for microalgae growth [27]. Furthermore, introducing exogenous NaAc to mixotrophic cultivation significantly increased the algal growth and lipid synthesis [27]. The growth of Scenedesmus obliquus was 2.40 times greater (from 0.2 mg L−1 to 0.48 mg L−1) with the addition of 1 g L−1 of sodium acetate than that in the municipal wastewater without supplement. Furthermore, this concentration enhanced the microalga removals of nitrogen and phosphorus by 1.75 (from 46.85% to 82.2%) and 2.23 times (from 34.18% to 76.35%), respectively, accompanied with a high lipid productivity of 22.08 mg L−1 d−1 [27].

The dilution approach was investigated as a strategy for improving Scenedesmus sp. nutrient recovery and biomass. The author of [41] investigated the impact of different dilutions of fresh leachate (5%, 10%, 15%, 20% and 25%) using treated municipal wastewater on the growth and nutrient recovery potential of Scenedesmus sp. They found the highest removal efficiencies of 100%, 94% and 96% in 15% of fresh leachate for nitrite, ammonium, and phosphorus removals, respectively. Musetsho et al. research [42] on Acutodesmus obliquus revealed that poultry litter extract (2 g) diluted in municipal wastewater (100 mL) has the potential to be utilized as a nutrient and water source for this species. A. obliquus produced the most biomass (1.90 g/L) and had the greatest NO3-N, NH4-N and PO4-P removal rates (79.51%, 81.82%, and 80.52%, respectively). Furthermore, raw poultry litter extract had a slightly greater COD recovery efficiency of 50.80% when compared to poultry litter diluted in municipal wastewater (40.47%), which might be attributed to the proliferation of heterotrophic microorganisms/bacteria in the raw poultry litter extract [42].

Figure 2.

Nutrients and COD removals from domestic wastewater by microalgae [12,13,16,20,21,23,25,27,28,31,33,34,35,37,41,42,43,44,45,46,47,48,49,50,51].

Figure 2.

Nutrients and COD removals from domestic wastewater by microalgae [12,13,16,20,21,23,25,27,28,31,33,34,35,37,41,42,43,44,45,46,47,48,49,50,51].

Table 3.

Treatment of domestic wastewater by the cultivation of microalgae.

Table 3.

Treatment of domestic wastewater by the cultivation of microalgae.

| Algae Used | Wastewater Type | Conditions of Culture | Nutrient Concentration | Average Nutrient Removal Rate | References |

|---|---|---|---|---|---|

| Acutodesmus obliquus | Municipal and poultry litter | 25 °C; 80 μE m−2 s−1; 16:8 light: dark | PO4-P: 21.05 mg L−1; NO3-N: 13.25 mg L−1; NH4-N: 108.0 mg L−1; | NO3-N: 79.51%; NH4-N: 81.82%; PO4-P: 80.52% | [42] |

| Botryococcus Braunii | Secondary treated sewage | 25 °C; 3000 lx; 1% CO2 (50 mL min−1) | TN: 8.9 mg L−1; TP: 0.04 mg L−1 | TN:86%; TP:50% | [13] |

| Botryococcus sp. | Domestic | 25 °C; 30 μE m−2 s−1; 16:8 light: dark | TN:18 mg L−1; COD: 328 mg L−1; PO4-P: 7 mg L−1 | nr | [14] |

| Chaetoceros sp. | Municipal | 25 °C; 100 μE m−2 s−1; 12:l2 light: dark | nr | NO2-N: 0.63%; TP: 83–84%; COD: 157 mg L−1 | [35] |

| Chlorella minutissima | Municipal | 24 °C | COD: 496.0 mg L−1; TN: 24.45 mg L−1; TP: 9.6 mg L−1 | TN: 28.46%; TP: 12.68%; COD: 61.69% | [23] |

| Chlorella pyrenoidosa | Sewage treatment plant | 26 °C; 1500 lx | PO4-P: 2.25 mg L−1; NO3-N: 10.72 mg L−1; COD: 702 mg L−1 | NO3-N: 99.2%; PO4-P: 70.1%; COD: 61.0% | [16] |

| Domestic | Open pond systems using direct sunlight: 18–31 °C (day) and 6–15 °C (night); the insolation 9 h a day | NH4-N: 46.2 mg L−1; TP: 3.22 mg L−1; COD: 426 mg L−1 | NH4-N: 95%; TP: 81%; COD: 78% | [20] | |

| Raw domestic | Continuous illumination of 1800 lx | TN: 197 mg L−1; NH4-N: 992 mg L−1; TP: 286 mg L−1 | NH4-N: 99%; TP: 96%; TN: 80% | [21] | |

| Chlorella pyrenoidosa (FACHB-9) | Municipal | 23.2 °C; 4000 lx; 24:0 light: dark | TN: 33 g L−1; TP: 0.6 g L−1; COD: 104 g L−1 | nr | [18] |

| Municipal | nr | TN: 50 mg L−1; NH4– N: 40 mg L−1; TP: 5 mg L−1; COD: 240 mg L−1 | nr | [43] | |

| Septic tank effluents (toilet) | 25 °C, 260 μE m−2 s−1; 12:12 light: dark | TN: 203.6 mg L−1; NH4-N: 157.5 mg L−1; TP: 22.3 mg L−1; COD: 5200 mg L−1 | NH4-N: 90.8%; TP: 62.9%; COD: 61.3% | [33] | |

| Chlorella Sorokiniana MCC33 | Municipal | 25 °C; | COD: 496.0 mg L−1; TN: 24.45 mg L−1; TP: 9.6 mg L−1 | TN: 40%; TP: 20.83%; COD: 72.17% | [23] |

| Chlorella sp. | Kitchen | 26 °C; 4000 lx; 12:12 light: dark | PO4-P: 2.037 mg L−1; NO3-N: 52.962 mg L−1; COD: 560 mg L−1 | NO3-N: 38%; PO4-P: 75%; COD: 32.14% | [12] |

| Sewage | 26 °C; 4000 lx; 12:12 light: dark | PO4-P: 1.7 mg L−1; NO3-N: 30.25 mg L−1; COD: 784 mg L−1 | NO3-N: 67%; PO4-P: 88% | [12] | |

| Primary effluent treatement plant | 20 °C; 16:8 light: dark; 60 μE m−2 s−1 | COD: 93 mg L−1; TN: 36.1 mg L−1; TP: 4.0 mg L−1 | TN: 95.7%; TP: 96.4% | [44] | |

| Raw centrate from municipal wastewater | 25 °C; 50 μE m−2 s−1 | COD: 2304 mg L−1; TN: 116.1 mg L−1; TP: 212.0 mg L−1 | TN: 89.1%; TP: 80.9%; COD: 90.8% | [45] | |

| Chlorella sp. IM-01 | Municipal | 27 °C; 2000 lx | NO2-N 1222.1 mg L−1; NO3-N: 112.7 mg L−1; NH4-N: 282.4 mg L−1; TP: 1.51 mg L−1 | NO2-N: 70.42%; NO3-N: 97.81%; NH4-N: 98.35%; TP: 89.39% | [46] |

| Chlorella variabilisTH03 | Domestic | 25.5–35 °C; 12,670 lx to 107,695 lx (outdoor) | nr | COD: 64.7% to 90.7%; TN: 85.1–96.8%; TP: 99.7% to 100% | [37] |

| Chlorella vulgaris | Municipal | 1200 lx; 16:8 light: dark | COD: 145 mg L−1; NH4-N: 48 mg L−1 | (>94% of COD and NH4-N) | [39] |

| Chlorella vulgaris (FC-16) | Municipal + glycerol | 25 °C, 100 μE m−2 s−1; 12:12 light: dark | TN: 45.1 mg L−1 | TN: 69.04% | [34] |

| Chlorella vulgaris Wu-G22 | Domestic (unsterilized) + Glycerol (50 mM) | 25 °C; 174 μE m−2 s−1; 12:12 light: dark 2.5% CO2 | COD: 6195.6 mg L−1; TN: 46.78 mg L−1; PO4-P: 9.79 mg L−1 | COD: 448.47 mg L−1; TN: 3.39 mg L−1; PO4-P: 0.75 mg L−1 | [40] |

| Chlorella zofingiensis | Municipal + effluent from anaerobic digestion of piggery waste (92% + 8%) | 25 °C, 150 μE m−2 s−1; 12:12 light: dark; 5% CO2; (Indoor); 5–6% CO2 (Outdoor) | TN: 76.34 mg L−1; TP: 16.56 mg L−1 | TN: ~93%, TP: ~90% | [31] |

| Dunaliella salina | 75% Municipal + 25% saline water | 20 °C; 120 μE m−2 s−1 | NO3-N: 40.7 mg L−1; NH4-N: 0.95 mg L−1; PO4-P: 3.8 mg L−1 | NO3-N: 84.2%; NH4-N: 71.0%; PO4-P: 47.5% | [38] |

| Haematococcus pluvialis | Raw primary effluent | 25 °C, 3000 lx (Green stage)/35,400 lx (Red stage); 12:12 light: dark; 5% CO2 | TN: 20.1 mg L−1; TP: 2.2 mg L−1 | TN: 90%; TP: 99% | [47] |

| Domestic secondary effluent | 25 °C, 55–60 μE m−2 s−1; 14:10 light: dark | TN: 7.0 mg L−1; TP: 0.46 mg L−1 | TN: 93.8%; TP: 97.3% | [48] | |

| Isochrysis sp. | Municipal | 25 °C; 100 μE m−2 s−1; 12:12 light: dark | nr | NO2-N: 5.57%; TP: 84–94%; COD: 93% | [35] |

| 80% Municipal | 25 °C; 100 μE m−2 s−1; 12:12 light: dark | nr | TP: 94% | ||

| Micractinium reisseri | Influent (Municipal) | 27 °C; 40 μE m−2 s−1 | TN: 15 mg L−1; TP: 3 mg L−1 | TN: 86%; TP: 95% | [49] |

| Secondary effluent | 27 °C; 40 μE m−2 s−1 | TN: 13 mg L−1; TP: 2 mg L−1 | TN: 85%; TP: 96% | ||

| Tertiary effluent | 27 °C; 40 μE m−2 s−1 | TN: 11 mg L−1; TP: 1.6 mg L−1 | TN: 89%; TP: 95% | ||

| Micractinium sp. | Primary effluent | 20 °C; 60 μE m−2 s−1; 16:8 light: dark | TN: 36.1 mg L−1; TP: 4.0 mg L−1 | TN: 93.9%; TP: 96.1% | [44] |

| Nannochloropsis oceanica | Municipal sewage | 25 °C; 60 μE m−2 s−1 | TN:0.22 mg L−1; TP: 2.28 mg L−1 | nr | [32] |

| Nannochloropsis oculata | Municipal + glycerol | 25 °C; 100 μE m−2 s−1; 12:12 light: dark | TN: 45.1 mg L−1; | TN: 80.6% | [34] |

| 75% of treated municipal | 24 °C;150 rpm mixing; Continuous illumination | TN: 3.77 mg L−1; | nr | [50] | |

| Municipal | 70–100 μE m−2 s−1 | TP: 4.4 mg L−1; TN: 57.9 mg L−1; | TN: 86%; TP: 81% | [51] | |

| Phaeodactylum tricornutum | Municipal and seawater (1:1) | 18 °C; 120 μE m−2 s−1; 12:12 light: dark | COD: 129 mg L−1; TN: 48 mg L−1; TP: 9 mg L−1; NH4-N: 37 mg L−1 | COD: 87.7%; TN: 86.7%; TP: 97.0%; NH4-N: 84.2% | [28] |

| Scenedesmus abundans | Raw domestic | Continuous illumination of 1800 lx; | TN: 197 mg L−1; NH4-N: 992 mg L−1; TP: 286 mg L−1 | NH4-N: 98%; TP: 95%; TN: 83% | [21] |

| Scenedesmus obliquus | Municipal | 25 °C; 40 ± 10 μE m−2 s−1 | TN: 30.46 mg L−1; TP: 2.60 mg L−1 | TN: 46.85%; TP: 34.18% | [27] |

| Municipal + 1 g L−1 of sodium acetate | 25 °C; 40 ± 10 μE m−2 s−1 | TN: 30.46 mg L−1; TP: 2.60 mg L−1 | TN: 82.20%; TP: 76.35% | ||

| Scenedesmus sp. | 15% Fresh leachate from transfer station | 25 °C; 75 μE m−2 s−1; 14:10 light: dark | NH4-N: 507 mg L−1; PO4-P: 109 mg L−1; NO2-N: 0.9 mg L−1 | NH4-N: 94%; PO4-P: 96%; NO2-N: 100% | [41] |

| Domestic | 20 °C; 12:12 light: dark | NO3-N: 2.39 mg mL−1; PO4-P: 18.53 mg mL−1; COD: 257 mg mL−1 | NO3-N: 71.2%; PO4-P: 89.6%; COD: 86.38% | [25] | |

| Primary urban | nr | PO4-P: 7.9–27.7 mg L−1; NH4-N: 58.2–136.9 mg L−1 | PO4-P: 0.65 mg m−2 d−1; NH4-N: 99%; | [26] | |

| Domestic | 24 °C; 60 μE m−2 s−1; 12:12 light: dark | TP: 98.3 mg L−1; NO2-N: 303.3 mg L−1; NO3-N: 131.4 mg L−1 | TP: 32 mg L−1; NO2-N: 2.36 mg L−1; NO3-N: 18.1 mg L−1; | [36] | |

| Tetraselmis suecica | 25% of treated municipal | 24 °C;150 rpm mixing; Continuous illumination | TN: 3.77 mg L−1 | nr | [50] |

COD (chemical oxygen demand), NO3-N (nitrate-nitrogen), NO2-N (nitrite-nitrogen), NH4-N (ammonium-nitrogen), PO4-P (orthophosphate phosphate), TN (total nitrogen), TP (total phosphate) and nr (not reported).

The possible utilization of a combined biogas slurry and municipal wastewater to grow Chlorella zofingiensis was studied [31]. They found that putting 8% of a pig biogas slurry in municipal wastewater (TN: 76.34 mg L−1; TP: 16.56 mg L−1) had a considerable impact on C. zofingiensis growth, removing 90% of total phosphorus and 93% of total nitrogen and increasing the lipid content by 8% compared to the BG11 medium [31].

Thus, the presented research has demonstrated that different species of microalgae can efficiently clean domestic wastewater, and that it would be much more beneficial if other nutrients such as glycerol and sodium acetate were introduced. Some of this research found that wastewater from the kitchen or laundry has an impact on microalgae growth and biochemical composition and suggested that kitchen wastewater can be diluted with water or anaerobically digested to improve bioremediation. This last procedure can remove organic debris and generate biogas under oxygen-free conditions, but the digestate includes a high concentration of ammonium.

Table 4.

Growth parameters and metabolites production of microalgae culture in domestic wastewater.

Table 4.

Growth parameters and metabolites production of microalgae culture in domestic wastewater.

| Algae Used | Wastewater Type | Growth Rate or Volumetric Productivity | Final Biomass Concentration | Production of Target Metabolites | References |

|---|---|---|---|---|---|

| Acutodesmus obliquus | Municipal and poultry litter | 140.36 mg L−1 d−1 | 1.9 g L−1 | Lipids: 38.49 mg L−1 d−1; Carbohydrates: 49.55 mg L−1 d−1 | [42] |

| Botryococcus Braunii | Secondary treated sewage | nr | 0.34 g L−1 | Hydrocarbon content: 53% | [13] |

| Botryococcus sp. | Domestic | 200 mg L−1 d−1 | 3.32 g L−1 | Carbohydrates: 1.12 g L−1; Lipids: 0.736 g L−1; | [14] |

| Chaetoceros sp. | Municipal | 2.79 g L−1 d−1 | 90.6 × 105 cells mL−1 | Lipids: 0.05 g L−1 d−1; Carbohydrates: 1.9 mg g−1 | [35] |

| Chlorella minutissima | Municipal | 0.196 d−1 | 191.66 mg L−1 d−1 | Lipids: 36.66 mg L−1 d−1 | [23] |

| Chlorella pyrenoidosa | Sewage treatment plant | nr | 4.5 g L−1 | nr | [16] |

| Domestic | nr | 1.71 g L−1 | nr | [20] | |

| Raw domestic | nr | 11.33 mg L−1; | nr | [21] | |

| Chlorella pyrenoidosa (FACHB-9) | Municipal | nr | 0.54 g L−1–0.67 g L−1 | Lipids: 30.61% | [18] |

| Municipal | nr | 0.6167 g L−1 | Lipids: 0.1083 g L−1; | [43] | |

| Septic tank effluents (toilet) | 0.54 d−1 | 1.68 g L−1 | Chlorophyll a: 4.3%; Lipids: 11.9%; Proteins: 57.2%; Carbohydrates: 19.3% | [33] | |

| Chlorella Sorokiniana MCC33 | Municipal | 0.269 d−1 | 208.35 mg L−1 d−1 | Lipids: 48.33 mg L−1 d−1 | [23] |

| Chlorella sp. | Kitchen | nr | 0.45 g L−1 | nr | [12] |

| Sewage | nr | 0.6 g L−1 | nr | [12] | |

| Primary effluent | 0.11 d−1 | nr | nr | [44] | |

| Raw centrate municipal | 0.677 d−1 | 0.92 g L−1 | FAMEs: 11.04%; | [45] | |

| Chlorella sp. IM-01 | Municipal | nr | nr | Carbohydrates: 61–94 µg mg−1 | [46] |

| Chlorella variabilisTH03 | Domestic | 0.41 d−1 | 1.67–1.85 g L−1 | nr | [37] |

| Chlorella vulgaris | Municipal | 0.32 d−1 | 0.89 g L−1 | Lipids: 0.16 g L−1 | [39] |

| Chlorella vulgaris (FC-16) | Municipal + glycerol | nr | 0.056 g L−1 d−1 | Lipids: 15.11% | [34] |

| Chlorella vulgaris Wu-G22 | Domestic (unsterilized) + Glycerol (50 mM) | nr | 1.65 g L−1 | Lipids: 15.7%; Carbohydrates: 7.3%; Proteins: 70% | [40] |

| Chlorella zofingiensis | Municipal + effluent from anaerobic digestion of piggery waste (92% + 8%) | 0.63 g L−1 d−1 | 2.51 g L−1 (indoor), 1.7 g L−1 (outdoor) | Lipids: 25.46% (indoor) 21.6% (outdoor); Carbohydrates: 21.2% (indoor) 26.9% (outdoor); | [31] |

| Desmodesmus sp. | Municipal (Ultrasound pretreatment) | nr | 75 g L−1 | Proteins: 97%; Carbohydrates: 89%; Lipids: 73%; | [52] |

| Municipal (Ozone pretreatment) | nr | 25 g L−1 | Carbohydrates: 85%; Lipids: 48%; Proteins: 25%; | ||

| Untreated Municipal | nr | nr | Lipids: 3.8%; Proteins: 8.23%; Carbohydrates: 37% | ||

| Dunaliella salina | 75% Municipal + 25% saline water | nr | 169.5 mg L−1 | nr | [38] |

| Haematococcus pluvialis | Raw primary effluent | 0.34 d−1 | nr | Astaxanthin: 3.26 mg L−1 | [47] |

| Domestic secondary effluent | 27.8 mg L−1 d−1 | 207 mg L−1 | Lipids: 43% | [48] | |

| Isochrysis sp. | 50% Municipal | 0.022 g L−1 d−1 | 110.5 × 105 cells mL−1 | Lipids: 0.02 g L−1 d−1; Carbohydrates: 2.6 mg g−1 | [35] |

| 80% Municipal | 1.27 g L−1 d−1 | nr | Lipids: 1.11 g L−1 d−1 | ||

| Micractinium reisseri | Municipal (Influent) | 1.15 d−1 | 0.22 g L−1 | Lipids: 23% | [49] |

| Municipal (Secondary effluent) | 1.04 d−1 | 0.19 g L−1 | Lipids: 30% | ||

| Municipal (Tertiary effluent) | 1.01 d−1 | 0.14 g L−1 | Lipids: 40% | ||

| Micractinium sp. | Primary effluent | 0.11 d−1 | nr | nr | [44] |

| Nannochloropsis gaditana | Municipal | 0.167 g L−1 d−1 | 2.33 g L−1 | Carbohydrates: 17.7% | [53] |

| Treatment plant | 0.15 mg L−1 d−1 | 72 mg L−1 | nr | [54] | |

| Nannochloropsis oceanica | Municipal sewage | 21.78 mg L−1 d−1 | nr | Lipids: 26.91% | [32] |

| Nannochloropsis oculata | Municipal + glycerol | nr | 0.044 g L−1 d−1 | Lipids: 8.91% | [34] |

| 75% of treated municipal | 0.5430 d−1 | 1.285 g L−1 | Carbohydrates: 2.39% | [50] | |

| Municipal | nr | 406 mg L−1 | nr | [51] | |

| Phaeodactylum tricornutum | Municipal and seawater (1:1) | 1.01 d−1 | 0.97 g L−1 | Lipids: 54.76 mg L−1 d−1 | [28] |

| Scenedesmus abundans | Raw domestic | nr | 7.23 mg L−1 | nr | [21] |

| Scenedesmus obliquus | Municipal | nr | 0.48 mg L−1 | Lipids: 9.02 mg L−1 d−1 | [27] |

| Municipal + 1 g L−1 of sodium acetate | nr | 0.2 mg L−1 | Lipids: 22.08 mg L−1 d−1 | ||

| Scenedesmus sp. | 15% Fresh leachate from transfer station | 0.17 d−1 | 133 mg L−1 d−1 | nr | [41] |

| Domestic | nr | 0.95 g L−1 | Lipids: 30.5% | [25] | |

| Primary urban | nr | 22.2 g m−2 d−1 | nr | [26] | |

| Domestic | nr | 0.84 g L−1 | Lipid productivity: 8.6 mg L−1 d−1 | [36] | |

| Tetraselmis suecica | 25% of treated municipal | 0.4778 d−1 | 0.76 g L−1 | Carbohydrates: 4.24% | [50] |

nr (not reported).

2.2. Agricultural Wastewater

2.2.1. Physicochemical Properties

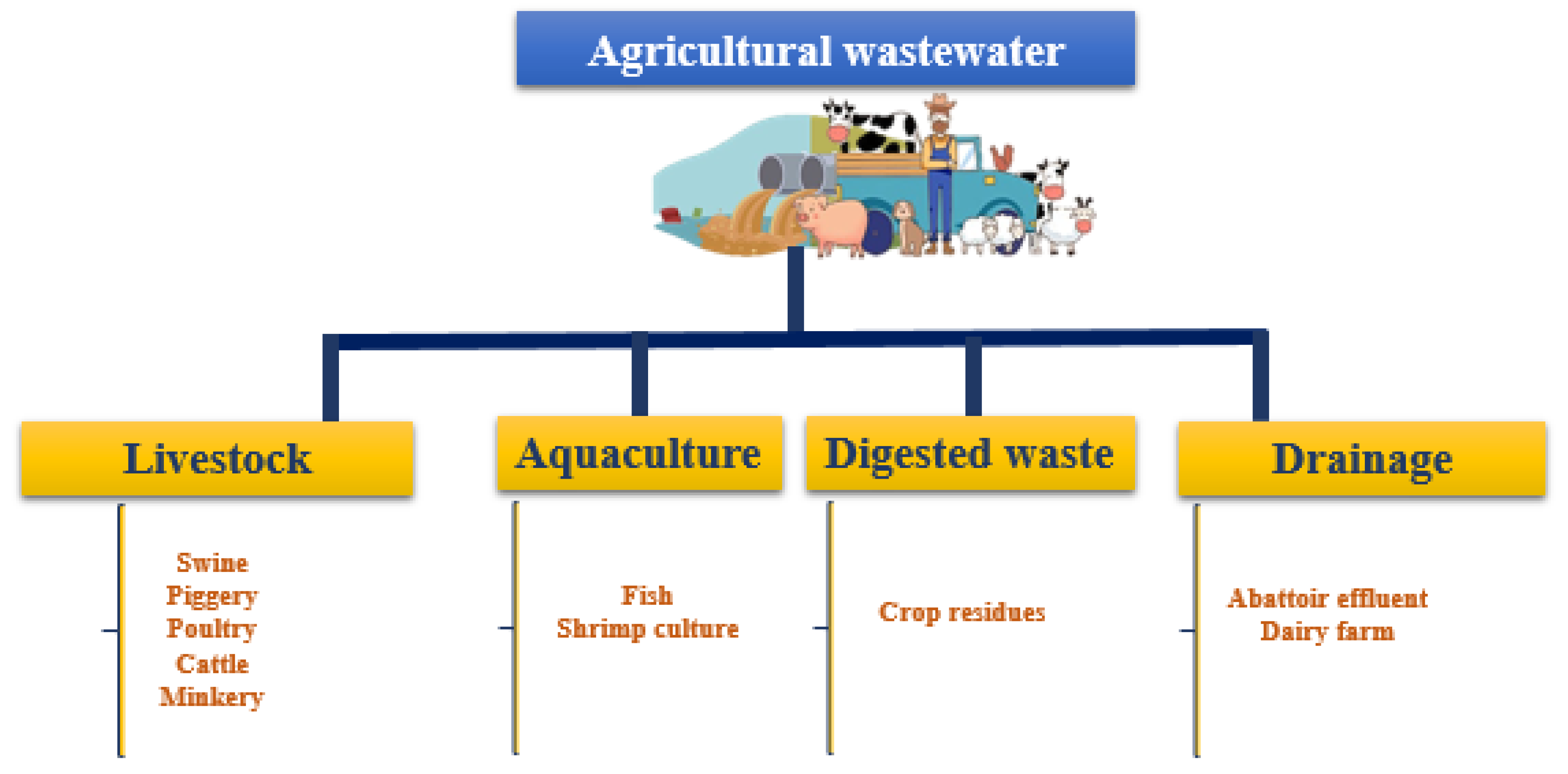

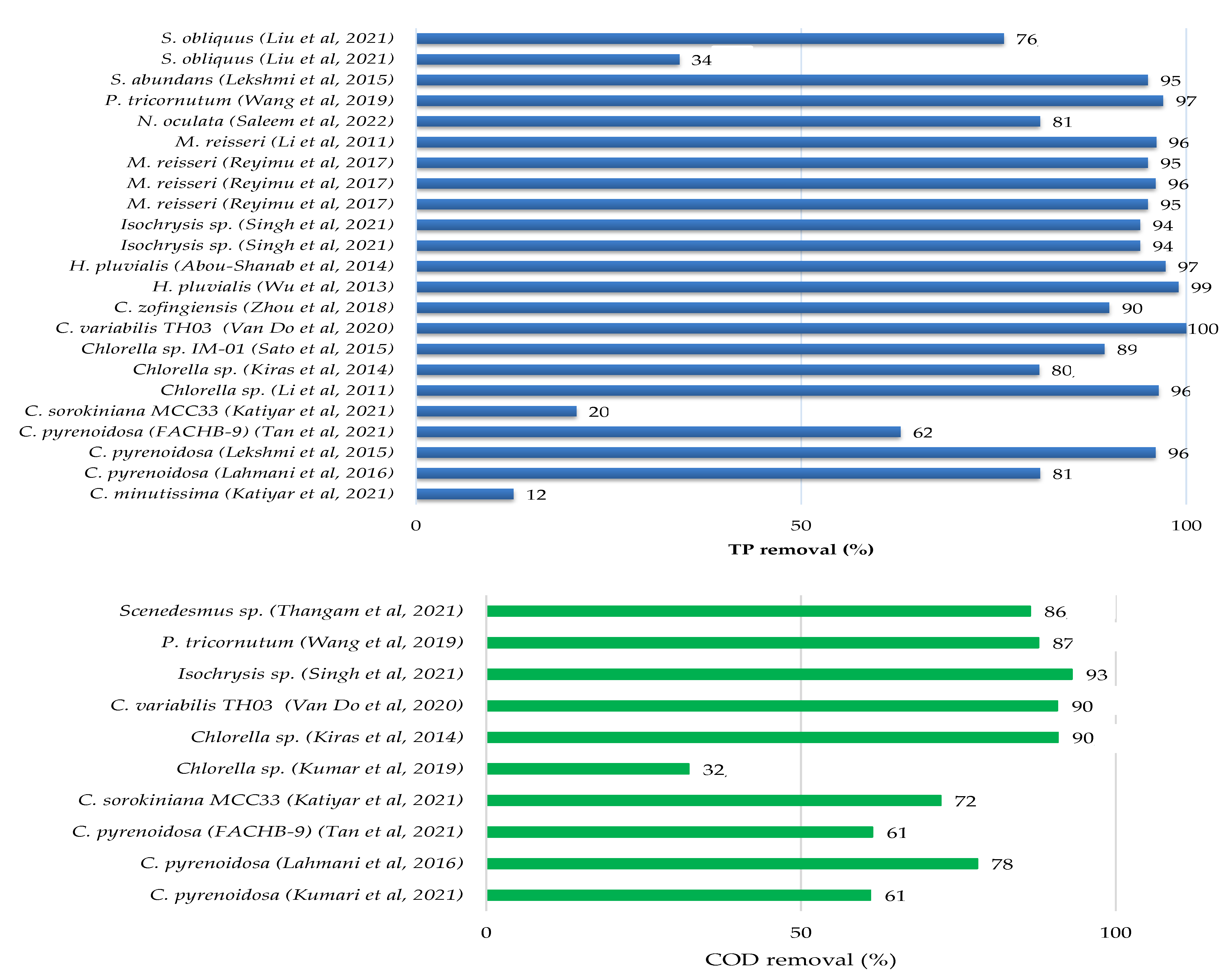

A potential alternative growing medium for microalgae has been presented as the wastewater produced by agricultural activities. The properties of this type of wastewater are determined by the effluent’s source. There are four primary sources of agricultural wastewater (Figure 3), which are livestock, aquaculture, digested agricultural waste and drainage agricultural wastewater [55]. Organic carbons, volatile fatty acids, nutrients and metal ions are among the substances found in these sources [55]. Table 5 summarizes the physicochemical properties of agricultural wastewater used as a growth medium for microalgae that have been found in the literature. As described in this table, raw poultry litter extract had a pH of 7.45, chemical oxygen demand of 482.2 mg L−1, 13.25 mg L−1 of NO3-N and 108 mg L−1 of NH4-N [42]. This composition is significantly different from anaerobically digested poultry litter wastewater, which is characterized by a high concentration of ammonium (2000 mg L−1 to 3000 mg L−1 of NH4-N) and total nitrogen (2900 mg L−1 to 3200 mg L−1 of TN) [56]. Swine wastewater contained a high concentration of chemical oxygen demand (419.88 mg L−1 to 85,600 mg L−1), total nitrogen (163.40 mg L−1 to 5685 mg L−1) and total phosphate (26.2 mg L−1 to 284 mg L−1), and the pH was reported at 6.83–8.1 [30,57,58,59,60,61,62]. The mass cultivation of fish necessitates a large volume of freshwater and produces a large amount of aquaculture wastewater [5]. Bioremediation of aquaculture wastewater by microalgae was reported in the literature [60,63,64,65]. The pH was at 7.82–8.5, COD was at 30.30 mg L−1 to 367.39 mg L−1, TN was at 4.12–60 mg L−1 and the TP was at 0.16 mg L−1 to 6.8 mg L−1 for aquaculture wastewater physicochemical composition [60,63,64,65]. In addition, Table 5 showed that agricultural wastewater contains a high content of suspended particles (32.15 mg L−1 to 32,951.5 mg L−1) and different metal ions such as Zn, Cu, Mg, Ca and K, with concentrations depending on the wastewater source.

Figure 3.

Agricultural wastewater types.

Table 5.

Agricultural wastewater composition.

Table 5.

Agricultural wastewater composition.

| Type | pH | TSS (mg L−1) | TOC (mg L−1) | COD (mg L−1) | NO3-N (mg L−1) | NO2-N (mg L−1) | NH4-N (mg L−1) | NH3-N (mg L−1) | PO4-P (mg L−1) | TN (mg L−1) | TP (mg L−1) | References |

| Raw Poultry Litter Extract | 7.45 | 34.40 | - | 482.2 | 13.25 | - | - | 108.0 | 21.05 | - | - | [42] |

| Anaerobically Digested Poultry Litter | 9–10 | - | 500–1000 | 400–900 | - | - | 2000–3000 | - | - | 2900–3200 | 20–25 | [56] |

| Pretreated Piggery | 7.5–9.3 | - | 1409–3935 | 430–11,100 | 2–352 | 10 | 70–644 | 1388 | 129 | 981–1356.75 | 20–168 | [66,67,68,69,70] |

| Swine | 6.83–8.1 | 2375–7120 | 20,075 | 419.88–85,600 | 1.19–334 | - | 260–5351 | 578.27 | 36.7–6608 | 163.40–5685 | 26.2–284 | [30,57,58,60,61,62] |

| Nejayote | 9.80 | 9060 | - | 9153.30 | - | - | - | - | - | 120.69 | 41.16 | [62] |

| Cattle | 6.11 | - | - | 674 | 3041 | - | 22,358 | - | 760 | - | - | [71] |

| Dairy Farm | 6.05–8.18 | 32.15–65.65 | - - | 119.21–2593 | 1.45–5.44 | - | 0.75–181.50 | - | 4.33–7.01 | 283 | 115.90 | [72,73] |

| Swine Lagoon | 5.5 | - | - | 2386 | 4.33 | - | 336.2 | - | - | 348.2 | 26.62 | [74] |

| Aerated Swine Lagoon | 8.9 | - | - | 2328 | 103 | - | 22.3 | - | - | 177.9 | 19.48 | [74] |

| Minkery | 8.84 | - | - | 1200 | 10 | 10 | 3250 | - | - | - | 1400 | [75] |

| Paddy-Soaked | 6 | 7255 | 2900 | 2250 | - | - | - | 265.30 | 211.50 | - | - | [76] |

| Shrimp Culture | 8.18 | 32,951.5 | - | 73.5–367.39 | 12.9–73.67 | 7.58 | 8.07–109.91 | - | 15.59 | 21.9 | <0.4 | [63,64] |

| Fish Farm | 7.82–8.5 | - | - | 30.30–112 | 3.93–12 | 0.08 | 5.6 | - | - | 4.12–60 | 0.16–6.8 | [60,65] |

| Anaerobically Digested Abattoir Effluent | 7.1–7.4 | - | - | 302–514 | 0–8 | 0–7.5 | - | 200–210 | 70–80 | - | - | [77] |

| Type | Chloride (mg L−1) | Na (mg L−1) | F (mg L−1) | Fe (mg L−1) | Cu (mg L−1) | Zn (mg L−1) | Mg (mg L−1) | Ca (mg L−1) | K (mg L−1) | Pb (mg L−1) | Turbidity NTU | References |

| Anaerobically Digested Poultry Litter | - | - | - | 0.085 | 0.085 | - | - | 0.044 | 1314.24 | - | - | [56] |

| Pretreated Piggery | 52,524 | 139.55 | - | 1.62 | 0.026 | 0.14 | 54.75–81 | 28.55–105 | 400.75 | 0.0025 | - | [66,67,70] |

| Swine | 154.7 | 66.24–583.8 | - | 0.52–0.728 | 0.0015–0.94 | 0.087–1.7 | 8.3–37.49 | 3.89–63.88 | 229.9–666.7 | - | - | [58,59,61,62] |

| Dairy Farm | - | 121–165 | - | 0.02–0.03 | 0.004–0.007 | 0.001–0.003 | - | - | - | - | - | [72,73] |

TSS (total suspended solids), TOC (total organic carbon), COD (chemical oxygen demand), NO3-N (nitrate-nitrogen), NO2-N (nitrite-nitrogen), NH4-N (ammonium-nitrogen), NH3-N (ammonia-nitrogen), PO4-P (orthophosphate phosphate), TN (total nitrogen), TP (total phosphate), Na (sodium), F (fluorine), Fe (iron), Cu (copper), Zn (zinc), Mg (magnesium), Ca (calcium), K (potassium), Pb (lead), NTU (nephelometric turbidity units) and nr (not reported).

2.2.2. Pretreatment

The high suspended particles concentration in agricultural wastewater, similar to domestic wastewater, necessitates the use of a first treatment procedure prior to the cultivation stage. The same pretreatment methods (filtration, autoclaving and centrifugation) as for domestic wastewater were used for agricultural wastewater pretreatment, with other pretreatments such as flocculation, acid precipitation, digestion and stripping, as described in Table 6. Previous research has used the filtering approach to pretreat wastewater, utilizing filters with varying pore sizes depending on the wastewater source and the materials that need to be removed. Khatoon et al. [78] filtered aquaculture wastewater using a 22 µm pore size filter, followed by a 1.2 µm pore size filter. For swine wastewater pretreatment, a recent study used an 8 µm pore size filter after the centrifugation technique [30]. The centrifugation method was used by the majority of these studies, with different durations and forces, for instance, 8000 rpm for 10 min [79], 7000 rpm (8656× g) for 5 min [30], 10,000× g for 10 min at 4 °C [52], 3000× g for 5 min [64] and 3000× g for 10 min [65,69]. However, once more, these methods can only be used at lab-scale.

An air-stripping method was used in the study of Kim et al. [66] for decreasing the concentration of free ammonia, that affect the growth of microalgae, from piggery wastewater. The results showed that the concentration was reduced from 644 mg L−1 to 14.1 mg L−1 [66]. For chemical oxygen demand reduction, acid precipitation was used by Teràn Hilares et al. and Musetsho et al. [42,80]. Teràn Hilares et al. [80] discovered that by adjusting the pH of the poultry slaughterhouse from six to four using H2SO4, almost 80% of the COD was eliminated as sludge [80].

Table 6.

Pretreatment methods of agricultural wastewater before microalgae cultivation.

Table 6.

Pretreatment methods of agricultural wastewater before microalgae cultivation.

| Wastewater | Pretreatment Method | Microalgae | References |

|---|---|---|---|

| Swine | Settled for 24 h, then centrifuged at 8000 rpm for 10 min | Chlorella sp. HL | [79] |

| Swine | Centrifuged at 7000 rpm (8656× g) for 5 min, filtered with filter of pore diameter 8 µm | Scenedesmus sp. | [30] |

| Cattle | Filtered using Whatman filter paper 42 | Chlorella thermophila (MF179624) | [71] |

| Poultry litter extract | Acid pretreatment using 5 M of HCl or H2SO4 | Acutodesmus obliquus | [42] |

| Swine | Natural precipitation method for 1 day; and added with 5% sodium hypochlorite for 1 day. | Chlorella vulgaris MBFJNU-1 | [57] |

| Aquaculture | Filtered using a filter pump (pore size: 22 μm), then filtered with GF/C Whatman glass microfiber filters (pore size: 1.2 μm). | Tetraselmis sp. | [78] |

| Fishery | Sterilized in an autoclave at 121 °C and 150 kPa for 30 min. | Thalassiosira pseudonana and Isochrysis galbana | [81] |

| Poultry slaughterhouse | Acid precipitation (H2SO4) at pH 4 | Chlorella vulgaris | [80] |

| Swine | Sedimentation for 2 days, and anaerobically digested at 55 °C for 10 days | Chlorella pyrenoidosa | [59] |

| Swine | Filtered with a sieve of mesh number 140 (100 μm) | Chlorella sorokiniana AK-1 | [58] |

| Anaerobic digested swine | Sterilized in an autoclave at 121 °C and 150 kPa for 30 min. | Chlorella zofingiensis | [60] |

| Fishery | Sterilized in an autoclave at 121 °C and 150 kPa for 30 min. | Chlorella zofingiensis | [60] |

| Piggery | Centrifuged at 10,000× g for 10 min at 4 °C and pre-autoclaved at 121 °C for 20 min | Chlorella sp. GD | [59] |

| Minkery | Filtered through a filter cloth then filtered using 1.5 µm glass microfiber filters, autoclaved at 121 °C and 15 psi for 20 min. | Haematococcus pluvialis | [75] |

| Aquaculture | Centrifuged at 3000× g for 5 min. | Chlorella Sorokiniana MB-1-M12 | [64] |

| Piggery | Sedimented and sterilized by passing through a 0.45 μm filter | Chlorella pyrenoidosa | [62] |

| Piggery | Flocculated and filtered through 0.2 µm cellulose acetate membranes followed by stripping with air using an acrylic column (ID 5 cm × H 100 cm) | Acutodesmus obliquus | [66] |

| Aquaculture | Centrifuged at 3000× g for 10 min | Chlorella sp. GD | [65] |

| Aquaculture | Filtered using 0.45 mm Whatman GF/C filter papers followed by autoclaving | Chlorella sp. | [82] |

| Piggery | Autoclaved for 30 min at 121 °C then centrifuged (3000× g for 10 min) | Chlorella sp. GD | [69] |

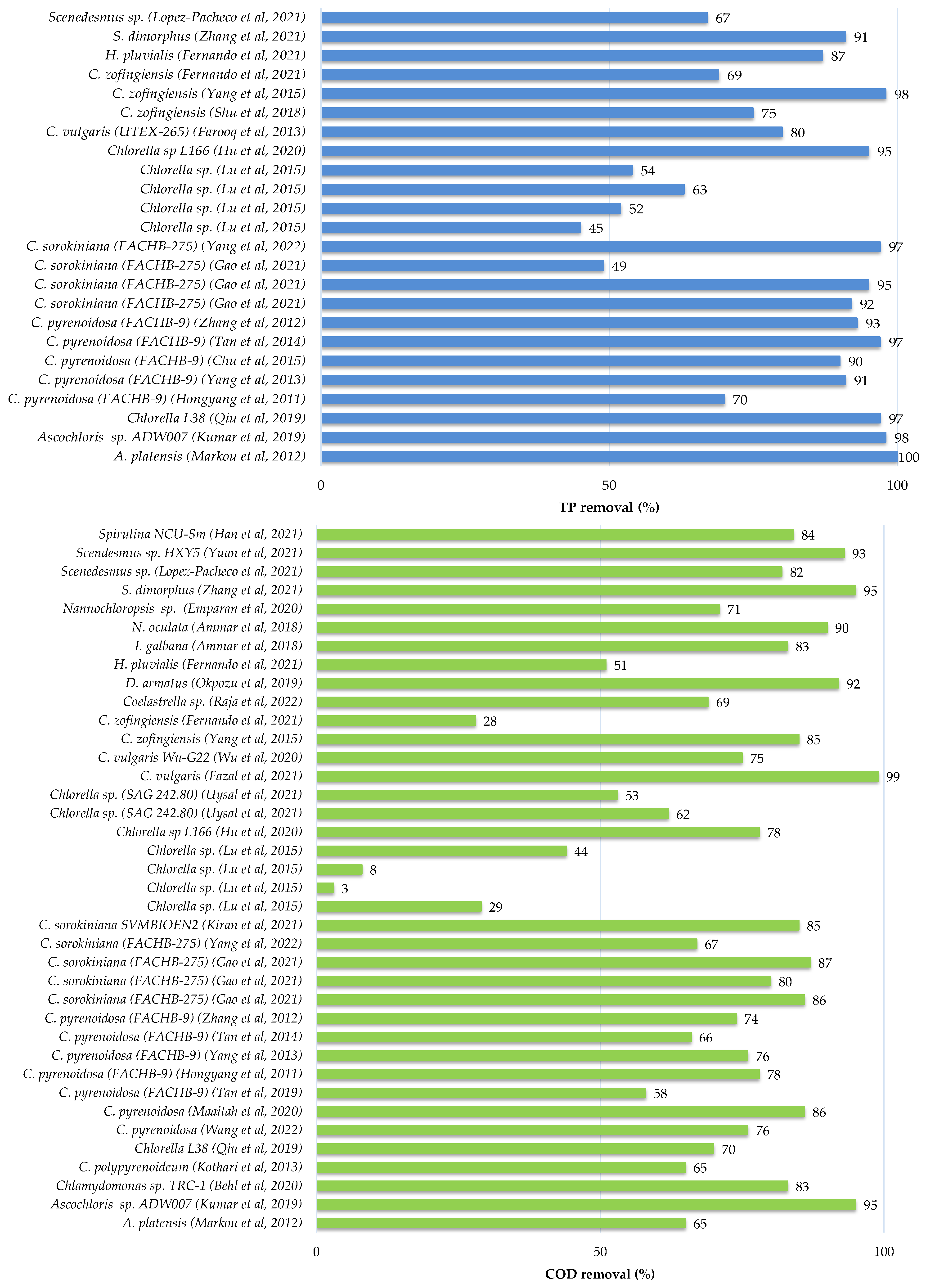

2.2.3. Microalgae Treatment of Agricultural Wastewater

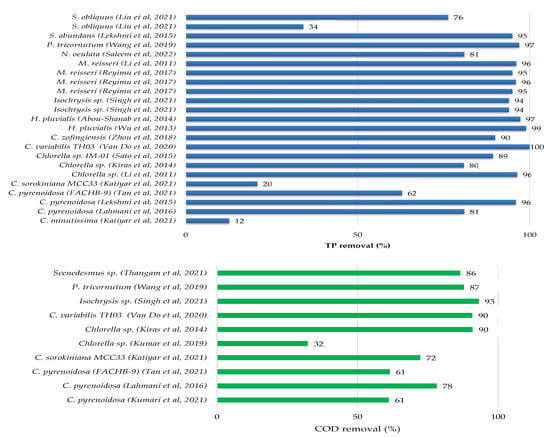

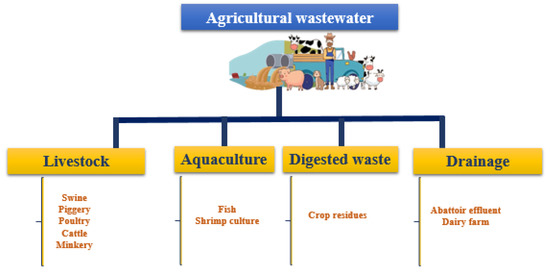

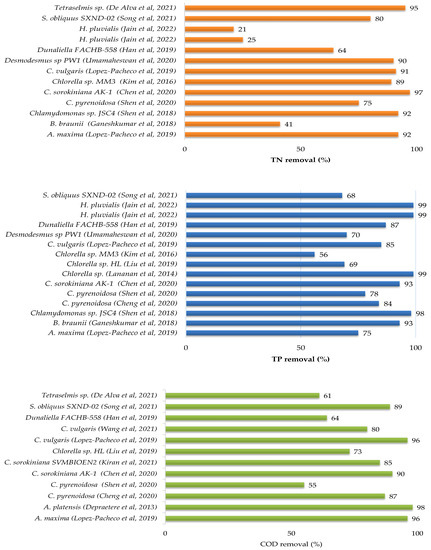

As shown in Table 5, nitrogen, phosphate, and some metal ions are present in agricultural effluent. Wastewaters are dangers to environmental safety if left untreated or cleaned incompetently, resulting in eutrophication of nearby water rivers and greenhouse gas emissions. Lately, considerable research has been conducted on the culture of microalgae in agricultural wastewater for their excellent nutrient removal, energy resource and the other products extracted from microalgal biomass (Table 7 and Table 8). The Figure 4 illustrates the removal efficiencies of total nitrate, total phosphate and chemical oxygen demand from agricultural wastewater by different species of microalgae.

Figure 4.

Nutrients and COD removals from agricultural wastewater by microalgae species [56,58,59,61,62,63,68,70,72,74,75,79,80,82,83,84,85,86,87].

Swine wastewater treatment by microalgae was investigated in a recent study [79]. They evaluated the potential of seven strains which are Chlorella sp. HQ, Scenedesmus sp. LX1, Chlorella vulgaris (FACHB-8), C. pyrenoidosa (FACHB-5), S. obliquus (FACHB-417), Selenastrum capricomutum (FACHB-271) and Chlorella sp. HL, to remove pollutants from a ten-fold dilution of swine wastewater [79] and they reported that Chlorella sp. HL had the highest potential for growth in swine wastewater and nutrient removal among the other species. This strain showed the greatest specific growth rate (µ) and cell density, both of which were 0.51 d−1 and 2.43 × 107 cells mL−1 after nine days of culture, with the TP and COD removal rates of 69.13% and 72.95%, respectively. In addition, [79] suggested that Chlorella sp. HL can be a suitable candidate for energy production due to the higher heating value of 18.25 MJ kg−1 of Chlorella sp. HL biomass. The author of [57] studied the aptitude of Chlorella vulgaris MBFJNU-1 strain to reduce the pollutants of swine wastewater using a column photobioreactor in outdoor environments. At the same time, they evaluated the carbon dioxide fixation by this species. Their results suggested that the cultivation of Chlorella vulgaris MBFJNU-1 at 3% carbon dioxide, provided the maximum of biomass productivity by about 36 mg L−1 d−1 and the best removal efficiency rate of TN, TP and COD by about 16.84 mg L−1 d−1, 1.40 mg L−1 d−1 and 8.47 mg L−1 d−1, respectively [57]. However, these two studies did not assess the biochemical composition of the studied species grown in swine wastewater, which is a critical parameter to be able to use these microalgae for both wastewater treatment and the generation of high-value products at the same time [57,79].

Other research examined the microalgae immobilization method as an innovative technique to remove contaminants from swine wastewater [58,61]. The author of [58] assessed the ability of three species of Chlorella sorokiniana genera to grow and remove pollutants of a 2-fold diluted swine wastewater. They reported that Chlorella sorokiniana AK-1 had the highest biomass and protein production rate compared to other species (5.45 g L−1 and 0.27 g L−1 d−1, respectively) [58]. In the same study, they immobilized Chlorella sorokiniana AK-1 cells using sponge, activated carbon, clay and alginate beads as solid carriers in a 2-fold diluted swine wastewater, and found that the sponge immobilization method improved the biomass concentration and protein productivity (8.08 g L−1 and 0.272 g L−1 d−1, respectively) compared to the control and other solid carriers [58]. In addition, using the sponge as the solid carrier enhanced the removal efficiency of TN, TP and COD from 88.6% to 94.1%, 99.3% to 99.5% and from 84.1% to 91.6%, respectively, compared to the control [58]. A fixed-bed biofilm reactor, as another immobilization technique of algal cells, was used [61] to improve the productivity of the biofilm and the removal efficiencies of total nitrate, total phosphate and metal ion (Cu(II)) from swine wastewater. In this research, they used Chlamydomonas sp. JSC4 cells as an attached culture and assessed the effect of different parameters such as the volume of the swine wastewater and the concentration of Cu(II) on the productivity of the biofilm and removal efficiencies [61]. They reported that the swine wastewater had the best productivity levels (49.70 g−1 m−2 d−1) at an initial composition of 600 mg L−1 of total nitrate and 0.23 mg L−1 of Cu(II), but when the concentration of Cu(II) was increased to 15 mg L−1, the productivity of the biofilm was decreased to 37.73 g m−2 d−1 with a TN removal of 85.79%, TP removal of 96.56% and Cu(II) removal of 93.70% [61].

The microalga Desmodesmus sp. PW1 was used to treat piggery wastewater [83]. The results showed that this isolated strain from piggery wastewater had two important potentials, the first was the ability to reduce the pollutants in piggery wastewater, and the second was to self-flocculate in it and overcome the harvesting problem [80]. It can remove about 90% of total nitrogen and about 70% of total phosphorus from piggery wastewater with an initial composition of 296.7 mg L−1 of TN and 28.6 mg L−1 of TP under 25 °C and 4000 lx [83]. In addition, as this strain can self-flocculate more than 90% in 2.5 h of sedimentation, it could be a promising candidate for biomass and biodiesel production (1.76 g L−1 and 7.2%, respectively) [83].

To improve the efficiency of piggery wastewater treatment, [84] used the digestion technique before microalgae treatment, and they used a marine microalgal specie rather than the genus Chlorella and Scenedesmus, which have been widely used in the literature [84]. In the same investigation, they used the CO2 produced by the digester to feed the microalgae culture bioreactor during its operation [84]. Under these conditions (CO2 from digester (94.7%) and pH 7.5), Tetraselmis suecica had the highest production of biomass, lipids and carbohydrates, which were 59.8, 25 and 6.5 mg L−1 d−1, respectively, with TN and TP removals of 96 and 72%, respectively [84].

Microalgae have also demonstrated their ability to remediate aquaculture effluents [64,78]. Chen et al. [64] reported that Chlorella sorokiniana MB-1-M12 was the best candidate to treat shrimp culture wastewater because of its biomass and lutein productivities (1.9 mg L−1 d−1 and 5.55 mg L−1 d−1, respectively) in 75% of shrimp culture effluent. Another recent study used the immobilization method to treat aquaculture wastewater [78]. In this research, they immobilized Tetraselmis sp., a marine microalga, using alginate beads in aquaculture wastewater [78]. Tetraselmis sp. beads removed about 0.08 mg L−1, 0.10 mg L−1 and 0.17 mg L−1 from the initial concentration of the total ammonium (7.7 mg L−1), nitrite (3.1 mg L−1) and phosphorus (2 mg L−1) after two days, which corresponds to the following removal efficiencies of 98.9%, 97.7% and 91.1%, respectively [78].

Different wastewaters can also be combined, such as piggery farm wastewater and winery industry wastewater, to be treated by Chlorella sp. MM3 strain from the soil [70]. At the ratio 20:80 of piggery and winery wastewaters, Chlorella sp. MM3 removed 89.36% for the TN removal efficiency and 56.56% for the TP removal efficiency, and achieved a high lipid yield of about 51% [70]. Recently, 2.5% of cattle wastewater was diluted with domestic wastewater as a substitute for freshwater to be treated by Chlorella thermophila (MF179624), isolated from sewage wastewater [71]. They reported that Chlorella thermophila grew well (2.17 g L−1 of biomass) in 2.5% of cattle wastewater, compared to domestic wastewater (1.22 g L−1 of biomass) and bold basal medium (1.24 g L−1 of biomass), and gave interesting compounds such as lipids (18.27%), carbohydrates (29.39%) and proteins (44.91%) [71]. Chlorella thermophila had the highest removal rates of ammonium (53.74 mg L−1 d−1), nitrate (6.96 mg L−1 d−1) and more than 99% of phosphorus [71].

Table 7.

Treatment of agricultural wastewater by the cultivation of microalgae.

Table 7.

Treatment of agricultural wastewater by the cultivation of microalgae.

| Algae Used | Wastewater Type | Conditions of Culture | Nutrient Concentration | Average Nutrient Removal Rate | References |

|---|---|---|---|---|---|

| Acutodesmus obliquus | Piggery | 25 °C for 138 h | COD: 11,100 mg L−1; TN: 981 mg L−1; TP: 81 mg L−1 | TN: 175 mg g−1 d−1; TP: 1.5 mg g−1 d−1 COD: 1923 mg g−1 d−1) | [66] |

| Arthrospira maxima | 10% Nejayote | 21 °C; 1.5 L m−2 min−1 of aeration; 12:12 light: dark | COD: 9153.3 mg L−1; TN: 120.69 mg L−1; TP: 41.16 mg L−1 | COD: 96%; TN: 92%; TP: 75% | [62] |

| Arthrospira platensis | Dairy farm | 30 °C; 160 μE m−2 s−1 (from initial today 6) and 300 μE m−2 s−1 (from day 7); 12:12 light: dark | COD: 131.691 mg L−1; NO3-N: 3.452 mg L−1; NH4-N: 2.998 mg L−1; PO4-P: 5.672 mg L−1 | COD: 98.4%; NO3-N: 99.6%; NH4-N: ~100%; PO4-P: 98.8% | [72] |

| Botryococcus braunii | Aerated swine | 25 °C; 10 μE m−2 s−1 | TN: 177.9 mg L−1; TP: 19.48 mg L−1 | TN: 40.8%; TP: 93.3% | [74] |

| Chlamydomonas sp. JSC4 | Swine | 26 °C; 150 μE m−2 s−1; 16:8 light: dark; 5% CO2 at an aeration rate of 0.2 L min−1 | TN: 600 mg L−1; TP: 26.2 mg L−1 | TN: 92%; TP: 98% | [61] |

| Chlorella pyrenoidosa | Paddy-soaked | 33 °C to 37 °C; 3826–4240 μE m−2 s−1 | PO4-P: 211.50 mg L−1; NH4-N: 265.30 mg L−1 | NH3-N: 75.89%; PO4-P: 73.71% | [76] |

| Five times diluted anaerobically Digested swine | 25 °C; 80 μE m−2 s−1; 12:12 light: dark | NH4-N: 134.17 mg L−1; NO3-N: 14.49 mg L−1; TP: 6.65 mg L−1; COD: 116.10 mg L−1 | NH4-N: 94.1%; NO3-N: 85.2%; TP: 84.0%; COD: 86.8% | [59] | |

| Piggery | 25 °C to 27 °C; 63 μE m−2 s−1 | TN: 980 mg L−1; TP: 158 mg L−1; COD: 1000 mg L−1 | TN: 74.6%; TP: 77.7%; COD: 55.4% | [68] | |

| Chlorella sorokiniana AK-1 | 50% Swine | 27 °C, 150 μE m−2 s−1 | TN: 510 mg L−1; TP: 76.1 mg L−1; COD: 506.8 mg L−1 | : 97.0%; TP: 92.8%; COD: 90.1% | [58] |

| Chlorella sorokiniana MB-1-M12 | Shrimp culture | 26 °C; 150 μE m−2 s−1 | TN: 21.9 ppm; TP < 0.4 ppm; COD: 73.5 ppm | nr | [64] |

| Chlorella sorokinianaSVMBIOEN2 | Dairy farm | 25 °C; 100 μE m−2 s−1; 12:12 light: dark | COD: 2000 mg L−1 | COD: 85%; | [85] |

| Chlorella sp. | Aquaculture | 28 °C | NH4-N: 0.91 mg L−1; PO4-P: 2.6 mg L−1 | NH4-N: 98.7%; PO4-P: 92.2%; | [82] |

| Aquaculture | 25 °C; 3350 Lm | TP: 6.75 mg L−1 | TP: 99.15% | [86] | |

| Chlorella sp. GD | Aquaculture | 26 °C; 300 μE m−2 s−1; aerated with boiler flue gas (approximately 8% CO2) | pH: 8.5; COD: 112 mg L−1; TN: 60 mg L−1; TP: 6.8 mg L−1 | nr | [65] |

| Piggery | 26 °C; 300 μE m−2 s−1; 2% CO2 aeration rate of 0.2 vvm | pH: 8.5; COD: 430 mg L−1;TN: 550 mg L−1; TP: 20 mg L−1 | nr | [69] | |

| Chlorella sp. HL | Swine wastewater | 25 °C; 60 μE m−2 s−1; 16:8 light: dark | TP: 74.61 mg L−1; COD: 12,431.9 mg L−1 | TP: 69.13%; COD: 72.95% | [79] |

| Chlorella sp. MM3 | Mixed piggery and winery (20:80 ratio) | 23 °C; | TN: 284 mg L−1; TP: 11 mg L−1 | TN: 89.36%; TP: 56.56% | [70] |

| Chlorella thermophila MF179624 | 2.5% Cattle | 25 °C; 100 μE m−2 s−1; aeration 0.5 vvm | pH: 6.11, NH4-N: 22,358 mg L−1; NO3-N: 3041 mg L−1; PO4-P: 760 mg L−1 | NH4-N: 53.74 mg L−1 d−1; NO3-N: 6.96 mg L−1 d−1; PO4-P: more than 99% | [71] |

| Chlorella vulgaris | 10% swine | 21 °C; 12:12 light: dark; 1.5 L m−2 min−1 of aeration | COD: 10.933 mg L−1; TN: 163.40 mg L−1; TP: 147.0 mg L−1 | COD: 96%; TN: 91%; TP: 85% | [62] |

| Poultry slaughterhouse | First stage: acid precipitation of wastewater; Second stage: batch conditions: 25–27 °C; continuous illumination 440 μE m−2 s−1; Continuous process: 25 °C; continuous illumination 440 μE m−2 s−1 | COD: 2185–7313 mg L−1 | COD (first step): 80%; COD (second step): more than 83% | [80] | |

| Chlorella vulgaris MBFJNU-1 | Swine | Outdoor: (sunlight) | pH: 5.5–6.0; COD: 492.4–500.7 mg L−1; TN: 472.5–547.8 mg L−1;TP: 31.8–42.6 mg L−1 | COD: 8.47 mg L−1 d−1; TN: 16.84 mg L−1 d−1; TP: 1.40 mg L−1 d−1 | [57] |

| Desmodesmus sp. PW1 | Piggery | 25 °C; 4000 lx. | TN: 296.7 mg L−1; TP: 28.6 mg L−1 | TN:90%; TP:70% | [83] |

| Dunaliella FACHB-558 | Anaerobically digested poultry litter | 25 °C; 200 μE m−2 s−1; 12:12 light: dark | TN: 100–120 mg L−1; TP: 15–20 mg L−1; TOC: 400–500 mg L−1 | TN:63.8%; TP: 87.2%; TOC: 64.1% | [56] |

| Haematococcus pluvialis | 1% Minkery | Green stage: 20 °C; 50 μE m−2 s−1 continuous light; Red stage: 20 °C; 200 μE m−2 s−1 continuous light | NH4-N: 32.5 mg L−1; NO3-N: 0.1 mg L−1; NO2-N: 0.1 mg L−1; TP: 14.0 mg L−1 | TN: 24.8%, TP: 99.7% | [75] |

| 1.5% Minkery | Green stage: 20 °C; 50 μE m−2 s−1 continuous light; Red stage: 20 °C; 200 μE m−2 s−1 continuous light | NH4-N: 48.75 mg L−1; NO3-N: 0.15 mg L−1; NO2-N: 0.15 mg L−1 TP: 21.0 mg L−1 | TN: 20.7%, TP: 99.8% | ||

| Scenedesmus obliquus SXND-02 | Chicken farm + (7 g L−1) sodium acetate | 25 °C; 120 μE m−2 s−1; 12:12 light: dark; | nr | TN: 80%; TP: 68%; COD: 89% | [87] |

| Scenedesmus sp. MUR 272 | Anaerobically digested abattoir | Micro-ponds: 20 cm depth; pH 6.5; CO2 addition on demand; batch mode; 7.3–39.8 °C; 427.6–815.8 W m−2 | NH4-N: 45 mg L−1; PO4-P: 6.3 mg L−1 | NH4-N: 86%; PO4-P: 89% | [77] |

| Anaerobically digested piggery | 175 ± 25 μE m−2 s−1; 12:12 light: dark | nr | TN: up to 99%; TP: up to 73% | [84] | |

| Tetraselmis sp. | Synthetic mariculture | 23 °C; 1500 μE m−2 s−1; 12:12 light: dark | NO3-N: 45 mg L−1; NO2-N: 10 mg L−1; Orthophosphates: 17 mg L−1; NH4-N: 30 mg L−1; COD: 270 mg L−1; | TN:95.5%; Orthophosphates: 94.4%; COD: 61.4% | [63] |

| Aquaculture | 24 °C; 50 μE m−2 s−1 | NH4-N: 7.7 mg L−1; NO2-N: 3.1 mg L−1; PO4-P: 2 mg L−1; | NH4-N: 0.08 mg L−1; NO2-N: 0.1 mg L−1; PO4-P: 0.17 mg L−1 | [78] |

COD (chemical oxygen demand), NO3-N (nitrate-nitrogen), NO2-N (nitrite-nitrogen), NH4-N (ammonium-nitrogen), PO4-P (orthophosphate phosphate), TN (total nitrogen), TP (total phosphate) and nr (not reported).

Table 8.

Growth parameters and metabolites production of microalgae culture in agricultural wastewater.

Table 8.

Growth parameters and metabolites production of microalgae culture in agricultural wastewater.

| Algae Used | Wastewater Type | Growth Rate or Volumetric Productivity | Final Biomass Concentration | Production of Target Metabolites | References |

|---|---|---|---|---|---|

| Acutodesmus obliquus | Piggery | 1850 mg-cell L−1 d−1 | nr | nr | [66] |

| Arthrospira maxima | 10% Nejayote | 0.27 d−1 | 32 × 104 cell mL−1 | nr | [62] |

| Arthrospira platensis | Dairy farm | 0.50 g L−1 d−1 | 4.98 g L−1 | Lipids: 30.23% | [72] |

| Botryococcus Braunii | Aerated swine | nr | 0,94 mg L−1 | Hydrocarbon: 23.8% | [74] |

| Chlamydomonas sp. JSC4 | Swine | 49.70 g m−2 d−1 | 37.73 mg L−1 | Carbohydrates: 3920% Lipids: 17.67% Protein: 33.94% | [61] |

| Chlorella pyrenoidosa | Paddy-soaked | 0.42 d−1 | 1.56 g L−1 | Chlorophyll: 15.57 mg L−1 Lipids: 27.47% Carbohydrates: 23.77% Proteins: 46.12% | [76] |

| Five times diluted anaerobically Digested swine | 4.21 g m−2 d−1 | 42.20 g m−2 | Proteins: 57.30% Extracellular polysaccharides: 14.87% Crude fibre: 3.08% Crude ash: 5.57% | [59] | |

| Piggery | nr | nr | Lipids: 6.3 mg L−1 d−1 | [68] | |

| Chlorella sorokiniana AK-1 | 50% Swine | nr | 5.45 g L−1 | Proteins: 0.27 g L −1 d−1 | [58] |

| Chlorella sorokiniana MB-1-M12 | Shrimp culture | nr | 1.9 g L−1 d−1 | Lutein: 5.19 mg g−1 | [64] |

| Chlorella sorokiniana SVMBIOEN2 | Dairy farm | nr | 2.33 g L−1 | Carbohydrates: 10.2 mg g−1 Proteins: 14 mg g−1 | [85] |

| Chlorella sp | Aquaculture | nr | 213 cell mL−1 d−1 | nr | [82] |

| Aquaculture | nr | nr | nr | [86] | |

| Chlorella sp. GD | Aquaculture | 0.487 d−1 | 17.4 g L−1 | Lipids: 21.3% | [65] |

| Piggery | 0.839 d−1 | 0.681 g L−1 d−1 | Lipids: 21% | [69] | |

| Chlorella sp. HL | Swine | 0.51 d−1 | 2.43 × 107 cells mL−1 | nr | [79] |

| Chlorella sp. MM3 | Mixed piggery and winery (20:80 ratio) | nr | 4.4 × 106 cells mL−1 | Lipids: 51% | [70] |

| Chlorella thermophila MF179624 | 2.5% Cattle | nr | 2.17 g L−1 | Lipids: 18.27% Carbohydrates: 29.39% Proteins: 44.91% | [71] |

| Chlorella vulgaris | 10% swine | 0.57 d−1 | 128 × 106 cells mL−1 | nr | [62] |

| Poultry slaughterhouse | nr | 1.2 g L−1 | nr | [80] | |

| Chlorella vulgaris MBFJNU-1 | Swine | 0.11 d−1 | 36 mg L−1 d−1 | nr | [57] |

| Desmodesmus sp. PW1 | Piggery | nr | 1.76 g L−1 | 7.2% | [83] |

| Dunaliella FACHB-558 | Anaerobically digested poultry litter | nr | 678 mg L−1 | β-carotene: 4.02 mg L−1 | [56] |

| Haematococcus pluvialis | 1% Minkery | 0.399 mg L−1 d−1 | 681 mg L−1 | Astaxanthin: 39.72 mg L−1 | [75] |

| 1.5% Minkery | 0.451 mg L−1 d−1 | 906.33 mg L−1 | Astaxanthin: 16.64 mg L−1 | ||

| Scenedesmus obliquus SXND-02 | Chicken farm + (7 g L−1) sodium acetate | nr | 2.18 g L−1 | Lipids: 50.22% | [87] |

| Scenedesmus sp. (MUR 272) | Anaerobically digested abattoir | nr | 19.24 g m−2 d−1 | nr | [77] |

| Anaerobically digested piggery | nr | 59.8 mg L−1 d−1 | Lipids: 25 mg L−1 d−1 Carbohydrates: 6.5 mg L−1 d−1 | [84] | |

| Tetraselmis sp. | Synthetic mariculture | 0.067 d−1 | 1.19 g L−1 | Lipids: 62.16 mg g−1 | [63] |

nr (not reported).

2.3. Industrial Wastewater

2.3.1. Physicochemical Properties

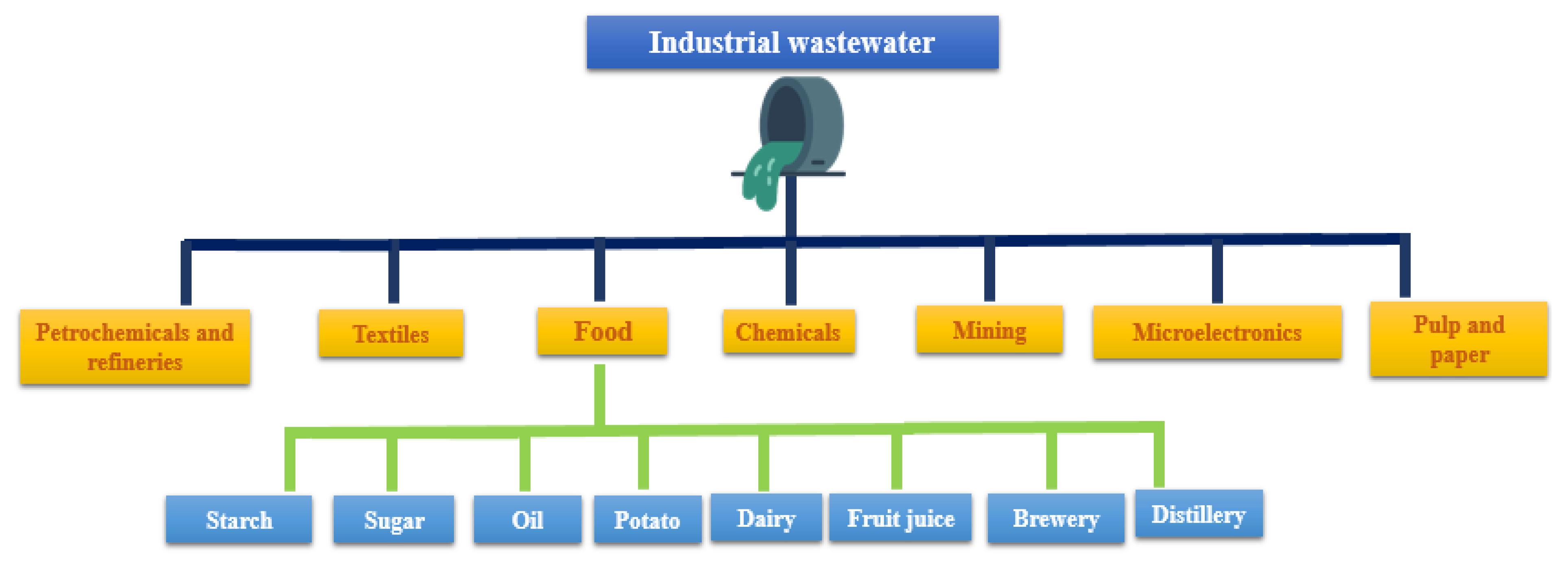

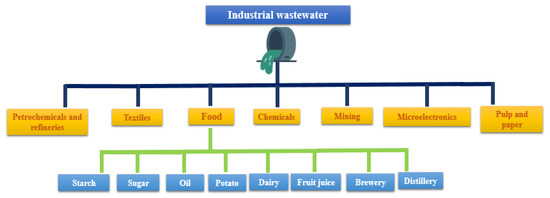

Industrial wastewater could come from a wide range of industries (Figure 5), such as the textile and food processing industries (sugar, starch, vegetable oil, shortening, potato, dairy, fruit juice and beverage, brewery and distillery industries) [88,89] and is one of the most significant pollution sources in the environment and has different properties. Different techniques have been used to treat this type of wastewater, among them is the treatment by microalgae [90]. Table 9 summarizes the properties of different industrial wastewaters which have been treated using microalgae, food-processing wastewater being the most investigated wastewater in the literature. This type of wastewater often has a high chemical oxygen demand and high total nitrate and total phosphate concentrations levels [5], for example, an olive oil mill wastewater contains 56,740–124,600 mg L−1 of COD, 130–190 mg L−1 of TN and 350 mg L−1 of TP, as well as soybean wastewater which has 5320–22,700 mg L−1 of COD, 267.1–950 mg L−1 of TN and 23.28–56.3 mg L−1 of TP [89,91,92,93,94,95,96]. Winery wastewater has a high COD content (119,300 mg L−1) and a lower TN (12.14 mg L−1) and TP content (3.46 mg L−1) [70]. On the other hand, textile wastewater is characterized by a high concentration of the total suspended and dissolved solids, chemical oxygen demand and a strong color [5,97]. As reported in Table 9, it contains 1050 mg L−1 of TSS, 1378.2–4458 mg L−1 of COD and 43.57 NTU, which is lower than a palm oil mill effluent (244 NTU) [98,99].

Figure 5.

Industrial wastewater types.

Chemical industry wastewater, such as that from pesticides and pharmaceutical processing industries, used in the literature as culture mediums for microalgae, contains high total organic carbon (TOC) and low total nitrate (TN) and total phosphate (TP) concentrations, with 7185.93 and 480.93 mg L−1 of TOC, 0.02 and 0.23 mg L−1 of TN and 1.01 and 0.52 mg L−1 of TP, for pharmaceutical and pesticide processing wastewaters, respectively [32].

Table 9.

Industrial wastewater composition.

Table 9.

Industrial wastewater composition.

| Type | pH | TSS (mg L−1) | TOC (mg L−1) | COD (mg L−1) | NO3-N (mg L−1) | NO2-N (mg L−1) | NH4-N (mg L−1) | NH3-N (mg L−1) | PO4-P (mg L−1) | TN (mg L−1) | TP (mg L−1) | References |

| Olive Oil Mill | 4–5.37 | 41,220–83,160 | - | 56,740–124,600 | 99.13 | - | 2.3 | 360 | 130–190 | 350 | [91,92] | |

| Textile | 10.5–10.9 | 1050 | - | 1378.2–4458 | 16.12 | - | 28.35 | - | 2.1–22.3 | 40 | - | [99,100] |

| Olive Oil Washing | 6.29 | - | 191.5 | 1362 | - | - | <4 | - | - | 7.49 | 1.63 | [17] |

| Starch | 2.13–7.3 | 1000–92,000 | 8770 | 792.28–7426 | 606 | 108 | 2.7–503 | - | 1.2–336 | 265.10–379.5 | 28.34–67.9 | [101,102,103,104,105] |

| Digested Starch | 7.3–7.5 | - | - | 702.4–102.5 | - | - | 217.6–334.7 | - | 19.3–32.9 | 240.3–382.7 | 22.7–40.2 | [106] |

| Alcohol | 3.2–4.5 | - | - | 45,638.06–65,000 | - | - | 214.56–279.72 | - | 19.71 | 618.68–725.34 | 47.16–64.38 | [104,105] |

| Reeling | 7.39 | - | - | 11 | - | - | - | - | - | 2.43 | 1.07 | [107] |

| Cooking Cocoon | 7.52 | - | - | 2925 | - | - | - | - | - | 267.5 | 23.1 | [107] |

| Frigon | >12 | - | - | 14,820 | - | - | - | - | - | 910.9 | 92.8 | [107] |

| Seafood | 7.92 | - | - | 1220.8 | 6.99 | 0.73 | 117.22 | - | - | 121.07 | 57.32 | [108] |

| Brewery | 5.5–6 | 300–320 | 1400–1500 | 2000–3000 | - | - | - | - | - | 30–45 | 12–16 | [109] |

| Rose Oil | 6.05–6.14 | - | - | 1200–2087 | 13.5 | - | 12.36 | - | <0.05 | - | - | [110] |

| Rolling Mill Industry | 6.05 | - | - | - | 11.5 | - | - | - | - | - | - | [111] |

| Vinegar | 5.6 | - | - | 740 | - | - | - | 17.7 | - | 20.5 | 7.4 | [112] |

| Dairy Industrial | 3.69–9.11 | 111–1510 | 143.3–722 | 342–7110 | 64 | 5.03 | 18.45–46.5 | 31.4–90.4 | 5.58–31.0 | 65.06–103.6 | 8–105.1 | [113,114,115,116,117,118] |

| Winery | 3.51–4.2 | 9780 | - | 119,300 | - | - | - | - | - | 12.14 | 3.46 | [70,119] |

| Soy Sauce | 6.548 | - | 992 | 3263.33 | - | - | 168.44 | - | - | 173.53 | 10.21 | [120] |

| Palm Oil Mill | 7–8 | 880–3900 | 1400 | 2898.72–4395.6 | - | - | 254 | - | 273 | 5.06–376 | 39.4–58 | [98,121,122,123] |

| Lactic Acid | 5.3 | - | - | 12,571 | - | - | - | 169 | - | 651 | 28.2 | [124] |

| Instant Coffee | 4.54 | 1000 | 7600 | 4940 | - | - | - | - | - | 75.63 | 7.81 | [125] |

| Dairy Products | 10.26 | 60 | 7420 | 190 | - | - | - | - | - | 18.04 | 2.63 | [125] |

| Pesticides Industry | 9.2 | - | 480.93 | - | - | - | - | - | - | 0.23 | 0.52 | [32] |

| Pharmaceutical Industry | 11.88 | - | 7185.93 | - | - | - | - | - | - | 0.02 | 1.01 | [32] |

| Petroleum Industry | 7.97 | - | 288.60 | - | - | - | - | - | - | 0.5 | 0.58 | [32] |

| Soybean | 4.2–6 | - | - | 5320–22,700 | - | - | 3–52.1 | 15.25 | 100 | 267.1–950 | 23.28–56.3 | [93,94,95,96] |

| Type | Chloride (mg L−1) | Na (mg L−1) | F (mg L−1) | Fe (mg L−1) | Cu (mg L−1) | Zn (mg L−1) | Mg (mg L−1) | Ca (mg L−1) | K (mg L−1) | Pb (mg L−1) | Turbidity NTU | References |

| Textile | 1019.46 | - | - | - | - | - | - | - | - | - | 43.57 | [99] |

| Olive Oil Washing | 172 | - | - | - | 1.6 | - | 62.4 | - | - | - | - | [17] |

| Starch | - | 315.21–719.40 | - | 0.94–32.86 | - | 0.86–1.24 | 3.711–181.16 | 98.40–126.36 | 112.34–174.47 | - | - | [102,104,105] |

| Digested Starch | - | 417.6–790.1 | - | 0.9–3.6 | 0.09–0.21 | - | 97.6–166.9 | 72.8–102.3 | - | - | - | [106] |

| Alcohol | - | 226.17–787.74 | - | 1.47–2.3 | - | 0.06–0.1 | 49.12–152.20 | 16.95–96.14 | 127.63–157.75 | - | - | [104,105] |

| Rolling Mill Industry | 172.3 | 60 | - | 3.51 | 8.5 | 0.75 | - | - | - | 2.48 | - | [111] |

| Vinegar Production | - | - | - | - | - | - | 13.9 | 39.5 | 69.9 | - | - | [112] |

| Dairy Industrial | 199–385 | 42 | 6 | - | - | - | 9.85 | 564 | - | - | - | [113,118] |

| Winery | - | 84.54 | - | 2.037 | 0.0059 | 0.6087 | 15.14 | 39.5 | 235.7 | 0.0004 | - | [70,119] |

| Palm Oil Mill | - | 2.99 | - | 1.67 | <0.01 | <0.01 | 3.8–672.22 | 0.8 | 3072.03–4393.89 | - | 244 | [98,121] |

| Instant Coffee | - | 0.059 | - | 9.762 | - | 0.032 | 28.10 | - | - | - | - | [125] |

| Dairy Products | - | 0.067 | - | - | - | 0.017 | 2.72 | - | - | - | - | [125] |

| Cassava Flour/Starch | - | 0.003 | - | - | 0.021 | 0.358 | 45.83 | - | - | - | - | [125] |

| Soybean Curd | 961 | 1387 | - | 5.16–41 | 0.55 | 6.91 | 35–173.5 | 51.47–366 | 1280 | - | - | [93,94,95] |

TSS (total suspended solids), TOC (total organic carbon), COD (chemical oxygen demand), NO3-N (nitrate-nitrogen), NO2-N (nitrite-nitrogen), NH4-N (ammonium-nitrogen), NH3-N (ammonia-nitrogen), PO4-P (orthophosphate phosphate), TN (total nitrogen), TP (total phosphate), Na (sodium), F (fluorine), Fe (iron), Cu (copper), Zn (zinc), Mg (magnesium), Ca (calcium), K (potassium), Pb (lead), NTU (nephelometric turbidity units) and nr (not reported).

2.3.2. Pretreatment

The industrial wastewater must be pretreated after characterization and before treatment with microalgae. Similarly to domestic and agricultural wastewaters, the procedures employed in the literature include sedimentation, filtration, acidification and centrifugation for the removal of suspended materials, as well as an autoclave or UV radiation sterilization for the removal of bacteria and other microorganisms found in industrial wastewater (Table 10). Filtration has also been used to remove germs depending on the pore size of the filter employed, for example, Hao et al. utilized the membrane filtration with a pore size of 0.22 µm to filter and sterilize industrial wastewater [8]. They reported that soy sauce wastewater composition had changed after sterilization by an autoclave at 121 °C for 30 min, with a change in the chemical oxygen demand from 3263.33 to 3463.33 mg L−1, total organic carbon from 992.00 to 1042.80 mg L−1, total nitrogen from 173.53 to 176.49 mg L−1, ammonium nitrogen from 168.44 to 158.85 mg L−1 and the total phosphorus from 10.21 to 5.57 mg L−1, and there was no change in the soy sauce wastewater color [120].

Table 10.

Pretreatment methods of industrial wastewater before microalgae cultivation.

Table 10.

Pretreatment methods of industrial wastewater before microalgae cultivation.

| Wastewater | Pretreatment Method | Microalgae | References |

|---|---|---|---|

| Tobacco | Filter-sterilized by a 0.22 μm membrane filter (Millipore, USA) | Chlorella pyrenoidosa (No.FACHB-863) | [8] |

| Palm oil mill (POME) | Filtered through a microfiber mesh and sterilized in an autoclave | Chlorella zofingiensis | [98] |

| Cassava processing | Autoclaved at 121 °C for 15 min, then filtered on filter paper | Arthrospira platensis | [101] |

| Palm oil mill (POME) | Filtered with filter cloth and re-filtered through glass microfibers filter (Whatman, Grade GF/C 1.2 mm) and autoclaved at 121 °C and at a pressure of 15 psi for 20–30 min | Nannochloropsis sp. | [121] |

| Soy sauce | Centrifuged (1644× g 5 min), then autoclaved at 121 °C for 30 min | Spirulina NCU-Sm | [120] |

| Potato | Acidified with sulfuric acid to pH 5, then autoclaved at 121 °C for 30 min | Scenedesmus sp. HXY5 | [126] |

| Olive oil washing | Centrifuged and filtered–sterilized through a glass wool pre-filter and cellulose nitrate membrane (0.45 μm) | Chlorella pyrenoidosa | [17] |

| Soybean processing | Centrifuged (5000 rpm), and filtered by a microporous filter membrane (0.45 μm), then sterilized by high-pressure steam at 121 °C | Chlorella sp. L166 | [96] |

| Vinegar production | Centrifuged for 10 min at 5000 rpm, and sterilized at 121 °C and 120 kPa for 20 min | Chlorella sp. | [112] |

| Soybean processing | Filtrated then autoclaved at 120 °C for 30 min | Chlorella L166 | [94] |

| Anaerobic palm oil mill | Centrifuged at 8000 rpm for 10 min | Scenedesmus sp. and Chlorella sp. | [122] |

| Starch processing plant | Filtered through 0.45 mm polyester filters and sterilized through UV-B radiation (UV doses 810 mJ cm−2 at a distance of 10 cm) | Chlorella pyrenoidosa (FACHB-9) | [102] |

| Cassava | Sterilized at 121 °C for 10 min | Desmodesmus aramatus | [103] |

| Anaerobically digested starch | Allowed to settle for 5–7 h in several tanks and filtered using polyester filters (1 μm) | Chlorella pyrenoidosa (FACHB-9) | [104] |

| Raw dairy | Filtered through a non-woven geotextile membrane (100 GSM grade) | Ascochloris sp. ADW007 | [113] |

| Seafood processing | Filtered using 0.45 μm pore size GF/C glass microfiber filters | Chlorella sp. | [108] |

| pesticides industry, pharmaceutical industry, petroleum industry | Filtered and sterilized using vacuum filtration unit and autoclaved at 121 °C for 15 min | Nannochloropsis oceanica | [32] |

| Anaerobic digested starch | Allowed to settle for several hours and filtered using a 0.45 µm polyester filter then sterilized | Chlorella pyrenoidosa (FACHB-9) | [105] |

| Anaerobic digested starch processing | Allowed to settle for 5–7 h in a settling tank and filtered with 270 mesh (53 lm) polyester filter bags | Chlorella pyrenoidosa (FACHB-9) | [127] |

| Raw dairy | Settled by gravity overnight and filtered through gauze | Chlorella sp. | [73] |

| Meat processing plant | Centrifuged at 8000 rpm for 10 min and sterilized at 121 °C for 30 min | Chlorella sp. | [128] |

| Pulp and paper industry | Addition of 1 mL of SuperFloc C-581 flocculant per 50 mL of effluent. Setteled for 20 min then filtred through a mesh filter with pore size of 5 µm and sterilized with a 500 mL bottle top polystyrene filter with pore size of 0.22 µm. | Nannochloropsis oculata | [129] |

| Raw dairy | Centrifuged (5000 rpm, 10 min) then autoclaved | Chlorella zofingiensis | [114] |

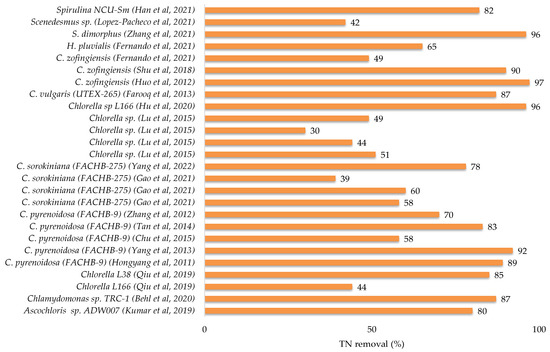

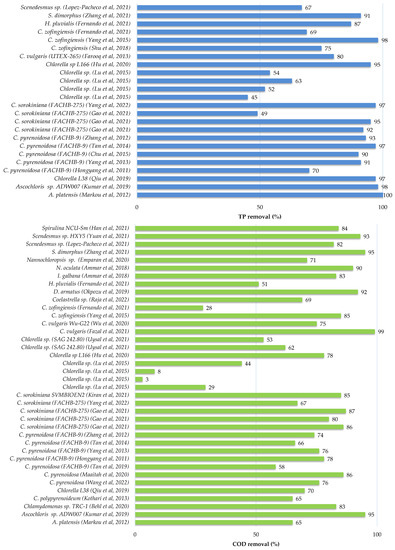

2.3.3. Microalgae Treatment of Industrial Wastewater