Techno-Economic Assessment of an Innovative Small-Scale Solar-Biomass Hybrid Power Plant

Abstract

1. Introduction

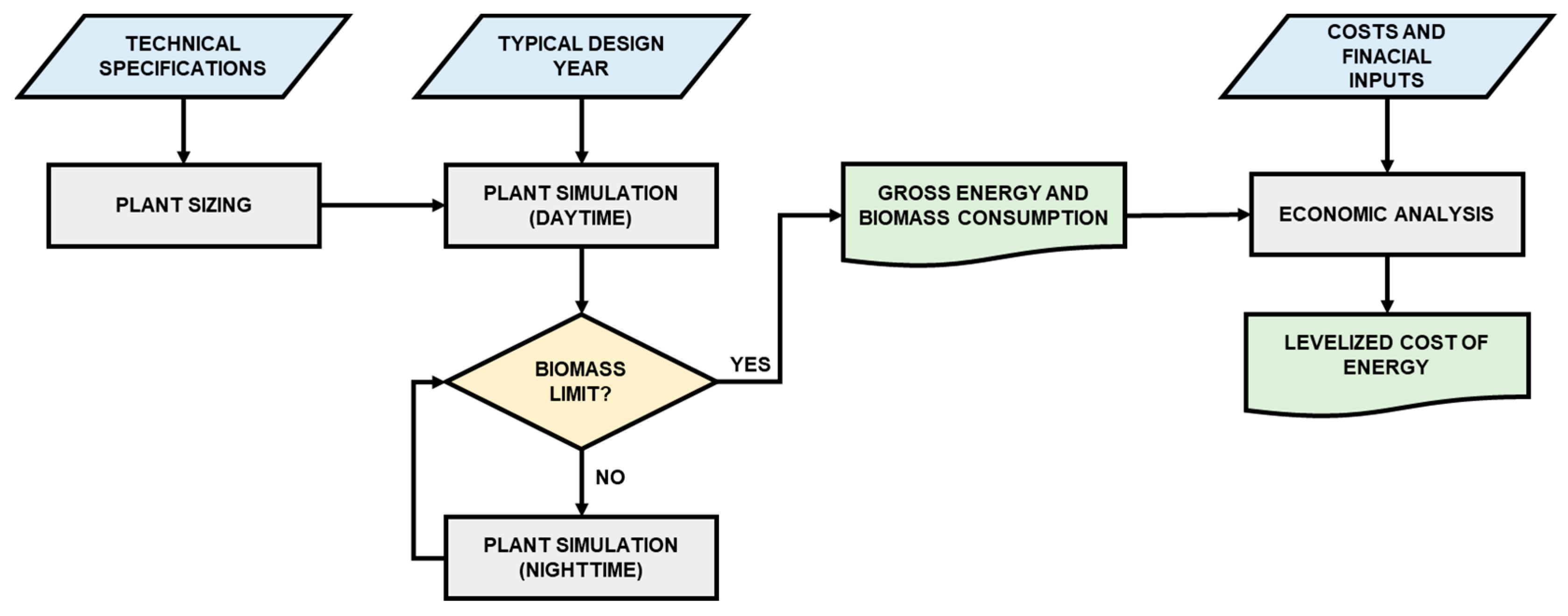

2. Materials and Methods

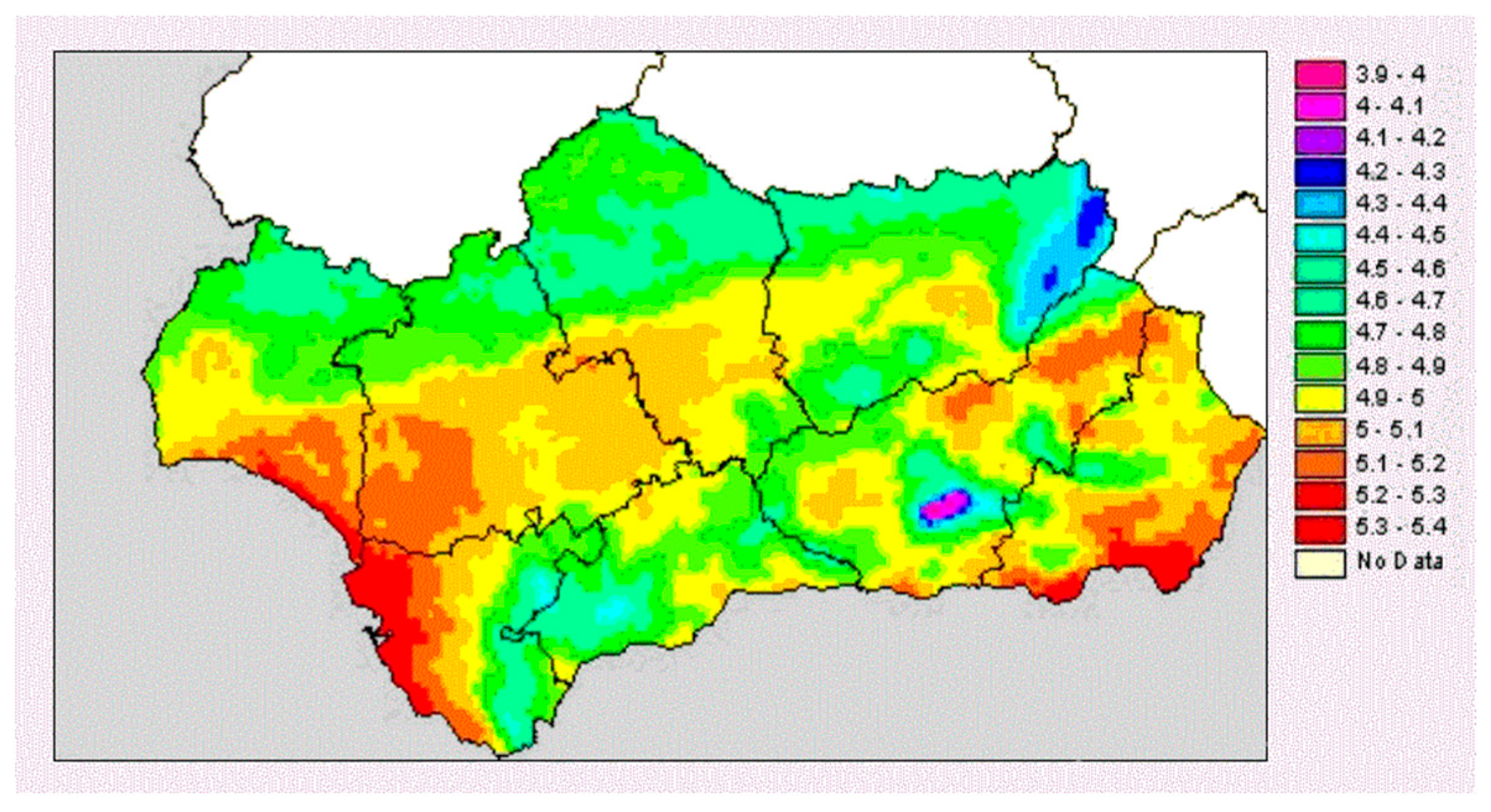

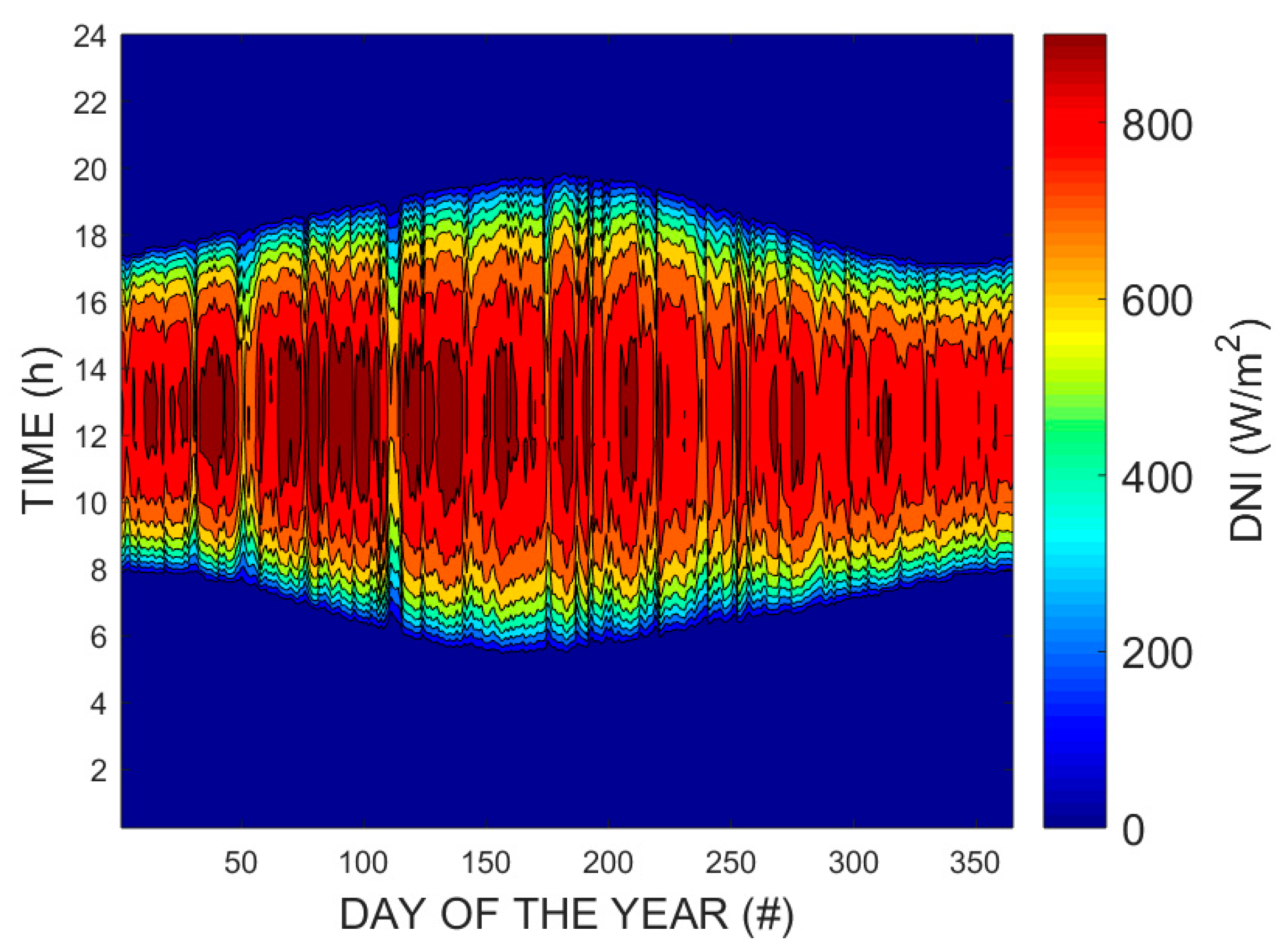

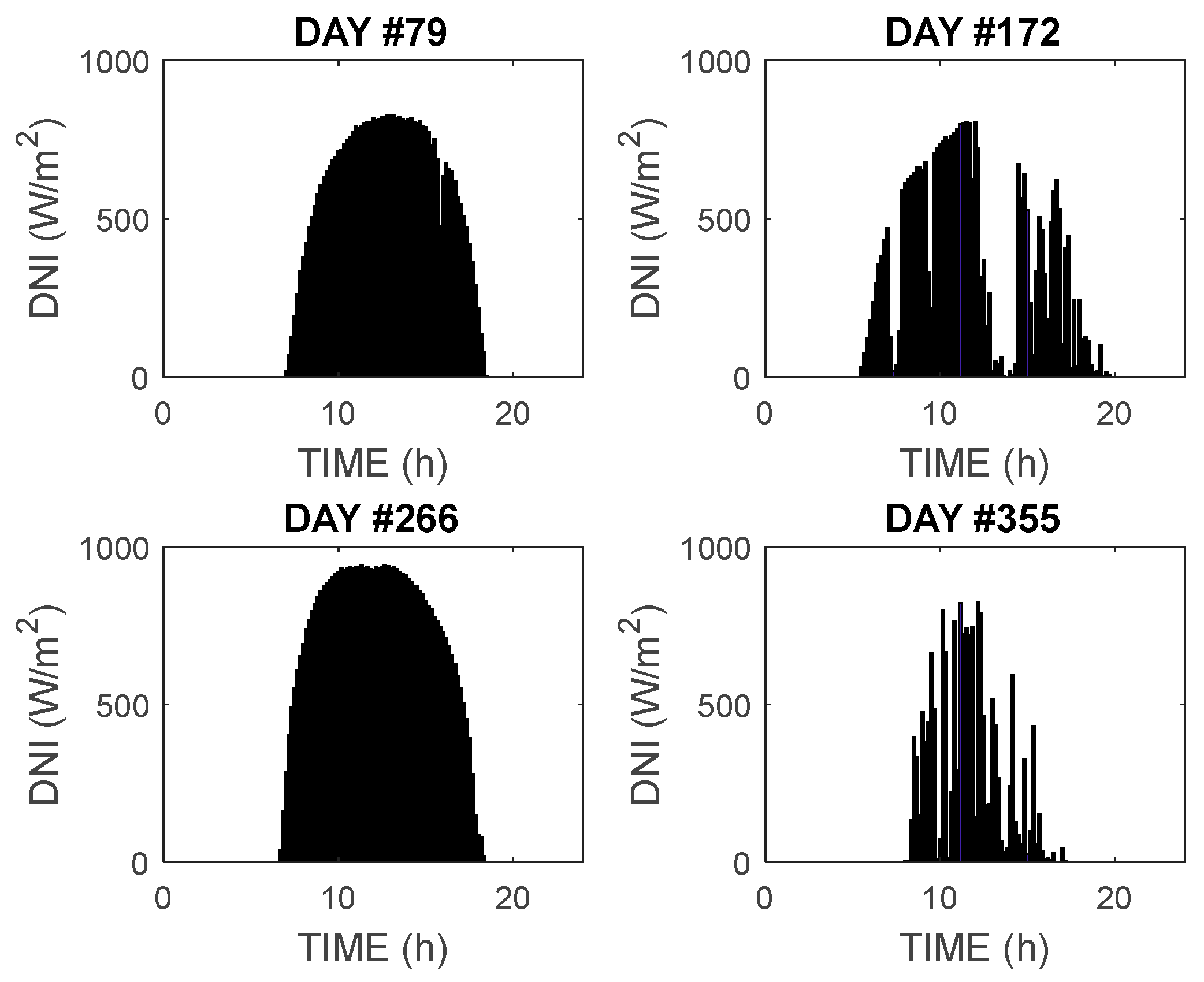

2.1. Plant Location Characterization

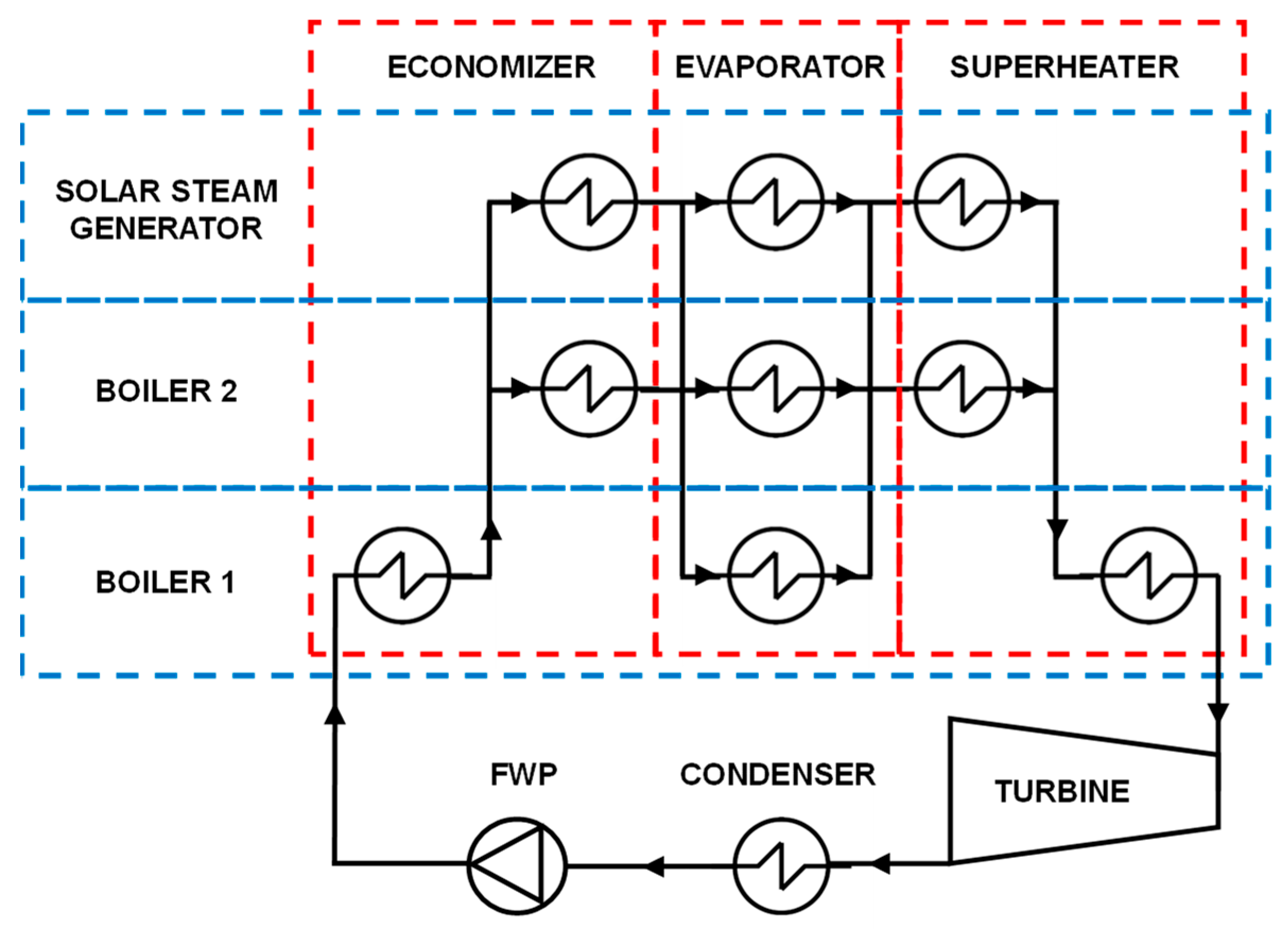

2.2. Technical Characterization

- The main advantage of series hybridization is that it allows for an increase in the live steam temperature of the Rankine cycle, which contributes to improving the thermal efficiency of the plant [35]. Additionally, this compensates the limitation of the maximum allowable temperature of the synthetic oil employed as heat transfer fluid in current parabolic trough solar power plants. One disadvantage of series hybridization is that the biomass boiler and the solar steam generator must operate simultaneously, limiting the operating time of the hybrid plant and linking its operation to the availability of solar radiation. This does not improve the dispatchability of the energy supplied to the electrical distribution grid and negatively affects the profitability of the plant.

- Although parallel hybridization designs do not improve the efficiency of the hybrid plant compared to conventional parabolic trough solar plants, this configuration allows the hybrid plant to operate during periods of null or low solar radiation [36]. This improvement has a very positive influence on the dispatchability of the electrical supply, decoupling it from the random nature of solar resources. Additionally, the increase in operating hours of this configuration has a positive impact on the profitability of the plant.

2.3. Economic Analysis

3. Results and Discussion

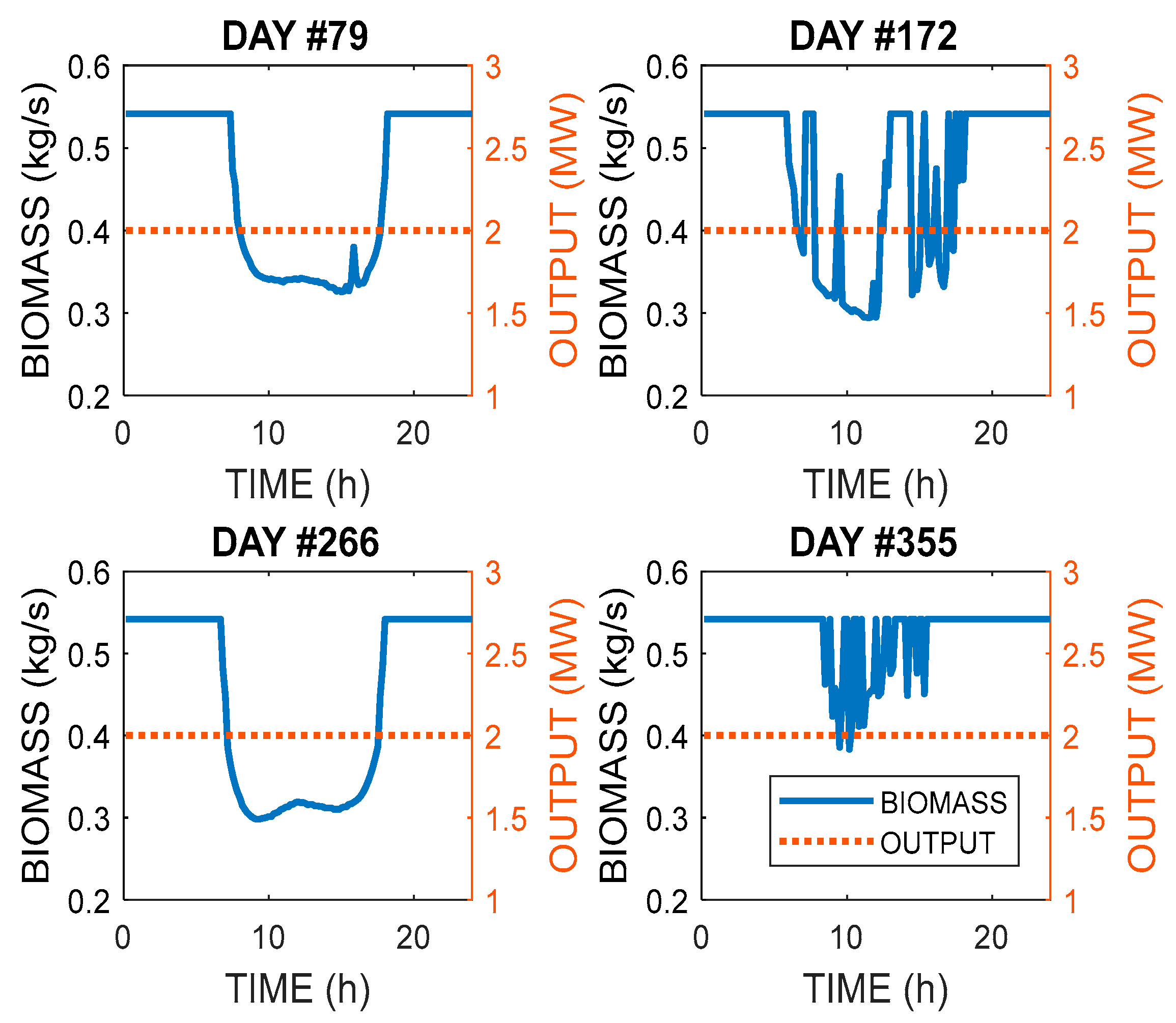

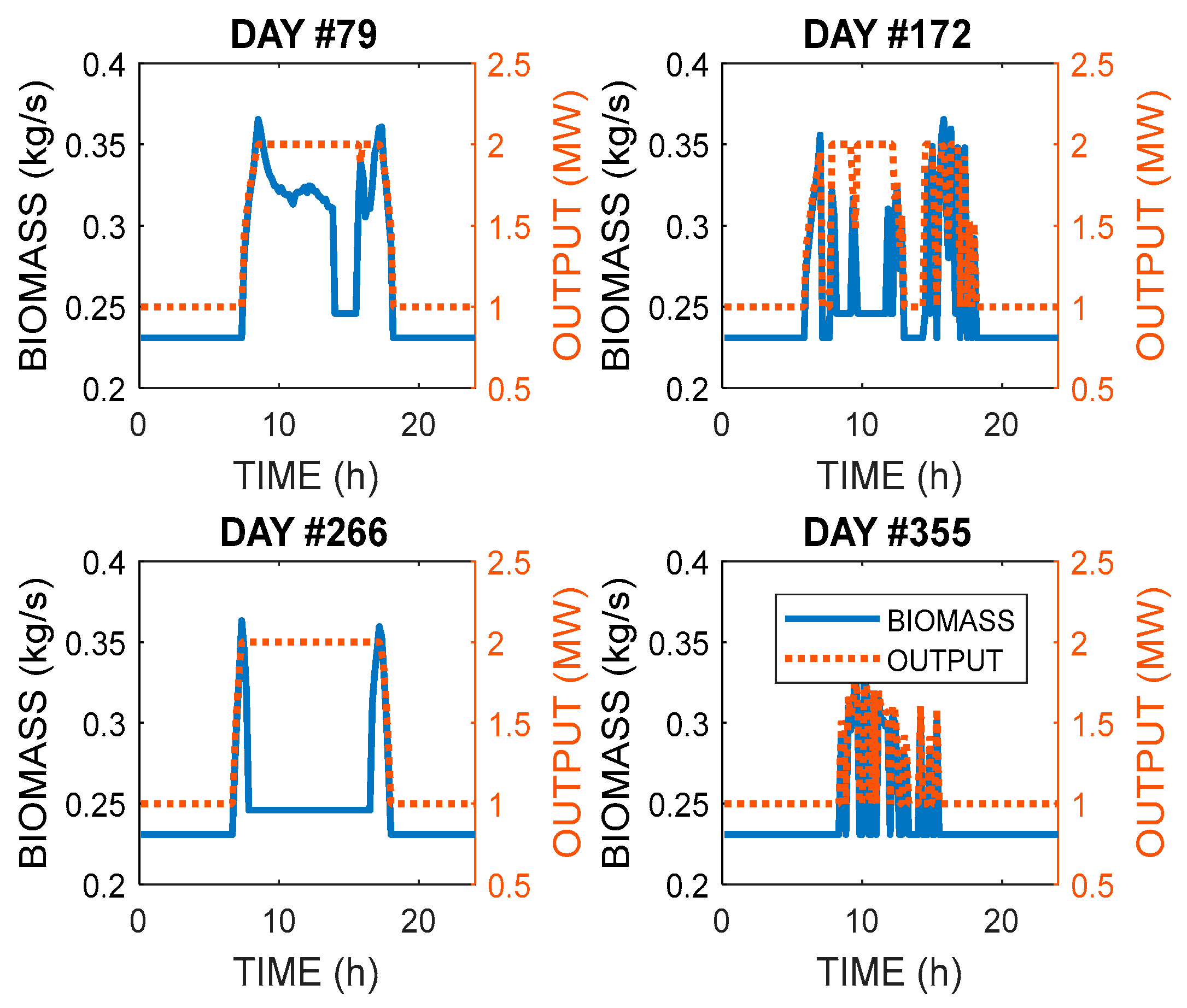

3.1. Simulation

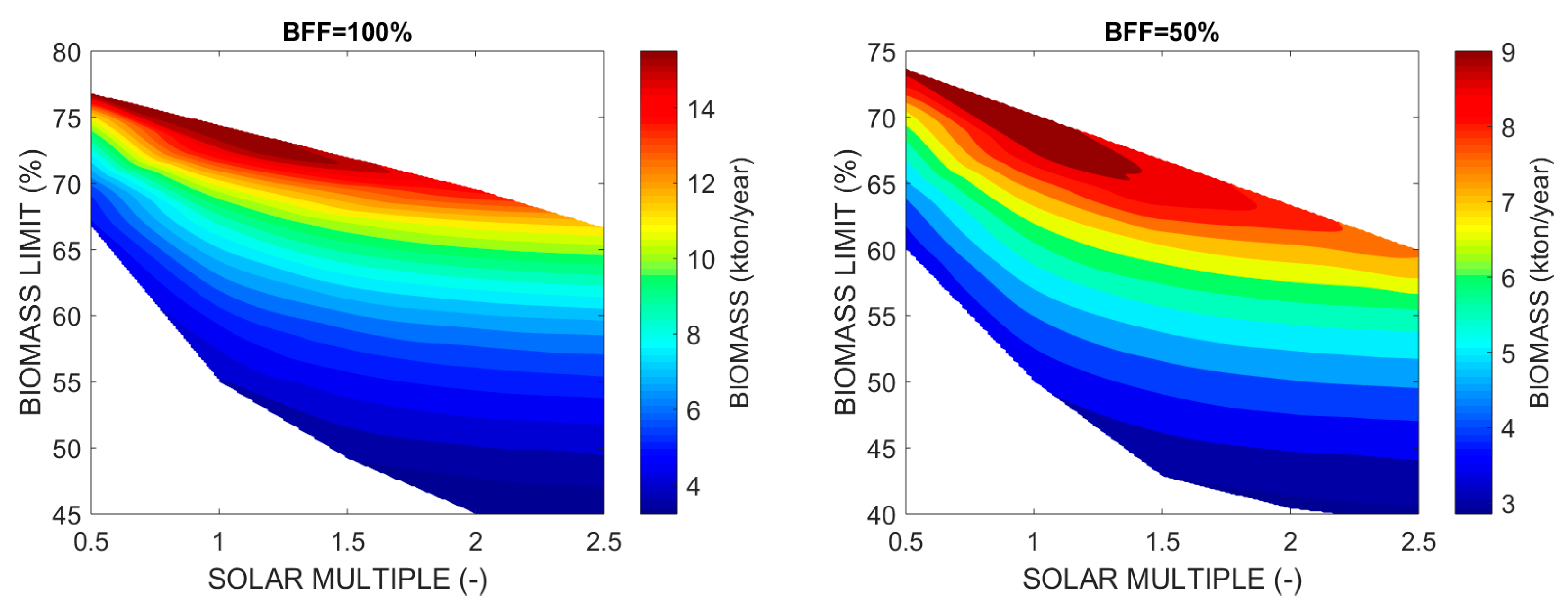

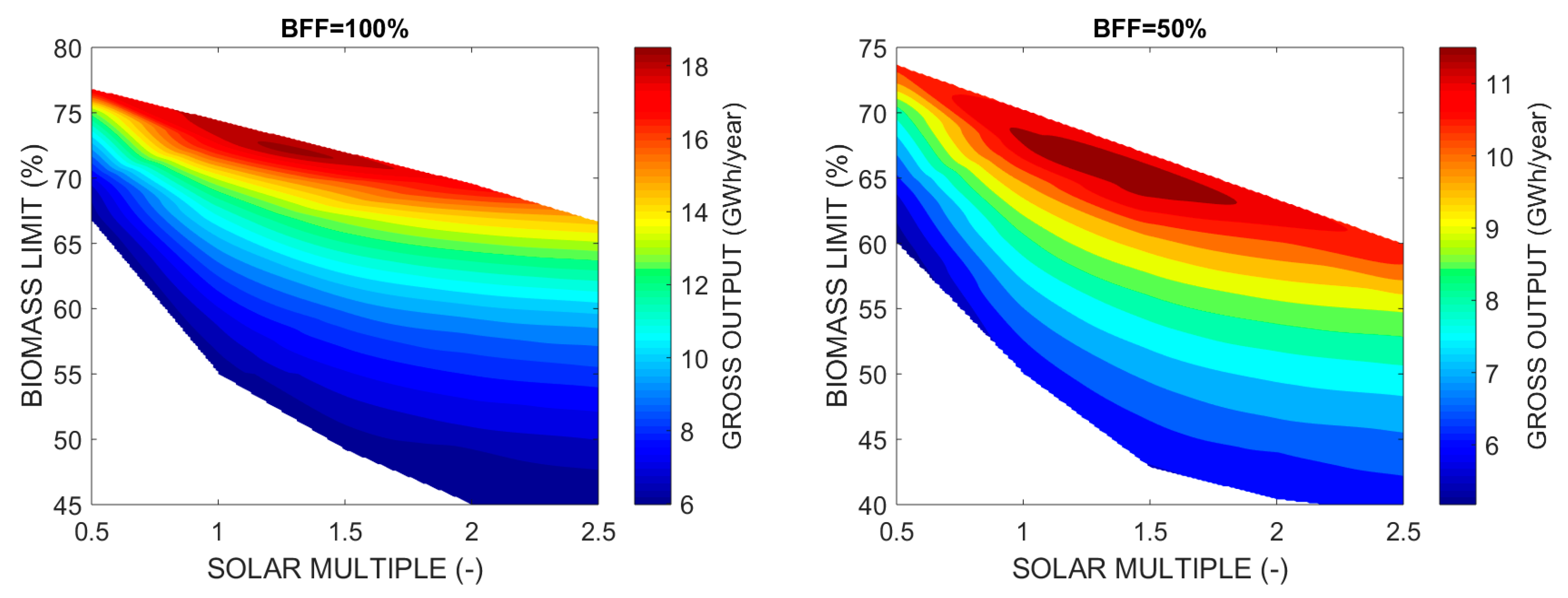

3.2. Annual Balances

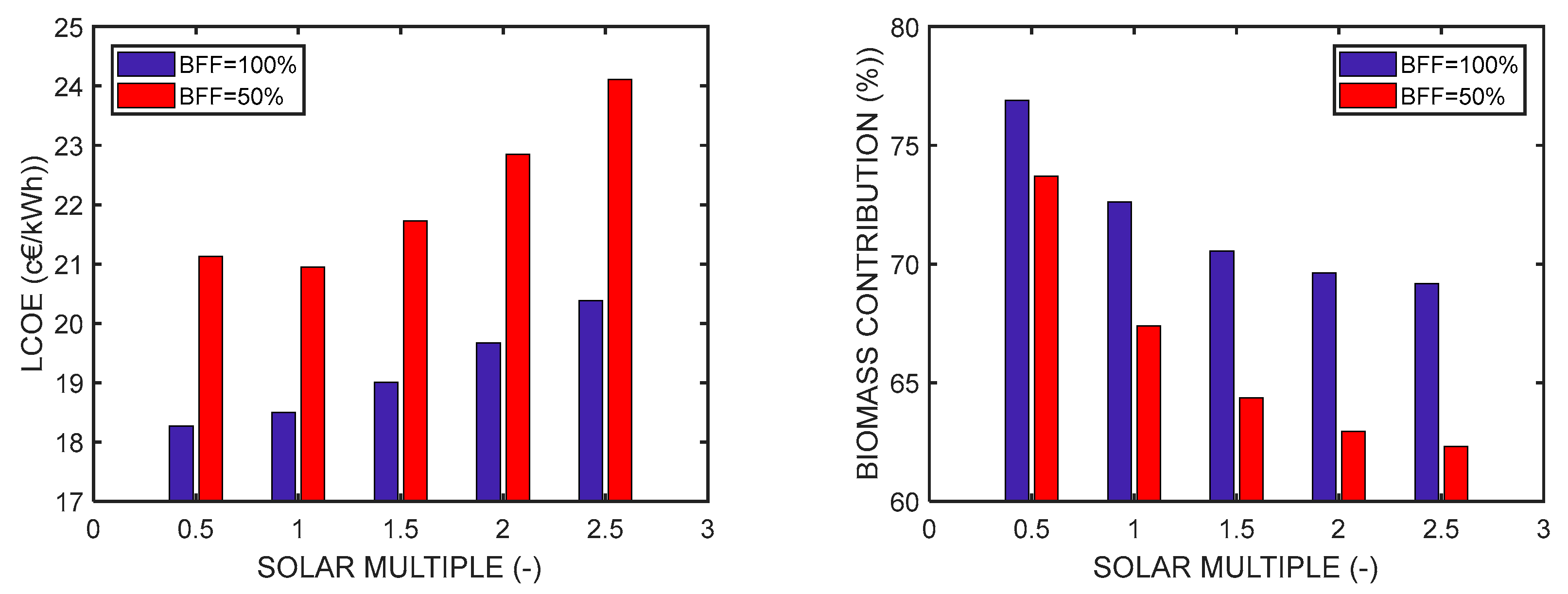

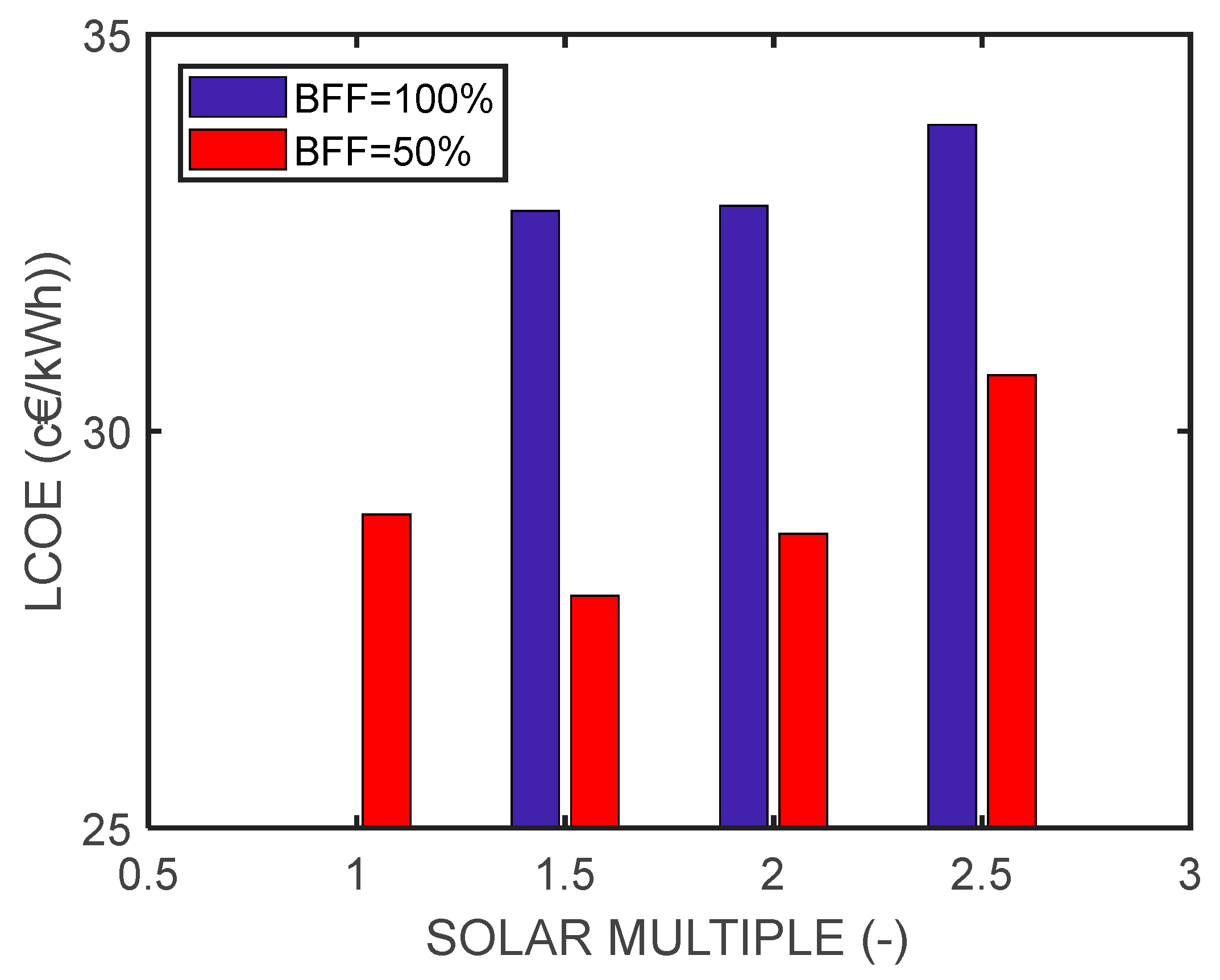

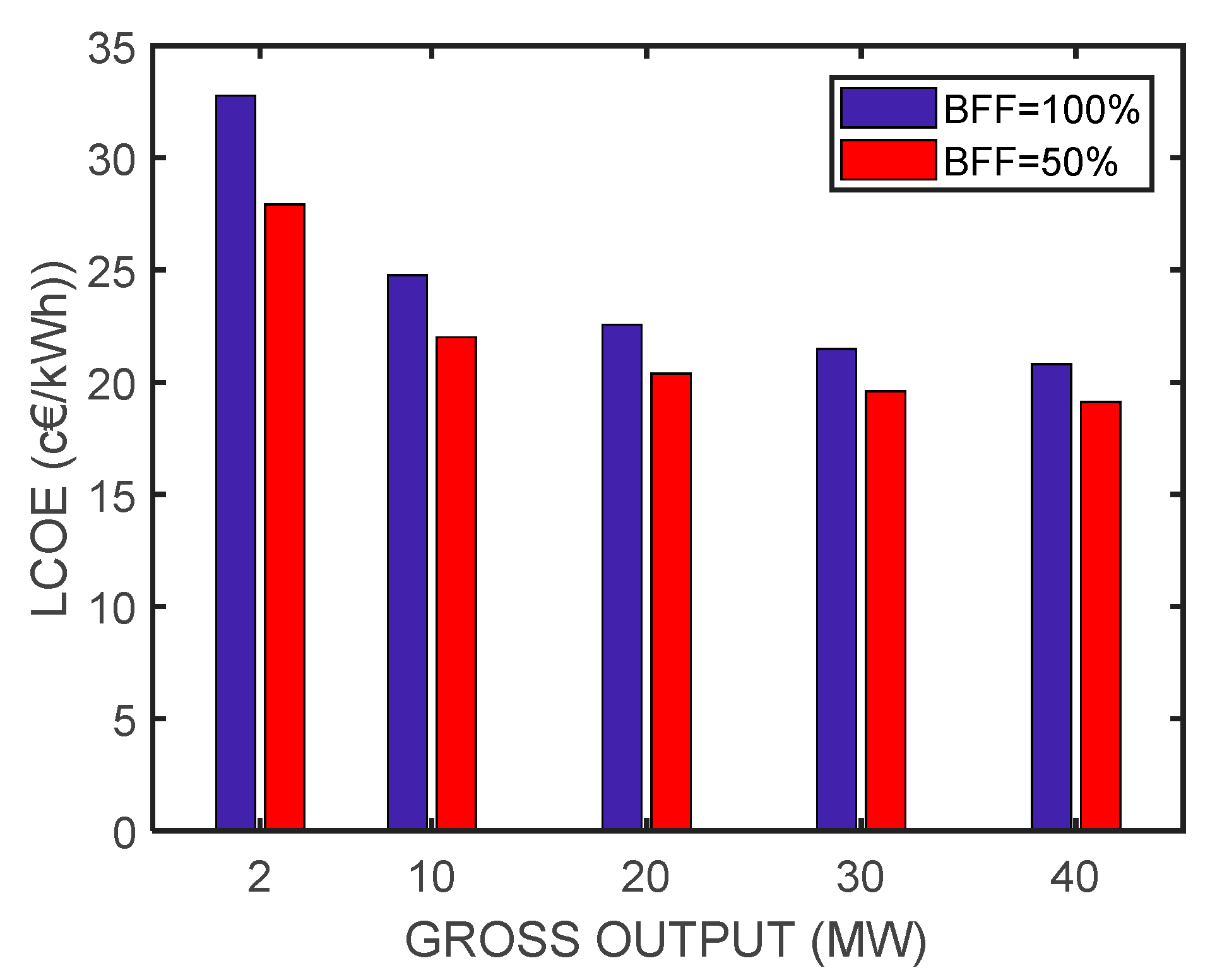

3.3. Levelized Cost of Energy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| BFF | Biomass Fill Fraction |

| Annual Operation and Maintenance Costs | |

| CSP | Concentrating Solar Power |

| Discount Rate | |

| DNI | Direct Normal Irradiance |

| Annual Energy Production | |

| FEGT | Furnace Exit Gas Temperature |

| FWP | Feed Water Pump |

| GHG | Greenhouse Gas |

| Initial Investment | |

| LCC | Life Cycle Cost |

| LCOE | Levelized Cost of Energy |

| Project’s Lifetime Period | |

| NREL | National Renewable Energy Lab |

| NSRDB | National Solar Radiation Data Base |

| SM | Solar Multiple |

| SSG | Solar Steam Generator |

References

- United Nations Working Group on the Issue of Human Rights and Transnational Corporations and Other Business Enterprises; Note A/73/163 by the Secretary General; United Nations General Assembly: New York, NY, USA, 2018.

- Collins, M.; Knutti, R.; Arblaster, J.; Dufresne, J.L.; Fichefet, T.; Friedlingstein, P.; Gao, X.; Gutowski, W.J.; Johns, T.; Krinner, G.; et al. Long-Term Climate Change: Projections, Commitments and Irreversibility. In Climate Change 2013—The Physical Science Basis: Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2013; pp. 1029–1136. [Google Scholar]

- Ogunkunle, O.; Ahmed, N.A. A review of global current scenario of biodiesel adoption and combustion in vehicular diesel engines. Energy Rep. 2019, 5, 1560–1579. [Google Scholar] [CrossRef]

- Kost, C.; Mayer, J.N.; Thomsen, J.; Hartmann, N.; Senkpiel, C.; Philipps, S.; Nold, S.; Lude, S.; Saad, N.; Schlegl, T. Levelized Cost of Electricity-Renewable Energy Technologies; Fraunhofer: Munich, Germany, 2013; Available online: https://www.ise.fraunhofer.de/content/dam/ise/en/documents/publications/studies/EN2018_Fraunhofer-ISE_LCOE_Renewable_Energy_Technologies.pdf (accessed on 8 June 2023).

- Malagueta, D.; Szklo, A.; Soria, R.; Dutra, R.; Schaeffer, R.; Borba, B.S.M.C. Potential and impacts of Concentrated Solar Power (CSP) integration in the Brazilian electric power system. Renew. Energy 2014, 68, 223–235. [Google Scholar] [CrossRef]

- Hussain, C.I.; Norton, B.; Duffy, A. Comparison of hybridizing options for solar heat, biomass and heat storage for electricity generation in Spain. Energy Convers. Manag. 2020, 222, 113231. [Google Scholar] [CrossRef]

- Del Moral, A.; Petrakopoulou, F. Evaluation of the coupling of a hybrid power plant with a water generation system. Appl. Sci. 2019, 9, 4989. [Google Scholar] [CrossRef]

- Soria, R.; Portugal-Pereira, J.; Szklo, A.; Milani, R.; Schaeffer, R. Hybrid concentrated solar power (CSP)–biomass plants in a semiarid region: A strategy for CSP deployment in Brazil. Energy Policy 2015, 86, 57–72. [Google Scholar] [CrossRef]

- Morrone, P.; Algieri, A.; Castiglione, T. Hybridisation of biomass and concentrated solar power systems in transcritical organic Rankine cycles: A micro combined heat and power application. Energy Convers. Manag. 2019, 180, 757–768. [Google Scholar] [CrossRef]

- Turchi, C.S.; Ma, Z.; Erbes, M. Gas Turbine/Solar Parabolic Trough Hybrid Designs. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition. Volume 3: Controls, Diagnostics and Instrumentation; Education; Electric Power; Microturbines and Small Turbomachinery; Solar Brayton and Rankine Cycle, Vancouver, BC, Canada, 6–10 June 2011; ASME: Washington, DC, USA, 2011; pp. 989–996. [Google Scholar]

- Peterseim, J.H.; Hellwig, U.; Tadros, A.; White, S. Hybridisation optimization of concentrating solar thermal and biomass power generation facilities. Sol. Energy 2014, 99, 203–214. [Google Scholar] [CrossRef]

- Marchenko, O.; Solomin, S.; Shamanskiy, V.; Donskoy, I. Evaluation of the Effectiveness of Joint Use of Wood and Other Renewable Energy Sources in the Baikal Region. Appl. Sci. 2022, 12, 1254. [Google Scholar] [CrossRef]

- Bai, Z.; Liu, Q.; Lei, J.; Wang, X.; Sun, J.; Jin, H. Thermodynamic evaluation of a novel solar-biomass hybrid power generation system. Energy Convers. Manag. 2017, 142, 296–306. [Google Scholar] [CrossRef]

- Sterrer, R.; Schidler, S.; Schwandt, O.; Franz, P.; Hammerschmid, A. Theoretical analysis of the combination of CSP with a biomass CHP-plant using ORC-technology in Central Europe. Energy Procedia 2014, 49, 1218–1227. [Google Scholar] [CrossRef]

- Li, M.; Lenzen, M.; Yousefzadeh, M.; Ximenes, F.A. The roles of biomass and CSP in a 100% renewable electricity supply in Australia. Biomass Bioenergy 2020, 143, 105802. [Google Scholar] [CrossRef]

- El-Sattar, H.A.; Kamel, S.; Sultan, H.; Tostado-Véliz, M.; Eltamaly, A.M.; Jurado, F. Performance analysis of a stand-alone pv/wt/biomass/bat system in alrashda village in egypt. Appl. Sci. 2021, 11, 10191. [Google Scholar] [CrossRef]

- Hussain, C.I.; Norton, B.; Duffy, A. Technological assessment of different solar-biomass systems for hybrid power generation in Europe. Renew. Sustain. Energy Rev. 2017, 68, 1115–1129. [Google Scholar] [CrossRef]

- Jensen, A.R.; Sifnaios, I.; Perers, B.; Rothmann, J.H.; Mørch, S.D.; Jensen, P.V.; Dragsted, J.; Furbo, S. Demonstration of a concentrated solar power and biomass plant for combined heat and power. Energy Convers. Manag. 2022, 271, 116207. [Google Scholar] [CrossRef]

- Loth, E.; Qin, C.; Simpson, J.G.; Dykes, K. Why we must move beyond LCOE for renewable energy design. Adv. Appl. Energy 2022, 8, 100112. [Google Scholar] [CrossRef]

- Nissen, U.; Harfst, N. Shortcomings of the traditional “levelized cost of energy” [LCOE] for the determination of grid parity. Energy 2019, 171, 1009–1016. [Google Scholar] [CrossRef]

- Shen, W.; Chen, X.; Qiu, J.; Hayward, J.A.; Sayeef, S.; Osman, P.; Meng, K.; Dong, Z.Y. A comprehensive review of variable renewable energy levelized cost of electricity. Renew. Sustain. Energy Rev. 2020, 133, 110301. [Google Scholar] [CrossRef]

- Tian, Z.; Perers, B.; Furbo, S.; Fan, J. Thermo-economic optimization of a hybrid solar district heating plant with flat plate collectors and parabolic trough collectors in series. Energy Convers. Manag. 2018, 165, 92–101. [Google Scholar] [CrossRef]

- Tilahun, F.B.; Bhandari, R.; Mamo, M. Design optimization of a hybrid solar-biomass plant to sustainably supply energy to industry: Methodology and case study. Energy 2021, 220, 119736. [Google Scholar] [CrossRef]

- Joskow, P.L. Comparing the costs of intermittent and dispatchable electricity generating technologies. Am. Econ. Rev. 2011, 101, 238–241. [Google Scholar] [CrossRef]

- Reichenberg, L.; Hedenus, F.; Odenberger, M.; Johnsson, F. The marginal system LCOE of variable renewables—Evaluating high penetration levels of wind and solar in Europe. Energy 2018, 152, 914–924. [Google Scholar] [CrossRef]

- Milani, R.; Szklo, A.; Hoffmann, B.S. Hybridization of concentrated solar power with biomass gasification in Brazil’s semiarid region. Energy Convers. Manag. 2017, 143, 522–537. [Google Scholar] [CrossRef]

- Bai, Z.; Liu, Q.; Gong, L.; Lei, J. Investigation of a solar-biomass gasification system with the production of methanol and electricity: Thermodynamic, economic and off-design operation. Appl. Energy 2019, 243, 91–101. [Google Scholar] [CrossRef]

- Mapa de Radiación Global de Andalucía. Agencia Andaluza de la Energía, Junta de Andalucía. Available online: https://www.agenciaandaluzadelaenergia.es/Radiacion/vermapas.php (accessed on 9 June 2023).

- Agencia Andaluza de la Energía, Junta de Andalucía. La Biomasa en Andalucía. 2016. Available online: https://www.agenciaandaluzadelaenergia.es/biomasa/biomasa/init.do?prefix=/biomasa&name=potencial (accessed on 9 June 2023).

- Wilcox, S.M. National Solar Radiation Database 1991–2010 Update: User’s Manual (No. NREL/TP-5500-54824); National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2012. [Google Scholar]

- Sengupta, M.; Xie, Y.; Lopez, A.; Habte, A.; Maclaurin, G.; Shelby, J. The national solar radiation data base (NSRDB). Renew. Sustain. Energy Rev. 2018, 89, 51–60. [Google Scholar] [CrossRef]

- Dominguez, J.; Marcos, M.J. Análisis de la producción potencial de energía con biomasa en la región de Andalucía (España) utilizando sistemas de información geográfica. Cybergeo Eur. J. Geogr. 2000. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Analytical expression of parabolic trough solar collector performance. Designs 2018, 2, 9. [Google Scholar] [CrossRef]

- Solutia Technical Bulletin 7239115C. Available online: https://www.therminol.com/products/Therminol-VP1 (accessed on 6 June 2023).

- Peterseim, J.H.; Tadros, A.; Hellwig, U.; White, S. Increasing the efficiency of parabolic trough plants using thermal oil through external superheating with biomass. Energy Convers. Manag. 2014, 77, 784–793. [Google Scholar] [CrossRef]

- Algieri, A.; Morrone, P. Thermo-economic investigation of solar-biomass hybrid cogeneration systems based on small-scale transcritical organic Rankine cycles. Appl. Therm. Eng. 2022, 210, 118312. [Google Scholar] [CrossRef]

- Kumar, B.; Raj, A.K.; Szepesi, G.; Szamosi, Z. A conspectus review on solar drying of wood: Regional and technical contrivances. J. Therm. Anal. Calorim. 2023, 2023, 1–25. [Google Scholar] [CrossRef]

- Talavera, D.L.; Pérez-Higueras, P.; Ruíz-Arias, J.A.; Fernández, E.F. Levelised cost of electricity in high concentrated photovoltaic grid connected systems: Spatial analysis of Spain. Appl. Energy 2015, 151, 49–59. [Google Scholar] [CrossRef]

- Idel, R. Levelized full system costs of electricity. Energy 2022, 259, 124905. [Google Scholar] [CrossRef]

- Peterseim, J.H.; White, S.; Tadros, A.; Hellwig, U. Concentrated solar power hybrid plants, which technologies are best suited for hybridisation? Renew. Energy 2013, 57, 520–532. [Google Scholar] [CrossRef]

- Bosch, J.; Staffell, I.; Hawkes, A.D. Global levelised cost of electricity from offshore wind. Energy 2019, 189, 116357. [Google Scholar] [CrossRef]

- System Advisor Model, Version 2022.11.21 (SAM 2022.11.21); National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2022.

- Srinivas, T.; Reddy, B.V. Hybrid solar–biomass power plant without energy storage. Case Stud. Therm. Eng. 2014, 2, 75–81. [Google Scholar] [CrossRef]

- Kearney, D.; Herrmann, U.; Nava, P.; Kelly, B.; Mahoney, R.; Pacheco, J.; Cable, R.; Potrovitza, N.; Blake, D.; Price, H. Assessment of a molten salt heat transfer fluid in a parabolic trough solar field. J. Sol. Energy Eng. 2003, 125, 170–176. [Google Scholar] [CrossRef]

- Răboacă, M.S.; Badea, G.; Enache, A.; Filote, C.; Răsoi, G.; Rata, M.; Lavric, A.; Felseghi, R.A. Concentrating solar power technologies. Energies 2019, 12, 1048. [Google Scholar] [CrossRef]

- Pantaleo, A.M.; Camporeale, S.M.; Miliozzi, A.; Russo, V.; Shah, N.; Markides, C.N. Novel hybrid CSP-biomass CHP for flexible generation: Thermo-economic analysis and profitability assessment. Appl. Energy 2017, 204, 994–1006. [Google Scholar] [CrossRef]

- Oyekale, J.; Heberle, F.; Petrollese, M.; Brüggemann, D.; Cau, G. Biomass retrofit for existing solar organic Rankine cycle power plants: Conceptual hybridization strategy and techno-economic assessment. Energy Convers. Manag. 2019, 196, 831–845. [Google Scholar] [CrossRef]

| Parameter | Value | Units |

|---|---|---|

| Live steam temperature | 400 | °C |

| Live steam pressure | 41 | bar |

| Live steam flow rate | 2.8 | kg/s |

| Turbine isentropic efficiency | 0.85 | - |

| Condenser pressure | 0.1 | bar |

| Feedwater temperature | 105 | °C |

| Parameter | Value | Units |

|---|---|---|

| Aperture width | 5.77 | m |

| Aperture area | 817.5 | m2 |

| Focal length | 1.71 | m |

| Absorber radius | 3.5 | cm |

| Concentration factor | 82.43 | - |

| Peak optical performance | 0.73 | - |

| Fouling factor | 0.90 | - |

| Parameter | Value | Units |

|---|---|---|

| Site improvement | 30 | EUR/m2 |

| Solar field | 175 | EUR/m2 |

| HTF system | 75 | EUR/m2 |

| Biomass system | 1750 | EUR/kWe |

| Power cycle | 1100 | EUR/kWe |

| Balance of plant | 400 | EUR/kWe |

| Contingency | 10 | % |

| EPC cost | 10 | % |

| O&M fixed cost | 66 | EUR/(kW·yr) |

| O&M variable cost (excl. biomass) | 5 | EUR/MWh |

| Parameter | Value | Units |

|---|---|---|

| Annual inflation rate | 2.5 | % |

| Income tax rate | 25.0 | % |

| Annual loan interest | 4.0 | % |

| Debt fraction | 70.0 | % |

| Plant life cycle | 30 | years |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vélez Godiño, J.A.; Torres García, M. Techno-Economic Assessment of an Innovative Small-Scale Solar-Biomass Hybrid Power Plant. Appl. Sci. 2023, 13, 8179. https://doi.org/10.3390/app13148179

Vélez Godiño JA, Torres García M. Techno-Economic Assessment of an Innovative Small-Scale Solar-Biomass Hybrid Power Plant. Applied Sciences. 2023; 13(14):8179. https://doi.org/10.3390/app13148179

Chicago/Turabian StyleVélez Godiño, José Antonio, and Miguel Torres García. 2023. "Techno-Economic Assessment of an Innovative Small-Scale Solar-Biomass Hybrid Power Plant" Applied Sciences 13, no. 14: 8179. https://doi.org/10.3390/app13148179

APA StyleVélez Godiño, J. A., & Torres García, M. (2023). Techno-Economic Assessment of an Innovative Small-Scale Solar-Biomass Hybrid Power Plant. Applied Sciences, 13(14), 8179. https://doi.org/10.3390/app13148179