Augmented Reality in a Lean Workplace at Smart Factories: A Case Study

Abstract

1. Introduction

2. Literature Review

2.1. Lean Thinking

2.2. Industry 4.0 and Industry 5.0

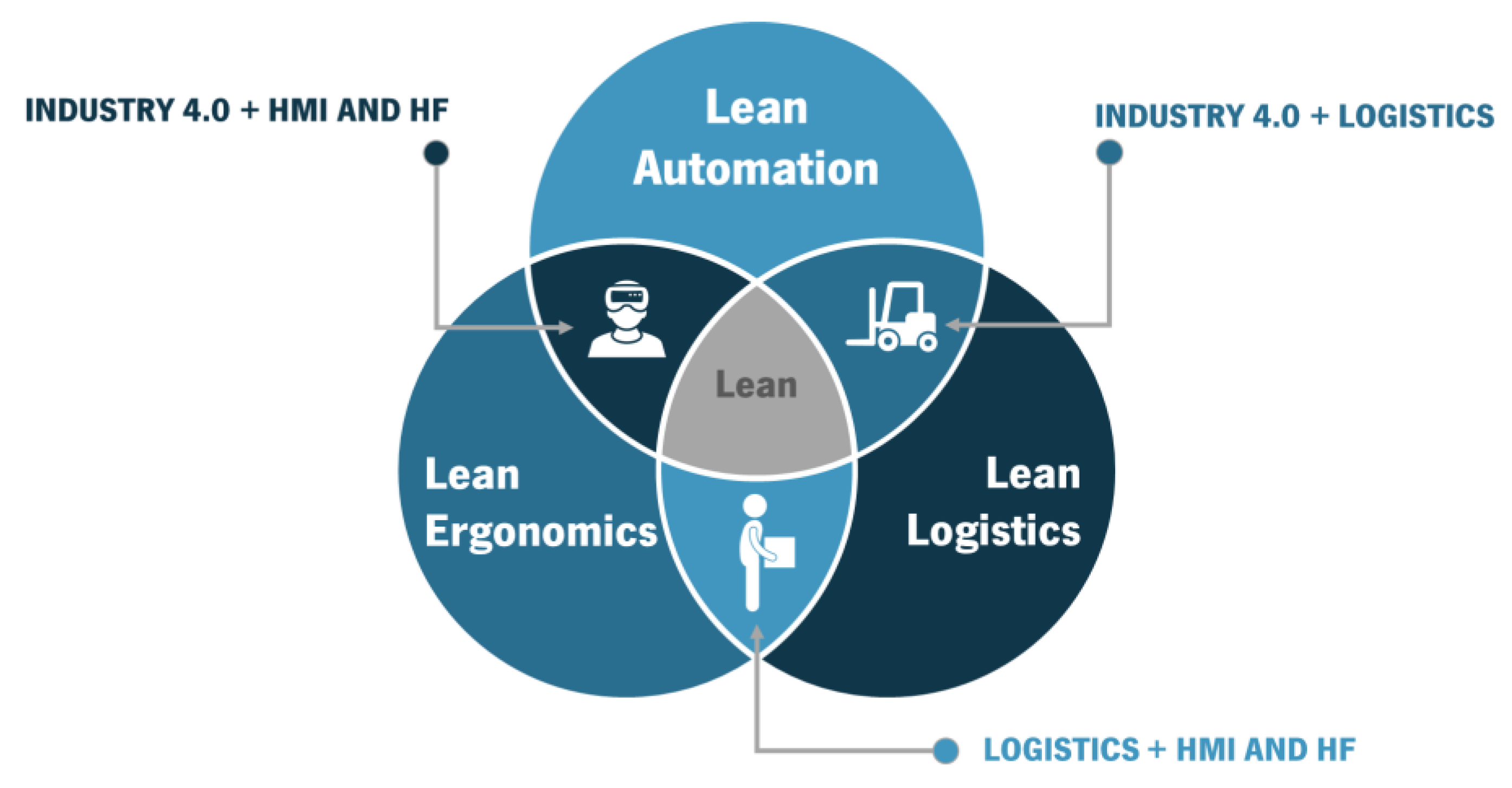

2.3. Lean Thinking, Industry 4.0 and Industry 5.0

2.4. Ergonomics and Human Factors

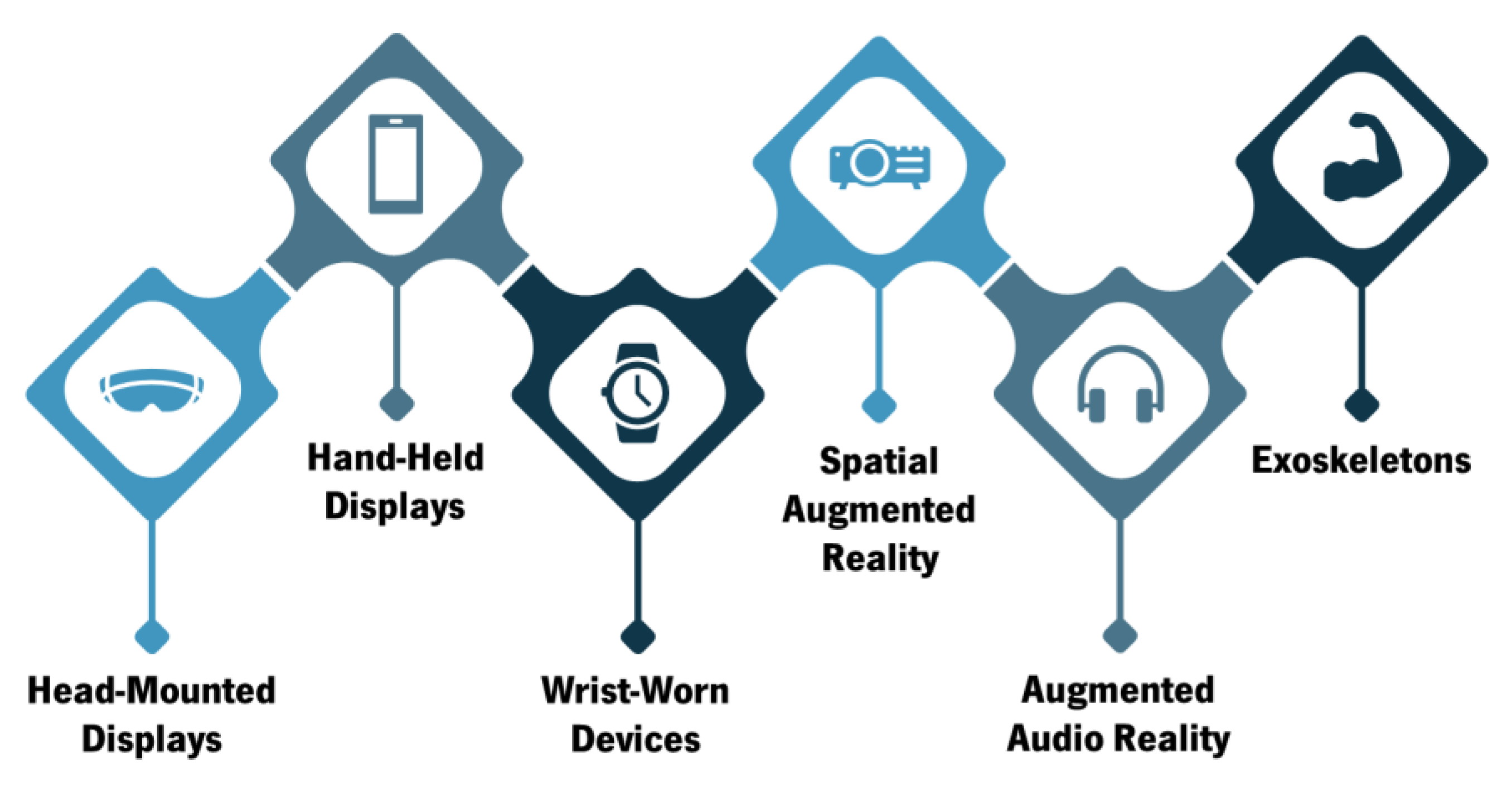

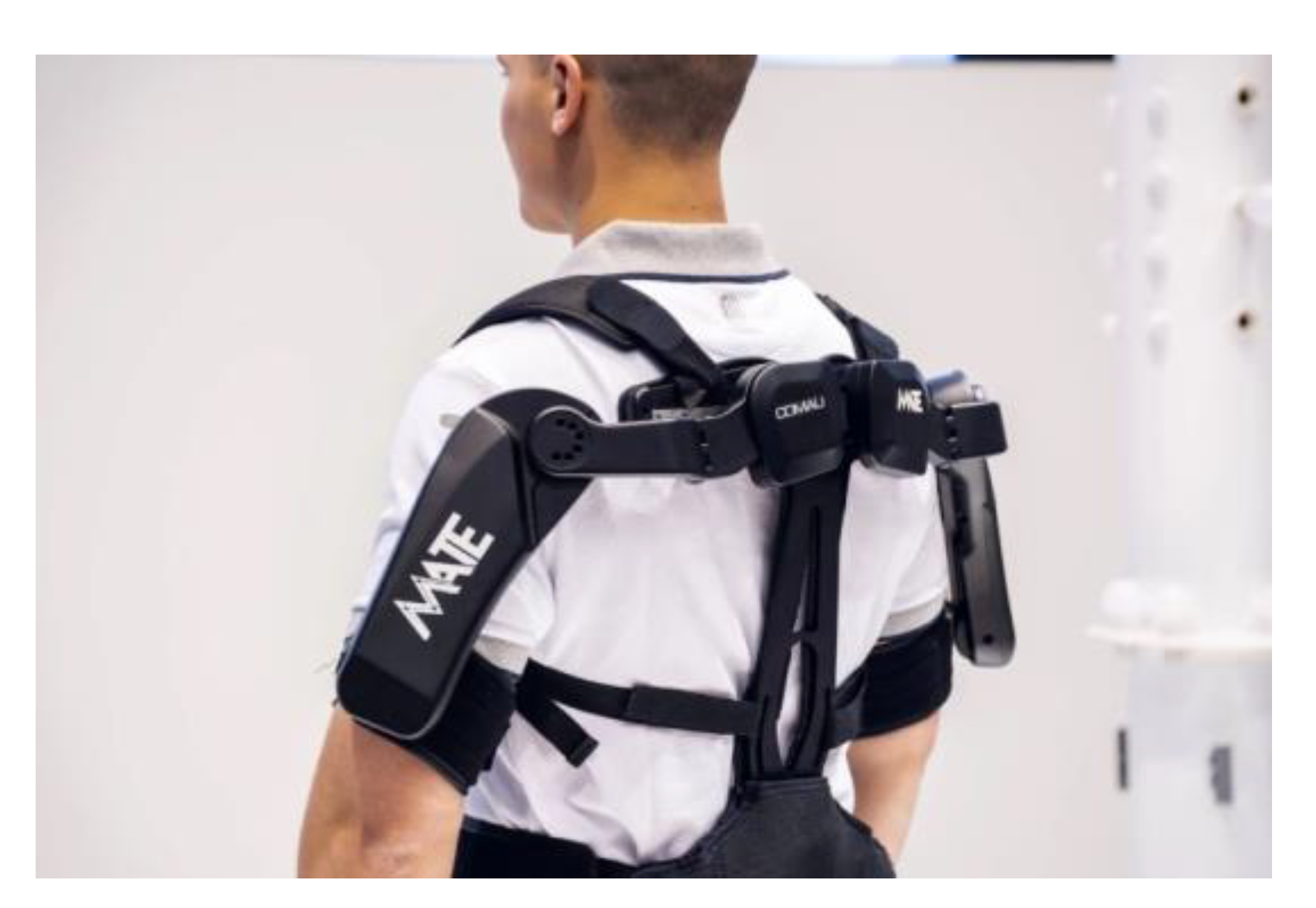

2.5. Augmented Reality and Human Augmentation

2.6. Critical Analysis

3. Research Methodology

3.1. Research Questions and Research Methodology Framework

- Literature review;

- Case study analysis;

- Methodology definition;

- Analysis and discussion.

3.2. Research Design and Strategy

4. Case Study Presentation

- Incoming;

- Internal logistics for final assembly;

- Internal logistics for Surface-Mount Device (SMD) assembly;

- Shipping.

- Incoming tasks;

- Warehousing tasks;

- Repacking tasks;

- Final and SMD assembly supermarkets tasks;

- Lines supply tasks;

- Shipping and dispatch tasks.

5. Methodology for Risk Assessment for Ergonomics and Safety in Logistics

- Occurrence analysis;

- OSH risk evaluation and mitigation measures;

- Ergonomic assessment and mitigation measures.

5.1. Occurrence Analysis (Phase 1)

5.2. OSH Risk Evaluation and Mitigation Measures (Phase 2)

5.3. Ergonomic Assessment and Mitigation Measures (Phase 3)

5.4. Methodology Overview

6. Analysis and Discussion

6.1. Identified Improvements Potential

- Incoming and raw materials warehouse;

- Internal logistics.

- Characterise the workers’ sample with demographic data;

- Analyse wellbeing and discomfort of workers;

- Assess physical exertion perceived by the workers and identify the most demanding tasks;

- Assess proposed AR solutions acceptance indicators based on the workers’ opinion.

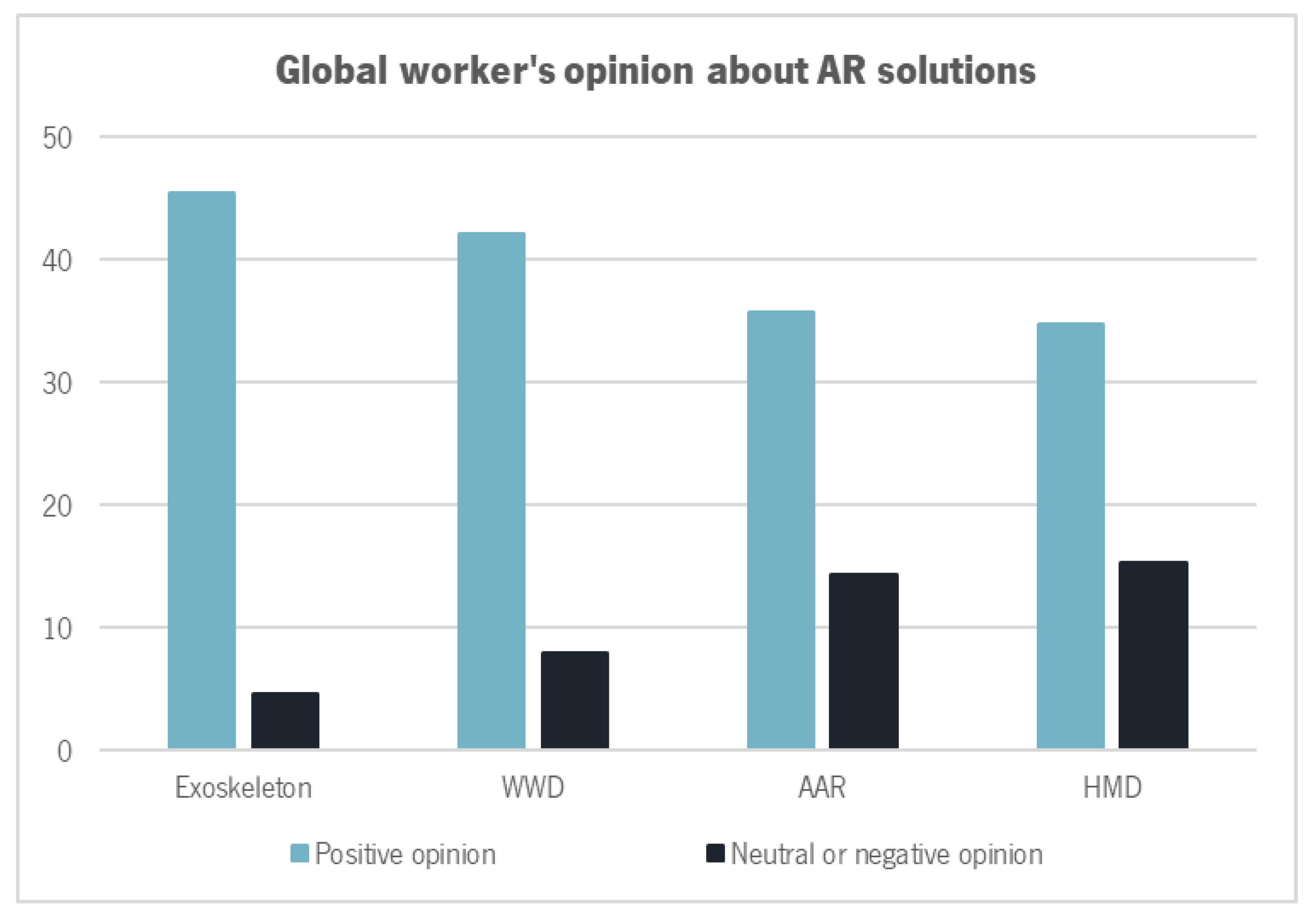

6.2. Results

7. Conclusions

7.1. Research Limitations

7.2. Future Work

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Questionnaire

- Category A. Worker’s Characterization

- Category B. Musculoskeletal Symptomatology

| Yes | No | |

| Neck | ○ | ○ |

| Shoulders | ○ | ○ |

| Elbows | ○ | ○ |

| Wrists and hands | ○ | ○ |

| Chest region | ○ | ○ |

| Lumbar region | ○ | ○ |

| Hips and thighs | ○ | ○ |

| Knees | ○ | ○ |

| Ankles and feet | ○ | ○ |

| Yes | No | |

| Neck | ○ | ○ |

| Shoulders | ○ | ○ |

| Elbows | ○ | ○ |

| Wrists and hands | ○ | ○ |

| Chest region | ○ | ○ |

| Lumbar region | ○ | ○ |

| Hips and thighs | ○ | ○ |

| Knees | ○ | ○ |

| Ankles and feet | ○ | ○ |

| Yes | No | |

| Neck | ○ | ○ |

| Shoulders | ○ | ○ |

| Elbows | ○ | ○ |

| Wrists and hands | ○ | ○ |

| Chest region | ○ | ○ |

| Lumbar region | ○ | ○ |

| Hips and thighs | ○ | ○ |

| Knees | ○ | ○ |

| Ankles and feet | ○ | ○ |

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

| Neck | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Shoulders | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Elbows | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Wrists and hands | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Chest region | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Lumbar region | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Hips and thighs | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Knees | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Ankles and feet | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

- Category C. Perception of Exertion

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | N/A | |

| Manual handling of heavy loads | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Pushing or pulling heavy loads | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Utensils too heavy (e.g., PDA) | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Repetitive movements | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Inappropriate trunk working postures | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Inappropriate upper limb working postures | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Inappropriate working postures of the lower limbs | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Workstations, shelves or material too high | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Workstations, shelves or material too low; | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| High distances covered; | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Too much information to assimilate; | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Hard to memorize work instructions; | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Find the fastest route (for picking, put-away or lines supply); | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Pay attention to all existing risks at the workplace; | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Too much product information to check; | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Quickly find product locations; | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Know all the tasks to perform; | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Detect errors or failures in processes; | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Know the specifications of each product (e.g., box type, packaging, location, etc.); | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Knowledge and compliance with all safety instructions | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Other: _________________________________ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

- Category D. AR Solutions: Workers’ Opinion and Acceptance

| 0 | 1 | 2 | 3 | 4 | 5 | |

| The equipment would make my tasks easier | ○ | ○ | ○ | ○ | ○ | ○ |

| The equipment could lighten my physical load | ○ | ○ | ○ | ○ | ○ | ○ |

| The equipment could reduce my physical effort | ○ | ○ | ○ | ○ | ○ | ○ |

| The equipment could reduce my discomfort | ○ | ○ | ○ | ○ | ○ | ○ |

| I would take less risk using the equipment | ○ | ○ | ○ | ○ | ○ | ○ |

| My job would improve with this equipment | ○ | ○ | ○ | ○ | ○ | ○ |

| I would use the equipment if the company made it available | ○ | ○ | ○ | ○ | ○ | ○ |

| 0 | 1 | 2 | 3 | 4 | 5 | |

| The equipment would make my tasks easier | ○ | ○ | ○ | ○ | ○ | ○ |

| The equipment could lighten my physical load | ○ | ○ | ○ | ○ | ○ | ○ |

| The equipment could reduce my physical effort | ○ | ○ | ○ | ○ | ○ | ○ |

| The equipment could reduce my discomfort | ○ | ○ | ○ | ○ | ○ | ○ |

| I would take less risk using the equipment | ○ | ○ | ○ | ○ | ○ | ○ |

| My job would improve with this equipment | ○ | ○ | ○ | ○ | ○ | ○ |

| I would use the equipment if the company made it available | ○ | ○ | ○ | ○ | ○ | ○ |

| 0 | 1 | 2 | 3 | 4 | 5 | |

| The equipment could lighten my cognitive load | ○ | ○ | ○ | ○ | ○ | ○ |

| The equipment could reduce my cognitive effort | ○ | ○ | ○ | ○ | ○ | ○ |

| The equipment could reduce my discomfort | ○ | ○ | ○ | ○ | ○ | ○ |

| I would take less risk using the equipment | ○ | ○ | ○ | ○ | ○ | ○ |

| My job would improve with this equipment | ○ | ○ | ○ | ○ | ○ | ○ |

| I would use the equipment if the company made it available | ○ | ○ | ○ | ○ | ○ | ○ |

| 0 | 1 | 2 | 3 | 4 | 5 | |

| The equipment would make my tasks easier | ○ | ○ | ○ | ○ | ○ | ○ |

| The equipment could lighten my cognitive load | ○ | ○ | ○ | ○ | ○ | ○ |

| The equipment could reduce my cognitive effort | ○ | ○ | ○ | ○ | ○ | ○ |

| The equipment could reduce my discomfort | ○ | ○ | ○ | ○ | ○ | ○ |

| I would take less risk using the equipment | ○ | ○ | ○ | ○ | ○ | ○ |

| My job would improve with this equipment | ○ | ○ | ○ | ○ | ○ | ○ |

| I would use the equipment if the company made it available | ○ | ○ | ○ | ○ | ○ | ○ |

References

- Kagermann, H.; Wahlster, W.; Helbig, J. Securing the Future of German Manufacturing Industry: Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0; Acatech— National Academy of Science and Engineering: München, Germany, 2013. [Google Scholar]

- Schmidt, R.; Möhring, M.; Härting, R.-C.; Reichstein, C.; Neumaier, P. Industry 4.0—Potentials for Creating Smart Products: Empirical Research Results. In Proceedings of the International Conference on Business Information Systems, Poznań, Poland, 24–26 June 2015; Springer: Berlin/Heidelberg, Germany, 2015; pp. 16–27. [Google Scholar]

- Weyer, S.; Schmitt, M.; Ohmer, M.; Gorecky, D. Towards Industry 4.0—Standardization as the Crucial Challenge for Highly Modular, Multi-vendor Production Systems. IFAC-PapersOnLine 2015, 48, 579–584. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W. Ten years of Industrie 4.0. Sci 2022, 4, 26. [Google Scholar] [CrossRef]

- Pereira, A.C.; Romero, F. A review of the meanings and the implications of the Industry 4.0 concept. Procedia Manuf. 2017, 13, 1206–1214. [Google Scholar] [CrossRef]

- Furht, B. Handbook of Augmented Reality; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Sääski, J.; Salonen, T.; Liinasuo, M.; Pakkanen, J.; Vanhatalo, M.; Riitahuhta, A. Augmented Reality Efficiency in Manufacturing Industry: A Case Study. In Proceedings of the NordDesign 2008 Conference, Tallinn, Estonia, 21–23 August 2008; pp. 99–109. [Google Scholar]

- Ho, P.T.; Albajez, J.A.; Santolaria, J.; Yagüe-Fabra, J.A. Study of augmented reality based manufacturing for further integration of quality control 4.0, A systematic literature review. Appl. Sci. 2022, 12, 1961. [Google Scholar] [CrossRef]

- Rupa, C.; Srivastava, G.; Ganji, B.; Tatiparthi, S.P.; Maddala, K.; Koppu, S.; Lin, J.C.-W. Medicine drug name detection based object recognition using augmented reality. Front. Public Health 2022, 10, 881701. [Google Scholar] [CrossRef]

- Bharath, G.; Ch, R.; Karthik, M.; Chowdary, M. Revelation of geospatial information using augmented reality. In Proceedings of the 2021 Sixth International Conference on Wireless Communications, Signal Processing and Networking (WiSPNET), Chennai, India, 25–27 March 2021; IEEE: New York City, NY, USA, 2021; pp. 303–308. [Google Scholar]

- Gorecky, D.; Schmitt, M.; Loskyll, M.; Zühlke, D. Human-machine-interaction in the industry 4.0 era. In Proceedings of the 2014 12th IEEE International Conference on Industrial Informatics, INDIN, Porto Alegre, Brazil, 27–30 July 2014; pp. 289–294. [Google Scholar]

- Gladysz, B.; Tran, T.A.; Romero, D.; van Erp, T.; Abonyi, J.; Ruppert, T. Current development on the Operator 4.0 and transition towards the Operator 5.0: A systematic literature review in light of Industry 5.0. J. Manuf. Syst. 2023, 70, 160–185. [Google Scholar] [CrossRef]

- Michalos, G.; Karagiannis, P.; Makris, S.; Tokçalar, O.; Chryssolouris, C. Augmented Reality (AR) Applications for Supporting Human-robot Interactive Cooperation. Procedia CIRP 2016, 41, 370–375. [Google Scholar] [CrossRef]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; CRC Press: Boca Raton, FL, USA, 1988. [Google Scholar]

- Kolberg, D.; Zühlke, D. Lean Automation Enabled by Industry 4.0 Technologies. IFAC-PapersOnLine 2015, 48, 1870–1875. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0, towards a Sustainable, Human-Centric and Resilient European Industry; European Commission, Directorate-General for Research and Innovation: Luxembourg, 2021. [Google Scholar]

- Huang, S.; Wang, B.; Li, X.; Zheng, P.; Mourtzis, D.; Wang, L. Industry 5.0 and Society 5.0—Comparison, complementation and co-evolution. J. Manuf. Syst. 2022, 64, 424–428. [Google Scholar] [CrossRef]

- Alves, A.C. Lean Thinking: An essential mindset. IEEE Eng. Manag. Rev. 2022, 50, 127–133. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine That Changed the World: The Story of Lean Production; Rawson Associates: New York, NY, USA, 1991. [Google Scholar]

- Liker, J.K. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill Education: New York, NY, USA, 2004. [Google Scholar]

- Alves, A.C.; Ferreira, A.C.M.; Maia, L.C.; Leao, C.; Carneiro, P. A symbiotic relationship between Lean Production and Ergonomics: Insights from Industrial Engineering final year projects. Int. J. Ind. Eng. Manag. 2019, 10, 243–256. [Google Scholar] [CrossRef]

- Dul, J.; Neumann, W.P. Ergonomics contributions to company strategies. Appl. Erg. 2009, 40, 745–752. [Google Scholar] [CrossRef] [PubMed]

- Maia, L.C.; Alves, A.C.; Leão, C.P. Do Lean Methodologies Include Ergonomic Tools? Portuguese Society of Occupational Safety and Hygiene (SPOSHO): Guimaraes, Portugal, 2012. [Google Scholar]

- Brito, M.F.; Ramos, A.L.F.A.; Carneiro, P.; Gonçalves, M.A.; de Vasconcelos Ferreira, J.A.; Frade, A.B.T. Improving the production performance and ergonomic aspects using lean and agile concepts. Open Cybern. Syst. J. 2018, 12, 122–135. [Google Scholar] [CrossRef]

- Nunes, I.L. Integration of ergonomics and lean six sigma. A model proposal. Procedia Manuf. 2015, 3, 890–897. [Google Scholar]

- Arezes, P.M.; Dinis-Carvalho, J.; Alves, A.C. Workplace ergonomics in lean production environments: A literature review. Work 2015, 52, 57–70. [Google Scholar] [CrossRef] [PubMed]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0, Towards Future Industrial Opportunities and Challenges. In Proceedings of the International Conference on Fuzzy Systems and Knowledge Discovery, Changsha, China, 13–15 August 2016; pp. 2147–2152. [Google Scholar]

- Ivanov, D. The Industry 5.0 framework: Viability-based integration of the resilience, sustainability, and human-centricity perspectives. Int. J. Prod. Res. 2023, 61, 1683–1695. [Google Scholar] [CrossRef]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0, Prospect and retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

- Shiroishi, Y.; Uchiyama, K.; Suzuki, N. Society 5.0, For human security and well-being. Computer 2018, 51, 91–95. [Google Scholar] [CrossRef]

- Lu, Y.; Zheng, H.; Chand, S.; Xia, W.; Liu, Z.; Xu, X.; Wang, L.; Qin, Z.; Bao, J. Outlook on human-centric manufacturing towards Industry 5.0. J. Manuf. Syst. 2022, 62, 612–627. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Operator 5.0, A survey on enabling technologies and a framework for digital manufacturing based on extended reality. J. Mach. Eng. 2022, 22, 43–69. [Google Scholar] [CrossRef]

- Deguchi, A.; Hirai, C.; Matsuoka, H.; Nakano, T.; Oshima, K.; Tai, M. What is society 5.0. In Society 5.0.; Springer: Singapore, 2020; pp. 1–23. [Google Scholar]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. A Literature Review of the Challenges and Opportunities of the Transition from Industry 4.0 to Society 5.0. Energies 2022, 15, 6276. [Google Scholar] [CrossRef]

- Keidanren, J.B.F. Toward Realization of the New Economy and Society—Reform of the Economy and Society by the Deepening of “Society 5.0.; Keidanren: Tokyo, Japan, 2016. [Google Scholar]

- Fukuyama, M. Society 5.0, Aiming for a new human-centered society. Jpn. Spotlight 2018, 1, 47–50. [Google Scholar]

- Rahardjo, B.; Wang, F.-K.; Yeh, R.-H.; Chen, Y.-P. Lean Manufacturing in Industry 4.0, A Smart and Sustainable Manufacturing System. Machines 2023, 11, 72. [Google Scholar] [CrossRef]

- Pereira, A.C.; Dinis-Carvalho, J.; Alves, A.C.; Arezes, P. How Industry 4.0 can enhance Lean practices. FME Trans. 2019, 47, 810–822. [Google Scholar] [CrossRef]

- Bittencourt, V.L.; Alves, A.C.; Leão, C.P. Industry 4.0 triggered by Lean Thinking: Insights from a systematic literature review. Int. J. Prod. Res. 2021, 59, 1496–1510. [Google Scholar] [CrossRef]

- Hancock, P.A.; Diaz, D.D. Ergonomics as a foundation for a science of purpose. Theor. Issues Ergon. Sci. 2002, 3, 115–123. [Google Scholar] [CrossRef]

- Berlin, C.; Adams, C. Production Ergonomics: Designing Work Systems to Support Optimal Human Performance; Ubiquity Press: London, UK, 2017. [Google Scholar]

- Nunes, I.L.; Bush, P.M. Work-related musculoskeletal disorders assessment and prevention. In Ergonomics—A Systems Approach; IntechOpen: London, UK, 2012; pp. 1–30. [Google Scholar]

- Nunes, I.L. Ergonomic risk assessment methodologies for work-related musculoskeletal disorders: A patent overview. Recent Pat. Biomed. Eng. (Discontin.) 2009, 2, 121–132. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, Y.; Shang, K.; Wu, A. Investigation on musculoskeletal disorders of the workers in automobile production logistics. In Proceedings of the 24th International Conference on Industrial Engineering and Engineering Management 2018; Springer: Berlin/Heidelberg, Germany, 2019; pp. 491–498. [Google Scholar]

- Afonso, T.; Alves, A.C.; Carneiro, P. Lean Thinking, Logistic and Ergonomics: Synergetic Triad to Prepare Shop Floor Work Systems to Face Pandemic Situations. Int. J. Glob. Bus. Compet. 2021, 16, 62–76. [Google Scholar]

- Rajesh, R.; Babu, R.V.; Ramachandran, S. Ergonomics Redesign of Material Handling Work System in Manufacturing Plant. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2. Available online: https://www.semanticscholar.org/paper/ERGONOMIC-REDESIGN-OF-A-MATERIAL-HANDLING-IN-A-Rajesh-Babu/ebe7e21c1a72f854d41de1498c0fb7502280636d (accessed on 21 December 2021).

- Bigliardi, B.; Casella, G.; Bottani, E. Industry 4.0 in the logistics field: A bibliometric analysis. IET Collab. Intell. Manuf. 2021, 3, 4–12. [Google Scholar] [CrossRef]

- Cimini, C.; Lagorio, A.; Pirola, F.; Pinto, R. Exploring human factors in Logistics 4.0, Empirical evidence from a case study. IFAC-PapersOnLine 2019, 52, 2183–2188. [Google Scholar] [CrossRef]

- Nee, A.Y.C.; Ong, S.K. Springer Handbook of Augmented Reality; Springer Nature: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Falcioni, J.G. Rewritting the Rules of Product Development. Mech. Eng. 2016, 138, 6. [Google Scholar]

- Azuma, R.; Baillot, Y.; Behringer, R.; Feiner, S.; Julier, S.; Maclntyre, B. Recent advances in augmented reality. IEEE Comput. Graph. Appl. 2001, 21, 34–47. [Google Scholar] [CrossRef]

- Kipper, G.; Rampolla, J. Augmented Reality: An Emerging Technologies Guide to AR; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Pereira, A.; Abreu, M.F.; Silva, D.; Alves, A.C.; Oliverira, J.A.; Lopes, I.; Figueiredo, M.C. Reconfigurable Standardized Work in a Lean Company—A Case Study. Procedia CIRP 2016, 52, 239–244. [Google Scholar] [CrossRef][Green Version]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Manufacturing personnel task allocation taking into consideration skills and remote guidance based on augmented reality and intelligent decision making. Int. J. Comput. Integr. Manuf. 2023, 36, 70–85. [Google Scholar] [CrossRef]

- Nee, A.Y.C.; Ong, S.K.; Chryssolouris, G.; Mourtzis, D. Augmented reality applications in design and manufacturing. CIRP Annals 2012, 61, 657–679. [Google Scholar] [CrossRef]

- Ho, P.T.; Albajez, J.A.; Yagüe, J.A.; Santolaria, J. Preliminary study of Augmented Reality based manufacturing for further integration of Quality Control 4.0 supported by metrology. In IOP Conference Series: Materials Science and Engineering, Volume 1193, Proceedings of the 9th Manufacturing Engineering Society International Conference (MESIC 2021), Gijόn, Spain, 23–25 June 2021; IOP Publishing: Bristol, UK, 2021; p. 012105. [Google Scholar]

- Syberfeldt, A.; Danielsson, O.; Holm, M.; Wang, L. Dynamic operator instructions based on augmented reality and rule-based expert systems. Procedia CIRP 2016, 41, 346–351. [Google Scholar] [CrossRef]

- Romero, D.; Stahre, J.; Wuest, T.; Noran, O.; Bernus, P.; Fast Berglund, Å.; Gorecky, D. Towards an operator 4.0 typology: A human-centric perspective on the fourth industrial revolution technologies. In Proceedings of the CIE 2016, 46th International Conferences on Computers and Industrial Engineering, Tianjin, China, 29–31 October 2016. [Google Scholar]

- Pereira, A.C.R. The Use of Augmented Reality in the Lean Workplaces at Smart Factories. Ph.D. Thesis, University of Minho, Braga, Portugal, 2022. [Google Scholar]

- Härmä, A.; Jakka, J.; Tikander, M.; Karjalainen, M.; Lokki, T.; Hiipakka, J.; Lorho, G. Augmented reality audio for mobile and wearable appliances. AES J. Audio Eng. Soc. 2004, 52, 618–639. [Google Scholar]

- Sylla, N.; Bonnet, V.; Colledani, F.; Fraisse, P. Ergonomic contribution of ABLE exoskeleton in automotive industry. Int. J. Ind. Ergon. 2014, 44, 475–481. [Google Scholar] [CrossRef]

- Tachi, S. From 3D to VR and further to telexistence. In Proceedings of the 23rd International Conference on Artificial Reality and Telexistence, ICAT 2013, Tokyo, Japan, 11–13 December 2013; pp. 1–10. [Google Scholar]

- Pereira, A.C.; Arezes, P.; Alves, A.C.; Duarte, F.J. An enhanced human-machine interface enabled by augmented reality—A new approach for human augmentation. In Proceedings of the XIX International Conference on Occupational Risk Prevention, Madrid, Spain, 5–7 June 2019; pp. 178–187. [Google Scholar]

- Kymäläinen, T.; Koskinen, H.; Aromaa, S. Design and research for advanced human augmentation in the industrial work context. In Proceedings of the 12th International Conference on Intelligent Environments, London, UK, 14–16 September 2016; IOS Press: Amsterdam, The Netherlands, 2016; pp. 608–614. [Google Scholar]

- Weber, A. Visual Work Instructions and the Paperless Factory. Assem. Mag. 2014, 57. Available online: https://www.assemblymag.com/articles/91946-visual-work-instructions-and-the-paperless-factory (accessed on 3 January 2022).

- Khoshnevis, M.; Lindberg, E. Development of a Demonstrator in the Aerospace Industry for Visualization of 3D Work Instructions; Linköpings Universitet: Linköping, Sweden, 2015. [Google Scholar]

- Wang, X.; Ong, S.K.; Nee, A.Y.C. A comprehensive survey of augmented reality assembly research. Adv. Manuf. 2016, 4, 1–22. [Google Scholar] [CrossRef]

- Ropp, T.D.; Thomas, E.; Lee, S.; Broyles, A.; Lewin, P.; Andreychek, C.; Nicol, J. Creating Hybrid Air Vehicle Technical Work Instructions Using Augmented Reality and 2D Barcode Visualization Technologies; White Paper; Hangar of the Future Research Laboratory, Purdue University: West Lafayette, IN, USA, 2013. [Google Scholar]

- Wang, W.; Wang, F.; Song, W.; Su, S. Application of augmented reality (AR) technologies in inhouse logistics. E3S Web Conf. 2020, 145, 02018. [Google Scholar] [CrossRef]

- Baumann, H. Order Picking Supported by Mobile Computing. Ph.D. Thesis, Universität Bremen, Bremen, Germany, 2012. [Google Scholar]

- Stein, R.; Ferrero, S.; Hetfield, M.; Quinn, A.; Krichever, M. Development of a commercially successful wearable data collection system. In Proceedings of the Digest of Papers. Second International Symposium on Wearable Computers (Cat. No. 98EX215), Pittsburgh, PA, USA, 19–20 October 1998; IEEE: New York City, NY, USA, 1998; pp. 18–24. [Google Scholar]

- Starner, T.E. Wearable computers: No longer science fiction. IEEE Pervasive Comput. 2002, 1, 86–88. [Google Scholar] [CrossRef]

- Reif, R.; Günthner, W.A. Pick-by-vision: Augmented reality supported order picking. Vis. Comput. 2009, 25, 461–467. [Google Scholar] [CrossRef]

- Stoltz, M.-H.; Giannikas, V.; McFarlane, D.; Strachan, J.; Um, J.; Srinivasan, R. Augmented Reality in Warehouse Operations: Opportunities and Barriers. IFAC-PapersOnLine 2017, 50, 12979–12984. [Google Scholar] [CrossRef]

- vom Stein, A.M.; Günthner, W.A. Using Smart Glasses for the Inclusion of Hearing-Impaired Warehouse Workers into Their Working Environment. In Proceedings of the International Conference on HCI in Business, Government, and Organizations, Toronto, ON, Canada, 17–22 July 2016; Springer: Berlin/Heidelberg, Germany, 2016; pp. 358–368. [Google Scholar]

- Romero, D.; Bernus, P.; Noran, O.; Stahre, J.; Fast-Berglund, Å. The operator 4.0, Human cyber-physical systems & adaptive automation towards human-automation symbiosis work systems. In Proceedings of the IFIP Advances in Information and Communication Technology, Iguassu Falls, Brazil, 3–7 September 2016; pp. 677–686. [Google Scholar]

- Ruppert, T.; Jaskó, S.; Holczinger, T.; Abonyi, J. Enabling Technologies for Operator 4.0, A Survey. Appl. Sci. 2018, 8, 1650. [Google Scholar] [CrossRef]

- Kaasinen, E.; Schmalfuß, F.; Özturk, C.; Aromaa, S.; Boubekeur, M.; Heilala, J.; Heikkilä, P.; Kuula, T.; Liinasuo, M.; Mach, S.; et al. Empowering and engaging industrial workers with Operator 4.0 solutions. Comput. Ind. Eng. 2020, 139, 105678. [Google Scholar] [CrossRef]

- Remenyi, D.; Williams, B.; Money, A.; Swartz, E. Doing Research in Business and Management: An Introduction to Process and Method; Sage Publications Ltd.: Newbury Park, CA, USA, 1998. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods; SAGE Publications: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Saunders, M.; Lewis, P.; Thornhill, A. Research Methods for Business Students, 5th ed.; Financial Times Prentice Hall: Edinburgh, Scotland, 2009. [Google Scholar]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Kuorinka, I.; Jonsson, B.; Kilbom, A.; Vinterberg, H.; Biering-Sørensen, F.; Andersson, G.; Jørgensen, K. Standardised Nordic questionnaires for the analysis of musculoskeletal symptoms. Appl. Erg. 1987, 18, 233–237. [Google Scholar] [CrossRef]

- Crawford, J.O. The Nordic musculoskeletal questionnaire. Occup. Med. (Chic. Ill.) 2007, 57, 300–301. [Google Scholar] [CrossRef]

- Jensen, M.P.; Karoly, P. Self-report scales and procedures for assessing pain in adults. In Handbook of Pain Assessment; Turk, D.C., Melzack, R., Eds.; The Guilford Press: New York, NY, USA, 2011. [Google Scholar]

- Borg, G. Psychophysical scaling with applications in physical work and the perception of exertion. Scand. J. Work. Environ. Health 1990, 16, 55–58. [Google Scholar] [CrossRef] [PubMed]

- Likert, R. A technique for the measurement of attitudes. Arch. Psychol. 1932, 140, 5–55. [Google Scholar]

- New Atlas. MATE Is Made to Look Out for Your Shoulders. 2018. Available online: https://newatlas.com/comau-mate-exoskeleton/56625/ (accessed on 3 January 2022).

- Etiden. Proglove Mark 2, BT, 2D, Sr., BT (BLE, 5.1). 2020. Available online: https://www.etiden.com/PT/m003-eu-proglove-1.html (accessed on 21 December 2021).

- Datalogic. HandScanner. 2021. Available online: https://www.datalogic.com/eng/retail-manufacturing-transportation-logistics-healthcare/handheld-scanners/handscanner-pd-886.html# (accessed on 3 January 2022).

- ILS Ltd. Vocollect A500 Mobile Device. 2017. Available online: http://inter-solutions.co.uk/solutions/honeywell-vocollect-voice-solutions/vocollet-werable-mobile-devices/vocollect-a500-mobile-device.html (accessed on 21 December 2021).

- Microsoft. Business-Ready Solutions for HoloLens 2. 2020. Available online: https://www.microsoft.com/en-gb/hololens/apps (accessed on 21 December 2021).

| RQ# | Research Question |

|---|---|

| RQ 1 | How can AR enhance human capabilities and senses in lean workplaces? |

| RQ 1.1 | How can AR enhance human capabilities and senses in order to mitigate risks? |

| RQ 1.2 | How can AR enhance human capabilities and senses in order to improve ergonomic conditions? |

| RQ 2 | Which AR solutions are more suitable for logistic processes? |

| Steps of Phase 1 | Inputs | Methods | Outputs |

|---|---|---|---|

| 1.1. Identification of the most critical logistic areas |

|

|

|

| 1.2. Identification of the most critical processes |

|

|

|

| 1.3. Identification of the most common consequences |

|

|

|

| 1.4. Conclusions and identification of improvement potential |

|

|

|

| Steps of Phase 1 | Inputs | Methods | Outputs |

|---|---|---|---|

| 2.1. Identification of hazards associated with each task performance |

|

|

|

| 2.2. Identification and categorisation of each OSH risk factor |

|

|

|

| 2.3. Assessment of each risk based on their severity and frequency |

|

|

|

| 2.4. Identification of human senses and capabilities to be augmented |

|

|

|

| 2.5. Definition of mitigation measures using AR |

|

|

|

| Steps of Phase 1 | Inputs | Methods | Outputs |

|---|---|---|---|

| 3.1. Analysis of the current situation |

|

|

|

| 3.2. Identification of extreme postures |

|

|

|

| 3.3. Application of quantitative ergonomic analysis method |

|

|

|

| 3.4. Identification of improvement potential and definition of mitigation measures using AR |

|

|

|

| Phase | Step | Output |

|---|---|---|

| Phase 1. Occurrence analysis | 1.1. Identification of the most critical logistic areas |

|

| 1.2. Identification of the most critical processes |

| |

| 1.3. Identification of the most common consequences |

| |

| 1.4. Conclusions and identification of improvement potential |

| |

| Phase 2. OSH risk evaluation and mitigation measures | 2.1. Identification of hazards associated with each task performance |

|

| 2.2. Identification and categorisation of each OSH risk factor |

| |

| 2.3. Assessment of each risk based on their severity and frequency |

| |

| 2.4. Identification of human senses and capabilities to be augmented |

| |

| 2.5. Definition of mitigation measures using AR |

| |

| Phase 3. Ergonomic risk assessment and mitigation measures | 3.1. Analysis of the current situation |

|

| 3.2. Identification of extreme postures |

| |

| 3.3. Application of quantitative ergonomic analysis method |

| |

| 3.4. Identification of improvement potential and definition of mitigation measures using AR |

|

| Logistic Area | Tasks |

|---|---|

| Incoming and raw materials warehouse | Incoming |

| Warehousing | |

| Internal logistics | Repacking |

| Final and SMD assembly supermarkets | |

| Lines supply |

| Category | Parameters Assessed | Used Instruments |

|---|---|---|

| A. Workers’ characterization |

| – |

| B. Musculoskeletal symptomatology |

| Numerical pain scale [85] |

| C. Perception of exertion |

| Category Ratio-10 [86] |

| D. Workers’ opinion and acceptance |

| Five-point Likert scale [87] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, A.C.; Alves, A.C.; Arezes, P. Augmented Reality in a Lean Workplace at Smart Factories: A Case Study. Appl. Sci. 2023, 13, 9120. https://doi.org/10.3390/app13169120

Pereira AC, Alves AC, Arezes P. Augmented Reality in a Lean Workplace at Smart Factories: A Case Study. Applied Sciences. 2023; 13(16):9120. https://doi.org/10.3390/app13169120

Chicago/Turabian StylePereira, Ana C., Anabela C. Alves, and Pedro Arezes. 2023. "Augmented Reality in a Lean Workplace at Smart Factories: A Case Study" Applied Sciences 13, no. 16: 9120. https://doi.org/10.3390/app13169120

APA StylePereira, A. C., Alves, A. C., & Arezes, P. (2023). Augmented Reality in a Lean Workplace at Smart Factories: A Case Study. Applied Sciences, 13(16), 9120. https://doi.org/10.3390/app13169120