Energy and Environmental Performance Comparison of Heat Pump Systems Working with Alternative Refrigerants

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

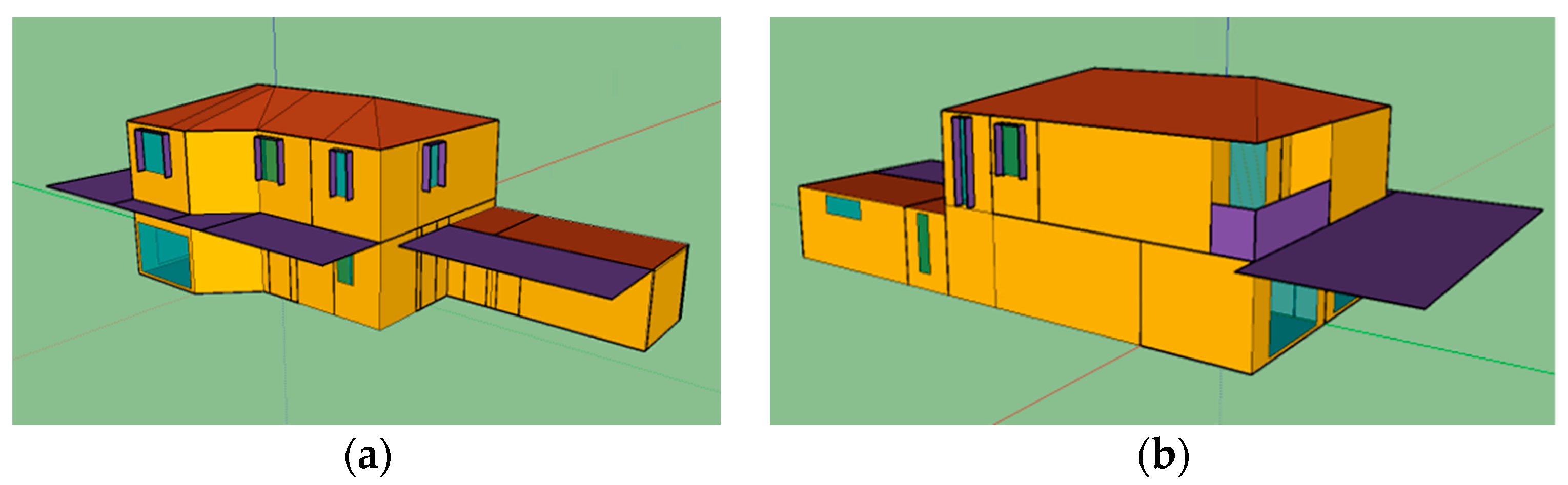

2.1. The Building

2.2. The HVAC System

3. Results and Discussion

3.1. Key Performance Indicators (KPIs)

3.2. Monthly Energy Performance

3.3. Seasonal Energy Performance and TEWI

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| L | annual refrigerant leak factor (%) |

| m | refrigerant charge (kg) |

| n | heat pump operating life (year) |

| Eel | electric energy (kWh) |

| Q | thermal energy (kWh) |

| Abbreviations | |

| APF | annual performance factor |

| ASHP | air-source heat pump |

| BHE | borehole heat exchanger |

| COP | coefficient of performance |

| DHW | domestic hot water |

| EER | energy efficiency ratio |

| GCHP | ground-coupled heat pump |

| GHG | greenhouse gas emission |

| GWP | global warming potential |

| HVAC | heating, ventilation and air-conditioning |

| KPI | key performance indicator |

| ODP | ozone depletion potential |

| SCOP | seasonal coefficient of performance |

| SEER | seasonal energy efficiency ratio |

| TEWI | total equivalent warming impact (kgCO2) |

| Greek symbols | |

| αrec | refrigerant end-of-life recovery factor (%) |

| β | emission factor of grid electricity (gCO2/kWh) |

| Subscripts | |

| c | cooling |

| compr | compressor |

| cool | cooling season |

| h | heating |

| heat | heating season |

| i | i-th month |

| n | net |

| pump | circulating pump |

References

- European Commission. 2030 Climate & Energy Framework; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Dongellini, M.; Naldi, C.; Morini, G.L. Seasonal performance evaluation of electric air-to-water heat pump systems. Appl. Therm. Eng. 2015, 90, 1072–1081. [Google Scholar] [CrossRef]

- Kaygusuz, K.; Ayhan, T. Experimental and theoretical investigation of combined solar heat pump system for residential heating. Energy Convers. Manag. 1999, 40, 1377–1396. [Google Scholar] [CrossRef]

- Lazzarin, R.M. Dual source heat pump system: Operation and performance. Energy Build. 2012, 52, 77–85. [Google Scholar] [CrossRef]

- Montero, O.; Brischoux, P.; Callegari, S.; Fraga, C.; Rüetschi, M.; Vionnet, E.; Calame, N.; Rognon, F.; Patel, M.; Hollmuller, P. Large Air-to-Water Heat Pumps for Fuel-Boiler Substitution in Non-Retrofitted Multi-Family Buildings—Energy Performance, CO2 Savings, and Lessons Learned in Actual Conditions of Use. Energies 2022, 15, 5033. [Google Scholar] [CrossRef]

- Al-Sayyab, A.K.S.; Navarro-Esbrí, J.; Barragan-Cervera, A.; Kim, S.; Mota-Babiloni, A. Comprehensive experimental evaluation of R1234yf-based low GWP working fluids for refrigeration and heat pumps. Energy Convers. Manag. 2022, 258, 115378. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, F.; Tian, C.; Jia, L.; Wu, W. Experimental comparisons on a gas engine heat pump using R134a and low-GWP refrigerant R152a. Int. J. Refrig. 2020, 115, 73–82. [Google Scholar] [CrossRef]

- United Nations. The Montreal Protocol on Substances that Deplete the Ozone Layer; United Nations: Montreal, QC, Canada, 1987. [Google Scholar]

- Rigby, M.; Prinn, R.G.; O’Doherty, S.; Miller, B.R.; Ivy, D.; Mühle, J.; Harth, C.M.; Salameh, P.K.; Arnold, T.; Weiss, R.F.; et al. Recent and future trends in synthetic greenhouse gas radiative forcing. Geophys. Res. Lett. 2014, 41, 2623–2630. [Google Scholar] [CrossRef] [Green Version]

- O’Doherty, S.; Rigby, M.; Mühle, J.; Ivy, D.J.; Miller, B.R.; Young, D.; Simmonds, P.G.; Reimann, S.; Vollmer, M.K.; Krummel, P.B.; et al. Global emissions of HFC-143a (CH3CF3) and HFC-32 (CH2F2) from in situ and air archive atmospheric observations. Atmos. Chem. Phys. 2014, 14, 9249–9258. [Google Scholar] [CrossRef] [Green Version]

- Velders, G.J.M.; Fahey, D.W.; Daniel, J.S.; McFarland, M.; Andersen, S.O. The large contribution of projected HFC emissions to future climate forcing. Proc. Natl. Acad. Sci. USA 2009, 106, 10949–10954. [Google Scholar] [CrossRef] [Green Version]

- United Nations. Kyoto Protocol to the United Nations Framework Convention on Climate Change; United Nations: Kyoto, Japan, 1997. [Google Scholar]

- European Parliament. Regulation (EU) N° 517/2014 of the European Parliament and of the Council of 16 April 2014 on Fluorinated Greenhouse Gases and Repealing Regulation (EC) No 842/2006; European Parliament: Brussels, Belgium, 2014. [Google Scholar]

- United Nations. Amendment to the Montreal Protocol on Substances that Deplete the Ozone Layer; United Nations: Kigali, Rwanda, 2016. [Google Scholar]

- Yang, Z.; Feng, B.; Ma, H.; Zhang, L.; Duan, C.; Liu, B.; Zhang, Y.; Chen, S.; Yang, Z. Analysis of lower GWP and flammable alternative refrigerants. Int. J. Refrig. 2021, 126, 12–22. [Google Scholar] [CrossRef]

- Shen, B.; Ally, M.R. Energy and Exergy Analysis of Low-Global Warming Potential Refrigerants as Replacement for R410A in Two-Speed Heat Pumps for Cold Climates. Energies 2020, 13, 5666. [Google Scholar] [CrossRef]

- Panato, V.H.; Marcucci Pico, D.F.; Bandarra Filho, E.P. Experimental evaluation of R32, R452B and R454B as alternative refrigerants for R410A in a refrigeration system. Int. J. Refrig. 2022, 135, 221–230. [Google Scholar] [CrossRef]

- Sieres, J.; Ortega, I.; Cerdeira, F.; Álvarez, E. Drop-in performance of the low-GWP alternative refrigerants R452B and R454B in an R410A liquid-to-water heat pump. Appl. Therm. Eng. 2021, 182, 116049. [Google Scholar] [CrossRef]

- Yu, B.; Ouyang, H.; Shi, J.; Liu, W.; Chen, J. Evaluation of low-GWP and mildly flammable mixtures as new alternatives for R410A in air-conditioning and heat pump system. Int. J. Refrig. 2021, 121, 95–104. [Google Scholar] [CrossRef]

- Ghanbarpour, M.; Mota-Babiloni, A.; Badran, B.E.; Khodabandeh, R. Theoretical Global Warming Impact Evaluation of Medium and High Temperature Heat Pumps Using Low GWP Refrigerants. Appl. Sci. 2021, 11, 7123. [Google Scholar] [CrossRef]

- Kong, X.; Zhang, Y.; Nie, J. A New Mixture Refrigerant for Space Heating Air Source Heat Pump: Theoretical Modelling and Performance Analysis. Appl. Sci. 2018, 8, 622. [Google Scholar] [CrossRef] [Green Version]

- Bellos, E.; Tzivanidis, C. Investigation of the Environmentally-Friendly Refrigerant R152a for Air Conditioning Purposes. Appl. Sci. 2019, 9, 119. [Google Scholar] [CrossRef] [Green Version]

- Devecioğlu, A.G. Seasonal performance assessment of refrigerants with low GWP as substitutes for R410A in heat pump air conditioning devices. Appl. Therm. Eng. 2017, 125, 401–411. [Google Scholar] [CrossRef]

- Bobbo, S.; Fedele, L.; Curcio, M.; Bet, A.; De Carli, M.; Emmi, G.; Poletto, F.; Tarabotti, A.; Mendrinos, D.; Mezzasalma, G.; et al. Energetic and Exergetic Analysis of Low Global Warming Potential Refrigerants as Substitutes for R410A in Ground Source Heat Pumps. Energies 2019, 12, 3538. [Google Scholar] [CrossRef] [Green Version]

- Inter-Ministerial Decree of 26th June 2015. Application of Methodologies for the Energy Calculation and Definition of Prescriptions and Minimum Requirements for Buildings; Ministero delle Imprese e del Made in Italy: Rome, Italy, 2022. Available online: https://www.mimit.gov.it (accessed on 15 June 2023). (In Italian)

- TEES company, TRNSYS 18: A Transient System Simulation Program. Available online: http://www.trnsys.com (accessed on 15 June 2023).

- Dongellini, M.; Morini, G.L. On-off cycling losses of reversible air-to-water heat pump systems as a function of the unit power modulation capacity. Energy Convers. Manag. 2019, 196, 966–978. [Google Scholar] [CrossRef]

- BS EN 13779-Ventilation for Non-Residential Buildings-Performance Requirements for Ventilation and Room-Conditioning Systems; British Standards Institution (BSI): London, UK, 2007.

- ANSI/ASHRAE Standard 34-2019; Designation and Safety Classification of Refrigerants; American Society of Heating. Refrigerating and Air-Conditioning Engineers Inc.: Atlanta, GA, USA, 2019.

- UNI EN 14825:2022; Air Conditioners, Liquid Chilling Packages and Heat Pumps, with Electrically Driven Compressors, for Space Heating and Cooling, Commercial and Process Cooling—Testing and Rating at Part Load Conditions and Calculation of Seasonal Performance. UNI (Ente Italiano di Normazione): Rome, Italy, 2022.

- UNI EN 378-1:2021; Refrigerating Systems and Heat Pumps—Safety and Environmental Requirements—Part 1: Basic Requirements, Definitions, Classification and Selection Criteria. UNI (Ente Italiano di Normazione): Rome, Italy, 2021.

- Bjønness, K.L.; Gustafsson, T.; Ishikawa, J.; Maione, M. Emissions of Fluorinated Substitutes for Ozone Depleting Substances. In 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Bern, Switzerland, 2019; Volume 3, p. 7.32. Available online: https://www.ipcc-nggip.iges.or.jp/public/2019rf/pdf/3_Volume3/19R_V3_Ch07_ODS_Substitutes.pdf (accessed on 15 June 2023).

- ISPRA. 363/2022. Efficiency and Decarbonization Indexes of the National Energy System and of the Electric Sector; ISPRA: Rome, Italy, 2022; (In Italian). Available online: https://www.isprambiente.gov.it/files2022/pubblicazioni/rapporti/r363-2022.pdf (accessed on 15 June 2023).

- Naldi, C.; Zanchini, E. A new numerical method to determine isothermal g-functions of borehole heat exchanger fields. Geothermics 2019, 77, 278–287. [Google Scholar] [CrossRef]

- Emmi, G.; Zarrella, A.; De Carli, M.; Donà, M.; Galgaro, A. Energy performance and cost analysis of some borehole heat exchanger configurations with different heat-carrier fluids in mild climates. Geothermics 2017, 65, 158–169. [Google Scholar] [CrossRef]

| Refrigerant | R-410A | R-454B |

|---|---|---|

| Composition (w/w) | R-32: 50% R-125: 50% | R-32: 68.9% HFO-1234yf: 31.1% |

| GWP | 2088 | 457 |

| ODP | 0 | 0 |

| Safety class | A1 | A2L |

| Molar weight (kg/kmol) | 72.6 | 62.6 |

| Critical temperature (°C) | 71.3 | 78.1 |

| Critical pressure (kPa) | 4901 | 5334 |

| Glide (K) | 0.1 | 1.3 |

| Refrigerant | R-410A | R-454B | ||

|---|---|---|---|---|

| Heat pump typology | GCHP | ASHP | GCHP | ASHP |

| Qh (kWh) | 5280 | 5203 | 5241 | 5145 |

| Qc (kWh) | 2435 | 2443 | 2438 | 2435 |

| Eel,comp,heat (kWh) | 980 | 1162 | 992 | 1166 |

| Eel,comp,cool (kWh) | 285 | 398 | 295 | 421 |

| Eel,pump,heat (kWh) | 148 | 66 | 159 | 68 |

| Eel,pump,cool (kWh) | 87 | 31 | 88 | 32 |

| SCOPn | 5.39 | 4.48 | 5.28 | 4.41 |

| SCOP | 4.68 | 4.24 | 4.55 | 4.17 |

| SEERn | 8.53 | 6.14 | 8.26 | 5.79 |

| SEER | 6.54 | 5.70 | 6.36 | 5.53 |

| APFn | 6.10 | 4.90 | 5.97 | 4.78 |

| APF | 5.14 | 4.62 | 5.00 | 4.53 |

| Direct GHG emissions (kgCO2) | 3383 | 3383 | 740 | 740 |

| Indirect GHG emissions (kgCO2) | 5738 | 6338 | 5869 | 6453 |

| TEWI (kgCO2) | 9120 | 9721 | 6609 | 7193 |

| Year | 2025 | 2030 | 2035 | 2040 | 2045 | 2050 |

|---|---|---|---|---|---|---|

| β [gCO2 kWh−1] | 216.8 | 170.9 | 127.5 | 86.7 | 38.3 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dongellini, M.; Natale, C.; Naldi, C.; Rossi di Schio, E.; Valdiserri, P.; Morini, G.L. Energy and Environmental Performance Comparison of Heat Pump Systems Working with Alternative Refrigerants. Appl. Sci. 2023, 13, 7238. https://doi.org/10.3390/app13127238

Dongellini M, Natale C, Naldi C, Rossi di Schio E, Valdiserri P, Morini GL. Energy and Environmental Performance Comparison of Heat Pump Systems Working with Alternative Refrigerants. Applied Sciences. 2023; 13(12):7238. https://doi.org/10.3390/app13127238

Chicago/Turabian StyleDongellini, Matteo, Christian Natale, Claudia Naldi, Eugenia Rossi di Schio, Paolo Valdiserri, and Gian Luca Morini. 2023. "Energy and Environmental Performance Comparison of Heat Pump Systems Working with Alternative Refrigerants" Applied Sciences 13, no. 12: 7238. https://doi.org/10.3390/app13127238