1. Introduction

Many countries are accelerating the construction of new-type power systems. With the development of distribution network technology and the establishment of the “dual carbon” target [

1], distributed generation (DG) has been widely used due to its characteristics of low energy consumption, cleanliness, and flexibility [

2]. Distributed power generation is characterized by randomness, intermittency, vulnerability to environmental impacts, and small reserves [

3]. With the access of DG to the distribution network, the uncertainty of the power flow direction leads to an increased risk of power grid failure [

4]. Investigating fault location methods with better performance is significant in improving the safety and stability of distribution network operations [

5].

After a fault occurs in the active distribution network, fast and accurate fault location is a prerequisite for ensuring the reliability of the power supply [

6]. The active distribution network is a multi-power system whose structure is more complex. The uncertainty of distributed power generation directly impacts the current, loss, voltage distribution, and short-circuit level of the entire line. The voltage of each point, such as the section switch and the circuit breaker, will increase significantly. With the access of DG, the problem of reverse power flow will be caused, which leads to the unsatisfactory effect of traditional fault location methods. Therefore, the fault location problem of the active distribution network is an important issue in the research of smart grids [

7].

In the context of the automation upgrades of distribution network equipment, many fault location methods based on feeder terminal unit (FTU) upload information have been proposed. There are direct and indirect methods for fault location [

8]. The direct method mainly includes the matrix algorithm [

9], and the indirect method primarily consists of the particle swarm optimization algorithm [

10], immune algorithm [

11], ant colony algorithm [

12], and other intelligent algorithms.

The principle of the matrix algorithm is to obtain the fault judgment matrix by matrix calculation to locate the fault sections [

13]. Reference [

14] adopts a specific correction method for different location results. However, this correction method can only adapt to one-third of cases of the error fault information. In Reference [

15], a method combining a matrix algorithm and an optimization algorithm is proposed. However, the “minimum set” cannot contain all suspected fault sections. Reference [

16] proposes a fault location matrix algorithm based on voltage magnitude comparison, determining the fault sections by comparing the voltage magnitudes at both ends of the suspected fault sections.

Based on the “minimum set” theory, the intelligent algorithm calculates the fault sections that best explain the fault information by solving the fitness function [

17]. Reference [

18] proposes to evaluate population individuals by calculating antibody affinity. However, the evaluation has to be realized between individuals in each generation, which seriously affects the convergence speed. Reference [

19] proposes adaptive crossover and mutation probabilities, adjusted nonlinearly according to the Sigmoid function. However, the parameter setting of this method is complicated. Reference [

20] is applied to fault location in the internet of things (IoT) power distribution. The improved unmanned aerial vehicle (UAV) model and particle swarm optimization algorithm are used for fault location, improving the operational efficiency and adaptability of the algorithm.

In summary, the following limitations exist in the research of active distribution network fault location methods: (1) With the increase in distribution network scale and the access of a large number of DGs, the existing fault location methods will find it hard to meet the requirements of fault location accuracy and rapidity. (2) The intelligent algorithm generally has the limitations of premature convergence, making it difficult to search for the correct fault sections. (3) When multiple elements of fault information are incorrect, fault location methods have the problem of balancing positioning speed and accuracy. In response to the above shortcomings, this paper advances a fault section location method of the active distribution network based on multi-source information. The main contents of this paper are as follows:

The fault region location algorithm is proposed to ensure that the fault region contains all possible faulted sections, simplifying the fault system and reducing the matrix calculation dimension.

An improved matrix algorithm using a non-square matrix form of computation is proposed to adapt to the access of multiple DGs. The algorithm can accurately locate single and multiple faults in non-T-connected sections.

A verification method suitable for the improved matrix algorithm positioning results is proposed to improve the tolerance performance.

A fault hypothesis and fitness function are proposed based on the FTU uploading equipment status and protection action information. Moreover, the genetic tabu algorithm is proposed to locate the fault section by optimization calculation. The method can accurately locate single and multiple faults when the fault information is incorrect.

The remainder of this paper is arranged as follows.

Section 2 proposes the construction of the node status list and topology search method for suspicious fault regions.

Section 3 analyzes the deficiencies of the traditional matrix algorithm and proposes an improved matrix algorithm.

Section 3.3 proposes a verification method suitable for the improved matrix algorithm.

Section 4 proposes a genetic tabu algorithm to quickly and accurately achieve fault location using equipment status and protection action information.

Section 5 builds an IEEE-34 node active distribution network model based on the PSCAD platform and implements the proposed algorithm using Python software. Different fault conditions are simulated to test the proposed algorithm and compared with other fault location methods.

2. Fault Region Location

This paper puts forward a fault region location method to reduce the fault location model. Firstly, the fault information needed for fault location is introduced. Secondly, the construction method of the node status list is proposed. Finally, a topology search method for suspicious fault regions and a method to obtain the fault regions are proposed.

2.1. Fault Information and Status Definition

The fault location method needs protection action and equipment status information. The protection action information is obtained through the FTU. The protection action region is between the action switch and the next-level protection switch. The FTU and the internal measuring point of DG upload the equipment status information. The positive direction is the system power pointing to each switch node or DG. The following definitions distinguish the fault current direction:

2.2. Node Status List

The system shown in

Figure 1 contains eight switching nodes from

S1 to

S8 and six feeder sections from

L1 to

L6. Here are the steps to create a node status list:

- (1)

Number each FTU and the internal measuring point of DG according to the positive direction.

Table 1 shows the numbering results for the system in

Figure 1.

- (2)

The node status list consists of five parts: node number, upstream node number, downstream node number, equipment status information, and whether the node is a DG internal measuring point. The node status list of

Figure 1 is shown in

Table 2.

2.3. Fault Region Location Method

The suspicious fault region is the connected region where all boundary nodes have alarm information. A suspicious fault region location algorithm is proposed to obtain the boundary nodes, which uses the idea of depth-first traversal in the tree search method.

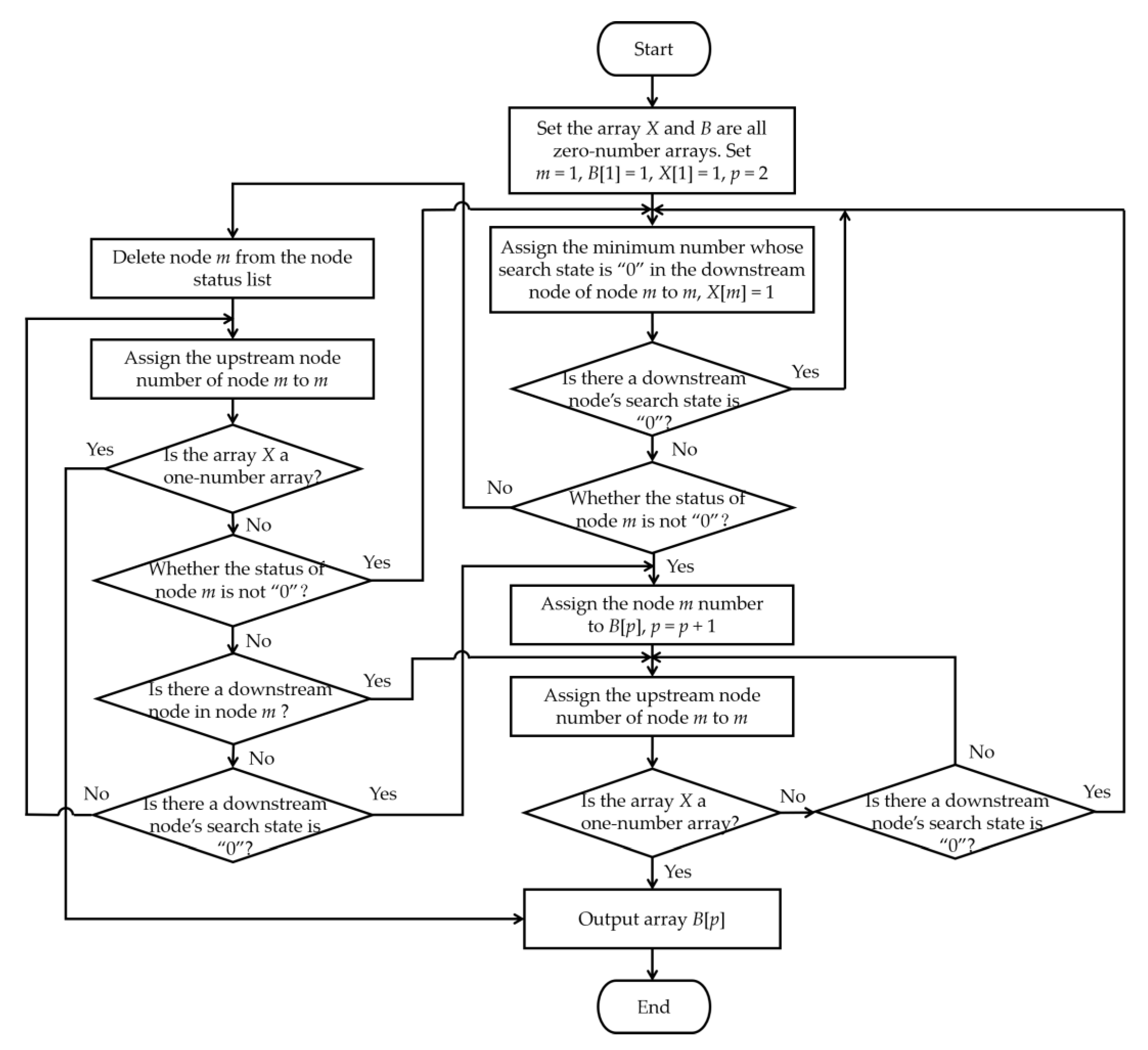

The algorithm sets two variables and arrays:

m,

p,

X,

B. Variable

m represents the node number of the temporary detection. Variable

p is the auxiliary iteration parameter. Array

X marks the node search state. Array

B records boundary nodes. The procedure is explained in detail in the following steps, and the flow chart is shown in

Figure 2.

Set the initial value of m as 1; the arrays X and B are all zero-number arrays; the initial node B[1] = 1, X[1] = 1, p = 2;

Assign the search state as “0” in the downstream node of node m to m, set X[m] = 1;

If node m has a downstream node, go back to step 2; otherwise, check whether the equipment status information of node m is not “0”. If it is not “0”, set B[p] = m, p = p + 1, then go to step 6; otherwise, delete node m from the node status list and go to step 4;

Assign the upstream node number of node m to m, and check whether the array X is a one-number array. If not, run the next step; otherwise, go to step 8;

Check whether a downstream node search status as “0” exists on node m. If it exists, go back to step 2; otherwise, check whether node m has a downstream node. If not, check whether the equipment status information of node m is not “0”. If it is not “0”, set B[p] = m, p = p + 1, go to step 6; otherwise, go back to step 4. If it exists, go to step 6;

Assign the upstream node number of node m to m, and check whether the array X is a one-number array. If not, run the next step; otherwise, go to step 8;

Check whether a downstream node whose search status as “0” exists on node m. If not, go back to step 6; otherwise, go back to step 2;

Terminate the program, output the array B, and obtain the boundary nodes.

The suspicious fault region is determined through the boundary nodes in array B. The protection action information obtains the protection action region. Check whether the suspicious fault region contains the protection action region. If it does, the suspicious fault region is the fault region; otherwise, the node farthest away from the system power in the protection action region is regarded as a boundary node. The fault region is determined together with the boundary nodes in array B. The fault node status list is generated from the fault region.

3. Improved Matrix Algorithm

This section introduces the calculation principle of the traditional matrix algorithm, proposes an improved matrix algorithm that can adapt to the access of DG, and presents a verification method to improve tolerance performance.

3.1. Traditional Matrix Algorithm

Firstly, the principle of the traditional matrix algorithm for the open-loop state is introduced. The number of switch nodes

Sj and feeder sections

Li is equal and assumed as

ml. The correlation matrix

D′ is defined as follows:

The elements of the 1 ×

ml feeder section status matrix

L′ are defined as follows:

The elements of the 1 ×

ml fault information matrix

I′ are defined as follows:

Define the following logical operation. Matrix

K and matrix

M are two matrices of the same dimension:

From the definition of the correlation matrix

D′, the following relationship can be calculated for radial distribution networks:

After simplification, we can obtain the equation for calculating the matrix

L′:

The fault section is the section in which the calculation result of “1” in matrix L′.

Secondly, the calculation principle for the closed-loop state is introduced. The algorithm adopts the method of separate analysis and superposition judgment. When analyzing one of the power supplies, set the positive direction as the power supply pointing to each node. Open the interface circuit breakers of other power supplies. The results of individual power supply are calculated separately, and the sets of fault sections are

F1,

F2, …, and

Fi. The set of fault sections

F of the entire active distribution networks is:

3.2. Improved Matrix Algorithm

An improved matrix algorithm is proposed to address the shortcomings of the traditional matrix algorithm, considering the internal measuring point of DG so that the number of switch nodes is greater than the feeder sections. The algorithm is computed in a non-square matrix form. Assuming the number of switch nodes

Si is

ms and feeder sections

Lj is

ml. The network description matrix

D is defined as follows:

The elements of the 1 ×

ms fault information matrix

I are defined as follows:

A 1 ×

ml matrix represents the fault judgment matrix

L:

The physical meaning is the number of nodes in which the fault current flows into the feeder section minus nodes in which the fault current flows out of the feeder section.

According to the definition of matrix

D, taking

l1 as an example, the following arithmetic relations exist for radial active distribution networks:

This relationship is further extended to the entire active distribution network. To attain the calculation equation of the fault judgment matrix

L:

According to the physical meaning of matrix

L, the fault criterion is as follows:

When the result of “1” appears in a specific section, check whether the section is a T-connected section. If not, the section is considered faulty; otherwise, check whether other sections are faulty. If there are faults in other sections, we assume that the T-connected section does not faulty; otherwise, the T-connected section is faulty.

3.3. Improved Matrix Algorithm Verification

The improved matrix algorithm cannot accurately locate multiple faults with T-connected sections. This section proposes a verification method based on the traditional matrix algorithm and superposition principle. According to I′ = |L′D′|, the matrix I* can be derived from the matrix L′ and the matrix D′. Determine whether the calculated matrix I* is the same as the matrix I brought by equipment status information. If they are the same, the positioning result is correct. Otherwise, further fault location is performed in the next section. Each positioning result of the improved matrix algorithm is verified. The calculation steps of the verification method are as follows:

- (1)

Write the feeder section status matrix L′ according to the positioning result.

- (2)

When analyzing one of the power supplies, the correlation matrix D′ considering the causality between the faulted section and the alarm of the switch, has the same structure as the matrix shown in Equation (2). Matrix D′ is defined as follows:

When analyzing one of the power supplies, the nodes nearest to the other power supplies are regarded as disconnected. Delete the rows corresponding to the disconnected nodes in the network description matrix

D to attain the network description matrix

Di in the square matrix form. When describing the same system, the network description matrix and the correlation matrix contain the same line topology. Through calculation, we find that the two matrices of the same system are inverse matrices to each other. Therefore, the correlation matrix of the system can be calculated using the following equation:

Each power supply is analyzed separately to obtain ms − ml + 1 correlation matrices Di′.

- (3)

Define the following logical operation. Matrix

K and matrix

M are two matrices of the same dimension:

Same as the traditional matrix algorithm principle, using the equation:

to obtain

ms −

ml + 1 fault information matrix

Ii.

- (4)

Each matrix

Ii must be supplemented with “0” at the nodes it does not contain to obtain a matrix

Ii* of 1 ×

ms. Then, through the equation:

obtain the fault information matrix

I*. Determine whether the matrix

I* and the matrix

I obtained from the equipment status information are the same.

The flow chart of the verification is shown in

Figure 3.

3.4. Improved Matrix Algorithm Analysis

The improved matrix algorithm cannot accurately deal with multiple faults with T-connected sections. Specifically, it includes the following two cases:

- (1)

As shown in

Figure 4, multiple faults with the T-connected section occur in (i), and a single fault occurs in (ii). In the two cases, the equipment status information of the

S1,

S2, and

S3 nodes is the same, which is 1, −1, and 1. In matrix

L, the results of these sections are all 1. According to the fault criterion, the T-connected section of

li = 1 is not faulty when other fault sections are present. Therefore, the algorithm cannot accurately locate whether the T-connection section of

li = 1 is faulty in the case of multiple faults.

- (2)

As shown in

Figure 5, multiple faults with the T-connected section occur in (i), and a single fault occurs in (ii). In the two cases, the equipment status information of the

S1,

S2, and

S3 nodes is the same, which is 1, 1, and 0. In matrix

L, the results of these sections are all 0. According to the fault criterion, the T-connected section of

li = 0 is not faulty. Therefore, the algorithm cannot accurately locate whether the T-connected section of

li = 0 is faulty in the case of multiple faults.

In summary, the improved matrix algorithm can accurately locate single and multiple faults in non-T-connected sections without error fault information. However, it cannot accurately judge whether the T-connected sections of li = 1 and li = 0 have failed under multiple faults.

4. Genetic Tabu Algorithm

This paper proposes a genetic tabu algorithm (GTA) to locate the fault section further. This section defines the fault hypothesis and the fitness function, derives the equation for calculating the expected status of fault information, and introduces the calculation principle and parameter selection of the genetic tabu algorithm.

4.1. Fault Hypothesis

The calculated fault sections, the T-connected sections with

li = 1 and

li = 0, and the sections inside the protection action region are used as the suspicious fault sections. The three factors, “different combinations of suspicious fault sections fail”, “protection of misoperation or rejection”, and “error equipment status information”, are taken as a fault hypothesis. Suppose there are

ml suspicious fault sections. There are

me protections and

ms nodes in the fault region. The basic form of the fault hypothesis is as follows:

- (1)

, and the control variable is set as li, depending on whether section i is faulty. li = 0 means section i is not faulty; li = 1 indicates section i is faulty.

- (2)

, and the control variable is set as oi, depending on whether protection i has a misoperation. oi = 0 indicates that protection i does not have a misoperation; oi = 1 shows protection i has a misoperation.

- (3)

, and the control variable is set as ri, depending on whether protection i has a rejection. ri = 0 indicates that protection i does not have a rejection; ri = 1 indicates that protection i has a rejection.

- (4)

, and the control variable is set as

Ai,1,

Ai,2, depending on whether there is error equipment status information for node

i. The error results are represented by

Ai,1,

Ai,2 shown in

Table 3.

4.2. Fitness Function

A fitness function reflects the difference between the expected and actual status of the protection action and equipment status information. The fitness function

F(

H) can provide feedback on the rationality of the fault hypothesis. The smaller the

F(

H) is, the higher the reliability of the fault hypothesis.

F(

H) is shown as follows:

F(

H) consists of two parts. The first part is the alarm difference index. This part reflects the difference between the expected and actual status of the fault information:

- (1)

ei is the actual status of protection i. ei = 0 indicates that the protection is inactive. ei = 1 indicates that it is active. Ij is the actual equipment status information of node j.

- (2)

ei′(H) and Ij′(H) represent the expected protection action status of protection i, and the expected equipment status information of node j, and are calculated according to the H.

- (3)

|ei − ei′(H)| is the difference between the expected and actual status of protection action information of protection i. |Ij − Ij′(H)| is the difference between the expected and actual status of equipment status information of node j.

The second part of the fitness function is the fault hypothesis minimization index:

This component shows that, when the alarm difference index is the same, the lower the total number of fault sections, misoperations, and rejection protections, and nodes with error equipment status information, the higher the reliability of the fault hypothesis.

To select the case where the alarm discrepancy index is the smallest, set

w1 >

w3,

w2 >

w3. According to the actual reliability of the relay, protection must be more than 99%, and the probability of misoperation and rejection can be selected as 0.1%. According to the statistics of the long-term operation of the active distribution system, the probability of error equipment status information can be selected as 1%. When the probabilities of false protection action and error equipment status information are the same, the alarm discrepancy index calculated from the protection action information is the same as the equipment status information. We can obtain the following equation:

w1 = 1.5

w2 is calculated. Therefore,

w1 = 150,

w2 = 100, and

w3 = 1 can be selected. The loss function and cost function of the optimization process are defined. The loss function is used to evaluate the difference between the predicted and true values of the model, which refers to the error of a sample. The cost function is defined on the entire training set, which refers to the average of all sample errors. Since the fault location is optimized according to the difference between the expected and actual status of the fault information, this paper uses the loss function as an absolute value to construct the cost function. The calculation equation of the loss function

L(

H) and the cost function

c(

H) are:

4.3. Expected Protection Action Status

This section derives the calculation equation of the expected protection action status during normal operation, and the expected protection action status ei′(H), which considers the protection of incorrect action.

4.3.1. Expected Protection Action Status When Incorrect Action Is Not Considered

At present, the majority of relay protection in the distribution system still adopts overcurrent protection. On this basis, the protection action expected status is discussed.

Set

ei is the main protection of section

Lj, and its action logic is that when section

Lj of protection

ei fails (

lj = 1), the protection

ei should act.

Set

ei is the remote backup protection of section

Lj, and

ex is the main protection of section

Lj. The section in the remote backup protection region of protection

ei is represented by

Y(

ei). When there is a section

Lj fault (

lj = 1) in

Y(

ei), and its main protection

ex refuses to operate (

rx = 1), the protection

ei should act.

4.3.2. Expected Protection Action Status Considering Incorrect Action

As shown in

Table 4, by combining

with the misoperation variable

oi and the rejection variable

ri, we can attain the expected protection action status

ei′(

H).

According to

Table 4, the calculation equation of

ei′(

H) can be obtained:

4.4. Equipment Expected Status Information

This section derives the calculation equation of the equipment expected status information when it is normal, and the equipment expected status information , which considers the hypothesis of “error equipment status information”.

4.4.1. Equipment Expected Status Information without Considering Error Information

Introducing the switching function, which establishes a conversion from the fault section to the equipment status information. The switching function is defined as:

The physical meaning of each element is as follows: is the switching function of the node j, which is “1” when there is a positive alarm, “−1” when there is a reverse alarm, and “0” when there is no alarm; and , respectively, represent the upstream and downstream switching functions of node j; and , respectively, represent the status of the section between the node j to the upstream power supply su and the downstream power supply sd; su and sd include the main power supply and DG; M’ and N’ are the number of upstream and downstream power supplies, respectively; lj,u and lj,d, respectively, represent the status of all upstream and downstream sections of node j; M and N are the number of all sections in the upstream and downstream, respectively; “” represents the logical “or” operation; Ku and Kd are the upstream and downstream power supply coefficients, respectively, and the power supply access is “1”; otherwise, it is “0”.

4.4.2. Equipment Expected Status Information Considering Error Information

As shown in

Table 3, by combining

with the error factor

Aj,k and the

, we can attain the calculation equation of the

. The calculation equation is as follows:

4.5. Genetic Tabu Algorithm

This section introduces the genetic tabu algorithm (GTA) overall design, calculation principle, and parameter selection. The genetic algorithm (GA) and tabu search (TS) are two commonly used algorithms for the fault location of the active distribution network. Among them, the core idea of the GA is “Natural selection, survival of the fittest”. The algorithm optimizes by simulating the evolutionary theory in nature and has strong robustness and flexibility. However, the search granularity of the GA is coarse, and it is prone to premature convergence or non-convergence. Based on the neighborhood search algorithm, TS introduces a tabu table to limit the optimal local solution. Hence, it is easier to achieve the global optimum, and the search accuracy is higher. However, due to the low search efficiency of neighborhood search on large-scale problems, this algorithm takes more time to deal with the fault location problem of the distribution network.

4.5.1. Genetic Tabu Algorithm Overall Design

A genetic tabu algorithm suitable for fault location of the large-scale active distribution network is proposed by combining the high search efficiency of the GA and the high search accuracy of TS to complete the optimization calculation together so that the algorithm can improve the accuracy based on ensuring the calculation speed and meet the requirements of power supply reliability of distribution network.

Firstly, according to the practical problem of fault location in the active distribution network, the genetic coding rules of the GA are designed. The suspicious fault section is encoded as a one-dimensional matrix. The value of each element in the matrix represents whether the section is faulty, where “1” represents that the section is faulty, and “0” represents that the section is not faulty. The individual in the GA is represented as such a binary gene string. In this design, once the fault section is detected, it will cause a rapid decrease in the fitness function’s value. The GA can retain this dominant gene, thus avoiding the repeated search of the algorithm, which greatly improves the optimization efficiency. At the same time, individuals can accurately reflect the fault situation.

Secondly, the natural selection rules are designed according to the idea of TS. In natural selection, the top 50% of fitness of the current population individuals are selected as the parent generation. Then, one individual gene is selected for the mutation to generate a neighborhood. The mutated individuals are also added to the parent generation to obtain the parent population of the same size. This natural selection rule corresponds to the actual fault location. The fault situation represented by individual neighborhoods is close to the current fault situation. In addition, to ensure the running speed of the algorithm, several individuals with the highest fitness in the child generation are updated into the tabu table after natural selection to prevent the algorithm from repeatedly searching and falling into the local optimum.

Then, the initial population is generated by the greedy algorithm. Considering that the probability of single faults is higher than that of multiple faults, the initial population preferentially generates all individuals of single faults. Then, it fills the initial population with a random method. On the one hand, it can quickly screen out the dominant individuals with smaller fitness function values in the initial population. On the other hand, it can also avoid the phenomenon that the algorithm converges too late or does not converge, thus accelerating the convergence speed of the algorithm.

Finally, according to the designed natural selection rules and genetic algorithm, the iteration is carried out to attain the fault section location result.

The GTA can accurately locate various complex fault conditions.

Section 5 uses the IEEE-34 node system to simulate and verify the algorithm’s performance. However, simulation experiments need to be carried out in larger-scale systems to make the algorithm more mature and adapt to the operation mode of large-scale systems.

4.5.2. Genetic Tabu Algorithm Implementation Process

The flowchart of fault location using the genetic tabu algorithm is shown in

Figure 6.

The implementation process of the genetic tabu algorithm is as follows:

Read the original data such as network node parameters, protection action and equipment status information, and set the population size, and the crossover and mutation rate, and encode according to the designed rules;

Generate the initial population according to the greedy algorithm;

According to the fitness function, the fitness of individuals in the population is calculated, respectively. Check whether the genetic algorithm termination condition is met. If the condition is not met, go to Step 4; otherwise, go to Step 8;

The individuals are cross-calculated according to the crossover rate;

Calculate the mutation of individuals according to the mutation rate;

Natural selection is carried out to generate new populations;

Record N individuals with the highest fitness to the tabu table according to the contempt criterion, and go back to Step 3;

Stop the operation and output the positioning result.

4.5.3. Genetic Tabu Algorithm Parameter Selection

Analyze and select the six parameters involved in the GTA. The population size

G is the number of individuals the algorithm searches at once. The population size selects 1% of the total size of

H to balance the search range of the algorithm iteration and the total number of iterations,

G = 1%2

x. The population dimension

D is the gene length of each individual. The gene length of the individual is equal to the number of feeder sections. The crossover rate

P1 is the probability of individual crossover in one iteration process. According to the operation experience of the genetic algorithm, the crossover rate

P1 = 80% is selected. The mutation rate

P2 is the probability of individual variation during an iteration. Since the process of natural selection includes mutation calculation, this paper selects a lower mutation rate,

P2 = 5%.

N is the number of individuals recorded in the tabu table after each iteration, and the tabu length

L is the length of the tabu table. To balance the convergence speed and avoid a repeated search,

N is selected as 1% of the population size,

N = 1%G;

L is selected to be updated once in five iterations,

L = 5

N. The values of the above six parameters will be set according to the system model in

Section 5.

5. Simulation Analysis

Based on the PSCAD platform, this section builds an IEEE-34 node active distribution network model, as shown in

Figure 7. The system contains thirty-four switching nodes from

S1 to

S34 and thirty-two feeder sections from

L1 to

L32. Python software programs the fault region location algorithm, improved matrix algorithm and verification, and GTA. The performance of the proposed algorithms is tested by simulating single faults, multiple faults in non-T-connected sections, multiple faults with T-connected sections, and faults with fault information errors.

Considering factors such as power supply reliability, investment, management, and maintenance workload, the number of distribution line sections should not exceed three, which means that a maximum of two switches are installed between two pieces of protection equipment. Therefore, the protection installation position in the system is shown in

Figure 7. The system comprises 15 pieces of protection equipment, 32 feeder sections, and 34 switching nodes.

Table 5 shows the node number corresponding to each protection.

Table 6 shows the system node status list.

When the IEEE-34 node active distribution network has complex faults, such as multiple faults with fault information errors, the maximum number of suspicious fault sections is about 15, and the fault hypothesis contains about 30,000 cases. According to the parameter selection rules in

Section 4.5.3, the specific data of the parameters of the genetic tabu algorithm are set. The population size

G is set to 1% of the total size of the fault hypothesis,

G = 300. The population dimension

D is the number of feeder sections in the system shown in

Figure 7,

D = 32. The crossover rate

P1 = 80%, and the mutation rate

P2 = 5%.

N is selected as 1% of the population size,

N = 3. The tabu length

L is selected to be updated once in five iterations,

L = 15.

5.1. Test Case 1: Single Fault

A single fault is simulated in the active distribution network shown in

Figure 7, assuming that

L24 is faulty. The master station receives the protection

e12 action information, and the protection action region includes sections

L24 and

L28. The equipment status information is

I = [1 1 1 1 0 1 1 1 1 0 0 0 1 0 1 1 1 0 1 1 −1 1 0 1 −1 −1 −1 0 0 0 0 0 −1 −1]. Firstly, the suspicious fault region is located, and the boundary nodes are

S1,

S33, and

S34. Secondly, it is judged that the suspicious fault region does not contain the entire protection action region. Therefore, node

S28 farthest from the power supply in the protection action region is the boundary node. Finally, the fault region is obtained according to all boundary nodes, including 23 switching nodes and 21 feeder sections.

The schematic diagram of the fault region is shown in

Figure 8. The fault node status list is shown in

Table 7.

The matrix

I = [1 1 1 1 1 1 1 1 1 1 1 1 1 1 −1 1 1 −1 −1 −1 0 −1 −1]. According to

L =

ID, obtain the matrix

L = [0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 2 0 0 0 0].

l24 = 2 illustrates that this section is faulty. Where the T-connected section

l20 = 1, search for the other fault section, or this is judged as a non-fault section. The location result is

L24. Calculate the matrix I when the power S, DG1, and DG2 are supplied separately: IS* = [1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 1 1 0 0 0 0 0 0],

IDG1* = [0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 −1 −1 −1 0 −1 0],

IDG2* = [0 0 0 0 0 0 0 0 0 0 0 0 0 0 −1 1 1 0 0 0 0 0 −1]. The matrix

I* = [1 1 1 1 1 1 1 1 1 1 1 1 1 1 −1 1 1 −1 −1 −1 0 −1 −1]. Because

I* =

I, verify that the positioning result is correct. The results of multiple simulation experiments on single faults in

Table 8 show that the improved matrix algorithm can accurately locate single faults.

5.2. Test Case 2: Multiple Faults in Non-T-Connected Sections

The calculation process of multiple faults in non-T-connected sections by the improved matrix algorithm is similar to that in the previous section and will not be repeated here. Multiple simulation experiments are carried out for multiple faults location in non-T-connected sections. The results in

Table 9 show that the improved matrix algorithm can accurately locate multiple faults in non-T-connected sections.

5.3. Test Case 3: Multiple Faults with T-Connected Sections

Multiple faults with T-connected sections are simulated in the distribution network shown in

Figure 7, assuming that

L9,

L11, and

L28 are faulty. This involves attaining the protection

e4,

e5, and

e12 action information and the equipment status information

I = [1 1 1 1 0 1 1 1 1 1 1 0 −1 0 −1 −1 −1 0 −1 −1 −1 0 0 0 −1 −1 −1 1 0 0 0 0 −1 −1]. The boundary nodes are

S1,

S12,

S28,

S33, and

S34. The matrix

I = [1 1 1 1 1 1 1 1 1 1 0 −1 −1 −1 −1 −1 −1 −1 0 0 −1 −1 −1 1 −1 −1].

The improved matrix calculation is carried out to obtain the matrix

L = [0 0 0 0 0 0 0 1 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 1]. Non-T-connected sections

l11 = 1 and

l28 = 1 illustrate that the two sections are fault sections. For the T-connected section

l9 = 1, search for the other fault sections; otherwise, it is judged as a non-fault section. The fault section location result is

L11 and

L28.

I* = [1 1 1 1 1 1 1 1 1 1 0 −1 −1 −1 −1 −1 −1 −1 1 1 −1 −1 −1 1 −1 −1]. Because

I* ≠

I, the positioning result is wrong. The suspicious fault sections are:

L4,

L8,

L9,

L10,

L11,

L12,

L13,

L17,

L20,

L22,

L24, and

L28. According to the operation rules of the GTA, the optimization process is shown in

Figure 9.

According to the calculation, the fault sections are

L9,

L11, and

L28, and the fitness function value is 3. Multiple simulation experiments are carried out on multiple faults with T-connected sections. The results in

Table 10 show that GTA can accurately locate multiple faults with T-connected sections.

5.4. Test Case 4: Fault Information Error Condition

Multiple faults with fault information errors are simulated in the active distribution network shown in

Figure 7. Suppose that

L9 and

L18 are faulty, and the fault information

I4 is wrong to change from 1 to 0 and

I24 from −1 to 1. Attain the protection

e4 and

e8 action information. The boundary nodes are

S1,

S18,

S33, and

S34. The matrix

I = [1 1 1 0 1 1 1 1 −1 −1 −1 −1 1 −1 −1 −1 −1 1 −1 −1 −1 −1 −1]. Obtain the matrix

L = [0 0 1 −1 0 0 0 2 0 0 0 −1 1 0 1 0 −2 2 0 0 0].

l9 = 2,

l24 = 2, and non-T-connected sections

l3 = 1 and

l18 = 1 illustrate that the four sections are faulty; where T-connected section

l20 = 1, search for other fault sections, otherwise it is judged as a non-fault section. The fault location result is

L3,

L9,

L18, and

L24. The matrix

I* = [1 1 1 −1 −1 −1 −1 −1 −1 −1 −1 −1 1 −1 −1 0 1 1 0 0 0 −1 −1]. Because

I* ≠

I, the positioning result is wrong. The suspicious fault sections are

L3,

L8,

L9,

L13,

L18,

L20, and

L24.

The optimization process is shown in

Figure 10. According to the calculation, the fault sections are

L9 and

L18, the fitness function value is 4, and the error fault information values

I4 and

I24 are detected. Multiple simulation experiments are carried out on faults with fault information errors. The results in

Table 11 show that the GTA has high tolerance performance.

In summary, the proposed algorithm can accurately locate various fault conditions. The algorithm proposed in this paper fully combines the advantages of the fast calculation speed of the improved matrix algorithm and the high tolerance performance of the GTA. The improved matrix algorithm is used to reduce the dimension of the optimization of the GTA, and the GTA is used to solve the problem that the improved matrix algorithm cannot accurately locate multiple faults with T-connected sections and faults with fault information errors. The simulation results show that the positioning algorithm can correctly locate the fault section in complex fault conditions with higher accuracy and solve the problem of fault information errors with better tolerance performance. The accuracy, tolerance performance, and rapidity of the location algorithm will be further verified by a large number of comparative experiments in the next section.

5.5. Algorithm Comparison

The four algorithms of the immune algorithm (IA), improved quantum genetic algorithm (IQGA), improved genetic algorithm (IGA), and GTA are compared and analyzed from four aspects: algorithm complexity, average positioning accuracy, average convergence algebra, and average execution time, to test the performance of the GTA.

The calculation complexity of the four algorithms is analyzed. Since this paper uses the fault region location and the improved matrix algorithm to perform two dimensionality-reduction operations, the fault hypothesis contains up to 215 cases or about thirty-thousand cases when performing the GTA. When assuming IA, IQGA, and IGA, calculations are performed in the smallest range of fault regions, and the fault hypothesis contains at least 222 or about four million cases. Moreover, the computational gap between the algorithms increases exponentially with the expansion of the active distribution network model. Therefore, from the perspective of calculation, the GTA is the simplest.

The conditions of single faults, multiple faults, and faults with fault information errors are simulated. The results of the algorithms are shown in

Table 12,

Table 13 and

Table 14.

The average positioning accuracy of the GTA is the highest, and it can still be maintained above 94% in the most complex fault conditions. Under the cooperation of the GA and the TA, the GTA has a fast convergence speed and strong search ability. The GTA can iterate to the optimal value within 20 generations, and the average execution time is kept within 2 s. IQGA converges to the optimal solution of about 25 generations in the case of simple faults and about 35 generations in the case of complex faults, and the convergence speed is significantly slower. IQGA has good accuracy and execution time.

Since the antibody and antigen in IA are encoded as binary codes, the intimacy calculation between each qubit in each population generation should be realized, which seriously affects the convergence speed. The simulation results show that the IA has slow convergence speed, low positioning accuracy, and long execution time. The iterative results of IGA are random, the iterative process is unstable, and it may not converge to the optimal value correctly. The positioning accuracy is the lowest, and the convergence speed is slow. In summary, compared with other algorithms, the GTA has simpler calculation, higher location accuracy, faster convergence speed, and shorter execution time, which is more suitable for fault section location of active distribution networks.

6. Conclusions

A fault section location algorithm combining the improved matrix algorithm and the GTA is proposed. The algorithm uses protection action and equipment status information, and can locate fault sections more efficiently. Firstly, considering the frequent changes in the topology of the active distribution network, a method for constructing the node status list is proposed. According to the idea of depth-first traversal in the tree search method, a topology search method for suspicious fault regions is proposed. The fault regions are obtained by combining the protection action regions to ensure they contain all possible fault sections. This algorithm can streamline the fault system and reduce the matrix calculation dimension.

Secondly, an improved matrix algorithm is proposed to adapt to the access of DG, which is computed in a non-square matrix form. It can accurately locate single faults and multiple faults in non-T-connected sections. However, due to the limitations of the matrix calculation, the algorithm cannot accurately determine whether the T-connected sections of li = 1 and li = 0 are faulty in multiple faults. Therefore, based on the traditional matrix algorithm and superposition principle, this section proposes a verification method to improve tolerance performance. The GTA locates the fault sections when the verification is incorrect. Taking advantage of the fast calculation speed of the matrix can reduce the dimension of GTA optimization.

Thirdly, the GTA is proposed to solve the problems that the improved matrix algorithm cannot accurately locate the multiple faults with T-connected sections and faults with fault information errors. A fault hypothesis based on equipment status and protection action information is proposed; a fitness function is constructed to reflect the difference between the actual and expected status of the fault information; the calculation equation of the expected status of the fault information is derived; the genetic coding rules, natural selection rules, greedy algorithm, and parameter selection are introduced. The GTA is used to find the fault hypothesis that reasonably explains received fault information, and the fault section location results are obtained. By comparing the optimization results with the fault information obtained by monitoring, error fault information can be obtained, which is convenient for the staff to maintain.

Finally, the proposed algorithm is simulated in various fault conditions in the IEEE-34 node active distribution network. According to the experimental results, the proposed algorithm can accurately locate single faults, multiple faults, and faults with fault information errors. According to the comparative simulation results of the proposed algorithm and the other three intelligent optimization algorithms, the proposed algorithm has the highest average positioning accuracy, faster convergence speed, shorter execution time, and simpler calculation, which is more suitable for fault section location of active distribution networks. The next step will focus on determining the specific branch of the T-connected section fault and the accurate fault location.

Author Contributions

Conceptualization, Y.S. and Q.C.; data curation, Y.S. and D.X.; formal analysis, Y.S., Q.C. and N.S.; funding acquisition, Q.C.; methodology, Y.S., Q.C. and D.X.; project administration, Q.C.; software, Y.S.; validation, Y.S. and Q.C.; visualization, Y.S. and W.D.; writing original draft, Y.S.; writing review and editing, Y.S., Q.C. and Y.D. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (No. 51877123).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in the article.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Nomenclature

| DG | Distributed Generation |

| FTU | Feeder Terminal Unit |

| IoT | Internet of Things |

| UAV | Unmanned Aerial Vehicle |

| GTA | Genetic Tabu Algorithm |

| GA | Genetic Algorithm |

| TS | Tabu Search |

| IA | Immune Algorithm |

| IQGA | Improved Quantum Genetic Algorithm |

| IGA | Improved Genetic Algorithm |

References

- Li, K.; Zhao, L.; Li, J. Dynamic fault recovery method of a photovoltaic distribution network considering switch state set adjustment. Power Syst. Prot. Control 2021, 49, 24–31. [Google Scholar]

- Ren, G.; Zha, X.; Jiang, B.; Hu, X.; Xu, J.; Tao, K. Location of Multiple Types of Faults in Active Distribution Networks Considering Synchronization of Power Supply Area Data. Appl. Sci. 2022, 12, 10024. [Google Scholar] [CrossRef]

- Chen, S.; Jing, W.; Shi, M. Review of harmonic source modeling methods with the background of renewable energy access. Power Syst. Prot. Control 2022, 50, 162–175. [Google Scholar]

- Jing, L.; Son, D.; Kang, S.; Nam, S. A Novel Protection Method for Single Line-to-Ground Faults in Ungrounded Low-Inertia Microgrids. Energies 2016, 9, 459. [Google Scholar] [CrossRef] [Green Version]

- Cheng, M.; Zhang, X.; Xu, M. Location method of an active distribution network fault section based on multi-target weighted grey target decision. Power Syst. Prot. Control 2021, 49, 124–132. [Google Scholar]

- Li, G.; Chen, Q.; Zhang, J. Novel Faulted Section Location Method for Distribution Network Based on Status Information of Fault Indicating Equipment. Appl. Sci. 2020, 10, 5910. [Google Scholar] [CrossRef]

- Zheng, C.; Zhou, H.; Zheng, D. An active distribution network fault location method based on improved multi-universe algorithm. Power Syst. Prot. Control 2023, 51, 169–179. [Google Scholar]

- Xu, Y.; Zhang, H.; Ma, T. Coordinated optimization strategy of fault emergency recovery and repair for distribution network with distributed generators. Autom. Electr. Power Syst. 2021, 45, 38–46. [Google Scholar]

- Xia, F.; Zhang, Q.; Wang, Q.; Wang, C. Reactive power optimization based on random matrix theory and improved particle swarm optimization-deep belief networks. Sci. Technol. Eng. 2021, 21, 14165–14172. [Google Scholar]

- Lin, W.; Huang, W.; Yao, K.; Chen, H.; Ma, C. Fault Location and Restoration of Microgrids via Particle Swarm Optimization. Appl. Sci. 2021, 11, 7036. [Google Scholar] [CrossRef]

- Li, W.; Tong, X.; Huang, C. A fault location method for a distribution network with DG based on a hierarchical location model. Power Syst. Prot. Control 2022, 50, 160–166. [Google Scholar]

- Tang, J.; Wang, Z.; Zhang, J.; Cao, H. High reliability multi-power distribution network planning model based on memetic ant colony algorithm. Power Syst. Prot. Control 2020, 48, 99–107. [Google Scholar]

- Mei, F.; Chen, Z.; Pei, X. Fault-tolerant method for fault location of active distribution network based on matrix algorithm. Electr. Power Eng. Technol. 2022, 41, 109–115. [Google Scholar]

- Lu, Y.; Wang, J.; Jiao, Q. An improved matrix algorithm for fault location of distribution networks with distributed generation. Sci. Technol. Eng. 2019, 19, 186–190. [Google Scholar]

- Xu, B.; Yin, X.; Zhang, Z. Fault location for distribution network based on matrix algorithm and optimization algorithm. Autom. Electr. Power Syst. 2019, 43, 152–158. [Google Scholar]

- Zeng, H.; Yang, C. Fault location matrix algorithm for distribution network based on voltage amplitude correction. Electr. Power Sci. Eng. 2020, 36, 41–46. [Google Scholar]

- Yang, G.; Feng, J.; Liu, X. Fault location of a distribution network hierarchical model with a distribution generator based on IBES. Power Syst. Prot. Control 2022, 50, 1–9. [Google Scholar]

- Chen, K.; Zhang, Y.; Wang, H. Fault-section location of distribution network containing distributed generation based on immune algorithm. Power Syst. Prot. Control 2017, 45, 57–62. [Google Scholar]

- Xie, T.; Kuai, S.; Zhu, X. Fault location method for distribution network based on improved genetic algorithm. J. Shenyang Univ. Technol. 2019, 41, 126–131. [Google Scholar]

- Jiang, C.; Wang, C. Fault location method for distribution internet of things using particle swarm optimization. In Proceedings of the IEEE International Conference on Advances in Electrical Engineering and Computer Applications (AEECA 2022), Dalian, China, 20–21 August 2022; pp. 706–708. [Google Scholar]

Figure 1.

A typical radial active distribution network.

Figure 1.

A typical radial active distribution network.

Figure 2.

Flow chart of the suspicious fault region location algorithm.

Figure 2.

Flow chart of the suspicious fault region location algorithm.

Figure 3.

The flow chart of the verification.

Figure 3.

The flow chart of the verification.

Figure 4.

Two kinds of li = 1 T-connected section fault schematic diagram. (i) Multiple faults with the T-connected section; (ii) Single fault.

Figure 4.

Two kinds of li = 1 T-connected section fault schematic diagram. (i) Multiple faults with the T-connected section; (ii) Single fault.

Figure 5.

Two kinds of li = 0 T-connected section fault schematic diagram. (i) Multiple faults with the T-connected section; (ii) Single fault.

Figure 5.

Two kinds of li = 0 T-connected section fault schematic diagram. (i) Multiple faults with the T-connected section; (ii) Single fault.

Figure 6.

Fault location flow chart of the genetic tabu algorithm.

Figure 6.

Fault location flow chart of the genetic tabu algorithm.

Figure 7.

Topology diagram of the IEEE-34 node active distribution network.

Figure 7.

Topology diagram of the IEEE-34 node active distribution network.

Figure 8.

Fault region diagram of a single fault in the IEEE-34 node active distribution network.

Figure 8.

Fault region diagram of a single fault in the IEEE-34 node active distribution network.

Figure 9.

The optimization process of multiple faults with T-connected sections.

Figure 9.

The optimization process of multiple faults with T-connected sections.

Figure 10.

The optimization process of multiple faults with fault information errors.

Figure 10.

The optimization process of multiple faults with fault information errors.

Table 1.

List of the numbering results.

Table 1.

List of the numbering results.

| Node Number | Equipment | Node Number | Equipment |

|---|

| 1 | FTU1 | 5 | FTU5 |

| 2 | FTU2 | 6 | FTU6 |

| 3 | FTU3 | 7 | DG1 |

| 4 | FTU4 | 8 | DG2 |

Table 2.

Node status list.

Table 2.

Node status list.

| Node | Upstream Node | Downstream Node | Equipment Status | DG | Node | Upstream Node | Downstream Node | Equipment Status | DG |

|---|

| 1 | 0 | 2 | 0 | 0 | 5 | 4 | 0 | 0 | 0 |

| 2 | 1 | 3, 4 | 0 | 0 | 6 | 4 | 7 | 0 | 0 |

| 3 | 2 | 8 | 0 | 0 | 7 | 6 | 0 | 0 | 1 |

| 4 | 2 | 5, 6 | 0 | 0 | 8 | 3 | 0 | 0 | 1 |

Table 3.

Equipment status information error situation.

Table 3.

Equipment status information error situation.

| Equipment Status Information | Error Factor Ai,1 | Error Factor Ai,2 | Upload Information |

|---|

| 1 | 0 | 1 | 0 |

| 1 | 0 | −1 |

| 0 | 0 | 1 | 1 |

| 1 | 0 | −1 |

| −1 | 0 | 1 | 0 |

| 1 | 0 | 1 |

Table 4.

Expected protection action status.

Table 4.

Expected protection action status.

| oi | ri | ei′(H) | Explanation |

|---|

| 1 | 0 | 0 | 1 | Protection should act and receive protection action information |

| 1 | 0 | 1 | 0 | Protection should act, but due to the rejection of the protection, we will not receive protection action information |

| 0 | 0 | 0 | 0 | Protection should not act and will not receive protection action information |

| 0 | 1 | 0 | 1 | Protection should not act, but due to the misoperation of the protection, we will receive protection action information |

Table 5.

Node number corresponding to the protection.

Table 5.

Node number corresponding to the protection.

| Protection | Corresponding

Node Number | Protection | Corresponding

Node Number |

|---|

| e1 | 1 | e9 | 19 |

| e2 | 4 | e10 | 21 |

| e3 | 5 | e11 | 22 |

| e4 | 8 | e12 | 24 |

| e5 | 10 | e13 | 25 |

| e6 | 14 | e14 | 29 |

| e7 | 15 | e15 | 30 |

| e8 | 18 | | |

Table 6.

The IEEE-34 node active distribution network node status list.

Table 6.

The IEEE-34 node active distribution network node status list.

| Node | Upstream Node | Downstream Node | Equipment Status | DG | Node | Upstream Node | Downstream Node | Equipment Status | DG |

|---|

| 1 | 0 | 2 | 0 | 0 | 18 | 17 | 0 | 0 | 0 |

| 2 | 1 | 3 | 0 | 0 | 19 | 17 | 20 | 0 | 0 |

| 3 | 2 | 4 | 0 | 0 | 20 | 19 | 21, 22 | 0 | 0 |

| 4 | 3 | 5, 6 | 0 | 0 | 21 | 20 | 34 | 0 | 0 |

| 5 | 4 | 0 | 0 | 0 | 22 | 20 | 23, 24 | 0 | 0 |

| 6 | 4 | 7 | 0 | 0 | 23 | 22 | 0 | 0 | 0 |

| 7 | 6 | 8 | 0 | 0 | 24 | 22 | 25, 28 | 0 | 0 |

| 8 | 7 | 9 | 0 | 0 | 25 | 24 | 26 | 0 | 0 |

| 9 | 8 | 10, 13 | 0 | 0 | 26 | 25 | 27 | 0 | 0 |

| 10 | 9 | 11 | 0 | 0 | 27 | 26 | 33 | 0 | 0 |

| 11 | 10 | 12 | 0 | 0 | 28 | 24 | 29 | 0 | 0 |

| 12 | 11 | 0 | 0 | 0 | 29 | 28 | 30, 32 | 0 | 0 |

| 13 | 9 | 14, 15 | 0 | 0 | 30 | 29 | 31 | 0 | 0 |

| 14 | 13 | 0 | 0 | 0 | 31 | 30 | 0 | 0 | 0 |

| 15 | 13 | 16 | 0 | 0 | 32 | 29 | 0 | 0 | 0 |

| 16 | 15 | 17 | 0 | 0 | 33 | 27 | 0 | 0 | 1 |

| 17 | 16 | 18, 19 | 0 | 0 | 34 | 21 | 0 | 0 | 1 |

Table 7.

Fault node status list of a single fault in the IEEE-34 node active distribution network.

Table 7.

Fault node status list of a single fault in the IEEE-34 node active distribution network.

| Node | Upstream Node | Downstream Node | Equipment Status | DG | Node | Upstream Node | Downstream Node | Equipment Status | DG |

|---|

| 1 | 0 | 2 | 1 | 0 | 19 | 17 | 20 | 1 | 0 |

| 2 | 1 | 3 | 1 | 0 | 20 | 19 | 21, 22 | 1 | 0 |

| 3 | 2 | 4 | 1 | 0 | 21 | 20 | 34 | −1 | 0 |

| 4 | 3 | 6 | 1 | 0 | 22 | 20 | 24 | 1 | 0 |

| 6 | 4 | 7 | 1 | 0 | 24 | 22 | 25, 28 | 1 | 0 |

| 7 | 6 | 8 | 1 | 0 | 25 | 24 | 26 | −1 | 0 |

| 8 | 7 | 9 | 1 | 0 | 26 | 25 | 27 | −1 | 0 |

| 9 | 8 | 13 | 1 | 0 | 27 | 26 | 33 | −1 | 0 |

| 13 | 9 | 15 | 1 | 0 | 28 | 27 | 0 | 0 | 0 |

| 15 | 13 | 16 | 1 | 0 | 33 | 27 | 0 | −1 | 1 |

| 16 | 15 | 17 | 1 | 0 | 34 | 21 | 0 | −1 | 1 |

| 17 | 16 | 19 | 1 | 0 | | | | | |

Table 8.

The results of single fault simulation experiments.

Table 8.

The results of single fault simulation experiments.

| Fault Section | Boundary Nodes | Location Result | Correct or Not |

|---|

| L8 | S1, S33, S34 | L8 | correct |

| L19 | S1, S33, S34 | L19 | correct |

| L11 | S1, S12, S33, S34 | L11 | correct |

| L26 | S1, S33, S34 | L26 | correct |

| L32 | S1, S32, S33, S34 | L32 | correct |

Table 9.

The results of multiple faults in non-T-connected section simulation experiments.

Table 9.

The results of multiple faults in non-T-connected section simulation experiments.

| Fault Sections | Boundary Nodes | Location Result | Correct or Not |

|---|

| L8, L28 | S1, S28, S33, S34 | L8, L28 | correct |

| L14, L19 | S1, S14, S33, S34 | L14, L19 | correct |

| L6, L11, L30 | S1, S12, S31, S33, S34 | L6, L11, L30 | correct |

| L5, L15, L26 | S1, S5, S33, S34 | L5, L15, L26 | correct |

| L7, L16, L25, L32 | S1, S32, S33, S34 | L7, L16, L25, L32 | correct |

Table 10.

The results of multiple faults with T-connected section simulation experiments.

Table 10.

The results of multiple faults with T-connected section simulation experiments.

| Fault Sections | Improved Matrix

Calculation | Verification

Result | Suspicious Fault Sections | Genetic Tabu Algorithm | Correct or Not |

|---|

| L4, L6 | L6 | unsuccess | L4, L6, L7, L9, L13, L15, L16, L17, L20, L22, L24 | L4, L6 | correct |

| L9, L30 | L9, L30 | success | —— | —— | correct |

| L8, L17, L26 | L8, L26 | unsuccess | L4, L8, L9, L13, L15, L16, L17, L22, L24, L25, L26, L27 | L8, L17, L26 | correct |

| L13, L18, L28 | L13, L18, L28 | success | —— | —— | correct |

| L13, L14, L22, L29 | L14, L22, L29 | unsuccess | L4, L8, L9, L13, L14, L17, L22, L23, L29, L32 | L13, L14, L22, L29 | correct |

| L5, L18, L20, L24 | L5, L18, L20 | unsuccess | L5, L9, L13, L18, L19, L20, L22, L24, L28 | L5, L18, L20, L24 | correct |

Table 11.

Multiple faults with fault information error simulation experiments.

Table 11.

Multiple faults with fault information error simulation experiments.

| Fault Sections | Error Fault Information | Suspicious Fault Sections | Genetic Tabu Algorithm | Fitness Function | Correct or Not |

|---|

| L8 | I16: −1→1 | L4, L8, L9, L13, L16, L17, L20, L22, L24 | L8 | 2 | correct |

| L20 | e4: 0→1 | L4, L8, L9, L13, L17, L20, L22, L24 | L20 | 2 | correct |

| L10, L16 | I4: 1→0, I24: −1→0 | L3, L10, L11, L12, L13, L15, L16, L17, L20, L24 | L10, L16 | 4 | correct |

| L17, L28 | e7: 1→0, I8: 1→−1

I18: 0→1 | L4, L7, L9, L13, L17, L18, L20, L22, L24, L28 | L17, L28 | 5 | correct |

| L3, L14, L24 | I8: −1→1, I17: −1→1

I22: 1→0 | L1, L2, L3, L4, L8, L9, L14, L17, L20, L24, L28 | L3, L14, L24 | 6 | correct |

| L9, L18, L30 | I11: 0→1, I18: 1→0

e15: 1→0 | L4, L8, L9, L11, L13, L17, L18, L20, L24, L29, L30, L31 | L9, L18, L30 | 6 | correct |

Table 12.

Comparison of results of algorithms for single fault location.

Table 12.

Comparison of results of algorithms for single fault location.

| Algorithm | Computational Complexity | Average Convergence

Algebra | Average Positioning

Accuracy/% | Average Execution

Time/s |

|---|

| IA | 222 | 74 | 70.3 | 3.747 |

| IQGA | 222 | 28 | 93.5 | 2.485 |

| IGA | 222 | 42 | 56.5 | 2.953 |

| GTA | 215 | 20 | 99.1 | 1.666 |

Table 13.

Comparison of results of algorithms for multiple fault location.

Table 13.

Comparison of results of algorithms for multiple fault location.

| Algorithm | Computational Complexity | Average Convergence

Algebra | Average Positioning

Accuracy/% | Average Execution

Time/s |

|---|

| IA | 222 | 79 | 68.2 | 3.809 |

| IQGA | 222 | 33 | 91.8 | 2.358 |

| IGA | 222 | 43 | 55.7 | 2.986 |

| GTA | 215 | 20 | 96.3 | 1.689 |

Table 14.

Comparison of results of algorithms for faults with fault information error location.

Table 14.

Comparison of results of algorithms for faults with fault information error location.

| Algorithm | Computational Complexity | Average Convergence

Algebra | Average Positioning

Accuracy/% | Average Execution

Time/s |

|---|

| IA | 222 | 87 | 68.1 | 3.822 |

| IQGA | 222 | 25 | 90.3 | 2.668 |

| IGA | 222 | 58 | 53.3 | 3.102 |

| GTA | 215 | 20 | 94.2 | 1.783 |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).