Biogas Production in AnMBRs via Treatment of Municipal and Domestic Wastewater: Opportunities and Fouling Mitigation Strategies

Abstract

:1. Introduction

2. Biogas Production in AnMBRs

2.1. AnMBR Configurations and Operating Conditions

2.2. Process Yield

2.2.1. Impact of HRT

2.2.2. Impact of Temperature

3. Fouling Mitigation Strategies

3.1. Physical Cleaning

3.2. Physio-Chemical and Chemical Cleaning

4. Conclusions

5. Challenges and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

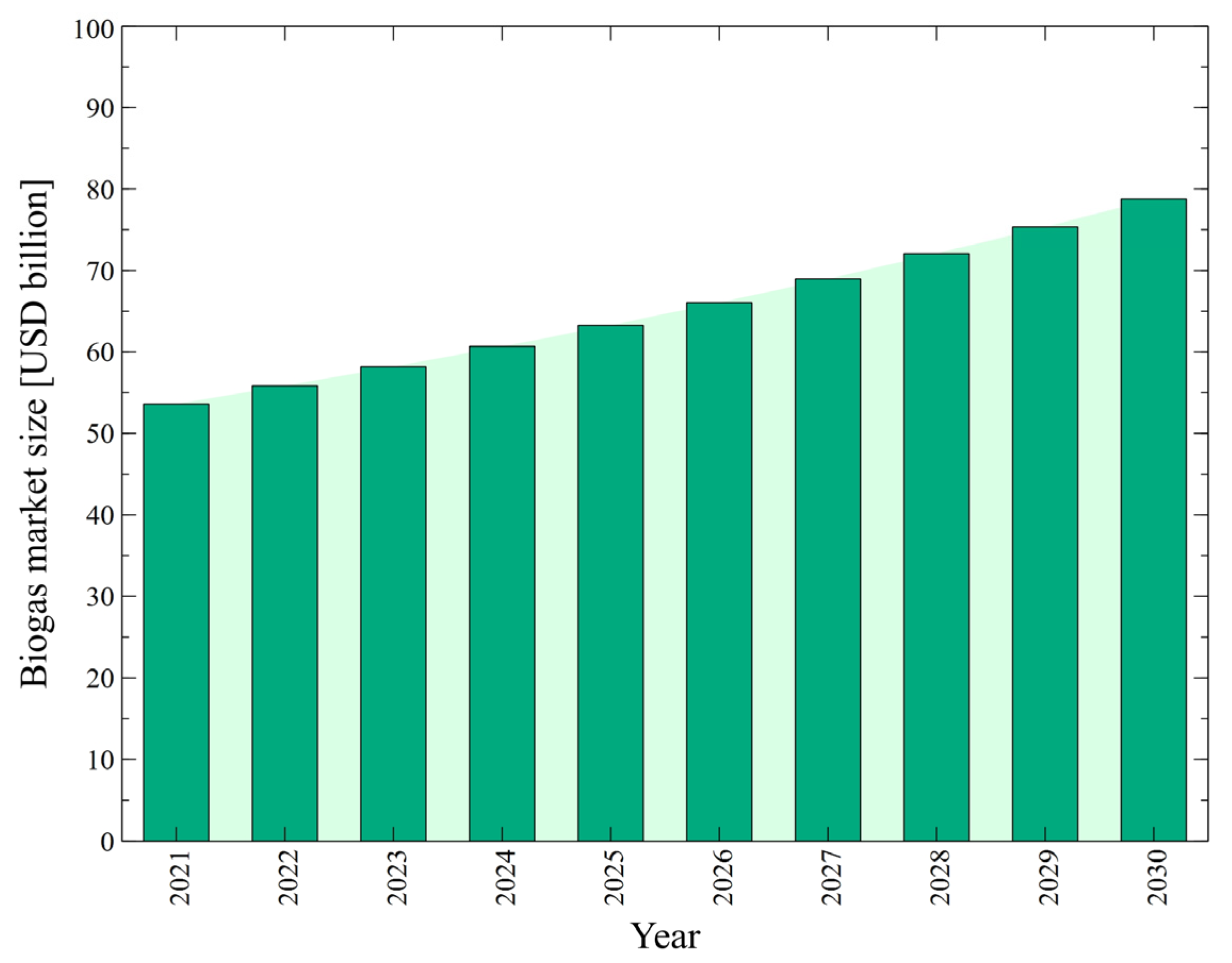

- Available online: https://www.precedenceresearch.com/biogas-market/ (accessed on 12 April 2023).

- Plugge, C.M. Biogas. Microb. Biotechnol. 2017, 10, 1128–1130. [Google Scholar] [CrossRef] [PubMed]

- Pavičić, J.; Novak Mavar, K.; Brkić, V.; Simon, K. Biogas and Biomethane Production and Usage: Technology Development, Advantages and Challenges in Europe. Energies 2022, 15, 2940. [Google Scholar] [CrossRef]

- Kapoor, R.; Ghosh, P.; Kumar, M.; Vijay, V.K. Evaluation of biogas upgrading technologies and future perspectives: A review. Env. Sci. Pollut. Res. 2019, 26, 11631–11661. [Google Scholar] [CrossRef] [PubMed]

- Beschkov, V. Biogas Production: Evaluation and Possible Applications. In Biogas—Basics, Integrated Approaches, and Case Studies; El-Fatah Abomohra, A., Salama, E.-S., Eds.; IntechOpen: London, UK, 2022; ISBN 978-1-80355-108-1. [Google Scholar]

- Sahota, S.; Shah, G.; Ghosh, P.; Kapoor, R.; Sengupta, S.; Singh, P.; Vijay, V.; Sahay, A.; Vijay, V.K.; Thakur, I.S. Review of trends in biogas upgradation technologies and future perspectives. Bioresour. Technol. Rep. 2018, 1, 79–88. [Google Scholar] [CrossRef]

- Sun, Q.; Li, H.; Yan, J.; Liu, L.; Yu, Z.; Yu, X. Selection of appropriate biogas upgrading technology—A review of biogas cleaning, upgrading and utilisation. Renew. Sustain. Energy Rev. 2015, 51, 521–532. [Google Scholar] [CrossRef]

- Angelidaki, I.; Xie, L.; Luo, G.; Zhang, Y.; Oechsner, H.; Lemmer, A.; Munoz, R.; Kougias, P.G. Biogas Upgrading: Current and Emerging Technologies. In Biofuels: Alternative Feedstocks and Conversion Processes for the Production of Liquid and Gaseous Biofuels; Elsevier: Amsterdam, The Netherlands, 2019; pp. 817–843. ISBN 978-0-12-816856-1. [Google Scholar]

- Aghel, B.; Behaein, S.; Wongwises, S.; Shadloo, M.S. A review of recent progress in biogas upgrading: With emphasis on carbon capture. Biomass Bioenergy 2022, 160, 106422. [Google Scholar] [CrossRef]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef]

- Awe, O.W.; Zhao, Y.; Nzihou, A.; Minh, D.P.; Lyczko, N. A Review of Biogas Utilisation, Purification and Upgrading Technologies. Waste Biomass Valorization 2017, 8, 267–283. [Google Scholar] [CrossRef]

- Available online: https://www.iea.org/ (accessed on 12 April 2023).

- Horvath, A.; Rachlew, E. Nuclear power in the 21st century: Challenges and possibilities. AMBIO 2016, 45, 38–49. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Elmoutez, S.; Abushaban, A.; Necibi, M.C.; Sillanpää, M.; Liu, J.; Dhiba, D.; Chehbouni, A.; Taky, M. Design and operational aspects of anaerobic membrane bioreactor for efficient wastewater treatment and biogas production. Environ. Chall. 2023, 10, 100671. [Google Scholar] [CrossRef]

- Kougias, P.G.; Angelidaki, I. Biogas and its opportunities—A review. Front. Environ. Sci. Eng. 2018, 12, 14. [Google Scholar] [CrossRef]

- Tabatabaei, M.; Aghbashlo, M.; Valijanian, E.; Kazemi Shariat Panahi, H.; Nizami, A.-S.; Ghanavati, H.; Sulaiman, A.; Mirmohamadsadeghi, S.; Karimi, K. A comprehensive review on recent biological innovations to improve biogas production, Part 1: Upstream strategies. Renew. Energy 2020, 146, 1204–1220. [Google Scholar] [CrossRef]

- Nkuna, R.; Roopnarain, A.; Rashama, C.; Adeleke, R. Insights into organic loading rates of anaerobic digestion for biogas production: A review. Crit. Rev. Biotechnol. 2022, 42, 487–507. [Google Scholar] [CrossRef] [PubMed]

- Fei, X.; Chen, T.; Jia, W.; Shan, Q.; Hei, D.; Ling, Y.; Feng, J.; Feng, H. Enhancement effect of ionizing radiation pretreatment on biogas production from anaerobic fermentation of food waste. Radiat. Phys. Chem. 2020, 168, 108534. [Google Scholar] [CrossRef]

- Abbasi, T.; Tauseef, S.M.; Abbasi, S.A. Anaerobic digestion for global warming control and energy generation—An overview. Renew. Sustain. Energy Rev. 2012, 16, 3228–3242. [Google Scholar] [CrossRef]

- Cheng, H.; Hiro, Y.; Hojo, T.; Li, Y.-Y. Upgrading methane fermentation of food waste by using a hollow fiber type anaerobic membrane bioreactor. Bioresour. Technol. 2018, 267, 386–394. [Google Scholar] [CrossRef]

- Dasa, K.T.; Westman, S.Y.; Millati, R.; Cahyanto, M.N.; Taherzadeh, M.J.; Niklasson, C. Inhibitory Effect of Long-Chain Fatty Acids on Biogas Production and the Protective Effect of Membrane Bioreactor. BioMed Res. Int. 2016, 2016, 7263974. [Google Scholar] [CrossRef]

- Tshemese, Z.; Deenadayalu, N.; Linganiso, L.Z.; Chetty, M. An Overview of Biogas Production from Anaerobic Digestion and the Possibility of Using Sugarcane Wastewater and Municipal Solid Waste in a South African Context. Appl. Syst. Innov. 2023, 6, 13. [Google Scholar] [CrossRef]

- Chew, K.R.; Leong, H.Y.; Khoo, K.S.; Vo, D.-V.N.; Anjum, H.; Chang, C.-K.; Show, P.L. Effects of anaerobic digestion of food waste on biogas production and environmental impacts: A review. Env. Chem. Lett. 2021, 19, 2921–2939. [Google Scholar] [CrossRef]

- Náthia-Neves, G.; Berni, M.; Dragone, G.; Mussatto, S.I.; Forster-Carneiro, T. Anaerobic digestion process: Technological aspects and recent developments. Int. J. Environ. Sci. Technol. 2018, 15, 2033–2046. [Google Scholar] [CrossRef]

- Aslam, A.; Khan, S.J.; Shahzad, H.M.A. Anaerobic membrane bioreactors (AnMBRs) for municipal wastewater treatment- potential benefits, constraints, and future perspectives: An updated review. Sci. Total Environ. 2022, 802, 149612. [Google Scholar] [CrossRef] [PubMed]

- Ganzoury, M.A.; Allam, N.K. Impact of nanotechnology on biogas production: A mini-review. Renew. Sustain. Energy Rev. 2015, 50, 1392–1404. [Google Scholar] [CrossRef]

- Zhen, G.; Lu, X.; Kato, H.; Zhao, Y.; Li, Y.-Y. Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: Current advances, full-scale application and future perspectives. Renew. Sustain. Energy Rev. 2017, 69, 559–577. [Google Scholar] [CrossRef]

- Hu, Y.; Cheng, H.; Ji, J.; Li, Y.-Y. A review of anaerobic membrane bioreactors for municipal wastewater treatment with a focus on multicomponent biogas and membrane fouling control. Environ. Sci. Water Res. Technol. 2020, 6, 2641–2663. [Google Scholar] [CrossRef]

- Natasha; Shahid, M.; Khalid, S.; Murtaza, B.; Anwar, H.; Shah, A.H.; Sardar, A.; Shabbir, Z.; Niazi, N.K. A critical analysis of wastewater use in agriculture and associated health risks in Pakistan. Environ. Geochem. Health 2020. [Google Scholar] [CrossRef]

- Rani, A.; Snyder, S.W.; Kim, H.; Lei, Z.; Pan, S.-Y. Pathways to a net-zero-carbon water sector through energy-extracting wastewater technologies. NPJ Clean Water 2022, 5, 49. [Google Scholar] [CrossRef]

- Abdel-Shafy, H.I.; Mansour, M.S.M. Solid waste issue: Sources, composition, disposal, recycling, and valorization. Egypt. J. Pet. 2018, 27, 1275–1290. [Google Scholar] [CrossRef]

- Qadir, M.; Drechsel, P.; Jiménez Cisneros, B.; Kim, Y.; Pramanik, A.; Mehta, P.; Olaniyan, O. Global and regional potential of wastewater as a water, nutrient and energy source. Nat. Resour. Forum 2020, 44, 40–51. [Google Scholar] [CrossRef]

- Morris, L.; Colombo, V.; Hassell, K.; Kellar, C.; Leahy, P.; Long, S.M.; Myers, J.H.; Pettigrove, V. Municipal wastewater effluent licensing: A global perspective and recommendations for best practice. Sci. Total Environ. 2017, 580, 1327–1339. [Google Scholar] [CrossRef]

- Ghosh, P.; Shah, G.; Sahota, S.; Singh, L.; Vijay, V.K. Biogas production from waste: Technical overview, progress, and challenges. In Bioreactors; Elsevier: Amsterdam, The Netherlands, 2020; pp. 89–104. ISBN 978-0-12-821264-6. [Google Scholar]

- Leca, E.; Zennaro, B.; Hamelin, J.; Carrère, H.; Sambusiti, C. Use of additives to improve collective biogas plant performances: A comprehensive review. Biotechnol. Adv. 2023, 65, 108129. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, S.; Prasad, N.; Selvaraju, S. Reactor Design for Biogas Production—A Short Review. J. Energy Power Technol. 2021, 4, 4. [Google Scholar] [CrossRef]

- Chen, C.; Guo, W.; Ngo, H.H.; Lee, D.-J.; Tung, K.-L.; Jin, P.; Wang, J.; Wu, Y. Challenges in biogas production from anaerobic membrane bioreactors. Renew. Energy 2016, 98, 120–134. [Google Scholar] [CrossRef]

- Kainthola, J.; Kalamdhad, A.S.; Goud, V.V. A review on enhanced biogas production from anaerobic digestion of lignocellulosic biomass by different enhancement techniques. Process Biochem. 2019, 84, 81–90. [Google Scholar] [CrossRef]

- Mao, C.; Feng, Y.; Wang, X.; Ren, G. Review on research achievements of biogas from anaerobic digestion. Renew. Sustain. Energy Rev. 2015, 45, 540–555. [Google Scholar] [CrossRef]

- Bond, T.; Templeton, M.R. History and future of domestic biogas plants in the developing world. Energy Sustain. Dev. 2011, 15, 347–354. [Google Scholar] [CrossRef]

- Andlar, M.; Belskaya, H.; Morzak, G.; Ivančić Šantek, M.; Rezić, T.; Petravić Tominac, V.; Šantek, B. Biogas Production Systems and Upgrading Technologies: A Review. Food Technol. Biotechnol. 2021, 59, 387–412. [Google Scholar] [CrossRef]

- Kunatsa, T.; Xia, X. A review on anaerobic digestion with focus on the role of biomass co-digestion, modelling and optimisation on biogas production and enhancement. Bioresour. Technol. 2022, 344, 126311. [Google Scholar] [CrossRef]

- Available online: https://www.worldbiogasassociation.org/ (accessed on 12 April 2023).

- Lim, S.J.; Kim, T.-H. Applicability and trends of anaerobic granular sludge treatment processes. Biomass Bioenergy 2014, 60, 189–202. [Google Scholar] [CrossRef]

- Wang, N.-X.; Lu, X.-Y.; Tsang, Y.-F.; Mao, Y.; Tsang, C.-W.; Yueng, V.A. A comprehensive review of anaerobic digestion of organic solid wastes in relation to microbial community and enhancement process: A comprehensive review of anaerobic digestion of organic solid wastes. J. Sci. Food Agric. 2019, 99, 507–516. [Google Scholar] [CrossRef]

- Liao, B.-Q.; Kraemer, J.T.; Bagley, D.M. Anaerobic Membrane Bioreactors: Applications and Research Directions. Crit. Rev. Environ. Sci. Technol. 2006, 36, 489–530. [Google Scholar] [CrossRef]

- Tomczak, W.; Gryta, M. Energy-Efficient AnMBRs Technology for Treatment of Wastewaters: A Review. Energies 2022, 15, 4981. [Google Scholar] [CrossRef]

- Vinardell, S.; Astals, S.; Peces, M.; Cardete, M.A.; Fernández, I.; Mata-Alvarez, J.; Dosta, J. Advances in anaerobic membrane bioreactor technology for municipal wastewater treatment: A 2020 updated review. Renew. Sustain. Energy Rev. 2020, 130, 109936. [Google Scholar] [CrossRef]

- Abuabdou, S.M.A.; Ahmad, W.; Aun, N.C.; Bashir, M.J.K. A review of anaerobic membrane bioreactors (AnMBR) for the treatment of highly contaminated landfill leachate and biogas production: Effectiveness, limitations and future perspectives. J. Clean. Prod. 2020, 255, 120215. [Google Scholar] [CrossRef]

- Ji, J.; Kakade, A.; Yu, Z.; Khan, A.; Liu, P.; Li, X. Anaerobic membrane bioreactors for treatment of emerging contaminants: A review. J. Environ. Manag. 2020, 270, 110913. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Cai, X.; Du, R.; Yang, Y.; Rong, C.; Qin, Y.; Li, Y.-Y. A review on anaerobic membrane bioreactors for enhanced valorization of urban organic wastes: Achievements, limitations, energy balance and future perspectives. Sci. Total Environ. 2022, 820, 153284. [Google Scholar] [CrossRef] [PubMed]

- Asante-Sackey, D.; Rathilal, S.; Tetteh, E.K.; Armah, E.K. Membrane Bioreactors for Produced Water Treatment: A Mini-Review. Membranes 2022, 12, 275. [Google Scholar] [CrossRef]

- Maaz, M.; Yasin, M.; Aslam, M.; Kumar, G.; Atabani, A.E.; Idrees, M.; Anjum, F.; Jamil, F.; Ahmad, R.; Khan, A.L.; et al. Anaerobic membrane bioreactors for wastewater treatment: Novel configurations, fouling control and energy considerations. Bioresour. Technol. 2019, 283, 358–372. [Google Scholar] [CrossRef]

- Lee, H.; Liao, B. Anaerobic membrane bioreactors for wastewater treatment: Challenges and opportunities. Water Environ. Res. 2021, 93, 993–1004. [Google Scholar] [CrossRef]

- Abdelrahman, A.M.; Ozgun, H.; Dereli, R.K.; Isik, O.; Ozcan, O.Y.; van Lier, J.B.; Ozturk, I.; Ersahin, M.E. Anaerobic membrane bioreactors for sludge digestion: Current status and future perspectives. Crit. Rev. Environ. Sci. Technol. 2021, 51, 2119–2157. [Google Scholar] [CrossRef]

- Kharraz, J.A.; Khanzada, N.K.; Farid, M.U.; Kim, J.; Jeong, S.; An, A.K. Membrane distillation bioreactor (MDBR) for wastewater treatment, water reuse, and resource recovery: A review. J. Water Process Eng. 2022, 47, 102687. [Google Scholar] [CrossRef]

- Egle, L.; Rechberger, H.; Zessner, M. Overview and description of technologies for recovering phosphorus from municipal wastewater. Resour. Conserv. Recycl. 2015, 105, 325–346. [Google Scholar] [CrossRef]

- Odjadjare, E.E.O.; Okoh, A.I. Physicochemical quality of an urban municipal wastewater effluent and its impact on the receiving environment. Environ. Monit. Assess. 2010, 170, 383–394. [Google Scholar] [CrossRef] [PubMed]

- Angassa, K.; Leta, S.; Mulat, W.; Kloos, H. Seasonal characterization of municipal wastewater and performance evaluation of a constructed wetland system in Addis Ababa, Ethiopia. Int. J. Energy Water Res. 2020, 4, 127–138. [Google Scholar] [CrossRef]

- Bakopoulou, S.; Emmanouil, C.; Kungolos, A. Assessment of wastewater effluent quality in Thessaly region, Greece, for determining its irrigation reuse potential. Ecotoxicol. Environ. Saf. 2011, 74, 188–194. [Google Scholar] [CrossRef]

- Shahid, M.K.; Kashif, A.; Rout, P.R.; Aslam, M.; Fuwad, A.; Choi, Y.; Banu, J.R.; Park, J.H.; Kumar, G. A brief review of anaerobic membrane bioreactors emphasizing recent advancements, fouling issues and future perspectives. J. Environ. Manag. 2020, 270, 110909. [Google Scholar] [CrossRef]

- Anjum, F.; Khan, I.M.; Kim, J.; Aslam, M.; Blandin, G.; Heran, M.; Lesage, G. Trends and progress in AnMBR for domestic wastewater treatment and their impacts on process efficiency and membrane fouling. Environ. Technol. Innov. 2021, 21, 101204. [Google Scholar] [CrossRef]

- Prattakorn Sittisom; Obey Gotore; Rameshprabu Ramaraj; Giang Tran Van; Yuwalee Unpaprom; Tomoaki Itayama Membrane fouling issues in anaerobic membrane bioreactors (AnMBRs) for biogas production. Maejo Int. J. Energy Environ. Comm. 2019, 1, 15–19. [CrossRef]

- Zielińska, M.; Ojo, A. Anaerobic Membrane Bioreactors (AnMBRs) for Wastewater Treatment: Recovery of Nutrients and Energy, and Management of Fouling. Energies 2023, 16, 2829. [Google Scholar] [CrossRef]

- Wang, T.; Jin, Z.; Yang, Y.; Ma, J.; Aghbashlo, M.; Zhang, H.; Sun, S.; Tabatabaei, M.; Pan, J. In-depth insights into the temporal-based fouling mechanism and its exploration in anaerobic membrane bioreactors: A review. J. Clean. Prod. 2022, 375, 134110. [Google Scholar] [CrossRef]

- Shin, C.; Bae, J. Current status of the pilot-scale anaerobic membrane bioreactor treatments of domestic wastewaters: A critical review. Bioresour. Technol. 2018, 247, 1038–1046. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Ma, J.; Tang, C.Y.; Kimura, K.; Wang, Q.; Han, X. Membrane cleaning in membrane bioreactors: A review. J. Membr. Sci. 2014, 468, 276–307. [Google Scholar] [CrossRef]

- Terán Hilares, R.; Singh, I.; Tejada Meza, K.; Colina Andrade, G.J.; Pacheco Tanaka, D.A. Alternative methods for cleaning membranes in water and wastewater treatment. Water Environ. Res. 2022, 94, e10708. [Google Scholar] [CrossRef] [PubMed]

- Ji, J.; Du, R.; Ni, J.; Chen, Y.; Hu, Y.; Qin, Y.; Hojo, T.; Li, Y.-Y. Submerged anaerobic membrane bioreactor applied for mainstream municipal wastewater treatment at a low temperature: Sludge yield, energy balance and membrane filtration behaviors. J. Clean. Prod. 2022, 355, 131831. [Google Scholar] [CrossRef]

- Mei, X.; Wang, Z.; Miao, Y.; Wu, Z. A pilot-scale anaerobic membrane bioreactor under short hydraulic retention time for municipal wastewater treatment: Performance and microbial community identification. J. Water Reuse Desalination 2018, 8, 58–67. [Google Scholar] [CrossRef]

- Gouveia, J.; Plaza, F.; Garralon, G.; Fdz-Polanco, F.; Peña, M. Long-term operation of a pilot scale anaerobic membrane bioreactor (AnMBR) for the treatment of municipal wastewater under psychrophilic conditions. Bioresour. Technol. 2015, 185, 225–233. [Google Scholar] [CrossRef] [PubMed]

- Gouveia, J.; Plaza, F.; Garralon, G.; Fdz-Polanco, F.; Peña, M. A novel configuration for an anaerobic submerged membrane bioreactor (AnSMBR). Long-term treatment of municipal wastewater under psychrophilic conditions. Bioresour. Technol. 2015, 198, 510–519. [Google Scholar] [CrossRef]

- Martinez-Sosa, D.; Helmreich, B.; Netter, T.; Paris, S.; Bischof, F.; Horn, H. Anaerobic submerged membrane bioreactor (AnSMBR) for municipal wastewater treatment under mesophilic and psychrophilic temperature conditions. Bioresour. Technol. 2011, 102, 10377–10385. [Google Scholar] [CrossRef]

- Martinez-Sosa, D.; Helmreich, B.; Horn, H. Anaerobic submerged membrane bioreactor (AnSMBR) treating low-strength wastewater under psychrophilic temperature conditions. Process Biochem. 2012, 47, 792–798. [Google Scholar] [CrossRef]

- Peña, M.; do Nascimento, T.; Gouveia, J.; Escudero, J.; Gómez, A.; Letona, A.; Arrieta, J.; Fdz-Polanco, F. Anaerobic submerged membrane bioreactor (AnSMBR) treating municipal wastewater at ambient temperature: Operation and potential use for agricultural irrigation. Bioresour. Technol. 2019, 282, 285–293. [Google Scholar] [CrossRef]

- Dong, Q.; Parker, W.; Dagnew, M. Influence of SRT and HRT on Bioprocess Performance in Anaerobic Membrane Bioreactors Treating Municipal Wastewater. Water Environ. Res. 2016, 88, 158–167. [Google Scholar] [CrossRef] [PubMed]

- Giménez, J.B.; Robles, A.; Carretero, L.; Durán, F.; Ruano, M.V.; Gatti, M.N.; Ribes, J.; Ferrer, J.; Seco, A. Experimental study of the anaerobic urban wastewater treatment in a submerged hollow-fibre membrane bioreactor at pilot scale. Bioresour. Technol. 2011, 102, 8799–8806. [Google Scholar] [CrossRef] [PubMed]

- Kong, Z.; Wu, J.; Rong, C.; Wang, T.; Li, L.; Luo, Z.; Ji, J.; Hanaoka, T.; Sakemi, S.; Ito, M.; et al. Large pilot-scale submerged anaerobic membrane bioreactor for the treatment of municipal wastewater and biogas production at 25 °C. Bioresour. Technol. 2021, 319, 124123. [Google Scholar] [CrossRef] [PubMed]

- Rong, C.; Wang, T.; Luo, Z.; Hu, Y.; Kong, Z.; Qin, Y.; Hanaoka, T.; Ito, M.; Kobayashi, M.; Li, Y.-Y. Pilot plant demonstration of temperature impacts on the methanogenic performance and membrane fouling control of the anaerobic membrane bioreactor in treating real municipal wastewater. Bioresour. Technol. 2022, 354, 127167. [Google Scholar] [CrossRef] [PubMed]

- Zayen, A.; Mnif, S.; Aloui, F.; Fki, F.; Loukil, S.; Bouaziz, M.; Sayadi, S. Anaerobic membrane bioreactor for the treatment of leachates from Jebel Chakir discharge in Tunisia. J. Hazard. Mater. 2010, 177, 918–923. [Google Scholar] [CrossRef] [PubMed]

- Seco, A.; Mateo, O.; Zamorano-López, N.; Sanchis-Perucho, P.; Serralta, J.; Martí, N.; Borrás, L.; Ferrer, J. Exploring the limits of anaerobic biodegradability of urban wastewater by AnMBR technology. Environ. Sci. Water Res. Technol. 2018, 4, 1877–1887. [Google Scholar] [CrossRef]

- Giménez, J.B.; Carretero, L.; Gatti, M.N.; Martí, N.; Borrás, L.; Ribes, J.; Seco, A. Reliable method for assessing the COD mass balance of a submerged anaerobic membrane bioreactor (SAMBR) treating sulphate-rich municipal wastewater. Water Sci. Technol. 2012, 66, 494–502. [Google Scholar] [CrossRef]

- Berkessa, Y.W.; Yan, B.; Li, T.; Tan, M.; She, Z.; Jegatheesan, V.; Jiang, H.; Zhang, Y. Novel anaerobic membrane bioreactor (AnMBR) design for wastewater treatment at long HRT and high solid concentration. Bioresour. Technol. 2018, 250, 281–289. [Google Scholar] [CrossRef]

- Huang, Z.; Ong, S.L.; Ng, H.Y. Submerged anaerobic membrane bioreactor for low-strength wastewater treatment: Effect of HRT and SRT on treatment performance and membrane fouling. Water Res. 2011, 45, 705–713. [Google Scholar] [CrossRef]

- Huang, Z.; Ong, S.L.; Ng, H.Y. Performance of submerged anaerobic membrane bioreactor at different SRTs for domestic wastewater treatment. J. Biotechnol. 2013, 164, 82–90. [Google Scholar] [CrossRef]

- Jeong, Y.; Hermanowicz, S.W.; Park, C. Treatment of food waste recycling wastewater using anaerobic ceramic membrane bioreactor for biogas production in mainstream treatment process of domestic wastewater. Water Res. 2017, 123, 86–95. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Hu, Y.; Lu, Y.-Z.; Zeng, R.J.; Sheng, G.-P. In-situ biogas sparging enhances the performance of an anaerobic membrane bioreactor (AnMBR) with mesh filter in low-strength wastewater treatment. Appl. Microbiol. Biotechnol. 2016, 100, 6081–6089. [Google Scholar] [CrossRef] [PubMed]

- Yue, X.; Koh, Y.K.K.; Ng, H.Y. Effects of dissolved organic matters (DOMs) on membrane fouling in anaerobic ceramic membrane bioreactors (AnCMBRs) treating domestic wastewater. Water Res. 2015, 86, 96–107. [Google Scholar] [CrossRef] [PubMed]

- Cirik, K.; Gocer, S. Performance of anaerobic membrane bioreactor treating landfill leachate. J. Environ. Health Sci. Eng. 2020, 18, 383–393. [Google Scholar] [CrossRef]

- Chen, R.; Nie, Y.; Ji, J.; Utashiro, T.; Li, Q.; Komori, D.; Li, Y.-Y. Submerged anaerobic membrane bioreactor (SAnMBR) performance on sewage treatment: Removal efficiencies, biogas production and membrane fouling. Water Sci. Technol. 2017, 76, 1308–1317. [Google Scholar] [CrossRef]

- Xu, B.; Ng, T.C.A.; Huang, S.; Ng, H.Y. Effect of quorum quenching on EPS and size-fractioned particles and organics in anaerobic membrane bioreactor for domestic wastewater treatment. Water Res. 2020, 179, 115850. [Google Scholar] [CrossRef]

- Nie, Y.; Kato, H.; Sugo, T.; Hojo, T.; Tian, X.; Li, Y.-Y. Effect of anionic surfactant inhibition on sewage treatment by a submerged anaerobic membrane bioreactor: Efficiency, sludge activity and methane recovery. Chem. Eng. J. 2017, 315, 83–91. [Google Scholar] [CrossRef]

- Nie, Y.; Tian, X.; Zhou, Z.; Li, Y.-Y. Impact of food to microorganism ratio and alcohol ethoxylate dosage on methane production in treatment of low-strength wastewater by a submerged anaerobic membrane bioreactor. Front. Environ. Sci. Eng. 2017, 11, 6. [Google Scholar] [CrossRef]

- Ji, J.; Ni, J.; Ohtsu, A.; Isozumi, N.; Hu, Y.; Du, R.; Chen, Y.; Qin, Y.; Kubota, K.; Li, Y.-Y. Important effects of temperature on treating real municipal wastewater by a submerged anaerobic membrane bioreactor: Removal efficiency, biogas, and microbial community. Bioresour. Technol. 2021, 336, 125306. [Google Scholar] [CrossRef]

- Ji, J.; Sakuma, S.; Ni, J.; Chen, Y.; Hu, Y.; Ohtsu, A.; Chen, R.; Cheng, H.; Qin, Y.; Hojo, T.; et al. Application of two anaerobic membrane bioreactors with different pore size membranes for municipal wastewater treatment. Sci. Total Environ. 2020, 745, 140903. [Google Scholar] [CrossRef]

- Ni, J.; Ji, J.; Li, Y.-Y.; Kubota, K. Microbial characteristics in anaerobic membrane bioreactor treating domestic sewage: Effects of HRT and process performance. J. Environ. Sci. 2022, 111, 392–399. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Chen, J.; Wang, F.; Ding, L.; Hong, H. Feasibility evaluation of submerged anaerobic membrane bioreactor for municipal secondary wastewater treatment. Desalination 2011, 280, 120–126. [Google Scholar] [CrossRef]

- Wei, C.-H.; Harb, M.; Amy, G.; Hong, P.-Y.; Leiknes, T. Sustainable organic loading rate and energy recovery potential of mesophilic anaerobic membrane bioreactor for municipal wastewater treatment. Bioresour. Technol. 2014, 166, 326–334. [Google Scholar] [CrossRef] [PubMed]

- Ho, J.; Sung, S. Anaerobic Membrane Bioreactor Treatment of Synthetic Municipal Wastewater at Ambient Temperature. Water Environ. Res. 2009, 81, 922–928. [Google Scholar] [CrossRef] [PubMed]

- Vinardell, S.; Astals, S.; Jaramillo, M.; Mata-Alvarez, J.; Dosta, J. Anaerobic membrane bioreactor performance at different wastewater pre-concentration factors: An experimental and economic study. Sci. Total Environ. 2021, 750, 141625. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; McDonald, J.; Price, W.E.; Khan, S.J.; Hai, F.I.; Ngo, H.H.; Guo, W.; Nghiem, L.D. Effects of salinity build-up on the performance of an anaerobic membrane bioreactor regarding basic water quality parameters and removal of trace organic contaminants. Bioresour. Technol. 2016, 216, 399–405. [Google Scholar] [CrossRef]

- Wijekoon, K.C.; McDonald, J.A.; Khan, S.J.; Hai, F.I.; Price, W.E.; Nghiem, L.D. Development of a predictive framework to assess the removal of trace organic chemicals by anaerobic membrane bioreactor. Bioresour. Technol. 2015, 189, 391–398. [Google Scholar] [CrossRef]

- Tran, V.H.; Lim, S.; Choi, P.J.; An, A.K.; Han, D.S.; Phuntsho, S.; Shon, H. Submerged versus side-stream osmotic membrane bioreactors using an outer-selective hollow fiber osmotic membrane for desalination. Desalination 2021, 515, 115196. [Google Scholar] [CrossRef]

- Yang, W.; Cicek, N.; Ilg, J. State-of-the-art of membrane bioreactors: Worldwide research and commercial applications in North America. J. Membr. Sci. 2006, 270, 201–211. [Google Scholar] [CrossRef]

- Ylitervo, P.; Akinbomi, J.; Taherzadeh, M.J. Membrane bioreactors’ potential for ethanol and biogas production: A review. Environ. Technol. 2013, 34, 1711–1723. [Google Scholar] [CrossRef]

- Jarvis, P.; Carra, I.; Jafari, M.; Judd, S.J. Ceramic vs polymeric membrane implementation for potable water treatment. Water Res. 2022, 215, 118269. [Google Scholar] [CrossRef] [PubMed]

- Mestre, S.; Gozalbo, A.; Lorente-Ayza, M.M.; Sánchez, E. Low-cost ceramic membranes: A research opportunity for industrial application. J. Eur. Ceram. Soc. 2019, 39, 3392–3407. [Google Scholar] [CrossRef]

- Palacio, L.; Bouzerdi, Y.; Ouammou, M.; Albizane, A.; Bennazha, J.; Hernández, A.; Calvo, J.I. Ceramic membranes from Moroccan natural clay and phosphate for industrial water treatment. Desalination 2009, 245, 501–507. [Google Scholar] [CrossRef]

- Tomczak, W.; Gryta, M. Comparison of Polypropylene and Ceramic Microfiltration Membranes Applied for Separation of 1,3-PD Fermentation Broths and Saccharomyces cerevisiae Yeast Suspensions. Membranes 2021, 11, 44. [Google Scholar] [CrossRef] [PubMed]

- Bortot Coelho, F.E.; Magnacca, G.; Boffa, V.; Candelario, V.M.; Luiten-Olieman, M.; Zhang, W. From ultra to nanofiltration: A review on the fabrication of ZrO2 membranes. Ceram. Int. 2023, 49, 8683–8708. [Google Scholar] [CrossRef]

- He, Z.; Lyu, Z.; Gu, Q.; Zhang, L.; Wang, J. Ceramic-based membranes for water and wastewater treatment. Colloids Surf. A Physicochem. Eng. Asp. 2019, 578, 123513. [Google Scholar] [CrossRef]

- Tomczak, W.; Gryta, M. Clarification of 1,3-propanediol fermentation broths by using a ceramic fine UF membrane. Membranes 2020, 10, 319. [Google Scholar] [CrossRef]

- Sandhya Rani, S.L.; Kumar, R.V. Insights on applications of low-cost ceramic membranes in wastewater treatment: A mini-review. Case Stud. Chem. Environ. Eng. 2021, 4, 100149. [Google Scholar] [CrossRef]

- Jiang, D.; Gao, C.; Liu, L.; Yu, T.; Li, Y.; Wang, H. Application of nanoporous ceramic membrane derived from Fe/S/Si/Al/O-rich mining solid waste in oil-water separation and heavy metal removal of industrial high concentrated emulsifying wastewater. Sep. Purif. Technol. 2022, 295, 121317. [Google Scholar] [CrossRef]

- Samadi, A.; Gao, L.; Kong, L.; Orooji, Y.; Zhao, S. Waste-derived low-cost ceramic membranes for water treatment: Opportunities, challenges and future directions. Resour. Conserv. Recycl. 2022, 185, 106497. [Google Scholar] [CrossRef]

- Kim, J.; Aslam, M.; Ahmad, R. Alumina Membrane Bioreactor. In Current Trends and Future Developments on (Bio-) Membranes; Elsevier: Amsterdam, The Netherlands, 2020; pp. 115–139. ISBN 978-0-12-816822-6. [Google Scholar]

- Tomczak, W.; Grubecki, I.; Gryta, M. The Use of NaOH Solutions for Fouling Control in a Membrane Bioreactor: A Feasibility Study. Membranes 2021, 11, 887. [Google Scholar] [CrossRef] [PubMed]

- Mao, Y.; Huang, Q.; Meng, B.; Zhou, K.; Liu, G.; Gugliuzza, A.; Drioli, E.; Jin, W. Roughness-enhanced hydrophobic graphene oxide membrane for water desalination via membrane distillation. J. Membr. Sci. 2020, 611, 118364. [Google Scholar] [CrossRef]

- Sitorus, B.; Sukandar; Panjaitan, S.D. Biogas Recovery from Anaerobic Digestion Process of Mixed Fruit—Vegetable Wastes. Energy Procedia 2013, 32, 176–182. [Google Scholar] [CrossRef]

- Golub, N.; Potapova, M.; Shinkarchuk, M.; Kozlovets, O. Biogas production in the concentrated distillery wastewater treatment. Altern. Energy Ecol. ISJAEE 2018, 51–59. [Google Scholar] [CrossRef]

- Khanal, S.K.; Tirta Nindhia, T.G.; Nitayavardhana, S. Biogas from Wastes. In Sustainable Resource Recovery and Zero Waste Approaches; Elsevier: Amsterdam, The Netherlands, 2019; pp. 165–174. ISBN 978-0-444-64200-4. [Google Scholar]

- Kwietniewska, E.; Tys, J. Process characteristics, inhibition factors and methane yields of anaerobic digestion process, with particular focus on microalgal biomass fermentation. Renew. Sustain. Energy Rev. 2014, 34, 491–500. [Google Scholar] [CrossRef]

- Jiang, M.; Westerholm, M.; Qiao, W.; Wandera, S.M.; Dong, R. High rate anaerobic digestion of swine wastewater in an anaerobic membrane bioreactor. Energy 2020, 193, 116783. [Google Scholar] [CrossRef]

- Kanafin, Y.N.; Kanafina, D.; Malamis, S.; Katsou, E.; Inglezakis, V.J.; Poulopoulos, S.G.; Arkhangelsky, E. Anaerobic Membrane Bioreactors for Municipal Wastewater Treatment: A Literature Review. Membranes 2021, 11, 967. [Google Scholar] [CrossRef]

- Ramaraj, R.; Unpaprom, Y. Effect of temperature on the performance of biogas production from Duckweed. Chem. Res. J. 2016, 1, 58–66. [Google Scholar]

- Lin, Q.; He, G.; Rui, J.; Fang, X.; Tao, Y.; Li, J.; Li, X. Microorganism-regulated mechanisms of temperature effects on the performance of anaerobic digestion. Microb. Cell Factories 2016, 15, 96. [Google Scholar] [CrossRef]

- Nie, E.; He, P.; Zhang, H.; Hao, L.; Shao, L.; Lü, F. How does temperature regulate anaerobic digestion? Renew. Sustain. Energy Rev. 2021, 150, 111453. [Google Scholar] [CrossRef]

- Gao, W.J.; Leung, K.T.; Qin, W.S.; Liao, B.Q. Effects of temperature and temperature shock on the performance and microbial community structure of a submerged anaerobic membrane bioreactor. Bioresour. Technol. 2011, 102, 8733–8740. [Google Scholar] [CrossRef] [PubMed]

- Appels, L.; Baeyens, J.; Degrève, J.; Dewil, R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Watanabe, R.; Nie, Y.; Wakahara, S.; Komori, D.; Li, Y.-Y. Investigation on the response of anaerobic membrane bioreactor to temperature decrease from 25 °C to 10 °C in sewage treatment. Bioresour. Technol. 2017, 243, 747–754. [Google Scholar] [CrossRef] [PubMed]

- Lim, K.; Evans, P.J.; Parameswaran, P. Long-Term Performance of a Pilot-Scale Gas-Sparged Anaerobic Membrane Bioreactor under Ambient Temperatures for Holistic Wastewater Treatment. Environ. Sci. Technol. 2019, 53, 7347–7354. [Google Scholar] [CrossRef]

- Crone, B.C.; Garland, J.L.; Sorial, G.A.; Vane, L.M. Significance of dissolved methane in effluents of anaerobically treated low strength wastewater and potential for recovery as an energy product: A review. Water Res. 2016, 104, 520–531. [Google Scholar] [CrossRef]

- Zsirai, T.; Buzatu, P.; Aerts, P.; Judd, S. Efficacy of relaxation, backflushing, chemical cleaning and clogging removal for an immersed hollow fibre membrane bioreactor. Water Res. 2012, 46, 4499–4507. [Google Scholar] [CrossRef]

- Habib, R.; Asif, M.B.; Iftekhar, S.; Khan, Z.; Gurung, K.; Srivastava, V.; Sillanpää, M. Influence of relaxation modes on membrane fouling in submerged membrane bioreactor for domestic wastewater treatment. Chemosphere 2017, 181, 19–25. [Google Scholar] [CrossRef]

- Bilad, M.R.; Vandamme, D.; Foubert, I.; Muylaert, K.; Vankelecom, I.F.J. Harvesting microalgal biomass using submerged microfiltration membranes. Bioresour. Technol. 2012, 111, 343–352. [Google Scholar] [CrossRef]

- Shi, X.; Tal, G.; Hankins, N.P.; Gitis, V. Fouling and cleaning of ultrafiltration membranes: A review. J. Water Process Eng. 2014, 1, 121–138. [Google Scholar] [CrossRef]

- Gruskevica, K.; Mezule, L. Cleaning Methods for Ceramic Ultrafiltration Membranes Affected by Organic Fouling. Membranes 2021, 11, 131. [Google Scholar] [CrossRef]

- Bagheri, M.; Mirbagheri, S.A. Critical review of fouling mitigation strategies in membrane bioreactors treating water and wastewater. Bioresour. Technol. 2018, 258, 318–334. [Google Scholar] [CrossRef] [PubMed]

- Katsoufidou, K.; Yiantsios, S.; Karabelas, A. A study of ultrafiltration membrane fouling by humic acids and flux recovery by backwashing: Experiments and modeling. J. Membr. Sci. 2005, 266, 40–50. [Google Scholar] [CrossRef]

- Chang, H.; Liang, H.; Qu, F.; Liu, B.; Yu, H.; Du, X.; Li, G.; Snyder, S.A. Hydraulic backwashing for low-pressure membranes in drinking water treatment: A review. J. Membr. Sci. 2017, 540, 362–380. [Google Scholar] [CrossRef]

- Puspitasari, V.; Granville, A.; Le-Clech, P.; Chen, V. Cleaning and ageing effect of sodium hypochlorite on polyvinylidene fluoride (PVDF) membrane. Sep. Purif. Technol. 2010, 72, 301–308. [Google Scholar] [CrossRef]

- Al-Amoudi, A.; Lovitt, R.W. Fouling strategies and the cleaning system of NF membranes and factors affecting cleaning efficiency. J. Membr. Sci. 2007, 303, 4–28. [Google Scholar] [CrossRef]

- Hakami, M.W.; Alkhudhiri, A.; Al-Batty, S.; Zacharof, M.-P.; Maddy, J.; Hilal, N. Ceramic Microfiltration Membranes in Wastewater Treatment: Filtration Behavior, Fouling and Prevention. Membranes 2020, 10, 248. [Google Scholar] [CrossRef]

- Mei, X.; Quek, P.J.; Wang, Z.; Ng, H.Y. Alkali-assisted membrane cleaning for fouling control of anaerobic ceramic membrane bioreactor. Bioresour. Technol. 2017, 240, 25–32. [Google Scholar] [CrossRef]

- Porcelli, N.; Judd, S. Chemical cleaning of potable water membranes: A review. Sep. Purif. Technol. 2010, 71, 137–143. [Google Scholar] [CrossRef]

- Koo, C.C.H.; Wong, K.H.; Chong, W.C.; Thiam, H.S. Chemical cleaning of nanofiltration membranes fouled by organic matters. J. Eng. Sci. Technol. 2016, 11, 987–1000. [Google Scholar]

- Rabuni, M.F.; Nik Sulaiman, N.M.; Awanis Hashim, N. A systematic assessment method for the investigation of the PVDF membrane stability. Desalination Water Treat. 2016, 57, 1–12. [Google Scholar] [CrossRef]

- Aguiar, A.; Andrade, L.; Grossi, L.; Pires, W.; Amaral, M. Acid mine drainage treatment by nanofiltration: A study of membrane fouling, chemical cleaning, and membrane ageing. Sep. Purif. Technol. 2018, 192, 185–195. [Google Scholar] [CrossRef]

- Rouaix, S.; Causserand, C.; Aimar, P. Experimental study of the effects of hypochlorite on polysulfone membrane properties. J. Membr. Sci. 2006, 277, 137–147. [Google Scholar] [CrossRef]

- Yusuf, Z.; Abdul Wahab, N.; Sahlan, S. Fouling control strategy for submerged membrane bioreactor filtration processes using aeration airflow, backwash, and relaxation: A review. Desalination Water Treat. 2016, 57, 17683–17695. [Google Scholar] [CrossRef]

- Li, H.; Chen, V. Membrane Fouling and Cleaning in Food and Bioprocessing. In Membrane Technology; Elsevier: Amsterdam, The Netherlands, 2010; pp. 213–254. ISBN 978-1-85617-632-3. [Google Scholar]

| Process | Description | Stoichiometric Equation | Equation |

|---|---|---|---|

| hydrolysis |

| nC6H10O5 + nH2O → nC6H12O6 | (1) |

| acidogenesis |

| C6H12O6 ↔ 2CH3CH2OH + 2CO2 C6H12O6 + 2H2 ↔ 2CH3CH2COOH + 2H2O C6H12O6 → 3CH3COOH | (2) (3) (4) |

| acetogenesis |

| CH3CH2COO− + 3H2O ↔ CH3COO− + H+HCO3− + 3H2 C6H12O6 + 2H2O ↔ 2CH3COOH + 2CO2 + 4H2 CH3CH2OH + 2H2O ↔ CH3COO− + 3H2 + H+ | (5) (6) (7) |

| methanogenesis |

| CH3COOH → CH4 + CO2 CO2 + 4H2 → CH4 + 2H2O 2CH3CH2OH + CO2 → CH4 + 2CH3COOH | (8) (9) (10) |

| AnMBR | Membrane Characteristics | Process Conditions | Biogas or Methane Production Yield [L/g COD] | Ref. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Scale | Configuration | Volume (L) | Type | Pore size (µm) | Material | Configuration | Area (m2) | Temperature (°C) | HRT (h) or (d) | SRT (d) | pH | ||

| pilot | submerged | 20 | MF | 0.4 | PVDF | hollow fiber | NI | 15 | 6–24 h | 20.7–515.7 d | NI | 0.17–0.28; 0.12–0.23 | [70] |

| pilot | submerged | 25 | MF | 0.2 | NI | hollow fiber | 5.4 | 35 | 2.2 h | NI | NI | 0.12 | [71] |

| pilot | submerged | 160 | UF | 0.045 | NI | hollow fiber | 0.93 | 18 ± 2 | 7.0–17.1 h | 20 d | NI | 0.18; 0.23 | [72] |

| pilot | submerged | 326 | UF | 0.045 | NI | hollow fiber | 0.93 | 18 | 9.8–20.3 h | NI | NI | 0.14 ± 0.01–0.26 ± 0.01 | [73] |

| pilot | submerged | 350 | UF | 0.038 | PES | flat sheet | 3.5 | 20–35 | 0.8 d | NI | NI | 0.23; 0.27 | [74] |

| pilot | submerged | 350 | UF | 0.038 | PES | flat sheet | 3.5 | 20 ± 1 | 0.74–1.10 d | NI | NI | 0.29 | [75] |

| pilot | submerged | 496 | UF | 0.045 | NI | hollow fiber | 1.86 | 10–28 | 8–10 h | NI | 8.2 ± 0.3 | 0.09–0.14 | [76] |

| pilot | submerged | 550 | UF | 0.04 | PVDF | hollow fiber | 5.4 | 23 ± 1 | 8.5 h | 40–100 d | 6.7–6.8 | 0.115 ± 0.021–0.072 ± 14 | [77] |

| pilot | submerged | 1300 | UF | 0.05 | NI | hollow fiber | 30 | 33.3 ± 0.2 | 6–21 h | 70 d | 6.72 ± 0.08 | 0.069 ± 0.022 | [78] |

| pilot | submerged | 5000 | MF | 0.4 | PVDF | hollow fiber | 72 | 25.3 ± 0.9–26.5 ± 0.8 | 6–48 h | 29.0–123.5 d | 6.69 ± 0.11–6.80 ± 0.26 | 0.16–0.27 | [79] |

| pilot | submerged | 5000 | MF | 0.4 | PVDF | hollow fiber | 72 | 15–25 | 8 h | 20–100 d | NI | 0.205–0.244 | [80] |

| pilot | external | 50 | UF | NI 1 | NI | cross-flow | 1 | 37 | 7 d | NI | 7.31–8.37 | 0.46 | [81] |

| pilot | external | 2100 | UF | 0.03 | NI | hollow fiber | 31.999 | 27 ± 1 | 24.4 ± 0.4 h | 140 ± 3 d | NI | 0.108 ± 0.018 | [82] |

| semi-industrial | submerged | 2100 | UF | 0.05 | NI | hollow fiber | 30 | 33 | 15 h | 70 d | NI | 0.333 | [83] |

| semi-pilot | submerged | 94 | MF | 0.4 | PVDF | flat sheet | 0.14 | 37 ± 1 | 47 d | NI | NI | 0.28; 0.29 | [84] |

| bench | submerged | 5 | MF | 0.45 | PES | plate and frame | 0.118 | 25–30 | 8–12 h | 30 d; 60 d and infinite | 7.0 ± 0.5 | 0.124 ± 0.012–0.219 ± 0.027 | [85] |

| bench | submerged | 5 | MF | 0.45 | PES | plate and frame | 0.118 | 25–30 | 10 h | 30–90 d | 7.0 ± 0.5 | NI 2 | [86] |

| bench | submerged | 8 | UF | 0.04 | PVDF | hollow fiber | 0.07 | 23 ± 1 | 12.5 h | 40 d | 6.7–6.8 | 0.072 ± 13 | [77] |

| bench | submerged | 24 | UF | 0.1 | ceramic | NI | 0.2 | 30–35 | 12 h | NI | NI | 0.185 ± 0.08; 0.222 ± 0.12 | [87] |

| laboratory | submerged | 3 | MF | 40 | NI | rectangular | 0.0108 | 35 ± 1 | 14 h | NI | NI | 0.24 | [88] |

| laboratory | submerged | 3.6 | MF and UF | 0.08–0.30 | ceramic | NI | NI | 25–30 | 7.5 h | 60 d | NI | 0.1 ± 0.02 | [89] |

| laboratory | submerged | 4 | MF | 0.2 | PP | hollow fiber | 0.06 | 35 ± 1 | 12–48 h | NI | NI | 0.15–0.35 | [90] |

| laboratory | submerged | 6 | MF | 0.2 | PE | flat sheet | 0.116 | 25 ± 1 | 8–48 h | infinite | 6.8–7.5 | NI 3 | [91] |

| laboratory | submerged | 6 | MF | 0.1 | ceramic | flat sheet | 0.045 | 30 ± 3 | 17 h | 30 d | 7.80 ± 0.21; 7.84 ± 0.11 | 0.064 ± 0.02; 0.070 ± 0.03 | [92] |

| laboratory | submerged | 6 | MF | 0.2 | PET | flat sheet | 0.116 | 25 ± 1 | 12 and 24 h | NI | 6.9–7.3 | NI 4 | [93] |

| laboratory | submerged | 6 | MF | 0.2 | PET | flat sheet | 0.116 | 25 ± 1 | 12 h | NI | NI | NI 5 | [94] |

| laboratory | submerged | 20 | MF | 0.4 | PVDF | hollow fiber | NI | 15–25 | 6 h | 20.7–93.9 d | 7.0–7.3 | 0.06 ± 0.01–0.17 ± 0.01; 0.09 ± 0.02–0.22 ± 0.02 | [95] |

| laboratory | submerged | 20 | MF | 0.4 | NI | NI | 0.146 | 25 | 12–24 h | infinite | 6.9 ± 0.1 | 0.15 ± 0.02–0.19 ± 0.02; 0.20 ± 0.03–0.24 ± 0.02; | [96] |

| laboratory | submerged | 20 | MF | 0.05 | NI | NI | 0.27 | 25 | 12–24 h | infinite | 6.9 ± 0.1 | 0.16 ± 0.04–0.20 ± 0.03; 0.21 ± 0.05–0.26 ± 0.04 | [96] |

| laboratory | submerged | 20 | MF | 0.4 | NI | NI | NI | 25.0 ± 0.2 | 4–24 h | NI | NI | NI 6 | [97] |

| laboratory | submerged | 20 | UF | 0.05 | NI | NI | NI | 25.0 ± 0.2 | 10–24 h | NI | NI | NI 7 | [97] |

| laboratory | submerged | 80 | UF | NI 1 | PVDF | flat sheet | 0.6 | 30 ± 3 | 10 h | NI | 7.0 ± 0.2 | 0.24 | [98] |

| laboratory | external | 2 | UF | 0.03 | PVDF | hollow fiber | 0.031 | 35 ± 1 | 6 h; 12 h | 1000 d | 7.0 ± 0.1 | 0.129 ± 0.004–0.396 ± 0.033 | [99] |

| laboratory | external | 4 | MF | 1 | PTFE | tubular | 0.090– 0.012 | 25 ± 1 | 6–12 h | NI | 7.3–7.9 | 0.21–0.22 | [100] |

| laboratory | external | 5.5 | UF | 0.05 | PVDF | flat sheet | 0.02 | NI | 2.4 ± 0.6–3.6 ± 1.1 d | NI | 7.6 ± 0.3–8.4 ± 0.2 | 0.214 ± 0.079–0.322 ± 0.060 | [101] |

| laboratory | external | 30 | MF | 0.1 | ceramic | NI | 0.09 | 35 ± 1 | 5 d | 140 d | 7.0 | 0.4–0.6 | [102] |

| laboratory | external | 30 | MF | 0.1 | ceramic | NI | 0.09 | 35 ± 1 | 4 d | 180 d | 7 | 0.2 | [103] |

| AnMBR | Membrane Characteristics | Fouling Mitigation Strategy | Ref. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Scale | Configuration | Type | Material | Configuration | Biogas Sparging | Manual Cleaning | Relaxation | Ultrasonic | (Chemically Enhanced) Backwashing | Chemical Cleaning/ Soaking | Used Agents | |

| pilot | submerged | UF | NI | hollow fiber | + | − | + | − | + | + | NaClO | [72] |

| pilot | submerged | UF | NI | hollow fiber | + | − | + | − | + | − | - | [73] |

| pilot | submerged | UF | PES | flat sheet | + | − | + | − | + | − | - | [74] |

| pilot | submerged | UF | PES | flat sheet | − | − | + | − | + | − | - | [75] |

| pilot | submerged | UF | NI | hollow fiber | − | − | − | − | + | + | NaClO | [76] |

| pilot | submerged | UF | NI | hollow fiber | + | − | + | − | − | − | - | [78] |

| pilot | submerged | MF | PVDF | hollow fiber | + | − | + | − | + | − | NaClO and citric acid | [79] |

| pilot | submerged | MF | PVDF | hollow fiber | + | − | − | − | + | + | NaClO and citric acid | [80] |

| pilot | external | UF | NI 1 | cross-flow | − | − | − | − | − | + | NaOH, NaHSO4, citric acid, EDTA | [81] |

| pilot | external | UF | NI | hollow fiber | − | − | + | − | + | − | - | [82] |

| semi-pilot | submerged | MF | PVDF | flat sheet | − | − | − | − | + | − | - | [84] |

| bench | submerged | MF | PES | plate and frame | − | − | − | − | − | + | NaClO | [85] |

| bench | submerged | UF | ceramic | NI | + | − | + | − | + | − | - | [87] |

| laboratory | submerged | MF | NI | rectangular | + | − | − | + | − | − | - | [88] |

| laboratory | submerged | MF, UF | ceramic | NI | − | + | − | − | + | − | - | [89] |

| laboratory | submerged | MF | PP | hollow fiber | − | + | − | − | − | + | NaOH and HNO3 | [90] |

| laboratory | submerged | MF | PE | flat sheet | − | − | − | − | − | + | NaClO and citric acid | [91] |

| laboratory | submerged | MF | ceramic | flat sheet | − | + | − | − | − | + | NaClO and citric acid | [92] |

| laboratory | submerged | MF | PVDF | hollow fiber | − | − | − | − | + | − | NaClO | [95] |

| laboratory | submerged | MF | NI | NI | − | + | − | − | + | + | NaClO and citric acid | [96] |

| laboratory | external | MF | PTFE | tubular | − | − | − | − | − | + | NaClO | [100] |

| laboratory | external | UF | PVDF | flat sheet | − | + | − | − | − | + | NaClO | [101] |

| laboratory | external | MF | ceramic | NI | − | − | − | − | − | + | NaOH | [102] |

| AnMBR | Membrane Characteristics | Biogas velocity (m/h) or (L/min) | Ref. | |||

|---|---|---|---|---|---|---|

| Scale | Configuration | Type | Material | Configuration | ||

| pilot | submerged | UF | NI | hollow fiber | 40–60 m/h | [72] |

| pilot | submerged | UF | NI | hollow fiber | 9–16 m/h | [73] |

| pilot | submerged | UF | NI | hollow fiber | 62 m/h | [74] |

| pilot | submerged | UF | NI | hollow fiber | NI 1 | [78] |

| pilot | submerged | MF | PVDF | hollow fiber | 0.75 m/h | [79] |

| laboratory | submerged | MF | NI | rectangular | 1 L/min | [88] |

| AnMBR | Membrane Characteristics | Time (s) or (h) | Ref. | |||

|---|---|---|---|---|---|---|

| Scale | Configuration | Type | Material | Configuration | ||

| pilot | submerged | UF | NI | hollow fiber | 5 s | [72] |

| pilot | submerged | UF | NI | hollow fiber | 10 s | [73] |

| pilot | submerged | UF | PES | flat sheet | 30 s | [74] |

| pilot | submerged | UF | PES | flat sheet | 30 s | [75] |

| pilot | submerged | UF | NI | hollow fiber | 50 s | [78] |

| pilot | submerged | MF | PVDF | hollow fiber | 60 s | [79] |

| pilot | external | UF | NI | hollow fiber | 50 s | [82] |

| bench | submerged | UF | ceramic | NI | 12 h | [87] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomczak, W.; Gryta, M.; Grubecki, I.; Miłek, J. Biogas Production in AnMBRs via Treatment of Municipal and Domestic Wastewater: Opportunities and Fouling Mitigation Strategies. Appl. Sci. 2023, 13, 6466. https://doi.org/10.3390/app13116466

Tomczak W, Gryta M, Grubecki I, Miłek J. Biogas Production in AnMBRs via Treatment of Municipal and Domestic Wastewater: Opportunities and Fouling Mitigation Strategies. Applied Sciences. 2023; 13(11):6466. https://doi.org/10.3390/app13116466

Chicago/Turabian StyleTomczak, Wirginia, Marek Gryta, Ireneusz Grubecki, and Justyna Miłek. 2023. "Biogas Production in AnMBRs via Treatment of Municipal and Domestic Wastewater: Opportunities and Fouling Mitigation Strategies" Applied Sciences 13, no. 11: 6466. https://doi.org/10.3390/app13116466

APA StyleTomczak, W., Gryta, M., Grubecki, I., & Miłek, J. (2023). Biogas Production in AnMBRs via Treatment of Municipal and Domestic Wastewater: Opportunities and Fouling Mitigation Strategies. Applied Sciences, 13(11), 6466. https://doi.org/10.3390/app13116466