Feasible Applicability of Deep Learning for Solid Detection in Concrete Wastewater: An Evaluation

Abstract

:1. Introduction

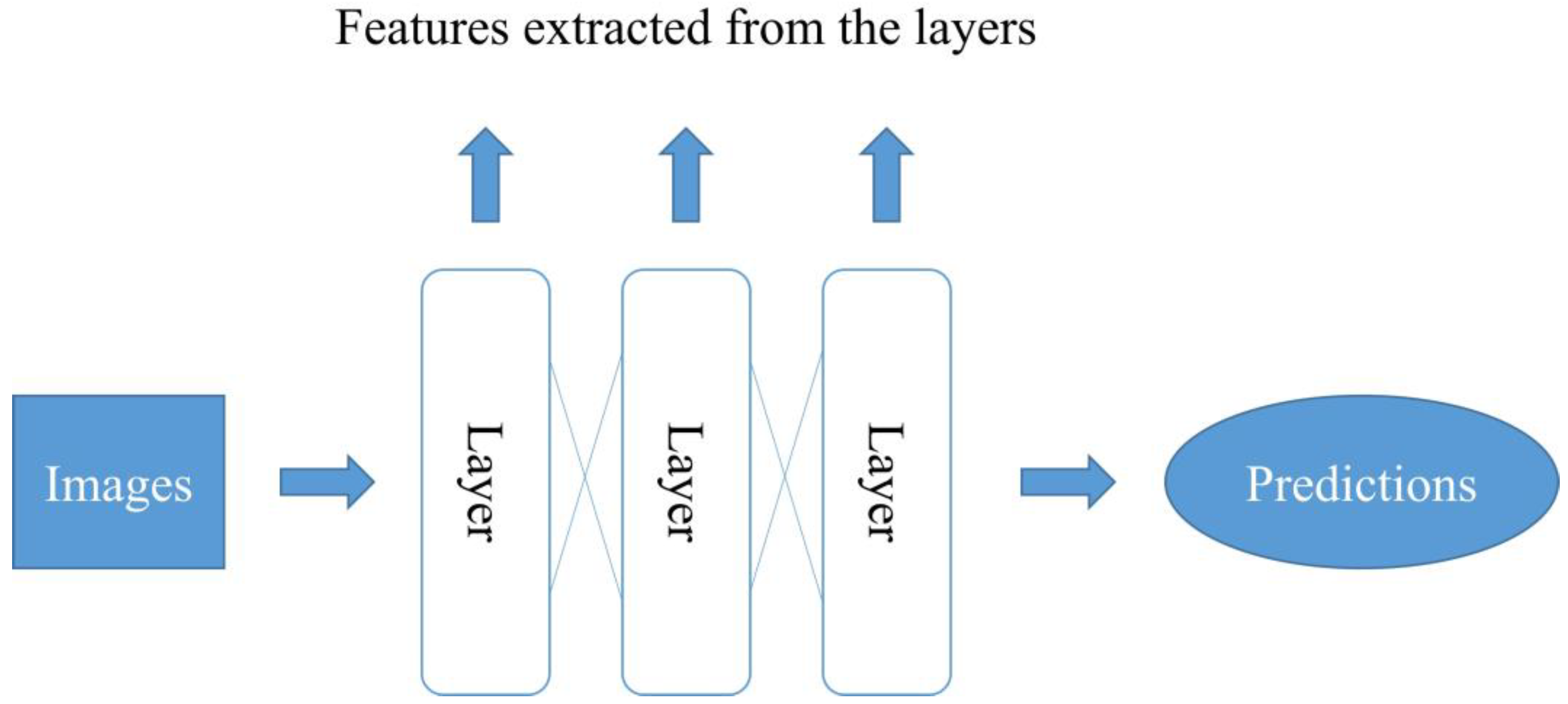

2. Deep Learning Technique

3. Discussion

3.1. Deep Learning Applications in Tiny Object Inspections

3.2. Deep Learning Applications in Solutions

3.3. The Challenges of Detecting Solid Content in Concrete Wastewater Using Deep Learning

- Data availability: The quality and quantity of data required for training deep learning models are critical to achieving a high accuracy. But, obtaining adequate datasets for solid-content detection in concrete wastewater can be challenging due to the variability in composition and particle size distribution [28]. Zhao et al. [29] investigated the particle size distribution of concrete wastewater and demonstrated that the particle size distribution of concrete wastewater is bimodal with a fine mode, which is dominated by particles less than 10 μm in diameter, and a coarse mode, which is dominated by particles greater than 100 μm in diameter. The non-uniformity of the particle size may lead to difficulty in extracting image features. Consequently, collecting an abundant amount of available data is critical to ensure the model’s reliability.

- Model selection: The selection of an appropriate deep learning model for solid-content detection in concrete wastewater is critical due to the varying functions of numerous available deep learning architectures. The model should have the capability to capture the heterogeneity of the particles, the variability in particle size and density, and the interferences in the wastewater [28]. Wang et al. [30] proposed a data-driven robust adaptive control system with deep learning (DRAC-DL) for enhancing the model adaptability, which used a robust controller to construct the closed-loop control scheme. Wang et al. [31] established an event-driven model of predictive control with deep learning (EMPC-DL), which is defined to trigger the action control to efficiently improve the running performance of wastewater treatment processes (WWTPs). Li et al. [32] applied a novel hybrid model integrated with a first-principal deep learning model to sufficiently adapt to the wastewater system and accurately predict the nitrous oxide (N2O) emissions from wastewater treatment plants (WWTPs). To reach an optimum processing speed, the selective model and the corresponding parameters become a necessity.

- Hardware requirements: Specialized hardware and significant computational power are a solid background when applying deep learning to detect solid content in concrete wastewater because deep learning models possess multiple layers and parameters that need to be optimized during training [33]. Therefore, high-end graphic processing units (GPUs) or tensor processing units (TPUs) are key components to efficiently and timely train the models, in addition to needing to meet the hardware requirements of high-end CPUs or GPUs, and having large amounts of memory (RAM) and fast storage devices such as solid-state drives (SSDs) [34].

- Generalization: The generalization of the deep learning model assures us that the algorithm is compatible with various sources of concrete wastewater due to the heterogeneity and variation in the wastewater. An investigation into the heterogeneity of concrete and its failure behavior presented an equivalent probabilistic model for the study of concrete failure [35]. Xu et al. [36] developed several transient shock models to profile the variation in three critical water quality parameters (conductivity, temperature, and pH) in a real-time mode with flat, thin milli-electrode array (MEA) sensors, which demonstrated that the MEA sensors possess the capability of efficiently profiling the corresponding parameters from different sources of wastewater. Moreover, Varshney et al. [37] conducted comprehensive investigations into the mechanical properties and durability aspects of concrete made with wastewater to point out the similarities in the properties from different sources of wastewater. All such research work has consolidated the significance of model generalization and its applications in industrial practices.

3.4. Future Research and Expectations

- The data augmentation technique is a technique of artificially increasing the training set by creating modified copies of a dataset using existing data, providing the model with a more extensive data range in variations and increasing the model’s accuracy [38].

- Hybrid approaches can mix different imaging techniques, which are combined with additional information and the improved accuracy from the deep learning models, such as by using hyperspectral imaging or X-ray imaging followed by deep learning algorithms [39] to improve the model performance.

- Transfer learning utilizes pre-trained models from other image recognition tasks, such as object detection or segmentation, to fine tune the target model with a small amount of image data, leading to faster and in-time model deployment [40].

- Multi-sensor integration is the process of combining data from multiple sensors, which can enhance the model generalization to improve the accuracy and reliability of the data [41]. Multi-sensor integration includes integrating different sensing technologies that capture different aspects of solid particles in concrete wastewater.

4. Conclusions

- The investigation of the use of deep learning practices in general solution concentration detection, metal ion concentration detection, metal element concentration detection, suspended particulate matter feature recognition, and horizontal-scale line detection shows that the technique can achieve high precision and display real-time data, providing a methodological basis for the use of deep learning to detect the concrete solid content of wastewater.

- The deep learning technique can be used to accurately detect the suspending particles in mineral water and the water level of rivers. So, it is feasible to apply the deep learning technique to test the solid content of wastewater, as the sedimentation dividing line in a solid and water is similar to that in the detection of the water level. Also, the OpenCV-based edge detection technique can be used to accurately and efficiently collect the image pattern and process the features. Such algorithms may consolidate the future experimental research on the solid detection of concrete wastewater.

- To overcome the challenges of deep learning applications, such as data availability and generalization, transfer learning, and data augmentation, hybrid approaches and multi-sensor integration techniques have the potential to be utilized to provide a more accurate model performance and adaptations.

- Test tubes can be used for sampling from wastewater sources. They can also be used as the targets for image data achievement when using deep learning, as the particle distribution and solid–liquid surface separation, which are representations of the target wastewater source, can be extracted as features with this method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taherlou, A.; Asadollahfardi, G.; Salehi, A.M.; Katebi, A. Sustainable use of municipal solid waste incinerator bottom ash and the treated industrial wastewater in self-compacting concrete. Constr. Build. Mater. 2021, 297, 123814. [Google Scholar] [CrossRef]

- Park, G.; Kim, Y.; Lee, H.H.; Lee, O.M.; Park, J.; Kim, Y.-J.; Lee, K.M.; Heo, M.-S.; Son, H.-J. Characterization and applicability of novel alkali–tolerant carbonatogenic bacteria as environment-friendly bioconsolidants for management of concrete structures and soil erosion. J. Environ. Manag. 2022, 321, 115929. [Google Scholar] [CrossRef]

- Alhumoud, J.M.; Terro, M.; Ghusain, I.A. Reuse of wastewater effluent in concrete mixing and the effect of high temperatures on its residual properties. Int. J. Environ. Sustain. Dev. 2010, 9, 310–324. [Google Scholar] [CrossRef]

- Ji, H.; Fu, Y.; Huang, Z.; Wang, B.; Li, H. Flow regime detection of mini-pipe gas-liquid two-phase flow based on PCA and SVM. In Proceedings of the Instrumentation and Measurement Technology Conference (I2MTC), Austin, TX, USA, 3–6 May 2010; pp. 771–774. [Google Scholar]

- Liu, J.H. Research on the influence of wastewater on cement performance. Highw. Transp. Inn. Mong. 2015, 6, 25–27. [Google Scholar] [CrossRef]

- Yuee Feng, W.F. Study on Solid Content Measurement of Liquid Accelerator based on Refractometer Method. China-Foreign Highw. 2022, 42, 251–253. [Google Scholar] [CrossRef]

- Maranhão, F.; Souza, F., Jr.; Soares, P.; Alcan, H.; Çelebi, O.; Bayrak, B.; Kaplan, G.; Aydin, A. Physico-mechanical and microstructural properties of waste geopolymer powder and lime-added semi-lightweight geopolymer concrete: Efficient machine learning models. J. Build. Eng. 2023, 72, 106629. [Google Scholar] [CrossRef]

- Sharifani, K.; Amini, M. Machine Learning and Deep Learning: A Review of Methods and Applications. Inf. Technol. Eng. J. 2023, 10, 3897–3904. [Google Scholar]

- Chauhan, R.; Ghanshala, K.K.; Joshi, R.C. Convolutional Neural Network (CNN) for Image Detection and Recognition. In Proceedings of the 2018 First International Conference on Secure Cyber Computing and Communication (ICSCCC), Jalandhar, India, 15–17 December 2018; pp. 278–282. [Google Scholar]

- Chapman, K.W.; Johnson, W.C.; Mclean, T.J. A High Speed Statistical Process Control Application of Machine Vision to Electronics Manufacturing. Comput. Ind. Eng. 1990, 19, 234–238. [Google Scholar] [CrossRef]

- Batchelor, B.G. Machine Vision for Industrial Applications. In Machine Vision Handbook; Batchelor, B.G., Ed.; Springer: London, UK, 2012; pp. 1–59. [Google Scholar] [CrossRef]

- Li, X. Review of machine vision research progress and industrial applications. China Ind. Inf. Technol. 2021, 11, 79–80. [Google Scholar] [CrossRef]

- Çınar, Z.M.; Abdussalam Nuhu, A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine learning in predictive maintenance towards sustainable smart manufacturing in industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Perng, D.-B.; Liu, H.-W.; Chang, C.-C. Automated SMD LED inspection using machine vision. Int. J. Adv. Manuf. Technol. 2011, 57, 1065–1077. [Google Scholar] [CrossRef]

- Geng, F.; Luo, G.; Zhou, F.; Zhao, P.; Ma, L.; Chai, H.; Zhang, T. Numerical investigation of dust dispersion in a coal roadway with hybrid ventilation system. Powder Technol. 2017, 313, 260–271. [Google Scholar] [CrossRef]

- Iakovidis, D.K.; Ooi, M.; Kuang, Y.C.; Demidenko, S.; Shestakov, A.; Sinitsin, V.; Henry, M.; Sciacchitano, A.; Discetti, S.; Donati, S. Roadmap on signal processing for next generation measurement systems. Meas. Sci. Technol. 2021, 33, 012002. [Google Scholar] [CrossRef]

- Bao, Y.; Li, H. Artificial intelligence for civil engineering. China Civ. Eng. J. 2019, 52, 1–11. [Google Scholar]

- Ayele, Y.Z.; Aliyari, M.; Griffiths, D.; Droguett, E.L. Automatic crack segmentation for UAV-assisted bridge inspection. Energies 2020, 13, 6250. [Google Scholar] [CrossRef]

- Huang, Z.; Tang, Y.; Zou, X.; Chen, M.; Zhou, H.; Zou, T. Visual measurement of crack width based on backbone dual-scale feature fusion. Adv. Lasers Optoelectron. 2022, 59, 1015005. [Google Scholar] [CrossRef]

- More, K.S.; Wolkersdorfer, C.; Kang, N.; Elmaghraby, A.S. Automated measurement systems in mine water management and mine workings–A review of potential methods. Water Resour. Ind. 2020, 24, 100136. [Google Scholar] [CrossRef]

- Liu, F.F.; Luo, X.P.; Xin, P.W.; Gong, Y.Z. Online Testing System for Tungsten Concentration Based on Machine Vision. China Tungsten Ind. 2015, 6, 73–76. [Google Scholar] [CrossRef]

- Cao, X.M.; Ying, Z.; Zhou, Z.Y.; Luo, X.W.; He, X.; Chen, S.D. Detection of copper ion concentration in paddy field irrigation based on machine vision. Guangdong Agric. Sci. 2015, 4, 147–152. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, S.; Zhang, W.; Zhang, Q. Rapid detection method of one-component dye solution concentration based on machine vision. Chin. J. Text. 2021, 42, 115–121. [Google Scholar] [CrossRef]

- Luo, D.; Liang, J. Detection of colored solution concentration based on machine vision. Comput. Digit. Eng. 2022, 50, 1459–1462. [Google Scholar] [CrossRef]

- Yao, R.; Dong, H.; Lin, Y. Rapid detection method for fabric defects based on machine vision. In Proceedings of the International Conference on Computer Application & System Modeling, Taiyuan, China, 22–24 October 2010. [Google Scholar]

- Sheng, Z.; Zhang, Y. Automatic detection method of suspended matter in bottled mineral water based on machine vision. Laser Optoelectron. Prog. 2020, 57, 141028. [Google Scholar] [CrossRef]

- Lin, Y.T.; Lin, Y.C.; Han, J.Y. Automatic water-level detection using single-camera images with varied poses. Measurement 2018, 127, 167–174. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Duan, H.; Yan, K.; Wang, J.; Wang, W. Deep learning based data-driven model for detecting time-delay water quality indicators of wastewater treatment plant influent. Chem. Eng. J. 2023, 467, 143483. [Google Scholar] [CrossRef]

- Zhao, H.; Ma, Y.; Fang, J.; Hu, L.; Li, X. Particle size distribution and total suspended solid concentrations in urban surface runoff. Sci. Total Environ. 2022, 815, 152533. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, Y.; Liu, C.; Qiao, J. Data-Driven Robust Adaptive Control with Deep Learning for Wastewater Treatment Process. IEEE Trans. Ind. Inform. 2023, 1–8. [Google Scholar] [CrossRef]

- Wang, G.; Bi, J.; Jia, Q.S.; Qiao, J.; Wang, L. Event-Driven Model Predictive Control With Deep Learning for Wastewater Treatment Process. IEEE Trans. Ind. Inform. 2023, 19, 6398–6407. [Google Scholar] [CrossRef]

- Li, K.; Duan, H.; Liu, L.; Qiu, R.; van den Akker, B.; Ni, B.-J.; Chen, T.; Yin, H.; Yuan, Z.; Ye, L. An Integrated First Principal and Deep Learning Approach for Modeling Nitrous Oxide Emissions from Wastewater Treatment Plants. Environ. Sci. Technol. 2022, 56, 2816–2826. [Google Scholar] [CrossRef]

- Jawandhiya, P. Hardware design for machine learning. Int. J. Artif. Intell. Appl 2018, 9, 63–84. [Google Scholar] [CrossRef]

- Azimi, M.; Eslamlou, A.D.; Pekcan, G. Data-Driven Structural Health Monitoring and Damage Detection through Deep Learning: State-of-the-Art Review. Sensors 2020, 20, 2778. [Google Scholar] [CrossRef]

- Tang, X.; Zhou, Y.; Zhang, C.; Shi, J. Chapter 23—Study on the Heterogeneity of Concrete and its Failure Behavior Using the Equivalent Probabilistic Model1. In Seismic Safety Evaluation of Concrete Dams; Zhang, C., Jin, F., Wang, J., Xu, Y., Eds.; Butterworth-Heinemann: Oxford, UK, 2013; pp. 541–570. [Google Scholar] [CrossRef]

- Xu, Z.; MahmoodPoor Dehkordy, F.; Li, Y.; Fan, Y.; Wang, T.; Huang, Y.; Zhou, W.; Dong, Q.; Lei, Y.; Stuber, M.D.; et al. High-fidelity profiling and modeling of heterogeneity in wastewater systems using milli-electrode array (MEA): Toward high-efficiency and energy-saving operation. Water Res. 2019, 165, 114971. [Google Scholar] [CrossRef] [PubMed]

- Varshney, H.; Khan, R.A.; Khan, I.K. Sustainable use of different wastewater in concrete construction: A review. J. Build. Eng. 2021, 41, 102411. [Google Scholar] [CrossRef]

- Mumuni, A.; Mumuni, F. Data augmentation: A comprehensive survey of modern approaches. Array 2022, 16, 100258. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, L.; Yin, H.; Lai, K.K. Integrating data augmentation and hybrid feature selection for small sample credit risk assessment with high dimensionality. Comput. Oper. Res. 2022, 146, 105937. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, Y.; Dai, W.; Pan, S.J. Transfer Learning; Cambridge University Press: Cambridge, UK, 2020. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, A.; Xiao, Y.; Chen, Z. A new combination method based on Pearson coefficient and information entropy for multi-sensor data fusion. Inf. Softw. Technol. 2023, 161, 107248. [Google Scholar] [CrossRef]

- Tulbure, A.-A.; Tulbure, A.-A.; Dulf, E.-H. A review on modern defect detection models using DCNNs—Deep convolutional neural networks. J. Adv. Res. 2022, 35, 33–48. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Yao, Q. Feasible Applicability of Deep Learning for Solid Detection in Concrete Wastewater: An Evaluation. Appl. Sci. 2023, 13, 8652. https://doi.org/10.3390/app13158652

Chen Y, Yao Q. Feasible Applicability of Deep Learning for Solid Detection in Concrete Wastewater: An Evaluation. Applied Sciences. 2023; 13(15):8652. https://doi.org/10.3390/app13158652

Chicago/Turabian StyleChen, Yongfang, and Qingyu Yao. 2023. "Feasible Applicability of Deep Learning for Solid Detection in Concrete Wastewater: An Evaluation" Applied Sciences 13, no. 15: 8652. https://doi.org/10.3390/app13158652

APA StyleChen, Y., & Yao, Q. (2023). Feasible Applicability of Deep Learning for Solid Detection in Concrete Wastewater: An Evaluation. Applied Sciences, 13(15), 8652. https://doi.org/10.3390/app13158652