2.2. WUFI Software

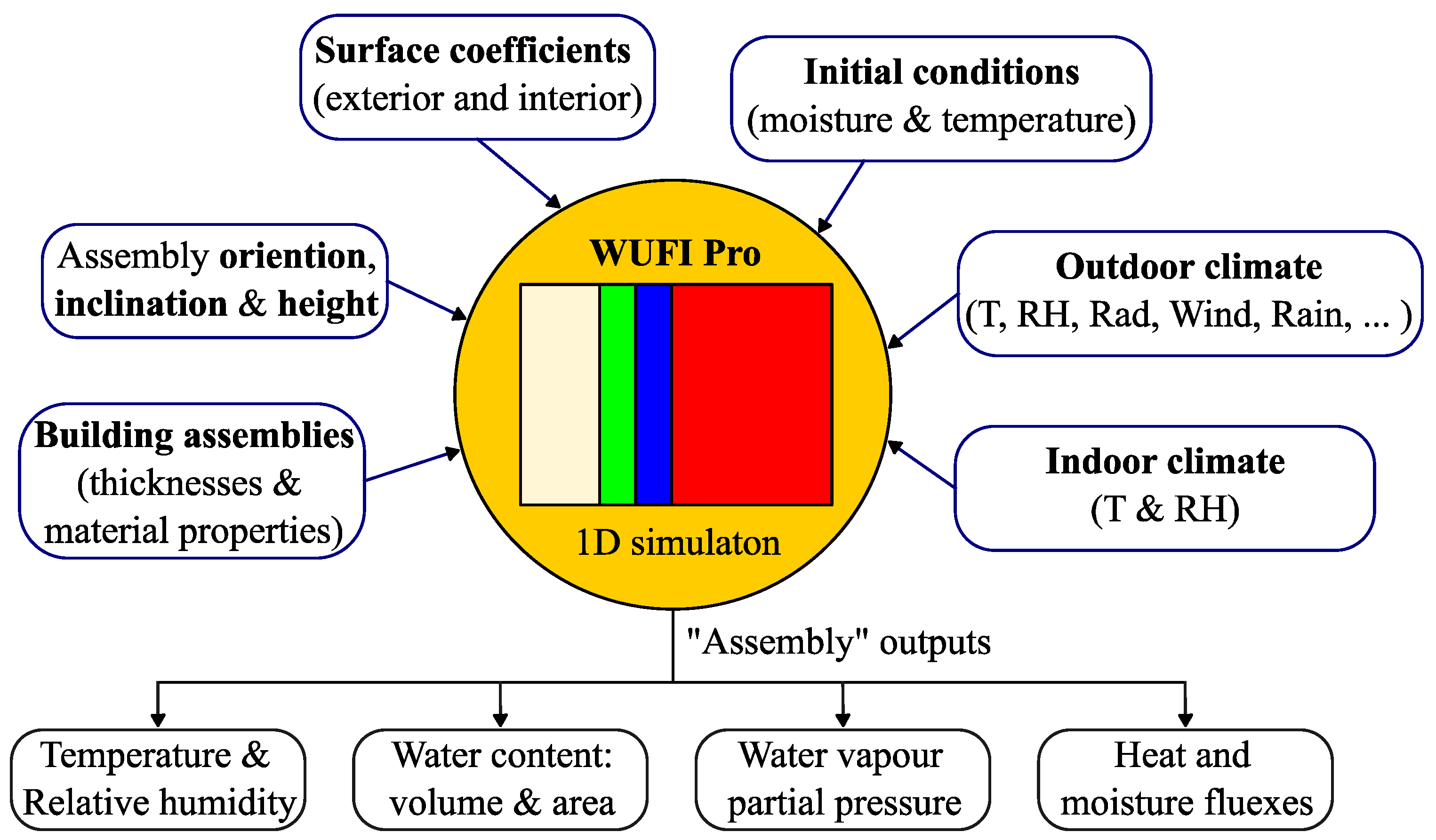

It is necessary to provide the following data for WUFI

®Pro to perform (

Figure 1): wall characteristics, physical and hygrothermal material properties, surface transport coefficients, initial conditions, and exterior and interior ambience conditions. The surface orientation and inclination are important inputs of a simulation since the solar radiation and wind-driven rain, if the element is not horizontal, are dependent on these parameters [

29,

30]. In terms of outputs for the selected assembly, it is possible to assess the temperature (°C), relative humidity (%), and water vapour partial pressure (hPa) for any of the selected locations within the assembly, water content for any layer (volume, kg/m

3) or in terms of equivalent water content for the assembly (area, kg/m

2), and the heat (W/m

2) and moisture fluxes (kg/m

2s) for the assembly surfaces and layer interfaces.

All these inputs are taken into account in WUFI’s calculation procedure. Enthalpy in a material varies according to the divergence between the heat flow through the material’s surfaces and the heat sources (condensation) or heat sinks (fusion and evaporation) in the material [

6]. Condensation is the change in the physical state of matter from gas into the liquid phase. This is an exothermic phenomenon since it changes from a superior to an inferior level of molecular excitement [

31]. Therefore, it releases energy, and, consequently, it increases temperature. On the other hand, evaporation is an endothermic process since the material changes from its liquid state (inferior level of molecular excitement) to its gas state (superior level of molecular excitement) [

31]. Hence, it consumes energy from the system, and, consequently, it decreases temperature. Fusion is also an endothermic process because the material changes from its solid state to its liquid state [

31].

In San Francisco and Lisbon, walls are not influenced by fusion, since their lowest exterior air temperature is 1.7 and 1.2 °C, respectively, and, in normal pressure conditions, water’s freezing point is near 0 °C. Hence, water never reaches the solid state, making it not possible to change from its solid to its liquid state.

The amount of moisture that exists in a wall is equal to the amount of moisture in the liquid state and gas state that is exchanged with the ambiences and the moisture sources or sinks contributions. Since moisture sources are scarce and moisture sinks related to chemical processes are low, these contributions are discarded in WUFI [

6].

Since the total enthalpy, the thermal conductivity, and the heat source term are dependent on the moisture inside a building material and also due to the dependency of the liquid flux and vapour diffusion flux on the temperature, it is possible to couple the heat balance and moisture balance equations [

6]. However, as it is a two-equation system, it is only solvable if there are just two variables. Taking the relations between the parameters into account, it is possible to have just two variables, i.e., temperature and relative humidity. Therefore, for one-dimensional heat and moisture transport, the following two-equation system is obtained [

6]:

where ∂

H/∂

θ is the heat storage capacity of the moist building material (J/(m

3K)),

H is the total enthalpy (J/m

3),

θ is the temperature (°C),

t is the time (s),

λ is the thermal conductivity of the moist building material (W/(m·K)),

hv is the evaporation heat of water (J/kg),

δp is the water vapour permeability of a building material (kg/(m·s·Pa)),

φ is the relative humidity (-),

pv,sat is the vapour saturation pressure (Pa), ∂

w/∂

φ is the moisture storage capacity of the building material (kg/m

3), and

Dφ is the liquid conduction coefficient of the moist building material (kg/(m·s)).

WUFI is an extremally used software to assess the hygrothermal performance of assemblies in countries, for example, Norway. This user-friendly software has been validated by experimental campaigns (e.g., [

32]), by comparison with other software (e.g., [

33]), and against EN 15026 [

34]. Finally, the software has been subjected to several updates across the years [

35], which allows it to stay up-to-date in this ever-evolving scientific field.

The material properties are divided into two categories [

9]. Basic properties, essential for the program, and advance properties, which can be left out. However, their omission has significant consequences for the results. The advance properties are the moisture storage function, the liquid transport coefficient for suction and for redistribution, the moisture-dependent thermal conductivity, and the moisture-dependent vapour diffusion resistance factor. The latter, in the simulated materials, is accounted for in the liquid coefficients [

9].

The liquid transport coefficient of a material changes in accordance with if it is constantly supplied with water (e.g., rain event) or not. During a rain event, since a great amount of water is supplied to the material and due to their lower flow resistance, the liquid transport is governed by the larger pores [

36]. On the other hand, in the absence of a water supply, the liquid transport is governed by the smaller pores due to their higher capillary pressure [

36]. WUFI uses the liquid transport coefficients for suction (D

ws) when water is constantly supplied to the material, and otherwise, it uses the liquid transport coefficients for redistribution (D

ww); both these coefficients are highly moisture dependent. The liquid transport coefficients for each of the simulated materials are featured in Figure 3 and their water absorption coefficient in

Table 1.

Surface transport coefficients describe heat and moisture exchanges between a wall surface and the ambience [

37]. They differ in exterior and interior ambiences. For an exterior surface, the program considers the surface heat resistance, short-wave radiation absorptivity, long-wave radiation emissivity, and rain water absorption factor. For an interior surface, the program only considers the heat resistance.

WUFI can consider the long-wave radiation exchanges between an exterior surface and its surroundings in three different ways [

9,

38,

39]: the heat transfer coefficient, the simplified method, and the explicit radiation balance method. However, the last two methods only run if the atmospheric counter-radiation is defined in the used climate file. Thus, in its absence, the radiation exchanges are accounted for by the heat transfer coefficient.

WUFI can calculate the heat transfer coefficient (inverse of surface heat resistance) according to the wind felt in the simulated location [

40]. The water vapour transfer coefficient is automatically obtained from the heat transfer coefficient; therefore, if the wind equations are used for the heat transfer coefficient, then the water vapour transfer coefficient will vary according to the wind characteristics.

The amount of solar radiation absorbed by an exterior surface depends on its orientation and inclination and on the exterior material properties (i.e., the short-wave radiation absorptivity). Therefore, the amount of solar radiation absorbed by a façade is obtained through the following equation:

where

q is the heat flux from solar radiation (W/m

2),

as is the short-wave radiation absorptivity (-), and

I is the solar radiation vertical to the façade (W/m

2).

The amount of water absorbed by a vertical surface is not equal to the quantity of rain that impacts that surface [

29]. This happens because some of the impacting water splashes off [

41]. WUFI takes this behaviour into consideration through the rain water absorption factor. It is normal to consider that 30% of the surface impacting water splashes off [

6]. It is important to bear in mind the key influence that this solicitation has on the hygrothermal behaviour of solid brick walls [

8,

12]. The amount of water absorbed by a façade, which is not completely wetted, is obtained through the following equation:

where

gw is the liquid flux (kg/m

2s),

ar is the rain water absorption factor (-), and

R is the precipitation load vertical to the building component surface (-).

WUFI needs the ambience boundary conditions to be able to account for the exchanges between the wall surfaces and the respective ambience. The boundary conditions used by the program are normal rain; global and diffuse solar radiation; exterior and interior air temperatures (T); exterior and interior relative humidities (RH); barometric pressure; cloud cover; and long-wave atmospheric counter-radiation. The interior climate can be obtained using sine curves or from a standard that uses the exterior conditions for their calculation (e.g., [

42]) or inputted into the model based on monitored/simulated data.

2.3. Wall Assemblies

With the purpose of identifying the alterations caused by the application of the mortar layers, all mortared assemblies were compared against a plain solid brick wall, i.e., a 220-mm solid brick wall (

Figure 2a), which is considered as the standard case (SC). The study includes three types of mortared walls—exterior surface (

Figure 2b), interior surface (

Figure 2c), and both surfaces (

Figure 2d)—and three types of mortar—lime, cement-lime, and cement. All tested mortars are 15 mm thick, and the solid brick is 220 mm thick.

In order to identify the differences between the steady-state and transient thermal transmittances, these factors were calculated for every studied wall in the four climates (

Section 2.4.1). The thermal transmittance in steady-state conditions was calculated using standard thermal conductivities and the usual surface thermal resistances (i.e., 0.0588 m

2K/W for the exterior ambience and 0.1250 m

2K/W for the interior ambience [

6]).

The thermal transmittance in transient conditions was calculated using the thermal conductivity that takes into account the moisture content of the material and the wind-dependent surface thermal resistance [

8]. WUFI was used to obtain the water contents for each layer, which allows the calculation of the thermal conductivity that considers the moisture. The surface thermal resistance was calculated using WUFI’s wind-dependent equations, which depend on the wind direction and wall inclination.

The simulated materials were characterized by the Fraunhofer—Institute for Building Physics (IBP), and their characteristics can be seen in

Table 1. By taking a closer look at the table, it is possible to notice that the moisture permeability decreases from lime to cement mortar. This is visible since the water absorption coefficient decreases (liquid moisture) and the water vapour diffusion resistance factor increases (vapour moisture), which means a lower drying potential [

36].

All of the mortars have a much lower A-value than the solid brick, which corroborates the values obtained in the simulations (

Section 3.2.1). The higher the mortar’s bulk density, the lower its thermal conductivity, which makes sense due to the fact that the thermal conductivity of the materials is related to the dimension and quantity of pores, which are inversely proportional to the bulk density [

43]. Lastly, it is visible that lime has the lowest thermal conductivity among the tested mortar, and cement the highest, but this is not very significant due to this layer thickness, corresponding to a small contribution to the total thermal resistance of the tested assemblies, which varies in the range of 3.3–5.5%.

Table 1.

Properties of the materials that constitute the simulated walls. Data taken from Fraunhofer-IBP database in WUFI [

9].

Table 1.

Properties of the materials that constitute the simulated walls. Data taken from Fraunhofer-IBP database in WUFI [

9].

| Building Properties | Solid Brick | Mortars |

|---|

| Lime | Lime-Cement | Cement |

|---|

| Bulk density, ρ (kg/m3) | 1900.0 | 1600.0 | 1900.0 | 2000.0 |

| Porosity, ε (m3/m3) | 0.24 | 0.30 | 0.24 | 0.30 |

| Specific heat capacity-Dry, cp (J/kg·K) | 850.0 | 850.0 | 850.0 | 850.0 |

| Thermal conductivity-Dry, λ (W/m·K) | 0.60 | 0.70 | 0.80 | 1.20 |

| Water vapour diffusion resistance factor, µ (-) | 10.0 | 7.0 | 19.0 | 25.0 |

| Reference water content, w80 (kg/m3) | 18.0 | 30.0 | 45.0 | 35.0 |

| Free water saturation, wf (kg/m3) | 190.0 | 250.0 | 210.0 | 280.0 |

| Moisture-related thermal conductivity supplement, b (%/M.-%) | 15.0 | 8.0 | 8.0 | 10.0 |

| Water absorption coefficient, A (kg/m2s0.5) | 0.1100 | 0.0470 | 0.0170 | 0.0076 |

The moisture storage capacity and liquid transport coefficients for the four studied materials are presented in

Figure 3.

Figure 3a shows that the mortar with the highest moisture storage capacity changes throughout the relative humidity range. From 0 to 88.6% RH, it is the lime-cement, and from 88.6 to 100% RH, it is the cement mortar. It is also interesting to notice that until 75.9% RH, the lime mortar has a higher moisture storage capacity than the cement mortar and that from 93.4 to 100% RH, the lime mortar has a higher moisture storage capacity than the lime-cement mortar.

Figure 3b shows that the mortar with the highest D

ws values is lime, then lime-cement, and, lastly, cement. However, the same observation cannot be made for D

ww since the lime-cement mortar reaches the highest values between 137.4 and 229.6 kg/m

3.

The wall’s radiation absorption behaviour differs according to the exterior layer characteristics. Since rendered and unrendered walls are simulated, two short-wave radiation absorptivity coefficients were used: 0.40 (for rendered walls) and 0.68 (for unrendered walls), which are in accordance with the literature [

31,

44,

45,

46]. The long-wave radiation exchange was determined through the simplified method for those climates.

The simulation period was chosen so that all the wall assemblies reached the dynamic equilibrium in each simulated climate. For Essen, seven years were necessary and five years for the other three climates. It is important that this level is reached because only after that will there be an equilibrium between the wall and the ambiences, and, consequently, the variation in any parameter for the following years will be the same [

9]. However, it is also vital not to discard the variation in the hygrothermal parameters in the years prior to reaching the dynamic equilibrium, since it helps explain certain behaviours. Nonetheless, it is important to take into account that WUFI does not directly consider the changes over time in the hygrothermal properties of the building material.