1. Introduction

The traffic safety of a vehicle depends on the braking system parameters. Braking is the vehicle’s ability to decelerate quickly and come to a complete stop at a minimum distance. The key vehicle braking parameters are breaking force and deceleration. However, in practice, braking time and braking distance are mostly used. According to the laws of physics, the braking factor does not change if the load on the tire varies [

1].

The vehicle kinetic energy changes into thermal energy during braking, and the temperature from the interface between the pads and brake disc, as well as the change in speed, have a significant impact on the coefficient of friction because it decreases with growing sliding speed and temperature. Brake wear is a phenomenon that occurs for any braking system when the friction coefficient decreases significantly depending on the temperature [

2,

3]. High-temperature values during braking cause brake degradation, premature wear, vaporization of brake fluid bearing failure, thermal cracking, and thermal vibrations. The ideal brake pads must ensure uniform and stable friction in all working conditions, without generating brake degradation, regardless of temperature. To achieve the desired braking performance, brake materials must have the appropriate composition, including stable friction coefficients and wear and noise generation reduced, in different (a wide range) braking conditions.

Mathematical models are frequently used which are intended for the analysis of vehicle braking parameters [

4]. However, the values of deceleration and braking distance parameters are random values in practice [

5].

During operation, the braking system components have a dominant effect on friction coefficient and brake wear, which are generally dependent on load, speed, sliding time, and the temperature at the interface between the disc and the brake pads temperature. Numerous studies have demonstrated the dependence of the friction coefficient on temperature, braking force, and speed [

6,

7,

8,

9]. In most studies, the friction coefficient is inversely proportional to the travel speed, while it shows a mixed trend depending on the vehicle mass [

10].

In steady-state based on some experimental tests, a very simple analytical formulation has been proposed that establishes the dependence of the thermal effects following the increase of friction materials temperature, pressure, sliding speed, friction temperature, and wear in the contact area between the disc and the brake pads [

5,

10,

11]. Current braking systems allow braking process optimization, considering the dynamic factors of grip, longitudinal and lateral accelerations, the semi-trailer/trailer presence, etc., from the brake pedal action to the final braking phase. The braking is estimated not only depending on the race or the brake pedal position but on its ability to perform emergency braking [

12,

13] and on its acceleration speed. Most studies and research analyze the friction process between two materials in detail, by friction coefficient variation for different pairs of materials in different test conditions [

14,

15]. Other studies and research are limited to wear process effects [

16] to identify its causes with the aim of increasing durability. Zhang et al. [

17] recognize that the wear phenomena study is in the empirical stage, as well as that there are some aspects present that are not yet fully understood. Most of the time, brake discs and pads mounted on used vehicles do not have the same properties as the original ones, thus leading to faster wear [

13].

Additionally, Kchaou et al. [

16] analyzed the variations of friction coefficient, depending on interfacial temperature and friction conditions through simulations using finite element analysis. These analyses provide quite conclusive values, as advantages, but also present disadvantages because they require some simplistic assumptions in complex situations [

18].

In the current environmental conditions (pollution), another aspect of great importance is the formation of material particles and their size classification, which analyzes air quality in a closed space by measuring, testing [

15], and considering the big number of vehicles in circulation. Related to the air quality with implications on life quality, there are experimental studies on noise (sound pollution) at braking using different materials and constructive variants for the brake pads. The noise produced at braking is in particular influenced by the friction conditions (type of material, contact surface, normal force, sliding speed, temperature, etc.) [

18].

The braking systems’ performance is also given by the constructive variant choice, the focus being on the grouping of the benefits and disadvantages of some variants of braking systems. The most common are disc or drum brakes and drive unit liquid or air [

12]. Some research highlights the advantages of disc brakes, compared to those of drum brakes [

18]. Modern vehicles are equipped on the front wheels with ventilated disc brakes while the rear wheels are equipped with either unventilated disks or drums, and high-performance vehicles always have disc brakes both on the front and rear.

Thus, Yin et al. [

19] analyzed the braking process and test methods and identified five main parameters to determine the braking performance of a vehicle, namely friction coefficient between the road surface and the tire, vehicle mass, driver physical effort, the braking command and control system, and the friction coefficient between disc and the brake pads during braking. Then, Rashid [

20] and Sharip [

21] investigated in extreme conditions the braking performance of the brake discs. Therefore, they claim that brake discs must have more efficient heat transfer, good thermal conductivity, good mechanical strength, friction high resistance, thermal shock, and good friction characteristics. Moreover, regarding wear, light weight, and convenient adjustment of the braking system components [

22], there must not be significant differences, and all these are depending on the constructive variant choice. Therefore, the regulations imposed, which must be fulfilled by braking systems, change continuously, and the performance requirements are constantly increasing as shown by Volkov et al. [

23]. Thus, numerous studies and research have been undertaken [

18,

22] to improve the reliability and performance of braking systems.

Considering all these aspects, this paper aims to study the behavior of the braking system in conditions of intense and moderate traffic by analyzing some important parameters, both theoretically and experimentally, to increase the safety of traffic participants. To determine the braking system tribological behavior in conditions of intense and moderate traffic, several successive tests were carried out on the vehicle, through which the wear tendency of the brake pads, even of the brake discs, was followed, as well as the efficiency evolution of the system braking. For this purpose, it was necessary to carry out tests on the dynamometer stand, as well as in traffic (off-road), with the purpose to determine the efficiency of the braking system depending on the vehicle mass, travel speed, braking distance, and time. Additionally, the degree of wear of the brake pads was periodically monitored.

Experimental tests were carried out with the aim to establish the braking system efficiency of a vehicle by measuring the distance and stopping time in relation to the initial speed, the mass of the vehicle, and the number of kilometers traveled, in conditions of intense and moderate traffic.

Thus, the braking system efficiency of a vehicle is defined as the braking force produced as a percentage of the total weight/mass of the vehicle, or braking efficiency is the ratio between the braking force and the weight of the vehicle, expressed in percentages, by the following relationship [

24]:

By processing relation (1), taking into account that the mechanical work,

W = F·s, deposited by the vehicle’s braking system from the moment of braking until the complete stop of movement (vehicle final velocity,

vf = 0) must be equal to the initial kinetic energy of the vehicle,

E = (

M·v2)/2 and the equation/relation (2) is obtained in the form

.

The measured parameters in equation/relation (2) are as follows: initial travel speed, v = S/t; braking distance, S = v·t − (d·t2)/2, implicitly and by braking/stopping time (braking application duration (t, (s)); and d, the deceleration of the vehicle in m/s2.

In the case of this paper, the efficiency of the braking system of the tested vehicle was established by measuring the distance and the stopping time, which is also the novelty of this study (the measurement of the stopping time). In addition, the measurement of these parameters (distance and stopping/braking time) also allowed the validation of the efficiency of the braking system in the vehicle used for research.

2. Materials and Research Method

For the experimental determination of the efficiency of the braking system, a vehicle was used in conditions of intense traffic in an urban area, where the braking system was heavily stressed, and the brake pedal was operated frequently, following the replacement of the brake pads.

Additionally, the vehicle under test was also used in extra-urban areas (characterized by road routes on the plain) at constant speeds, where the braking system was not used intensively but moderately. The vehicle (equipped with an ABS system and braking assisting devices) chosen for the experiments has a disc and pad braking system, both on the front axle and as well as the rear one. On the front axle, the vehicle has ventilated discs (

Figure 1a), while on the rear axle, it is equipped with solid (non-ventilated) discs (

Figure 1b).

The vehicle’s technical specifications are presented in

Table 1.

The Nussbaum VISIO dynamometer (ATT Nussbaum Prüftechnik GmbH, Kehl-Auenheim, Germany) was used to measure parameters useful to establish the brake system efficiency of the vehicle under test, with a BT110/410 roller set (3.5 kW, 6.0 kN, 5.0 km/h), and is presented in

Figure 2.

This dynamometer model is used for testing the braking system for vehicles and light commercial vehicles and is equipped with an analog display that indicates the braking force on a circular scale with a diameter of 350 mm (see

Figure 2a). A brake force excessive imbalance is indicated by warning lamps [

23]. The analog display has the advantage of clearly and quickly indicating the results, and a computer can graphically display values and results that can be presented and stored in a database.

Braking force values are quickly and easily read on the 350 mm circular scale of the analog display (see

Figure 2a). Warning lamps light up when the braking slip limit values and maximum braking force difference are exceeding values that can be adjusted. Values such as the mass on the axle, braking forces (on the wheels, axles, the difference between the braking forces, and the ratio on the axle, as parameters for determining the braking efficiency (defined above by relations/Equations (1) and (2)) are shown on the 14-digit LCD (see

Figure 2b).

Therefore, the braking efficiency of the vehicle is evaluated by measuring the braking forces at the roller brake dynamometer (see

Figure 2a).

The modern software system (see

Figure 2a,b) offers many possibilities and is essentially simple and intuitive to use on an interface with two levels. According to your own requirements, the software can be configured so that the display of the braking force can be represented in analog or graphical form. The graphic display of braking force can be represented analogically or in columns. The test can be started by the displacement of the vehicle on the test strip. Two or more sequences can be configured, and subsequently, the test procedure that best suits the requirements can be selected [

23].

After the dynamometer rollers (

Figure 3a,b) have been put into operation, with the help of an electric motor, the test stand recognizes if all vehicle wheels are correctly positioned on the dynamometer rollers. Otherwise, it automatically changes the test sequence to irregular rolling left–right [

23].

The brake pedal force sensor (

Figure 3c) is another important accessory of the dynamometer, whose signal can be read from a distance or sent via wire. This will allow the calculation of the difference between the braking forces using the brake pedal force. The difference in braking force can be printed on the test report protocol or viewed on the LCD display.

Testing the braking system’s effectiveness was made at the speed of 5 km/h and a braking force of 6 kN, according to the specifications in ref. [

23]. The dynamometer rollers are made of plastic corundum or in welded construction, and both have adhesion coefficients that fulfill international requirements.

The test stand is also equipped with an optional weighing device, which measures the mass of the vehicle under test [

23] mounted under the dynamometer rollers useful for establishing the braking efficiency (see relations/Equations (1) and (2)). In

Table 2, the parameters that influence the braking system efficiency, determined by measuring/weighing on the test stand, are presented. Both the vehicle mass and the wheels and axles mass were measured on the test stand in stationary conditions, with the help of the weighing device with which the stand is provided.

To determine the service and parking brake parameters, further tests were performed. Thus, the vehicle wheels on the front and rear axles were placed on the set of rollers of the test stand. The electric motor of the test stand sets the rollers in motion, which rotate the wheels of the vehicle with a number of rotations equivalent to a travel speed of 5 km/h.

To test the service brake, the operator operates the brake pedal which is connected to a sensor measuring the pedal pressure. With this device, the test stand software can determine the difference in braking force.

By pressing the brake pedal, the brake pads press against the disc, thus stopping its rotational movement. Thus, with the help of the sensors mounted on the test stand, the software can determine and calculate the important parameters of the service braking system. The pedal is operated repeatedly in order to determine the most accurate results. Instead, for testing the parking brake, after the operator actuates, the brake pads press on the disc via the caliper and stop the rotational movement of the brake disc, but with a much lower braking force than the service brake. And in this case, the sensors and the test stand software determine the important parameters of the parking brake system. The following devices were used for field tests: timer, roulette, mobile radar, and reference points for actuating the brake pedal.

Therefore, the experimental procedure/methodology intends to study the behavior of the braking system of a vehicle in intense and moderate traffic conditions to increase traffic safety by establishing its efficiency.

The establishment of the braking system efficiency of the vehicle chosen for testing was based on a series of successive experimental tests, through which the degree of wear of the brake pads and discs was monitored, with the aim of observing the efficiency evolution of the braking system. The experimental tests were carried out both in the laboratory (on the stand with the help of the dynamometer) and in traffic (urban and extra-urban), according to road safety regulations, depending on some parameters considered essential. On the other hand, the determination of the braking system efficiency (defined above by relations/Equations (1) and (2)), was achieved by measuring the distance and time of stopping/braking (output parameters together with the degree of wear of the brake pads and discs) in relation to the initial speed, the mass of the vehicle, and the number of kilometers traveled (input parameters). At the same time, the experimental tests carried out in series and successively showed the need for more frequent replacement of some elements of the braking system.

The results of the experimental tests are discussed, analyzed, and presented through tables and graphically in what follows.

3. Experimental Results and Discussions

Intense traffic places a faster deterioration on the vehicle’s braking system, leading to premature wear of the brake disc and pads. Moreover, limited situations, such as sudden and strong braking, contribute frequently to the destruction of the braking system.

Studies have shown that, on average, the lifespan of brake pads is between 40,000 and 100,000 km. The range is relative, considering the fact that the life of the brake pads is also influenced by the number of actuation of the brake pedal. Drivers who drive in urban areas are recommended to change their brake pads every 40,000 km, while drivers who drive outside urban areas are recommended to change them every 100,000 km.

After installing a new set of pads, the vehicle was subjected to a set of tests on the brake system test stand (although the brake discs (from cast iron) showed little signs of wear, scratches, and rust on the contact surface). Along with changing the pads, the brake fluid was also replaced, so that the efficiency of the braking system was as high as possible. The efficiency of the tested vehicle’s braking system was established during road tests and on the test stand. The test conditions took into account the condition of the vehicle in terms of mass, which must be the one prescribed for each type of test; the tests were carried out at the speeds prescribed for each type of test, namely at a multiple of 5 km/h; the force applied to the braking system to achieve the prescribed efficiency must not exceed the maximum force provided; the road must be dry and have a surface that provides a coefficient of adhesion in the range of 0.8–0.9; tests should be performed when there is no wind to affect the results. In

Figure 4a, the scratches on the brake disc surface are shown. Traces of wear caused by the use of defective brake pads can be observed, which leads to the destruction of the brake disc.

Figure 4b, shows the degradation of the brake disc caused by the presence of rust.

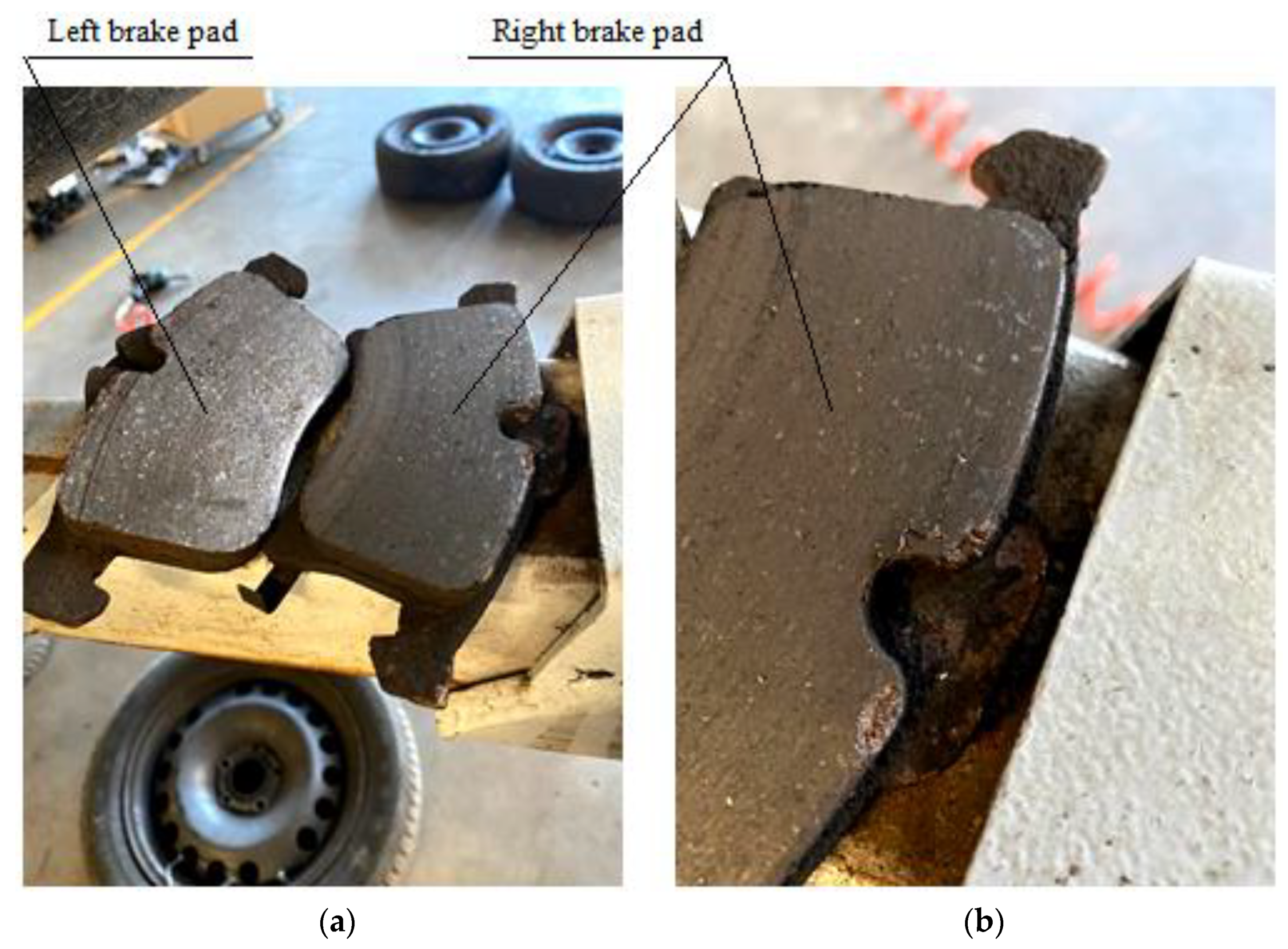

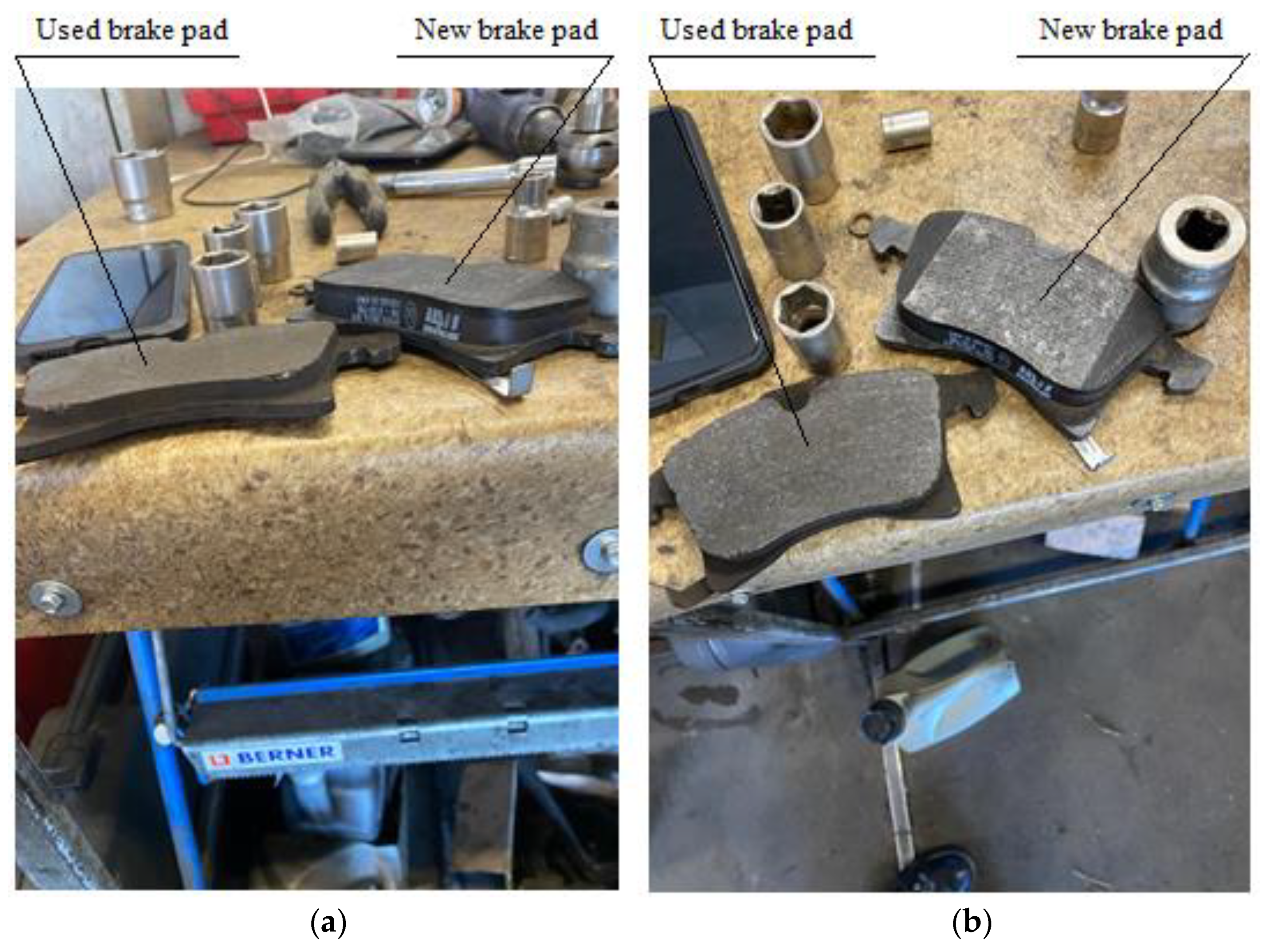

After removing the brake pads, the degree of wear can be observed, compared to a set of new brake pads, as well as the signs of wear and detachment of the friction material. These aspects are presented in

Figure 5 and

Figure 6.

To determine the degree of wear of the pads on the front axle, a special thickness measuring system was used (

Figure 7). The thickness of the friction material of a new pad was 13 mm (see

Figure 7a), and after the brake pad has been worn, the system indicated an average thickness of 10 mm (see

Figure 7b), thus resulting in average wear of 3 mm after 18,664 km traveled.

For rear axle brake pads, the friction material thickness of a new pad was 10 mm, and after they have been used, the measurement system indicated a thickness of 7 mm, thus resulting in wear of 3 mm after the 18,664 km traveled (see

Figure 7b). It is surprising, knowing that the front brakes are more demanding than the rear ones. The explanation would be that the testing was done under the same conditions both for the front and rear brakes.

Thus, the discs and pads were replaced with new ones. The brake fluid was also replaced, and the brakes were aired out, respectively, in order to obtain optimal pressure in the braking system. Following the replacement of the pads, a series of tests of the braking system were carried out to determine its efficiency, the braking force, as well as other parameters concerning the entire braking system.

The brake dynamometer rollers set the vehicle’s wheels in motion at a speed of 5 km/h. At the same time, the test stand software collects data regarding the braking system parameters (

Figure 8), obtained by successive actuation of the braking system by the operator, so that at the end, this generates a report with the exact results.

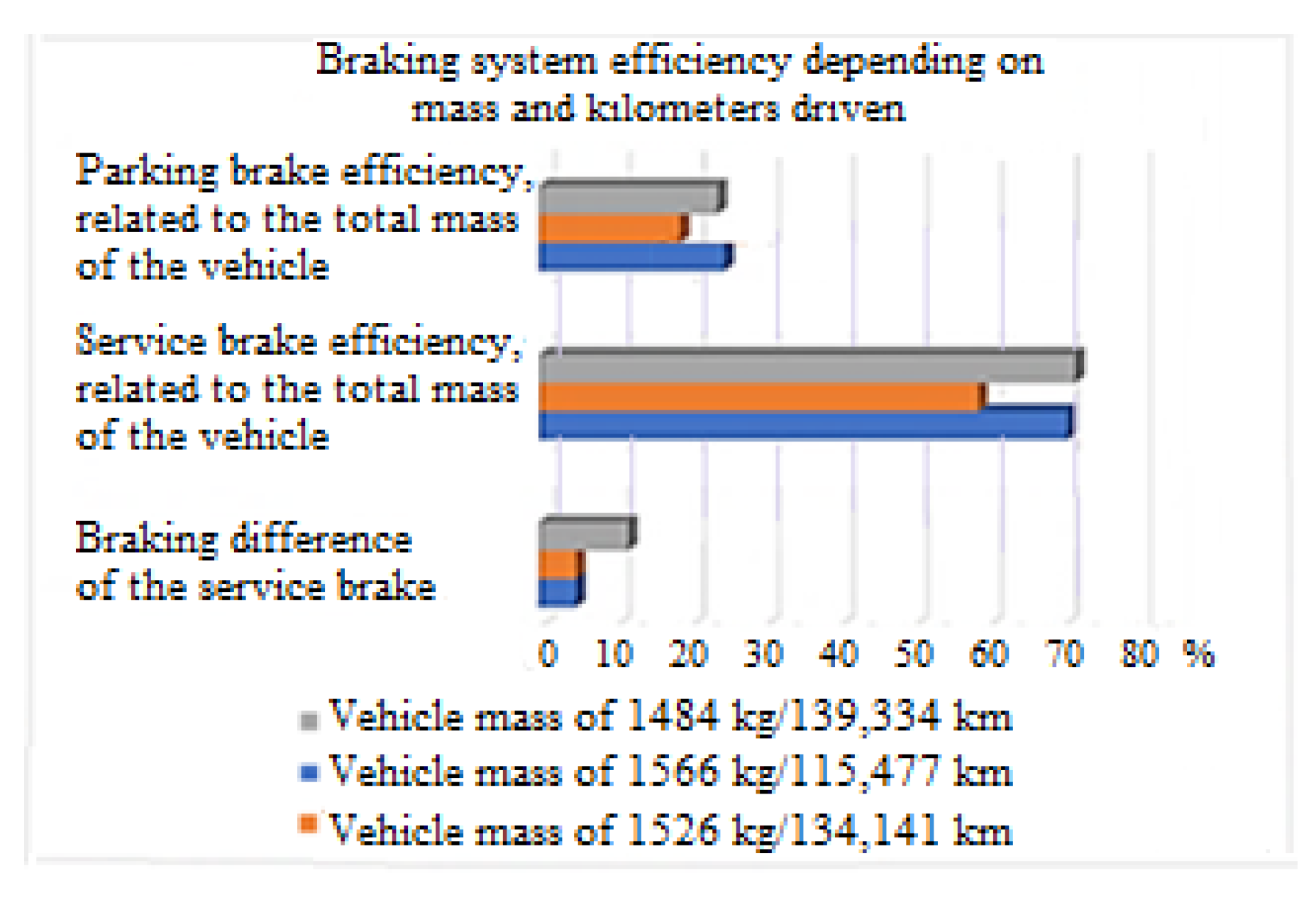

The results according to the vehicle mass and the number of driven kilometers are presented in

Table 3 and graphically in

Figure 9.

Additionally, in

Table 4 and

Figure 10, the evolution of the efficiency of the braking system is presented, as well as the measured braking force, depending on the mass of the vehicle and the number of kilometers driven.

By using relation (1), service brake efficiency,

ηs, and parking brake efficiency,

ηp, can be calculated thus

respectively,

.

As mentioned, the braking force values of the parking brake were measured on the dynamometer stand and were as follows: 3.60 (2.05 + 1.55) kN for /1566 kg/115,477 km: 2.92 (1.62 + 1.30) kN for 1462 kg/134,141 km; 2.67 (1.48 + 1.19) kN for 1480 kg/134,141 km; 2.89 (1.68 + 1.21) kN for 1526 kg/134,141 km.

From the analysis of results in

Table 4 and

Figure 10, a significant reduction in the efficiency of the braking system can be observed, namely by 16% after 18,664 km driven. This is explained by the facts that the vehicle was used in urban traffic conditions (intense), which have led to more accelerated wear of the brake pads and discs.

In

Table 5 and

Figure 11, the evolution of the efficiency of the braking system is presented, as well as the measured braking force, depending on the variation in the vehicle mass (1484, 1526, and 1566 kg, with the share of 946, 948, and 975 kg on the front axle (axis 1), and of 534, 536, and 551 kg on the rear axle (axis 2), respectively) and the number of driven kilometers (115,477, 134,141, and 139,334, when the traveled distance increased by 5193 km, from 134,141 to 139,334 km).

The condition of choosing these vehicle masses was to observe the efficiency of the braking system when the mass was approximately the same (1480 and 1484 kg) and the number of kilometers traveled increased significantly (from 115,477 to 139,334 km), on the one hand, and on the other hand, when both the mass (from 1480 to 1526 kg) and the number of kilometers traveled increased.

To determine the braking time and distance, depending on the auto-vehicle speed, a successive test series were carried out in the field. At the time of the tests, the vehicle had a mass of 1526 kg.

Under normal vehicle load conditions (mass of 1526 kg), an efficiency of the braking system of only 59% was observed. Considering the fact that the minimum acceptable efficiency of the braking system is 43.5% (see

Table 6), the results are worrying, suggesting the need to replace the braking system at a much shorter interval than the recommended one.

After the change of the worn brake disc and pads, it was found that the efficiency of the braking system increased to 72%.

Therefore, from the analysis of the results of experimental tests carried out on a vehicle both with used discs and pads, as well as with new discs and pads, it was found that the braking system efficiency increases by 13% (from 59 to 72%) when the vehicle has been equipped with new brake discs and pads.

Additionally, the braking system efficiency, in both cases (with used and new discs and pads) was well above the minimum allowed limit of 43.5%. At the same time, it was observed that the measured parameters (distance and time of stopping/braking) for determining the braking efficiency increased with increasing vehicle speed (from 20 to 50 km/h), being lower in the case of the braking system with new discs and pads. Additionally, in order to establish the braking system efficiency, the wear of the brake discs and pads was also monitored in relation to the initial speed, the mass of the vehicle, and the number of kilometers traveled to demonstrate the need for more frequent replacement of some elements of the braking system, especially in conditions of heavy traffic.

In

Table 6 and

Figure 12, the average comparative values of the vehicle’s braking distance and time are shown, respectively, of braking system efficiency for three speeds. The braking speeds and distances were compared both on the worn braking system and on the braking system with new discs and pads.

4. Conclusions

There are many studies and research based on models that closely mimic reality, but studies with exploitation data collected in real-time are still few. The experimental results in this paper were validated by experimental testing methods as close as possible to operational reality.

The braking system of the tested vehicle was tested in accordance with prescriptions and regulations enforced related to road safety.

Following the performance of the experimental tests, a significant reduction in the efficiency of the braking system was found after only 18,664 km driven in conditions of intense and moderate traffic in the urban environment.

Under normal vehicle load conditions (mass of 1526 kg), an efficiency of the braking system of only 59% was observed. Bearing in mind that the minimum accepted point of brake system efficiency is 43.5%, the results are worrying, suggesting the need to replace the brake system at a much shorter interval than recommended.

At the same time, experimental tests have shown that the recommendations regarding the frequency of brake disks and pad replacement are inconsistent with the actual braking system wear.

Therefore, the research on the behavior of the braking system must continue under conditions of intense demand to increase the safety of all traffic participants.

Based on the obtained results, a statistical calculation model will be proposed, which can be used in simulations regarding the wear tendency of the braking system.

Later, after 23,857 km (from 115,477 to 139,334 km) is performed, in conditions of intense and moderate traffic, the theoretical results will be compared with the experimental ones.

Moreover, studies have demonstrated the psychological effect that heavy traffic has on drivers who tend to behave more aggressively—a fact that directly demonstrates the need for an efficient braking system.