1. Introduction

An assembly line is a manufacturing process consisting of various tasks in which multiple parts are sequentially assembled into a product at several workstations to produce the final product. It is widely used in mass production for manufacturing various types of product, such as automobiles or electronic products. The workstations are arranged sequentially, with tasks being performed by workers simultaneously. The main layout problem is determining the optimal arrangement of tasks to workstations, which is commonly known as the assembly line balancing problem (ALBP). ALBP is a classical optimization problem in industrial engineering with the main objective of optimizing the efficiency (number of workstations and cycle time) of assigning tasks to workstations. This approach has been widely discussed and presented [

1,

2,

3,

4,

5].

Setting up an assembly line is usually a long-term process that involves major investments. In addition to planning new assembly lines, existing assembly lines must also be periodically redesigned to accommodate various changes in the production process. Therefore, companies constantly face the challenge of changing their assembly systems quickly and economically.

In light of the ideas of Industry 5.0, with its focus on the human-friendly, human-centered, and sustainable design of production environments, our study focused on less-publicized approaches to time analysis of the assembly process. Although time analysis is a well-known approach, it has recently become more interesting because it is directly related to workers and their activities. Workers have different skills and perform tasks in different ways in terms of speed, motivation, and diligence, a topic that is also considered in ergonomics, and this could be a future direction of ALBP approaches. ALBP and time analyses are closely related, so new variations and combinations of the two approaches that are still being developed represent a new and interesting area for future research.

This study presents an approach to solving ALBP using the Methods-Time Measurement (MTM) time standard and simulation software. A new time analysis using MTM was performed to assess the current process and was balanced with the use of Work-Factor. The new time analysis was used to prepare the rebalancing of an assembly line. Scenarios before and after rebalancing were then compared in a simulated environment. The assembly line simulation was performed using Simio software to evaluate different design options and operating scenarios. The usefulness of the presented approach was demonstrated by running the assembly line in a three-shift serial production in a large manufacturing company for household appliances.

Although the focus of the present study is on time analysis, an in-depth analysis of the work and work methods, including an ergonomic evaluation using the European Assembly Worksheet (EAWS), was performed at the same time. Due to the complexity of the optimization process, which requires the consideration of many influencing factors, the present study was limited to time analysis.

2. Literature Review

2.1. Simulation Modeling

As a powerful tool for analyzing complex stochastic systems, of which assembly lines are undoubtedly one, computer simulation modeling has been widely used [

6,

7,

8,

9]. Simulation modeling is the process of creating and testing a computer-based mathematical model of a physical system. The main objectives of simulation modeling can be summarized as follows:

Gaining insight into the operation of a system; it is difficult to study the system at standstill.

Developing operational or resource strategies to improve system performance; existing operating systems should be improved.

Testing new concepts and/or systems prior to implementation, and typically, testing how well the new proposed model will work and reviewing and refining the configuration of the selected equipment.

Obtaining information without interfering with the actual system.

Simulation modeling has several advantages, but also some disadvantages that should be considered. The main advantage is the ability to examine systems dynamically and in real time during the simulation run, which usually takes less time than testing in a real environment. With a computer model, operation and interaction with different scenarios can be simulated in seconds. The reduced analysis effort allows practitioners to analyze many more different types of system than was previously possible. Simulation software with the ability to dynamically animate the operation of the model is useful for demonstrating system operation and troubleshooting potential failures. In addition to the obvious advantages, there are some disadvantages to simulation modeling.

Simulation cannot provide accurate results if the input data are inaccurate. Therefore, data collection is a very important part of the simulation process, even though it is often neglected. Another challenge is problem solving. Although the simulation model provides management with several possible solutions, simulation alone does not solve the problem—this is still the responsibility of management.

The use of various simulation software programs has been covered in several papers [

10,

11,

12,

13] and books [

6,

14,

15]. One of the most important decisions in conducting a simulation study concerns the choice of software. We can choose a simulation package or a general-purpose programming language. The advantages of simulation packages can be summarized as follows:

They provide all the segments needed to build a simulation model (shorter time and lower cost);

The basic modeling constructs are usually more user-friendly (easy to use);

Simulation models are easier to modify and maintain;

Automatic checking for possible errors (better error detection).

In contrast, simulation models written in a general programming language have some other advantages:

An analyst already knows the programming language;

A model written in a specific programming language (C, C++, Java) can be better tailored to a specific application, and is therefore faster (shorter execution time);

Greater flexibility in programming.

Discrete-event simulation packages are usually of two main types: general-purpose simulation packages and application-oriented simulation packages. The former can be used for any application, but may have specific features for certain applications (e.g., manufacturing or process optimization). The second type of simulation software is tailored to a specific type of application, such as manufacturing or healthcare.

2.2. Simulation Software

There are several general-purpose simulation packages on the market, such as Arena [

16,

17], ExtendSim [

18], Simio [

19,

20], Anylogic [

21,

22], and others. Arena is typically used for applications such as manufacturing, supply chains, defense, and healthcare. The modeling structures are functionally organized into different “templates” that are used to model arrivals, departures, services, and unit decision logic. This is the basic approach. The Arena software also allows for an advanced process approach with access to external data files in Excel, Access, and SQL databases. A model is created by dragging modules into the main model window and connecting them together to represent the flow of units through the simulated system. Detailed modules can be designed using dialog boxes. Three-dimensional (3D) animations can be created simultaneously using the “Visual Designer”. In addition, there is activity-based costing that provides value-added and non-value-added cost and time reports. The Arena simulation package has not been widely used in previous research, but there are two cases where it has been used for assembly lines [

23,

24].

ExtendSim is the name for a family of four general-purpose simulation packages targeted toward specific market segments. A simulation model is created in a virtual environment by selecting blocks from libraries, placing them in selected locations in the model window, similar to Arena, and connecting them together to represent the flow of units through the system. Detailed modules can be designed using dialog boxes. The software can create a wide range of different system configurations. It has activity-based costing, which allows fixed and variable costs to be assigned to a unit as it moves through the simulated system. The “Scenario Manager” allows us to explore different scenarios and shows us the model responses from one scenario to another. This literature review shows that there are some applications of ExtendSim simulation packages in logistics [

25], transportation [

26], and some other non-processing areas.

Simio is an object-oriented suite of simulation and planning products [

20]. It is a simulation modeling framework based on smart objects that allow models to be created either using a standard library (for discrete-event simulations) or by allowing the user to create new objects. An object in a library can be a customer or a machine. A model is created by dragging objects into the 2D “Facility” window, connecting them with links to show the flow of entities through the simulated system. Similar to the previously presented software packages, detailed modules can be designed using a property editor. A 3D perspective view is also available for better visualization. The structure of an object in Simio is identical to the structure of a model, and each model is automatically a module that can be used to build hierarchical models. Specific properties (e.g., the machining time of a machine) and states (e.g., idle or busy) can be defined for each inserted object. Simio also provides a set of sophisticated functions for running and analyzing simulation experiments with different scenarios. The Simio simulation package is more widely used than the previous two simulation software packages, but not for assembly lines. It has some applications in logistics [

27], service planning [

28], production planning [

29], and cellular manufacturing [

30].

Anylogic is a powerful and flexible simulation software package that can be used to model and analyze complex systems in a variety of industries, including healthcare, transportation, and logistics. Anylogic offers users three different modeling approaches: discrete-event, agent-based, and system dynamics. This makes it a versatile tool that can be used to model a wide range of systems. Like other software solutions, Anylogic also has powerful visualization and analysis tools, including the ability to create 2D and 3D animations of models, and perform advanced statistical analysis. There are some previous research papers that use the Anylogic simulation package, but it is used for manufacturing simulation, lean six sigma implementation, value stream analysis, lean manufacturing, smart factories, material handling, and cloud simulation [

31,

32,

33,

34,

35].

2.3. Assembly Line Balancing

The assembly line balancing problem (ALBP) deals with the allocation of tasks to workstations while optimizing one or more previously selected goals, without violating precedence constraints on the tasks or other constraints imposed on the assembly line.

The simple assembly line balancing problem (SALBP), which envisions a single-mode line with a fixed cycle time and deterministic task times, does not consider all the features typical of real problems. Real AL problems should consider several additional features, such as cost functions, equipment selection, parallelization, stochastic task times, and others, and can be solved via the so-called generalized assembly line balancing problem (GALBP).

The mixed-model assembly line balancing problem (MALBP) can be considered a special case of GALBP where several similar models, which are variations of the same basic product and differ only in certain adaptable product properties, can be assembled simultaneously and continuously [

36].

Parallelization is another feature that should be considered in assembly line configurations. Different forms of parallelization can occur in the real environment and increase the solution space of the problem, such as parallel lines [

37], parallel workstations performing the same set of tasks [

38], or parallel bipartite lines [

39]. Parallel assembly sequence planning (PASP) is best explained in the work of Gulivindala [

40,

41]. PASP is treated as an NP-hard problem because of methodological difficulties in its development phase and computational complexity in its implementation for solution generation.

Based on the assembly line layout, two types of assembly line balancing are known: the one-sided assembly line balancing problem and the two-sided assembly line balancing problem (TALBP), the latter of which is widely used in the assembly of large products such as busses and trucks [

42]. TALBP is characterized by a set of tasks that must be divided and processed at a series of paired stations, where each station contains two opposing workstations with two workers [

43]. The TALBP approach, with four specific constraints (precedence, cycle time, allocation, and direction), is much more complex than the one-sided ALBP approach, although simple ALBP with minimization of the number of workstations is already an NP-hard problem [

44]. The methods used to solve ALBP can be divided into three groups: exact methods, heuristic methods, and meta-heuristic methods. With all the different possibilities and approaches, the field of ALBP solutions continues to grow and evolve [

45].

NP-hard problems are described as a class of computational problem for which a solution can be verified in polynomial time, but for which no known algorithm can solve the problem in polynomial time. NP-problems are of great interest in computer science because many important problems, such as the traveling salesman problem and the satisfiability problem, are known to be NP-problems. The class NP is defined as a set of decision problems for which a proposed solution can be verified in polynomial time. This means that the amount of time required to solve or verify the problem grows faster than a polynomial function of the size of the input [

46].

2.4. Assembly Line and Industry 4.0

In addition to classical mathematical approaches, new technologies in the context of Industry 4.0 (I4.0) can accelerate workplace design on the assembly line. Industry 4.0 is leading companies to gradually and continuously automate traditional manufacturing processes [

12], but at the same time, Industry 5.0, with its focus on a more human-centered approach to industrial work system design, is just around the corner [

47]. Industry 5.0 emphasizes explicit attention to consequences for employees in the system in order to design production environments that are human-friendly, human-centered, and sustainable.

Assembly systems are also affected by this revolution, with the concept of Assembly System 4.0 (AS4.0) aiming to improve performance and workplace design [

9,

48,

49,

50,

51,

52,

53,

54,

55].

Traditional approaches to optimizing assembly systems mainly consider time and cost variables, but some studies also consider ergonomic aspects [

56]. On the assembly line, the work is repetitive and requires the full attention of the worker. The processes are flexible and must also be organized while taking into account the workers’ skills [

57]. Workers are an integral and very important part of production systems, as they still perform the majority of operations. They usually have different skills and expertise and perform tasks in different ways in terms of speed, motivation and diligence.

The current trend of Industry 4.0, with “smart” paradigms such as sensors, communication platforms, simulation, data-intensive modeling, and predictive engineering, offers us the opportunity to recreate the work environment in a virtual scenario where it is possible to simulate manual activities, evaluate ergonomic metrics, and perform time analyses simultaneously [

58]. Software-based time analyses and simulations allow us to study different operating scenarios before setting up an assembly line in a real environment, and also represent the added value of new technologies.

2.5. Assembly Line Reliability

System reliability should also be considered in the optimal design of assembly lines. Optimizing system reliability involves formalizing and continuously improving the methods and techniques used to address the reliability of a complex system [

1]. Within assembly lines, system reliability refers to cycle time uncertainty. Changes in cycle time (e.g., increases in cycle time) can cause a line to become unbalanced, resulting in production losses. Therefore, maximizing assembly line reliability is another important goal for ALBP, in addition to minimizing cycle time.

3. Problem Definition

The latest product produced on an observed assembly line, presented in

Figure 1, exceeded the expected production quantity. This was the result of the unforeseen positive diffusion of a new technology on the market. Since the new planned output could not be achieved on the current assembly line, the question arose as to whether the current task workflow from one workstation to another was optimally balanced or whether it was necessary to order a twin of the current assembly line.

The product assembled on the production line (

Figure 1) is a fully automated espresso machine with external dimensions of 400 × 300 × 400 (cm × cm × cm). There are approximately 216 operations composed of 864 steps of time analysis, which need to be completed to assemble the whole product. The process time for assembly is 1102 s.

This problem is commonly known as the assembly line balancing problem and is best described in [

7]. The ALBP is represented by a set of tasks with fixed times that must be assigned to a set of sequential workstations. The order in which the tasks can be executed is constrained by a set of priority relationships. The most important constraint to consider is the time available at each station, referred to as the cycle time.

If the station utilization is lower than the cycle time, then the idle time for each cycle is the difference between the station utilization and the assembly line cycle time. The goal of ALBP’s solution is to minimize the total idle time across all stations on the assembly line. In this way, the assembly cost per product is reduced to a minimum [

59,

60].

For better knowledge of all project participants, a new assembly time analysis was created for this product. It was based on the Methods-Time Measurement time standard. The newly created time analysis was used to compare the current state with the improvement possibilities on the assembly line. Similar to [

61], MTM was used because of its use in production process planning. It assumes that individual basic movements in the correct sequence are more time-efficient and can be performed with fewer errors.

After rebalancing of the assembly line, the European Assembly Worksheet (EAWS) was used to assess workers’ posture and movements [

62,

63]. EAWS is a screening tool used to assess workers’ biomechanical workload (postures, forces, manual handling, and repetitions) that identifies key ergonomic issues and provides the opportunity to develop solutions to overcome them. Although ergonomic assessment was a part of our work analysis, the ergonomic results are not presented in detail in this paper.

The assembly line was split into three logical zones: A, B, and C. To obtain the results of the study as soon as possible and implement the improvements, only zones A and B were included in the study, because the cycle time of zone C was lower than the new planned cycle time of the assembly line. The layout zones are highlighted in

Figure 2.

The assembly line was divided into three logical zones based on the effect of the fully automated inspection stations used on the assembly line. Zone A included eight workstations. After Zone A, an automated PreCheck camera station was used to perform a visual inspection of all assembly work performed to date. This was the last step before sealing the product with the housings. Zone B included 2 workstations where assembly of the housings and preparation of the product took place prior to the fully automated functional and safety testing of the product. Zone C represents the last two workstations where the finishing operations of assembly and packaging were performed, which are not relevant to the possible safety-critical aspects of the product.

To minimize disruptions on the assembly line, which was running in a three-shift serial production, it was decided to display all collected information in a simulated environment. The simulated environment was prepared using Simio simulation software.

The main goal of the study was to simulate whether the new desired output of the assembly line can be achieved, without disturbing the current assembly line, which is in serial production.

Study Limitations and Assumptions

Our study was limited to the production line in a selected medium-sized company, so that all specifics and characteristics were limited to the type of production and equipment. The other limitations of the present study are as follows:

We came to an agreement with the manufacturer that prevents the publication of some data.

The precedence graph for the assembly had to be respected.

Because of the test stations, the operations had to remain in their designated zones. This means that operations that were in Zone A before rebalancing remained in Zone A after rebalancing.

Two of the operations in the assembly line required oiling and had fixed oiling devices. To reduce costs and ease the transition to the new assembly order, these operations remained at the same workstations.

This study’s assumptions are based, first, on the anticipated need to increase assembly line output due to increased market demand. Second, the MTM time analysis is assumed to accurately reflect the time required for each step of the assembly operations.

4. Materials and Methods

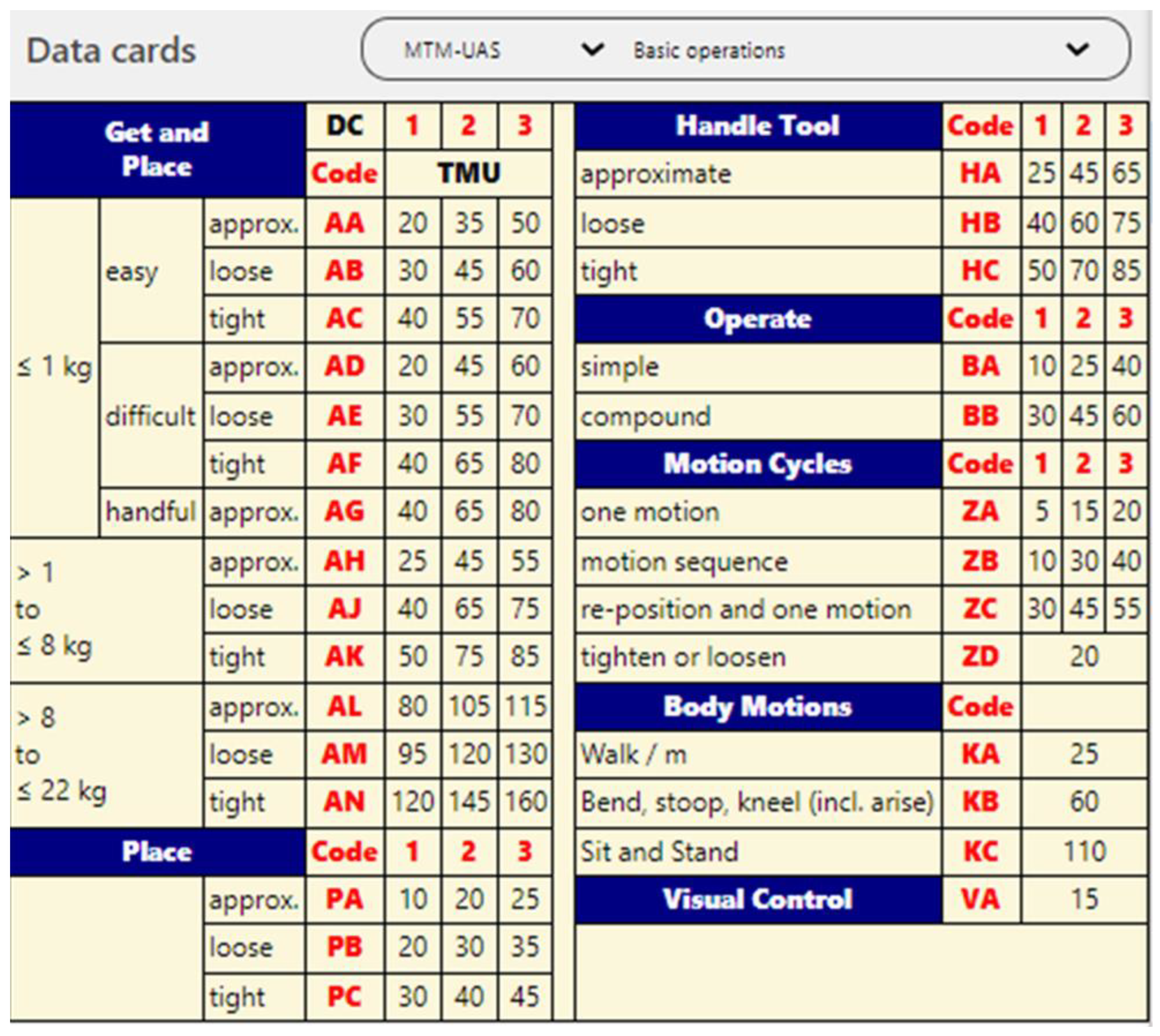

The ALBP was analyzed using the MTM time standard. This is a widely used method for scheduling production processes because it assumes that individual basic movements in the correct sequence are more time-efficient and can be executed with fewer errors. Due to the cycle times in the observed assembly line, the use of the MTM Universal Analysis System (MTM-UAS) was recommended. This method of predetermined motion time system was described in the last review article [

64] as state-of-the-art in practice.

The Work-Factor (WF) system and the Methods-Time Measurement (MTM) system are well known approaches from a group of predetermined times. Both systems have some benefits and obstacles and have undergone many changes and variants over time. The MTM system was first described by Maynard, Stegemerten, and Schwab [

65] for production process planning. Both approaches, WF and MTM, are based on the assumption that individual basic movements can be performed in the correct sequence more time efficiently and with fewer errors. The time units used are referred to as TMUs (Time Management Units). The components of the process follow each other in a linear sequence, which is reflected in their sequential process.

The basic concept of MTM is to decompose a task into its basic human activities, use basic times for them from tables, and combine them into a basic time for the entire task. Several variants of MTM have been developed, differing in their focus. Because of the length of the process time, the MTM Universal Analysis System (MTM-UAS) was chosen in this study (

Figure 3). MTM-UAS, which assigns a pre-determined time standard to specific individual process steps, was created to meet manufacturers’ demands for productivity improvement in batch production. Today, it is widely used in the automotive industry [

66]. The categorization MTM-UAS aims for serial production and minimization of the time units used. Sequences of movements and tasks occur regularly and in rapid succession. Taylor and Gilbreth analyzed the ideal workflow from the point of view of efficiency. In addition to the personal skills and abilities of the workers, they emphasized the sequence of work steps as particularly important [

67].

The cycle times of the observed production line range from 60 to 120 s, and the detailed MTM analysis with all the required steps was extensive. To illustrate the application of MTM analysis, a brief example based on a laboratory demonstration of a workstation was prepared and is shown in

Figure 4. The example shows 7 assembly operations consisting of 14 assembly steps. For each movement that is performed, the starting position of the worker must be known. Code is then developed based on factors such as the difficulty of grasping and positioning the object, which depend on the size, weight, and type of packaging of the object. Accurately measuring the length of the movement is critical to determining the specific code for each step. Additionally, codes for body motion, including side steps, are used in this example.

MTM-UAS allows for the creation of building blocks that represent operations that are repeated in the assembly process. It is recommended that these building blocks are used to avoid discrepancies in the different phases of the timing analysis.

Originally, the analysis was divided into seven parts. Splitting the timing analysis is recommended when the results show that the output is not achieved and realignment of the assembly line is required. The split parts were later combined into one workstation for presentation purposes [

58]. The sum of all steps in the example in

Figure 4 results in a base time of 21.96 s. The base time represents the cycle time of the workstation.

In our analysis, the European Assembly Worksheet (EAWS) was used to assess workers’ posture and movements. EAWS was originally developed for the assessment of assembly work in the automotive industry, where work is performed in short cyclic segments. The EAWS structure consists of the following sections: the general section, the working posture section, action forces, manual material handling, and repetitive upper limb movements. The EAWS index is composed of two values: one related to the whole body and the other to the upper limbs. The risk zones are classified as follows:

- -

Green, 0–25 points, low risk—no action is needed,

- -

Yellow, 26–50 points, moderate risk—further risk assessment and analysis are performed, taking into account additional risk factors (redesign or recovery actions)

- -

Red, >50 points, high risk—action to reduce the risk is required.

For our simulation, final solutions with a total score below 25 were considered (

Figure 5).

To evaluate the accuracy of the prepared time analysis, a statistical analysis of a previous time analysis project was performed. The collected data of the project, which is now in serial production, were used to create a time distribution using ExpertFit software.

Using ExpertFit, any analyst, regardless of prior knowledge of statistics, can avoid pitfalls that undermine the success of simulation studies. ExpertFit identifies the best of the probability distributions under consideration and helps the analyst decide whether the fit is a good one. If no adequate fits are found, ExpertFit [

68] can be used to create an empirical distribution function.

To minimize disruptions on the assembly line during three-shift serial production, new scenarios created using the MTM method were tested in a simulated environment. Simio simulation software was used to prepare the simulated environment. One of the main advantages of Simio is that it allows users to test and evaluate different design options and operating scenarios to determine the best solutions to improve performance and reduce costs [

19].

The assembly line in question met most of the conditions that determine whether it is appropriate to build a simulation model. The reasons for this were the longer simulated time interval of the assembly line process under study and the variant planning without interfering with the real system [

69].

As mentioned earlier, a model of the assembly line was created using Simio simulation software. The assembly line model was then used to simulate different scenarios (

Figure 6). The effects of variables on the performance of the assembly line and its bottleneck stations were simulated. The simulation results had to be critically analyzed, and the lessons learned had to be applied to the real environment in which the assembly line was optimized.

Simio simulation software was used because we are familiar with it and have had good experience using it to study various problems in manufacturing. Similar to [

27], it was chosen for its ability to represent the system in three dimensions and model realistic spatial relationships in the layout. This resulted in a user-friendly interface that facilitated model verification and validation.

5. Results

5.1. Line Balancing

The previous time analysis was performed by another engineer using the Work-Factor method. To keep the rebalancing results as accurate as possible, a new time analysis was created from scratch using MTM.

The cycle times of the observed production line were between 60 and 120 s. Due to the nature of the assembly and the length of the cycle times at the workstation, the use of the MTM Universal Analysis System (MTM-UAS) was recommended. The assembly operations were simple and were all performed manually, except for the screw driving operations, which were performed using electric screwdrivers. No above-average training or certification was required to perform nine of the ten jobs mentioned. The one that required more in-depth training took place at Workstation 9, which was responsible for handling the results and responding appropriately to the results of the automated PreCheck station.

The time analysis was prepared by an expert engineer, but there was still a possibility that the results prepared by different engineers may differ. To evaluate the accuracy of the engineers’ time analyses, a statistical analysis of a previous time analysis project was performed.

The cycle time for a particular workstation was estimated to be 59.8 s. After the new work procedure was implemented and the learning curve of the two weeks was completed, 14 cycles were measured, which are shown in

Table 1.

Based on the times recorded and shown in

Table 1, a time distribution was generated using ExpertFit software. The results of the distribution show that the normal distribution 59.643; 6.105; delta 0.401 is the best fit for the acquired cycle times.

After comparing the engineer’s estimated time based on method MTM-UAS and the distribution of times measured on the assembly line, there is a 0.26% difference in the results. The results show that the method and the expert engineer are suitable for preparing the time analysis for this type of assembly production. The results of the MTM-UAS method, which was prepared for the assembly line in question, were used in the simulation model.

After the time analysis was prepared, the assembly line adjustment had to be planned, also known as the rebalancing process. Each task and each step of the tasks were coded using MTM-UAS and organized using the EasyPlan software. Examples of the coding, determination of frequency, determination of quantity, and time of the steps (TG) are shown in

Table 2. The TG Sum column shows the assigned time of operations in seconds.

When tasks were assigned to a workstation, the sum of all steps of the tasks at each workstation must be less than the desired cycle time of the assembly line.

The results of the new time analysis were combined with the original assembly process and are shown in

Table 3.

After seeing the results shown in

Table 3, rebalancing was performed. The results of the rebalancing are shown in

Table 4.

The bottleneck for the new rebalancing in Zone A is workstation 1, which is the pacemaker of the assembly line. The problem is that Zone B, with workstations 9 and 10, is the real bottleneck of the assembly line. For further improvements and studies on the assembly line, a worker would need to be added to Zone B. This would mean that a lot of workers would have to be added in Zone A to maintain the desired workstation occupancy.

5.2. Simulation Model

The purpose of creating a simulation model of the assembly line was to study the effects of rebalancing on the efficiency of the assembly process. To improve the quality of the results obtained using time analysis, a simulation model was created using the time analysis data. The additional benefit of the simulation model is its consideration of the influences and disturbances that are present in an assembly environment. In the simulation model, they are represented by:

- -

The calculated distribution of the time analysis data;

- -

The first pass yield of the workers and the inspection stations in the first run;

- -

The repair station effect;

- -

The work schedule;

- -

Breaks.

5.2.1. Preparation of the Simulation Model

A simulation model of the assembly line was created using Simio simulation software. The model contained all the information that could be collected in the real environment.

Figure 7 shows the layout of workstations 1–10 represented in the rebalancing data. The layout also includes workstations 11 and 12, which were excluded from the analysis due to their clear lower cycle time, and which are repair stations to which the devices must go if they fail the device tests at the PreCheck, End of Line, or Complete stations.

The first pass yields (FPY) of each test station and the average repair times were also used in the simulation models.

Because the calculated distribution of the previously prepared time analysis reflects the repeatability of the prepared time analysis, the calculated normal distribution was included in the simulation model for each workstation cycle time.

Two sources were used because the packaging cell was shared by two assembly lines to check if there were problems with the availability of the packaging cell.

A three-shift schedule was implemented in the simulation model, which is shown in

Table 5. The time spent on breaks, lunch breaks, cleaning the workplace, and talking to the production manager affects the final production and must be included in the simulation model.

To test the effects of rebalancing, two simulation scenarios were created. The first scenario used the assembly process before rebalancing, and the second scenario used the assembly process after rebalancing.

Figure 8 presents the 3D view in the simulation software Simio. Workstations in idle states are presented in gray, and the bottleneck effect is presented in yellow color as the buffer becomes filled; the entities that represent the product flow through the assembly workstations can be tracked.

5.2.2. Results of the Simulation Scenarios

The PreCheck station split the assembly process into two logical parts, since the tasks of workstations 9 and 10 could not be executed before the tests of correct assembly had been performed on the device in the PreCheck station. For this reason, the results of the simulation scenario and the distribution of balance on the assembly line were divided into two separate parts, as shown in

Table 6 and

Table 7.

After running the simulation scenario for a simulated month of assembly, average output rates per shift were created. The assembly line output per shift increased from 218 to 243 products per shift after rebalancing.

6. Discussion

This study aimed to evaluate the performance of an assembly line by analyzing the current task workflow and rebalancing it, if necessary, to achieve optimal production quantity. The study utilized the MTM-UAS time standard and simulation software Simio to perform a new time analysis and assess the effectiveness of the rebalancing process. The results show that the current assembly line was not optimally balanced and required rebalancing to improve production efficiency.

The distribution of the results of the time analysis, prepared by an expert engineer, shows that the decision to use MTM-UAS was correct and best suited to the type of assembly line that was observed.

The results of the new time analysis show that there was a clear need for rebalancing, as there was a 38.37% difference between the bottleneck workstation and the least occupied workstation. After rebalancing, the difference in occupancy between the new bottleneck workstation and the new least occupied workstations was reduced to 8.52%.

To confirm the idea of rebalancing, a simulation model was created to have as little negative impact as possible on the actual assembly line before we could make sure that the rebalancing decision was correct.

There is a slight difference between the previous results of the timing analysis due to all the other variables that the simulation model can also include. The results of the simulation scenario before rebalancing showed that there was a 47.23% difference in occupancy between the bottleneck workstation and the least occupied workstation. The results of the simulation scenario after rebalancing showed that the difference in occupancy between these workstations was reduced to 12.89%.

The simulation scenarios also had an impact on the performance of the assembly line, which was increased by 11.4%. This means that a twin assembly line is still needed, but a reduction from the planned three shifts to two on the twin assembly line can be realized.

All this was achieved without any disturbances to the observed assembly line that was in serial production, which was the main goal of the study.

Changes have already been made to test the impact of the new balance on the current assembly line. Work steps were changed between workstations so that the learning curve was rerun. The planned output from the simulation scenario results was achieved, and there was positive feedback from the assembly workers as the differences in workstation occupancy were reduced and clearly visible from their point of view.

This study showed the optimization of balancing results checked using simulation scenarios, but ALBP was still solved by hand. The next step is to use genetic algorithms to solve ALBPs that outperform existing heuristics [

70]. In addition, the ergonomic design of the assembly line is an important component of a stable production process. Therefore, the ergonomic weighting of tasks should also be included in the process of solving an ALBP.

7. Conclusions

Under the conditions of never-ending competition, the importance of an efficient production system has become more and more important. The need for reductions in production costs and quick responses to customer demand have forced us to look for new approaches and solutions. Assembly lines, with their specifics of design, balancing, and scheduling for mass production, are an important part of these optimization efforts. The case presented, using an existing simulation software package, shows us a useful approach to successful assembly line optimization.

Production system simulation modeling is a powerful tool for optimizing manufacturing processes and improving productivity. It involves creating a mathematical model of the production system and simulating its behavior to study the effects of various changes on the system. For more detailed and tailored solutions, the use of metaheuristic methods should also be considered. Metaheuristic methods are powerful optimization techniques that have become increasingly popular in recent years. These methods are often used to solve complex optimization problems that cannot be solved using traditional optimization techniques. Traditional optimization techniques are often better suited to well-structured problems, while metaheuristics are better suited to complex, unstructured problems. In addition, traditional techniques are often deterministic and provide theoretical guarantees on the quality of the solution, while metaheuristics are often stochastic and do not provide such guarantees.

The results of this study could be useful to both academia and industry. For researchers, our study provides insight into the effectiveness of various methods for balancing assembly lines, and can serve as a basis for further research. For practitioners, our work can serve as a basis for decision-making processes and help determine the most appropriate approach to balancing assembly lines for their specific needs. In addition, the methodology we used can be applied to other similar systems and help improve their efficiency. Overall, we hope that our study contributes to ongoing efforts in the field of industrial engineering and stimulates further research and practical applications.

For future research, the latest industrialization concept, known as Industry 5.0, should also be considered in the development of industrial manufacturing. Its focus is on integrating advanced technologies with human-centered values to enable smarter, more efficient, and more sustainable production processes. Ergonomics should also be considered as an appropriate tool for worker assignment, taking into account their experience and physical abilities. Industry 5.0, characterized by the integration of cyber–physical systems, artificial intelligence, machine learning, and Big Data analytics with human operators, will be the focus of further research to create a more collaborative and personalized production environment. The results of this new research could help improve worker safety and comfort, reduce the risk of musculoskeletal disorders, and increase overall productivity.