1. Introduction

Expanded polystyrene (EPS) is a lightweight and closed-cell rigid plastic foam made from polystyrene (PS) beads. Its good thermal insulation properties with sufficient stiffness and strength under compression [

1] make it an ideal material for transporting perishable foodstuffs, e.g., fresh fish, that are susceptible to temperature fluctuation [

2] in the food industry. The subject of this study was a 3-kg capacity EPS box for transporting fresh fish fillets. A certain structural strength of the box is essential for holding the load of the shipment goods during transportation and decreases the probability of damage that occasionally happens during movement. Therefore, in industrial practice, manufacturers tend to use excessive raw materials to ensure structural strength. In order to minimize environmental impact, it is possible to maintain original strength while consuming less material by introducing lightweight designs using the finite element method (FEM).

FEM is a popular modern method in structural analysis and optimization. By developing a numerical model with acceptable accuracy, the predictions made from the model iterate fast and are trustworthy. Applying optimal designs in manufacturing at the first opportunity is advantageous for companies. In the FEM analysis, crucial parameters of commonly-used materials can be pulled out directly from the engineering database. However, the parameters of a material such as EPS are usually not predefined and should be derived from mechanical properties, either from the literature or through experiments. The work conducted in this study is a prelude to the structural optimization of EPS boxes.

The mechanical properties of EPS have been studied widely in the field of civil engineering regarding uni-axial and triaxial compressive properties [

3,

4,

5,

6,

7] and breaking load/flexural properties [

7,

8,

9] via quasi-static experiments. Compared to compressive properties, which directly link to the structural optimal design of EPS, flexural properties are more of an indicator of fusion between polystyrene beads [

8]. Aside from quasi-static structural characteristics, dynamic structural behaviors have also been studied. For instance, EPS can be put inside helmets to absorb energy, thus protecting the human head; its dynamic compressive properties, shear strength, and behavior under impact have been investigated [

10,

11,

12,

13]. However, studies focused on the structural strength and other mechanical properties of EPS in the field of fresh fish packaging are very few.

Certain characteristics of EPS are universal, regardless of varied applications. For instance, the compressive properties of EPS are influenced by material density, strain rate, and temperature [

1,

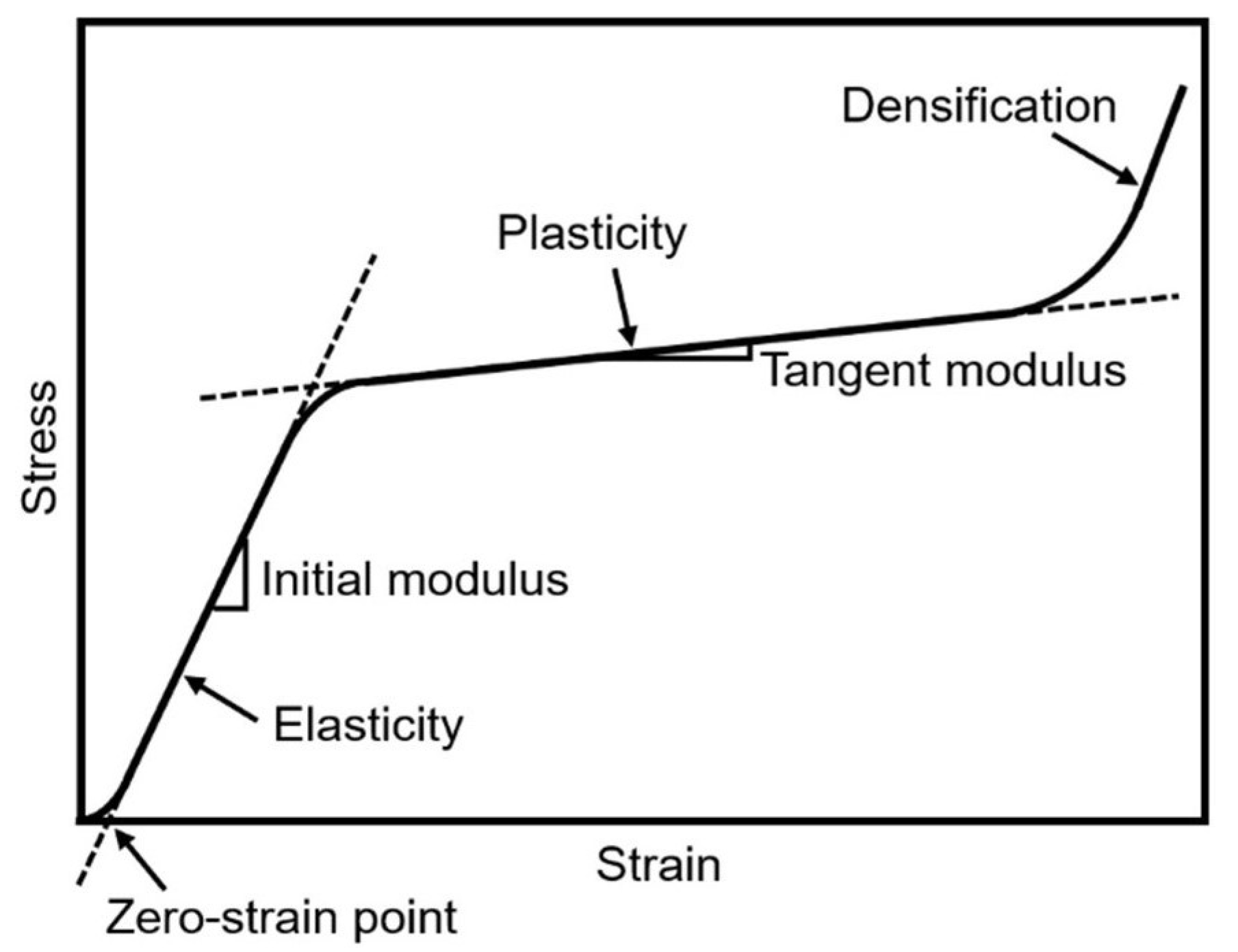

4]. The typical behavior of EPS under compression is shown in

Figure 1. At the beginning stage, the material is elastic and satisfies Hooke’s law; the slope of this part is referred to as the initial modulus in this paper. A toe region usually appears before elasticity, therefore, the ASTM standard specified a method named toe compensation to correct this [

14], and the modified zero-strain point is shown in

Figure 1. This method was also applied in the other tests whenever a toe region emerged in this study. Then, due to bending or buckling of the closed cell walls, the initial elasticity recedes and enters a plateau zone, where plasticity takes place, and the tangent modulus is herein described. At the last stage, when most of the energy dissipates through air breakout from the closed cells and the cellular structure collapses, the material becomes more dense, and this stage is called densification. In this study, elasticity and plasticity were investigated, and initial moduli and tangent moduli were obtained, but no characteristics of densification were studied.

Multiple researchers have developed correlations relating the initial modulus or the tangent modulus to density and strain rate [

15,

16] and through regression analysis [

4,

17]. In addition to that method, Akis [

18] introduced artificial neural networks to predict the initial modulus and the compressive strength values at 1%, 5% and 10% strain, and both methods yield satisfactory results with a coefficient of correlation values greater than 0.901. In terms of the compressive strength correlating to density and strain rate, Vilau [

19] developed four coefficients for EPS foam with densities of 11, 15, 20 and 25 kg/m

under low and high strain rates. Unlike the compressive properties of EPS that have been studied extensively, investigations into flexural properties are relatively scarce. It has been discovered that, with the increase in density, the flexural strength of EPS increases, the rupture happens at smaller deformation, and the stiffness of EPS also rises [

7]; Vilau [

19] validated this in recent studies. In another study, the initial modulus was found to be almost 350 times greater in compression than in flexure testing, meaning this material is more suitable for the case of compression [

9], although this conclusion conformed poorly with other studies [

1,

8,

20]. Aside from flexural properties, research into tensile properties is seldom conducted and the standard test method for tensile properties of EPS is not specified in ASTM D 6817: Standard Specification for Rigid Cellular Polystyrene Geofoam [

21]. Wang and David [

8] designed bone-shaped tensile specimens of EPS based on ASTM D 638 and found that the ultimate tensile strength of EPS rises with density. Akin to the results in the flexure test, the stiffness rises along with the increase in the density of EPS. However, ASTM D 638 was originally developed for rigid plastics with higher density and without cellular structures; for this reason, variances might be caused in the final results. ASTM has provided another standard—ASTM D1623: Standard Test Method for Tensile and Tensile Adhesion Properties of Rigid Cellular Plastics [

22]—which is supposed to be more appropriate for the material. Zouzias [

23] performed lengthy experiments to characterize the tensile behavior of EPS foams of densities ranging from 60–120 kg/m

and verified that the tensile strength also rises with the increase of strain rates and density. Apart from fundamental mechanical properties investigation, Ellouze [

24] carried out a heat treatment process on EPS foams and enhanced the hardness. Nevertheless, the mechanical properties test for the treated and non-treated EPS foam followed different standards, which could impair the comparability of experimental results.

Several papers related to the topic of this investigation, specifically the 3 kg capacity EPS boxes, may offer valuable insights. In an article from Mai et al. [

25], the staggered pattern of stacking up the 3 kg capacity EPS boxes was illustrated and further inspired the test for the stacking strength of the boxes. Margeirsson [

26] tested the stacking strength of EPS boxes with a shipment capacity of between 3 and 25 kg and obtained the maximum stacking load from 11 types of boxes provided by Tempra (

Tempra: EPS manufacturer in Hafnarfjordur, Iceland). It was found that the smallest boxes (capacity 3 kg) had relatively higher safety factors compared to larger boxes. This finding indicates that there is room for improvement on smaller boxes, which motivated this study. Helgason [

27] tested the strength of EPS boxes with a capacity of 23 kg under three different load conditions and then used FEM to simulate lightweight design ideas, including changing the radius of rounding on edges, and thin either the bottom or the lid. However, there is uncertainty remaining in the lightweight design of Helgason’s study on account of the material parameters derived from the equations in the literature. In particular, Young’s modulus has considerable variance compared to obtaining it from the experiment.

In this study, compression and flexure tests were performed on specimens sampled from the EPS boxes manufactured by Tempra, as well as stacking strength and bottom strength tests on the boxes as a whole to study the behavior of 3 kg EPS boxes with densities of 22 and 23 kg/m. The data obtained in the compression test were used as material parameters in a finite element model of the EPS boxes under stacking load; the simulation outcomes were then compared with the experimental results.

4. Conclusions

Specimens sampled from the bottom of EPS boxes with a capacity of 3 kg were used in the uni-axial quasi-static compression test and flexure test, and EPS boxes with densities of 22 and 23 kg/m were involved. The data obtained from the compression test were used as material parameters in the following FEM analysis simulating EPS boxes under stacking; the results of the FEM analysis were then compared with the results of the stacking strength test performed in this study. In addition, as one of the constraints for the future optimal design, the bottom strength of EPS boxes was examined.

In the mechanical properties test, the compressive strength and flexure strength were primarily influenced by density. Roughly an 8% rise in compressive strength was observed in EPS23 compared to EPS22, and the initial modulus had around a 10–15% rise. However, the specimen’s size and the preparation method had a minor influence on the compression and flexure tests. Specimen size did not affect the compressive strength and tangent modulus in the compression test; there was only a 20% rise in the initial modulus of the compression test if specimens were 2 mm thicker, and it affected almost nothing in the flexure test. As for the method of preparation, around 2% higher stress was observed in the results of specimens cut with a hot wire in most test groups.

The difference was not as distinct as in the compression and flexure tests when the boxes were tested as a whole. In the stacking strength test, with density increased by 1 kg/m, there was a 2.7% increase in load when breaking the box. The corresponding number was −10.3% for the bottom strength test. It is not necessarily that density affected the strength of EPS deeper in compression and flexure tests than in strength tests as a whole. The most plausible explanation is that EPS boxes with a density of 23 kg/m used in whole-box tests were of inferior quality. An attempt to make the structure of the box lighter was also investigated in the stacking strength test and the bottom strength test. With 4 mm material shaved by a hot wire from the bottom, the rounding on the bottom edge was almost eliminated, whilst the walls were shorter, and this difference gave an 8.8% and 5.1% rise at 10 mm deformation in the stacking strength experiment and simulation, respectively. Meanwhile, the bottom strength decreased by 20.4% if 4 mm thick material was shaved off. This suggested that it was possible to consume less material and improve the stacking strength merely through topological modifications; however, bottom strength might be impaired. For now, the wall shortening that increased the critical force in buckling or the radius change of the foot corner could be the underlying cause of the improvement in stacking strength with the 4 mm material removed from the bottom of EPS boxes.

The simulation results of the EPS boxes were in good agreement with the experimental results, indicating that the material parameters obtained from experiments and then included in the simulation material model were capable of delivering a satisfactorily accurate prediction. As mechanical properties could be varied to a remarkable extent if derived from the literature, for the accuracy of simulation, performing mechanical properties tests for the particular EPS is highly recommended. In future work on optimal lightweight designs of the box, the numerical model developed in this study will be an important tool.

As for the method of preparing specimens, cutting with a table saw complied with the methods of specimen preparation suggested in ASTM D1621 and presented better results in conformance statistically. However, cutting with a hot wire was acceptable if the specimens’ tension and compression sides were preserved as original surfaces, especially in a flexure test. Therefore, adopting the methods depends on specific demands. Additionally, to determine the safety factor of a brittle material in FEM analysis, a tensile test may be conducted. Despite testing on a specimen sampled from an EPS box or on the box as a whole, taking EPS boxes from different batches would be better for the sampling process in the future if possible. During the movement of EPS boxes inside the cold chain, the boxes are occasionally under high impact. Therefore, energy absorption properties can be further studied. As FEM is an efficient and powerful tool in reproducing and predicting behaviors of structures, the parameters could be modified by simulating the bending of the material. An even more precise model could probably be developed for more accurate prediction.