Compressive Behavior of a Novel Hexagonal Nodes-Based 3D Chiral Auxetic Structure

Abstract

:1. Introduction

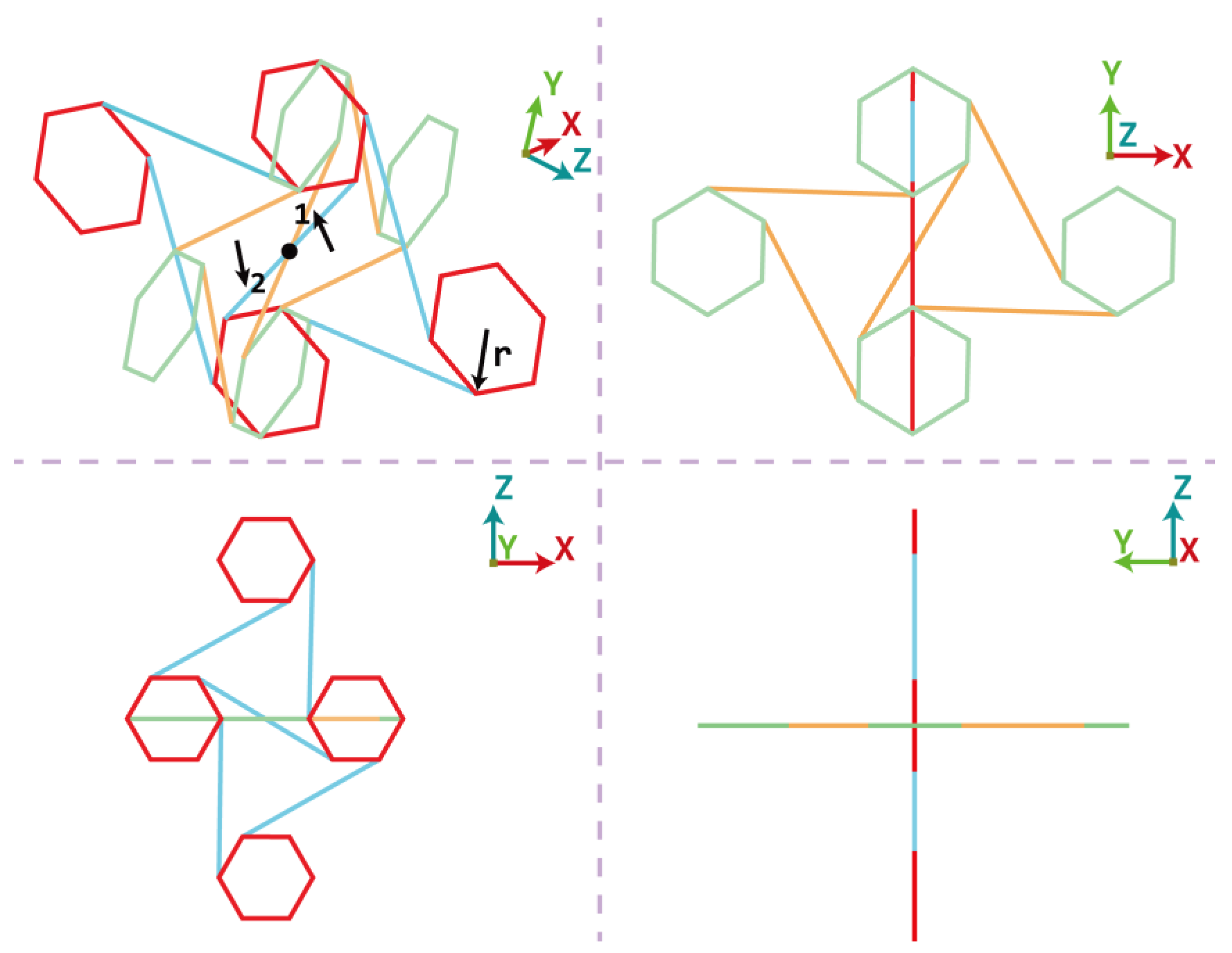

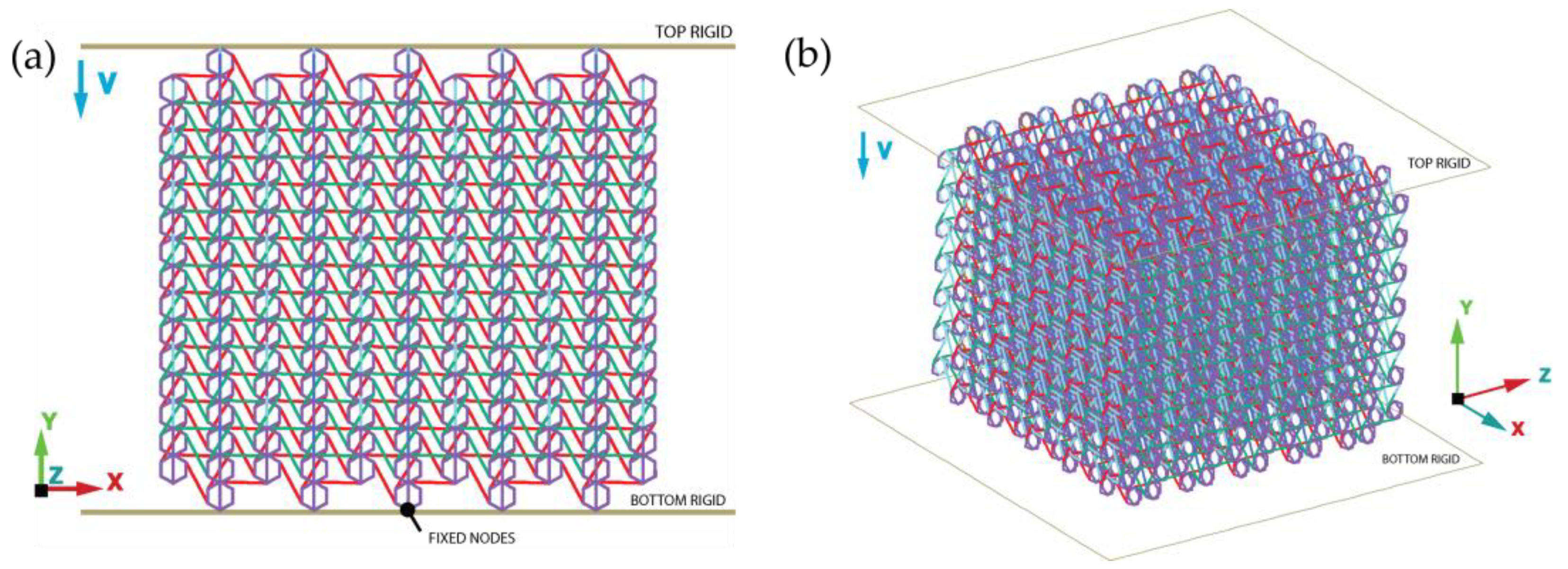

2. Geometric Design

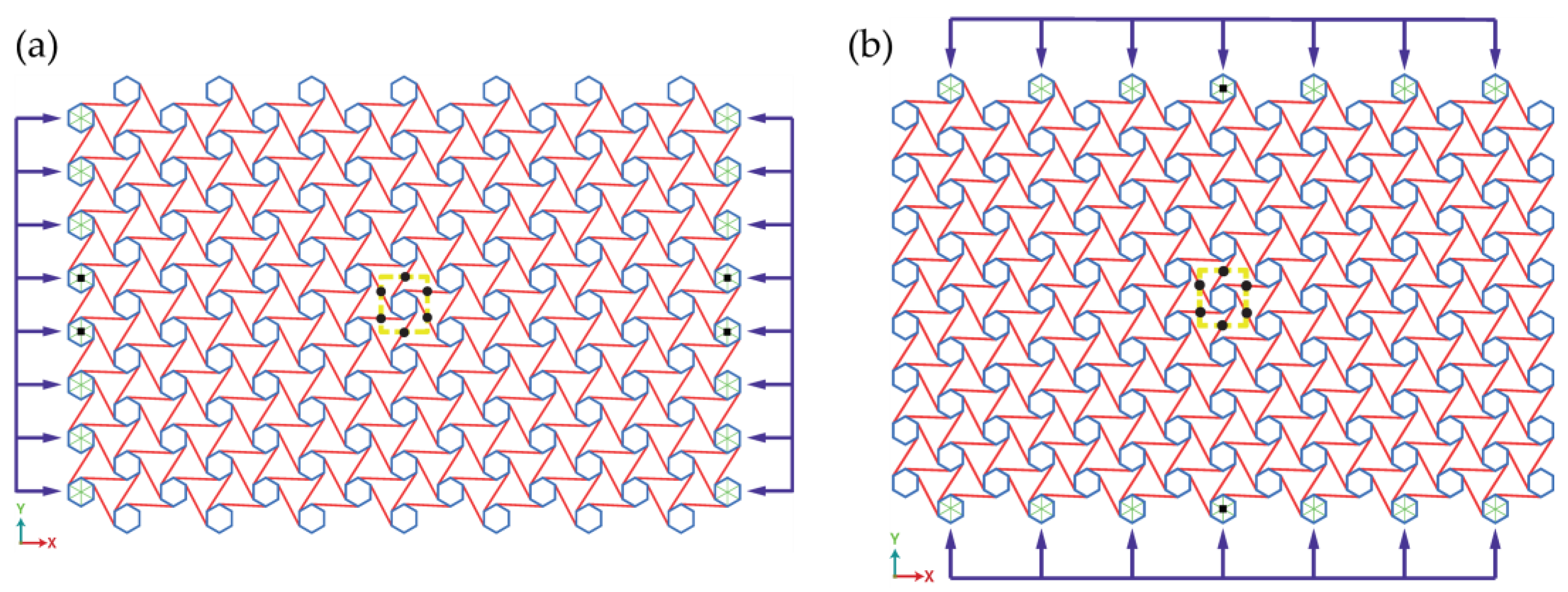

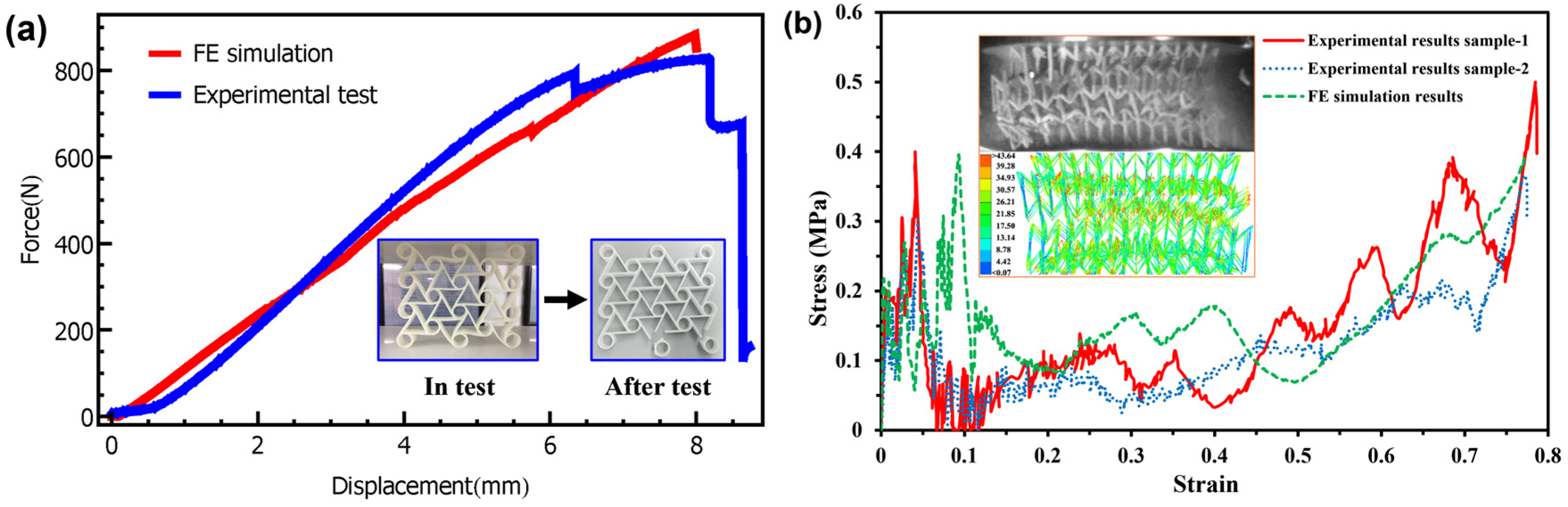

3. Poisson’s Ratio

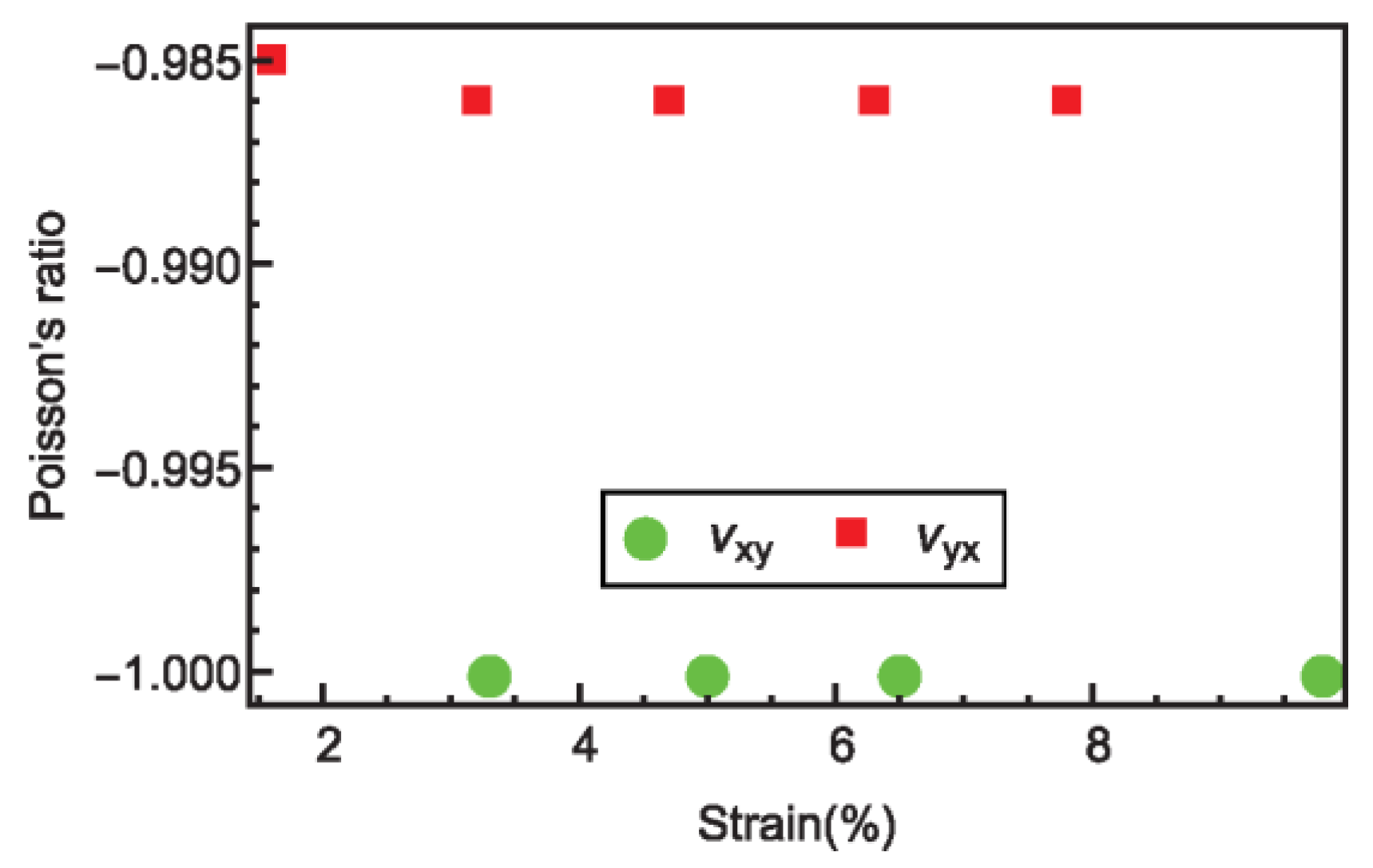

3.1. Poisson’s Ratio of 2D AH

3.2. Poisson’s Ratio of 3D AH

4. Compressive Behavior

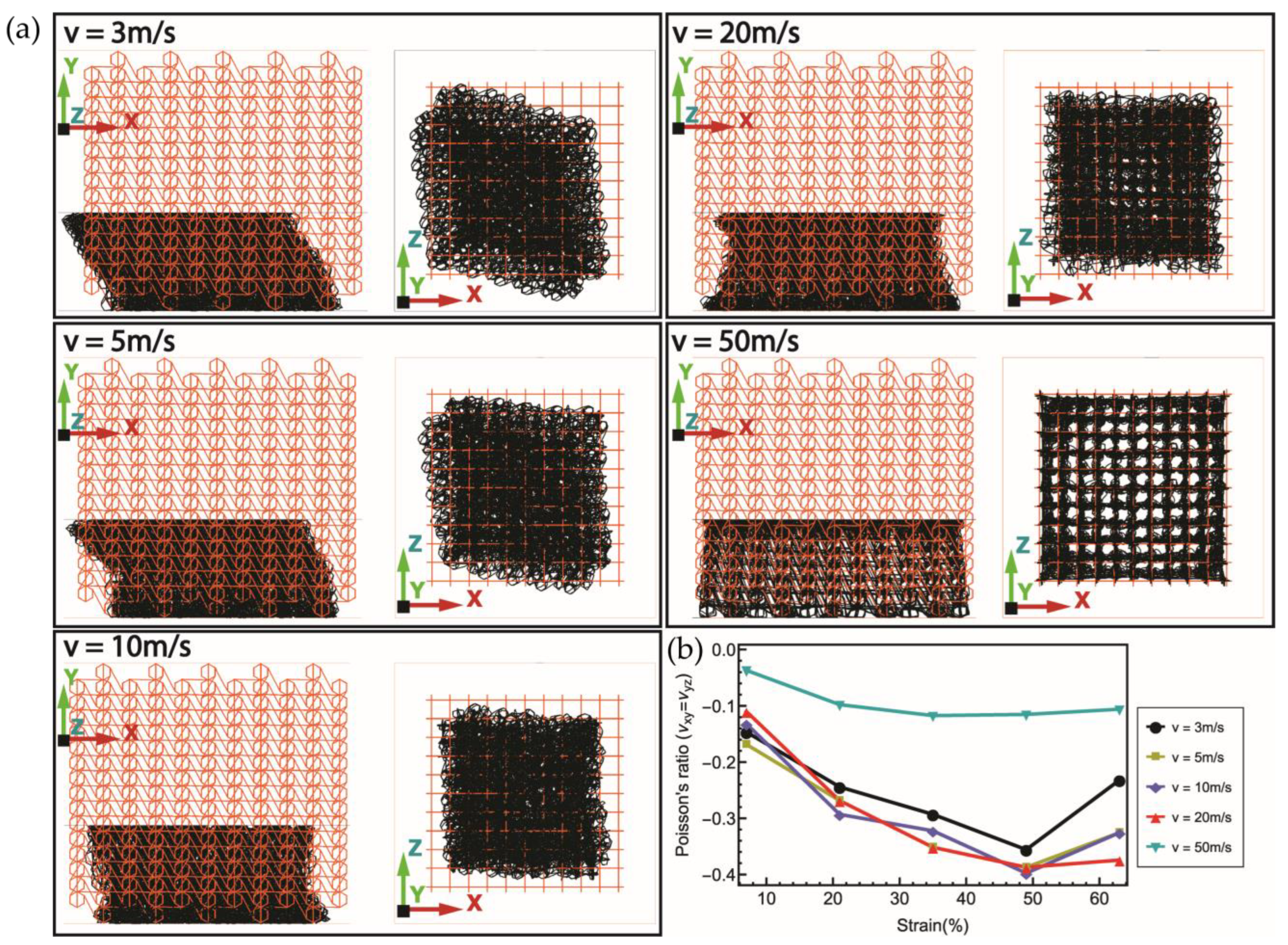

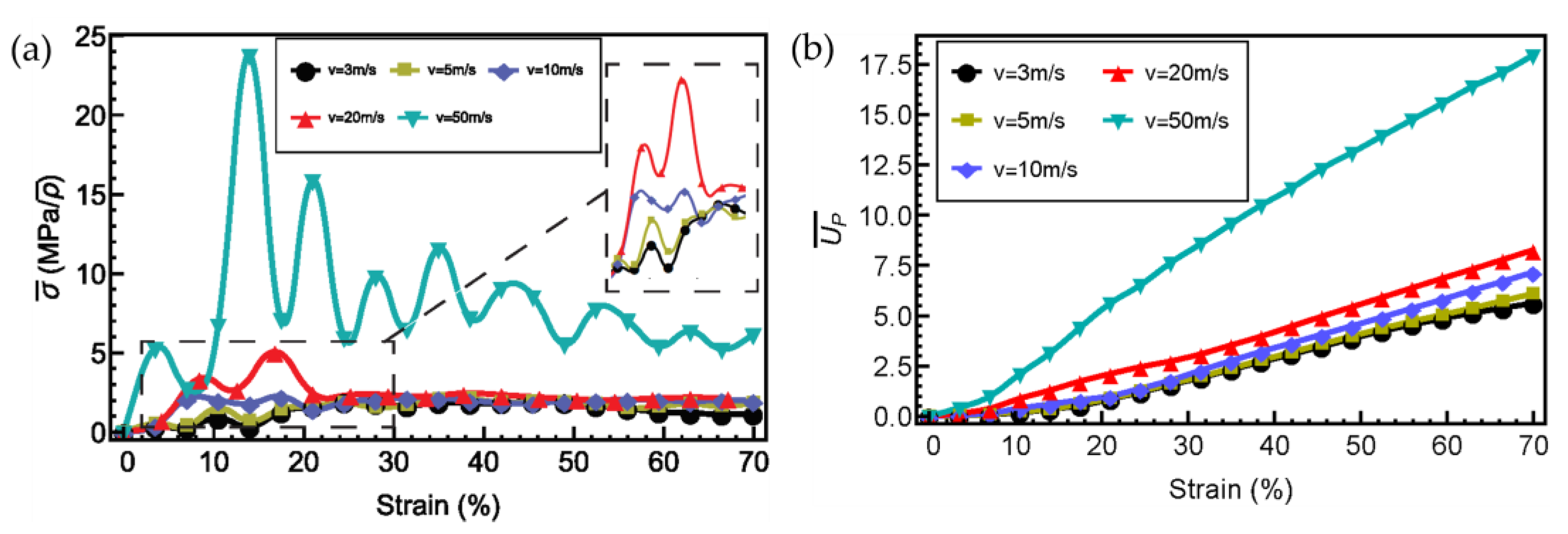

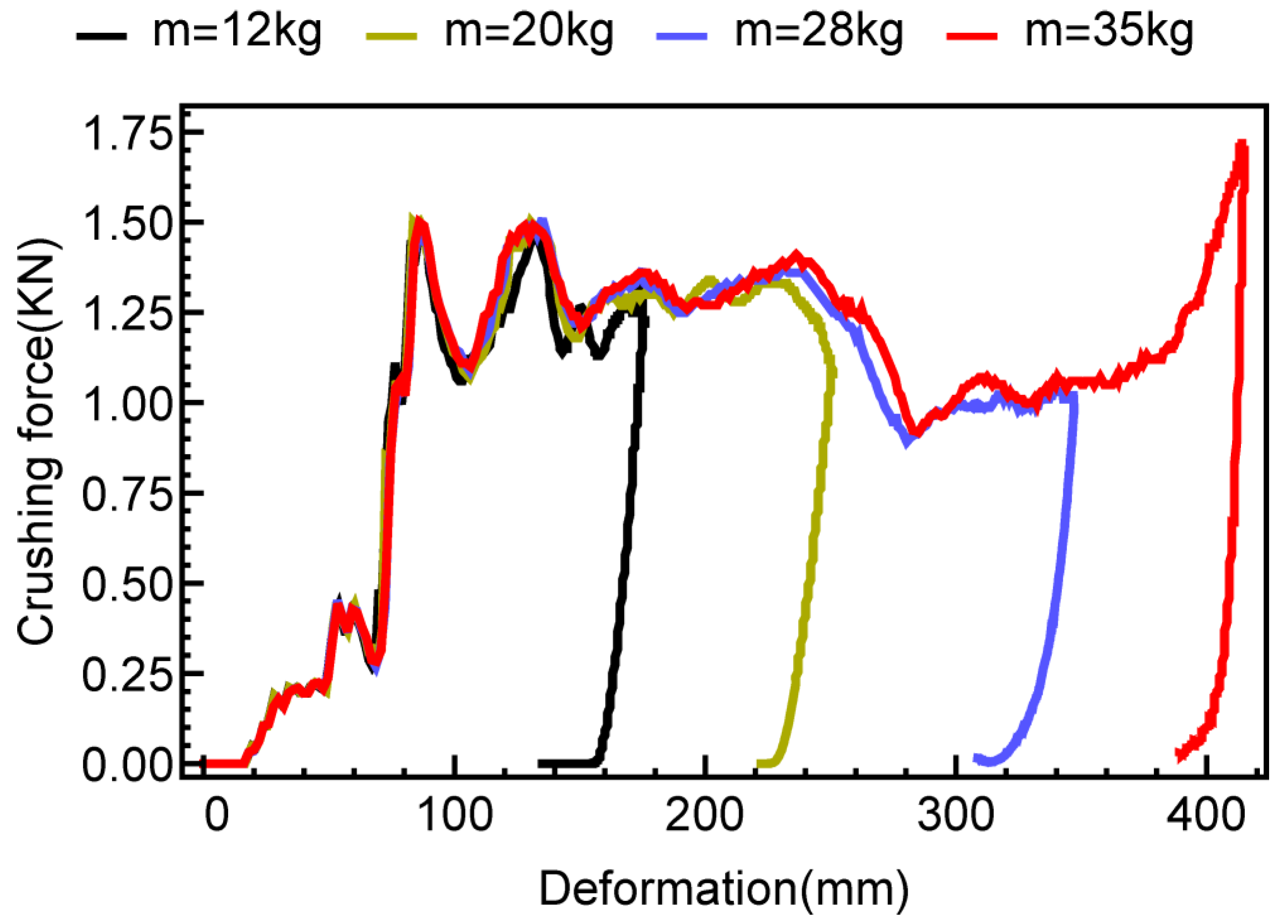

4.1. Effects of Impact Velocity and Mass

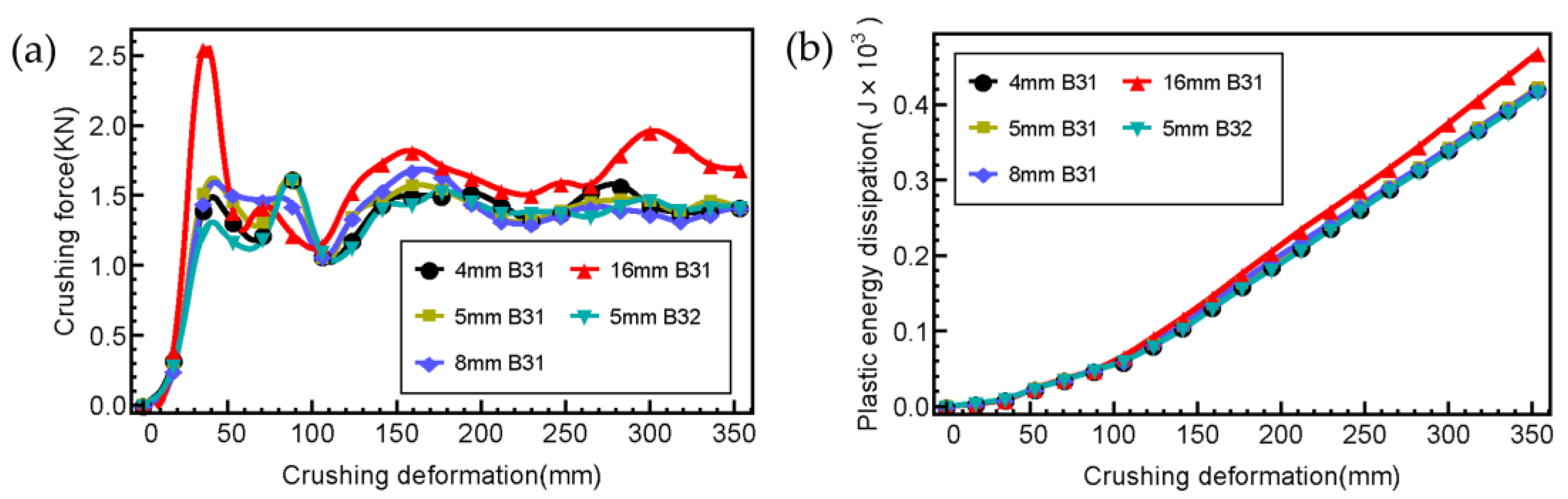

4.2. Effects of Beam Radius and Node Yield Strength

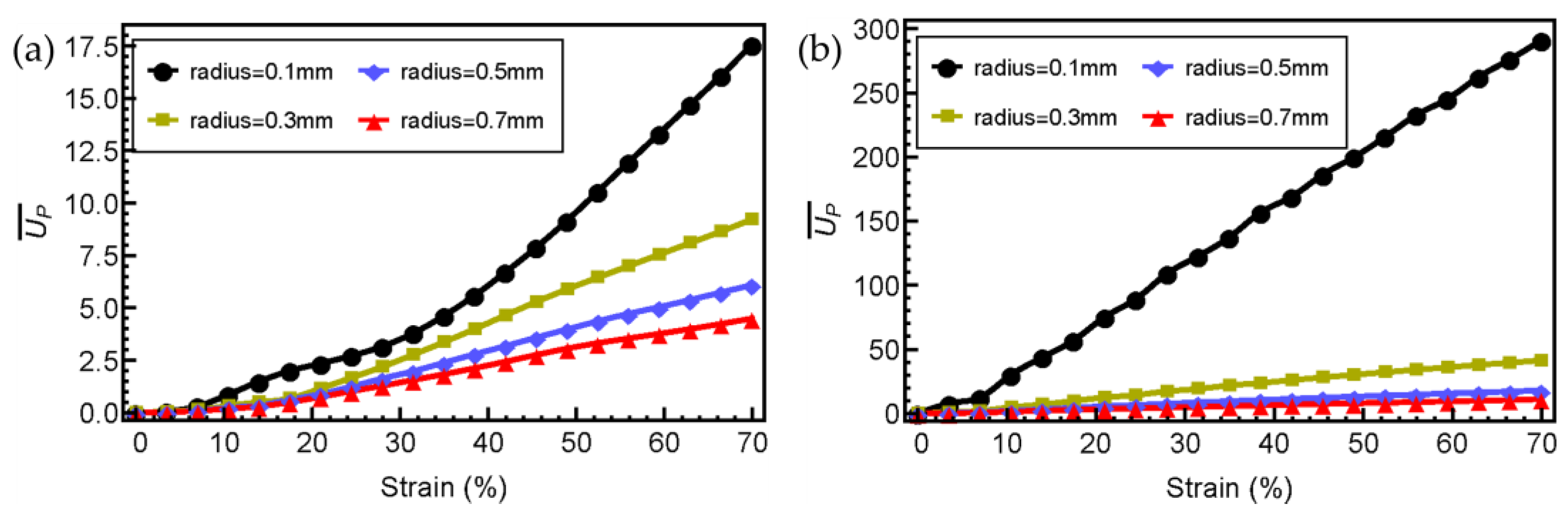

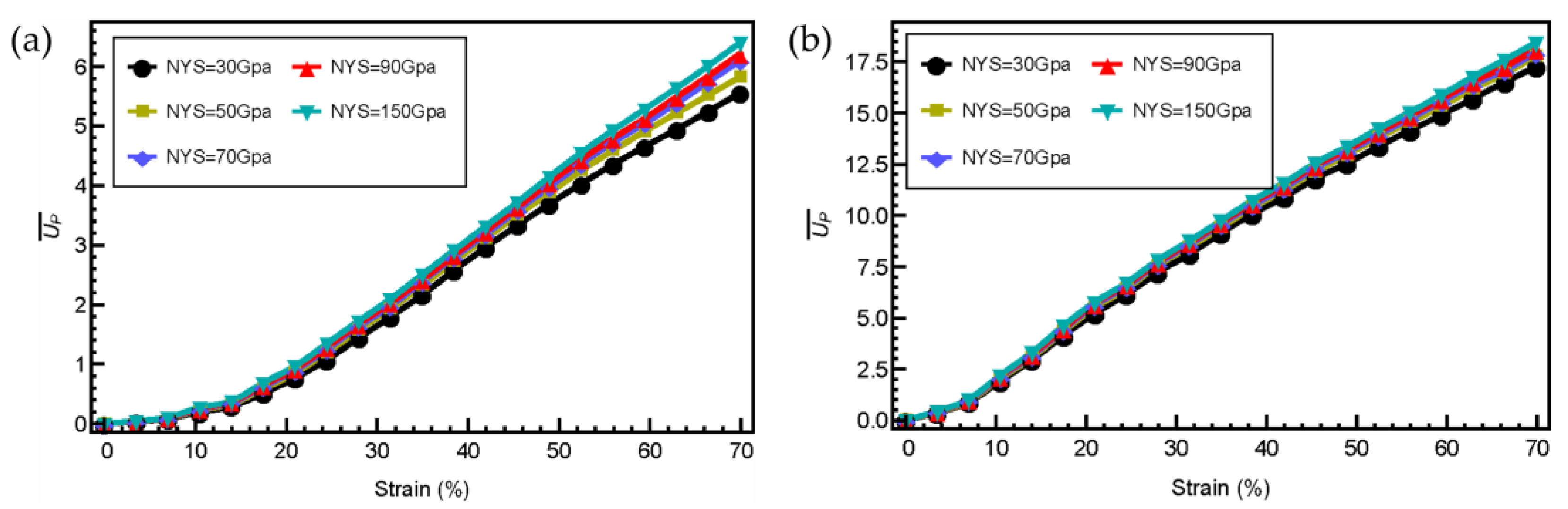

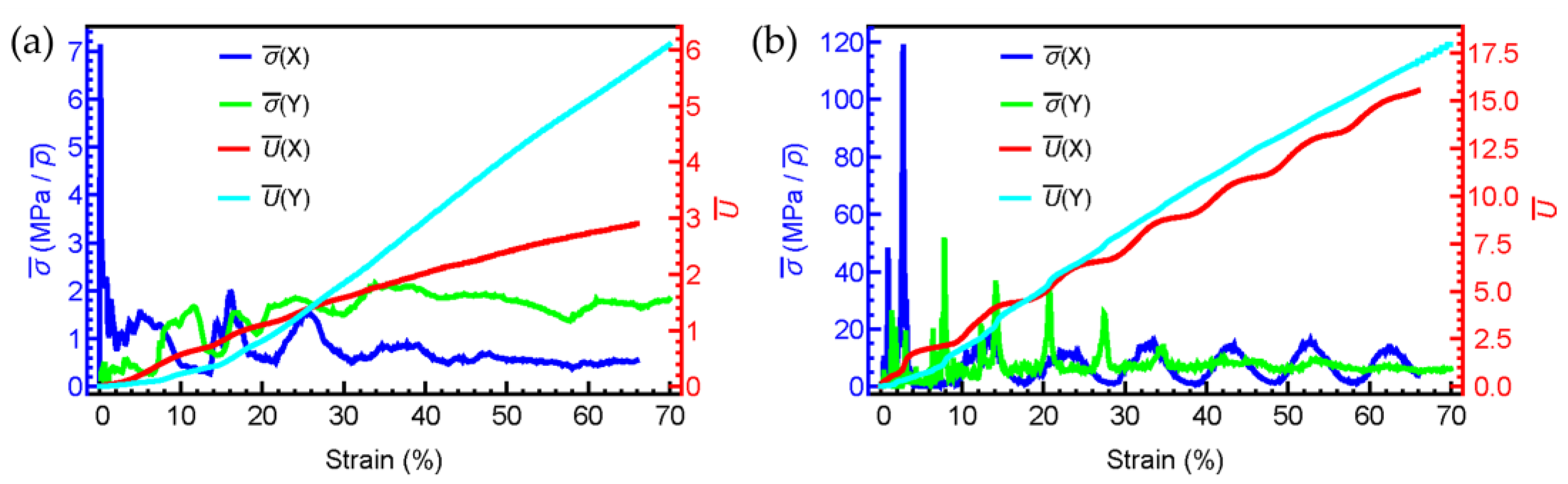

4.3. Effect of Impact Direction

5. Conclusions

- The deformation modes of 3D AH highly depend on impact velocities. The and increase as the impact velocity increases. When the impact velocity remains constant, larger initial impact mass results in an increase in maximum crushing deformation.

- Increasing the beam radius leads to a decrease in specific energy absorption under both low-speed and high-speed compressive loadings. However, the energy absorption capability of 3D AH is not sensitive to the yield strength of nodes.

- The impact behavior that occurred in the X direction results in higher impact stress and better energy absorption performance than the impact in the Y direction in the initial stage of compression (approximately 25% for low-speed impact and 19% for high-speed impact). Afterwards, the crushing deformation in the Y direction gives rise to a stronger capability of plastic energy dissipation than the impact in the X direction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peroni, M.; Solomos, G.; Pizzinato, V. Impact behaviour testing of aluminium foam. Int. J. Impact Eng. 2013, 53, 74–83. [Google Scholar] [CrossRef]

- Ashab, A.S.M.; Ruan, D.; Lu, G.; Wong, Y.C. Quasi-static and dynamic experiments of aluminum honeycombs under combined compression-shear loading. Mater. Des. 2016, 97, 183–194. [Google Scholar] [CrossRef]

- Nian, W.; Subramaniam, K.V.L.; Andreopoulos, Y. Experimental investigation on blast response of cellular concrete. Int. J. Impact Eng. 2016, 96, 105–115. [Google Scholar] [CrossRef] [Green Version]

- Yahaya, M.A.; Ruan, D.; Lu, G.; Dargusch, M.S. Response of aluminium honeycomb sandwich panels subjected to foam projectile impact—An experimental study. Int. J. Impact Eng. 2015, 75, 100–109. [Google Scholar] [CrossRef] [Green Version]

- Imbalzano, G.; Linforth, S.; Ngo, T.D.; Lee, P.V.S.; Tran, P. Blast resistance of auxetic and honeycomb sandwich panels: Comparisons and parametric designs. Compos. Struct. 2018, 183, 242–261. [Google Scholar] [CrossRef]

- Zarei, H.; Kröger, M. Optimum honeycomb filled crash absorber design. Mater. Des. 2008, 29, 193–204. [Google Scholar] [CrossRef]

- D’Mello, R.J.; Waas, A.M. Inplane crush response and energy absorption of circular cell honeycomb filled with elastomer. Compos. Struct. 2013, 106, 491–501. [Google Scholar] [CrossRef]

- Liu, Q.; Fu, J.; Wang, J.; Ma, J.; Chen, H.; Li, Q.; Hui, D. Axial and lateral crushing responses of aluminum honeycombs filled with EPP foam. Compos. Part B-Eng. 2017, 130, 236–247. [Google Scholar] [CrossRef]

- Evans, K.E.; Alderson, A. Auxetic materials: Functional materials and structures from lateral thinking! Adv. Mater. 2000, 12, 617–628. [Google Scholar] [CrossRef]

- Evans, K.E. Auxetic polymers: A new range of materials. Endeavour 1991, 15, 170–174. [Google Scholar] [CrossRef]

- Love, A.E.H. A Treatise on the Mathematical Theory of Elasticity; Dover Publications: New York, NY, USA, 1944. [Google Scholar]

- Ren, X.; Das, R.; Tran, P.; Ngo, T.D.; Xie, Y.M. Auxetic metamaterials and structures: A review. Smart Mater. Struct. 2018, 27, 023001. [Google Scholar] [CrossRef]

- Pelliciari, M.; Pasca, D.P.; Aloisio, A.; Tarantino, A.M. Size effect in single layer graphene sheets and transition from molecular mechanics to continuum theory. Int. J. Mech. Sci. 2022, 214, 106895. [Google Scholar] [CrossRef]

- Pelliciari, M.; Tarantino, A.M. A nonlinear molecular mechanics model for graphene subjected to large in-plane deformations. Int. J. Eng. Sci. 2021, 167, 103527. [Google Scholar] [CrossRef]

- Qin, Z.Z.; Qin, G.Z.; Hu, M. Origin of anisotropic negative Poisson’s ratio in graphene. Nanoscale 2018, 10, 10365–10370. [Google Scholar] [CrossRef] [PubMed]

- Gao, D.; Wang, S.; Zhang, M.; Zhang, C. Experimental and numerical investigation on in-plane impact behaviour of chiral auxetic structure. Compos. Struct. 2021, 267, 113922. [Google Scholar] [CrossRef]

- Yu, R.; Luo, W.; Yuan, H.; Liu, J.; He, W.; Yu, Z. Experimental and numerical research on foam filled re-entrant cellular structure with negative Poisson’s ratio. Thin Wall Struct. 2020, 153, 106679. [Google Scholar] [CrossRef]

- Bettini, P.; Airoldi, A.; Sala, G.; Landro, L.D.; Ruzzene, M.; Spadoni, A. Composite chiral structures for morphing airfoils: Numerical analyses and development of a manufacturing process. Compos. Part B-Eng. 2010, 41, 133–147. [Google Scholar] [CrossRef] [Green Version]

- Li, T.T.; Chen, Y.Y.; Hu, X.Y.; Li, Y.B.; Wang, L.F. Exploiting negative Poisson’s ratio to design 3D-printed composites with enhanced mechanical properties. Mater. Des. 2018, 142, 247–258. [Google Scholar] [CrossRef]

- Wang, X.-T.; Wang, B.; Li, X.-W.; Ma, L. Mechanical properties of 3D re-entrant auxetic cellular structures. Int. J. Mech. Sci. 2017, 131–132, 396–407. [Google Scholar] [CrossRef]

- Wu, W.; Geng, L.; Niu, Y.; Qi, D.; Cui, X.; Fang, D. Compression twist deformation of novel tetrachiral architected cylindrical tube inspired by towel gourd tendrils. Extrem. Mech. Lett. 2018, 20, 104–111. [Google Scholar] [CrossRef]

- Wu, X.; Su, Y.; Shi, J. In-plane impact resistance enhancement with a graded cell-wall angle design for auxetic metamaterials. Compos. Struct. 2020, 247, 112451. [Google Scholar] [CrossRef]

- Liu, W.; Wang, N.; Luo, T.; Lin, Z. In-plane dynamic crushing of re-entrant auxetic cellular structure. Mater. Des. 2016, 100, 84–91. [Google Scholar] [CrossRef]

- Ingrole, A.; Hao, A.; Liang, R. Design and modeling of auxetic and hybrid honeycomb structures for in-plane property enhancement. Mater. Des. 2017, 117, 72–83. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, K.; Wang, X.; Xiong, M.-X.; Wang, Y. Experimental and numerical investigation of low velocity impact response of foam concrete filled auxetic honeycombs. Thin Walled Struct. 2020, 154, 106898. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, C. Theoretical and numerical investigation on in-plane impact performance of chiral honeycomb core structure. J. Struct. Integr. Main. 2018, 3, 95–105. [Google Scholar] [CrossRef]

- Airoldi, A.; Novak, N.; Sgobba, F.; Gilardelli, A.; Borovinšek, M. Foam-filled energy absorbers with auxetic behaviour for localized impacts. Mater. Sci. Eng. A 2020, 788, 139500. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, H.; Schlangen, E.; Luković, M.; Šavija, B. Cementitious cellular composites with auxetic behavior. Cem. Concr. Comp. 2020, 111, 103624. [Google Scholar] [CrossRef]

- Imbalzano, G.; Tran, P.; Ngo, T.D.; Lee, P.V.S. A numerical study of auxetic composite panels under blast loadings. Compos. Struct. 2016, 135, 339–352. [Google Scholar] [CrossRef]

- Logakannan, K.P.; Ramachandran, V.; Rengaswamy, J.; Ruan, D. Dynamic Performance of a 3D Re-entrant Structure. Mech. Mater. 2020, 148, 103503. [Google Scholar] [CrossRef]

- Mohsenizadeh, S.; Alipour, R.; Shokri Rad, M.; Farokhi Nejad, A.; Ahmad, Z. Crashworthiness assessment of auxetic foam-filled tube under quasi-static axial loading. Mater. Des. 2015, 88, 258–268. [Google Scholar] [CrossRef]

- Frenzel, T.; Kadic, M.; Wegener, M. Three-dimensional mechanical metamaterials with a twist. Science 2017, 358, 1072. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fu, M.-H.; Zheng, B.-B.; Li, W.-H. A novel chiral three-dimensional material with negative Poisson’s ratio and the equivalent elastic parameters. Compos. Struct. 2017, 176, 442–448. [Google Scholar] [CrossRef]

- Wang, Q.S.; Yang, Z.Y.; Lu, Z.X.; Li, X. Mechanical responses of 3D cross-chiral auxetic materials under uniaxial compression. Mater. Des. 2020, 186, 108226. [Google Scholar] [CrossRef]

- Ha, C.S.; Plesha, M.E.; Lakes, R.S. Chiral three-dimensional lattices with tunable Poisson’s ratio. Smart Mater. Struct. 2016, 25, 054005. [Google Scholar] [CrossRef] [Green Version]

- Fu, M.H.; Liu, F.M.; Hu, L.L. A novel category of 3D chiral material with negative Poisson’s ratio. Compos. Sci. Technol. 2018, 160, 111–118. [Google Scholar] [CrossRef]

- Prall, D.; Lakes, R.S. Properties of a chiral honeycomb with a poisson’s ratio of—1. Int. J. Mech. Sci. 1997, 39, 305–314. [Google Scholar] [CrossRef]

- Spadoni, A.; Ruzzene, M. Elasto-static micropolar behavior of a chiral auxetic lattice. J. Mech. Phys. Solids 2012, 60, 156–171. [Google Scholar] [CrossRef] [Green Version]

- Hassan, M.R.; Scarpa, F.; Ruzzene, M.; Mohammed, N.A. Smart shape memory alloy chiral honeycomb. Mater. Sci. Eng. A 2008, 481–482, 654–657. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, D.; Zhang, C.; Zhang, J. Compressive Behavior of a Novel Hexagonal Nodes-Based 3D Chiral Auxetic Structure. Appl. Sci. 2023, 13, 8480. https://doi.org/10.3390/app13148480

Gao D, Zhang C, Zhang J. Compressive Behavior of a Novel Hexagonal Nodes-Based 3D Chiral Auxetic Structure. Applied Sciences. 2023; 13(14):8480. https://doi.org/10.3390/app13148480

Chicago/Turabian StyleGao, Dianwei, Chunwei Zhang, and Jianhua Zhang. 2023. "Compressive Behavior of a Novel Hexagonal Nodes-Based 3D Chiral Auxetic Structure" Applied Sciences 13, no. 14: 8480. https://doi.org/10.3390/app13148480

APA StyleGao, D., Zhang, C., & Zhang, J. (2023). Compressive Behavior of a Novel Hexagonal Nodes-Based 3D Chiral Auxetic Structure. Applied Sciences, 13(14), 8480. https://doi.org/10.3390/app13148480