Laboratory Testing and Analysis of Clay Soil Stabilization Using Waste Marble Powder

Abstract

:1. Introduction

2. Materials and Method

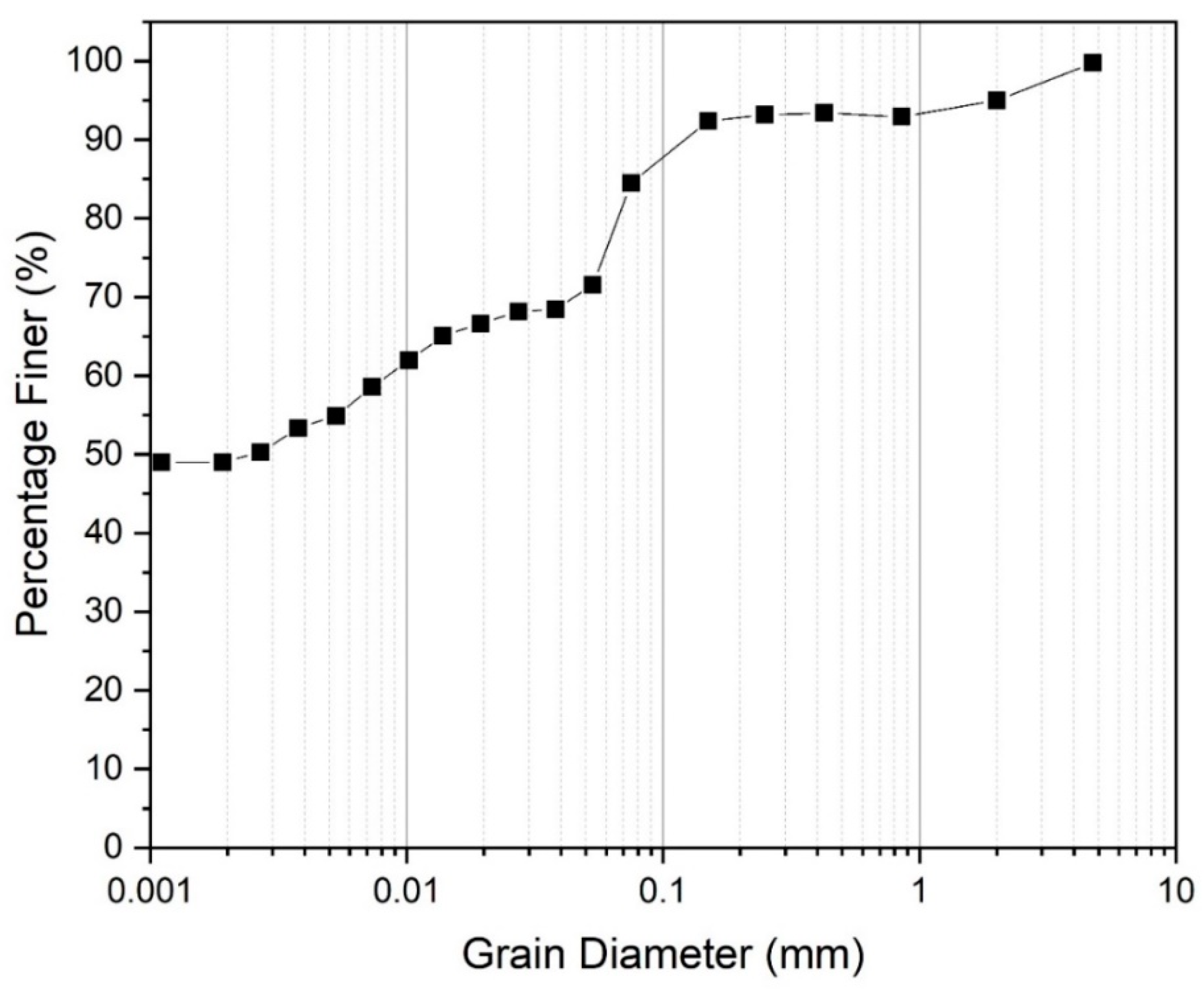

2.1. Soil

2.2. Waste Marble Powder (WMP)

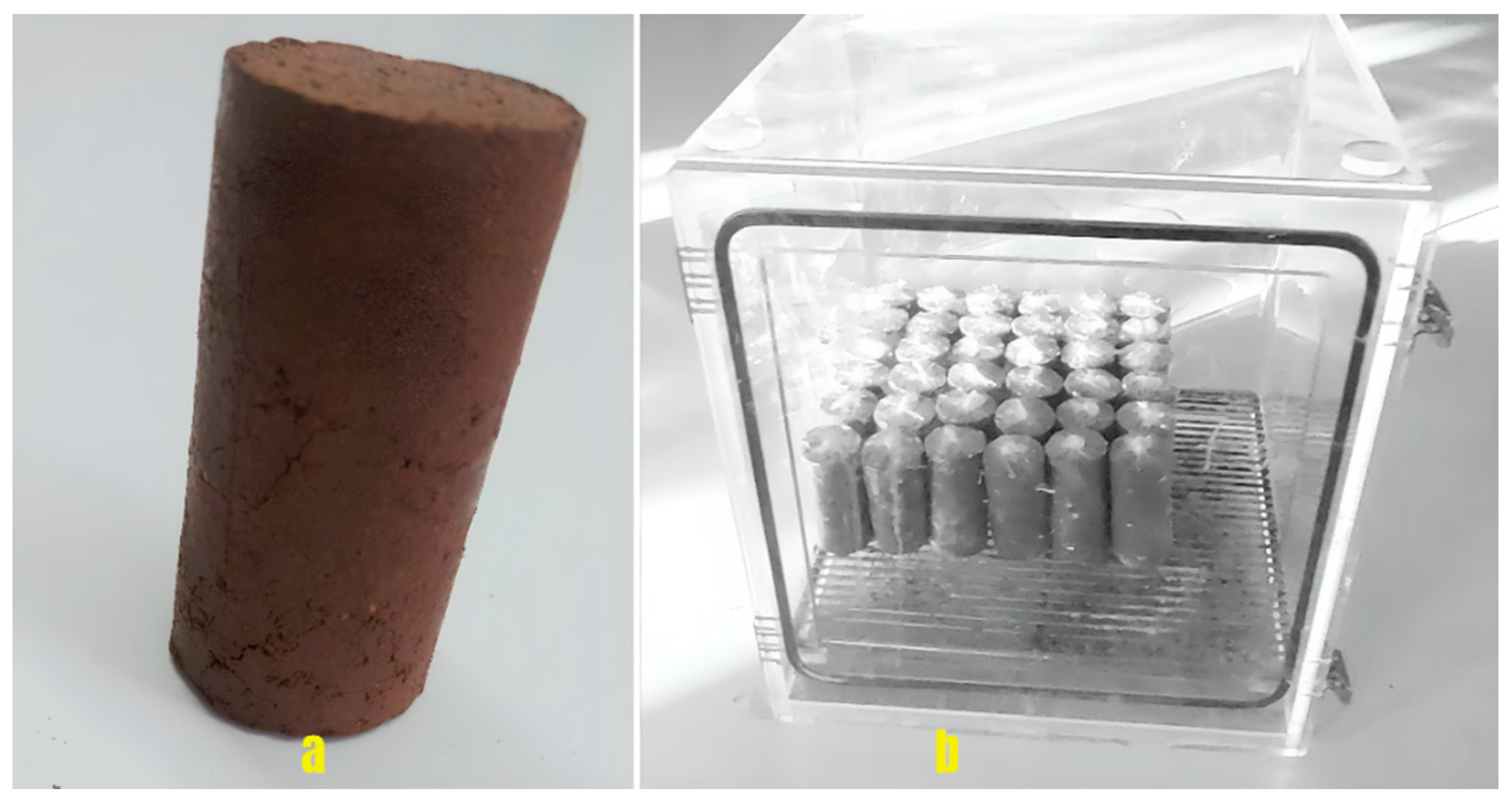

2.3. Specimen Preparation

2.4. UCS Test

2.5. UPV Test

2.6. ANNs Analysis

2.6.1. Data Used by the Network

2.6.2. Development of a Neural Network

2.6.3. Sensitivity Analysis

3. Results and Discussion

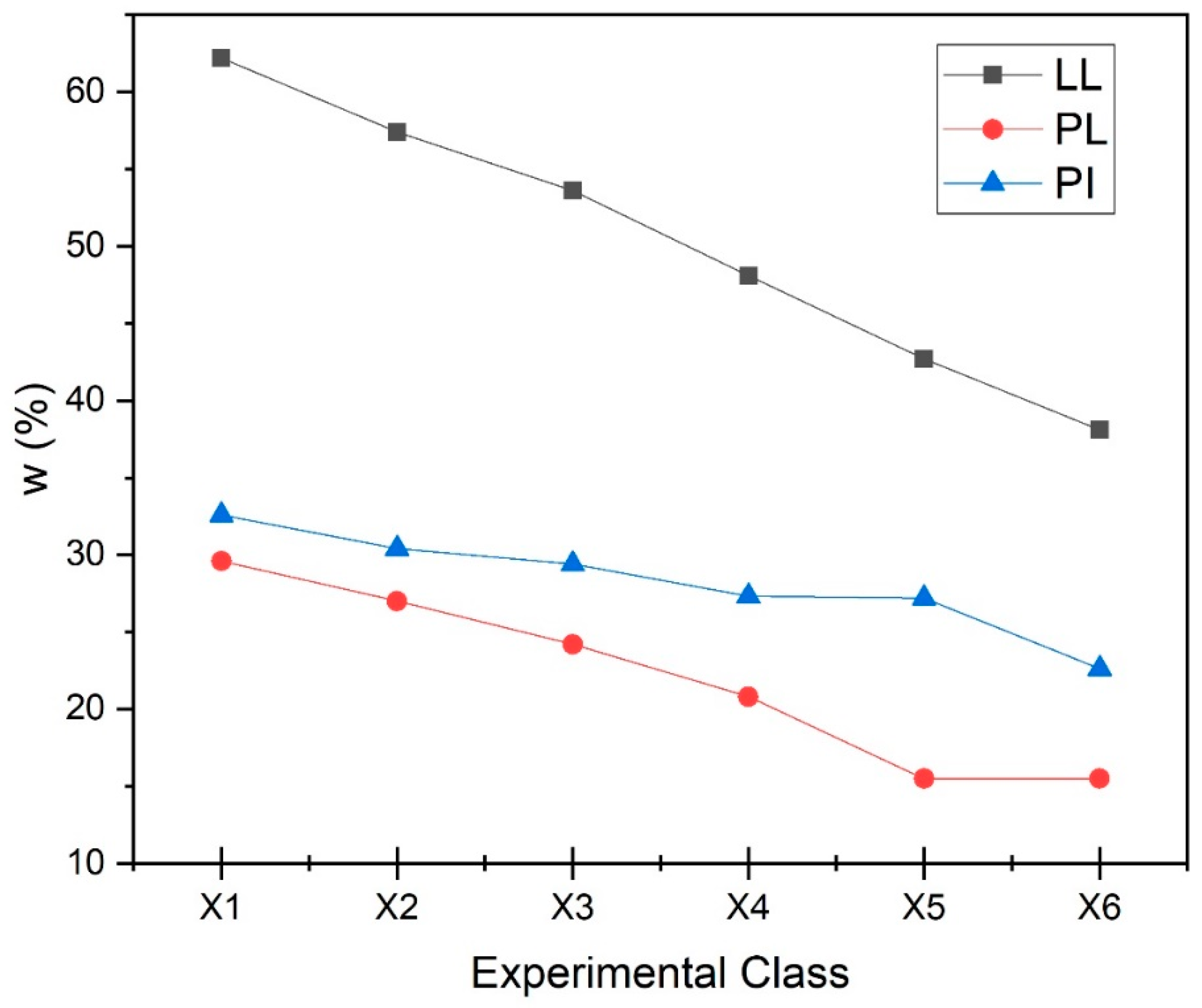

3.1. The Physical Behavior of Stabilized and Unstabilized Soils

3.1.1. Specific Gravity

3.1.2. Atterberg Limits

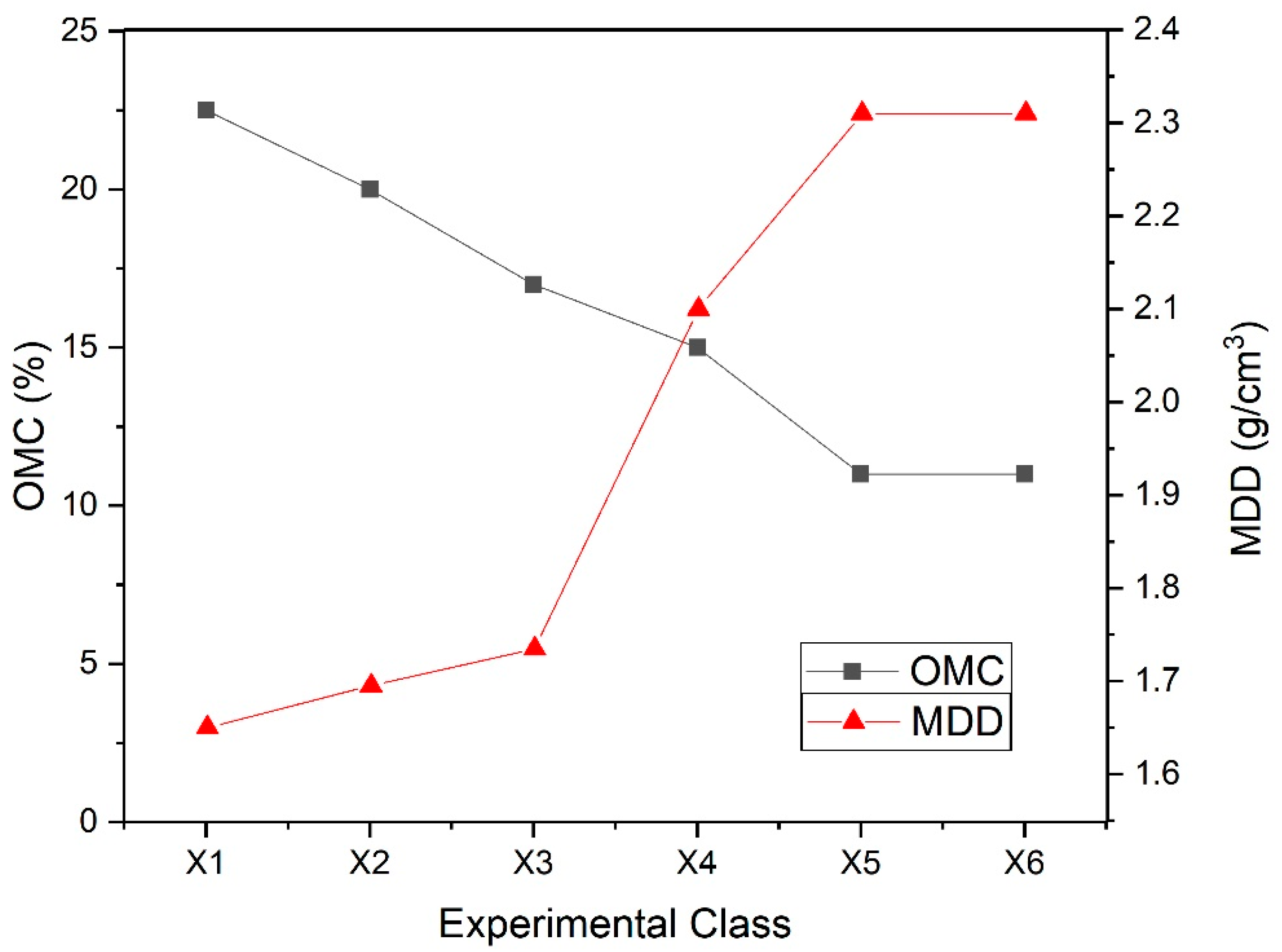

3.2. Compacted Behavior

3.2.1. MDD

3.2.2. OMC

3.3. The Mechanical Behavior of Stabilized and Unstabilized Soil

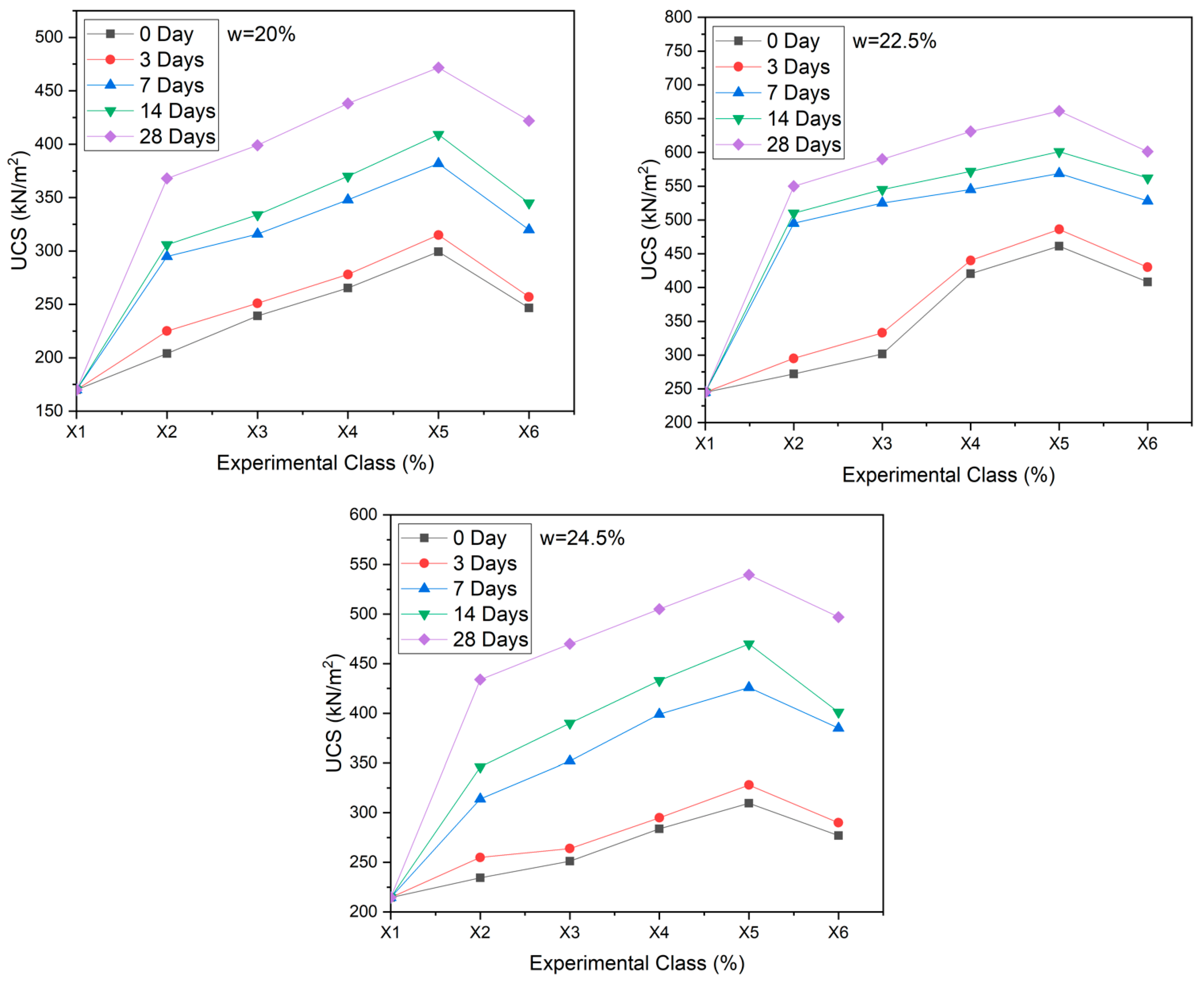

3.3.1. The Impacts of Water Content on the UCS

3.3.2. The Impact of Curing Time on the UCS

3.3.3. The Impact of WMP on the UCS

3.3.4. UPV Impacts

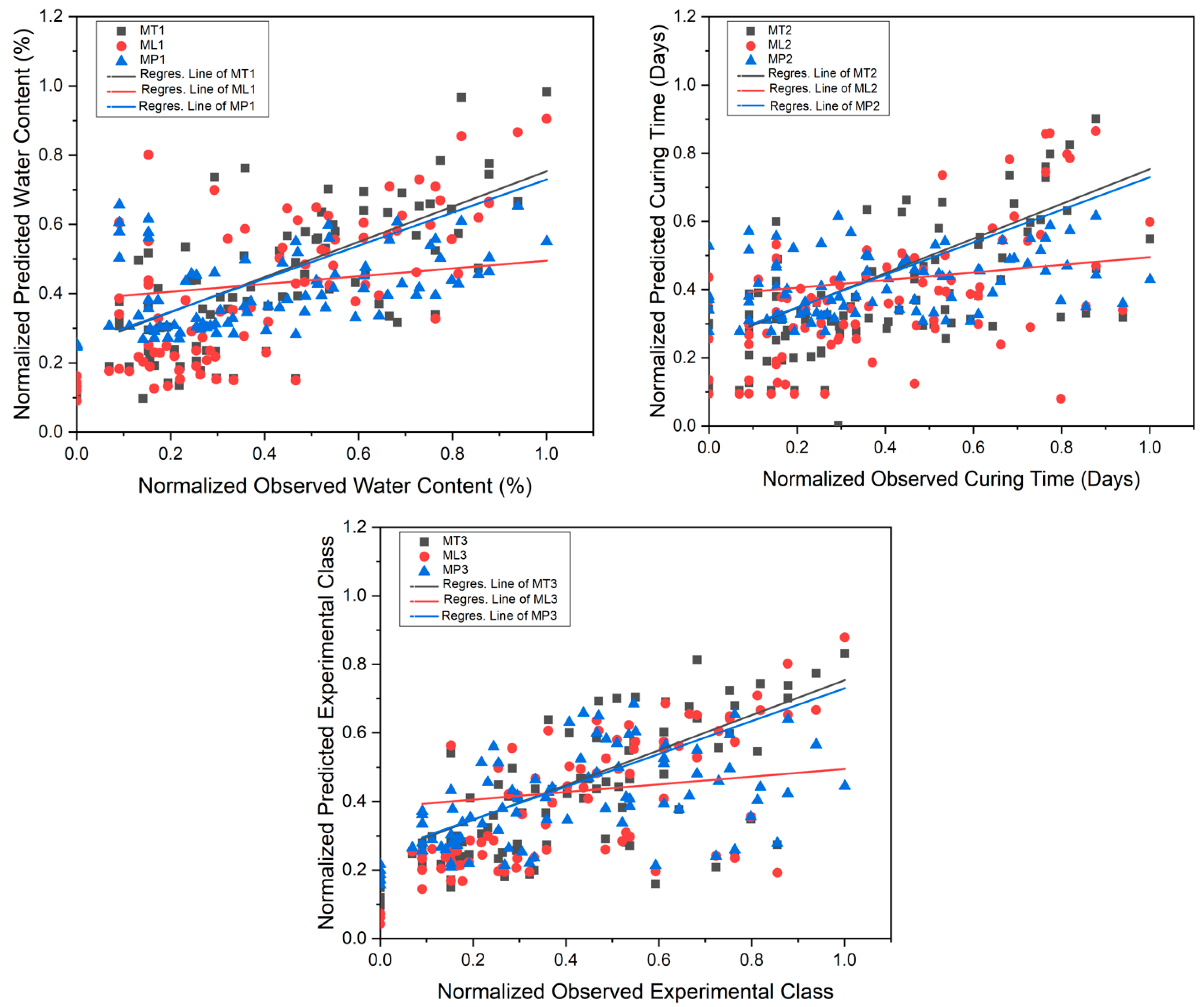

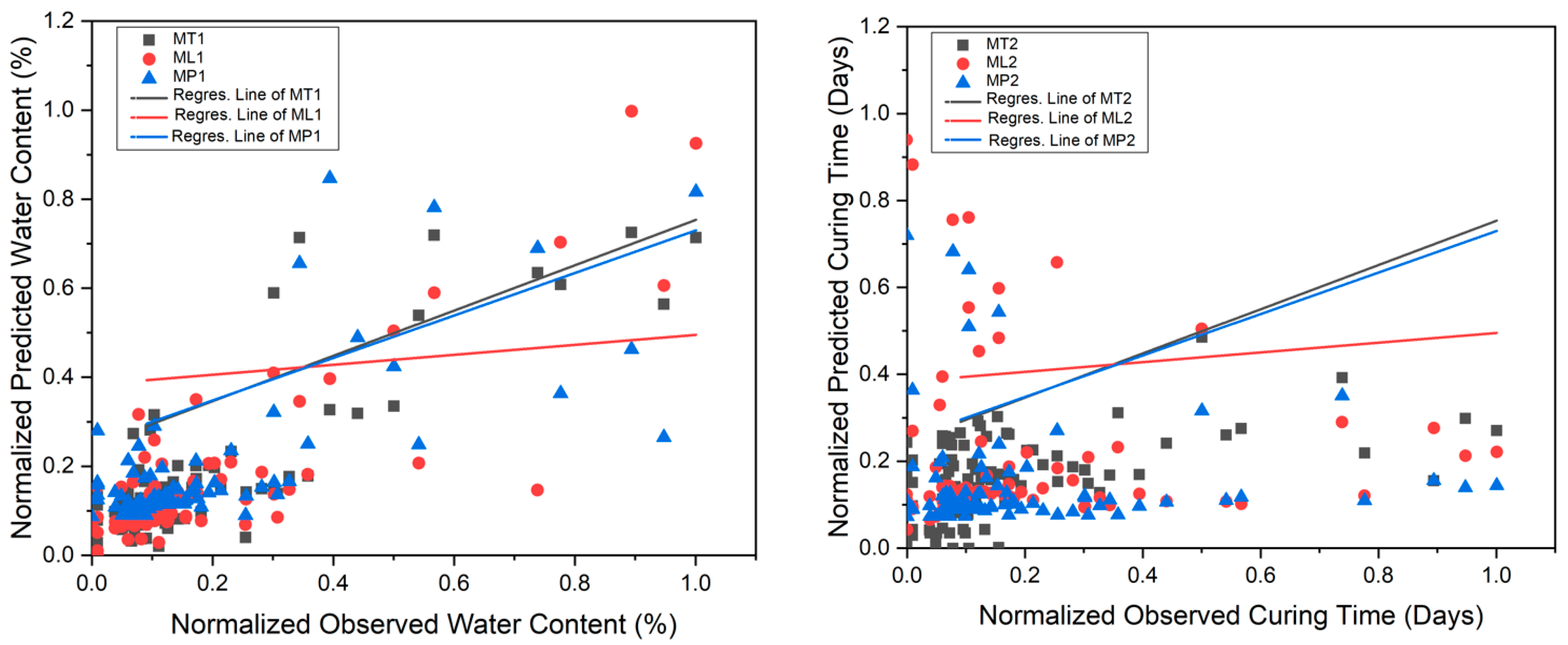

3.4. Developing Artificial Neural Networks

3.4.1. Pearson Correlation Matrix

3.4.2. ANN Generated UCS

3.4.3. ANN-Generated UPV

3.5. Validation of Models

4. Conclusions

- (1)

- The incorporation of increasing amounts of WMP into clay soil increases specific gravity from 2.73 to 2.83, primarily due to increased soil density, void filling, and reduced air content. Additionally, marble dust waste stabilizer improves clay engineering properties by reducing the liquid limit from 62.2% to 31.8%. It also reduces the plastic limit from 29.6 to 15.5% with increasing WMP content. Marble powder particles occupy spaces between clay particles, reducing the plasticity index from 32.6% to 22.6%.

- (2)

- Marble powder stabilizes clay, increasing maximum dry density (MDD) values from 1.65 to 2.31 Mg/m3, over 40% at 60% WMP content. WMP also reduces OMC values from 22.5% at 0% marble powder to 11% at 60 and 75% marble powder, making it useful for soil stabilization and engineering applications due to its high specific surface area and pozzolanic activity.

- (3)

- After 28 days of curing, the clay showed an increase in UCS as the maximum UCS of the specimens is attained at X5 (60%), with DMC, OMC, and WMC paths of 472 kN/m2, 661 kN/m2, and 540 kN/m2, respectively. The best strength (661 kN/m2) is achieved at 22.5 percent OMC, 60 percent WMP, and 28 days of curing. The strength enhancement depends on factors such as WMP quality, clay mineralogy, and curing time. Unconfined compressive strength testing successfully evaluated stabilization effectiveness, whereas, after a 28-day curing test, maximum UPV values were seen in clay soil stabilized with marble powder, with X5 powder providing the maximum boost. We found the UPV to be 412 m/s at DMC, 849 m/s at OMC, and 561 m/s at WMC. This further verified the improved structural integrity of stabilized and unstabilized clay soils. UPV values increased with WMP addition, correlating well with UCS trends. Combined UCS and UPV testing provides comprehensive strength characterization.

- (4)

- This study analyzed the Pearson correlation matrix to determine the relationship between the input parameters and the ANN model’s predicted UCS and UPV values. The results showed a positive correlation, indicating the model’s effectiveness in predicting the strength of stabilized and unstabilized soil samples. Validation confirmed the model’s accuracy in predicting strength, as the correlation coefficients are close to 1. Finally, the long-term performance of soil stabilized with WMP and the consequence of environmental elements, e.g., rainfall and temperature in applications such as foundations and road subgrades, could be the subject of future research.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Driss, A.A.-E.; Harichane, K.; Ghrici, M.; Gadouri, H. Assessing the effect of moulding water content on the behaviour of lime-stabilised an expansive soil. Geomech. Geoeng. 2021, 17, 896–908. [Google Scholar] [CrossRef]

- Turan, C.; Javadi, A.A.; Vinai, R.; Zali, R.B. Geotechnical Characteristics of Fine-Grained Soils Stabilized with Fly Ash, a Review. Sustainability 2022, 14, 16710. [Google Scholar] [CrossRef]

- Corrêa-Silva, M.; Miranda, T.; Rouainia, M.; Araújo, N.; Glendinning, S.; Cristelo, N. Geomechanical behaviour of a soft soil stabilised with alkali-activated blast-furnace slags. J. Clean. Prod. 2020, 267, 122017. [Google Scholar] [CrossRef]

- Al-Khafaji, R.; Dulaimi, A.; Jafer, H.; Mashaan, N.S.; Qaidi, S.; Obaid, Z.S.; Jwaida, Z. Stabilization of Soft Soil by a Sustainable Binder Comprises Ground Granulated Blast Slag (GGBS) and Cement Kiln Dust (CKD). Recycling 2023, 8, 10. [Google Scholar] [CrossRef]

- Dassekpo, J.-B.M.; Ning, J.; Zha, X. Potential solidification/stabilization of clay-waste using green geopolymer remediation technologies. Process. Saf. Environ. Prot. 2018, 117, 684–693. [Google Scholar] [CrossRef]

- Modarres, A.; Nosoudy, Y.M. Clay stabilization using coal waste and lime—Technical and environmental impacts. Appl. Clay Sci. 2015, 116–117, 281–288. [Google Scholar] [CrossRef]

- Wang, X.; Ren, B.; Zhou, Y.; Shi, X. Study on the mechanism and kinetics of manganese release from waste manganese ore waste rock under rainfall leaching. Environ. Sci. Pollut. Res. 2022, 29, 5541–5551. [Google Scholar] [CrossRef]

- Perri, G.; De Rose, M.; Domitrović, J.; Vaiana, R. CO2 Impact Analysis for Road Embankment Construction: Comparison of Lignin and Lime Soil Stabilization Treatments. Sustainability 2023, 15, 1912. [Google Scholar] [CrossRef]

- Khasreen, M.M.; Banfill, P.F.G.; Menzies, G.F. Life-Cycle Assessment and the Environmental Impact of Buildings: A Review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Vukićević, M.; Marjanović, M.; Pujević, V.; Jocković, S. The Alternatives to Traditional Materials for Subsoil Stabilization and Embankments. Materials 2019, 12, 3018. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Lin, H.; Chen, Y.; Liu, J.; Guo, C.; Xu, X.; He, M.; Shang, J.; Zheng, W. Deformation Stability Response of Adjacent Subway Tunnels considering Excavation and Support of Foundation Pit. Lithosphere 2022, 2022, 7227330. [Google Scholar] [CrossRef]

- Yang, G.; Lin, T.; Tan, P.; Xiao, H. Matrix transfer solutions for deformation and internal force of bridge piles with large diameter in high steep slope ground. Zhongnan Daxue Xuebao (Ziran Kexue Ban)/J. Cent. South Univ. (Sci. Technol.) 2022, 53, 2974–2987. [Google Scholar] [CrossRef]

- Umar, I.H.; Firat, M.E.O. Investigation of Unconfined Compressive Strength of Soils Stabilized with Waste Elazig Cherry Marble Powder at Different Water Contents. 2022. pp. 703–711. Available online: https://www.researchgate.net/publication/362680145_investigation_of_unconfined_compressive_strength_of_soils_stabilized_with_waste_elazig_cherry_marble_powder_at_different_water_contents (accessed on 24 May 2023).

- Babu, S.V.; Sharmila, M.R. Soil stabilisation using marble dust. Int. J. Civ. Eng. Technol. (IJCIET) 2017, 8, 1706–1713. Available online: https://iaeme.com/MasterAdmin/Journal_uploads/IJCIET/VOLUME_8_ISSUE_4/IJCIET_08_04_192.pdf (accessed on 24 May 2023).

- Zada, U.; Jamal, A.; Iqbal, M.; Eldin, S.M.; Almoshaogeh, M.; Bekkouche, S.R.; Almuaythir, S. Recent advances in expansive soil stabilization using admixtures: Current challenges and opportunities. Case Stud. Constr. Mater. 2023, 18, e01985. [Google Scholar] [CrossRef]

- Ali, F.; Khan, M.A.; Qurashi, M.A.; Shah, S.A.R.; Khan, N.M.; Khursheed, Z.; Rahim, H.S.; Arshad, H.; Farhan, M.; Waseem, M. Utilization of Pyrolytic Carbon Black Waste for the Development of Sustainable Materials. Processes 2020, 8, 174. [Google Scholar] [CrossRef] [Green Version]

- Sharma, L.; Sirdesai, N.; Sharma, K.; Singh, T. Experimental study to examine the independent roles of lime and cement on the stabilization of a mountain soil: A comparative study. Appl. Clay Sci. 2018, 152, 183–195. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, X.; Zhang, P.; Chen, Z. Strength Performance and Stabilization Mechanism of Fine Sandy Soils Stabilized with Cement and Metakaolin. Sustainability 2023, 15, 3431. [Google Scholar] [CrossRef]

- Zhang, B.; Song, F.; Li, W. Stability Analysis of Retaining Walls with Geocell-Reinforced Road Milling Materials. Sustainability 2023, 15, 4297. [Google Scholar] [CrossRef]

- Argyroudis, S.; Kaynia, A.M.; Pitilakis, K. Development of fragility functions for geotechnical constructions: Application to cantilever retaining walls. Soil Dyn. Earthq. Eng. 2013, 50, 106–116. [Google Scholar] [CrossRef]

- Yang, G.; Chen, Z.; Zhang, H.; Duan, J.; Xia, X.; Lin, Y. Collapse mechanism of gentle expansive soil slope in drying and wetting cycles. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 95–103. [Google Scholar] [CrossRef]

- Wei, G.; Zhao, D.; Xu, H.; Zhou, Y.; Chen, C. Study on soil deformation caused by overlapping shield tunnel construction based on uniform solution. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 589–598. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Kampala, A.; Jitsangiam, P.; Horpibulsuk, S. Performance and evaluation of calcium carbide residue stabilized lateritic soil for construction materials. Case Stud. Constr. Mater. 2020, 13, e00389. [Google Scholar] [CrossRef]

- Barman, D.; Dash, S.K. Stabilization of expansive soils using chemical additives: A review. J. Rock Mech. Geotech. Eng. 2022, 14, 1319–1342. [Google Scholar] [CrossRef]

- Alwosheel, A.; van Cranenburgh, S.; Chorus, C.G. ‘Computer says no’ is not enough: Using prototypical examples to diagnose artificial neural networks for discrete choice analysis. J. Choice Model. 2019, 33, 100186. [Google Scholar] [CrossRef]

- Helin, R.; Indahl, U.; Tomic, O.; Liland, K.H. Non-linear shrinking of linear model errors. Anal. Chim. Acta 2023, 1258, 341147. [Google Scholar] [CrossRef]

- Gunaydin, O.; Gokoglu, A.; Fener, M. Prediction of artificial soil’s unconfined compression strength test using statistical analyses and artificial neural networks. Adv. Eng. Softw. 2010, 41, 1115–1123. [Google Scholar] [CrossRef]

- Sarker, I.H. Deep Learning: A Comprehensive Overview on Techniques, Taxonomy, Applications and Research Directions. SN Comput. Sci. 2021, 2, 1–20. [Google Scholar] [CrossRef]

- Lendo-Siwicka, M.; Zabłocka, K.; Soból, E.; Markiewicz, A.; Wrzesiński, G. Application of an Artificial Neural Network (ANN) Model to Determine the Value of the Damping Ratio (D) of Clay Soils. Appl. Sci. 2023, 13, 6224. [Google Scholar] [CrossRef]

- Jalal, F.E.; Xu, Y.; Iqbal, M.; Javed, M.F.; Jamhiri, B. Predictive modeling of swell-strength of expansive soils using artificial intelligence approaches: ANN, ANFIS and GEP. J. Environ. Manag. 2021, 289, 112420. [Google Scholar] [CrossRef]

- Gharaibeh, A.; Shaamala, A.; Obeidat, R.; Al-Kofahi, S. Improving land-use change modeling by integrating ANN with Cellular Automata-Markov Chain model. Heliyon 2020, 6, e05092. [Google Scholar] [CrossRef]

- Vincevica-Gaile, Z.; Teppand, T.; Kriipsalu, M.; Krievans, M.; Jani, Y.; Klavins, M.; Setyobudi, R.H.; Grinfelde, I.; Rudovica, V.; Tamm, T.; et al. Towards Sustainable Soil Stabilization in Peatlands: Secondary Raw Materials as an Alternative. Sustainability 2021, 13, 6726. [Google Scholar] [CrossRef]

- Wurie, N.N.; Zheng, J.; Traore, A.F. Mechanical, Leaching, and Microstructure Properties of Mine Waste Rock Reinforced and Stabilised with Waste Oyster Shell for Road Subgrade Use. Materials 2022, 15, 2916. [Google Scholar] [CrossRef]

- Wang, J.; Hong, T.; Li, Z.; Xue, X.; Lyu, S. Experiment on compaction of air-dried soil under drop shocks. PLoS ONE 2021, 16, e0250076. [Google Scholar] [CrossRef]

- Das, B.M. Soil Mecahanics Laboratory Manual; Oxford University Press: Oxford, UK, 2002. [Google Scholar]

- Bhange, N.A. Engineering Characterization of Clayey Soil by Ultrasonic Pulse Velocity Tests. Int. J. Eng. Sci. (IJES) 2018, 21–26. [Google Scholar]

- Umar, I.H.; Elif, M.; Firat, O. A Study on Uniaxial Compressive Strength and Ultrasonic Non-Destructive Analysis of Fine- Grained Soil in Seasonally Frozen Regions Mevsimsel Donmuş Bölgelerde İnce Taneli Zeminlerin Tek Eksenli Basınç Dayanımları ve Ultrasonik Tahribatsız Analizleri Üzer. Turk. J. Sci. Technol. 2022, 17, 267–277. [Google Scholar]

- Agrawal, V.; Gupta, M. Expansive Soil Stabilization Using Marble Dust. Int. J. Earth Sci. Eng. 2011, 4, 59–62. [Google Scholar]

- Jain, A.K.; Jha, A.K. Shivanshi Geotechnical behaviour and micro-analyses of expansive soil amended with marble dust. Soils Found. 2020, 60, 737–751. [Google Scholar] [CrossRef]

- Abdelkader, H.A.M.; Hussein, M.M.A.; Ye, H. Influence of Waste Marble Dust on the Improvement of Expansive Clay Soils. Adv. Civ. Eng. 2021, 2021, 3192122. [Google Scholar] [CrossRef]

- Jassim, N.W.; Hassan, H.A.; Mohammed, H.A.; Fattah, M.Y. Utilization of waste marble powder as sustainable stabilization materials for subgrade layer. Results Eng. 2022, 14, 100436. [Google Scholar] [CrossRef]

- Nawar, A.; Ghaedi, H.; Ali, M.; Zhao, M.; Iqbal, N.; Khan, R. Recycling waste-derived marble powder for CO2 capture. Process. Saf. Environ. Prot. 2019, 132, 214–225. [Google Scholar] [CrossRef]

- Umar, I.H.; Muhammad, A.; Ahmad, A.; Yusif, M.A. Suitability of Geotechnical Properties of Bentonite-Bagasse Ash Mixtures Stabilized Lateritic Soil as Barrier in Engineered Waste Landfills. 2022. pp. 162–203. Available online: https://www.researchgate.net/publication/359993732_Suitability_of_Geotechnical_Properties_of_Bentonite-Bagasse_Ash_Mixtures_Stabilized_Lateritic_Soil_as_Barrier_in_Engineered_Waste_Landfills (accessed on 24 May 2023).

- Gurbuz, A. Marble powder to stabilise clayey soils in sub-bases for road construction. Road Mater. Pavement Des. 2016, 16, 481–492. [Google Scholar] [CrossRef]

- Saygili, A. Use of Waste Marble Dust for Stabilization of Clayey Soil. Mater. Sci. 2015, 21, 601–606. [Google Scholar] [CrossRef] [Green Version]

- Khrissi, S.; Bejjit, L.; Haddad, M.; Falguères, C.; Lyazidi, S.A.; El Amraoui, M. Study of marbles from Middle Atlas (Morocco): Elemental, mineralogical and structural analysis. IOP Conf. Ser. Mater. Sci. Eng. 2018, 353, 012013. [Google Scholar] [CrossRef]

- Umar, I.H.; Firat, M.E.O. Study on Unconfıned Compressıon Strength and Non-destructıve Analysıs of Soıl Stabılızed wıth Waste Marble Powder under Freeze-Thaw Cycles 2022.

- Ho, T.-O.; Chen, W.-B.; Yin, J.-H.; Wu, P.-C.; Tsang, D.C. Stress-Strain behaviour of Cement-Stabilized Hong Kong marine deposits. Constr. Build. Mater. 2021, 274, 122103. [Google Scholar] [CrossRef]

- Vitales, V.V.; Amaludin, A.E.; Ho, Y.; Amaludin, N.A. Soil plasticity and standard proctor compaction characteristics of stabilized Kota Kinabalu clay using biomass silica (SH-85). IOP Conf. Ser. Mater. Sci. Eng. 2022, 1217, 012006. [Google Scholar] [CrossRef]

- Shah, S.H.A.; Habib, U.; Mohamed, A.; Aziz, M.; Rehman, Q.U.; Saleem, A. Laboratory and In Situ Stabilization of Compacted Clay through Granite Waste Powder. Sustainability 2022, 14, 14459. [Google Scholar] [CrossRef]

- Arabani, M.; Haghsheno, H. The effect of water content on shear and compressive behavior of polymeric fiber-reinforced clay. SN Appl. Sci. 2020, 2, 1759. [Google Scholar] [CrossRef]

- Min, C.; Li, X.; He, S.; Zhou, S.; Zhou, Y.; Yang, S.; Shi, Y. Effect of mixing time on the properties of phosphogypsum-based cemented backfill. Constr. Build. Mater. 2019, 210, 564–573. [Google Scholar] [CrossRef]

- Chamling, P.K.; Biswal, D.R.; Sahoo, U.C. Effect of moulding water content on strength characteristics of a cement-stabilized granular lateritic soil. Innov. Infrastruct. Solut. 2021, 6, 82. [Google Scholar] [CrossRef]

- Antinoro, C.; Arnone, E.; Noto, L.V. The use of soil water retention curve models in analyzing slope stability in differently structured soils. Catena 2017, 150, 133–145. [Google Scholar] [CrossRef]

- Vardhan, K.; Siddique, R.; Goyal, S. Strength, permeation and micro-structural characteristics of concrete incorporating waste marble. Constr. Build. Mater. 2019, 203, 45–55. [Google Scholar] [CrossRef]

- Bikoko, T.G.L.J.; Bayiha, B.N. Effects of marble addition on the fresh, physical, mechanical, and optical microscopic properties of metakaolin-based geopolymer binders. Innov. Infrastruct. Solut. 2022, 8, 3. [Google Scholar] [CrossRef]

- Song, Y.-S.; Hong, S. Effect of clay minerals on the suction stress of unsaturated soils. Eng. Geol. 2020, 269, 105571. [Google Scholar] [CrossRef]

- Neeraj, K.; Chandra, M. Basics of Clay Minerals and Their Characteristic Properties. In Lay and Clay Minerals; Gustavo Morari Do, N., Ed.; IntechOpen: Rijeka, Croatia, 2021; p. 2. [Google Scholar]

- MolaAbasi, H.; Kharazmi, P.; Khajeh, A.; Saberian, M.; Chenari, R.J.; Harandi, M.; Li, J. Low plasticity clay stabilized with cement and zeolite: An experimental and environmental impact study. Resour. Conserv. Recycl. 2022, 184, 106408. [Google Scholar] [CrossRef]

- Chaiyaput, S.; Arwaedo, N.; Kingnoi, N.; Nghia-Nguyen, T.; Ayawanna, J. Effect of curing conditions on the strength of soil cement. Case Stud. Constr. Mater. 2022, 16, e01082. [Google Scholar] [CrossRef]

- Khimi, S.R.; Pickering, K.L. A new method to predict optimum cure time of rubber compound using dynamic mechanical analysis. J. Appl. Polym. Sci. 2013, 131. [Google Scholar] [CrossRef]

- Yao, K.; Li, N.; Chen, D.-H.; Wang, W. Generalized hyperbolic formula capturing curing period effect on strength and stiffness of cemented clay. Constr. Build. Mater. 2019, 199, 63–71. [Google Scholar] [CrossRef]

- Sakr, M.A.H.; Omar, A.E.; Saad, A.M.; Moayedi, H. Geotechnical parameters modelling and the radiation safety of expansive clayey soil treated with waste marble powder: A case study at west Gulf of Suez, Egypt. Environ. Earth Sci. 2021, 80, 1–18. [Google Scholar] [CrossRef]

- Yang, Q.; Du, C. Experimental Study on the Effect of Plant Ash on Soft Clay Stabilized with Cement-Based Composites. Geotech. Geol. Eng. 2020, 39, 105–117. [Google Scholar] [CrossRef]

- Wang, Z.-F.; Shen, S.-L.; Yin, Z.-Y.; Xu, Y.-S. Rapid field evaluation of the strength of cement-stabilized clayey soil. Bull. Eng. Geol. Environ. 2014, 74, 991–999. [Google Scholar] [CrossRef]

- Athanasopoulou, A. The role of curing period on the engineering characteristics of a cement-stabilized soil. Rom. J. Transp. Infrastruct. 2016, 5, 38–52. [Google Scholar] [CrossRef] [Green Version]

- Rong-Rong, Z.; Dong-Dong, M. Effects of Curing Time on the Mechanical Property and Microstructure Characteristics of Metakaolin-Based Geopolymer Cement-Stabilized Silty Clay. Adv. Mater. Sci. Eng. 2020, 2020, 9605941. [Google Scholar] [CrossRef] [Green Version]

- Ghasemzadeh, H.; Mehrpajouh, A.; Pishvaei, M. Compressive Strength of Acrylic Polymer-Stabilized Kaolinite Clay Modified with Different Additives. ACS Omega 2022, 7, 19204–19215. [Google Scholar] [CrossRef]

- Zorluer, I.; Gucek, S.; Afyon Kocatepe University. The usability of industrial wastes on soil stabilization. Rev. De La Construcción 2020, 19, 80–89. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, S.; Li, J.; Huang, X.; Li, C.; Wu, J. Engineering and mineralogical properties of stabilized expansive soil compositing lime and natural pozzolans. Constr. Build. Mater. 2018, 187, 1031–1038. [Google Scholar] [CrossRef]

- Sabat, A.K.; Nanda, R.P. Effect of marble dust on strength and durability of Rice husk ash stabilised expansive soil Effect of marble dust on strength and durability of Rice husk ash. Int. J. Civ. Struct. Eng. 2011, 1, 939–948. [Google Scholar]

- Debnath, A.; Saha, S.; Chattaraj, R. Stabilization of Clayey Soil with Marble Dust. In Recent Developments in Sustainable Infrastructure; Das, B.B., Barbhuiya, S., Gupta, R., Saha, P., Eds.; Springer: Singapore, 2021; pp. 175–183. [Google Scholar]

- Sivrikaya, O.; Uysal, F.; Yorulmaz, A.; Aydin, K. The Efficiency of Waste Marble Powder in the Stabilization of Fine-Grained Soils in Terms of Volume Changes. Arab. J. Sci. Eng. 2020, 45, 8561–8576. [Google Scholar] [CrossRef]

- Yesiller, N.; Hanson, J.L.; Usmen, M.A. Ultrasonic Assessment of Stabilized Soils. Civ. Environ. Eng. 2001, 40552, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Mustafa, Y.M.H.; Zami, M.S.; Al-Amoudi, O.S.B.; Al-Osta, M.A.; Wudil, Y.S. Analysis of Unconfined Compressive Strength of Rammed Earth Mixes Based on Artificial Neural Network and Statistical Analysis. Materials 2022, 15, 9029. [Google Scholar] [CrossRef]

- Hall, M.A. Correlation-Based Feature Selection for Machine Learning 1999. Available online: https://www.cs.waikato.ac.nz/~mhall/thesis.pdf (accessed on 24 May 2023).

- Cherkassky, V.; Krasnopolsky, V.; Solomatine, D.; Valdes, J. Computational intelligence in earth sciences and environmental applications: Issues and challenges. Neural Netw. 2006, 19, 113–121. [Google Scholar] [CrossRef]

- Padhma, M. End-to-End Introduction to Evaluating Regression Models. 2021. Available online: https://www.analyticsvidhya.com/blog/2021/10/evaluation-metric-for-regression-models/ (accessed on 24 May 2023).

| Experimental Class | Symbol | Tests | Specimen Dimension | Soil Class | w (%) | Curing Period (Days) | ET (°C) | ||

|---|---|---|---|---|---|---|---|---|---|

| Natural Soil (%) | Marble Dust (%) | D (mm) | H (mm) | ||||||

| 100 | 0 | X1 | PP, UCS | 38 | 76 | CH | 20, 22.5, 24.5 | 0, 3, 7, 14, 28 | ~20–28 |

| 85 | 15 | X2 | UCS, UPV | ||||||

| 70 | 30 | X3 | |||||||

| 55 | 45 | X4 | |||||||

| 40 | 60 | X5 | |||||||

| 25 | 75 | X6 | |||||||

| Geo-Engineering Characteristics of the Clay Soil | Amount | |

|---|---|---|

| Specific Gravity, % | 2.73 | |

| Atterberg Limits | Liquid Limit, % | 62.2 |

| Plastic Limit, % | 29.6 | |

| Plasticity Index, % | 32.6 | |

| Finer Component | % Passed No. 200 Mesh, % | 71.6 |

| USCS Classification | CH | - |

| Compaction Parameter | Optimum Moisture Content, % | 22.5 |

| Maximum Dry Density, Mg/m3 | 1.60 | |

| UCS, kN/m2 | 245 | |

| UPV, m/s | 223 | |

| Initial Void Ratio (eo) | 0.665 | |

| Color | Dark Beige | |

| pH | 5.51 | |

| Dominant Soil Mineral | Kaolinite |

| Composition | CaO | SiO2 | P2O5 | Fe2O3 | Al2O3 | MnO | Na2O | K2O | MgO | LOI | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Values (%) | 56.33 | 0.28 | 0.01 | 0.37 | 0.07 | 0.01 | 0.06 | 0.02 | 0.65 | 42.27 | 100.07 |

| w (%) | WMP (%) | CT | UCS | |

|---|---|---|---|---|

| w (%) | 1 | |||

| WMP (%) | 0.442476 | 1 | ||

| CT | 0.100023 | 0.350106 | 1 | |

| UCS | 1 | 0.442476 | 0.100023 | 1 |

| w (%) | WMP (%) | CT | UPV | |

|---|---|---|---|---|

| w (%) | 1 | |||

| WMP (%) | 0.738375 | 1 | ||

| CT | 0.032906 | 0.01804 | 1 | |

| UPV | 1 | 0.738375 | 0.032906 | 1 |

| Performance Criteria for UCS | ||||

|---|---|---|---|---|

| ANN | ||||

| Training | R2 | MSE | RMSE | R |

| TANSIG-1 | 0.904147 | 0.023242 | 0.152452 | 0.817482 |

| TANSIG-2 | 0.831887 | 0.061215 | 0.247416 | 0.692036 |

| TANSIG-3 | 0.798742 | 0.032909 | 0.181408 | 0.637989 |

| PURELIN-1 | 0.904147 | 0.023242 | 0.152452 | 0.817482 |

| PURELIN-2 | 0.686603 | 0.105066 | 0.324139 | 0.471424 |

| PURELIN-3 | 0.754218 | 0.039194 | 0.197976 | 0.568844 |

| LOGSIGM-1 | 0.846953 | 0.035995 | 0.189723 | 0.71733 |

| LOGSIGM-2 | 0.82197 | 0.064475 | 0.253919 | 0.675635 |

| LOGSIGM-3 | 0.814882 | 0.030541 | 0.17476 | 0.664032 |

| Testing | ||||

| TANSIG-1 | 0.601973 | 0.042325 | 0.20573 | 0.362372 |

| TANSIG-2 | 0.622862 | 0.069647 | 0.263908 | 0.387956 |

| TANSIG-3 | 0.874912 | 0.030024 | 0.173274 | 0.765472 |

| PURELIN-1 | 0.54196 | 0.046882 | 0.216522 | 0.293721 |

| PURELIN-2 | 0.471229 | 0.088526 | 0.297533 | 0.222057 |

| PURELIN-3 | 0.703579 | 0.064647 | 0.254257 | 0.495023 |

| LOGSIGM-1 | 0.741733 | 0.029859 | 0.172798 | 0.550168 |

| LOGSIGM-2 | 0.558 | 0.078363 | 0.279934 | 0.311364 |

| LOGSIGM-3 | 0.887453 | 0.027195 | 0.164908 | 0.787573 |

| Performance Criteria for UPV | ||||

|---|---|---|---|---|

| ANN | ||||

| Training | R2 | MSE | RMSE | R |

| TANSIG-1 | 0.86345 | 0.012736 | 0.112853 | 0.745547 |

| TANSIG-2 | 0 | 0 | 0 | −1.67406 |

| TANSIG-3 | 0.741965 | 0.015311 | 0.123738 | 0.550511 |

| PURELIN-1 | 0.773548 | 0.020102 | 0.141781 | 0.598376 |

| PURELIN-2 | 0 | 0 | 0 | −6.6081 |

| PURELIN-3 | 0.635361 | 0.020313 | 0.142522 | 0.403684 |

| LOGSIGM-1 | 0.860028 | 0.013031 | 0.114154 | 0.739648 |

| LOGSIGM-2 | 0 | 0 | 0 | −10.4289 |

| LOGSIGM-3 | 0.900973 | 0.006412 | 0.080077 | 0.811752 |

| Testing | ||||

| TANSIG-1 | 0.793585 | 0.009322 | 0.096551 | 0.629777 |

| TANSIG-2 | 0 | 0 | 0 | −0.08955 |

| TANSIG-3 | 0.798659 | 0.019459 | 0 | 0.637856 |

| PURELIN-1 | 0.408841 | 0.020971 | 0.144813 | 0.167151 |

| PURELIN-2 | 0 | 0 | 0 | −0.64634 |

| PURELIN-3 | 0.723872 | 0.025578 | 0.159931 | 0.52399 |

| LOGSIGM-1 | 0.412758 | 0.02089 | 0.144533 | 0.170369 |

| LOGSIGM-2 | 0 | 0 | 0 | −0.85259 |

| LOGSIGM-3 | 0.90483 | 0.009741 | 0.098697 | 0.818717 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Umar, I.H.; Lin, H.; Ibrahim, A.S. Laboratory Testing and Analysis of Clay Soil Stabilization Using Waste Marble Powder. Appl. Sci. 2023, 13, 9274. https://doi.org/10.3390/app13169274

Umar IH, Lin H, Ibrahim AS. Laboratory Testing and Analysis of Clay Soil Stabilization Using Waste Marble Powder. Applied Sciences. 2023; 13(16):9274. https://doi.org/10.3390/app13169274

Chicago/Turabian StyleUmar, Ibrahim Haruna, Hang Lin, and Awaisu Shafiu Ibrahim. 2023. "Laboratory Testing and Analysis of Clay Soil Stabilization Using Waste Marble Powder" Applied Sciences 13, no. 16: 9274. https://doi.org/10.3390/app13169274

APA StyleUmar, I. H., Lin, H., & Ibrahim, A. S. (2023). Laboratory Testing and Analysis of Clay Soil Stabilization Using Waste Marble Powder. Applied Sciences, 13(16), 9274. https://doi.org/10.3390/app13169274