Research on the Operational Performance of Organic Rankine Cycle System for Waste Heat Recovery from Large Ship Main Engine

Abstract

:1. Introduction

2. Materials and Methods

2.1. Main Engine Parameters

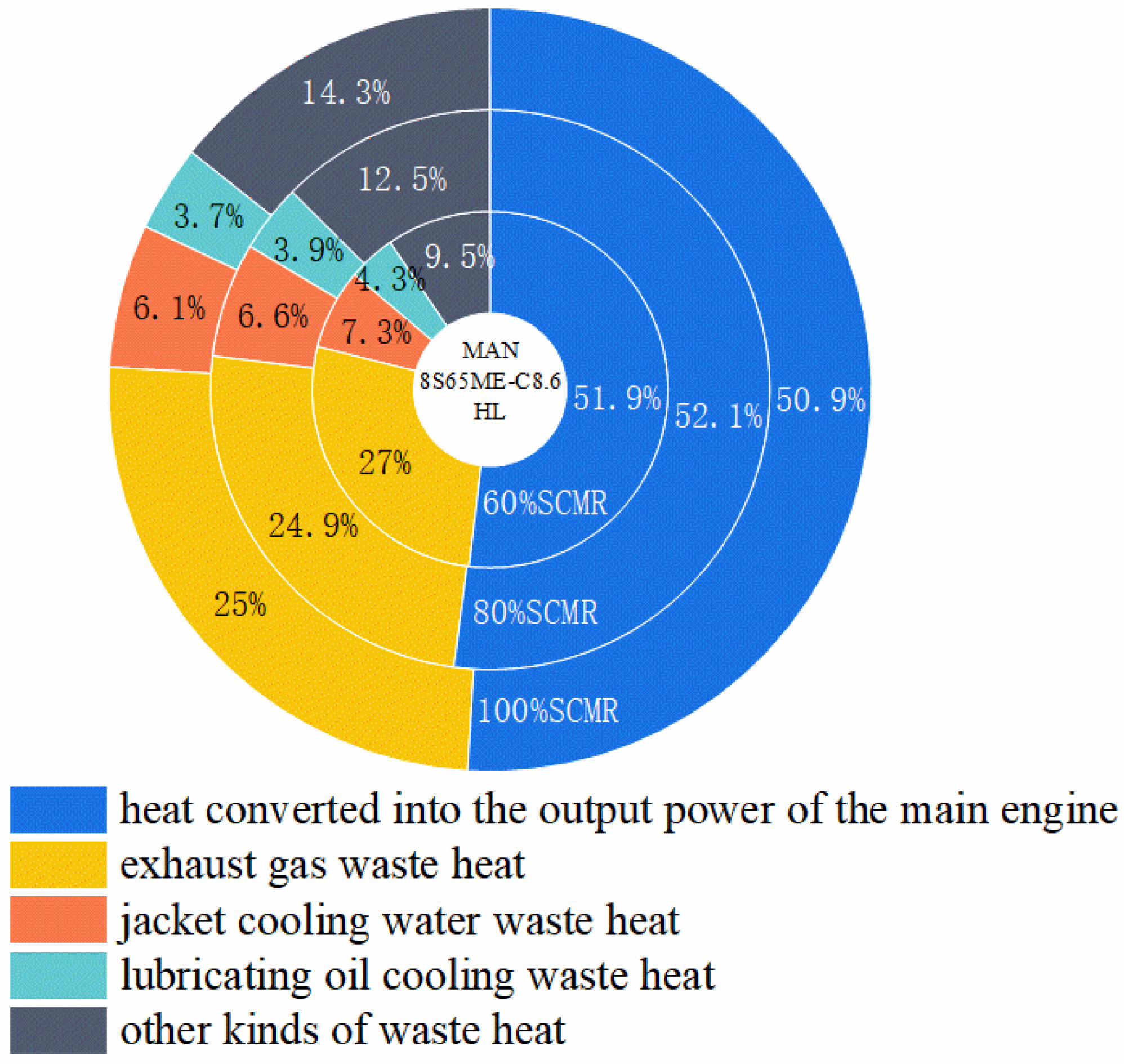

2.2. Distribution of Main Engine Waste Heat

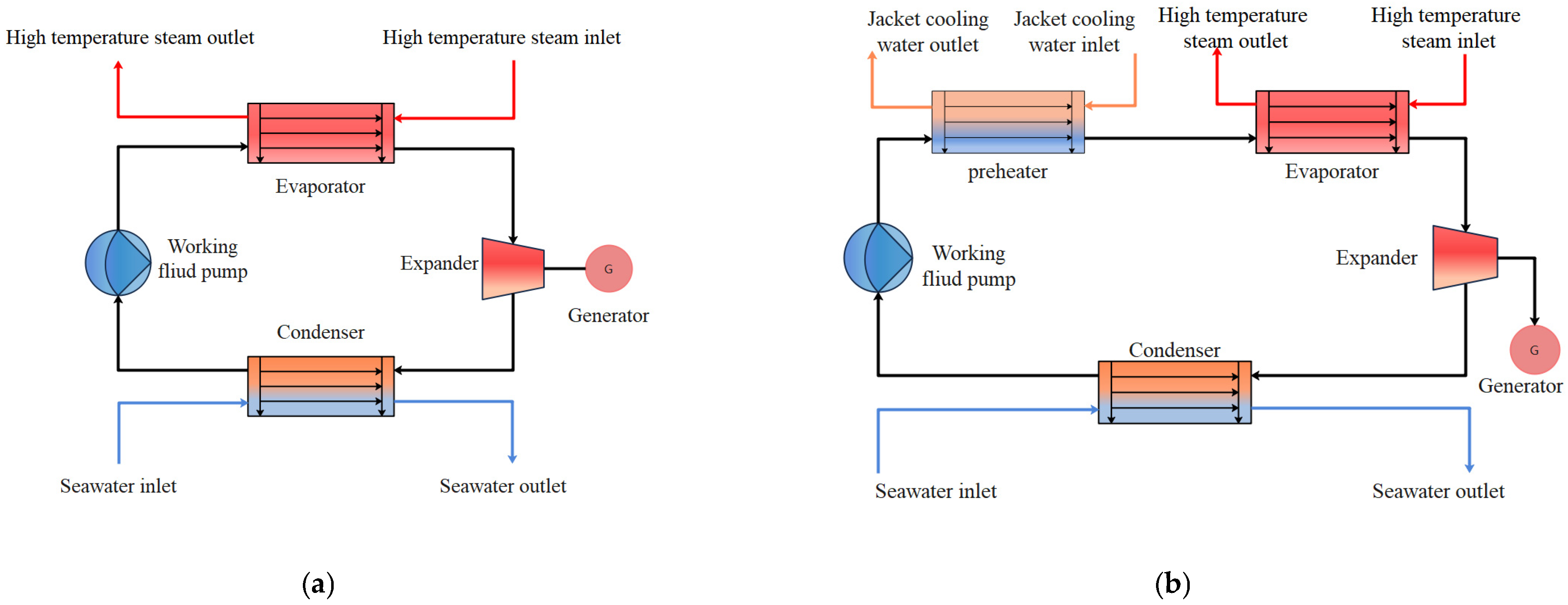

3. ORC System Structure and Design Parameters

4. Evaluation Index of ORC System

5. Discussion

5.1. Influence of Seawater Temperature on System Performance

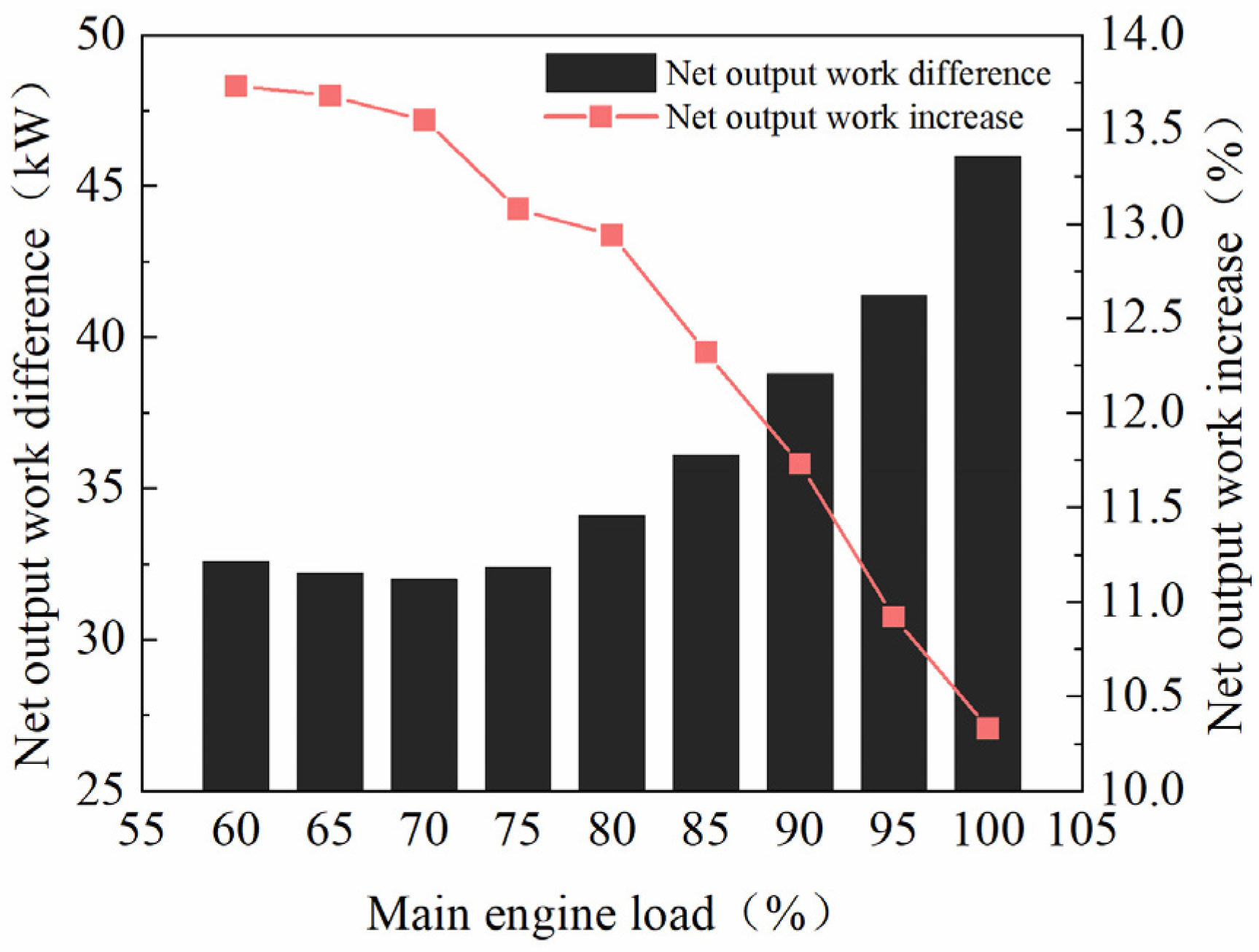

5.2. Influence of Main Engine Load on System Performance

5.3. Analysis of Carbon Emission Reduction and Payback Period

6. Conclusions

- (1)

- The net output power of the PORC system is always higher than that of the BORC system under different outboard sea temperatures. When the seawater temperature is 20 °C, the BORC and PORC systems can obtain the highest net output power of 445.3 kW and 491.3 kW, respectively. Due to the addition of the preheater, in comparison to the BORC system, the inclusion of a preheater leads to a 10.3% enhancement in the net output power of the PORC system. However, when the seawater increases in temperature from 20 °C to 30 °C, the net output power produced by the BORC and PORC systems drops to 405.5 kW and 426 kW, respectively, and the PORC system’s net output power ratio falls to 5%. Compared to the BORC system, the net output power of the PORC system experiences a substantial increase when the outboard seawater temperature is lower. Therefore, when the ship mainly operates in the sea area where the sea temperature is low, the PORC system should be preferred to recover unused energy from the main engine.

- (2)

- Under various load circumstances encountered in navigation, the PORC system’s net output power is always greater than the BORC system. As the main engine load rises from 60% to 100%, the net output power of the BORC system escalates from 237.4 kW to 445.6 kW, while the net output power of the PORC system surges from 270 kW to 491.3 kW. The net output power of the PORC system exhibits a more pronounced increase compared to the BORC system as the main engine load rises. Therefore, when the ship mainly operates under high load conditions (80% SMCR or above), the advantage of using the PORC system to recover unused energy from the main engine is more evident by adding a preheater in the ORC system.

- (3)

- If we adopt the CO2 emission ratio of 3.1t-CO2/t-fuel for the heavy oil burned by this main engine, the PORC system studied in this paper can save a large amount of fuel consumption during the ship’s voyage. According to the data calculated in this paper, taking MAN 8S65ME-C8.6HL main engine as an example, it can save 510 tons of fuel oil per year and reduce transportation costs by $230,265 per year, and the payback period for PORC systems is about 4.86 years. PORC system can reduce carbon emission by 1581 tons per year, which is of great significance to realize energy saving and emission reduction plans for ships.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ng, C.; Tam, I.; Wu, D. System modelling of organic Rankine cycle for waste energy recovery system in marine applications. Energy Procedia 2019, 158, 1955–1961. [Google Scholar] [CrossRef]

- Singh, D.V.; Pedersen, E. A review of waste heat recovery technologies for maritime applications. Energy Convers. Manag. 2016, 111, 315–328. [Google Scholar] [CrossRef]

- Mathijsse, T.; Trapp, C. Organic Rankine Cycle power systems: From the concept to current technology, applications and an outlook to the future. J. Eng. Gas Turbines Power 2015, 137, 100801. [Google Scholar]

- Francesco, B.; Cecilia, G. A feasibility analysis of waste heat recovery systems for marine applications. Energy 2015, 80, 654–665. [Google Scholar]

- Shu, G.Q.; Liu, P.; Tian, H.; Wang, X.; Jing, D. Operational profile based thermal-economic analysis on an Organic Rankine cycle using for harvesting marine engine’s exhaust waste heat. Energy Convers. Manag. 2017, 146, 107–123. [Google Scholar] [CrossRef]

- Girgin, I.; Ezgi, C. Design and thermodynamic and thermoeconomic analysis of an organic Rankine cycle for naval surface ship applications. Energy Convers. Manag. 2017, 148, 623–634. [Google Scholar] [CrossRef]

- Diao, A.N.; Yang, X.Q.; Feng, M.Z.; Peng, X.Y. Thermodynamic analysis of organic Rankine cycle for marine diesel engine exhaust energy recovery. Chin. Intern. Combust. Engine Eng. 2018, 39, 47–53. [Google Scholar]

- Yang, F.B.; Zhang, H.G.; Song, S.S.; Bei, C.; Wang, H.; Wang, E. Thermoeconomic multi-objective optimization of an organic Rankine cycle for exhaust waste heat recovery of a diesel engine. Energy 2015, 93, 2208–2228. [Google Scholar] [CrossRef]

- Han, F.H.; Wang, Z.; Ji, Y.L.; Li, W.; Sundén, B. Energy analysis and multi-objective optimization of waste heat and cold energy recovery process in LNG-fueled vessels based on a triple organic Rankine cycle. Energy Convers. Manag. 2019, 195, 561–572. [Google Scholar] [CrossRef]

- Liu, X.Y.; Nguyen, M.Q.; Chu, J.C.; Lan, T.; He, M. A novel waste heat recovery system combing steam Rankine cycle and organic Rankine cycle for marine engine. J. Clean. Prod. 2020, 265, 121502. [Google Scholar] [CrossRef]

- Ma, J.C.; Liu, L.C.; Zhu, T.; Zhang, T. Cascade utilization of exhaust gas and jacket water waste heat from an Internal Combustion Engine by a single loop Organic Rankine Cycle system. Appl. Therm. Eng. 2016, 107, 218–226. [Google Scholar] [CrossRef]

- Akman, M.; Ergin, S. An investigation of marine waste heat recovery system based on organic Rankine cycle under various engine operating conditions. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2019, 233, 586–601. [Google Scholar] [CrossRef]

- Song, J.; Song, Y.; Gu, C. Thermodynamic analysis and performance optimization of an Organic Rankine Cycle (ORC) waste heat recovery system for marine diesel engines. Energy 2015, 82, 976–985. [Google Scholar] [CrossRef]

- Soffiat, M.; Frangopoulos, C.A.; Manente, G.; Rech, S.; Lazzaretto, A. Design optimization of ORC systems for waste heat recovery on board a LNG carrier. Energy Convers. Manag. 2015, 92, 523–534. [Google Scholar] [CrossRef]

- Grljusic, M.; Medicav, R.; Radica, G. Calculation of efficiencies of a ship power plant operating with waste heat recovery through combined heat and power production. Energies 2015, 8, 4273–4299. [Google Scholar] [CrossRef] [Green Version]

- Sung, T.; Kim, K.C. Thermodynamic analysis of a novel dual-loop organic Rankine cycle for engine waste heat and LNG cold. Appl. Therm. Eng. 2016, 100, 1031–1041. [Google Scholar] [CrossRef]

- Luo, W.H.; Chen, W.; Jiang, A.G.; Tian, Z. Comparative analysis of thermodynamics performances of ORC systems recovering waste heat from ship diesel engines. China Mech. Eng. 2022, 33, 452–458. [Google Scholar]

- CEAS Engine Calculations. Available online: https://www.man-es.com/marine/products/planning-tools-and-downloads/ceas-engine-calculations (accessed on 1 June 2023).

- Peng, B.; Liu, S.; Liu, H.X.; Zhou, T.H. Influence of different working fluids on performance of organic Rankine cycle low temperature waste heat power generation system. Therm. Power Gener. 2022, 51, 43–48. [Google Scholar]

- Chen, J. Calculation method and evaluation result analysis of existing ship energy efficiency index. Shipp. Manag. 2021, 43, 15–19. [Google Scholar]

- IMO. Resolution MEPC.245(66), Guidelines on the Method of Calculation of the Attained Energy Efficiency Design Index (EEDI) for New Ships; IMO: London, UK, 2014. [Google Scholar]

- Tian, Z.; Zeng, W.; Gu, B.; Zhang, Y.; Yuan, X. Energy, exergy, and economic (3E) analysis of an organic Rankine cycle using zeotropic mixtures based on marine engine waste heat and LNG cold energy. Energy Convers. Manag. 2021, 228, 113657. [Google Scholar] [CrossRef]

- Chemical Engineering. Available online: https://www.chemengonline.com/cepci (accessed on 4 July 2023).

- Shipping News and Bunker Price Indications. Available online: https://shipandbunker.com (accessed on 4 July 2023).

| Main Engine Load (%SMCR) | Exhaust Gas Flow (kg/s) | Exhaust Gas Temperture (°C) | Power (kW) | Fuel Consumption Rate (g/kWh) | High-Temperature Steam Flow (kg/h) |

|---|---|---|---|---|---|

| 60 | 33.8 | 219 | 13,104 | 162.5 | 2050 |

| 65 | 36.1 | 216 | 14,196 | 161.8 | 2020 |

| 70 | 38.2 | 214 | 15,288 | 161.5 | 2050 |

| 75 | 40.3 | 214 | 16,380 | 161.6 | 2120 |

| 80 | 42.2 | 215 | 17,472 | 161.9 | 2250 |

| 85 | 44.1 | 218 | 18,564 | 162.5 | 2450 |

| 90 | 45.9 | 222 | 19,656 | 163.3 | 2730 |

| 95 | 47.6 | 227 | 20,748 | 164.3 | 3090 |

| 100 | 49.3 | 234 | 21,840 | 165.5 | 3520 |

| Main Engine Load (%SMCR) | Exhaust Gas Waste Heat kW (Calculation) | Jacket Water Waste Heat kW (Query) | Lubricating Oil Waste Heat kW (Query) | Other Kinds of Waste Heat kW (Calculation) | High-Temperature Steam Heat kW (Calculation) |

|---|---|---|---|---|---|

| 60 | 6820 | 1840 | 1090 | 2403 | 6138 |

| 65 | 7171 | 1930 | 1150 | 2798 | 6454 |

| 70 | 7509 | 2030 | 1200 | 3258 | 6758 |

| 75 | 7921 | 2130 | 1260 | 3706 | 7129 |

| 80 | 8839 | 2220 | 1320 | 4201 | 7955 |

| 85 | 8852 | 2320 | 1380 | 4665 | 7967 |

| 90 | 9404 | 2420 | 1440 | 5152 | 8464 |

| 95 | 10,000 | 2510 | 1500 | 5675 | 9000 |

| 100 | 10,716 | 2610 | 1570 | 6136 | 9644 |

| ORC Design Parameters | Value |

|---|---|

| Isentropic efficiency of working medium pump (ηpump/%) | 80 |

| Isentropic efficiency of expander (ηexp/%) | 80 |

| Boiler thermal efficiency (ηg/%) | 90 |

| Evaporator heat transfer area (Ae/m2) | 370 |

| Evaporator pinch point temperature (Te/K) | 5 |

| Heat transfer area of condenser (Ac/m2) | 93 |

| Condenser pinch point temperature (Tc/K) | 5 |

| High-temperature steam inlet temperature (Tv,in/K) | 453.15 |

| High-temperature steam outlet temperature (Tv,out/K) | 443.15 |

| Seawater inlet temperature (Tw,in/K) | 293.15 |

| Seawater outlet temperature (Tw,out/K) | 303.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Fu, B.; Zeng, J.; Luo, W. Research on the Operational Performance of Organic Rankine Cycle System for Waste Heat Recovery from Large Ship Main Engine. Appl. Sci. 2023, 13, 8543. https://doi.org/10.3390/app13148543

Chen W, Fu B, Zeng J, Luo W. Research on the Operational Performance of Organic Rankine Cycle System for Waste Heat Recovery from Large Ship Main Engine. Applied Sciences. 2023; 13(14):8543. https://doi.org/10.3390/app13148543

Chicago/Turabian StyleChen, Wu, Binchun Fu, Jingbin Zeng, and Wenhua Luo. 2023. "Research on the Operational Performance of Organic Rankine Cycle System for Waste Heat Recovery from Large Ship Main Engine" Applied Sciences 13, no. 14: 8543. https://doi.org/10.3390/app13148543

APA StyleChen, W., Fu, B., Zeng, J., & Luo, W. (2023). Research on the Operational Performance of Organic Rankine Cycle System for Waste Heat Recovery from Large Ship Main Engine. Applied Sciences, 13(14), 8543. https://doi.org/10.3390/app13148543