1. Introduction

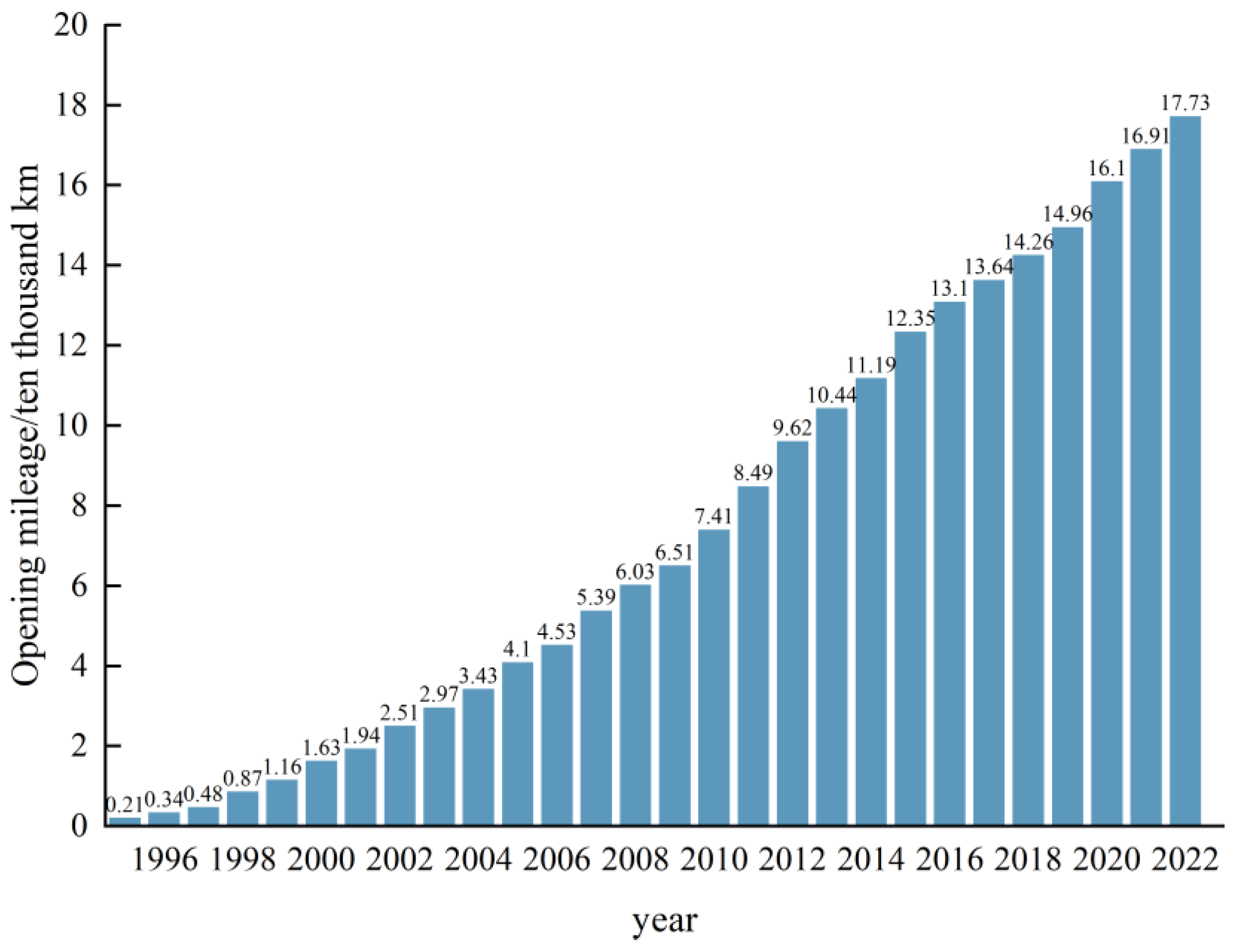

Since its reform and opening up, China has made tremendous achievements in highway construction. According to the Statistical Bulletin on the Development of the Transportation Industry, the development process of high-speed highways in China in recent years is shown in

Figure 1.

With the continuous development of the highway industry, under the combined effects of traffic loads and natural environmental factors, the road surface has experienced varying degrees of diseases, and the performance of the road surface has also declined. The maintenance task of the road surface is also becoming increasingly heavy. The focus of China’s highway work has gradually shifted from construction to maintenance and management. On the basis of such a large road network scale, facing such a large number of road mileage, effectively managing, improving the efficiency of maintenance fund utilization, and ensuring the level of road service have become important tasks for China’s highway maintenance and management department.

Unlike project-level road maintenance decisions that aim to maximize the benefits of specific road sections, network-level decision optimization generally focuses on a certain scale of the road network as the research object. Under budget and other resource constraints, it seeks the optimal combination of maintenance strategies and fund allocation schemes to maximize the benefits objectives (such as road performance); alternatively, under certain pavement performance requirements and resource constraints, seeking the optimal maintenance strategy to minimize cost objectives (maintenance costs, user costs, etc.) [

1]. With the rapid growth of China’s highway pavement maintenance scale, the contradiction between limited maintenance funds and huge maintenance mileage has become more prominent. How to reasonably allocate funds for each section of the road network has become more difficult. Meanwhile, due to the long-term period of reconstruction and light maintenance, the investment in maintenance funds is relatively small. The occurrence of road surface diseases mostly relies on the experience of on-site construction personnel. However, due to a lack of maintenance funds and unscientific maintenance decisions, some road sections that require maintenance have not received timely maintenance and repair, resulting in accelerated degradation of road performance [

2].

Currently, the main decision-making methods for network-level pavement maintenance are the sorting method and the optimization method. In the research of pavement maintenance decision making based on the sorting method, most scholars construct project or road section value functions by comprehensively considering various factors that affect decision making, or use methods such as the Analytic Hierarchy Process, Cluster Analysis, Matter Element Model, and Benefit Cost Analysis to rank the importance of projects and select projects based on priority [

3,

4,

5]. However, decision-making methods based on priority ranking often provide the sum of a set of project decisions, and decision makers cannot consider trade-offs between projects when selecting projects. Optimization rules can simultaneously consider the maintenance plan and maintenance time of each section of the road network to obtain a better maintenance plan. Many achievements have been made in the research of pavement maintenance decision making based on the optimization method at home and abroad. Zhang et al. [

6] established a multi-objective optimization model of pavement maintenance based on Dynamic programming with the objective of minimizing the cost of pavement maintenance and greenhouse gas emissions as the optimization goal; Elhaddy et al. [

7] established a multi-objective pavement maintenance optimization model based on a genetic algorithm with the goal of minimizing maintenance costs and maximizing pavement performance; Bryce et al. [

8] proposed a multi-objective optimization-based road maintenance analysis and decision-making method, and used this method to balance maintenance costs, road conditions, and energy consumption; Peng et al. [

1] proposed a project two-layer network-level pavement maintenance decision-making optimization model consisting of a multiyear fund allocation model and a project selection model with the goal of maintenance efficiency; Xie [

9] established a multi-objective decision model for pavement maintenance with the minimum maintenance cost and maximum maintenance benefit as the maintenance goal under the financial constraints; Mao [

10] constructed a two-layer optimization model for network-level road surface decision making, with the maximum sum of vehicle travel cost savings and traffic revenue increase, and the minimum generalized cost of vehicle travel as the upper and lower objectives, respectively; Feng [

2] established a multi-objective network-level pavement maintenance decision optimization model under both deterministic and uncertain conditions, with the goal of achieving the average pavement performance and the percentage of road length that meets a certain pavement performance index threshold. In summary, existing research mostly establishes decision optimization models from the perspective of operating units, with objective functions mostly targeting maintenance costs, road network performance, investment benefit ratio, etc., and less considering optimization of user costs and the environmental impact of maintenance. There is a lack of comprehensive consideration of maintenance costs, road network performance, user costs, and the environmental impact of maintenance.

In summary, based on the review of the existing literature, this article first analyzes and quantifies the user costs that affect the effectiveness of road maintenance. Secondly, through the concept of sustainable development of roads, the optimization of road maintenance decision making is divided into two steps: the first step is to determine the minimum maintenance budget funds, and the second step is to determine the optimal plan. The specific optimization method adopts the 0-1 mathematical programming method, establishes a network-level pavement maintenance decision optimization model based on a quantitative model, and identifies the most reasonable maintenance optimization plan among the four aspects of maintenance funds, maintenance performance improvement value, user benefit improvement, and environmental impact reduction. Finally, a road network in a province is selected for the case study. This study can help decision makers consider the diversity of practical problems from the perspectives of managers, users, and the environment, and make road maintenance decisions from a more reasonable perspective as China is about to enter a new era of “focusing on maintenance”.

4. Conclusions

This study is based on the analysis of the current research status of domestic network-level road maintenance decision making and establishes an optimization model for road maintenance decision making that comprehensively considers maintenance funds, road performance, user costs, and environmental costs. Based on case analysis, the following conclusions are drawn:

- (1)

Based on existing research, the user costs that affect the effectiveness of road maintenance were determined as the cost of vehicle travel time and the cost of vehicle fuel consumption, and quantitative models were established for each.

- (2)

Based on a user cost quantification model that affects the effectiveness of pavement maintenance, and applying the AHP model, an evaluation system for the effectiveness of highway asphalt pavement maintenance was established. A network-level pavement maintenance decision-making optimization model was established with the objective function of maximizing comprehensive maintenance benefits.

- (3)

Taking a certain road network in a certain province as an example for network-level maintenance decision making, the final maintenance plan was obtained using Lingo software. The case results validate the effectiveness of the proposed optimization model, indicating that the research findings of this article can assist decision makers in making road maintenance decisions more reasonably by considering the diversity of practical problems from multiple perspectives.

In addition, this study also has the following shortcomings: Firstly, when analyzing the quantification of vehicle operating costs, this article only considers one type of passenger car. In order to construct a more comprehensive user cost quantification model from a more comprehensive perspective, future research can increase the consideration of other vehicle models. Secondly, when building the network-level pavement maintenance decision model, this paper does not consider the user costs caused by the closure or semi-closure of road sections due to construction barriers. Finally, for future research, more components of user costs (e.g., vehicle safety costs and vehicle tire wearing costs) and environmental costs (traffic noise pollution costs) can be incorporated into the optimization model.