Numerical Study of Turbulent Flows over a NACA 0012 Airfoil: Insights into Its Performance and the Addition of a Slotted Flap

Abstract

1. Introduction

Novelty and Theory

2. Model Description

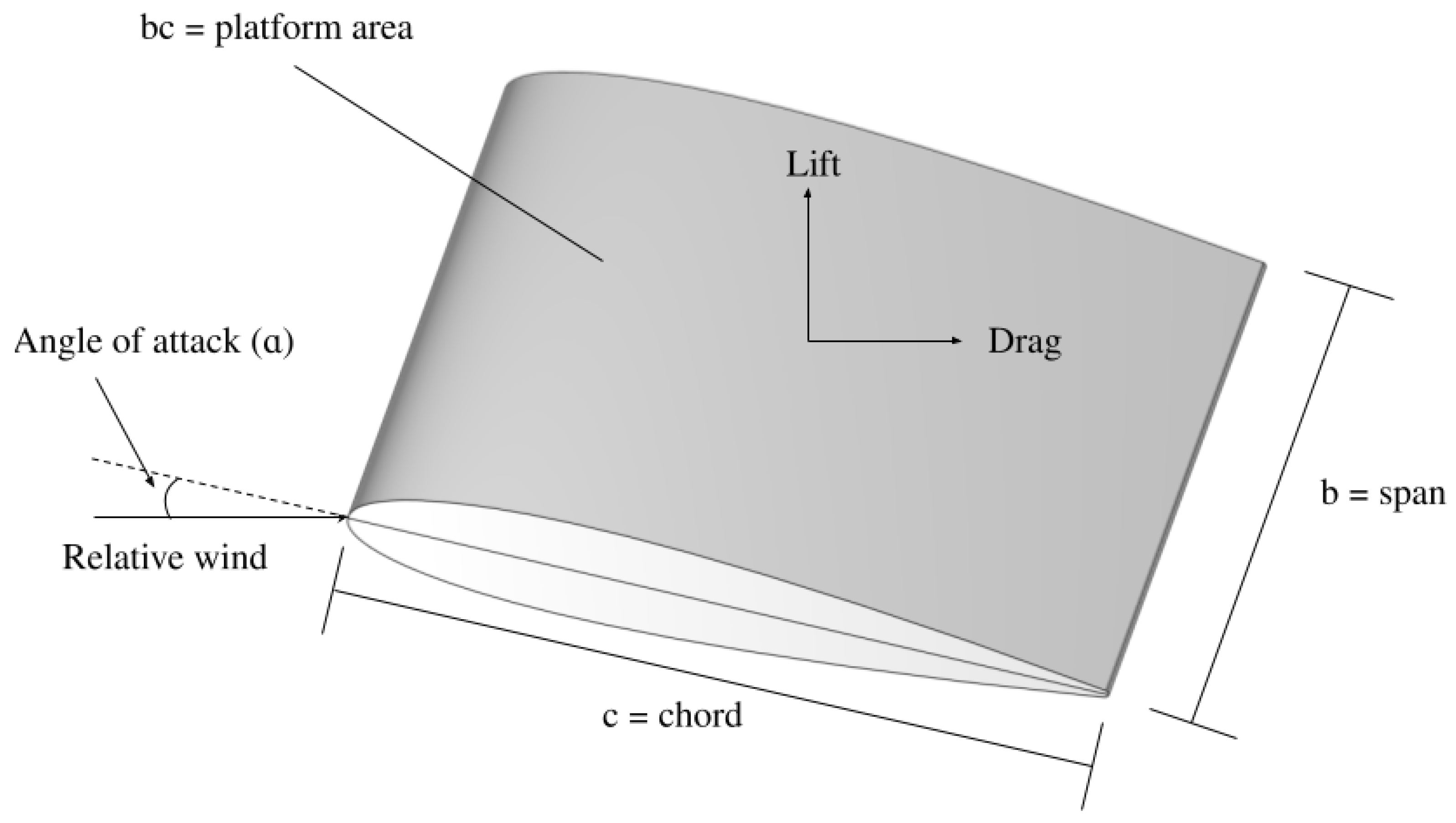

2.1. Physical Model

Performance Metrics

2.2. Turbulent Flow Modeling

Wall Velocity Profile

2.3. Numerical Model

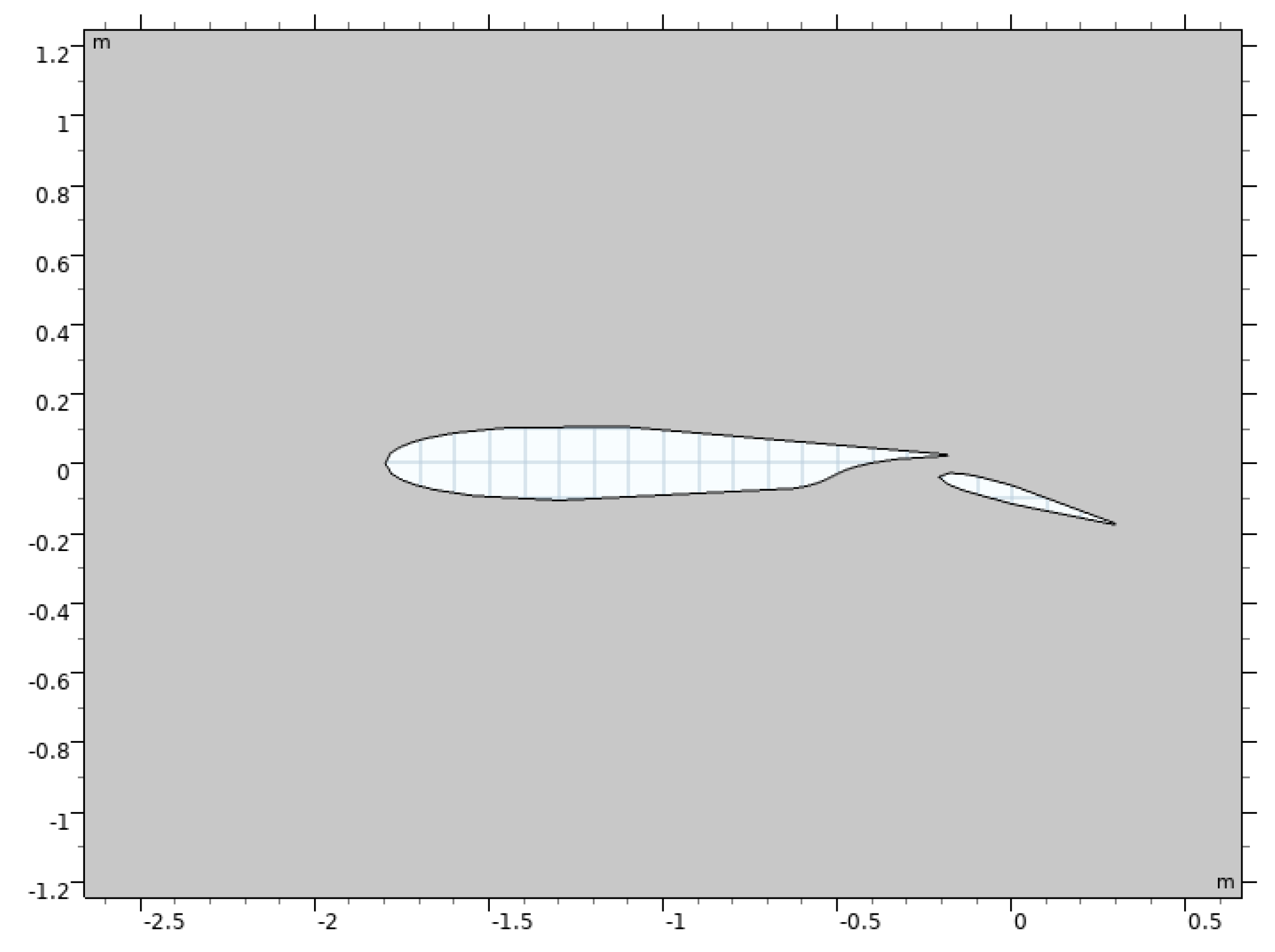

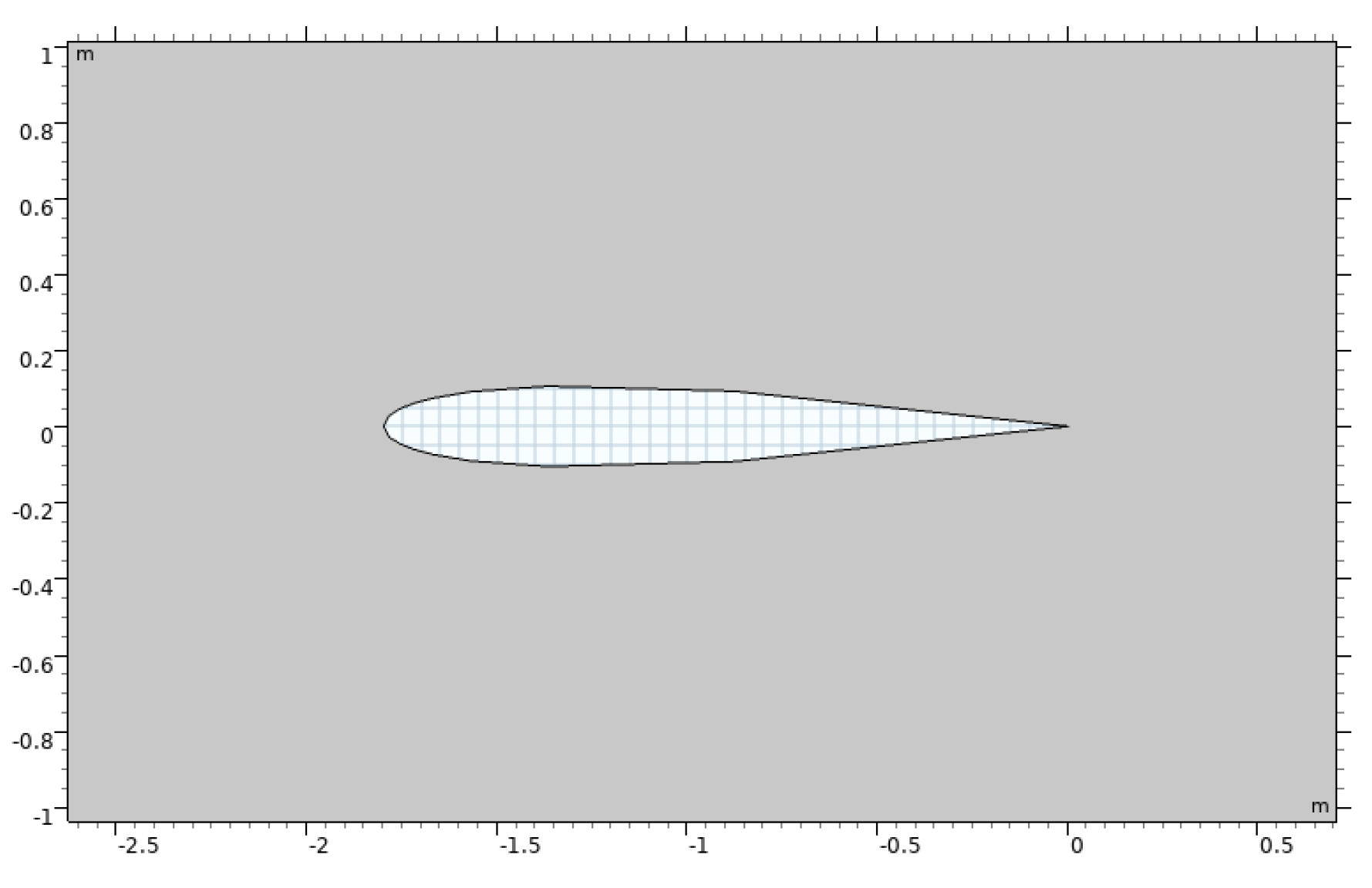

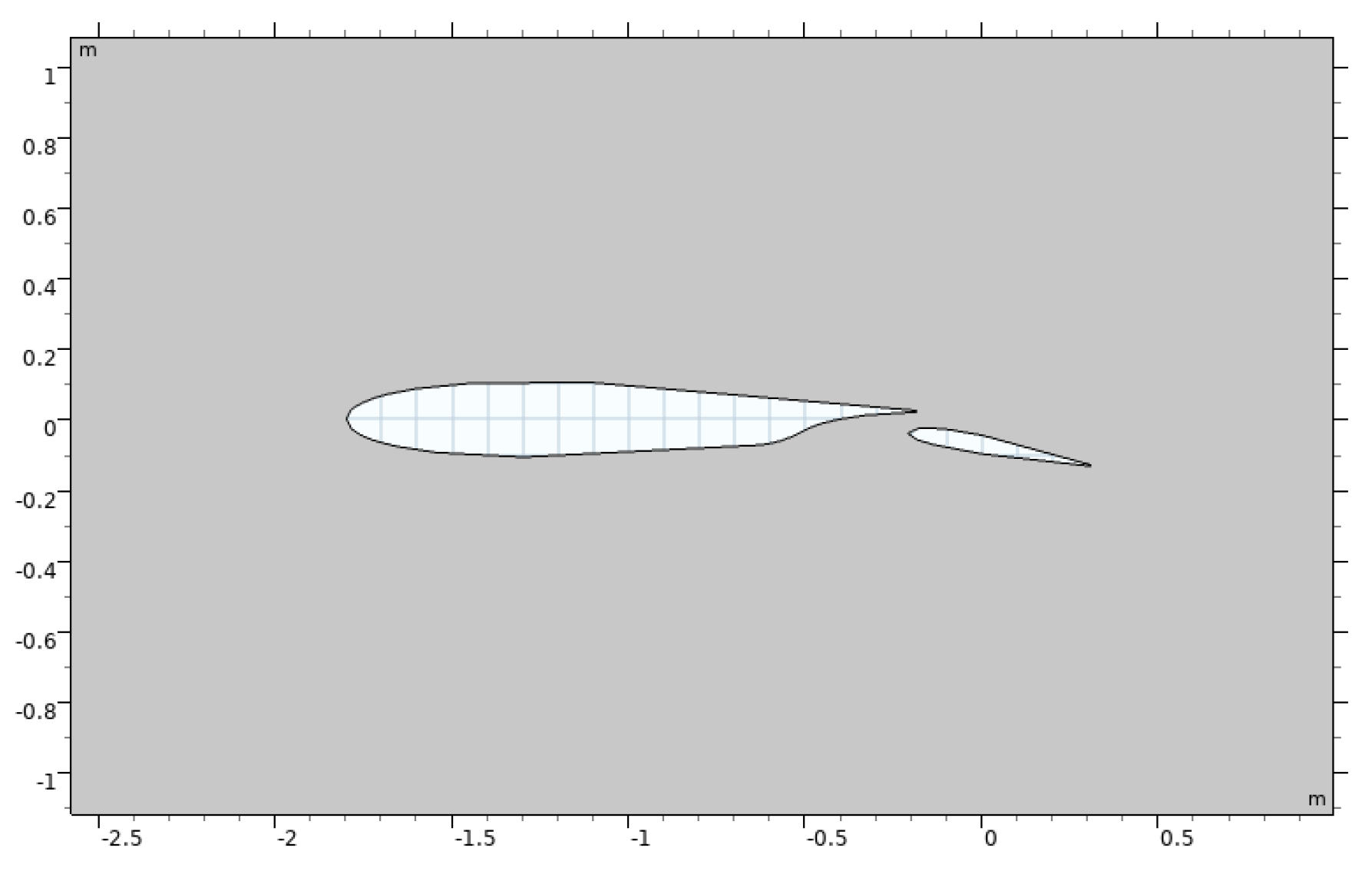

2.3.1. Wing Geometry

2.3.2. Governing Equations and Flow Models

2.3.3. Boundary Conditions

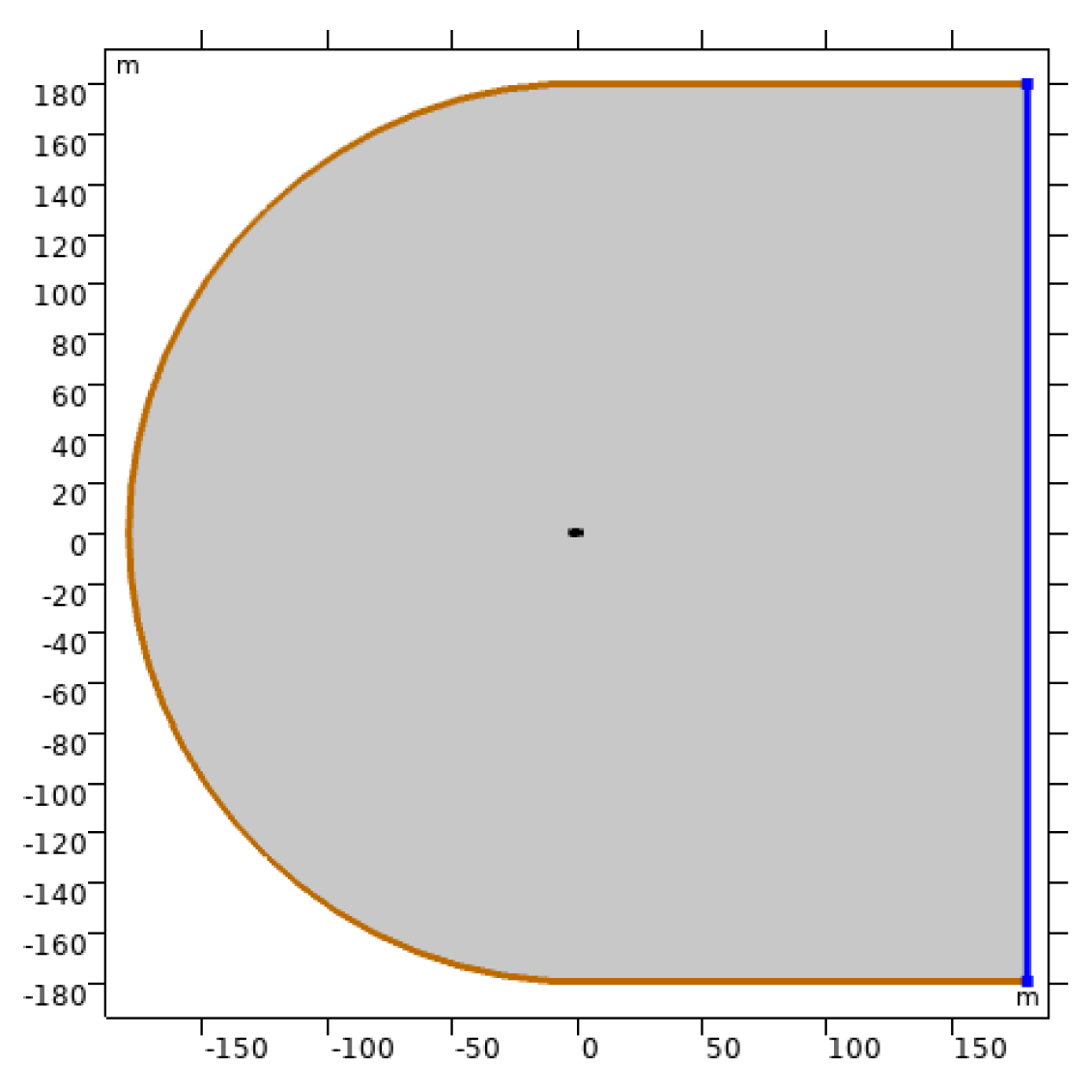

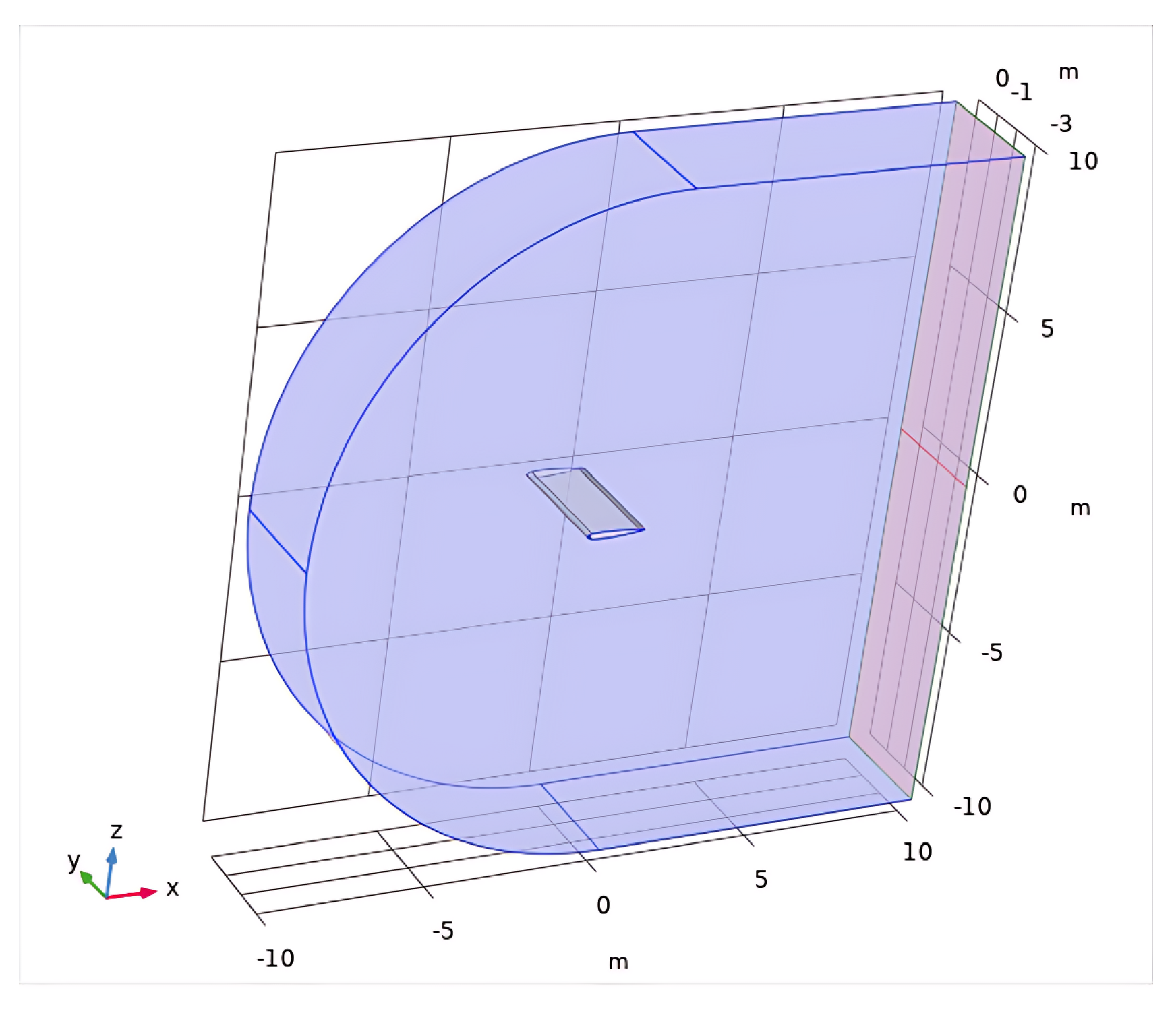

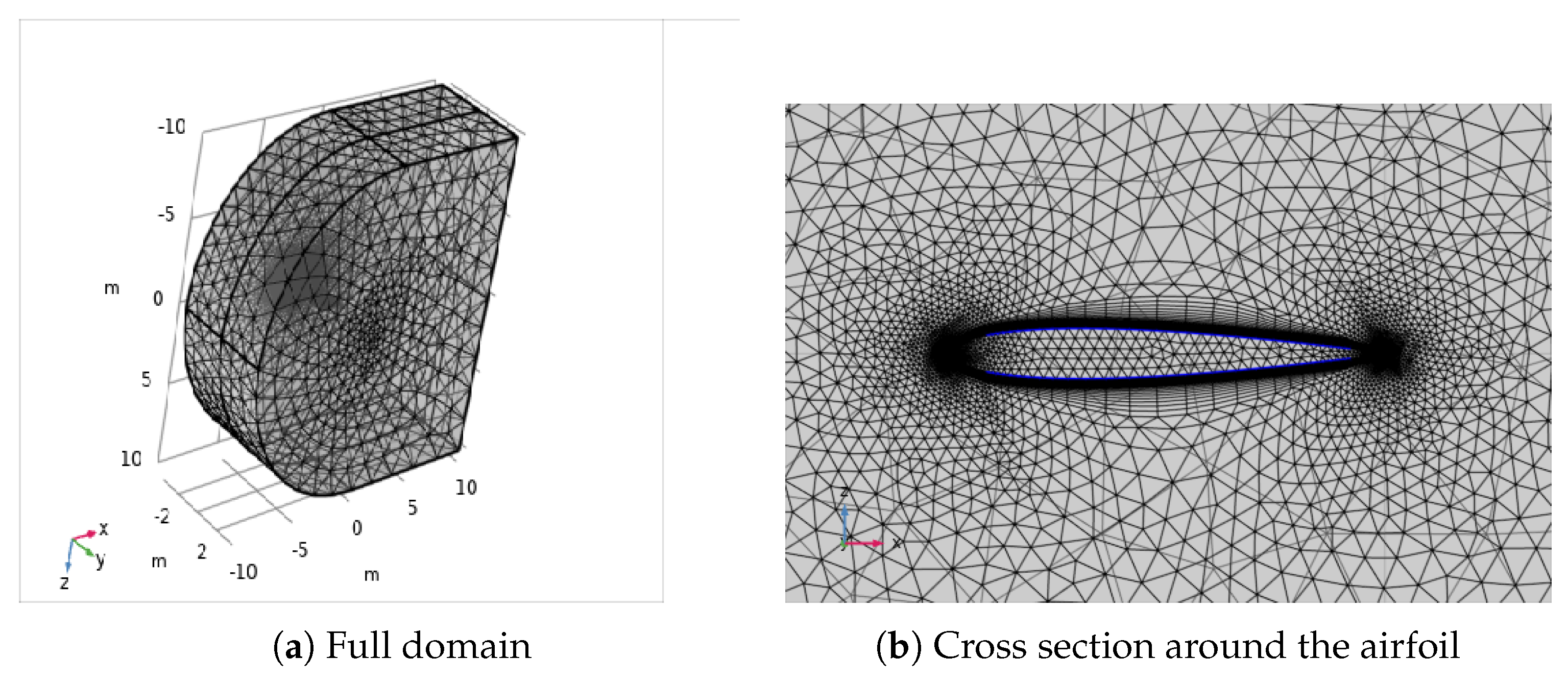

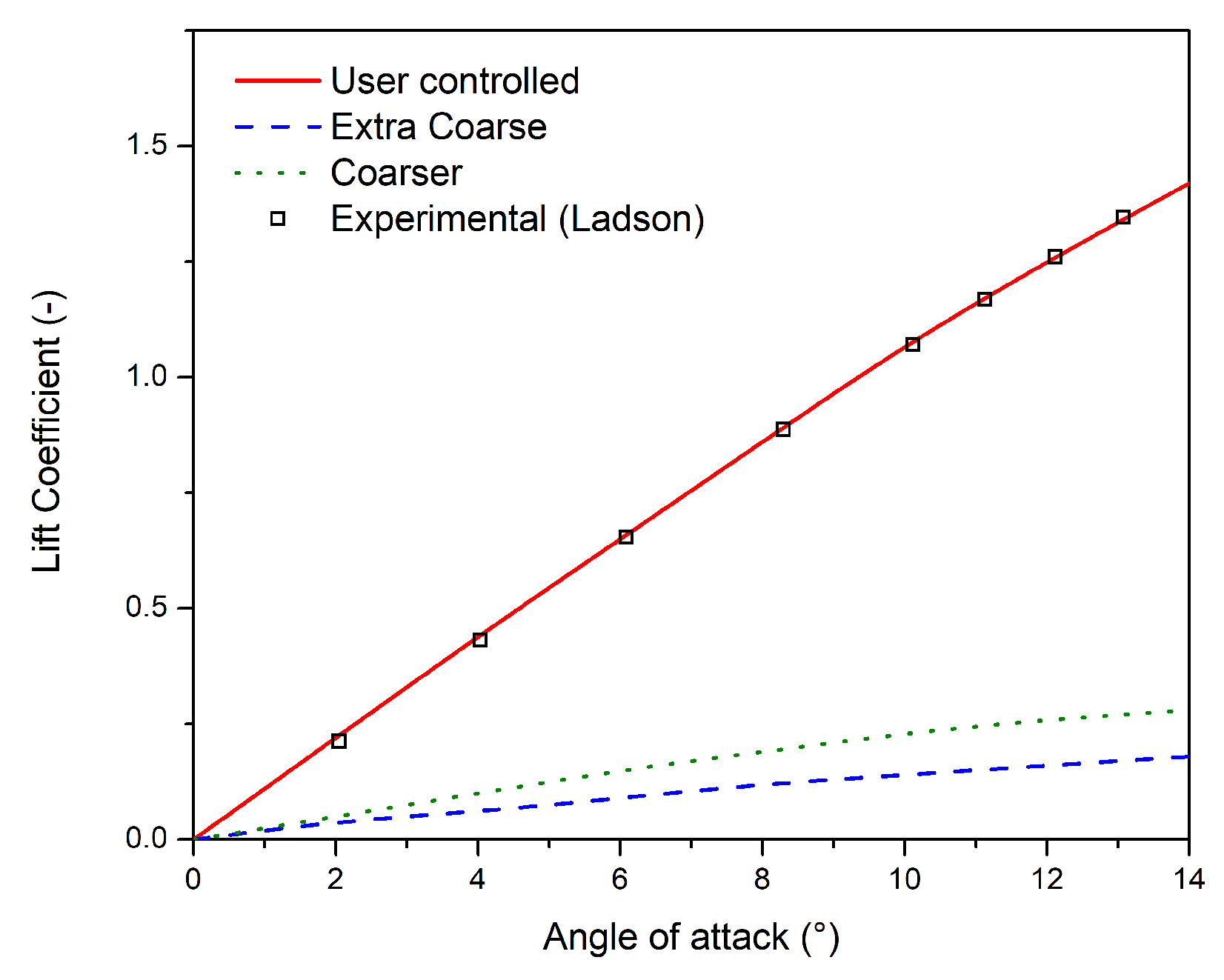

2.3.4. Meshes

3. Results and Discussion

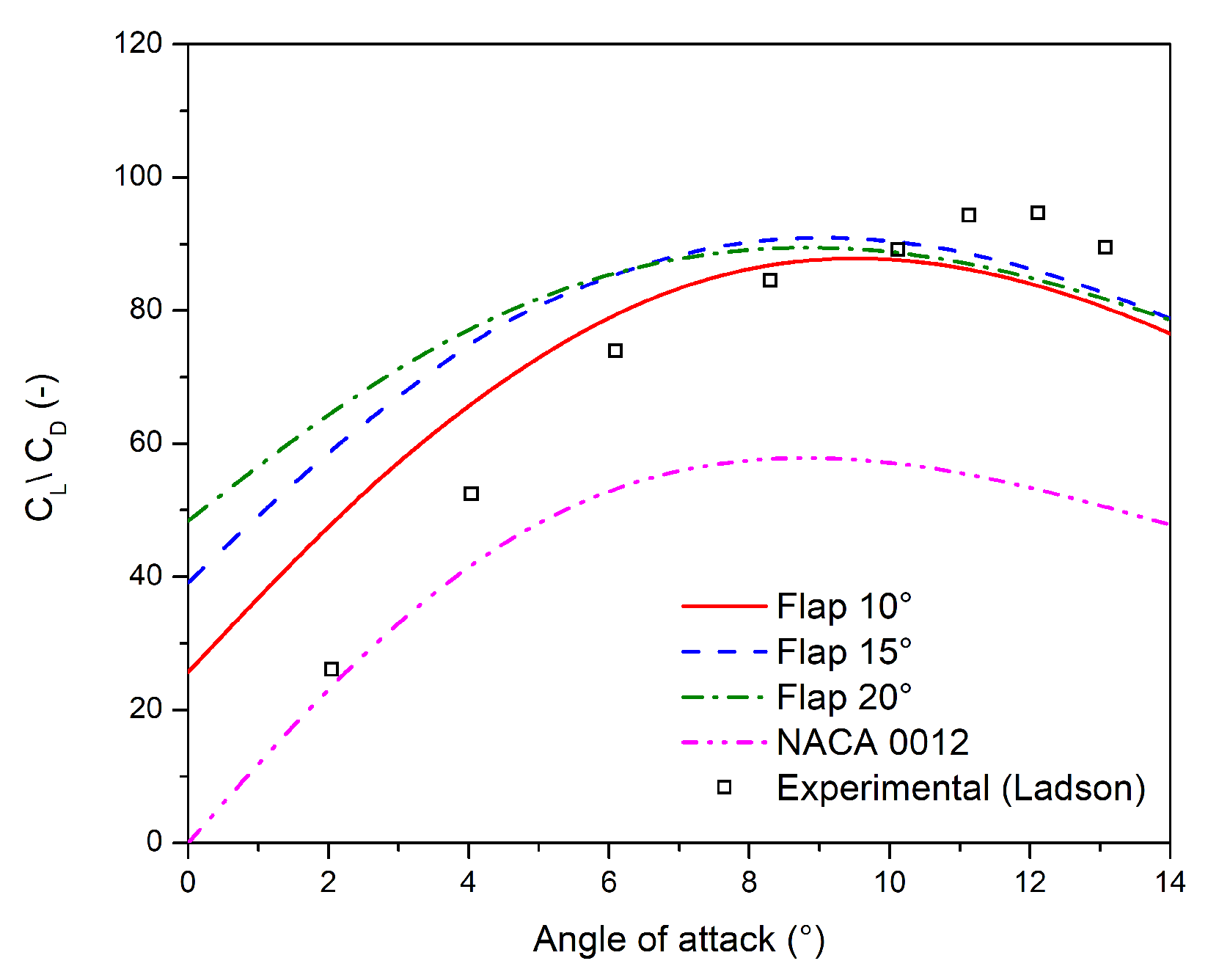

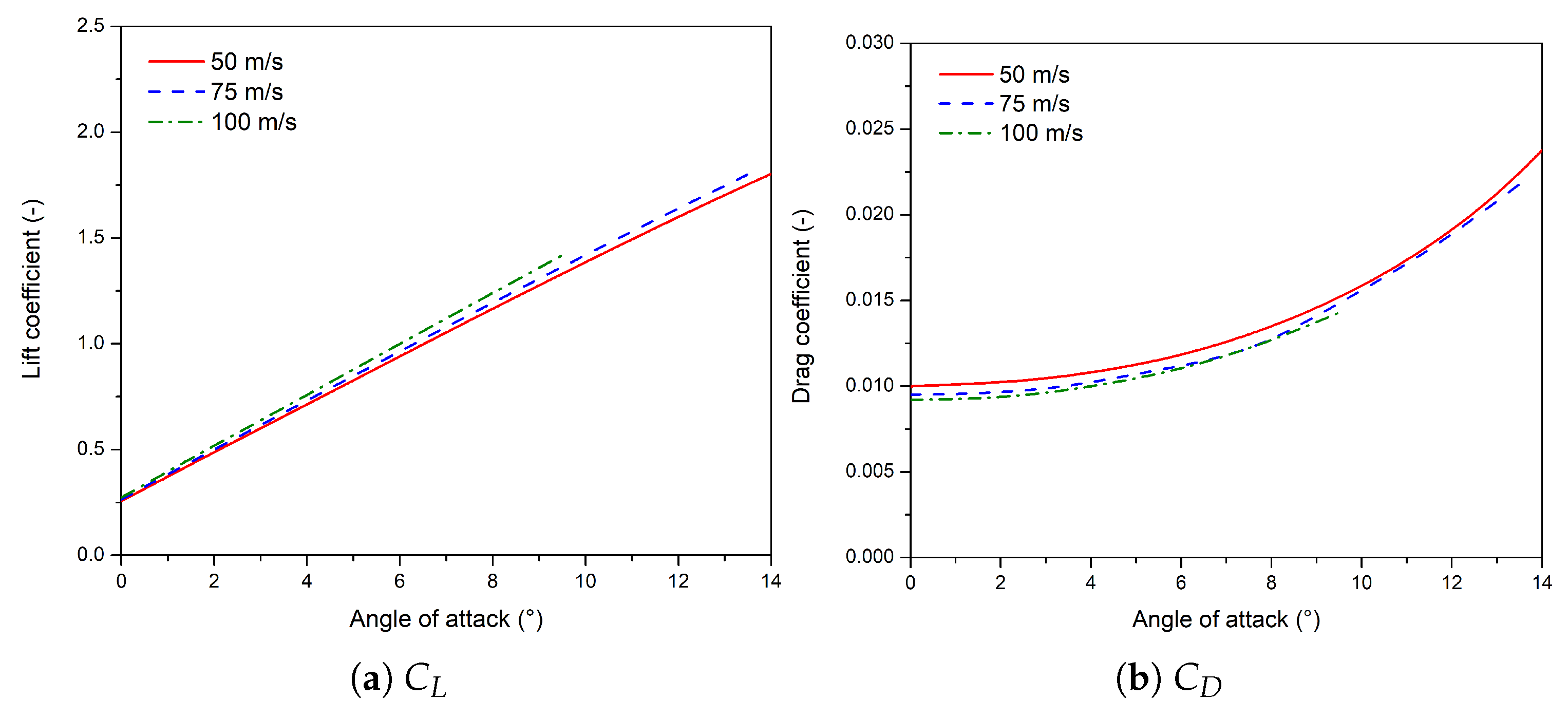

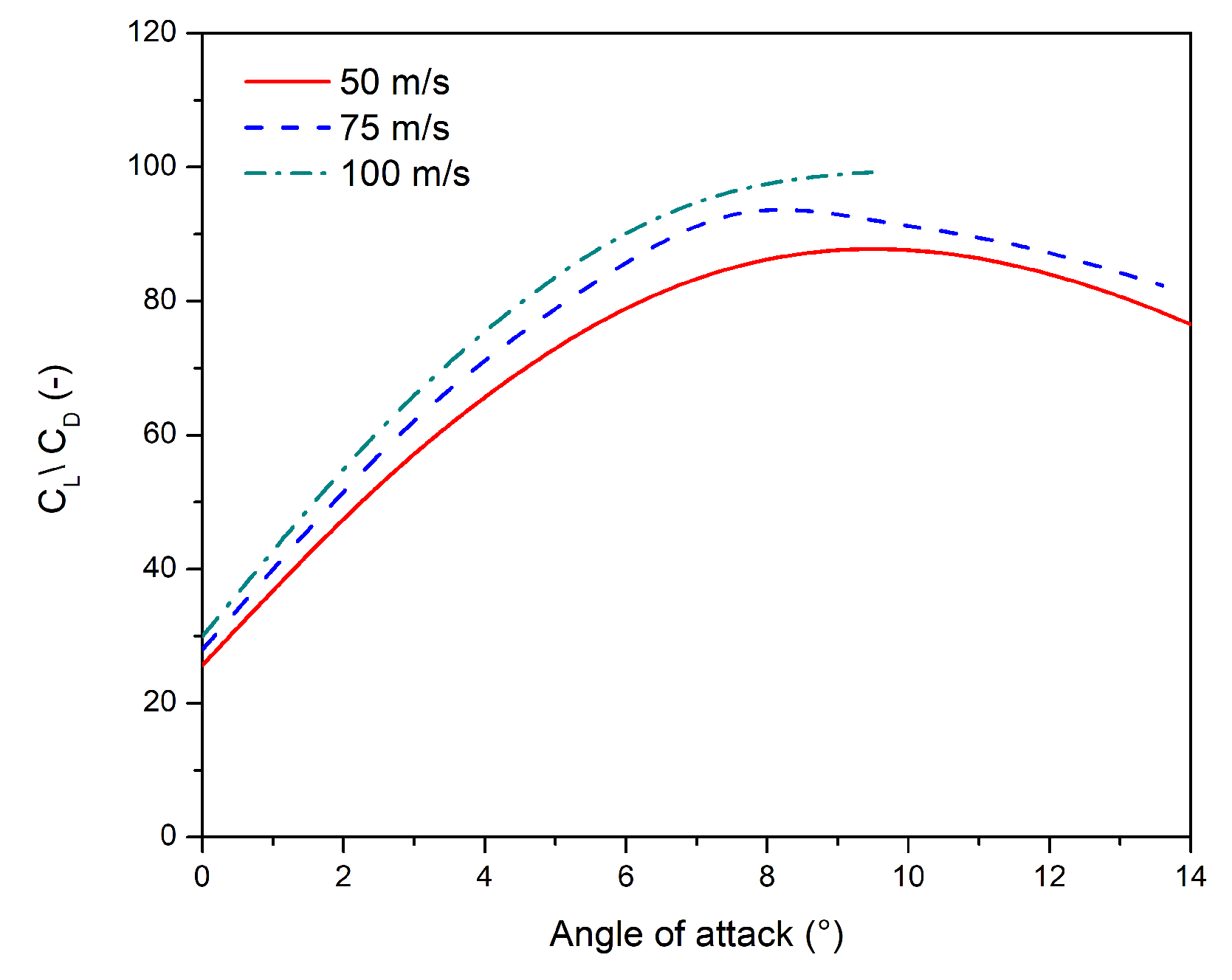

3.1. Modified Airfoil

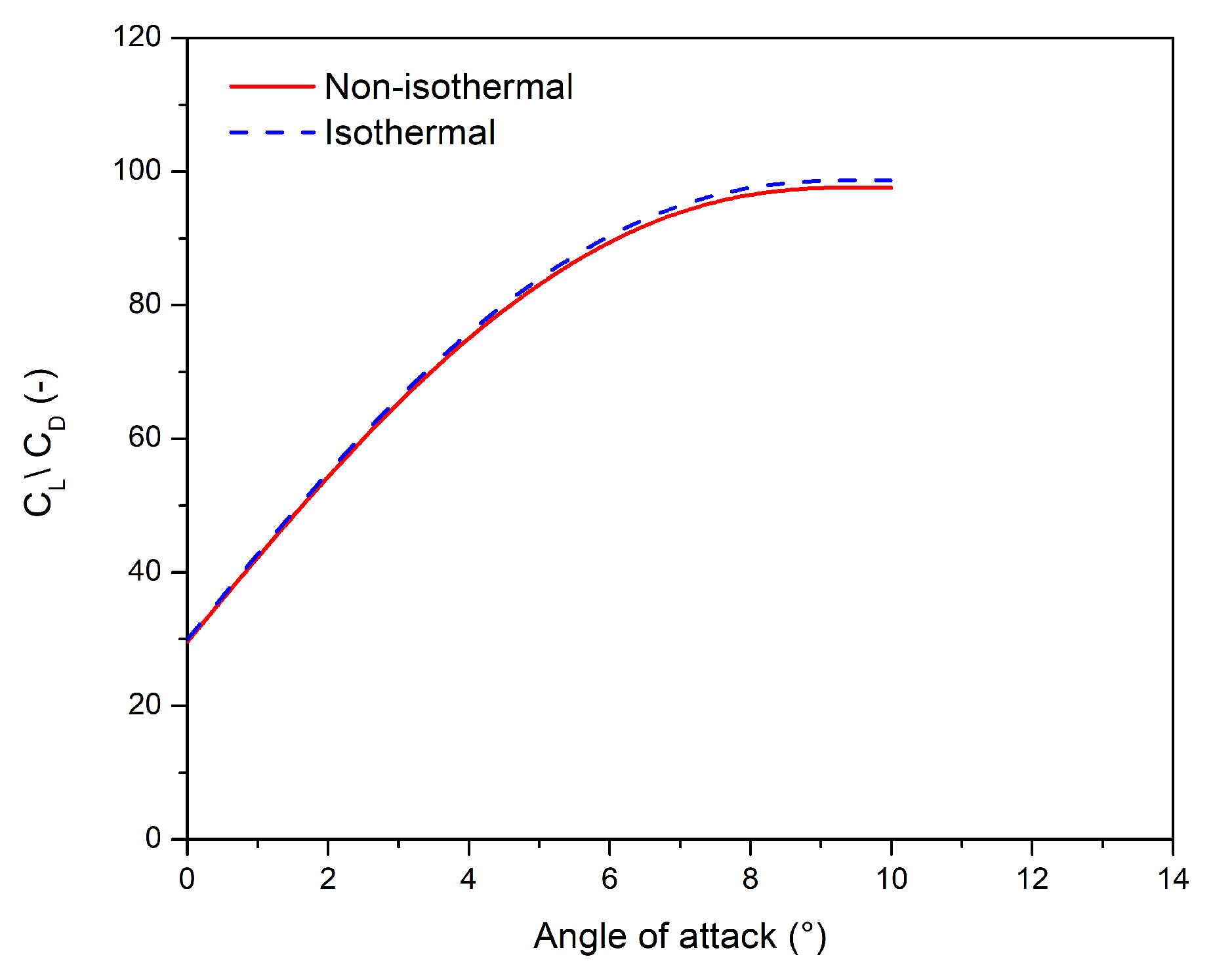

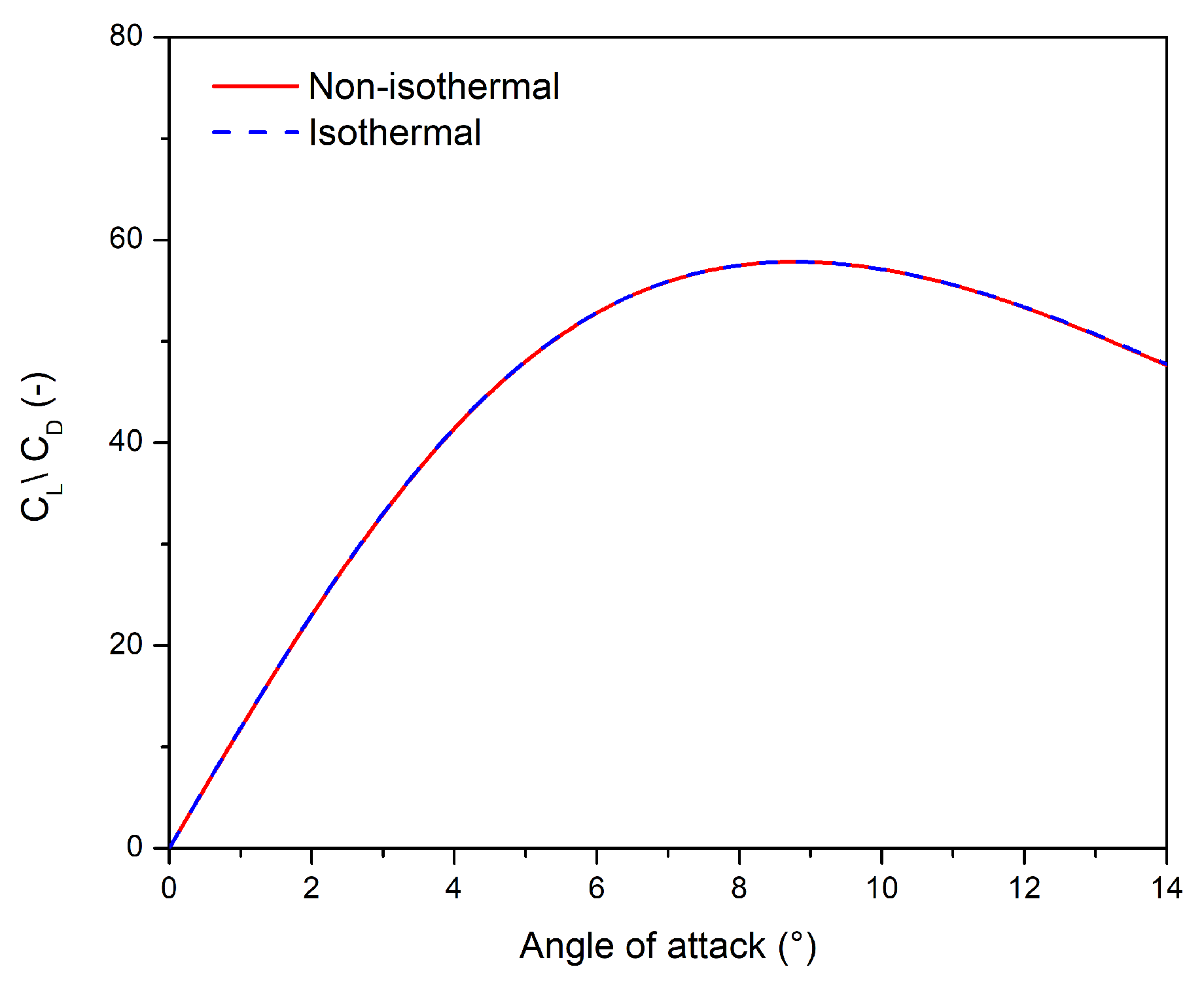

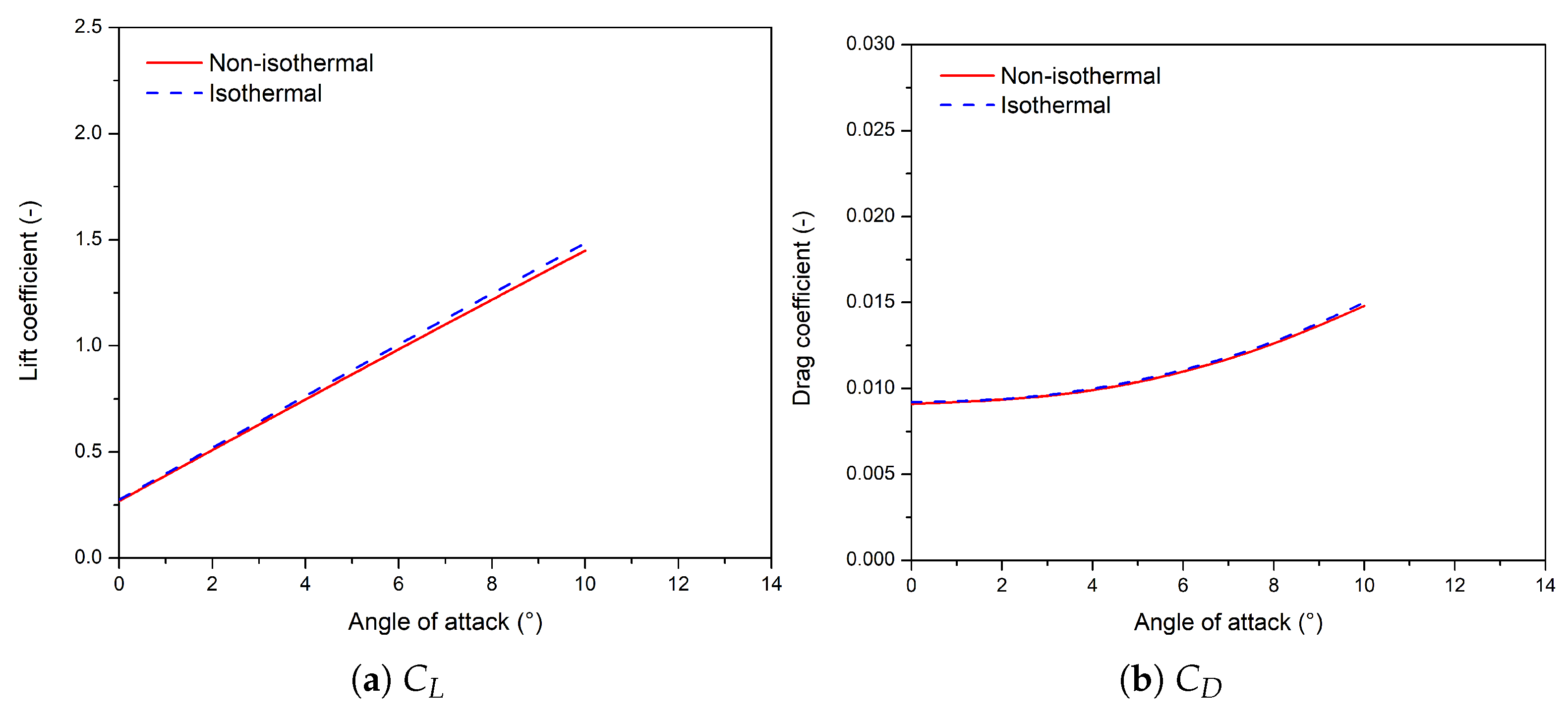

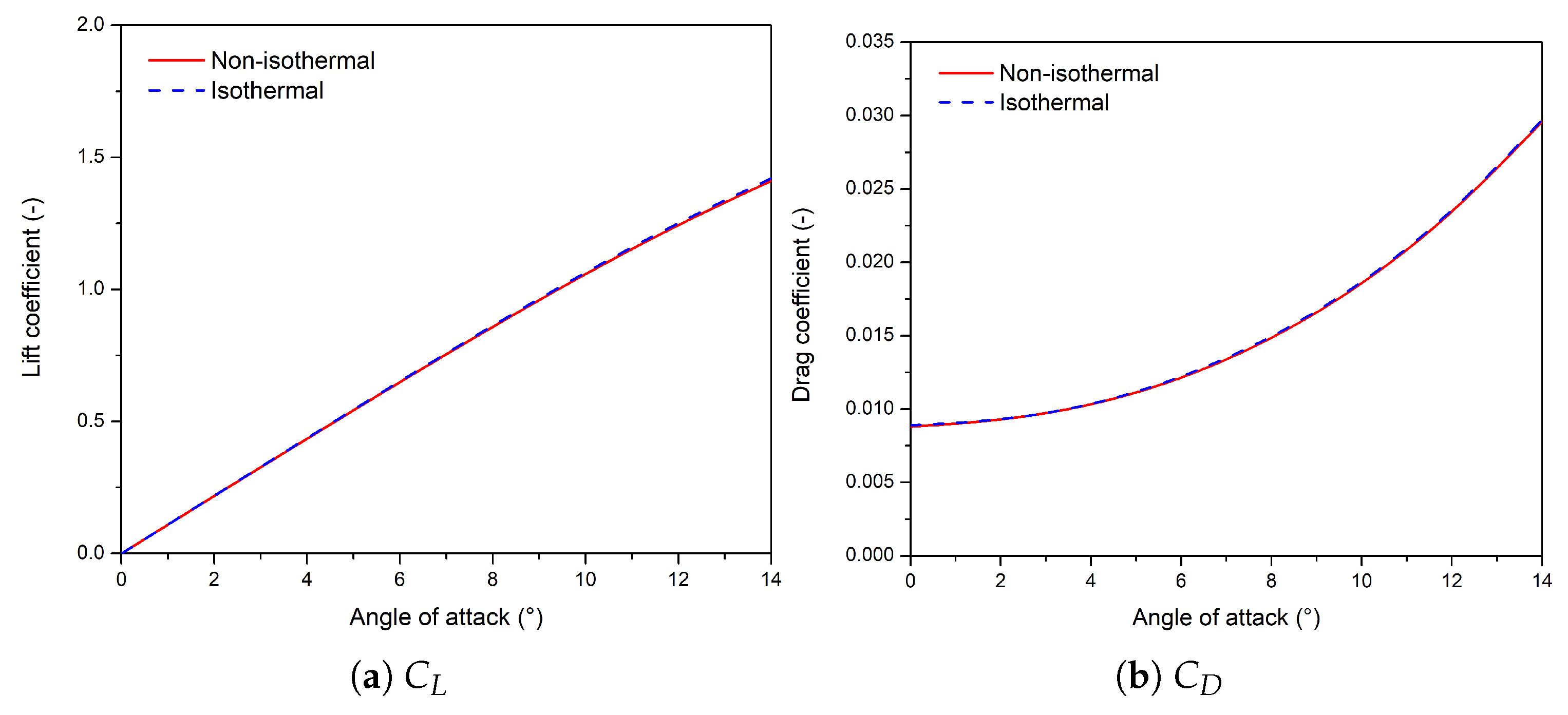

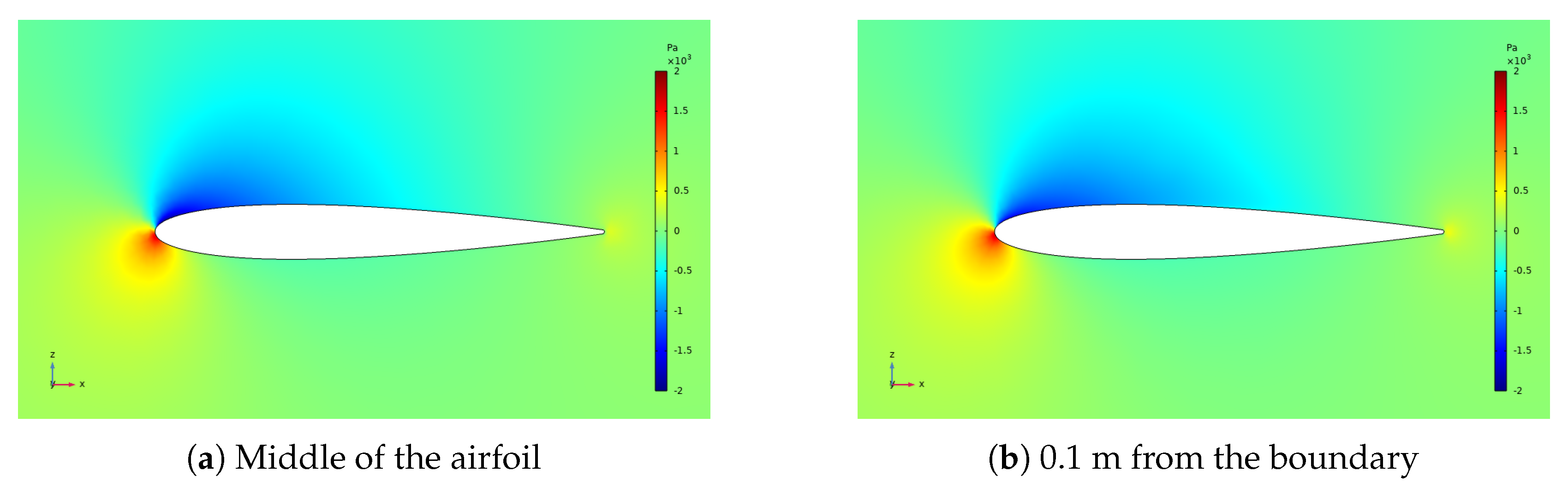

3.2. Non-Isothermal Flow

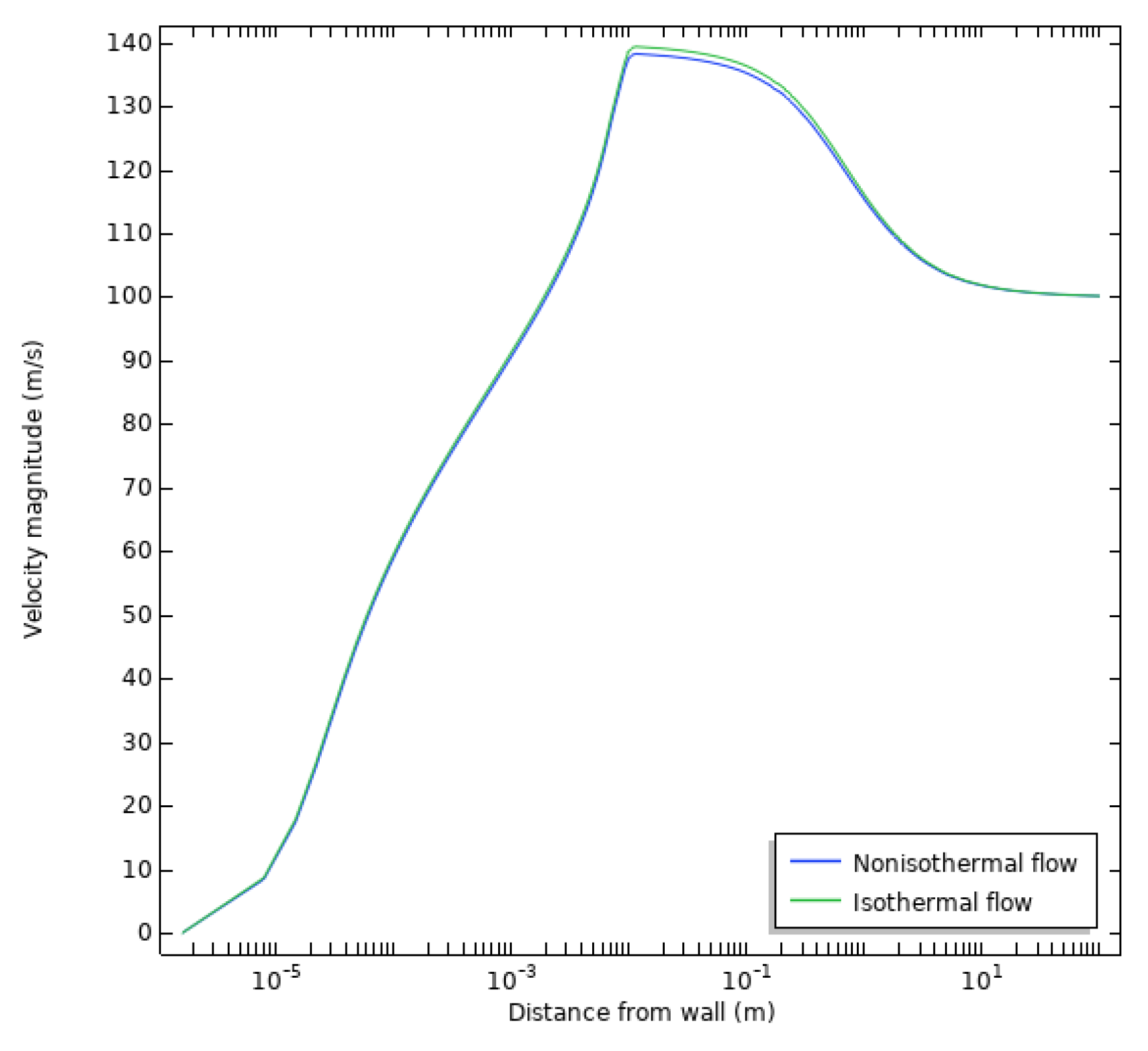

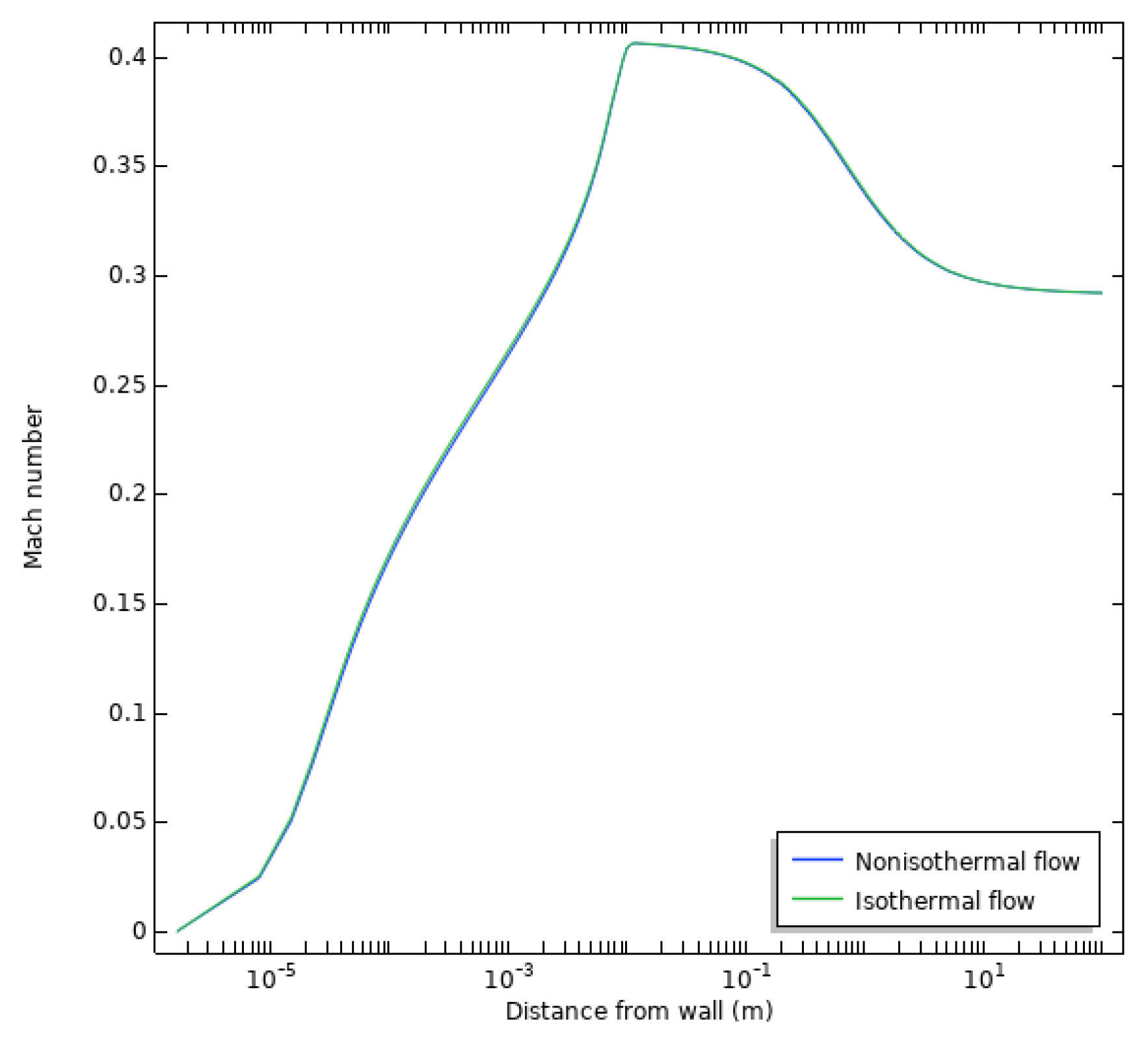

Wall Profiles

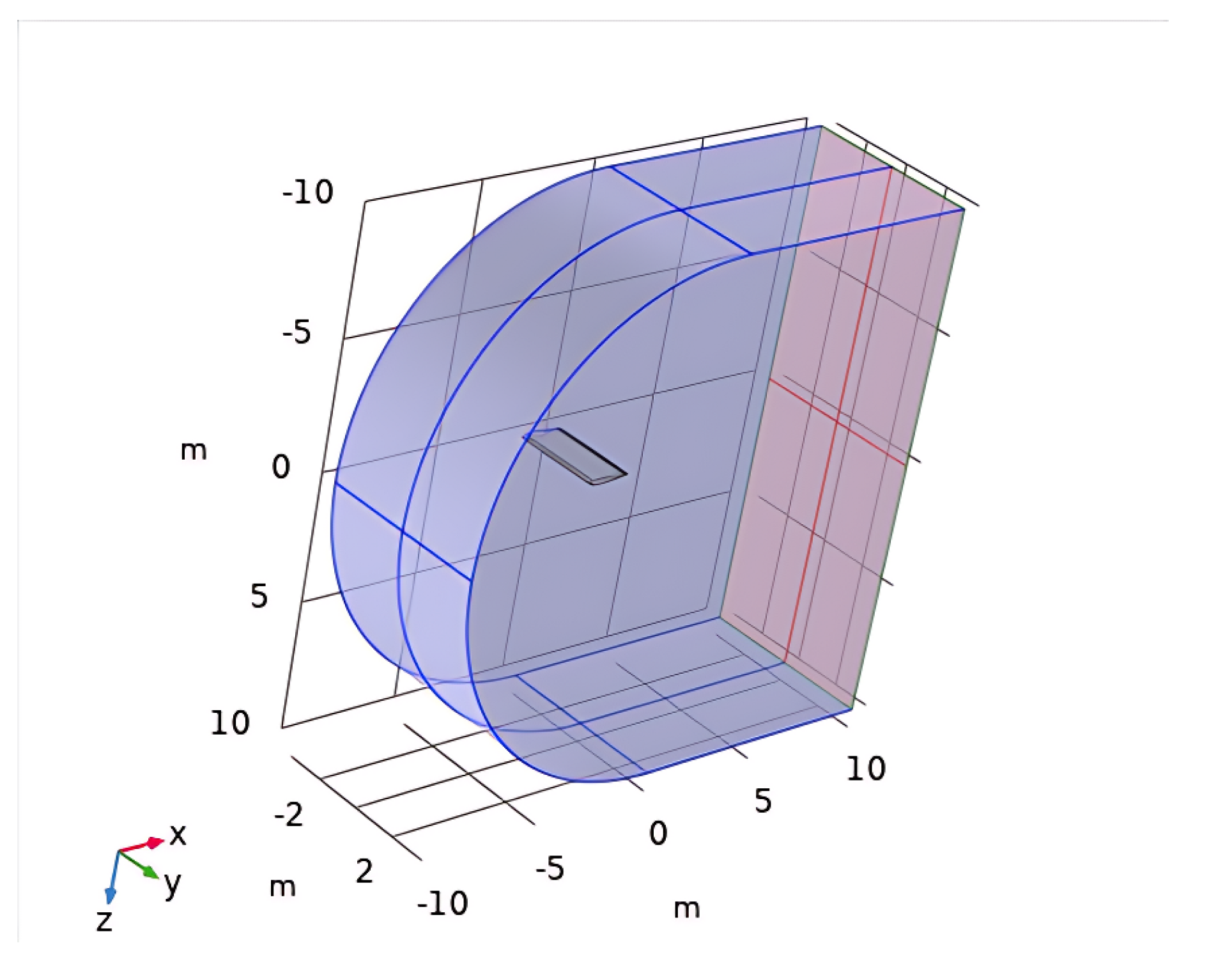

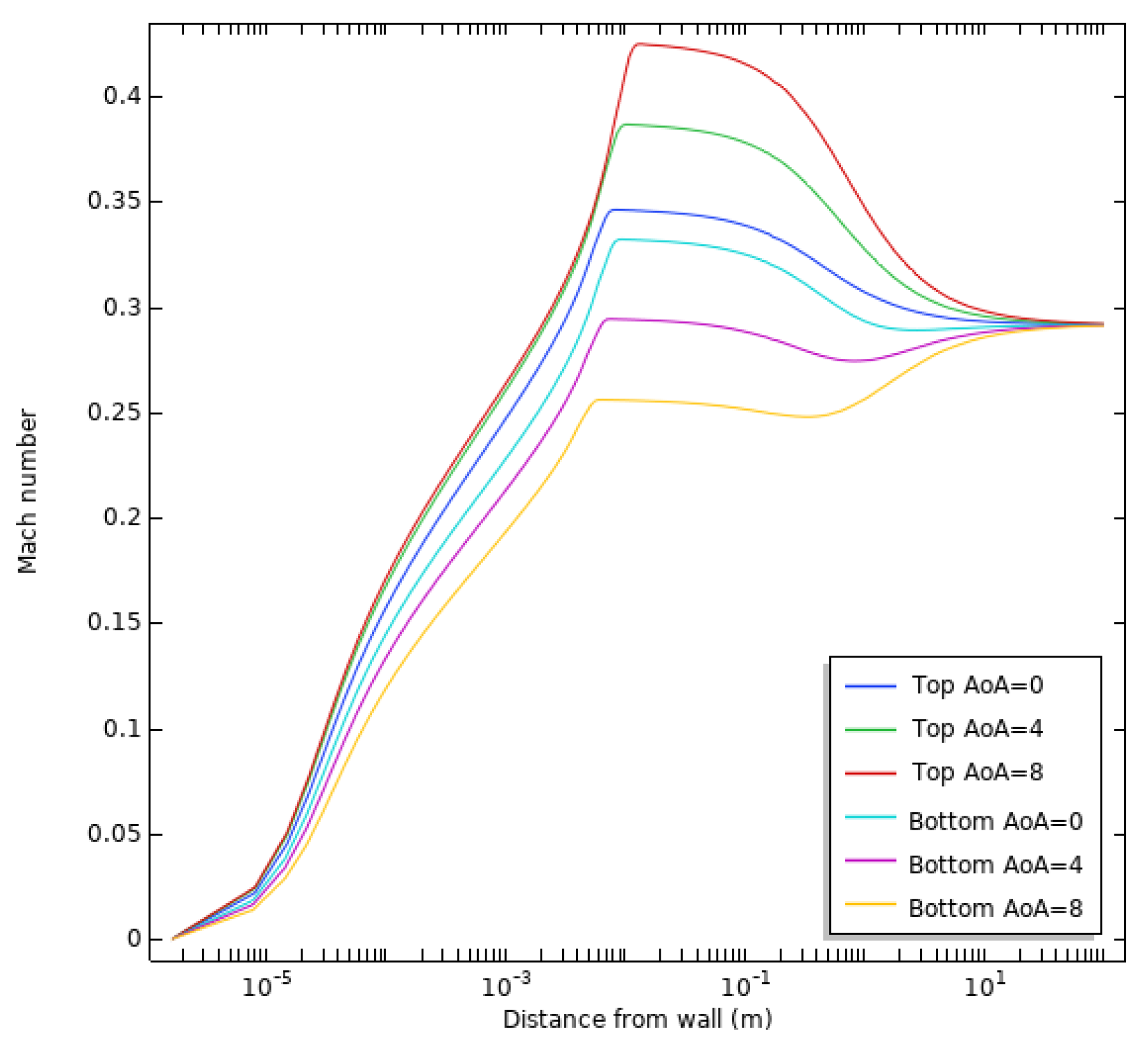

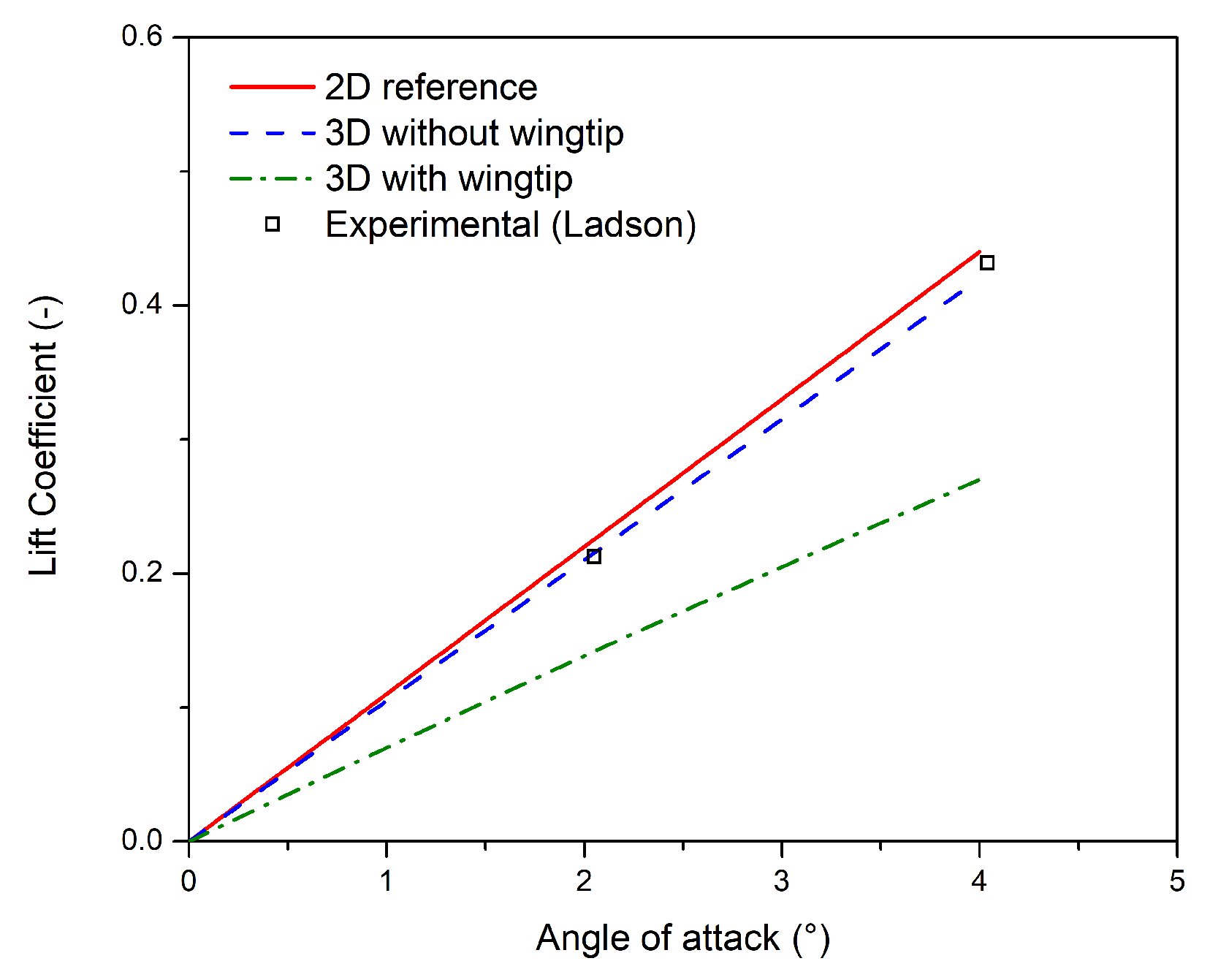

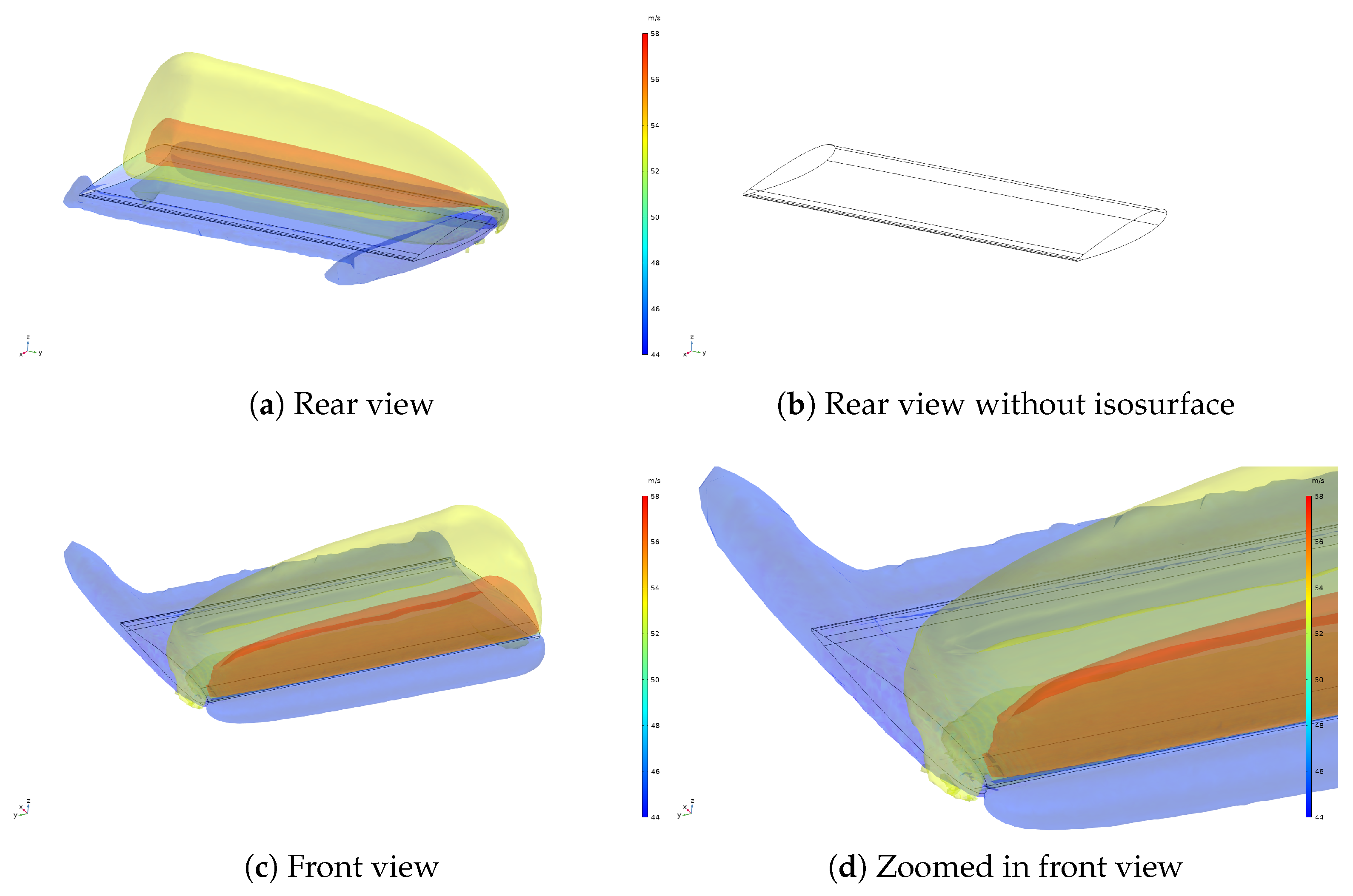

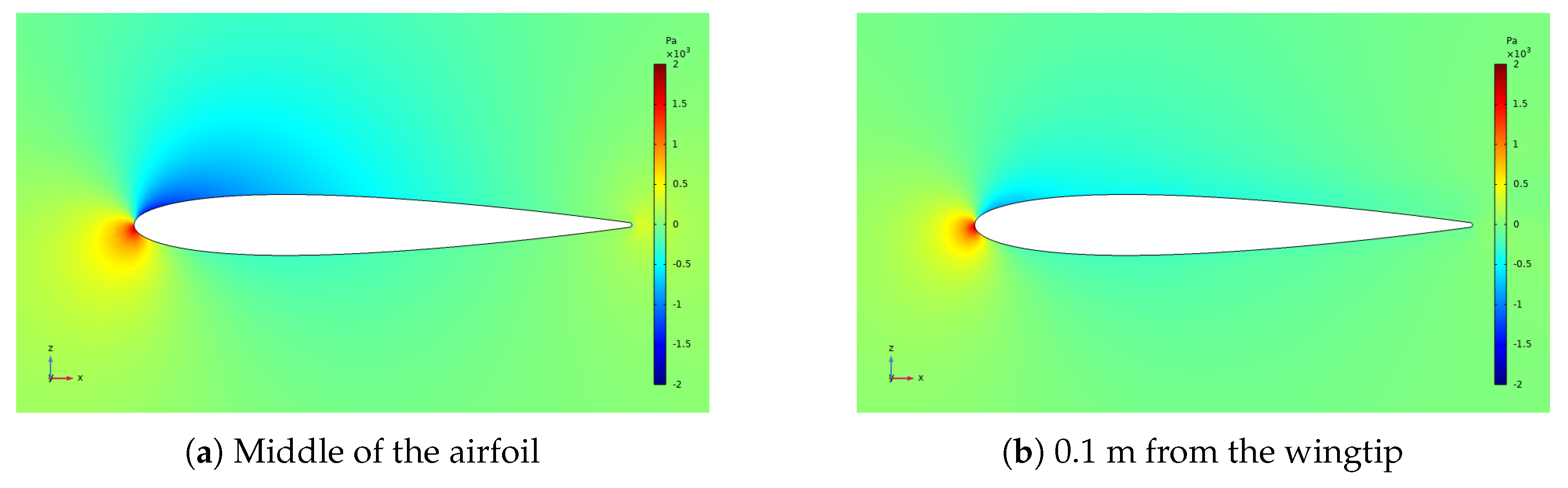

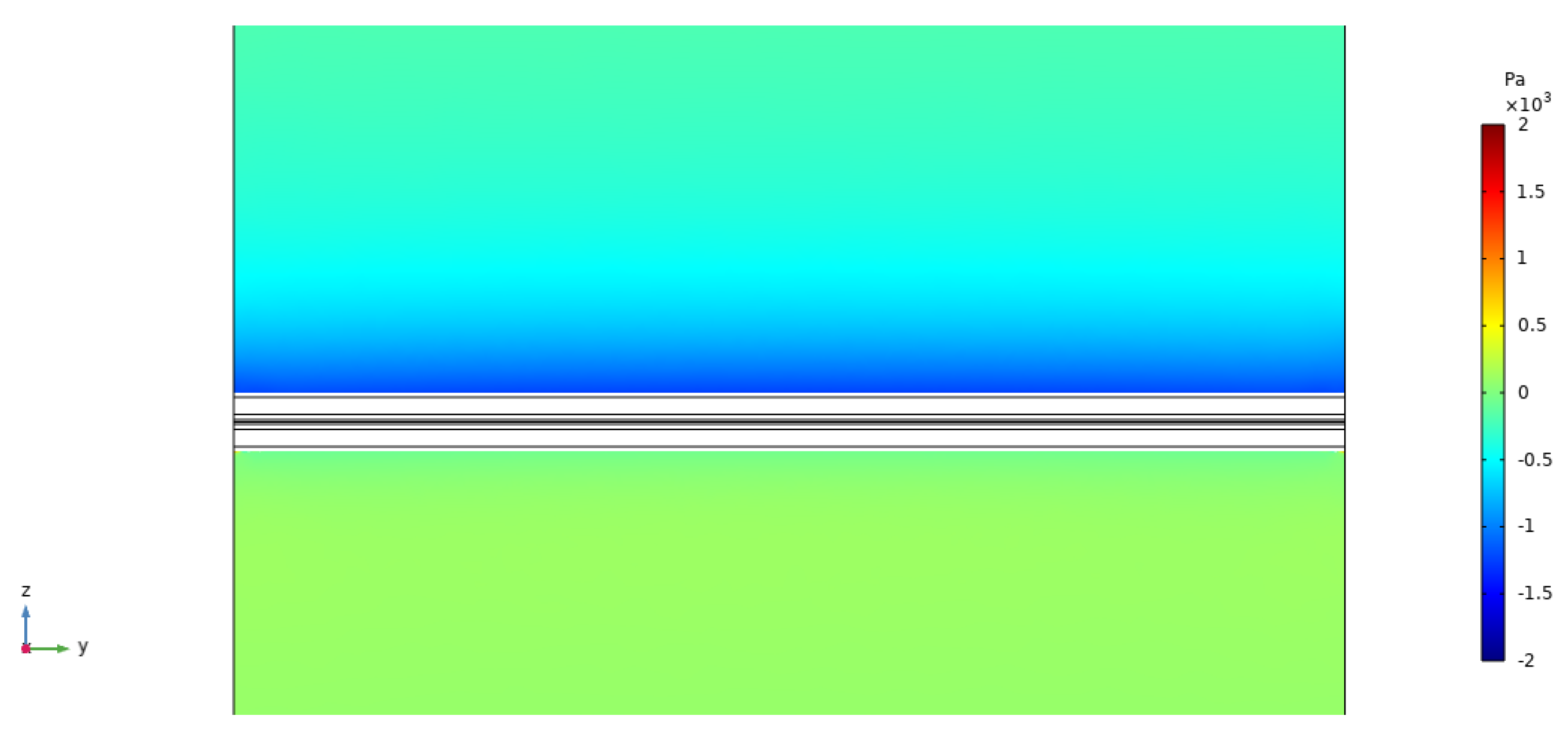

3.3. 3D Model

4. Conclusions

- A first numerical conclusion of this study is that the COMSOL physics-controlled meshing settings are not suitable for this airfoil simulation as they are either unable to converge or give results that do not match those of experiments. User-controlled meshes are required to yield good results.

- The SST turbulence flow model with a user-controlled mesh shows good agreement with experimental results. The results need to be considered carefully when trying to apply it to real life wings, as the flow model assumes turbulent flow across the entire airfoil. The degree to which this assumption is valid will depend on the wing roughness. The modified airfoil has increased and values compared to the stock NACA 0012. Increasing the flap angles further increases and . The free stream velocity has a minor impact, with a very slightly higher and slightly higher at higher velocities. Overall, the simulated results correspond well to what is expected from theory and real-life experiments.

- No significant difference was found in or between the isothermal and non-isothermal models. In turn, the use of a non-isothermal model is not required for good results in these simulations.

- The 3D model shows some interesting avenues for future research, but the current results are limited and more verifications are necessary.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFD | Computational Fluid Dynamics |

| LES | Large Eddy Simulation |

| NACA | National Advisory Committee for Aeronautics |

| RANS | Reynolds-Averaged Navier–Stokes |

| SA | Spalart–Allmaras |

| SST | Shear-Stress Transport |

| Nomenclature | |

| A | Area (m) |

| c | Speed of sound (m/s) |

| Drag coefficient (-) | |

| Lift coefficient (-) | |

| Drag force (N) | |

| Lift force (N) | |

| k | Specific heat ratio (-) |

| p | Pressure (Pa) |

| Particular gas constant (J/kg · K) | |

| T | Temperature (K) |

| Fluid velocity field (m/s) | |

| Greek Letters | |

| Angle of attack () | |

| Fluid density (kg/m) | |

| Phase viscosity (mPa · s) |

Appendix A. Figures

Appendix B. CL, CD, and CL/CD Date

| Alpha | Extra Coarse | Coarser |

|---|---|---|

| 0 | 0.00 | 0.00 |

| 2 | 0.04 | 0.05 |

| 4 | 0.06 | 0.10 |

| 6 | 0.09 | 0.15 |

| 8 | 0.12 | 0.19 |

| 10 | 0.14 | 0.23 |

| 12 | 0.16 | 0.26 |

| 14 | 0.18 | 0.28 |

| Number of elements | 1742 | 2688 |

| Flap 10° | Flap 15° | Flap 20° | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Alpha | 50 m/s | 75 m/s | 100 m/s | Alpha | 50 m/s | 75 m/s | 100 m/s | Alpha | 50 m/s | 75 m/s | 100 m/s |

| 0 | 0.257 | 0.265 | 0.274 | 0.0 | 0.412 | 0.425 | 0.442 | 0.0 | 0.557 | 0.576 | 0.601 |

| 2 | 0.489 | 0.502 | 0.520 | 2.0 | 0.643 | 0.662 | 0.687 | 2.0 | 0.784 | 0.809 | 0.842 |

| 3.6 | 0.668 | 0.685 | 0.710 | 4.0 | 0.872 | 0.896 | 0.929 | 4.0 | 1.010 | 1.041 | 1.082 |

| 5.6 | 0.896 | 0.919 | 0.952 | 4.8 | 0.961 | 0.988 | 1.025 | 6.0 | 1.233 | 1.269 | 1.320 |

| 7.6 | 1.122 | 1.149 | 1.193 | 6.8 | 1.186 | 1.219 | 1.265 | 8.0 | 1.451 | 1.494 | 1.555 |

| 9.6 | 1.343 | 1.376 | 1.431 | 8.8 | 1.407 | 1.446 | 1.502 | 10.0 | 1.666 | 1.715 | 1.786 |

| 11.6 | 1.559 | 1.598 | 10.8 | 1.623 | 1.669 | 12.0 | 1.873 | 1.930 | |||

| 13.6 | 1.766 | 1.811 | 12.8 | 1.831 | 1.884 | 14.0 | 2.072 | 2.136 | |||

| 15.6 | 1.958 | 14.8 | 2.027 | 2.086 | 16.0 | 2.257 | |||||

| 16.6 | 2.045 | 16.8 | 2.204 | 18.0 | 2.419 | ||||||

| 17.6 | 2.122 | 17.8 | 2.281 | 19.0 | 2.484 | ||||||

| 18.8 | 2.343 | 20.0 | 2.528 | ||||||||

| Flap 10° | Flap 15° | Flap 20° | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Alpha | 50 m/s | 75 m/s | 100 m/s | Alpha | 50 m/s | 75 m/s | 100 m/s | Alpha | 50 m/s | 75 m/s | 100 m/s |

| 0.0 | 0.010 | 0.009 | 0.009 | 0.0 | 0.011 | 0.010 | 0.010 | 0.0 | 0.012 | 0.011 | 0.011 |

| 2.0 | 0.010 | 0.010 | 0.009 | 2.0 | 0.011 | 0.010 | 0.010 | 2.0 | 0.012 | 0.012 | 0.011 |

| 3.6 | 0.011 | 0.010 | 0.010 | 4.0 | 0.012 | 0.011 | 0.011 | 4.0 | 0.013 | 0.012 | 0.012 |

| 5.6 | 0.012 | 0.011 | 0.011 | 4.8 | 0.012 | 0.011 | 0.011 | 6.0 | 0.014 | 0.014 | 0.014 |

| 7.6 | 0.013 | 0.012 | 0.012 | 6.8 | 0.013 | 0.013 | 0.013 | 8.0 | 0.016 | 0.016 | 0.015 |

| 9.6 | 0.015 | 0.015 | 0.014 | 8.8 | 0.015 | 0.015 | 0.015 | 10.0 | 0.019 | 0.018 | 0.018 |

| 11.6 | 0.018 | 0.018 | 10.8 | 0.018 | 0.017 | 12.0 | 0.022 | 0.021 | |||

| 13.6 | 0.022 | 0.022 | 12.8 | 0.022 | 0.021 | 14.0 | 0.026 | 0.026 | |||

| 15.6 | 0.028 | 14.8 | 0.027 | 0.027 | 16.0 | 0.033 | |||||

| 16.6 | 0.033 | 16.8 | 0.034 | 18.0 | 0.042 | ||||||

| 17.6 | 0.038 | 17.8 | 0.039 | 19.0 | 0.048 | ||||||

| 18.8 | 0.046 | 20.0 | 0.056 | ||||||||

| Flap 10° | Flap 15° | Flap 20° | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Alpha | 50 m/s | 75 m/s | 100 m/s | Alpha | 50 m/s | 75 m/s | 100 m/s | Alpha | 50 m/s | 75 m/s | 100 m/s |

| 0 | 25.7 | 28.0 | 29.9 | 0.0 | 39.1 | 42.6 | 45.7 | 0.0 | 48.4 | 52.7 | 56.4 |

| 2 | 48.0 | 52.1 | 55.7 | 2.0 | 59.3 | 64.2 | 68.6 | 2.0 | 64.9 | 70.3 | 75.1 |

| 3.6 | 63.0 | 68.5 | 72.4 | 4.0 | 75.1 | 81.1 | 86.3 | 4.0 | 77.9 | 84.0 | 89.2 |

| 5.6 | 77.7 | 83.5 | 89.0 | 4.8 | 80.1 | 86.4 | 91.9 | 6.0 | 86.1 | 92.4 | 97.7 |

| 7.6 | 86.3 | 95.8 | 97.8 | 6.8 | 88.7 | 95.2 | 100.8 | 8.0 | 89.8 | 96.0 | 101.0 |

| 9.6 | 88.7 | 91.7 | 99.4 | 8.8 | 91.7 | 98.1 | 103.1 | 10.0 | 89.4 | 95.1 | 99.2 |

| 11.6 | 85.8 | 88.8 | 10.8 | 89.9 | 95.7 | 12.0 | 85.4 | 90.5 | |||

| 13.6 | 78.8 | 82.3 | 12.8 | 84.1 | 89.1 | 14.0 | 78.6 | 82.7 | |||

| 15.6 | 68.8 | 14.8 | 75.3 | 78.6 | 16.0 | 69.4 | |||||

| 16.6 | 62.9 | 16.8 | 64.2 | 18.0 | 58.2 | ||||||

| 17.6 | 56.3 | 17.8 | 58.0 | 19.0 | 51.9 | ||||||

| 18.8 | 51.0 | 20.0 | 45.0 | ||||||||

| Non-Isothermal | Isothermal | |||||

|---|---|---|---|---|---|---|

| Alpha | Cd | Cl | Cl/Cd | Cd | Cl | Cl/Cd |

| 0 | 0.0091 | 0.269 | 29.6 | 0.0092 | 0.275 | 29.9 |

| 2 | 0.0093 | 0.509 | 55.0 | 0.0093 | 0.520 | 55.7 |

| 4 | 0.0098 | 0.748 | 76.1 | 0.0099 | 0.764 | 76.9 |

| 6 | 0.0109 | 0.984 | 90.7 | 0.0110 | 1.007 | 91.6 |

| 8 | 0.0125 | 1.218 | 97.8 | 0.0126 | 1.247 | 98.8 |

| 10 | 0.0148 | 1.449 | 97.6 | 0.0150 | 1.484 | 98.7 |

| Non-Isothermal | Isothermal | |||||

|---|---|---|---|---|---|---|

| Alpha | Cd | Cl | Cl/Cd | Cd | Cl | Cl/Cd |

| 0 | 0.009 | 0.00 | 0.0 | 0.009 | 0.00 | 0.0 |

| 2 | 0.009 | 0.22 | 23.8 | 0.009 | 0.22 | 23.9 |

| 4 | 0.010 | 0.44 | 42.7 | 0.010 | 0.44 | 42.7 |

| 6 | 0.012 | 0.65 | 54.0 | 0.012 | 0.65 | 54.0 |

| 8 | 0.015 | 0.86 | 58.3 | 0.015 | 0.86 | 58.3 |

| 10 | 0.018 | 1.06 | 57.7 | 0.018 | 1.07 | 57.7 |

| 12 | 0.023 | 1.25 | 53.7 | 0.023 | 1.25 | 53.7 |

| 14 | 0.030 | 1.41 | 47.6 | 0.030 | 1.42 | 47.8 |

| Alpha | 2D Reference | 3D without Wingtip | 3D with Wingtip |

|---|---|---|---|

| 0 | 0.00 | 0.00 | 0.00 |

| 2 | 0.22 | 0.21 | 0.14 |

| 4 | 0.44 | 0.42 | 0.27 |

| Alpha | 2D Reference | 3D without Wingtip | 3D with Wingtip |

|---|---|---|---|

| 0 | 0.009 | 0.024 | 0.019 |

| 2 | 0.009 | 0.026 | 0.020 |

| 4 | 0.01 | 0.031 | 0.026 |

| Alpha | 2D Reference | 3D without Wingtip | 3D with Wingtip |

|---|---|---|---|

| 0 | 0.0 | 0.0 | 0.0 |

| 2 | 24.4 | 8.3 | 6.6 |

| 4 | 43.8 | 13.7 | 10.5 |

References

- Hirsch, C. Numerical Computation of Internal and External Flows: Introduction to the Fundamentals of CFD; Butterworth-Heinemann: Oxford, UK, 2007. [Google Scholar]

- Ouahabi, M.H.; El Khachine, H.; Benabdelouahab, F. Aerodynamic Analysis of Wind Turbine Blade of NACA 0006 Using a CFD Approach. In Proceedings of the WITS 2020, Fez, Morocco, 14–16 October 2020; Bennani, S., Lakhrissi, Y., Khaissidi, G., Mansouri, A., Khamlichi, Y., Eds.; Springer: Singapore, 2022; pp. 541–552. [Google Scholar]

- Gregory, N.; O’Reilly, C.L. Low-Speed Aerodynamic Characteristics of NACA 0012 Aerofoil Section, including the Effects of Upper-Surface Roughness Simulating Hoar Frost; AERADE: Cranfield, UK, 1970. [Google Scholar]

- Du, Y.; Gao, Z.; Wang, C.; Huang, J. Experiment and Numerical Simulation of Crossflow Transition on A Large-Swept Supercritical Tapered Thin Wing Based on Surface Roughness. In Processing of the 11th Asian Computational Fluid Dynamics Conference (ACFD11), Dalian, China, 16–20 September 2016. [Google Scholar]

- Hasham Ali, M.; Nawazish Mehdi, S.; Naik, M. Comparative analysis of low velocity vertical axis wind turbine NACA blades at different attacking angles in CFD. Mater. Today Proc. 2021, 80, 2091–2100. [Google Scholar] [CrossRef]

- Blinov, V.L.; Zubkov, I.S. Influence of the axial compressor blade row defects on the industrial gas turbine performance. J. Phys. Conf. Ser. 2020, 1683, 42–49. [Google Scholar] [CrossRef]

- Irfan Sadaq, S.; Nawazish Mehdi, S.; Danish Mehdi, S.; Yasear, S. Analysis of NACA 0020 aerofoil profile rotor blade using CFD approach. Mater. Today Proc. 2022, 64, 147–160. [Google Scholar] [CrossRef]

- Yossri, W.; Ben Ayed, S.; Abdelkefi, A. Airfoil type and blade size effects on the aerodynamic performance of small-scale wind turbines: Computational fluid dynamics investigation. Energy 2021, 229, 120739. [Google Scholar] [CrossRef]

- Wenzinger, C.J.; Harris, T.A. Wind-Tunnel Investigation of an NACA 23012 Airfoil with Various Arrangements of Slotted Flaps; Technical Report; NASA: Washington, DC, USA, 1939. [Google Scholar]

- Todorov, M. Aerodynamic Characteristics of Airfoil with Single Slotted Flap for Light Airplane Wing. In Proceedings of the International Conference of Scientific Paper AFASES 2015, Brasov, Romania, 28–30 May 2015; pp. 509–514. [Google Scholar]

- Hussein, E.; Azziz, H.; Rashid, F. Aerodynamic study of slotted flap for NACA 24012 airfoil by dynamic mesh techniques and visualization flow. J. Therm. Eng. 2021, 7, 230–239. [Google Scholar] [CrossRef]

- Prabhakar, A. CFD analysis on MAV NACA 2412 Wing in high lift take-off configuration for enhanced lift generation. J. Aeronaut. Aerosp. Eng. 2013, 2, 5. [Google Scholar] [CrossRef]

- Saha, N. Gap Size Effect on Low Reynolds Number Wind Tunnel Experiments. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 1999. [Google Scholar]

- Yavuz Hakan Ozdemir, B.B. 2D and 3D Potential Flow Simulations around NACA 0012 with Ground Effect. Res. Sq. 2021, preprint. [Google Scholar]

- Ladson, C.L. Effects of Independent Variation of Mach and Reynolds Numbers on the Low-Speed Aerodynamic Characteristics of the NACA 0012 Airfoil Section; NASA: Washington, DC, USA, 1988. [Google Scholar]

- Chakraborty, S.; Ghosh, S. A CFD study on the structural parameters of NACA 2412 airfoil based air-wing using different composite materials. Mater. Today Proc. 2022, 60, 894–901. [Google Scholar] [CrossRef]

- Çakıroğlu, R.; Erdi Tanurun, H.; Acir, A.; Üçgül, F.; Olkun, S. Optimization of NACA 4412 augmented with a gurney flap by using grey relational analysis. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 167. [Google Scholar] [CrossRef]

- Yusop, F.; Mustafa, S.S.; Awang, M.; Hassan, N.N.M.; Noor, H.M. Comparison of Pressure Distribution of NACA 0012 Between CFD Code and Experimental. CFD Lett. 2022, 14, 35–41. [Google Scholar] [CrossRef]

- Loutun, M.J.T.; Didane, D.H.; Batcha, M.F.M.; Abdullah, K.; Ali, M.F.M.; Mohammed, A.N.; Afolabi, L.O. 2D CFD Simulation Study on the Performance of Various NACA Airfoils. CFD Lett. 2021, 13, 38–50. [Google Scholar] [CrossRef]

- White, F.M. Fluid Mechanics, 8th ed.; McGraw-Hill Education: New York, NY, USA, 2016; pp. 492–499. [Google Scholar]

- Anderson, J.D. Fundamentals of Aerodynamics, 6th ed.; McGraw-Hill Education: New York, NY, USA, 2017; pp. 567–577. [Google Scholar]

- Jacobs, E.N.; Pinkerton, R.M.; Ward, K.E. The Characteristics of 78 Related Airfoil Sections from Tests in the Variable-Density Wind Tunnel; NACA: Hampton, VA, USA, 1933. [Google Scholar]

- Rao, Y.S.R.; Manohar, M.V.N.S.; Praveen, S.V.V.S. CFD simulation of NACA airfoilsat various angles of attack. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1168, 012011. [Google Scholar] [CrossRef]

- Cihan, B. Numerical drag reduction of a ground vehicle by NACA2415 airfoil structured vortex generator and spoiler. Int. J. Automot. Technol. 2019, 20, 943–948. [Google Scholar] [CrossRef]

- Rogowski, K.; Królak, G.; Bangga, G. Numerical Study on the Aerodynamic Characteristics of the NACA 0018 Airfoil at Low Reynolds Number for Darrieus Wind Turbines Using the Transition SST Model. Processes 2021, 9, 477. [Google Scholar] [CrossRef]

- Michna, J.; Rogowski, K. Numerical Study of the Effect of the Reynolds Number and the Turbulence Intensity on the Performance of the NACA 0018 Airfoil at the Low Reynolds Number Regime. Processes 2022, 10, 1004. [Google Scholar] [CrossRef]

- Hussein, E.; El, M. Boundary-Layer Theory of Fluid Flow past a Flat-Plate: Numerical Solution using MATLAB. Int. J. Comput. Appl. 2018, 180, 6–8. [Google Scholar] [CrossRef]

- Reggente, M. Statistical Gas Distribution Modelling for Mobile Robot Applications. Ph.D. Thesis, Örebro University, Örebro, Sweden, 2014. [Google Scholar]

- Rashid, F.L.; Abd, H.S.; Hussein, E.Q. Numerical study of the air flow over modified NACA 2412 airfoil using CFD. AIP Conf. Proc. 2022, 2415, 020005. [Google Scholar] [CrossRef]

- Abobaker, M.; Elfaghi, A.M.; Addeep, S. Numerical Study of Wind-Tunnel Wall Effects on Lift and Drag Characteristics of NACA 0012 Airfoil. CFD Lett. 2020, 12, 72–82. [Google Scholar] [CrossRef]

- Benoit, M.; Roger, M.; Bosschaerts, W. Multidisciplinary Optimization of Aircraft Propeller Blades. Ph.D. Thesis, Royal Military Academy, Camberley, UK, 2011. [Google Scholar]

- Lyu, P. How Do I Compute Lift and Drag? 2015. Available online: https://www.comsol.com/blogs/how-do-i-compute-lift-and-drag/ (accessed on 15 June 2022).

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten years of industrial experience with the SST turbulence model. Turbul. Heat Mass Transf. 2003, 4, 625–632. [Google Scholar]

- NASA. Menter Shear Stress Transport Model. 2021. Available online: https://turbmodels.larc.nasa.gov/sst.html (accessed on 1 May 2023).

- Douvi, C.E.; Tsavalos, I.A.; Margaris, P.D. Evaluation of the turbulence models for the simulation of the flow over a National Advisory Committee for Aeronautics (NACA) 0012 airfoil. J. Mech. Eng. Res. 2012, 4, 100–111. [Google Scholar]

- Fatahian, E.; Lohrasbi Nichkoohi, A.; Salarian, H.; Khaleghinia, J. Effects of the hinge position and suction on flow separation and aerodynamic performance of the NACA 0012 airfoil. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 86. [Google Scholar] [CrossRef]

- Shan, H.; Jiang, L.; Liu, C. Direct numerical simulation of flow separation around a NACA 0012 airfoil. Comput. Fluids 2005, 34, 1096–1114. [Google Scholar] [CrossRef]

- Uranai, S.; Fukudome, K.; Mamori, H.; Fukushima, N.; Yamamoto, M. Numerical simulation of the anti-icing performance of electric heaters for icing on the NACA 0012 airfoil. Aerospace 2020, 7, 123. [Google Scholar] [CrossRef]

- Smith, A.M. High-lift aerodynamics. J. Aircr. 1975, 12, 501–530. [Google Scholar] [CrossRef]

| Flap Angle | Wind Angle Adjustment | Chord Length (m) |

|---|---|---|

| No flap | 0.00 | 1.80 |

| 10 | −3.55 | 2.11 |

| 15 | −4.78 | 2.10 |

| 20 | −6.01 | 2.09 |

| Symbol | Value | Description |

|---|---|---|

| Variable m/s | Free-stream velocity | |

| 1.2043 kg/m3 | Free-stream density | |

| 1.814 Pa·s | Free-stream dynamic viscosity | |

| P | 101,325 Pa | Free-stream pressure |

| T | 293.13 K | Free-stream temperature |

| C | 1.8 m | Chord length |

| Variable | Angle of attack |

| COMSOL Element | Number of | Average Element | Number of |

|---|---|---|---|

| Size Setting | Elements | Skewness Quality | Boundary Layers |

| Extra coarse | 1742 | 0.870 | 12 |

| Coarser | 2688 | 0.881 | 12 |

| Airfoil Geometry | Flap | Number of | Average Element | Number of |

|---|---|---|---|---|

| Angle | Elements | Skewness Quality | Boundary Layers | |

| 2D NACA 0012 | - | 52,240 | 0.796 | 100 |

| Modified with flap | 10 | 105,800 | 0.738 | 100 |

| Modified with flap | 15 | 105,752 | 0.743 | 100 |

| Modified with flap | 20 | 105,755 | 0.745 | 100 |

| 3D no wingip | - | 665,131 | 0.750 | 25 |

| 3D with wingtip | - | 1,169,579 | 0.735 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Steenwijk, B.; Druetta, P. Numerical Study of Turbulent Flows over a NACA 0012 Airfoil: Insights into Its Performance and the Addition of a Slotted Flap. Appl. Sci. 2023, 13, 7890. https://doi.org/10.3390/app13137890

Steenwijk B, Druetta P. Numerical Study of Turbulent Flows over a NACA 0012 Airfoil: Insights into Its Performance and the Addition of a Slotted Flap. Applied Sciences. 2023; 13(13):7890. https://doi.org/10.3390/app13137890

Chicago/Turabian StyleSteenwijk, Brian, and Pablo Druetta. 2023. "Numerical Study of Turbulent Flows over a NACA 0012 Airfoil: Insights into Its Performance and the Addition of a Slotted Flap" Applied Sciences 13, no. 13: 7890. https://doi.org/10.3390/app13137890

APA StyleSteenwijk, B., & Druetta, P. (2023). Numerical Study of Turbulent Flows over a NACA 0012 Airfoil: Insights into Its Performance and the Addition of a Slotted Flap. Applied Sciences, 13(13), 7890. https://doi.org/10.3390/app13137890