1. Introduction

Offsite construction is becoming more popular nowadays, and an increasing number of construction products are manufactured and controlled out of site. Although previous studies have shown that offsite production could improve construction quality and save time and money for buildings of any architectural style [

1], the current implementation of BIM (building information modeling) in prefabricated construction is far from being perfect and correct [

2]. BIM methodology with precise model information and quantity take-offs can be used in alternative evaluation of any construction elements or buildings, but it is very effective for use in precise design and time-consuming construction works such as suspended brickwork façade. BIM can be used effectively in brickwork façade projects, providing accurate models, detection of clashes, material takeoff, construction sequencing works, 3D visualization connected with workshop design, and other project documentation. Due to the complexity of brickwork façades as architectural products, BIM can implement the production data of support elements for brickwork and a brickwork architectural façade from a prepared BIM model. Knowing that the support elements of a brickwork façade can be manufactured based on a BIM model design, and that the reconstruction of the façade requires actual measurements on site, it is important to request and develop new manufacturing products.

The main novelty of this research is its practical application of building information modeling (BIM) and multiple-criteria decision making (MCDM) for the effective evaluation of suspended brickwork façade production. This paper proposes a BIM-based production for reconstructing a brickwork façade using a BIM building construction (structural) model and applying survey data.

This paper focuses on the Wroblewski Library of the Lithuanian Academy of Sciences in Vilnius (Lithuania). The library was built at the beginning of the previous century. Using old 2D paper design drawings of building, the precise site measurements and the application of the BIM methodology led to a new BIM model for building reconstruction with a detailed brickwork façade design. Then, a brickwork-façade BIM model was prepared to be compatible with heritage conservation requirements. By identifying the brickwork support elements, masonry brick for the façade manufacturing operations was calculated for trial production. After the success of the trial production from the BIM model, the MCDM (multiple-criteria decision making) methodology was applied and three types of installation of brick façades were analyzed, aiming to promote the most cost-effective production method.

The structure of this paper consists of a literature review presented in

Section 2; the research methodology is presented in

Section 3; the case study and the research results are described in

Section 4; the discussion is provided in

Section 5; and, finally, the conclusions are presented in

Section 6.

2. Literature Review

The implementation of BIM is used in different construction areas to make the right decisions [

3,

4]. A BIM project based on multiple evaluation methods, such as structural models, architectural models, and sustainable evaluation [

5,

6], facilitates the approach based on the concept of a digital twin of buildings, which provides digital representation of real buildings including all models and necessary data for production [

7]. Digital twin technology has great potential to form a BIM system that enables digital construction through a building’s entire life cycle [

8]. In this paper, the main focus is on the use of a BIM structural project for brickwork façade design and production. Nevertheless, the production of construction elements is not yet linked in the BIM environment, as manufacturing construction products is a sequential process that involves numerous manual operations [

9]. However, during the design stage of brickwork façade, the implementation of BIM could ensure cost savings, and some researchers have proven that BIM supports production from a model and ensures cost reduction [

10]. BIM applications provide new possibilities to save costs [

11] not only during the design stage [

12,

13,

14] but also during the production stage [

15]. Some examples are offsite production with minimum activities on site [

16], which saves energy and material consumption, proving the benefits of BIM application during the production stage [

17]. Another benefit of BIM is the application of scanning technologies, which increases the accuracy of construction details and improves cost savings [

18]. BIM models that receive detailed information can provide a good information environment for assessing the quality of construction [

19] and ensure the best results. BIM models include the data of building components and offer the possibility of tracking the supply chains of construction products and materials [

20].

Due to the complex decisions on how to implement architectural brickwork façades and the progress of production technologies, there is an urgent need to improve production processes based on BIM models, together with innovative brickwork façade installation methods. This provides an opportunity for all stakeholders in the process [

21] not only to design 3D products but also to manage them according to PLM (Product Lifecycle Management) methodology during the production stage. It is established that BIM and LCA (Life Cycle Assessment) provide better quantity calculations for further steps of a project [

22,

23], but production modeling requires skilled stakeholders with design and construction competencies [

24] as construction managers are more experienced in project management than in offsite production management, although the latest research shows the benefits of offsite production [

10]. To summarize, BIM can be used to produce, manage, and share data of building structures, while GIS (Geographic Information System) can be used for the logistical aspect of a building project, including to collect, manage, and analyze data [

19,

25].

With the development of BIM technologies for brickwork masonry façades, and due to the complexity of such projects, information needs to be quickly available and shared between the design and production stages. However, using BIM technologies in construction projects requires data during all implementation stages of such projects, such as planning [

2,

26], design [

7,

11], production [

9,

24], construction [

16,

27], maintenance [

19], and reconstruction [

28,

29], to make the right decisions.

Various MCDM (multiple-criteria decision making) methods have been applied to solve different problems of the building life cycle stages [

30,

31]. Decision making always faces certain challenges, and the impact of risk and uncertainty must be assessed. A new area of multidisciplinary application of BIM with MCDM methods for selecting alternatives in the construction industry [

32,

33] is related to the integration of BIM and MCDM for implementation at various stages of the building life cycle [

34]. The authors of [

35] demonstrated the benefits of implementing an MCDM method with BIM adaption through cost savings on life cycle assessment and project facilities. Moreover, assessment using MCDM could track projects costs for BIM projects [

36]. The efficiency of the design and production chain depends on decision making at each stage. First, BIM works, then MCDM data processing takes place, after which MCDM generates the results to make the final solution implementation in the BIM project [

37]. Another example of using the operations research method is BIM application for performance evaluation [

38] and evaluation of the compliance of existing buildings with the latest standards [

39]. Some research has integrated a multiple-criteria method with BIM for quantitative construction quality evaluation [

19], material selection, and production [

40]. Some researchers emphasize the application of BIM together with MCDM methods because it can provide greater success in decision making [

37] and it can be applied to both small and large projects [

41] to reduce energy consumption and contribute to sustainable development.

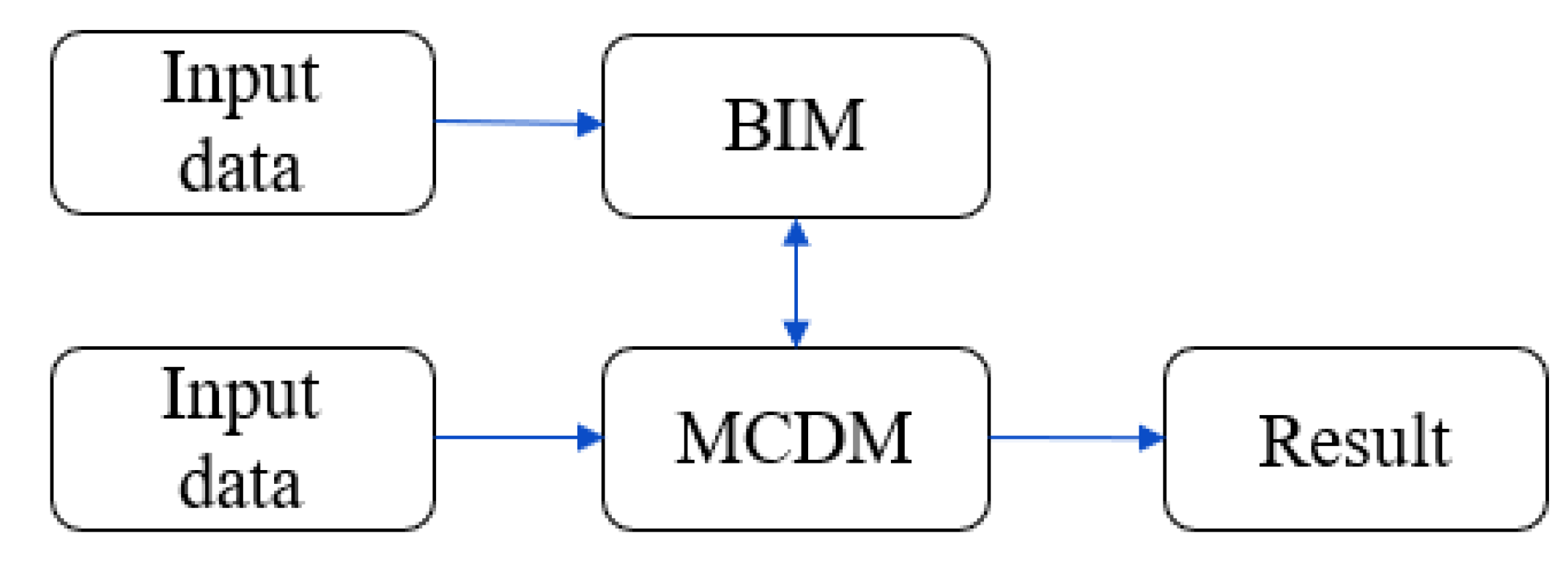

There is, however, limited research on the practical integration of MCDM with BIM and how to perform this integration effectively. Two integration methods are offered: linear and integrated [

37] (

Figure 1). The linear structure is a one-way workflow from BIM to MCDM, and the integrated structure has a two-way interaction. BIM first acts as a data foundation for MCDM processing, and then the MCDM processing generates results which are exported back to the BIM platform, which presents the results and stores the performance evaluation results for further use.

The integration of MCDM with BIM is applied in various areas of the construction industry, including the selection of design alternatives for a new building and reconstruction of an old building [

28], the selection of building materials and elements, precise quantity take-offs, estimation and evaluation procedures [

29], the selection of materials for production, the selection of suppliers, and simulations. Although the linear method of integration is generally used, an integrated method could help to fully realize the advantages of BIM technology and MCDM methodology [

27]. In order to fully utilize the possibilities of BIM, it is better to apply two-way integration of MCDM with BIM to obtain greater benefits of use [

37].

Considering the performed literature review, this research proposes a new method of the installation of a suspended brickwork façade as prefabricated building elements to improve project performance, reduce time, and increase cost savings [

42,

43]. An assessment of the proposed alternative installation methods at the production stage by using the building construction model obtained via the application of BIM and MCDM is suggested and described in the next sections in terms of methodology and case study. In the current research, the WASPAS (Weighted Aggregated Sum Product Assessment) method is applied based on the benefits identified during the literature review in terms of material selection [

44], manufacturing [

45], and production management [

46,

47].

3. Methodology

The proposed research methodology is based on the evaluation of three alternatives for brickwork production with BIM application and the production alternatives’ assessment using MCDM methods. The proposed methodology consists of a principal approach and suggested steps.

3.1. Principal Approach of the Proposed Methodology

The steps of the suggested research approach to rebuild a masonry brick façade by applying MCDM and BIM methodologies are listed below and detailed in

Figure 2:

Step 1. Defining the criteria of the production stage in terms of cost savings by analyzing three groups of criteria: preparation for production (purchasing), production, and logistics. Each group of criteria consists of six criteria. These criteria evaluate the alternatives in terms of cost savings and promote an economic approach for suspended brickwork façade elements at the production stage.

Step 2. Applying an expert survey to estimate the relative weights of the criteria. The experts are asked to arrange the three groups of criteria according to their importance and then to arrange the six criteria in each group according to their relative importance.

Step 3. Implementation of precise site measurements before the design of the brickwork façade.

Step 4. Using precise site measurements and the construction data of the brickwork façade design, the BIM construction model is implemented.

Step 5. Preparing a building information model based on the design of the three alternatives of suspended brickwork elements.

Step 6. Defining compatibility with heritage conservation requirements as the brickwork façade must be rebuilt, and the architecture and volume of the building must be the same. If compatibility with heritage conservation requirements is not accepted, then it is necessary to return to step 4 and the BIM construction model must be corrected.

Step 7. Preparing trial production and labor tests. After designing the newly promoted alternative, it is tested in the laboratory for load-bearing capability and deflections (

Figure 2).

Step 8. Ranking the alternatives by applying the multiple-criteria assessment and finding the most rational suspended brickwork façade production alternative by using the WASPAS method.

Step 9. Preparation for production, production, and logistic phases according to the BIM model.

3.2. Methods for Multi-Criteria Ranking of Alternatives

Our task of multi-criteria evaluation and ranking of suspended brickwork facades consists of m alternative facades and n criteria, describing the performance of the alternatives. The variable xij means the performance of alternative i when it is described by the criterion j, where i = 1, …, m, and j = 1, …, n. The variable wj means the weight (relative significance) of the criterion j.

The basis for estimating the weights of the criteria is via the application of an expert survey. Then, the responses of the experts tjk, k = 1, …, r (where r is number of experts), as scores obtained according to the scale, are statistically processed.

First, the mean value of scores

is calculated as follows:

The weight of every criterion

wj is calculated as follows:

The compatibility of expert opinions is evaluated by applying the concordance coefficient

W [

48,

49]:

The significance of the concordance coefficient

is calculated by applying the following equation:

The calculated value is compared to the normative value at a certain level of significance. If the calculated value exceeds the normative value , we can conclude that the hypothesis regarding the compatibility of expert opinions is accepted.

Next, to evaluate and rank the alternatives, the WASPAS (Weighted Aggregated Sum Product Assessment) method developed by Zavadskas et al. is applied [

50]. The steps of calculation are presented below according to the initial source of the method.

The method involves two classical criteria of optimality; namely, WSM (weighted sum) and WPM (weighted product). A joint generalized criterion involving the two mentioned criteria of optimality (weighted aggregated function, using aggregation coefficient λ, λ = 0, …, 1) for calculating the relative importance of alternative Qi is suggested.

The first criterion of optimality is based on WSM. The relative importance of alternative

i is defined as follows:

where linear normalization of the initial criteria values is applied according to Equation (6) for maximized (benefit) criteria and Equation (7) for minimized (cost) criteria:

According to the second criterion of optimality—namely, the multiplicative exponential generalized criterion—the relative importance of alternative

i, is defined as follows:

Assuming that there is an increase in ranking accuracy and, subsequently, the effectiveness of decision making, a joint generalized criterion of the WSM and WPM methods and the methodology for optimization of weighted aggregated function is proposed [

50]:

In this paper, the authors take the value of the aggregation coefficient

, given the equal weights of both criteria of optimality. Therefore, the following equation is used for further calculations:

4. Case Study

In this section, a case study involving the rebuilding of the suspended brickwork façade of the Wroblewski Library of the Lithuanian Academy of Sciences in the center of Vilnius is presented. The library was established in 1912–1931 by Tadeusz Stanislaw Wroblewski. It was known as the Wroblewski State Library in 1931–1940 and, after 1941–2009, as the library of the Lithuanian Academy of Sciences. The library was renamed the Wroblewski Library of the Lithuanian Academy of Sciences on September 29 in 2009. According to the managers of the library, the building was often flooded during rain and, due to the intensive traffic and construction of the Mindaugas bridge nearby, the walls of the library cracked. This is why the building of the library was in a state of emergency; therefore, during this project, the main structures were strengthened, and the brickwork façade was rebuilt. The book storage building, which was built in 1885, was partially demolished because of functional and technical reasons. Furthermore, the main façade of the library featured a brickwork with unique reliefs and unique patterns, so the view of the book storage building blended with the great heritage façade of the library. The architecture and the volume of the building remained the same, and the brickwork façade was restored as before the reconstruction works.

4.1. BIM Application Process

The brickwork masonry façade is the main “skin” of a building structure and gives the shape and appearance to the building. Modern architectural practice includes a wide range of digital tools that give an original appearance to building structures. Architectural brickwork masonry elements, such as 3D brickwork, lintels, columns, and load-bearing elements, are modeled by applying BIM tools. The application of BIM tools by all project participants allows collaboration during the production stage of the suspended brickwork masonry façade. The design for the production of the suspended brickwork masonry façade is one of the optimal tools used for cost savings due to its complexity. This research promotes BIM application during the production stage of suspended brickwork masonry façades to achieve better results.

Manufacturers of building materials and elements are increasingly providing BIM data. It has become important for the production industry to use building material models and to distribute them to existing BIM model participants. The data form the BIM materials and elements to promote economic decisions between designers and architects at the production phase. However, to promote BIM data delivery during the production stage and to manage the BIM process, a BIM working group is needed to facilitate collaboration.

The BIM application in this research is based on a list of various ways and steps applied during the reconstruction of the Wroblewski Library of the Lithuanian Academy of Sciences. It can be described as follows:

The collection of initial design data was performed via the evaluation and digitalization of the initial paper design using the basic design software AUTODESK AutoCAD 2020 (

Figure 3 was created by the designers before partial demolishing works, showing the detail of the initial design in the DWG format).

Real situation analysis was started after the partial demolishing works (

Figure 4). The visual investigation conducted by the structural experts identified which parts of the construction had marginal deviations from the acceptable tolerance level (mostly gaps, levels, and inclinations). Then, a precise geodesical survey and laser scanning was initiated to obtain the point cloud array connected to the precise georeferenced points, which were exported from the point cloud and AUTODESK AutoCAD 2020 software, and later used as the background for 3D modeling (

Figure 5).

The construction model was prepared with a deeper BIM application for the whole multidiscipline design using the AUTODESK Revit 2022 (not only for architecture and construction but also for HVAC and other collaboration design in IFC format).

The final design of the suspended brickwork façade layout and suspending load-bearing elements was prepared as a BIM model using the BENTLEY Open Building Designer.

The design elements were exported and modeled up to an acceptable level for production using SOLIDWORKS 2022, and the element layout was optimized for resource savings.

The improvement made to the BIM model and production occurred through several internal cycles to ensure sustainable design, production intents, and time savings for construction.

The BIM technologies can help to implement architectural solutions for masonry façades and analyze the capabilities and limitations of brickwork façades with real façade parameters. The suggested BIM operations and project participants for collaboration in the production stage are shown in

Table 1 and the BIM application (

Figure 5).

The BIM model was used for production preparation, production, and logistics. It is necessary to increase the LOD (level of development) of the brickwork support system and brickwork façade as the quality of the design has a great influence on the production.

During the construction stage, the required level of design documentation development is the LOD 300 or LOD 350 [

51]. However, the recommended level of detail for the suspended brickwork façade is the LOD 400 because, for the MDP (design for production), a higher level of detail is required. Data for the support elements of the brickwork and brickwork façade are necessary to define the elements and create BOM (building object model) elements [

52] for trial production. A full characterization of the BOM elements has great importance in production preparation. A BOM is a building product model which is a component of the BIM model [

53]. All data were generated from the model (

Figure 6 and

Figure 7), and all BOM elements were used to prepare for production (3D model and production drawing) and to calculate the estimated value of the project elements (

Figure 8).

Furthermore, the BIM model was used for a lean process in logistics and in storage for cost savings [

54]. Moreover, the BIM model and the MCDM technique were used during the selection of the suspended brickwork façade installation method to save costs in this research. The BIM construction model was used to design the architectural model and suspended brickwork system in order to compare the three installation methods through the three production stages. The preparation for production stage was first analyzed, followed by the production stage and, finally, the logistic stage. The model was also used for trial production and estimation of quantitative take-off of materials during the production and logistic stages. The greatest benefits of applying BIM in the production stage are production management, schedule control, and cost monitoring.

4.2. Description of Alternatives

Alternative No. 1. The installation of the suspended brickwork and the mounting of the brickwork lintels were up to two meters. The veneer brick façade was suspended on the frame of the building by dividing it into individual fragments with expansion spacers (

Figure 9). Every suspended brickwork element was supported by a line of brackets. Stainless steel was used for the brickwork suspension brackets in accordance with the base, on which the brackets were mounted on cast-in-place reinforced concrete (C20/25). The first brick line was laid on the bracket and the two next bricks were laid to reinforce. The brickwork lintels were installed using mounting lintel hooks and steel reinforcement.

Alternative No. 2. The installation of the suspended brickwork and pre-prefabricated stainless-steel components, which were manufactured offsite, was completed with adhesively bonded brick slips (

Figure 10). Every suspended brickwork façade fragment was fixed as in alternative No. 1, but the brickwork lintels were prefabricated offsite. This is a lightweight brick tile solution to achieve a deeper soffit and seamless brickwork with the same view as on site. Moreover, the brickwork lintels do not need any construction formwork as is required for alternative No. 1.

Alternative No. 3. The prefabricated suspended brickwork masonry panels are shown in

Figure 11. These brickwork panels (51 mm thick) were prefabricated offsite. The design of these brickwork panels enabled the installation of a volume of bricks that was twice larger than alternative No.1 and alternative No. 2. The suspended brickwork panels were produced using perforated bricks and mounted with suspending brackets on cast-in-place reinforced concrete (C20/25).

4.3. Description of Criteria

A supply chain for production typically consists of multiple phases such as purchasing, manufacturing, logistics, and inventory [

55]. In this research, the production stage was analyzed using three alternatives and three groups of criteria: G

1—preparation for production (purchasing); G

2—production; and G

3—logistics. Each group of criteria consists of six sub-criteria. The criteria and sub-criteria used to evaluate the alternatives for cost savings and to promote an economic approach during the production stage of suspended brickworks are described in

Table 2,

Table 3 and

Table 4.

4.4. Expert Survey

The expert survey was used to determine the relative weights of the criteria (this survey was completed in the spring of 2023). Ten experts with 6–18 years of experience from the construction industry were involved in this survey, and the distribution of the experts’ characteristics is presented in

Table 5.

First, the experts were asked to rank the three groups of criteria according to their importance. The experts had to rank the scores of the three groups of criteria (G1, G2, and G3) based on a scale of 1–3, where 3 means the highest importance and 1 means the lowest importance. Second, to determine the importance of the sub-criteria in each group, the experts were asked to rank the six sub-criteria according to their relative importance using a scale of 1–6, where 6 means the highest importance and 1 means the lowest importance.

The next step was calculating the weights of the three groups of criteria and sub-criteria (Equations (1) and (2)). As the hypothesis regarding the compatibility of expert opinions is accepted (Equations (3) and (4)), we can conclude that, according to the expert survey, the G

2 (production) group of criteria is the most important, followed by the G

1 group (preparation for production), and the least important is the G

3 group (logistics). The weights of the different criteria in the groups are distributed from 0.10 to 0.25. The results of the expert survey are presented in

Table 6.

4.5. Calculation Results Applying WASPAS

The evaluation of the three alternatives, A

1, A

2, and A

3, was performed by using the relative criteria weights obtained from the expert survey and applying the WASPAS method. An initial decision-making matrix (criteria values of the alternatives) for the preparation for production, production, and logistic groups of criteria is presented in

Table 7. The normalized criteria values (Equations (6) and (7)) are presented in

Table 8, and the weighted normalized matrices and the results of the WSM and WPM methods (Equations (5), (8)–(10)) are presented in

Table 9 and

Table 10, respectively.

The next step of the study was to calculate the WSM and WPM and, finally, determining a joint criterion of optimality

Qj. The results of the final evaluation and the final ranking of the alternatives are provided in

Table 11.

5. Discussion

The final results of the G1 (preparation for production) group of criteria show that the third alternative A3 gained the first rank, the alternative A1 gained the second rank, and the third rank was gained by alternative A2. The results of the G1 group show that A3 exceeds A1 by 26.88% and A2 by 39.78%. Next, the final results of the G2 (production) group of criteria show that A1 gained the first rank by a very small margin, A3 gained the second rank, and A2 gained the third rank. The percentage ratio in the G2 group is as follows: alternative A1 is above A3 with a lead of only 1.02% and above A2 by 20.62%. Finally, the results of the G3 (logistic) group of criteria show that A1 gained the first rank, being above alternative A3 in the second rank by a small lead of 2.47% and above alternative A2 in the third rank by 7.41%.

The final assessment and the overall ranking of the suspended brickwork façade installation methods at the production stage by considering the weights of each group of criteria are as follows: alternative A3 (installation of prefabricated suspended brickwork masonry panels) is ranked first, with alternative A1 (installation of suspended brickwork and mounting of brickwork lintels up to two meters) in the second rank, being 6.59% behind the first position, and alternative A2 (installation of suspended brickwork and pre-prefabricated stainless-steel components that were manufactured offsite completed with adhesively bonded brick slips) in the third rank, being 23.08% behind the first position.

The literature review and practical experience showed that offsite production could improve construction quality and save time and money, but current implementation of BIM in prefabricated construction is far from perfect and correct.

In this research, a BIM brickwork façade model was prepared based on survey data and analyzed design solutions. The designed building object model elements did not have sufficient level of detail for the production stage, but the masonry bricks and brickwork support elements emulated the geometric and non-geometric data in the BIM model. Nevertheless, the model data of the building object model elements was used for production and the BIM model was applied for the calculation of elements, such as masonry bricks, mortar, reinforcement, stainless-steel wall ties, stainless-steel masonry support elements, and stainless-steel anchor rods. Moreover, in terms of cost savings, the BIM application showed benefits in terms of shareholder collaboration, reduction in errors, and optimization of production process for better construction results.

6. Conclusions

Three alternative methods of suspended brickwork façade installation during the production stage were compared in this research using multiple criteria. Experts from the construction industry were asked to estimate the relative significance of three groups of criteria and each sub-criterion in each group. According to the expert survey, the production group of criteria (G2) was the most important (wj = 0.47). The application of typical elements, in % (weight wj = 0.23) from the preparation for production group of criteria; the production time of steel elements, in workdays (weight wj = 0.25) from the production group of criteria; and supply cost, in 150 km/euro (weight wj = 0.25) from the logistic group of criteria were established as the most important criteria among the 18 criteria from the three groups.

Based on the results of this research, the authors promote the application of the best alternative as a new cost-saving method for the production of a suspended brickwork façade. The new installation method of a suspended brickwork façade was compared to two common installation methods during the production stage by applying the Weighted Aggregated Sum Product Assessment method. Alternative A3 (installation of prefabricated suspended brickwork masonry panels of 51 mm thickness) was ranked first, with Qj = 0.91 showing a superior value ranging from 6.59% to 23.08% over the other alternatives. Accordingly, the prepared BIM brickwork façade model was adapted for the production of suspended brickwork elements.

All research work by the authors, including previously published studies, consists of assessing the three above-described alternative methods of suspended brickwork façade installation together with the application of multiple-criteria decision making and building information modeling during the whole project life cycle, including the design, production, and construction stages. In a previous study, the evaluation of masonry façade installation methods was performed at the design stage, and the most advanced alternative A

3 was ranked second, but the distance from the first-ranking alternative was insignificantly minor (only 0.50%) [

56]. However, during this research and other relative analysis in the production stage, the superiority of the suggested new method of installation for a masonry brickwork façade over the other alternative methods was analyzed and showed a larger distance from the other alternatives. Future research will focus on analyzing these alternatives at the construction stage using multiple-criteria decision making and including a deep analysis of building information modeling application benefits at the construction site. The proposed sustainable approach and overall assessment of suspended brickwork façade installation methods combining the results of and insights into the design, production, and construction stages will be analyzed.