Preparation Methods and Properties of CNT/CF/G Carbon-Based Nano-Conductive Silicone Rubber

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

2.2. Main Instruments and Equipment

2.3. Preparation Process and Method of Conductive Silicone Rubber

- (1)

- Preparation of the base solution: LSR is formed by cross-linking and curing of AB glue. AB glue is the silicone rubber (component A) and curing agent (component B). The role of the curing agent is to achieve curing at room temperature. Weigh AB glue at a ratio of 1:1 and mix it with n-heptane at a volume ratio of 1:2. Stir the mixture for 30 min by mechanical stirring and ultrasonically disperse it for 1 h to evenly mix the n-heptane solvent with LSR.

- (2)

- Preparation of the mix conductive filler solution: weigh the proper amounts of the carbon-based materials and add them into n-heptane. Mechanically stir the mixture for 30 min, and ultrasonically disperse it for 1 h.

- (3)

- Preparation by the solution blending method: add the LSR solvent into the conductive filler solution, mechanically stir it for 30 min, and ultrasonically vibrate it for 1 min for uniform dispersion.

- (4)

- Molding preparation: Vacuum filter the mixture in a vacuum drying oven, pour it into a Petri dish, and let it rest for 24 h. After n-heptane completely volatilizes, cure it in a constant-temperature drying oven at 125 °C for 30 min to obtain the final sample.

2.4. Performance Testing and Structural Characterization Methods

- (1)

- Electrical performance test

- (2)

- Tensile sensitivity test

- (3)

- Thermogravimetric analysis and testing

- (4)

- Glass transition temperature and melting point test

- (5)

- Raman spectrum test

- (6)

- X-ray diffraction test

3. Results and Discussion

3.1. Properties of the PREPARED Single-Filler Conductive Silicone Rubbers

- (1)

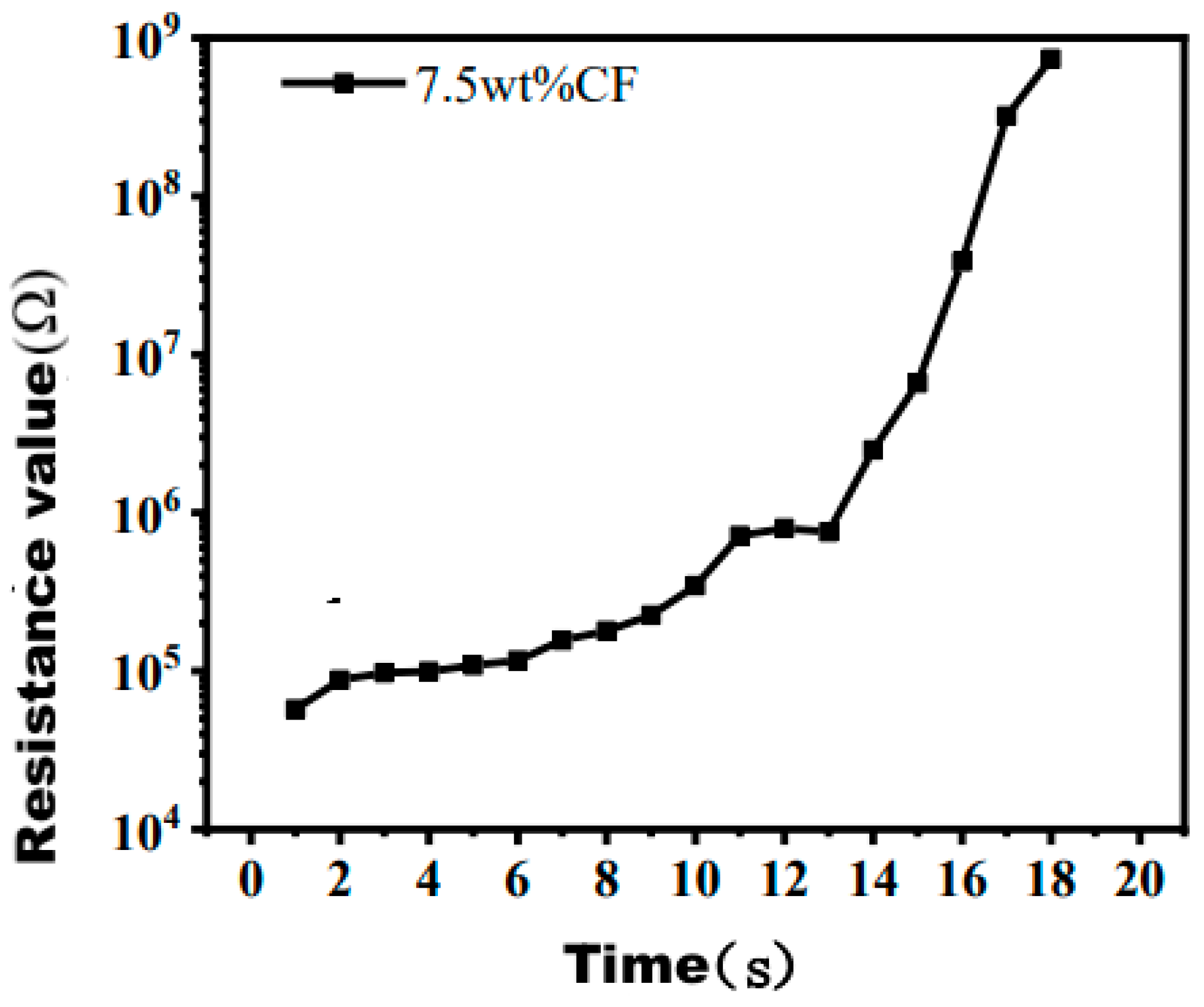

- Properties of the CF conductive silicone rubber

- (a)

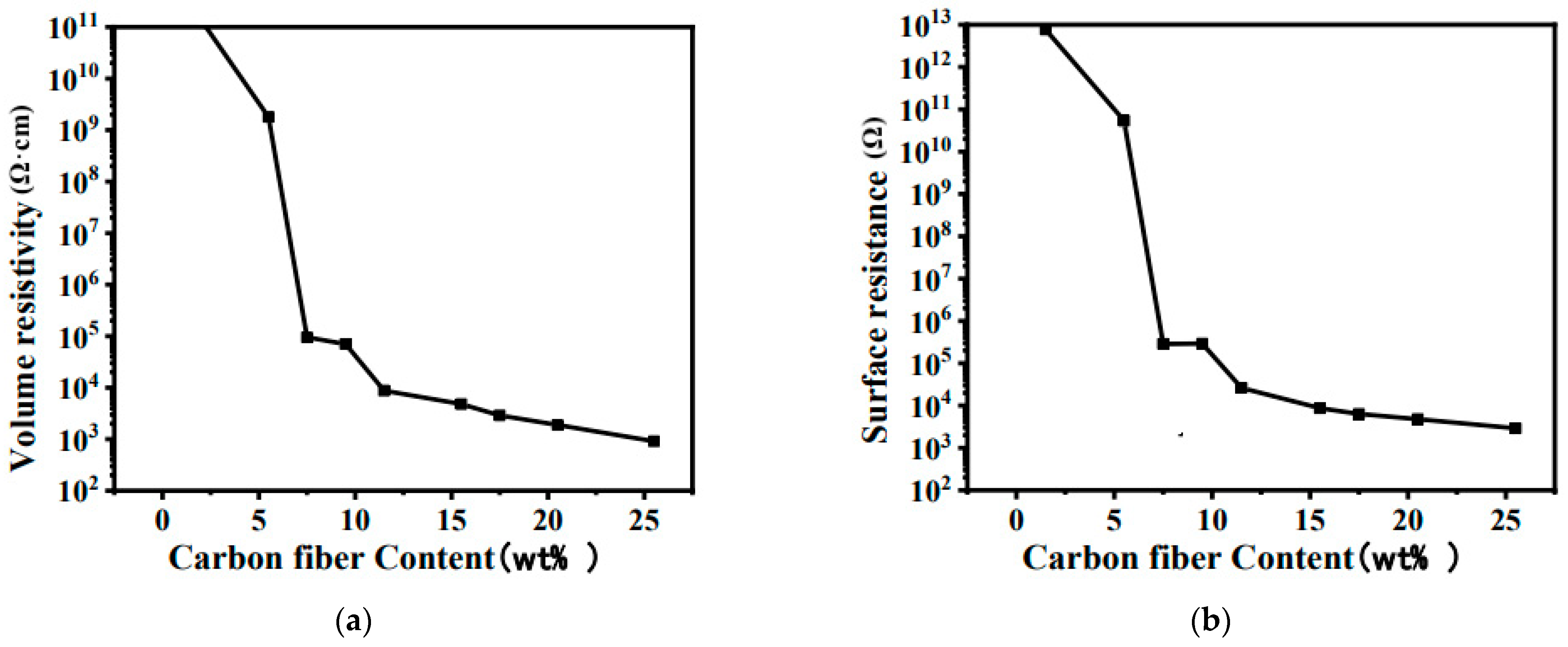

- Electrical properties of the CF conductive silicone rubber

- (b)

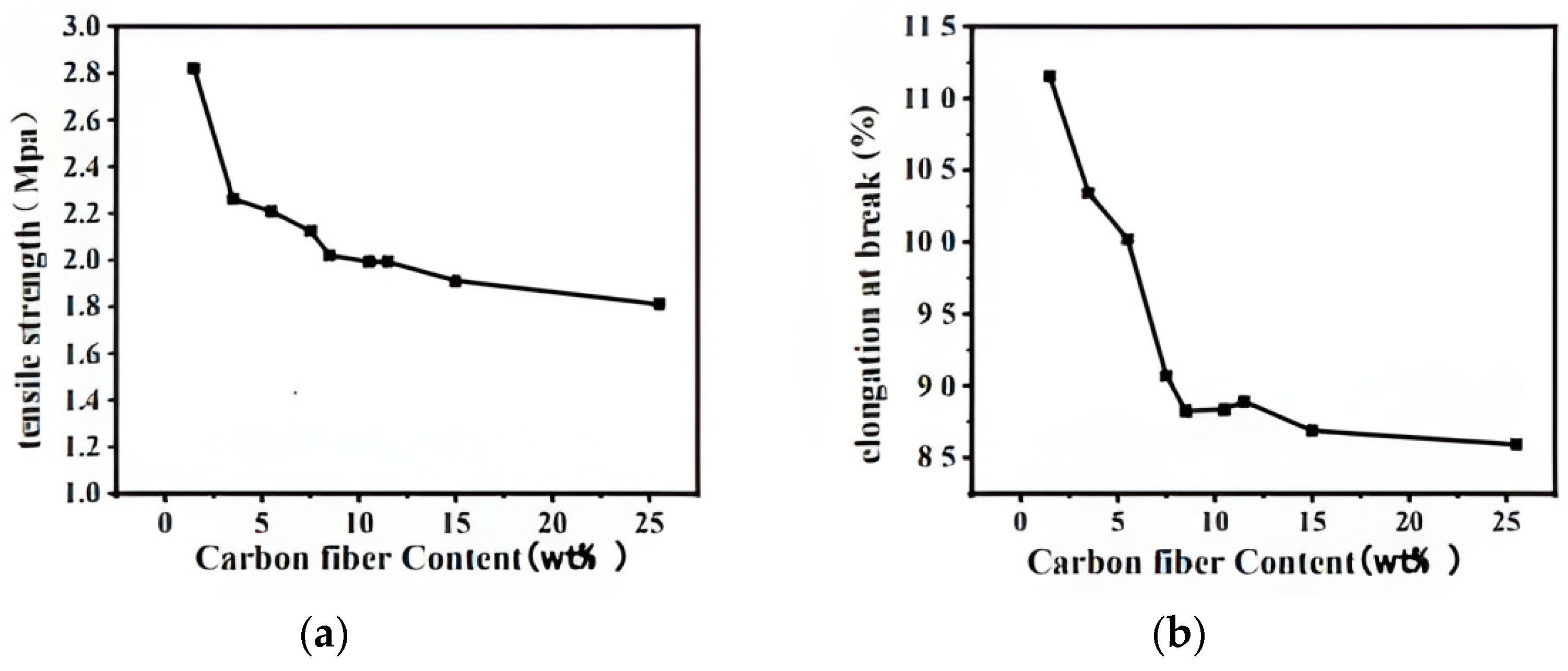

- Mechanical properties of the CF conductive silicone rubber

- (c)

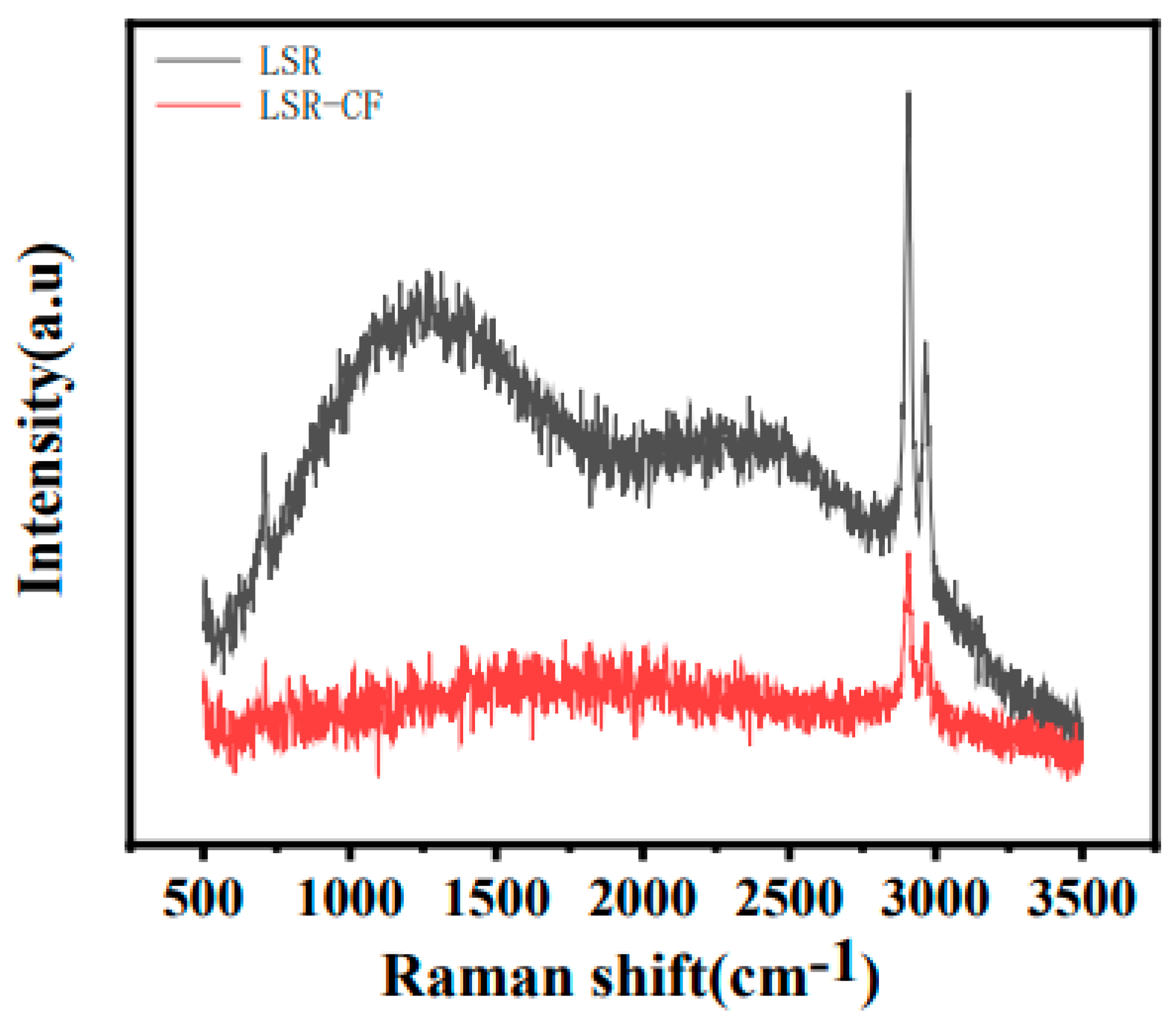

- Dispersion and heat resistance analysis of LSR/CF.

- (1)

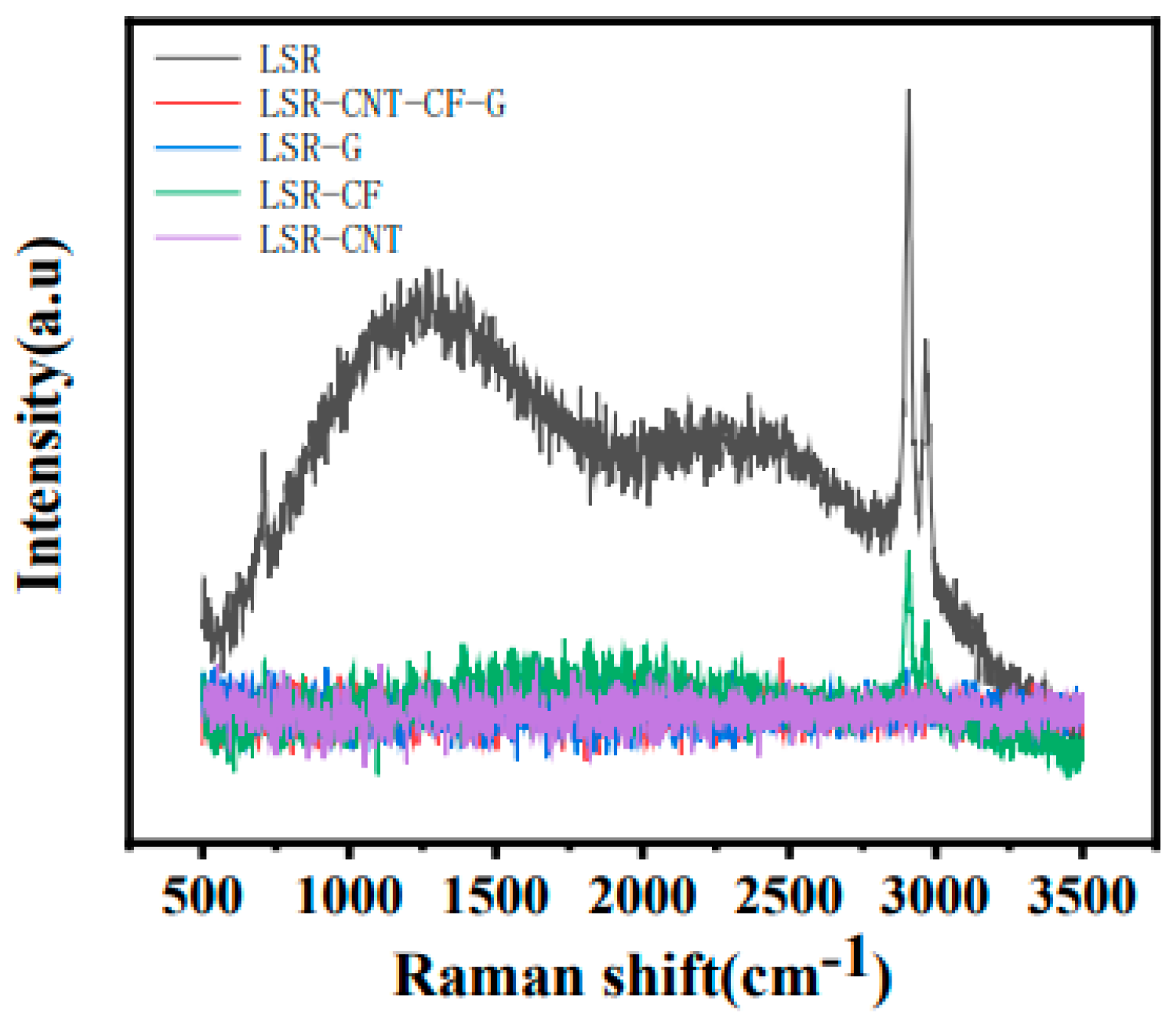

- Dispersion analysis

- (2)

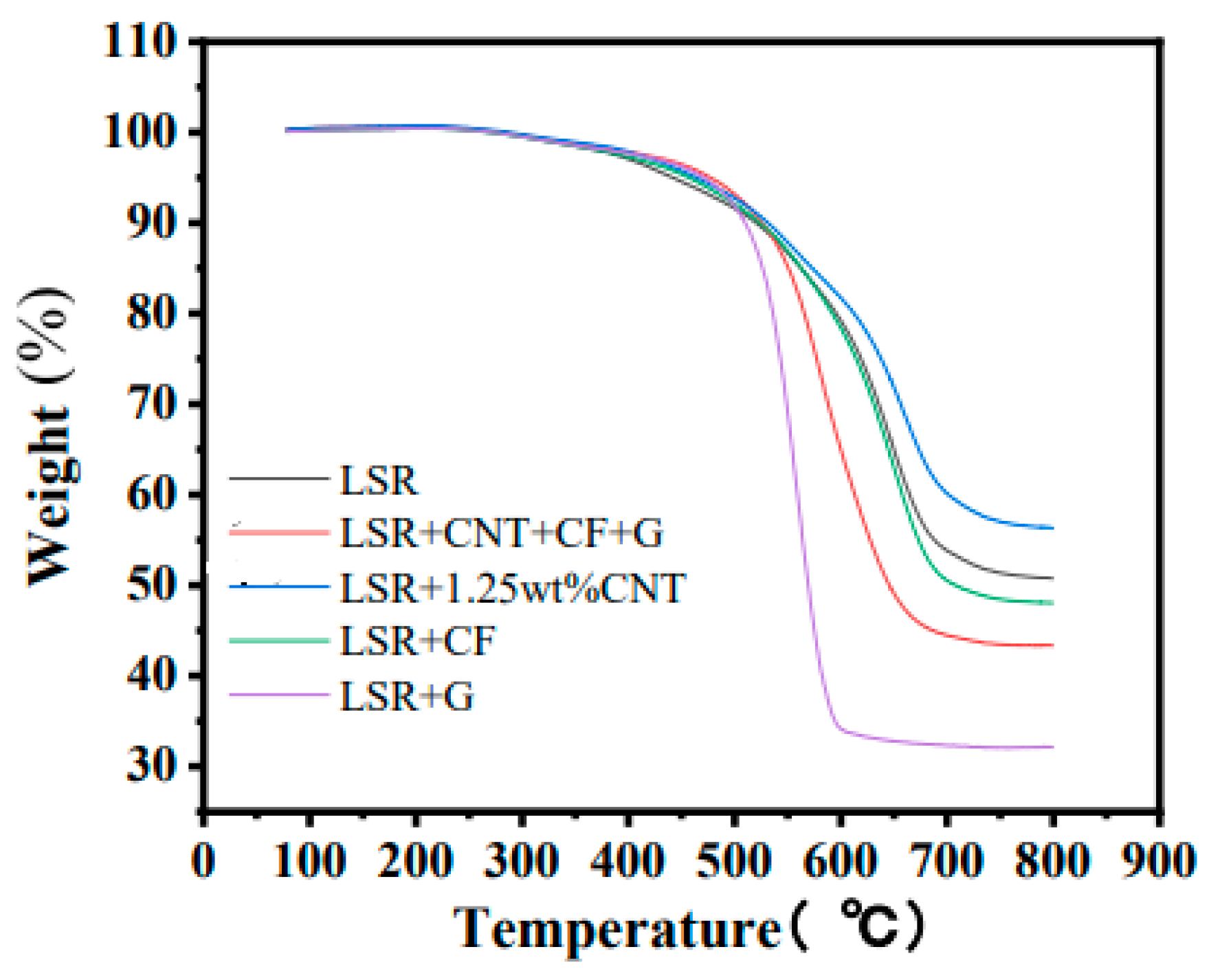

- Heat resistance

- (2)

- Properties of graphene conductive silicone rubber

- (a)

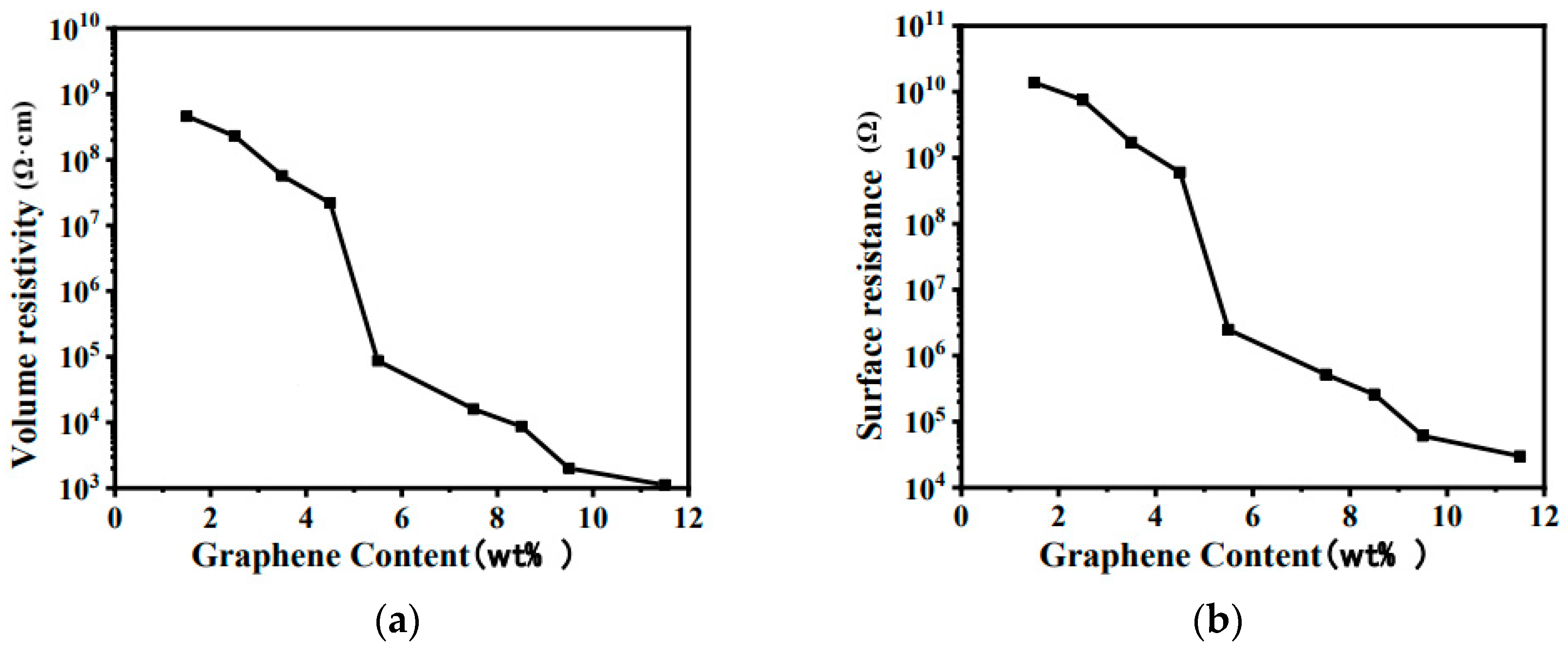

- Electrical properties of graphene conductive silicone rubber

- (b)

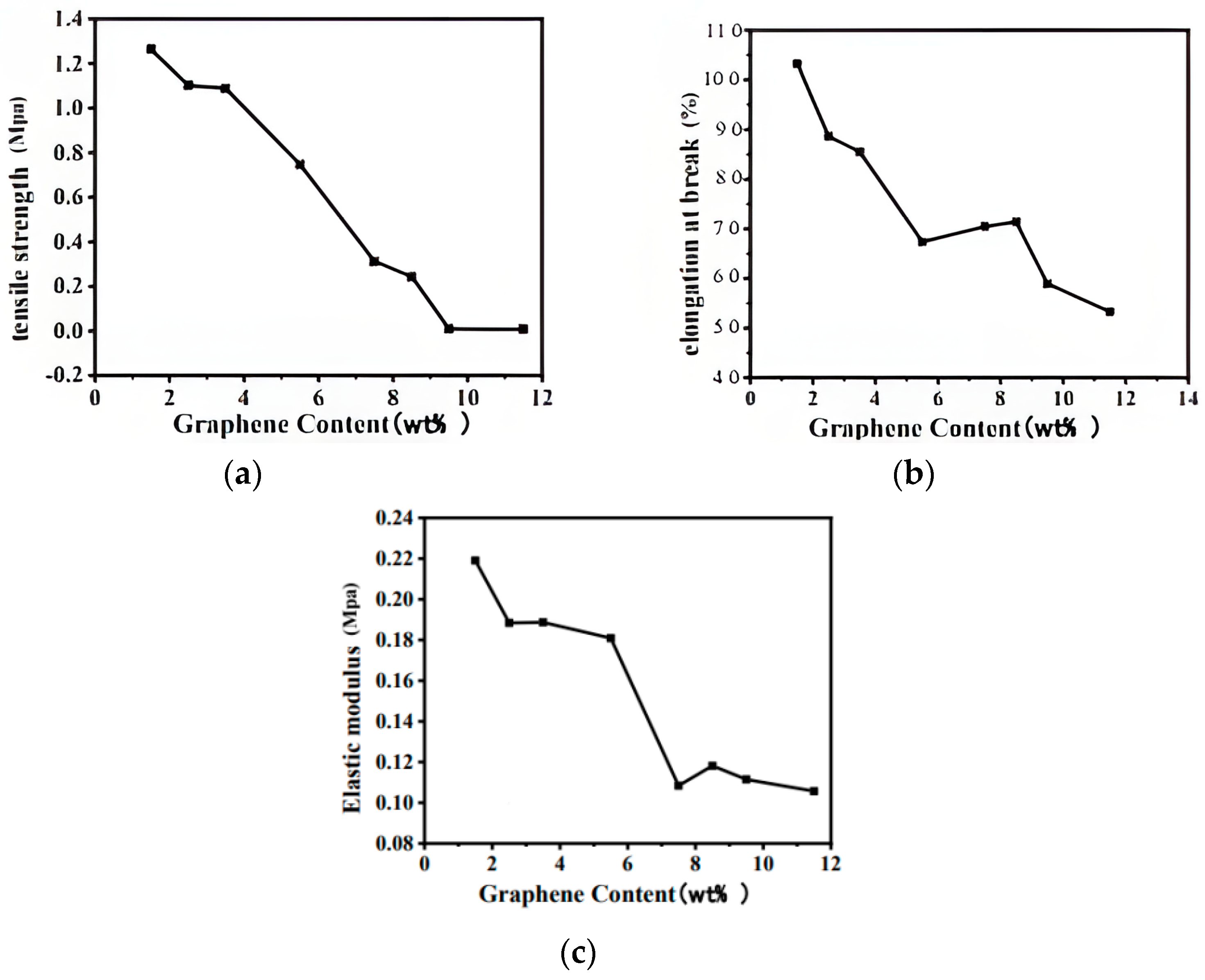

- Mechanical properties of LSR/G

- (a)

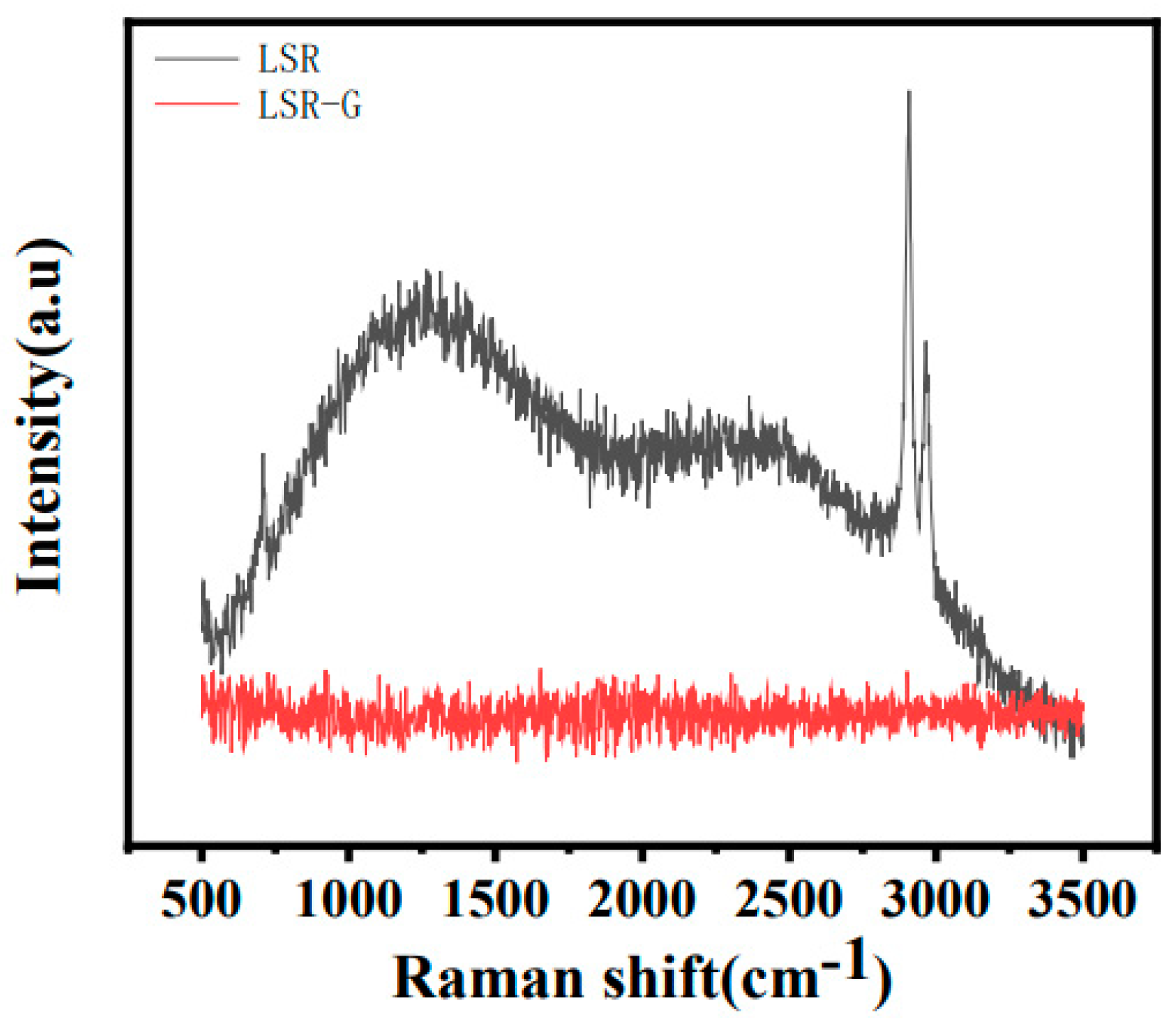

- Analysis of dispersibility and heat resistance of LSR/G.

- (1)

- Dispersion analysis

- (2)

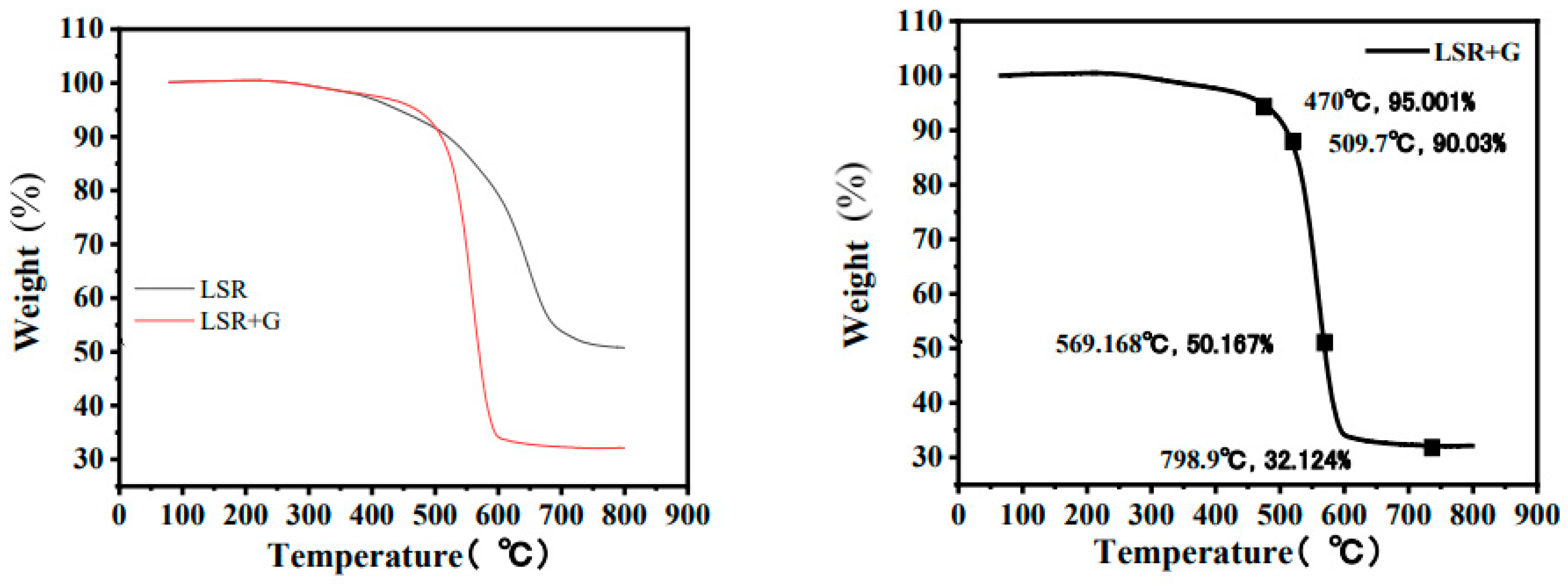

- Heat resistance

- (3)

- Properties of carbon nanotube conductive silicone rubber

- (a)

- Electrical properties of LSR/CNT.

- (b)

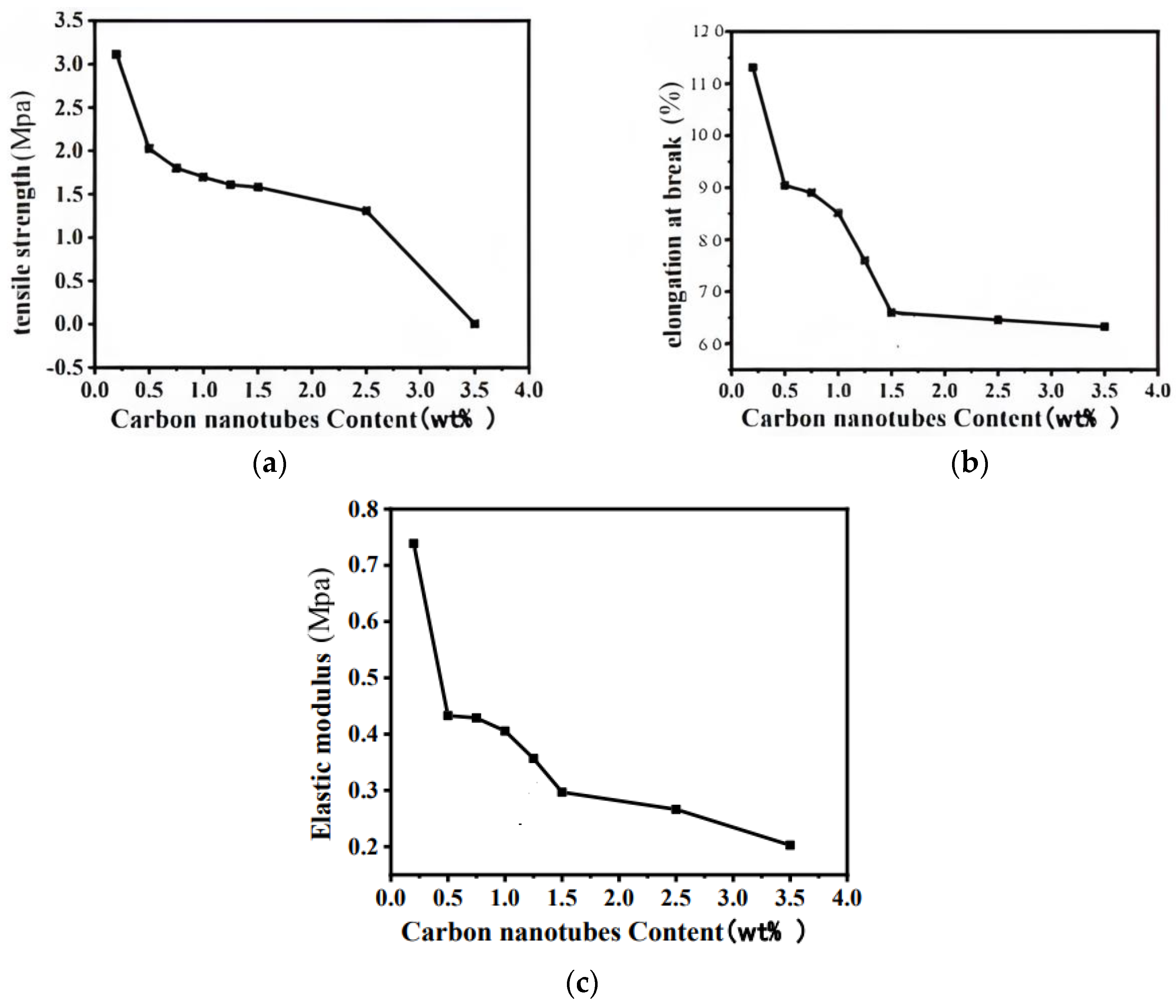

- Mechanical properties of LSR/CNT.

- (a)

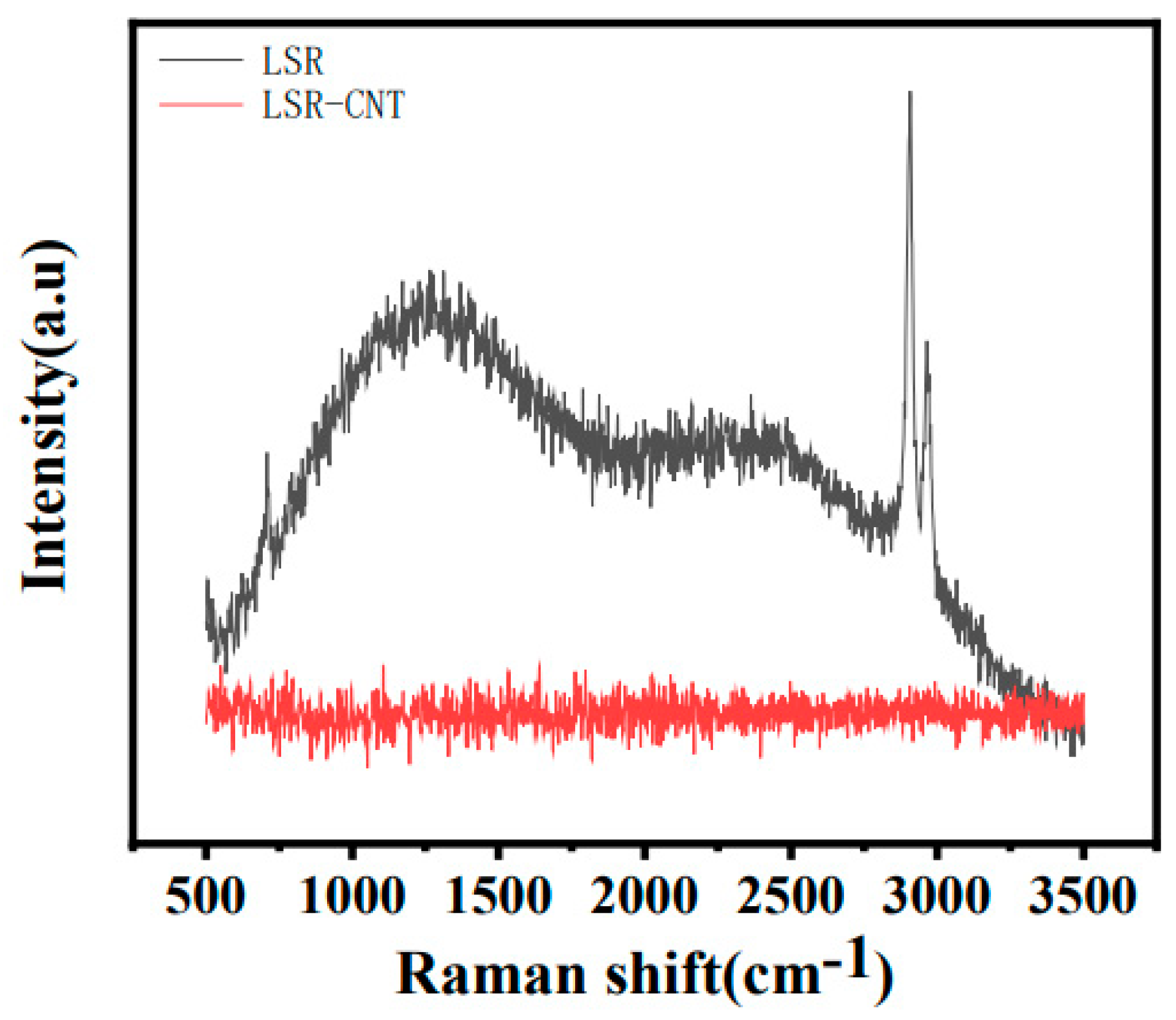

- Spectrum and heat resistance analysis of LSR/CNT.

- (1)

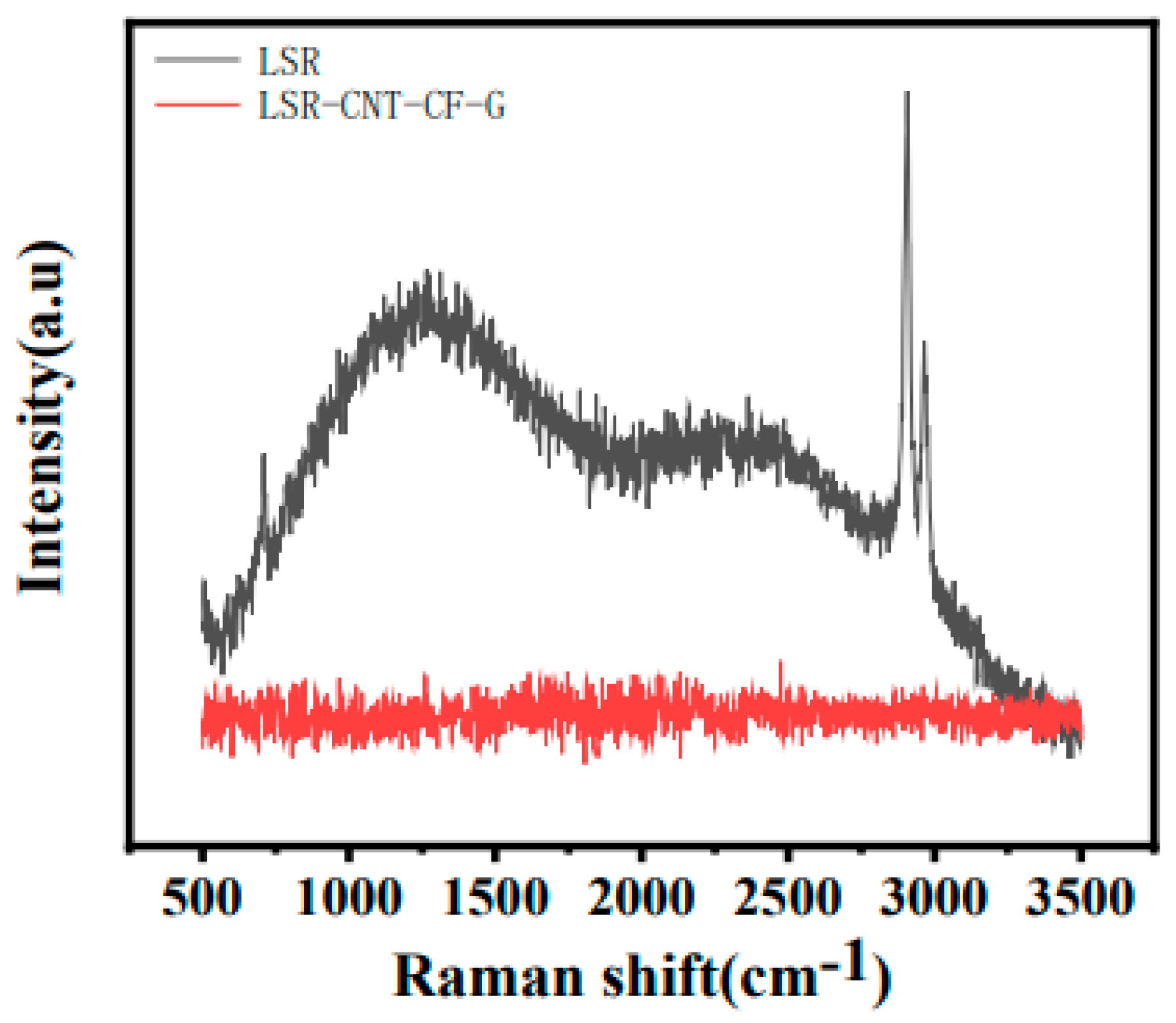

- Dispersion analysis

- (2)

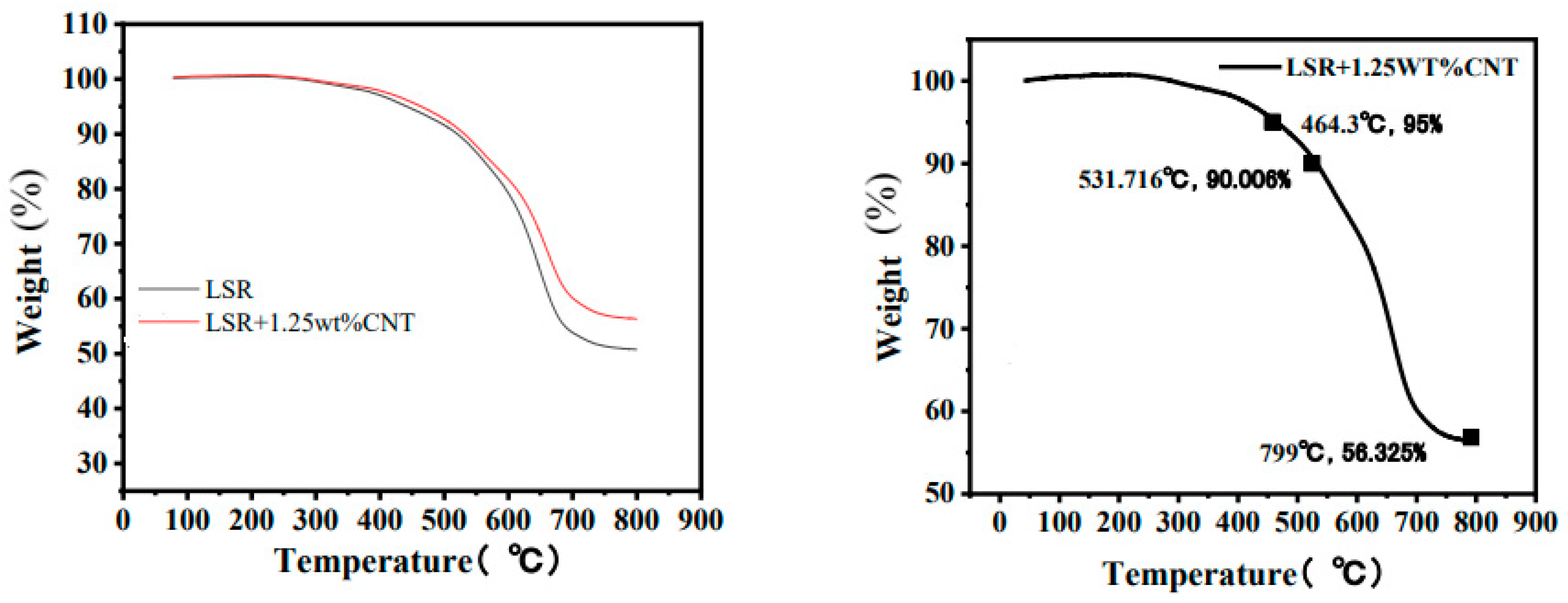

- Heat resistance

3.2. Properties of Blended Carbon Nano-Conductive Silicone Rubber

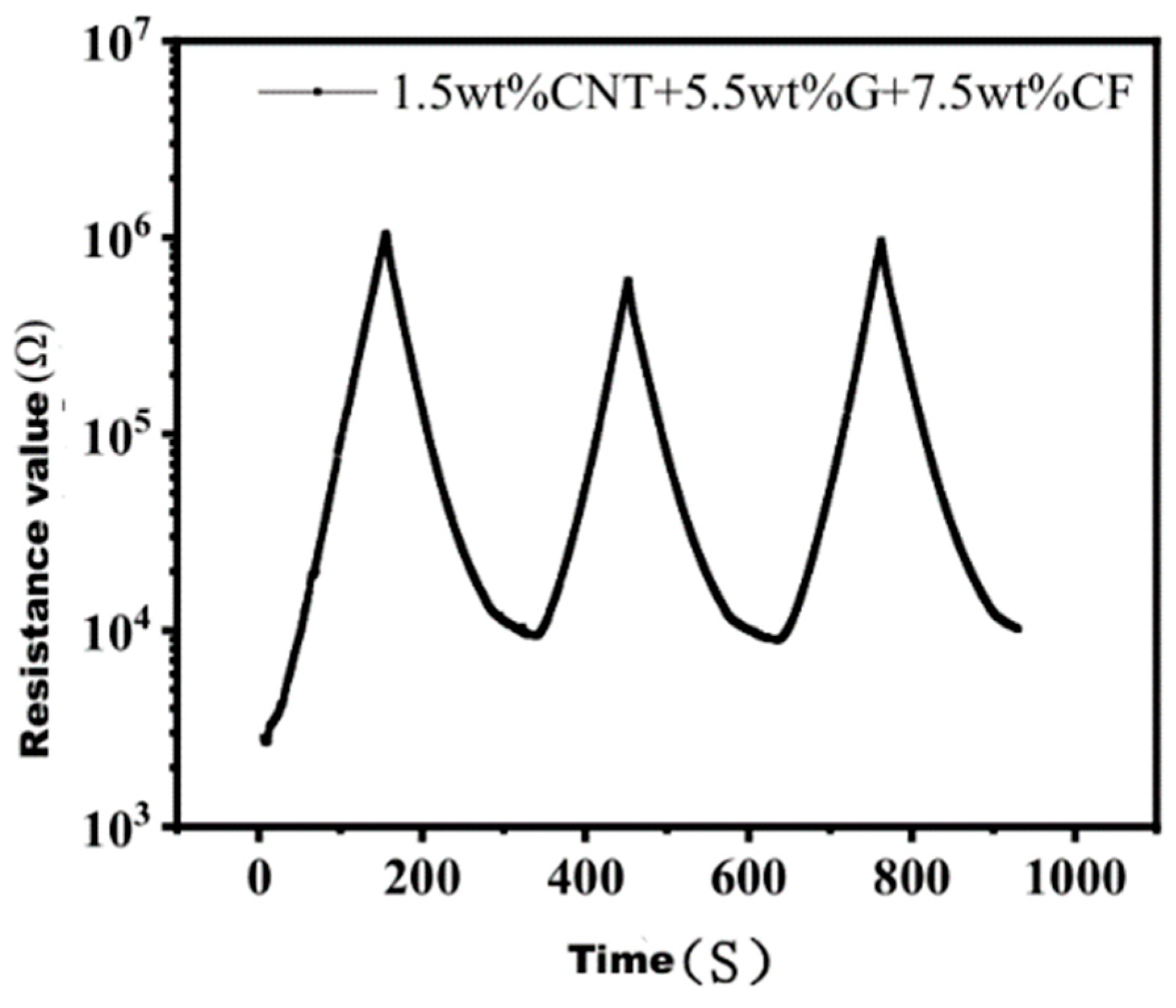

- (1)

- Analysis of the tensile sensitivity of LSR/CNT/CF/G.

- (2)

- Dispersion analysis of LSR/CNT/CF/G

- (3)

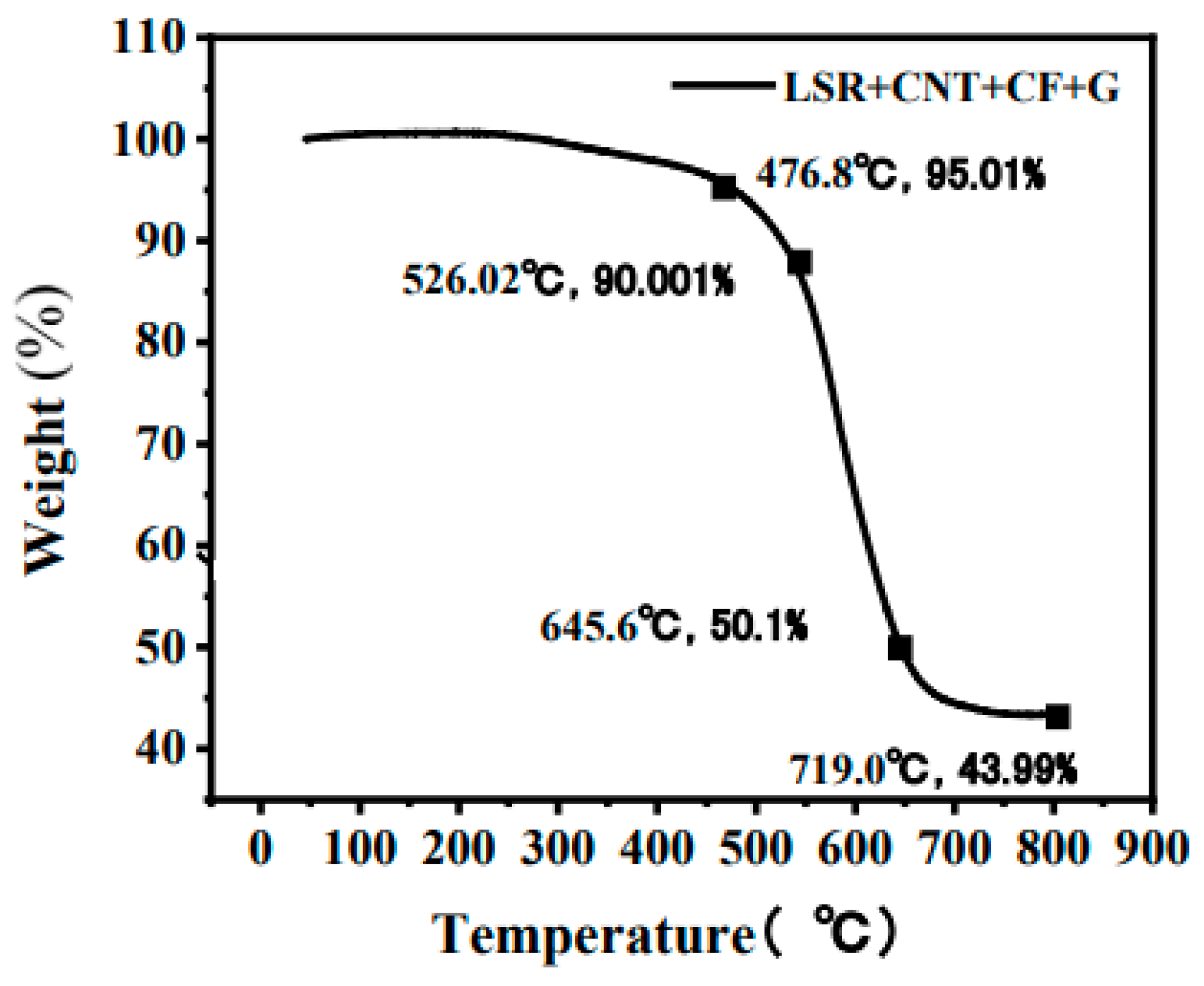

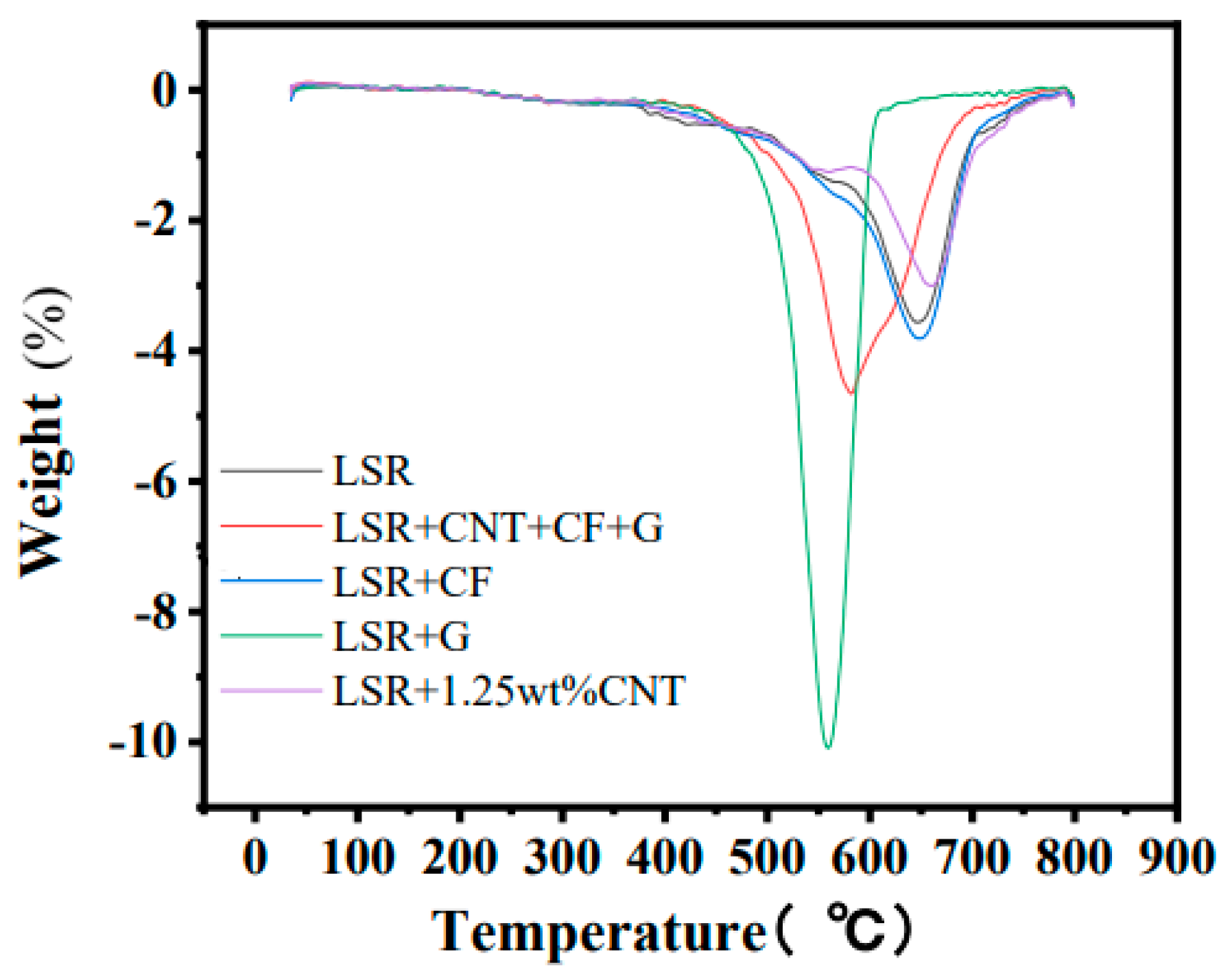

- Thermal stability analysis of the carbon-based nano-conductive silicone rubbers

- (4)

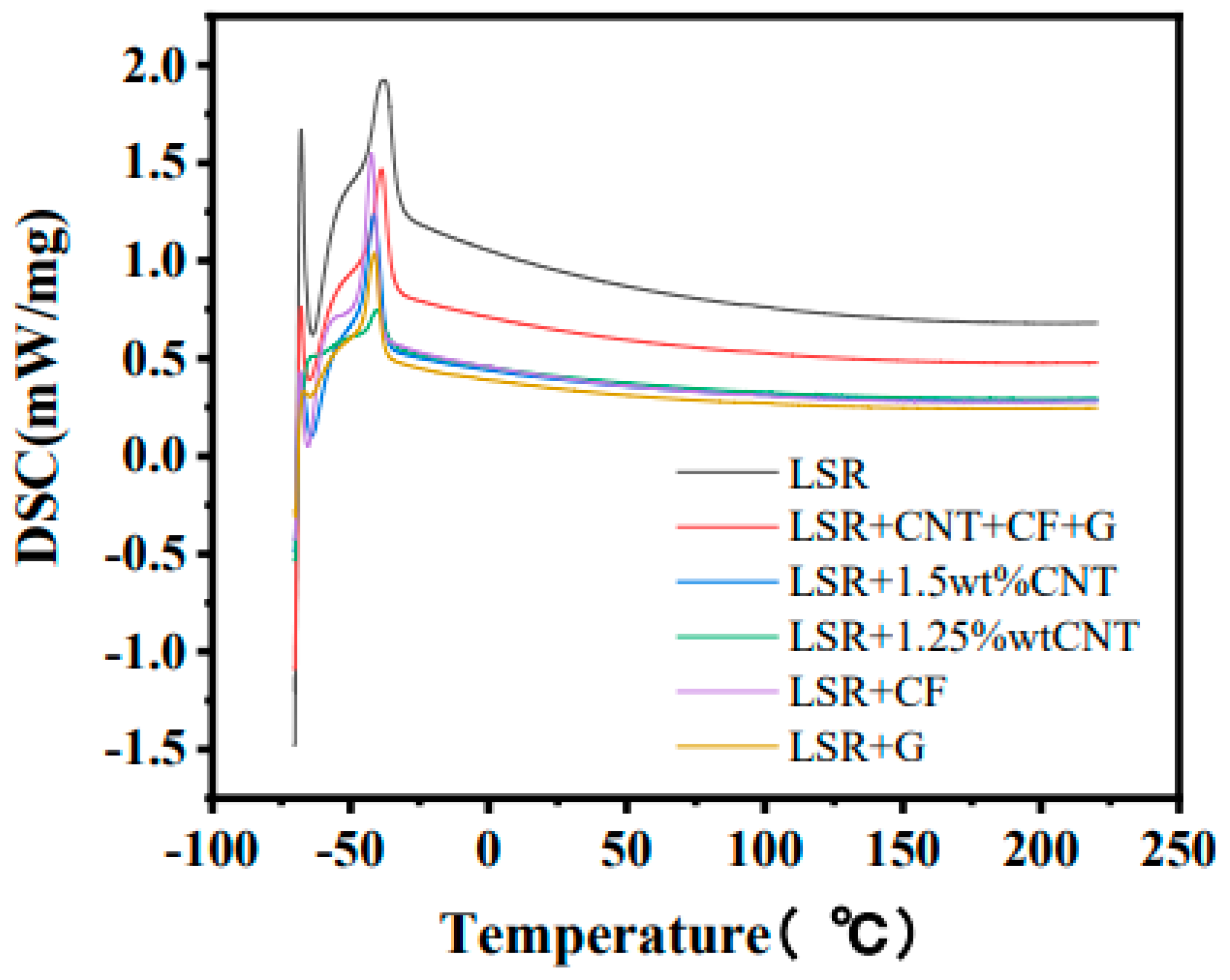

- Analysis of the glass transition temperature of LSR/CNT/CF/G.

- (5)

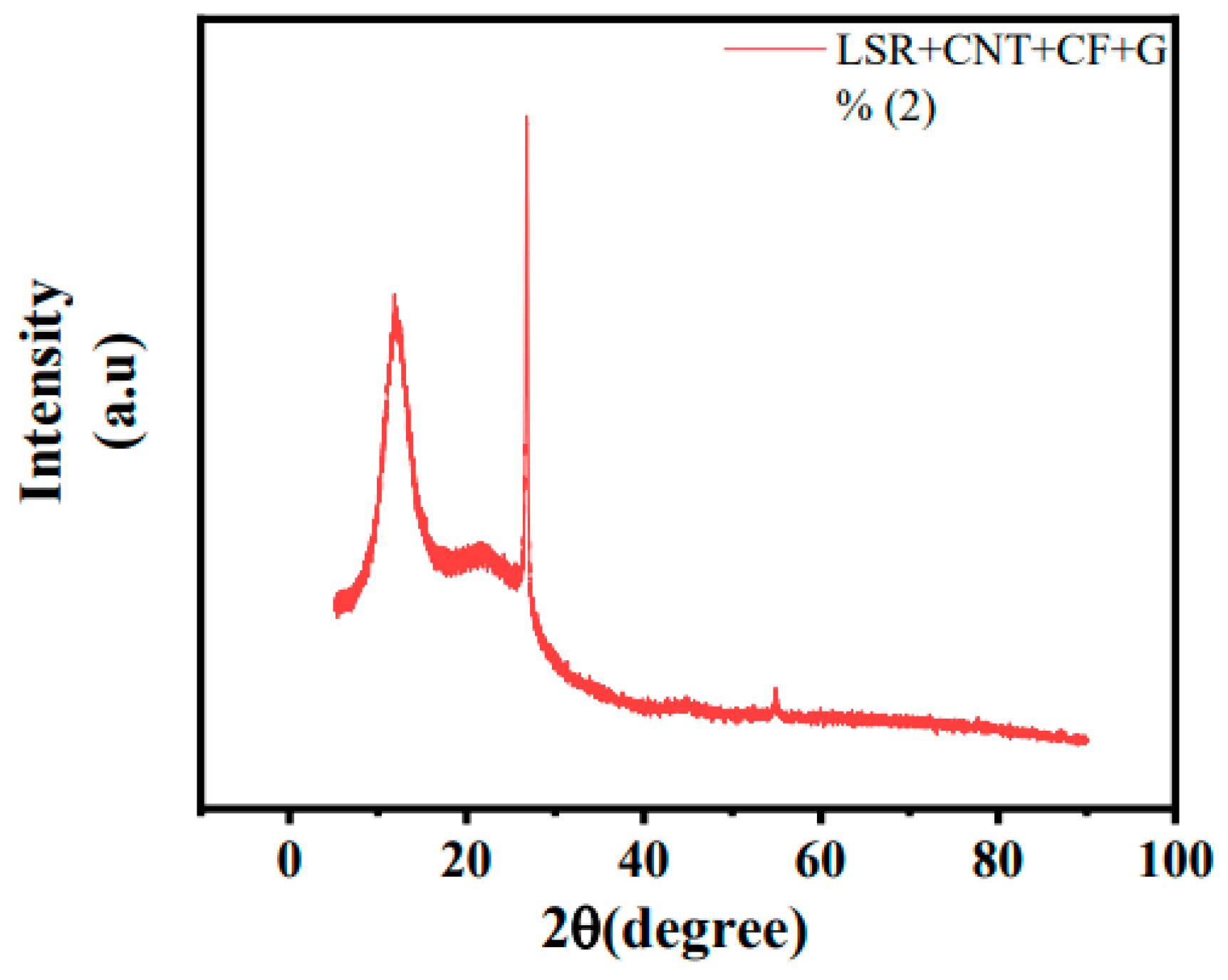

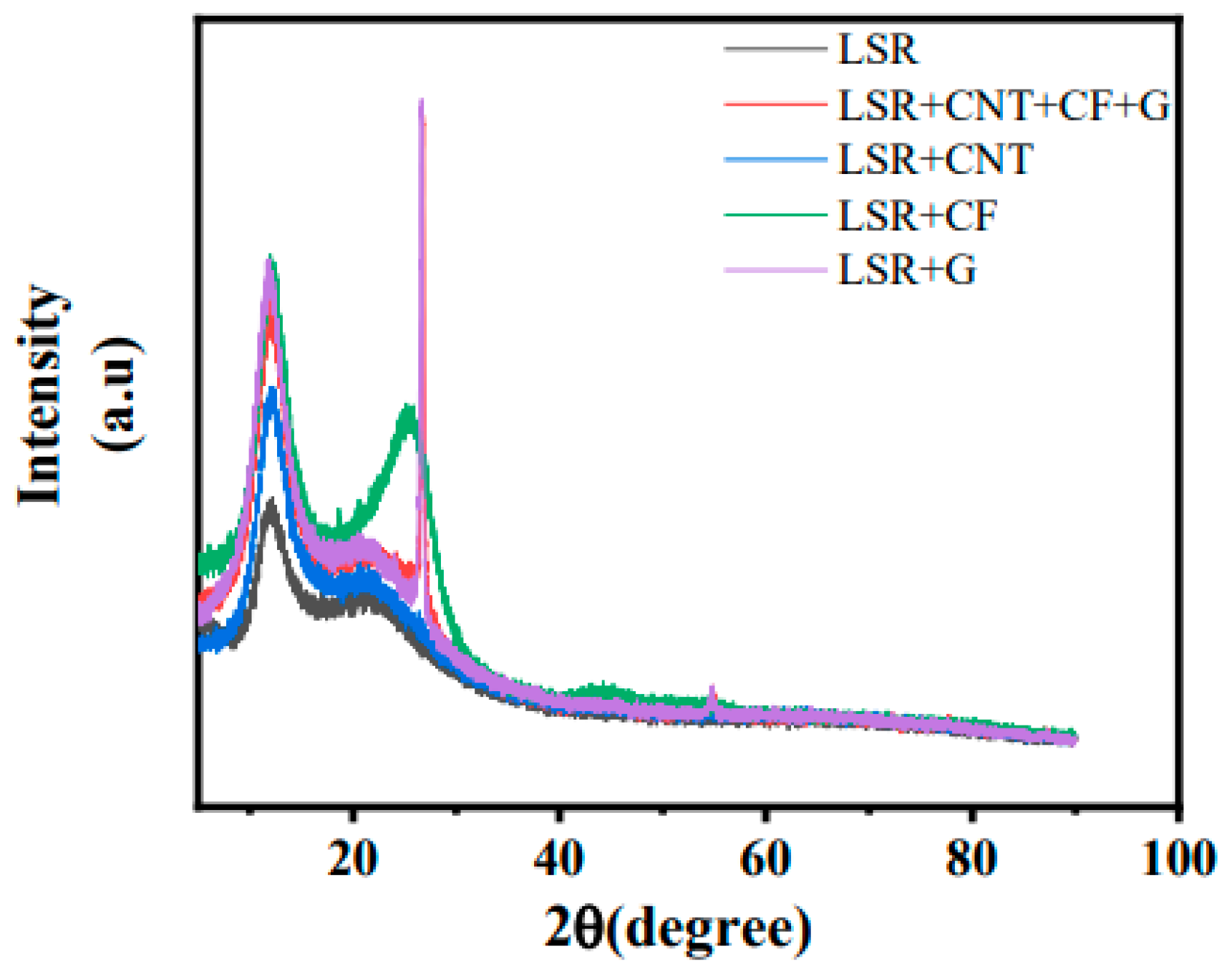

- Crystal structure analysis of the LSR/CNT/CF/G.

4. Conclusions

- (1)

- Raman spectrum analysis showed that, compared to single-filler nano-conductive silicone rubbers, the interfacial adhesion and dispersibility of blended carbon-based nano-conductive silicone rubber were better.

- (2)

- Thermogravimetric analysis showed that the heat resistance of LSR/CNT/CF/G was better than that of LSR/CF, LSR/G, LSR/CNT, and pure LSR, and the initial decomposition temperature reached 476.8 °C.

- (3)

- DSC analysis showed that the Tg of LSR/CNT/CF/G was similar to that of the single-filler nano-conductive silicone rubbers (around −50 °C), which can meet the working environment of most varistors.

- (4)

- XRD analysis showed that all the fillers were uniformly dispersed during ultrasonic dispersion and had strong interfacial forces.

- (5)

- The tensile conductivity test showed that the effective tensile rates of LSR/CF, LSR/G, and LSR/CNT were 100%, 140%, and 300%, respectively, and the maximum effective tensile rate of LSR/CNT/CF/G was 520%. In addition, the resistance fluctuation range of LSR/CNT/CF/G was smaller than that of the single-filler nano-conductive silicone rubbers, which has good resistance and pressure sensitivity characteristics.

- (1)

- Enrich the types of conductive fillers, carry out surface treatment or modification treatment on the fillers, and improve the process according to the performance of different fillers.

- (2)

- The fatigue strength and durability of conductive silicone rubber with mixed fillers were further investigated, which laid a foundation for the application of conductive silicone rubber in flexible sensors and other fields.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pei, Z.; Yu, Z.; Li, M.; Bai, L.; Wang, W.; Chen, H.; Yang, H.; Wei, D.; Yang, L. Self-healing and toughness cellulose nanocr ystals nanocomposite hydrogels for strain-sensitive wearable flexible sensor. Int. J. Biol. Macromol. 2021, 179, 324–332. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Shen, W.; Lv, D.; Chen, W.; Song, W.; Tan, R. An enhanced flexible room temperature ammonia gas sensor based on GP-PANI/PV DF multi-hierarchical nanocomposite film. Sens. Actuators B Chem. 2021, 334, 129630. [Google Scholar] [CrossRef]

- Yang, X.; Chen, S.; Shi, Y.; Fu, Z.; Zhou, B. A flexible highly sensiti ve capacitive pressure sensor. Sens. Actuators A Phys. 2021, 324, 12629. [Google Scholar] [CrossRef]

- Mao, R.; Yao, W.; Qadir, A.; Chen, W.; Gao, W.; Xu, Y.; Hu, H. 3-D graphene aerogel sphere-based flexible sensors for healthcare applications. Sens. Actuators A Phys. 2020, 312, 112144. [Google Scholar] [CrossRef]

- Moriche, R.; Jiménez-Suárez, A.; Sánchez, M.; Prolongo, S.; Ureña, A. Sensitivity, influence of the strain rate and reversibility of GNPs based multiscale composite materials for high sensitive strain sensors. Compos. Sci. Technol. 2018, 155, 100–107. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Farahani, M.; Faller, L.-M.; Zangl, H. Structural health monitoring of defective single lap adhesive joints using graphene nanoplatelets. J. Manuf. Process. 2020, 55, 119–130. [Google Scholar] [CrossRef]

- Moriche, R.; Sánchez, M.; Jiménez-Suárez, A.; Prolongo, S.; Ureña, A. Electrically conductive functionalized-GNP/epoxy based composites: From nanocomposite to multiscale glass fibre composite material. Compos. Part B Eng. 2016, 98, 49–55. [Google Scholar] [CrossRef]

- Pratik, P.; Pataniya, P.M.; Bhakhar Sanjay, A.; Tannarana, M.; Zankat, C.; Patel, V.; Solanki, G.K.; Patel, K.D.; Jha Prafulla, K.; Late Dattatray, J.; et al. Highly sensitiv e and flexible pressure sensor based on two-dimensional MoSe2 nanosheets for on line wrist pulse monitoring. J. Colloid Interface Sci. 2021, 584, 495–504. [Google Scholar]

- Xiao, W.; Lei, Y.; Xia, Z.; Chen, X.; Han, Y.; Nie, J. Effect of sil ver plating time on the properties of conductive silicone rubber filled with silvercoated carbonyl nickel powder. J. Alloys Compd. 2017, 724, 24–28. [Google Scholar] [CrossRef]

- Xue, Y.; Wang, H.; Li, X.; Chen, Y. Exceptionally thermally condu ctive and electrical insulating multilaminar aligned silicone rubber flexible composites with highly oriented and dispersed filler network by mechanical shearing. Compos. Part A Appl. Sci. Manuf. 2021, 144, 106336. [Google Scholar] [CrossRef]

- Song, Z.; Xia, Z.; Nie, J.; Tian, Z. Improving the electrical and electromagnetic shielding properties of conductive silicon rubber filled with Ni-coated carbon fibre by magnetic field. Plast. Rubber Compos. 2016, 45, 224–228. [Google Scholar] [CrossRef]

- Ding, D.; Huang, R.; Wang, X.; Zhang, S.; Wu, Y.; Zhang, X.-A.; Qin, G.; Liu, Z.; Zhang, Q.; Chen, Y. Thermally conductive silicone rubber composites with vertically oriented carbon fibers: A new perspective on the heat conduction mechanism. Chem. Eng. J. 2022, 441, 136104. [Google Scholar] [CrossRef]

- Wang, L.; Wang, W.; Fu, Y.; Wang, J.; Lvov, Y.; Liu, J.; Lu, Y.; Zhang, L. Enhanced Electrical and Mechanical Properties of Rubber/Graphene Film through Layer-by-layer Electrostatic Assembly Composites. Part B Eng. 2016, 90, 457–464. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, Y.; An, J.; Yuan, C.; Zhao, Y.; Xiang, Y.; Yang, J. Thermally conductive silicone composites modified by graphene-oxid e aerogel beads loaded with phase change materials as efficient heat sinks. Appl. Therm. Eng. 2021, 189, 116713. [Google Scholar] [CrossRef]

- Ge, T.; Zhang, M.; Tang, K.; Tang, H. Diisocyanate-modified gra phene oxide/hydroxyl-terminated silicone rubber composites for improved thermal conductivity. Mater. Chem. Phys. 2020, 252, 123250. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Pu, N.-W.; Liu, Y.-M.; Chen, L.-H.; Wu, C.-H.; Cheng, T.; Lin, M.-H.; Ger, M.-D.; Gong, Y.-J.; Peng, Y.-Y.; et al. Microwave absorption properties of holey graphene/silicon e rubber composites. Compos. Part B Eng. 2018, 135, 119–128. [Google Scholar] [CrossRef]

- Song, P.; Song, J.; Zhang, Y. Stretchable conductor based on carbon nanotu be/carbon black silicone rubber nanocomposites with highly mechanical, electrical properties and strain sensitivity. Compos. Part B Eng. 2020, 191, 107979. [Google Scholar] [CrossRef]

- Lin, J.-L.; Su, S.-M.; He, Y.-B.; Kang, F.-Y. Improving thermal and mechanical properties of the alumina filled silicone rubber composite by incorporating carbon nanotubes. New Carbon Mater. 2020, 35, 66–72. [Google Scholar] [CrossRef]

- Chen, Y.F.; Huang, M.L.; Cai, J.H.; Weng, Y.X.; Wang, M. Piezoresistive anisotropy in conductive silicon rubber/multi-walled carbon nanotube/nickel particle composites via alignment of nickel particles. Compos. Sci. Technol. 2022, 225, 109520. [Google Scholar] [CrossRef]

- Guo, Y.; Qiu, H.; Ruan, K.; Wang, S.; Zhang, Y.; Gu, J. Flexible and insulating silicone rubber composites with sandwich structure for thermal management and electromagnetic interference shielding. Compos. Sci. Technol. 2022, 219, 109253. [Google Scholar] [CrossRef]

- Imiela, M.; Anyszka, R.; Bieliński, D.M.; Pędzich, Z.; Zarzecka-Napierała, M.; Szumera, M. Effect of carbon fibers on thermal properties and mechanical strength of ceramizable composites based on silicone rubber. J. Therm. Anal. Calorim. 2016, 124, 197–203. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, X.; Li, Q.; He, J.; Hu, J. Synergistic effect of ZnO microspherical varistors and carbon fibers on nonlinear conductivity and mechanical properties of the silicone rubber-based material. Compos. Sci. Technol. 2017, 150, 187–193. [Google Scholar] [CrossRef]

- Xie, J.; Li, C.; Fu, Y.; Chen, Z.; Wang, X.; Qin, H.; Zhang, X.; Zhang, S.; Wang, S.; Xiong, C.; et al. Spherical boron nitride/pitch-based carbon fiber/silicone rubber composites for high thermal conductivity and excellent electromagnetic interference shielding performance. J. Appl. Polym. Sci. 2022, 139, e52734. [Google Scholar] [CrossRef]

- Deng, B.; Shi, Y.; Zhang, X.; Ma, W.; Liu, H.; Gong, C. Thermally Conductive and Electrically Insulated Silicone Rubber Composites Incorporated with Boron Nitride- Multilayer Graphene Hybrid Nanofiller. Nanomaterials 2022, 12, 2335. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, N.; Manikkavel, A.; Park, S.-S. Efficacy of graphitic allotrope’s surface area in silicone rubber based composites for reverse piezo-electric actuation: Nano effect. Sens. Actuators A Phys. 2022, 336, 113411. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. The mechanical behavior of CNT reinforced nanocomposites assuming imperfect interfacial bonding between matrix and nanoparticles and percolation of interphase regions. Compos. Sci. Technol. 2017, 144, 18–25. [Google Scholar] [CrossRef]

- Ouyang, Y.; Yang, Z.; Long, T.; Tian, H.; Bai, L.; Li, X.; Yuan, F. Preparation of branched Al2O3 and its synergistic effect with carbon nanotubes on the enhancement of thermal conductive and electrical insulation properties of silicone rubber composites. Mater. Today Commun. 2023, 34, 105239. [Google Scholar] [CrossRef]

- Hu, Y.-J.; Zhang, H.-Y.; Li, F.; Cheng, X.-L.; Chen, T.-L. Investigation into electrical conductivity and electromagnetic interference shielding effectiveness of silicone rubber filled with Ag-coated cenosphere particles. Polym. Test. 2010, 29, 609–612. [Google Scholar] [CrossRef]

| Name | Manufacturer | Model |

|---|---|---|

| Mechanical stirrer | Suzhou Yinganyang Instrument Co., Ltd., Suzhou, China | JJ-1 |

| Ultrasonic disperser | Ningbo Xinzhi Biotechnology Co., Ltd., Ningbo, China | Scientz-750F |

| Electric blast drying oven | Shanghai Yiheng Technology Co., Ltd., Shanghai, China | BPG-9050BH |

| Electrometer | Tektronix Technology Co., Ltd., Beaverton, OR, USA | Keithley 6514 |

| Scanning electron microscope | Hitachi, Tokyo, Japan | Hitachi SU8010 |

| X-ray diffractometer | PANalytical Company, Malvern, UK | Empyrean |

| Raman spectrometer | Renishaw company, Wotton-under-Edge, UK | RM1000 |

| Thermogravimetric analyzer | German NETZSCH Instrument Manufacturing Co., Ltd., Selb, Germany | TG 209 F1 |

| Instron Electronics Universal Materials Testing Machine | Instron Corporation, Norwood, MA, USA | 68TM-10 |

| Carbon Fiber Content wt% | Volume Resistivity Ω·cm | Surface Resistance Ω |

|---|---|---|

| 1.5 | 2.5 × 1011 | 7.6 × 1012 |

| 3.5 | 1.8 × 109 | 5.4 × 1010 |

| 5.5 | 9.5 × 104 | 2.8 × 105 |

| 7.5 | 7.0 × 104 | 2.9 × 105 |

| 8.5 | 8.7 × 103 | 2.6 × 104 |

| 10.5 | 4.8 × 103 | 8.7 × 103 |

| 11.5 | 2.9 × 103 | 6.3 × 103 |

| 15 | 1.8 × 103 | 4.8 × 103 |

| Carbon Fiber Content wt% | 1.5 | 3.5 | 5.5 | 7.5 | 8.5 | 10.5 | 11.5 | 15 | 25 |

| Tensile-Strength /Mpa | 2.81 | 2.26 | 2.20 | 2.12 | 2.02 | 1.99 | 1.99 | 1.91 | 1.81 |

| Elongation at Break /% | 111.5 | 103.4 | 100 | 90.6 | 88.2 | 88.3 | 88.9 | 86.8 | 85.9 |

| Elastic Modulus /Mpa | 0.67 | 0.46 | 0.37 | 0.38 | 0.40 | 0.31 | 0.35 | 0.21 | 0.36 |

| Graphene Content /wt% | 1.5 | 2.5 | 3.5 | 4.5 | 5.5 | 7.5 | 8.5 | 9.5 |

| volume Resistivity /Ω·cm | 4.6 × 108 | 2.3 × 108 | 5.7 × 107 | 2.2 × 107 | 8.7 × 104 | 1.6 × 104 | 8.7 × 103 | 2.0 × 103 |

| surface Resistance /Ω | 1.3 × 1010 | 7.5 × 109 | 1.7 × 109 | 6.0 × 108 | 2.4 × 106 | 5.2 × 105 | 2.6 × 105 | 6.1 × 104 |

| Graphene Content wt% | 1.5 | 2.5 | 3.5 | 5.5 | 7.5 | 8.5 | 9.5 | 11.5 |

| Tensile Strength /Mpa | 1.26387 | 1.1018 | 1.08860 | 0.07479 | 0.03127 | 0.24404 | 0.00917 | 0.00759 |

| Elongation at Break /% | 103.2555 | 88.6389 | 85.4772 | 67.3561 | 70.4911 | 71.3661 | 58.9406 | 53.29772 |

| Elastic Modulus /Mpa | 0.21906 | 0.18840 | 0.18864 | 0.18089 | 0.10840 | 0.11815 | 0.11145 | 0.10566 |

| Carbon Nanotube Content wt% | 0.2 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2.5 |

| Volume Resistivity Ω·cm | 0.83 × 1010 | 1.61 × 107 | 1.55 × 107 | 4.32 × 104 | 1.34 × 104 | 0.50 × 104 | 5.1 × 103 |

| Surface Resistance Ω | 1.33 × 1011 | 1.71 × 1010 | 8.01 × 108 | 5.16 × 107 | 1.00 × 106 | 9.87 × 104 | 7.00 × 104 |

| Carbon Nanotube Content wt% | 0.2 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2.5 | 3.5 |

| Tensile Strength /Mpa | 3.10 | 2.02 | 1.80 | 1.69 | 1.60 | 1.58 | 1.30 | 0.004 |

| Elongation at Break /% | 113.0 | 90.4 | 89.0 | 85.0 | 75.9 | 65.9 | 64.5 | 63.2 |

| Elastic Modulus /Mpa | 0.738 | 0.43 | 0.42 | 0.40 | 0.35 | 0.29 | 0.26 | 0.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mei, S.; Wang, J.; Wan, J.; Wu, X. Preparation Methods and Properties of CNT/CF/G Carbon-Based Nano-Conductive Silicone Rubber. Appl. Sci. 2023, 13, 6726. https://doi.org/10.3390/app13116726

Mei S, Wang J, Wan J, Wu X. Preparation Methods and Properties of CNT/CF/G Carbon-Based Nano-Conductive Silicone Rubber. Applied Sciences. 2023; 13(11):6726. https://doi.org/10.3390/app13116726

Chicago/Turabian StyleMei, Shunqi, Jian Wang, Jitao Wan, and Xichun Wu. 2023. "Preparation Methods and Properties of CNT/CF/G Carbon-Based Nano-Conductive Silicone Rubber" Applied Sciences 13, no. 11: 6726. https://doi.org/10.3390/app13116726

APA StyleMei, S., Wang, J., Wan, J., & Wu, X. (2023). Preparation Methods and Properties of CNT/CF/G Carbon-Based Nano-Conductive Silicone Rubber. Applied Sciences, 13(11), 6726. https://doi.org/10.3390/app13116726